A kind of purification technology of methyl tert-amyl ether purity standard substance raw material

A technology of methyl tert-amyl ether and standard substances, which is applied in the field of purity standard substances, can solve the problems of high raw material purity requirements, difficult separation, difficult removal, etc., and achieve good economic benefits, simple process, and stable product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

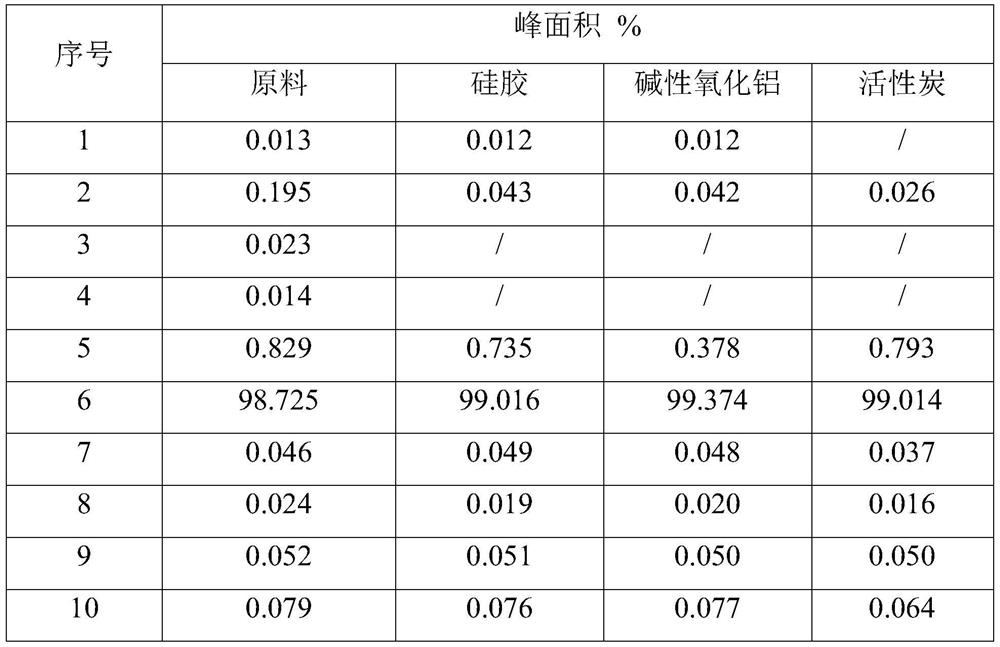

[0041] Example 1 Purification of technical-grade methyl tert-amyl ether by means of sophisticated rectification-adsorption coupling technology.

