Rigid cellular plastic with improved property and preparation method thereof

A rigid foam plastic and performance technology, applied in the field of polymer chemical materials, can solve the problems of low thermal conductivity, high raw material price, no mention of foam formulation technology, etc., to achieve the effect of reducing thermal conductivity and wide operating range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following provides a set of embodiments in the refrigerator field in conjunction with the present invention, but the present invention is not limited thereto. Prepare sucrose polyether (polyol), aromatic polyether (polyol), foam stabilizer, catalyst and water in proportion to form a combined polyether, then mix it with the previously prepared mixed foaming agent, and then react with isocyanate to generate foam. Foam, prepared polyurethane rigid foam with improved properties.

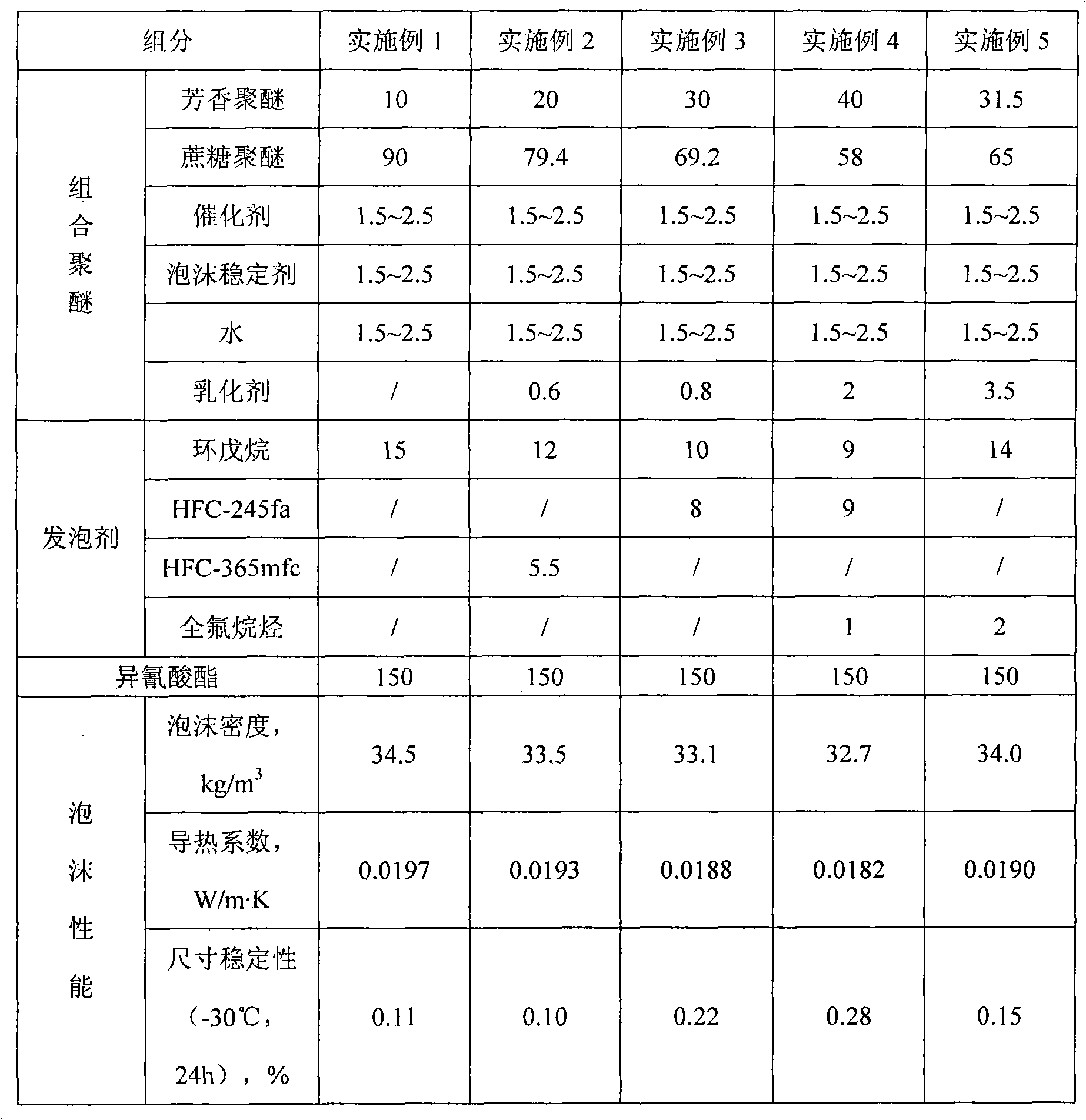

[0023] Table 1

[0024]

