Polyether polyvalent alcohol for preparing no-freon polyurethane hard foam plastic and preparation method thereof

A technology of rigid foam plastics and polyether polyols, applied in the field of polyether polyols and its preparation, can solve problems such as poor fluidity, high viscosity of the system, and influence on physical properties, and achieve no environmental pollution and mutual solubility High and simple production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation of embodiment 1 polyether polyol

[0024] Put 100g of mixed starter (30g of sorbitol, 20g of toluenediamine, 50g of propylene glycol) and 0.3% solid KOH catalyst based on the total mass of the final synthesized polyether into the autoclave, start the stirrer, and replace the reactor with nitrogen several times , At the same time, under the condition of about 100 ℃, vacuum dehydration for 1h makes it generate alcohol potassium system. Control the temperature of the reaction kettle at 90 to 120°C and the pressure at about 0.3MPa, and continuously add propylene oxide to the kettle until the hydroxyl value of the polyether is about 400mgKOH / g. After feeding, continue to react until the system pressure drops to -0.05MPa, and keep warm for 1 hour to replace the gas in the reactor with nitrogen, open the reactor, and add a certain amount of phosphoric acid to it to neutralize the KOH catalyst in the reactor, so that the polyether acid value is less than 0.2mgK...

Embodiment 2

[0026] The preparation of embodiment 2 polyether polyols:

[0027] The preparation of polyether polyol was carried out according to the steps in Example 1, except that the 100g mixed starter formula was changed to be composed of 20g sorbitol, 25g pentaerythritol, 25g bisphenol S, and 30g glycerin to obtain polyether polyol B. The measured polyether polyol B has a hydroxyl value of 405 mgKOH / g, a viscosity of 2450 mPa.s, and a cyclopentane solubility of 32 parts per 100 parts of polyether. Preparation of Foam Sample 2:

[0028] With the step in embodiment 1, just change polyether polyol A into polyether polyol B.

Embodiment 3

[0029] The preparation of embodiment 3 polyether polyols

[0030] The preparation of the polyether polyol is carried out according to the steps in Example 1, except that the 100g mixed initiator formula is changed to be composed of 20g sucrose, 15g bisphenol S and 65g glycerin, and the pre-synthesized polyether hydroxyl value is changed to 350mgKOH / g, To obtain polyether polyol C. The measured polyether polyol C has an actual hydroxyl value of 356 mgKOH / g, a viscosity of 900 mPa.s, and a solubility of cyclopentane of 38 parts per 100 parts of polyether. Preparation of Foam Sample 3

