Safe solution spinning method

A technology of solution spinning and solvent spinning, which is applied in flash spinning, filament generation, rayon recycling, etc. It can solve the problems of ozone layer pollution, safe production and low explosion limit, so as to improve production safety and reduce organic compounds Content, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] (1) producing a spinning solution, which includes a polymer and a spinning solvent;

[0074] The polymer used is polyester, and the content of polyester in the spinning solution is 10wt%;

[0075] The spinning solvent used is 1,1,1,3,3-pentafluorobutane;

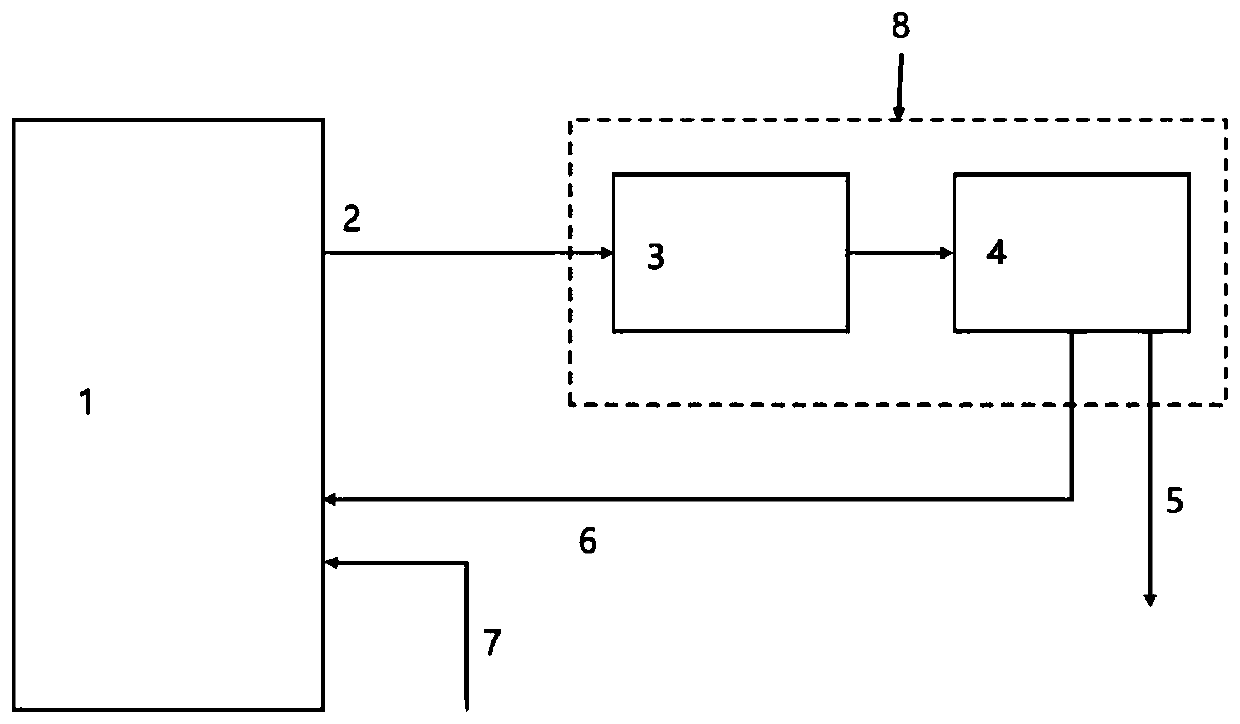

[0076] (2) Nitrogen is passed into the spinning beam body 1 so that the oxygen content in the spinning beam body is less than or equal to 16vol%; the pipeline 7 of the non-combustible gas is set on the spinning beam body 1 for feeding Nitrogen is passed into; during the spinning process, the VOC-rich tail gas is discharged from the spinning housing through the discharge pipe 2 and enters the rich VOC tail gas treatment system 8, which sequentially includes a cooling device 3 and a VOC-rich tail gas treatment system 8 Adsorption device 4, through the treatment of cooling device 3 and adsorption device 4, obtains low-VOC gas (the content of its volatile organic compound is 500ppm), and low-VOC gas returns in the spinni...

