Patents

Literature

94results about How to "Has anti-mildew effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

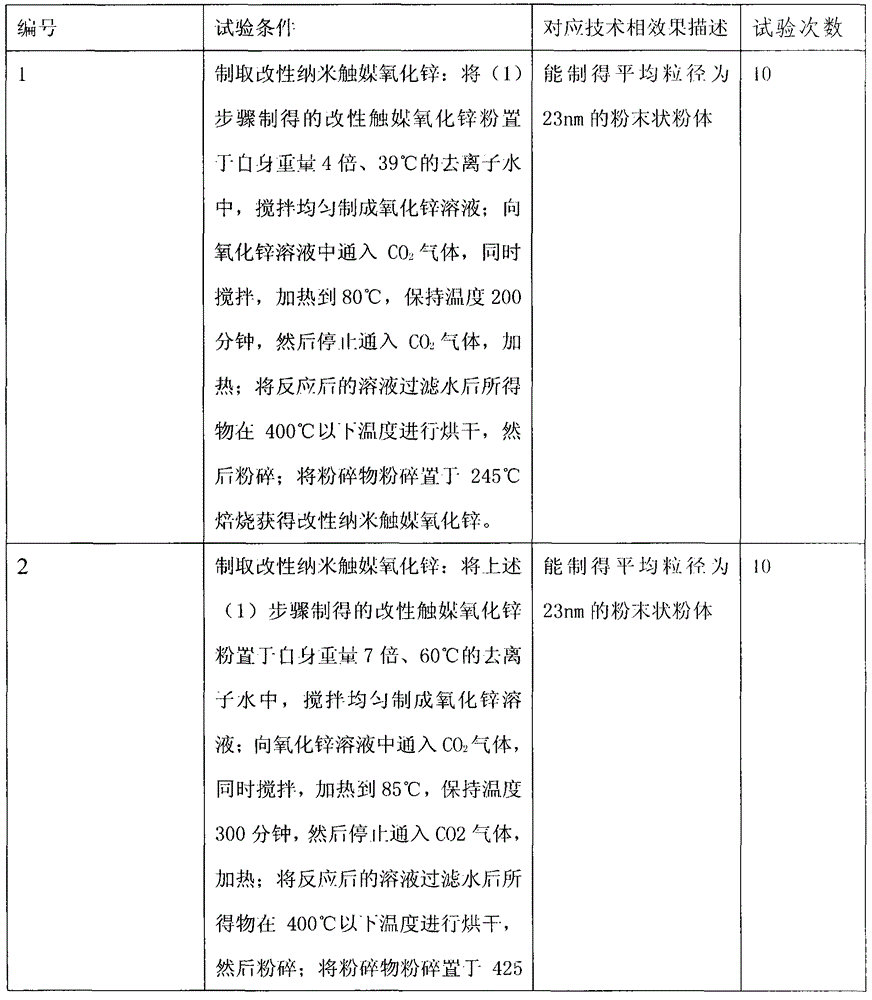

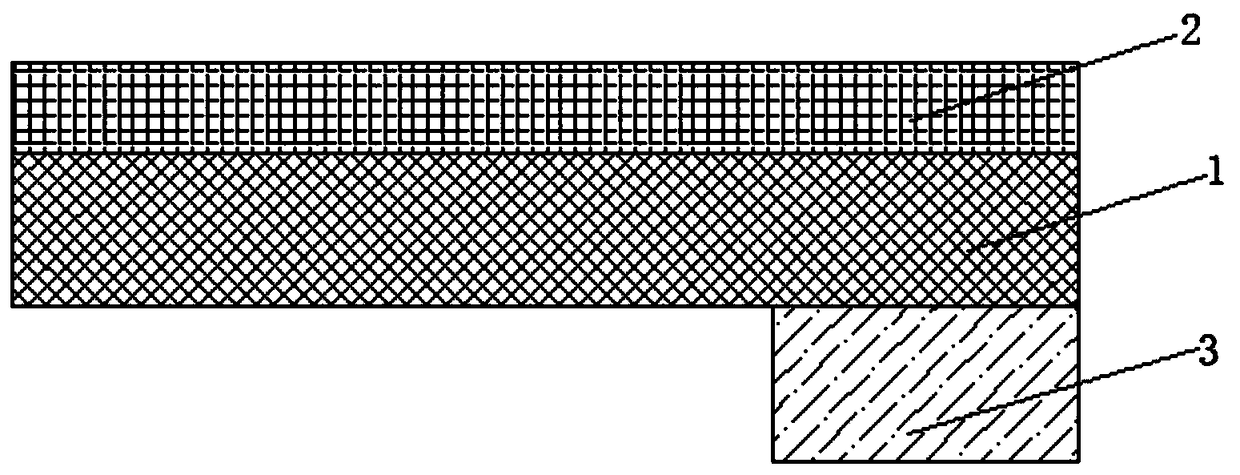

Manufacturing method for high-accuracy coating filter material

InactiveCN102512877AGood acid and alkali resistanceImprove water resistanceSynthetic resin layered productsGlass/slag layered productsFiberLoss strength

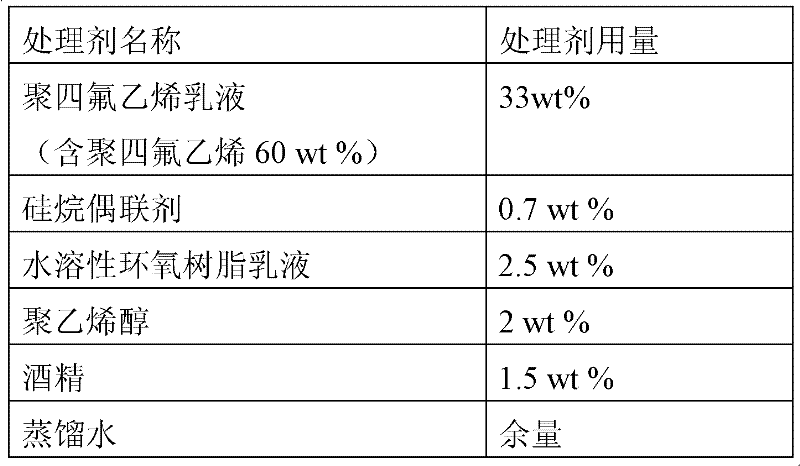

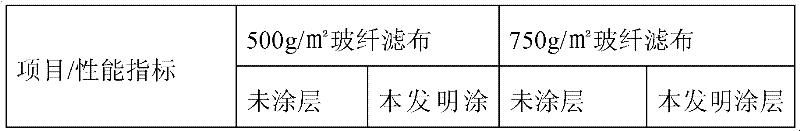

The invention provides a manufacturing method for a high-accuracy coating filter material, which has the advantages of good binding effect between the filter material and PTFE (Polytetrafluoroethylene) and capability of improving the performance of the filter material. The method comprises the following steps of: (1) thermal cleaning treatment, performing the thermal cleaning treatment on the filter material and removing various auxiliary agents on the surface of the filter material through high temperature; (2) dipping treatment, performing PTFE dipping treatment on the filter material which is subjected to the thermal cleaning treatment; (3) sequentially performing baking, drying and thermal forming treatment on the filter material which is subjected to the dipping treatment; (4) performing coating treatment on the filter material which is subjected to thermal forming; and (5) sequentially performing volatile treatment, baking treatment, sintering treatment and thermal forming treatment on the filter material which is subjected to the coating treatment. In the manufacturing method for the high-accuracy coating filter material, the thermal cleaning treatment is performed before the filter material is subjected to the dipping treatment, so that a wire drawing impregnating agent remained on the surfaces of fibers can be effectively removed, meanwhile, no loss strength of a textile is guaranteed; and the acid and alkali resistance, water resistance, oxidation resistance, wear resistance and folding resistance of the filter material are effectively improved, and the service life of the filter material is prolonged.

