Dimethoxymethane gasoline based on various non-national-standard gasoline components

A dimethoxymethane, non-national standard technology, applied in the field of dimethoxymethane gasoline, can solve the problems of transportation, storage, use difficulties, not widely used, low-temperature stratification, etc., and achieve resistance to separation when encountering water High resistance to low temperature separation, improved cost performance, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

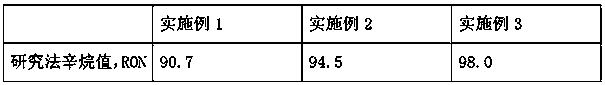

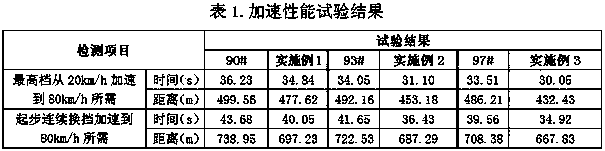

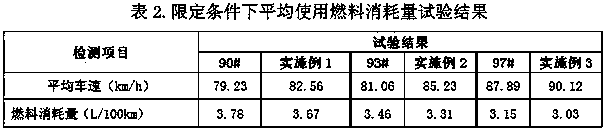

Embodiment 1

[0033] 1. Preparation of functional additives: under normal temperature and pressure, take 5 kg of polyisobutenyl succinimide, 3 kg of fatty acid, and 0.5 kg of cerium dioxide and add them into the tank and stir to mix evenly;

[0034] 2. Preparation of mixed solution: under normal temperature and pressure, add 88 kg of dimethoxymethane (DMM) and 5 kg of tert-amyl methyl ether (TAME) into the tank and mix naturally to obtain a mixed solution;

[0035] 3. Preparation of blended fuel: add 2kg of functional additives to the mixed solution, fully stir and mix evenly;

[0036] 4. Preparation of dimethoxymethane gasoline: Take 10kg of blended fuel, 70kg of naphtha, and 20kg of aromatized gasoline components and mix them in the tank.

Embodiment 2

[0038] 1. Preparation of functional additives: under normal temperature and pressure, take 6.5 kg of polyisobutenyl succinimide, 4 kg of fatty acid, and 1 kg of cerium oxide and add them into the tank, stir and mix evenly;

[0039] 2. Preparation of mixed solution: under normal temperature and pressure, add 95 kg of dimethoxymethane (DMM) and 8 kg of tert-amyl methyl ether (TAME) into the tank and mix naturally to obtain a mixed solution;

[0040] 3. Preparation of blended fuel: add 5kg of functional additives to the mixed solution, stir well and mix evenly;

[0041] 4. Preparation of dimethoxymethane gasoline: Take 20kg of blended fuel, 70kg of naphtha, and 10kg of isomerized gasoline components and mix them in the tank.

Embodiment 3

[0043]1. Preparation of functional additives: under normal temperature and pressure, take 5.5kg of polyisobutenyl succinimide, 3.5kg of fatty acid, and 1kg of cerium dioxide into the tank and stir to mix evenly;

[0044] 2. Preparation of mixed solution: under normal temperature and pressure, add 90 kg of dimethoxymethane (DMM) and 5 kg of tert-amyl methyl ether (TAME) into the tank and mix naturally to obtain a mixed solution;

[0045] 3. Preparation of blended fuel: add 5kg of functional additives to the mixed solution, stir well and mix evenly;

[0046] 4. Preparation of dimethoxymethane gasoline: Take 30kg of blended fuel, 40kg of naphtha, and 30kg of aromatized gasoline components and mix them in the tank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com