Embodiment 2

[0080] (1) producing a spinning solution, which includes a polymer and a spinning solvent;

[0081] The polymer used is polyethylene, and the content of polyethylene in the spinning solution is 12wt%;

[0082] The spinning solvent used was 90% dichloromethane and 10% 1,1-difluoroethane (HC-152a).

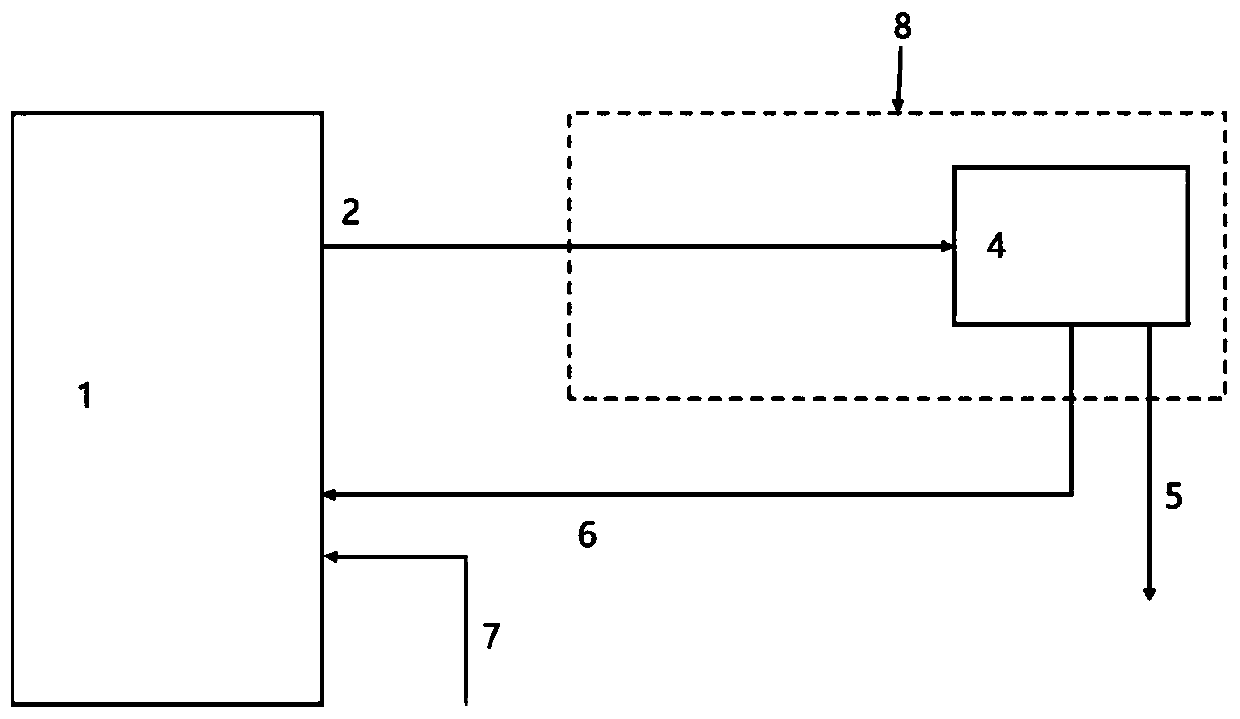

[0083] (2) Pass into carbon dioxide gas in the spinning box body, make the oxygen content in the spinning box body be less than or equal to 16vol%; The pipeline 7 of incombustible gas is set on the described spinning box body 1, is used for to the spinning box body Nitrogen was introduced. During the spinning process, the VOC-rich tail gas is discharged from the spinning box through the discharge pipe 2 and enters the VOC-rich tail gas treatment system 8. The VOC-rich tail gas treatment system 8 only includes the adsorption device 4, and the adsorption device 4 process to obtain low-VOC gas (the content of its volatile organic compound is 700ppm), and the low-VOC gas returns to th...

