Hard polyurethane foam plastic and producing method thereof

A technology of foam plastics and production methods, applied in the field of foam plastics, can solve the problems of complex production process, poor heat preservation, high price, etc., and achieve the effects of increasing economic benefits, reducing core density, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

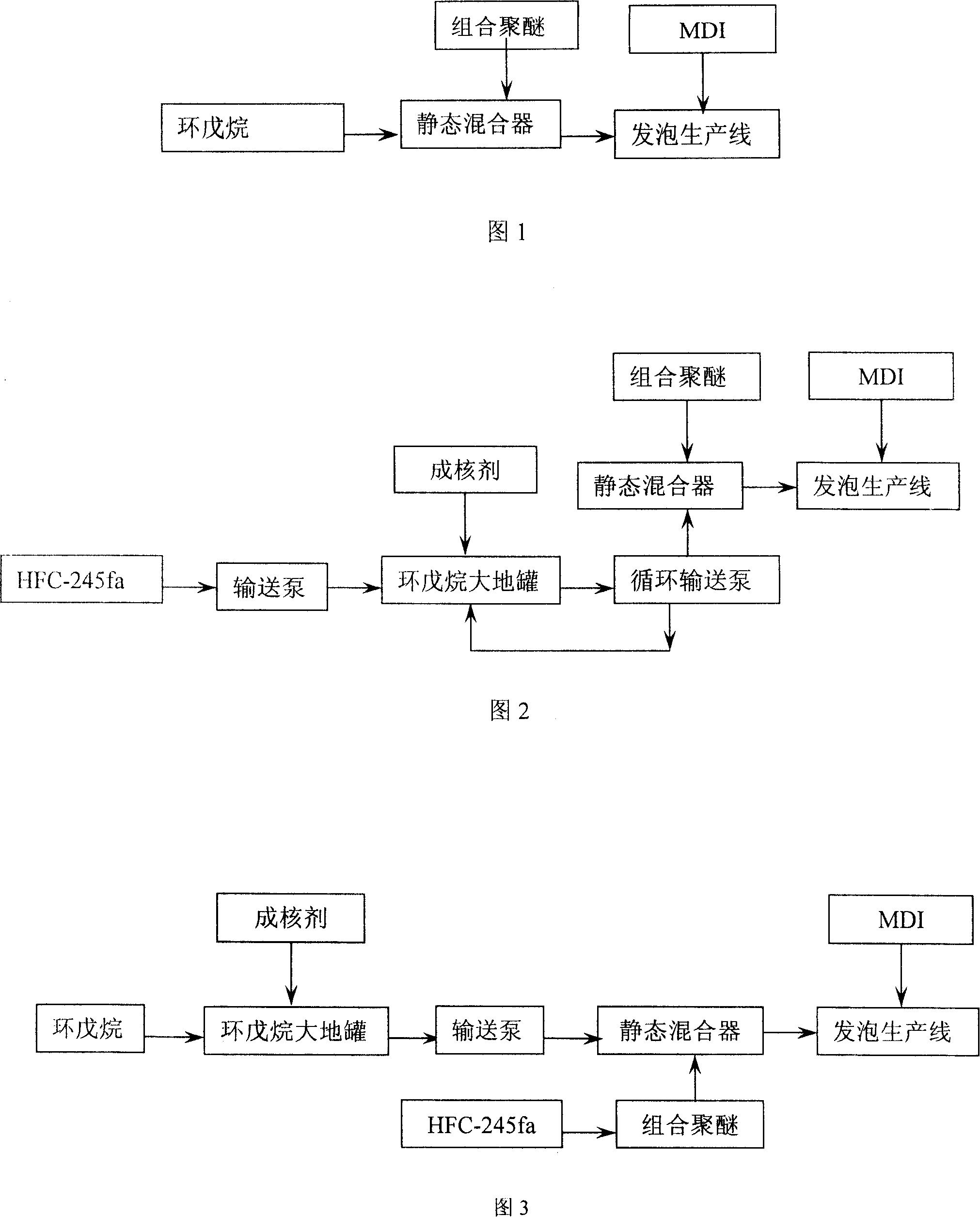

Method used

Image

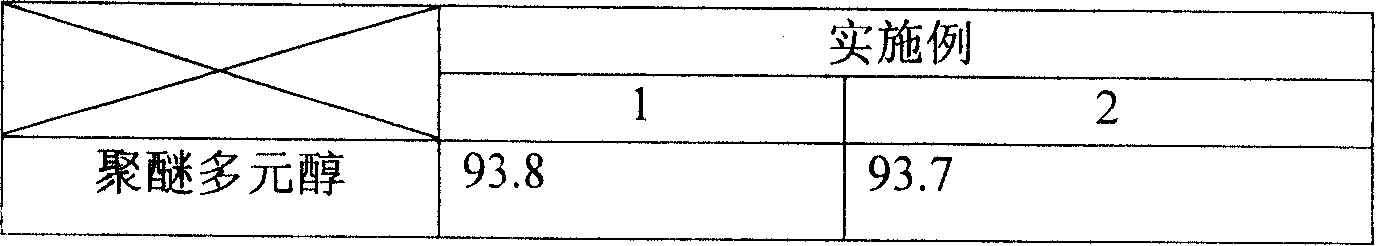

Examples

Embodiment Construction

[0029] Among the foaming agents used in PU plastics at present, c-pentane has poor thermal insulation performance, and HFC-245fa nucleating agent can improve thermal insulation performance, but it is expensive. Each of the above materials has its significant advantages and disadvantages. The purpose of the present invention is to make full use of their respective advantages, overcome their shortcomings, and learn from each other, so as to obtain the PU (polyurethane) that meets market requirements in terms of environmental protection and is close to the CFC-11 system in comprehensive performance. Density rigid foam. The production method of the rigid polyurethane foam of the present invention uses polyisocyanate, combined polyether, blowing agent and a small amount of nucleating agent as raw materials. The nucleating agent is an organic fluorine compound, the main varieties include 3M's FA-188 and other brands of perfluorocarbons, ODP = 0, GWP value in the range of tens to hun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com