Owner:辽宁鸿顺环保新材料有限公司

Mildewproof additive for microcrystal stone-wood floor processing

InactiveCN105176105AFragrantEffective against mildew and indoor air qualityActivated carbonSoda lime

The invention discloses a mildewproof additive for microcrystal stone-wood floor processing, relating to the technical field of floor processing. The mildewproof additive for microcrystal stone-wood floor processing is prepared from the following raw materials in parts by weight: 15-20 parts of nano silver, 100-110 parts of zeolite powder, 50-60 parts of soda lime, 25-30 parts of modified gypsum powder, 15-20 parts of tea slag, 12-18 parts of traditional Chinese medicine extract, 12-18 parts of sodium chloride, 10-15 parts of sodium carboxymethyl cellulose, 10-15 parts of activated carbon, 8-12 parts of coffee grounds, 8-12 parts of acetic acid, 6-10 parts of chili powder, 6-10 parts of pepper powder, 40-50 parts of ethanol and 500-600 parts of water. By using the zeolite powder as the main raw material, modifying the zeolite powder with the nano silver and using the multiple mildewproof assistants as the auxiliary materials, the prepared mildewproof additive has the characteristics of fresh smell, high safety and environment friendliness, and can effectively prevent the floor from mildewing and improve the indoor air quality. When in use, the mildewproof additive can be directly added into the floor manufacturing raw material, and has favorable and enduring mildewproof effects.

Owner:安徽温禾新材料科技股份有限公司

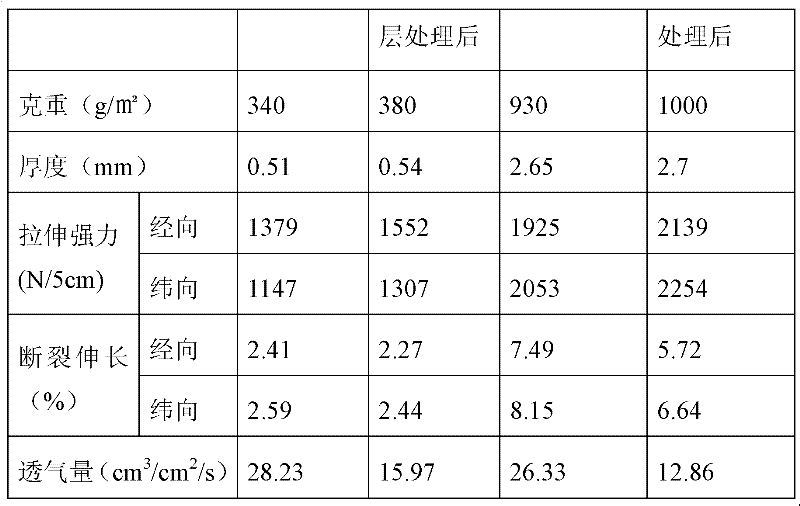

Novel two-dimensional nano paint

The invention relates to a novel two-dimensional nano paint which is characterized by comprising the following components in parts by mass: 20-25 parts of epoxy resin, 10-18 parts of kaolin, 1-3 parts of antimicrobial agent, 1-5 parts of mold preventive, 30-45 parts of two-dimensional nano sericite, 10-20 parts of water, 10-14 parts of titanium white, 10-13 parts of aluminum oxide powder, 1-2 parts of dispersing agent, 2-4 parts of expanded perlite, 1-2 parts of film-forming assistant, 5-10 parts of quartz powder, 15-25 parts of melamine, 20-30 parts of aluminum silicate, 8-15 parts of silicon oxide, 1-3 parts of barium sulfate, 1-3 parts of defoamer, 1-3 parts of wetting agent, 30-35 parts of mixed solvent, 10-18 parts of zinc oxide, 20-38 parts of zinc phosphate, 5-10 parts of sodium hydroxide and 1-8 parts of hydrochloric acid. According to the technical scheme, after the added two-dimensional nano sericite is mixed with other paints to generate a series of reactions, the finally formed paint has the advantages of high chemical stability, excellent heat resistance and excellent acid / alkali resistance, can absorb and reflect ultraviolet rays, and has the antimicrobial and moldproof functions.