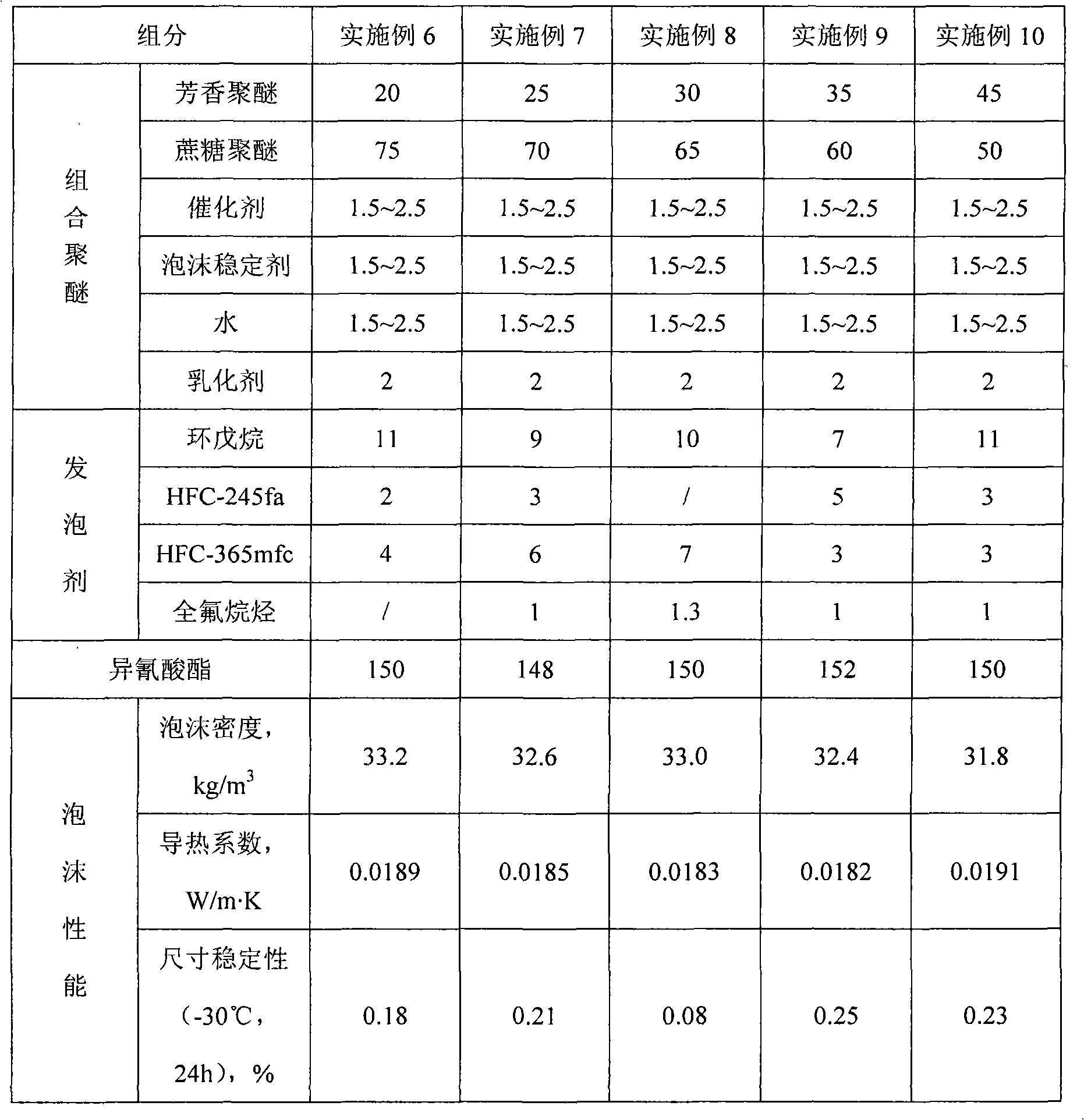

[0025] Table 2

[0026]