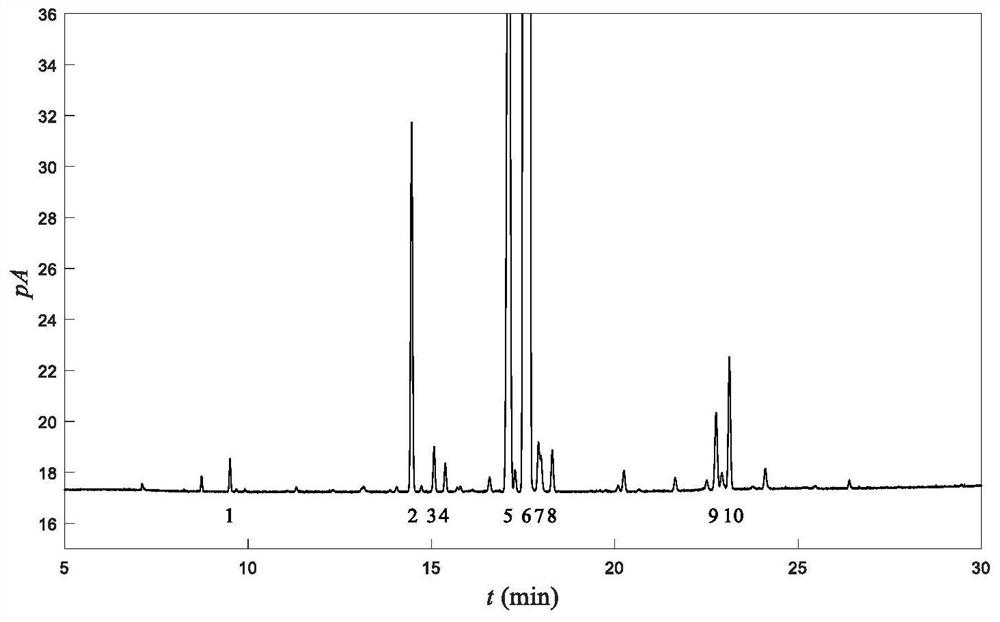

[0042] The raw material of industrial grade methyl tert-amyl ether is purchased from Sigma Company of the United States, the Lot number is BCBS3844V, and the purity of gas chromatography (GC) is 98.73%. According to the analysis of impurities by gas chromatography-mass spectrometry, it contains about 0.23% of various olefin impurities, Alkanes are about 0.21%, and tert-amyl alcohol impurities are about 0.83%.

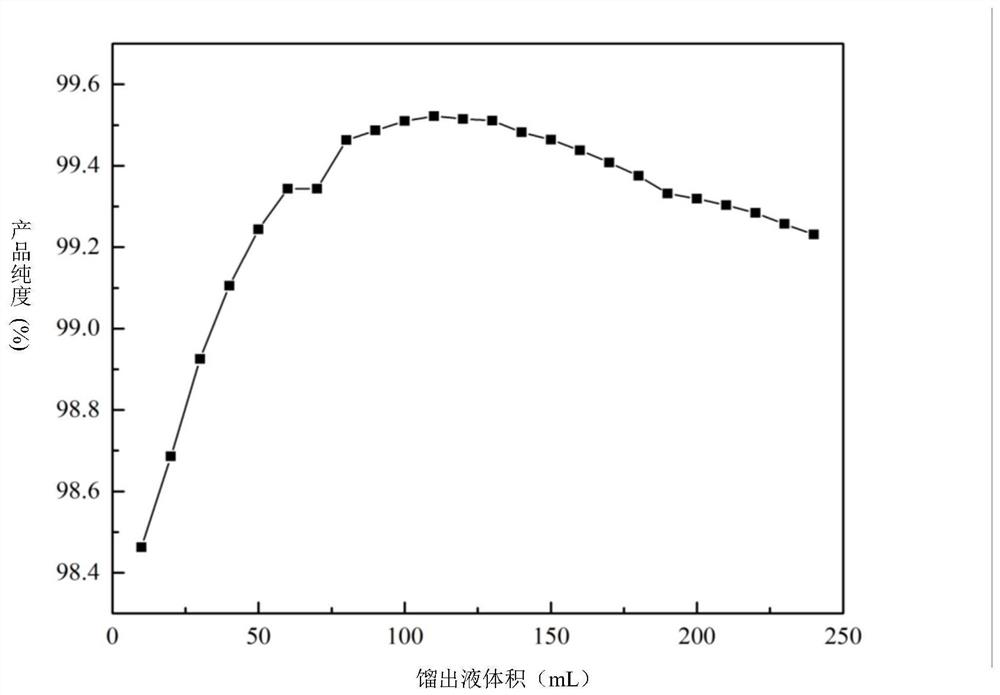

[0043] The inner diameter of the rectification tower is 29mm, the outer diameter is 32mm, the height of the rectification tower is 1m, and the built-in 3mm×3mmθ ring packing, the packing height is 0.6m. The heating voltage of the kettle is 200V, the liquid is boiling and the reflux liquid at the top of the tower just flows down in a stream, and the total reflux is for 3 hours. The product is extracted at a reflux ratio of 10:1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com