Owner:安徽格锐新材料科技有限公司

Manufacturing technique for mildew resistant middle, high-density pressed-fibre board

InactiveCN101269507AExtended service lifeHas anti-mildew effectDomestic articlesFlat articlesFiberFirming agent

The invention belongs to the technical field of artificial board production. The technical proposal comprises the working procedures of wood chip screening and washing, stewing, hot grinding, glue blending and spreading, drying, paving and molding, heat pressing, and cooling. Mildew preventive is directly added in glue solution which is used during the glue blending and spreading, the weight of the mildew preventive is 0.1 to 0.2 percent of the glue solution; then ammonium sulphate which is used as a firming agent is added in, wherein, the weight of the ammonium sulphate is 3 to 4.5 percent of the glue solution, and the concentration is 20 to 30 percent; urea liquid which is used as buffer solution is added in, wherein, the weight of the urea liquid is 1.5 to 2 percent of the glue solution, and the concentration is 20 to 30 percent; the pH value of mixed liquid cement is adjusted to 7.0 to 8.0 by using sodium hydroxide solution the concentration of which is 20 percent, and the mixed liquid cement is used within 30 minutes; the modulated mixed liquid cement is added into fibre to be dried together before the fibre is dried; in the heat pressing stage, the heat pressing temperature is controlled between 170 to 190 DEG C, the heat pressing factors are 8 to 10s / mm, the plank stuff density is controlled between 850 to 870<3>. A medium and high density fibre panel which is manufactured in the invention is led to have mildewproof effect through adding with the mildew preventive, thus the service life of the plank stuff is prolonged, and the application range of the plank stuff is enlarged.

