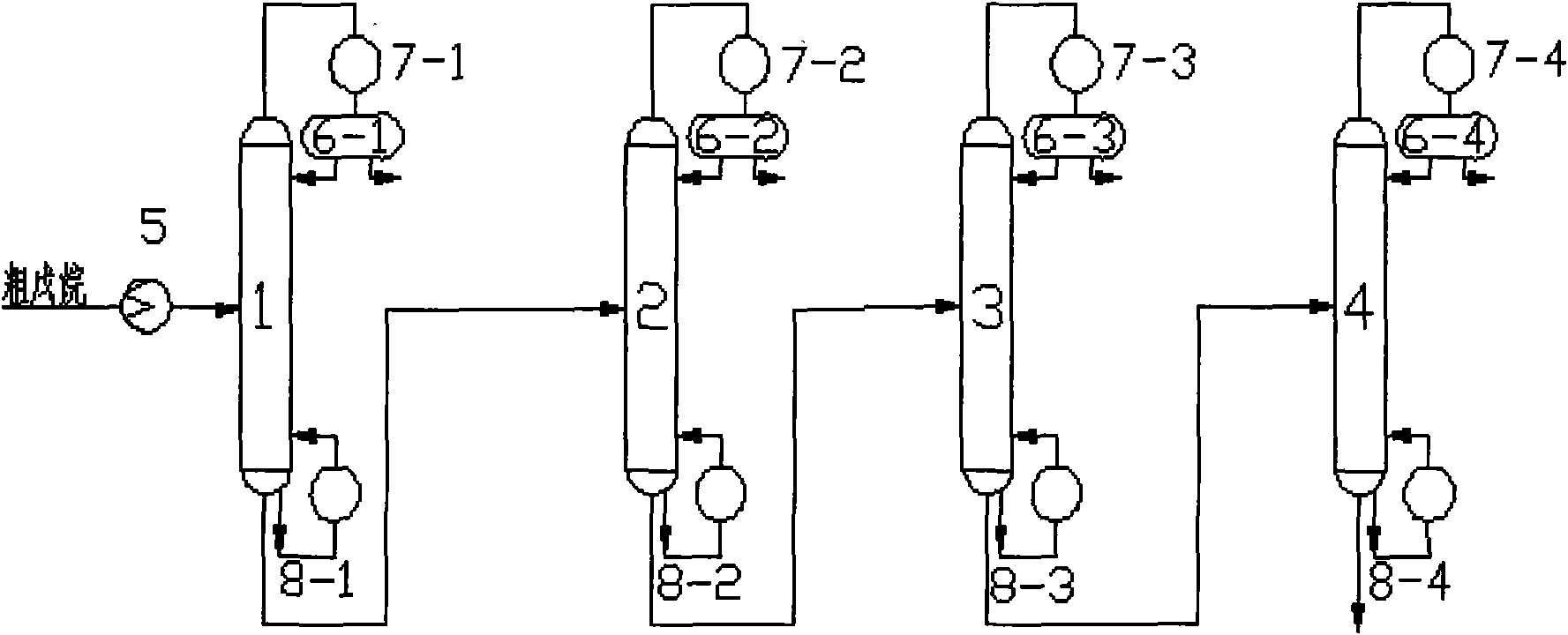

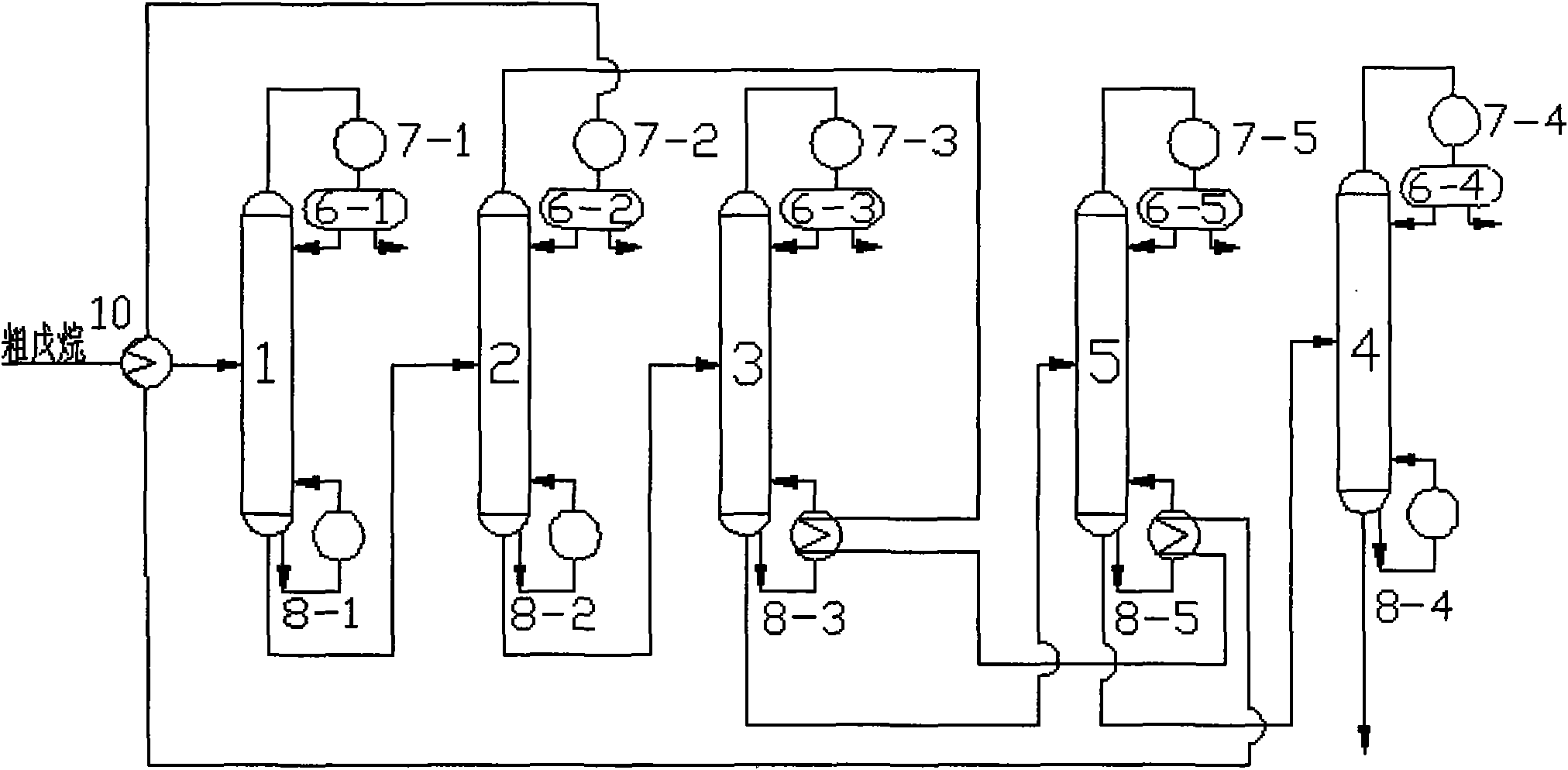

Double-effect rectification method and system thereof for finely separating hybrid pentane isomer

A technology for isomers and fine separation, which is applied in the field of double-effect distillation energy-saving and water-saving systems, can solve the problems of high energy consumption and low product quality, achieve reasonable process design, remove key impurities, and improve product quality. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The annual processing capacity of C5 raw materials is 4×10 4 kg, 35% isopentane content (wt%, hereinafter the same), 50% n-pentane content, 5% cyclopentane content, 99% isopentane product is extracted from the isopentane tower, and the temperature after raw material preheating is 72 ℃, the pressure at the top of the light removal tower is 540Kpa, the temperature at the top of the tower is 54°C, the pressure at the top of the isopentane tower is 650Kpa, the temperature at the top of the tower is 95°C, the reflux ratio is 11, the pressure at the top of the n-pentane tower is 195Kpa, the temperature at the top of the tower is 57°C, The reflux ratio is 3.8, and the vaporization rate of the n-pentane bottom reboiler 8-3 is 0.25. The pressure at the top of the azeotrope tower is 175kpa, the temperature at the top of the tower is 66°C, the number of theoretical stages is 70, the reflux ratio is 100, and the mass ratio of new hexane and cyclohexane at the top of the tower is 1:...

Embodiment 2