Embodiment 3

[0087] (1) producing a spinning solution, which includes a polymer and a spinning solvent;

[0088] The polymer used is polyvinylidene fluoride, and the content of polyvinylidene fluoride in the spinning solution is 15wt%;

[0089] The spinning solvent used is cyclopentane.

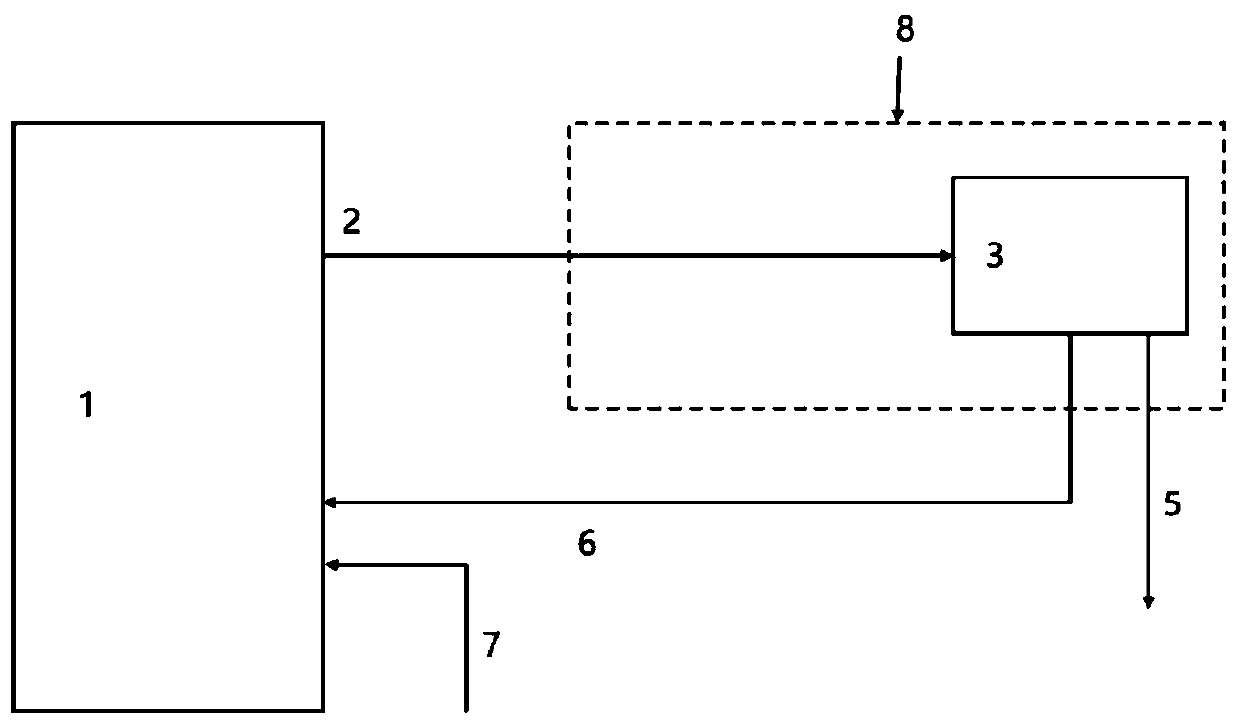

[0090] (2) Pass into helium in the spinning box body, make the oxygen content in the spinning box body be less than or equal to 17vol%; The pipeline 7 of incombustible gas is set on the described spinning box body 1, is used for to the spinning box body Nitrogen was introduced. During the spinning process, the VOC-rich tail gas is discharged from the spinning box through the discharge pipe 2 and enters the VOC-rich tail gas treatment system 8. The VOC-rich tail gas treatment system 8 only includes the cooling device 3, and the cooling device 3 process to obtain low-VOC gas (the content of its volatile organic compound is 300ppm), and the low-VOC gas returns to the spinning beam body 1 again through the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com