Owner:DONGYING ZHENGHE WOOD IND

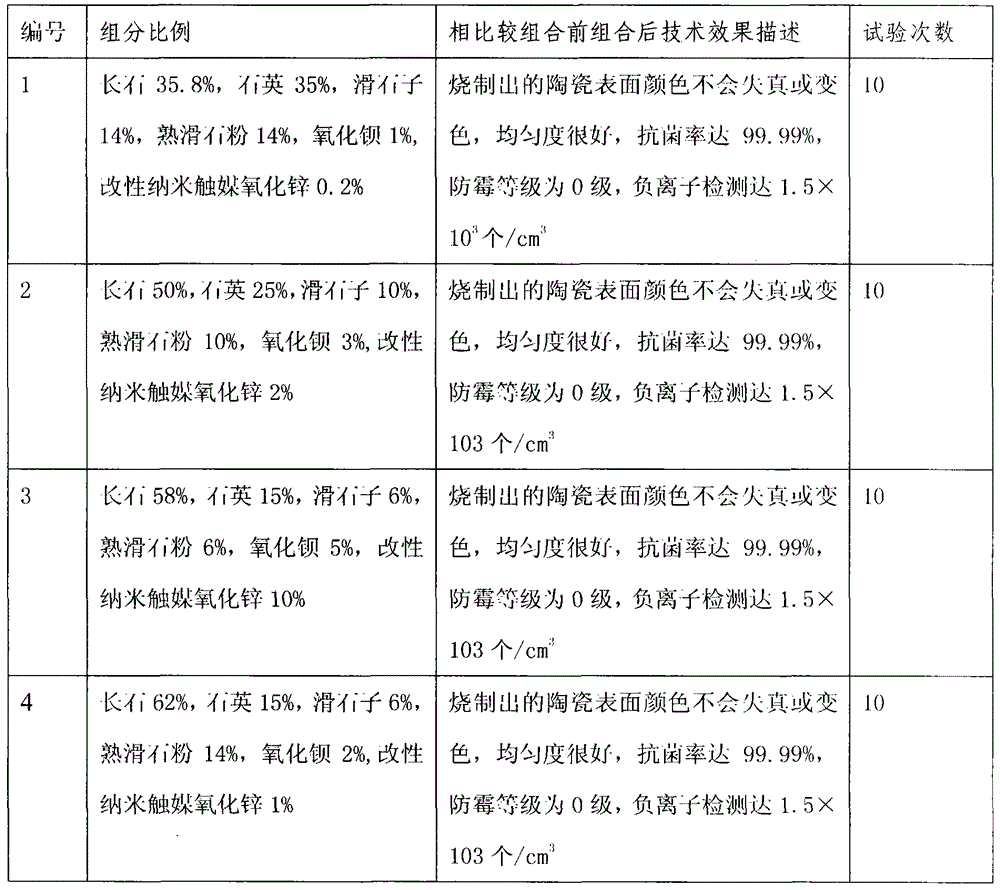

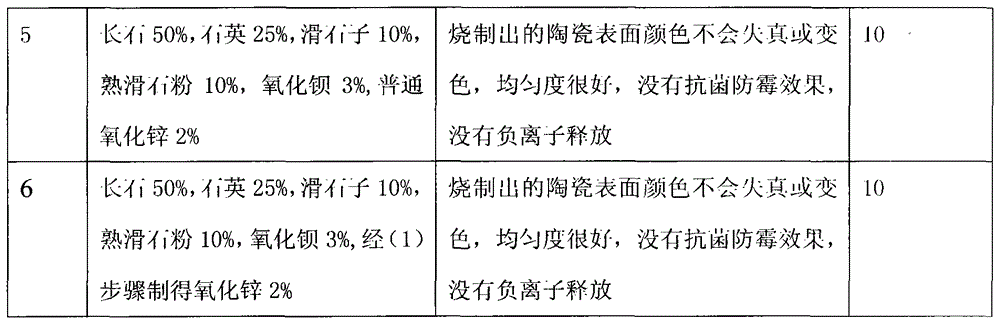

Method for preparing modified nano catalytic zinc oxide antimicrobial ceramic

ActiveCN105985141AFar Infrared Health CareLong-lasting performance of far-infrared health careMaterials scienceIon

The invention provides a method for preparing modified nano catalytic zinc oxide antimicrobial ceramic. The method is characterized in that a sterile antibacterial agent which is the modified nano catalytic zinc oxide antimicrobial liquid or powder is added in glaze, the multifunctional ceramic glaze is prepared. The prepared antimicrobial ceramic has the advantages of antibiosis and mildew-resistant functions, and has the advantages of fast disinfection effect, strong bactericidal activity, good endurance, no secondary pollution, good stability, deodorization, negative ion releasing, and far-infrared health care, the antibacterial rate can reach 99.99%, the mildew-resistant level is 0 grade, and the released negative ions is 1500 / cm<3>. The prepared ceramic can be widely used; distortion or discoloration on the surface of the ceramic cannot be generated; the antibacterial action can be effectively performed for long term; zinc oxide and ceramic basic glaze can be easily mixed; under natural illumination, and the modified nano catalytic zinc oxide can perform multiple functions of antibiosis mildew-resistance, deodorization, negative ion releasing, and far-infrared health care.

Owner:浙江汇千纳米科技有限公司

Preparation method of antimicrobial moldproof MDI (methylenediphenyl diisocyanate) polyurethane foam

ActiveCN102675576AGive full play to antibacterial propertiesGood compatibilityDisinfectantsAfter treatment8-Hydroxyquinoline

The invention discloses a preparation method of antimicrobial moldproof MDI (methylenediphenyl diisocyanate) polyurethane foam, which comprises the following steps: 1) impregnating muscovite powder in oxydol, and treating to obtain expanded muscovite powder; 2) adding the expanded muscovite powder obtained in the step 1 into the trisodium phosphate solution, and treating to obtain a solid product; 3) adding the solid product obtained in the step 2) into an AgNO3 solution, stirring and carrying out after-treatment to obtain immobilized silver muscovite antimicrobial powder; 4) adding the product obtained in the step 3) into a diluter-coupling agent mixed solution, mixing and stirring to obtain a plastic antimicrobial agent; and 5) adding the plastic antimicrobial agent and a mold preventive into a butter PPG reaction kettle, dissolving by stirring, adding auxiliary materials and MDI, stirring at high speed, pouring into a reaction tank, and naturally aging to obtain the product. By using the immobilized silver muscovite powder and the 8-hydroxyquinoline copper mold preventive, the product prepared by the method has antimicrobial performance and moldproof effect.