[0020] The annual processing capacity of C5 raw materials is 4×10 4kg, isopentane content 35% (wt%, hereinafter the same), n-pentane content 50%, cyclopentane content 5%, isopentane tower output mass ratio 5: 5 n-isopentane mixed blowing agent product , the temperature of the raw material after preheating is 45°C, the pressure at the top of the dehydrogenation tower is 540Kpa, the temperature at the top of the tower is 54°C, the pressure at the top of the isopentane tower is 650Kpa, the temperature is 100°C, the reflux ratio is 1.7, the pressure at the top of the n-pentane tower is 195Kpa, The temperature at the top of the tower is 57° C., the reflux ratio is 4.5, and the vaporization rate of the n-pentane bottom reboiler is 0.25. The pressure at the top of the azeotrope tower is 180kpa, the temperature at the top of the tower is 63°C, the theoretical number of stages is 75, the reflux ratio is 95, and the mass ratio of new hexane and cyclohexane taken from the top of the towe...

Embodiment 3

[0023] The annual processing capacity of C5 raw materials is 4×10 4 Kilogram, isopentane content 35% (wt%, hereinafter the same), n-pentane content 50%, cyclopentane content 5%, isopentane tower takes out mass ratio 3: 7 n-isopentane mixed foaming agent products , the temperature of the raw material after preheating is 45°C, the pressure at the top of the dehydrogenation tower is 540Kpa, the temperature at the top of the tower is 54°C, the pressure at the top of the isopentane tower is 650Kpa, the temperature is 100°C, the reflux ratio is 1.7, the pressure at the top of the n-pentane tower is 195Kpa, The temperature at the top of the column is 57° C., the reflux ratio is 4.5, and the vaporization rate ratio of the n-pentane bottom reboiler 8-3 is 0.25. The pressure at the top of the azeotrope tower is 160kpa, the temperature at the top of the tower is 65°C, the theoretical number of stages is 80, the reflux ratio is 90, and the mass ratio of neo-hexane and cyclohexane at the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com