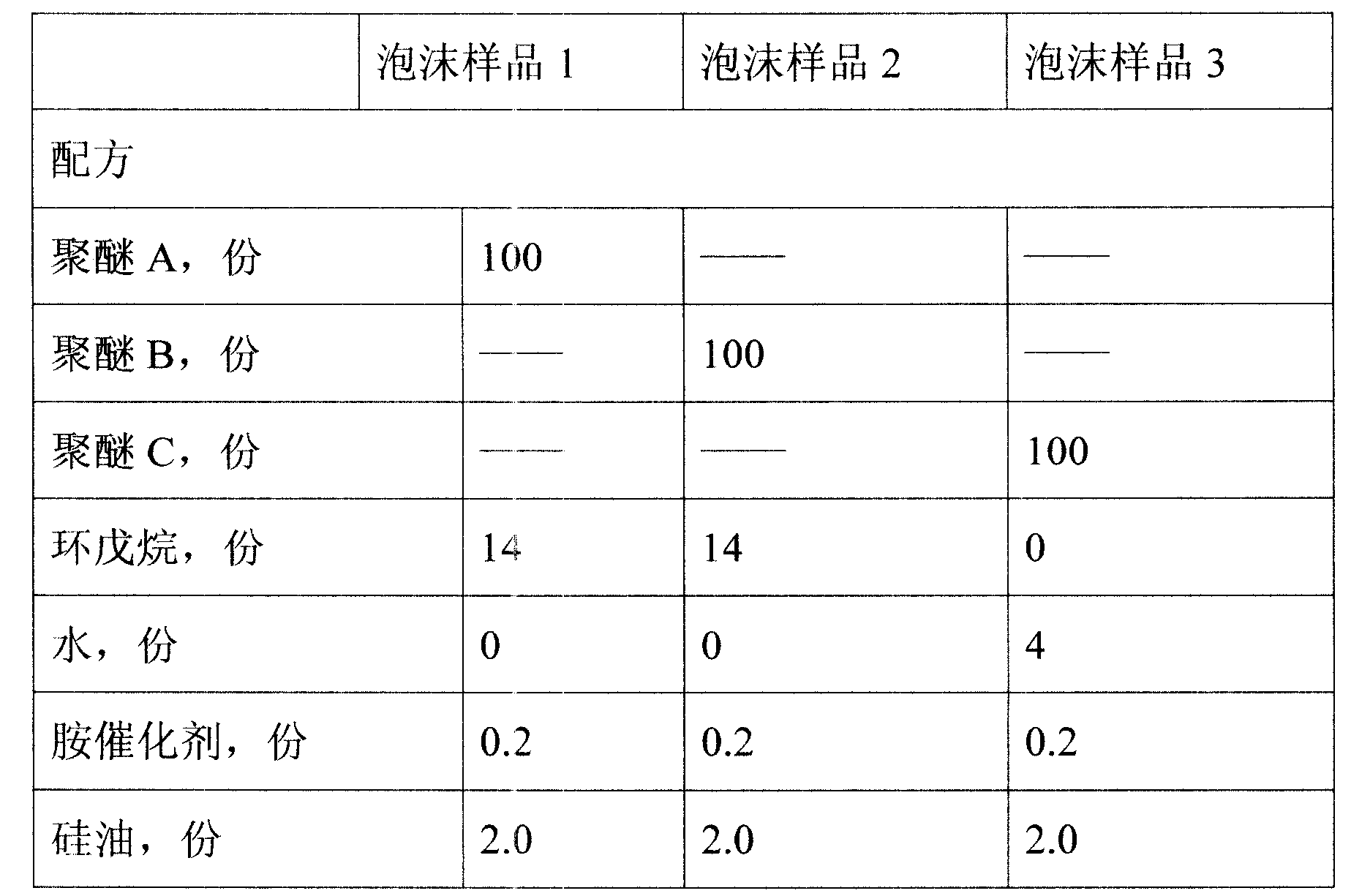

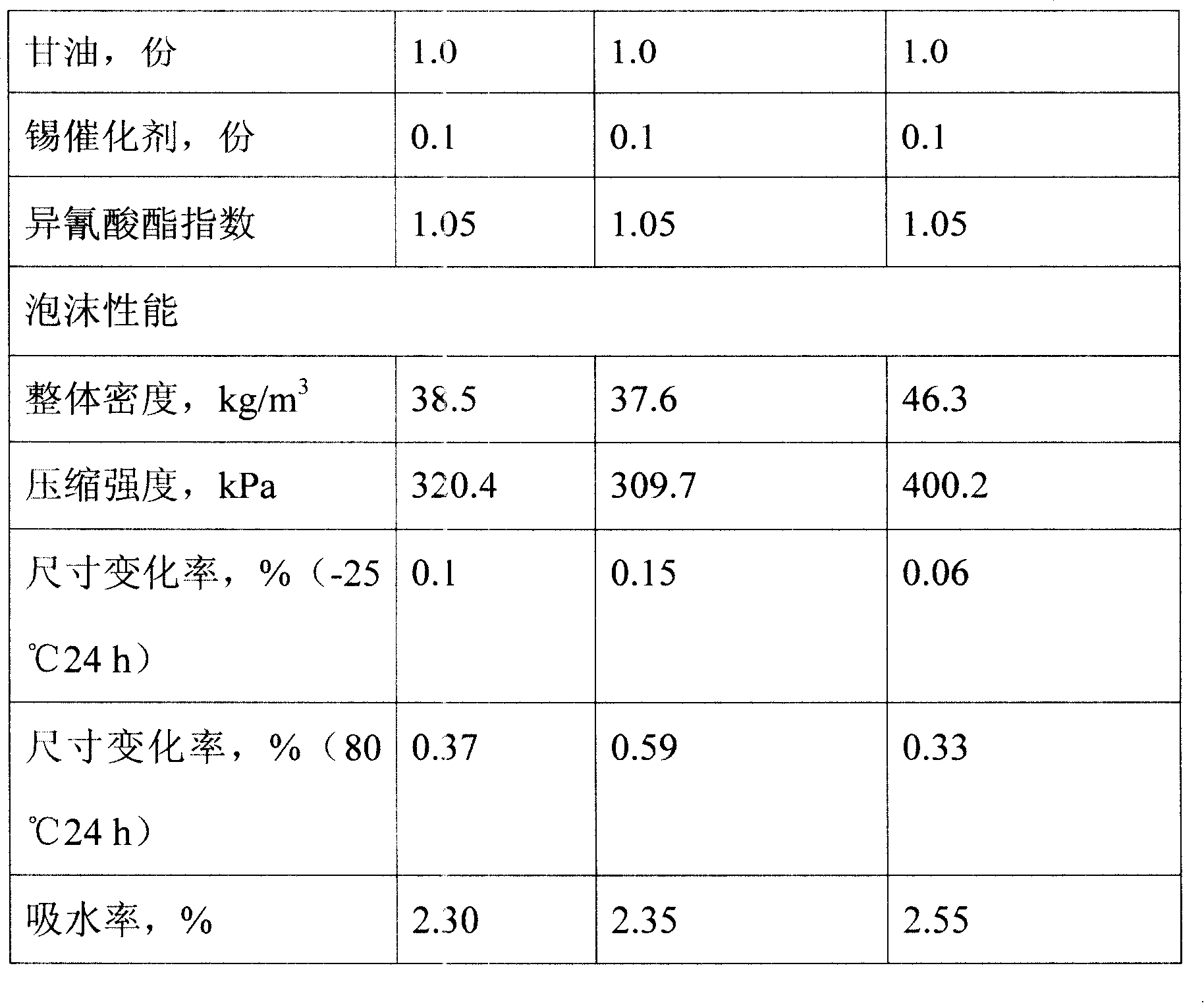

[0031] With the step in embodiment 1, just change polyether polyol A into polyether polyol c. For the foaming conditions and foam properties during the preparation of the above foam samples, please refer to the attached table.

[0032] The foaming conditions and properties of foam samples in the attached table

[0033]

[0034]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com