Owner:FUJIAN YUETE NEW MATERIAL TECH

Preparation method of high-precision coating filter material

ActiveCN104436861AImprove acid and alkali resistanceExtended service lifeSynthetic resin layered productsGlass/slag layered productsPolytetrafluoroethyleneFilter material

The invention provides a preparation method of a high-precision coating filter material. According to the preparation method, the filter material can be well combined with PTFE (Polytetrafluoroethylene), and the performances of the filter material can be improved. The method comprises the following steps: (1) carrying out heat cleaning treatment, namely, performing the heat cleaning treatment on the filter material and removing various assistants on the surface of the filter material at high temperature; (2) performing immersion treatment, that is, performing PTFE immersion treatment on the filter material after heat cleaning treatment; (3) baking, drying, and carrying out heat setting on the filter material after immersion treatment sequentially; (4) coating the filter material after heat setting; and (5) performing volatilization, drying, sintering and heat setting on the filter material after coating treatment sequentially. According to the preparation method of the high-precision coating filter material, the filter material is subjected to heat cleaning treatment before immersion treatment, thus, wiredrawing impregnating compound remained on the surface of the fiber can be effectively removed, and the fabric strength can be ensured not to be lost; the acidic and alkali resistances, the water resistance, the oxidation resistance and the abrasion and folding resistances of the filter material can be effectively improved, and the service life of the filter material can be prolonged.

Owner:辽宁新洪源环保材料有限公司

Method for mildew-proof treatment of bamboos

InactiveCN106042114AAnti-corrosionMildew proofNervous disorderWood treatment detailsCooking & bakingMildew

The invention discloses a method for mildew-proof treatment of bamboos and belongs to the technical field of bamboo processing. According to the method, the raw materials comprising, by weight, 7-9 parts of mildew-proof liquid, 73-82 parts of water and 11-18 parts of quick lime are adopted. The method includes the following steps that a, the quick lime is placed in a pool, the mildew-proof liquid and the water are added into the pool afterwards and evenly stirred, and then a bamboo product is placed in the pool to be soaked for 65-70 hours; b, the bamboo product is taken out of the pool and placed in a shade place to be air-dried for 68-72 hours; and c, the bamboo product air-dried in the step b is placed in a baking oven to be baked at the temperature of 72-80 DEG C for 20-23 minutes, so that a finished product is obtained. By means of the method, the problem that existing bamboo products are prone to mildew can be solved.

Owner:三江县善茶轩工艺品有限公司

Preparation method of antibacterial wool flocculus

InactiveCN106400472ABreathableImprove dehumidification effectCarbon fibresBiochemical fibre treatmentReducerCell metabolism

The invention provides a preparation method of antibacterial wool flocculus. The preparation method mainly comprises the following steps: supplying a kind of wool flocculus, a nanometer silver dispersed solution and a reducer; and impregnating the wool flocculus in the nanometer silver solution to carry out impregnation reduction, and then carrying out press-rolling and drying treatment to obtain the antibacterial wool flocculus. The preparation method is simple and feasible and is suitable for automation production in a large scale. Meanwhile, a product prepared by the preparation method has the characteristics of air permeability, strong moisture exhaust performance and capabilities of promoting sleep and cell metabolism, enhancing vitality, delaying aging and inhibiting germs, and can effectively prevent various skin lesions and pruritus.

Owner:HENAN INST OF ENG

Quartz sand/fire clay composite alcohol group casting coating and preparation method thereof

InactiveCN104014720AGood suspensionLow gas productionFoundry mouldsFoundry coresFire resistanceMaterials science

The invention discloses a quartz sand / fire clay composite alcohol group casting coating. The quartz sand / fire clay composite alcohol group casting coating is characterized by comprising following raw materials in part by weight: 40-60 of quartz sand, 30-40 of fire clay, 3-4 of rosin, 1-2 of kieselguhr, 0.2-0.4 of zinc borate, 0.1-0.3 of calcium stearate, 0.4-0.8 of magnesium chloride, 1-4 of waste foam plastic particles, 1.2-3.2 of ammonium sulfate, 1.1-2.4 of abietate, 4-7 of traditional Chinese medicine dregs, 0.3-0.6 of dichloromethane, 40-50 of ethyl alcohol, and 3-6 of an adjuvant. The coating provided by the invention has the advantages that the coating is not easy to settle, the suspension property is good, air sending volume is small, high temperature is resisted, the fire resistance is good, the coating property is good, the traditional Chinese medicine dregs after processing are added into the raw materials, the coating has an anti-mould effect, the suspension effect of the coating is improved, and thus the coating is suitable for different castings.