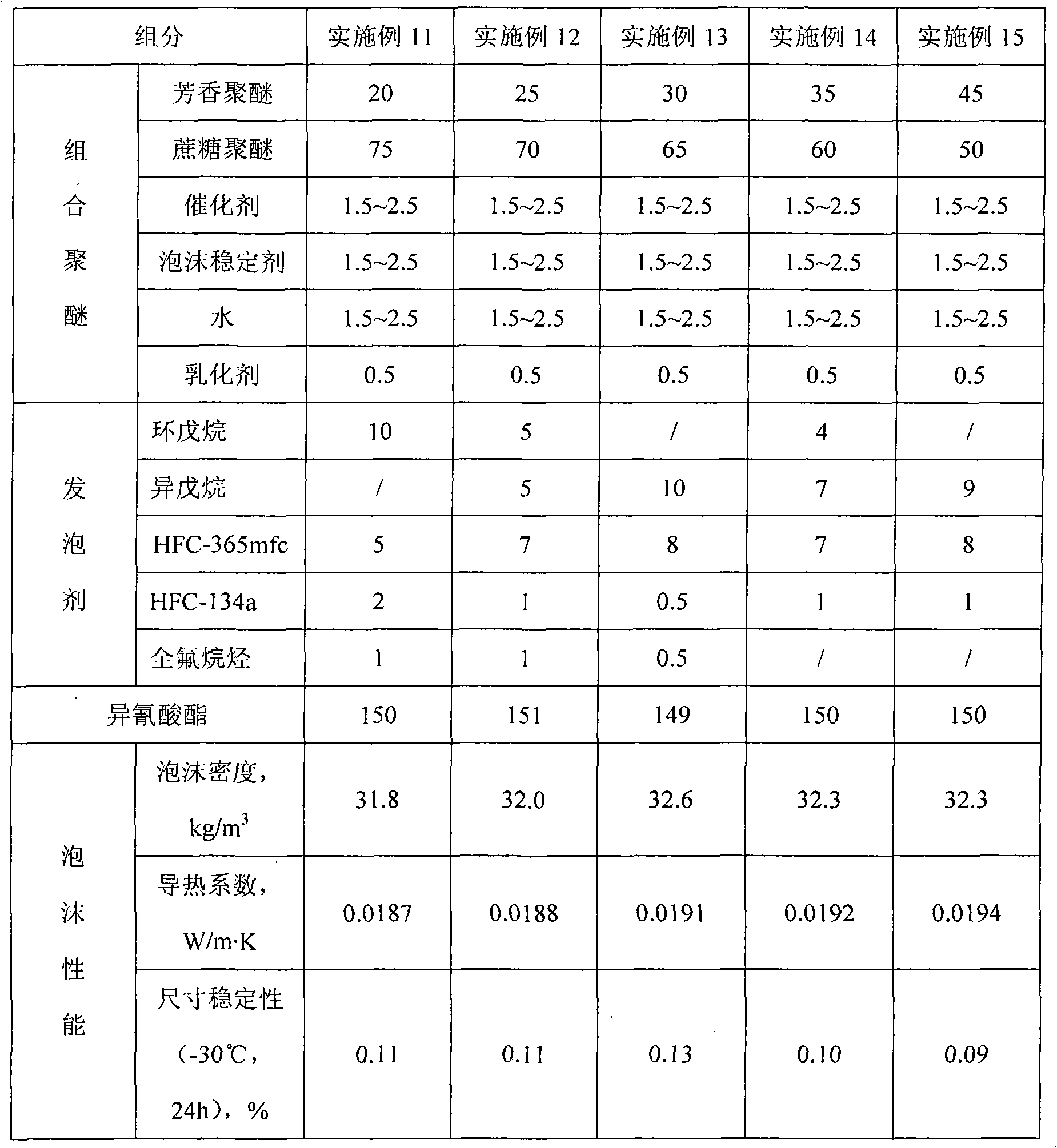

[0027] table 3

[0028]

[0029] Note:

[0030] 1) The raw materials are calculated in parts by weight;

[0031] 2) Foam density, dimensional change rate, and thermal conductivity are all measured according to national standards;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com