Owner:方学军

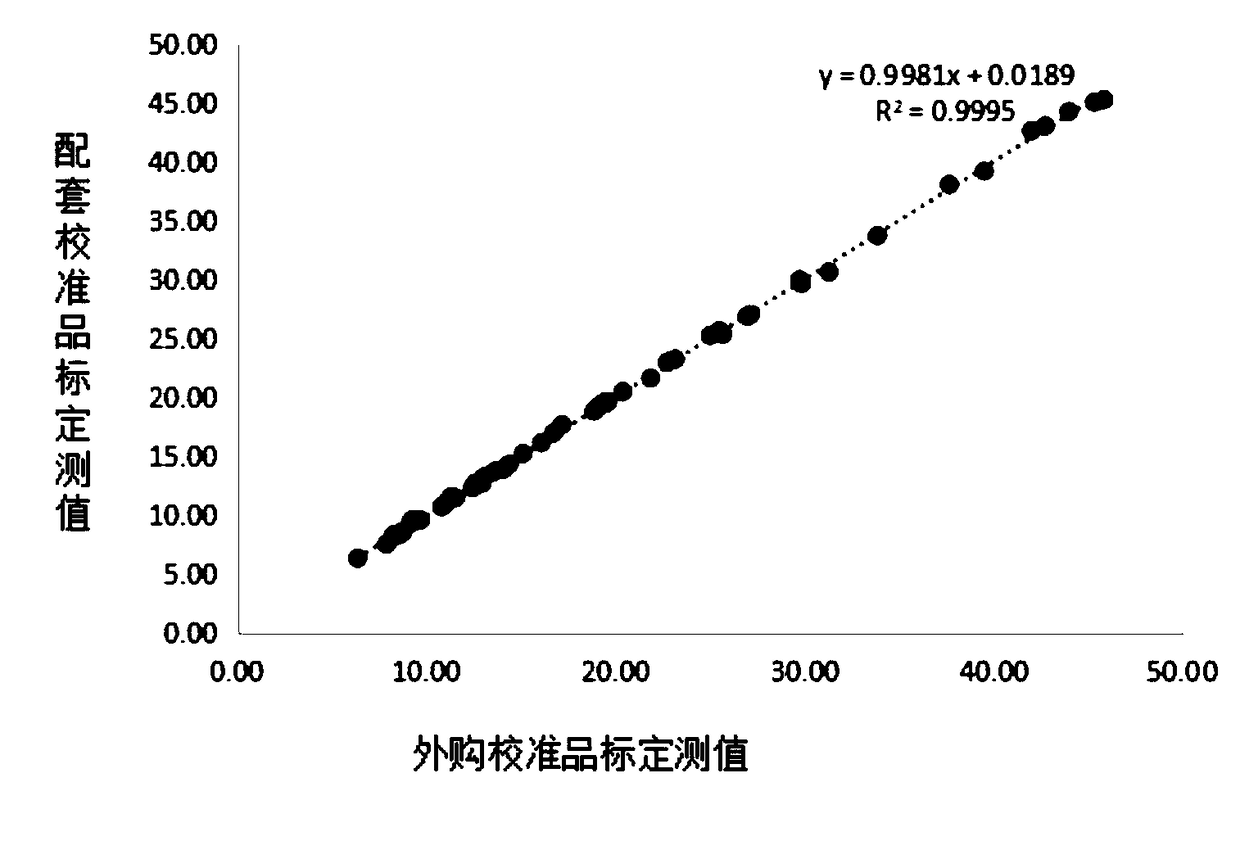

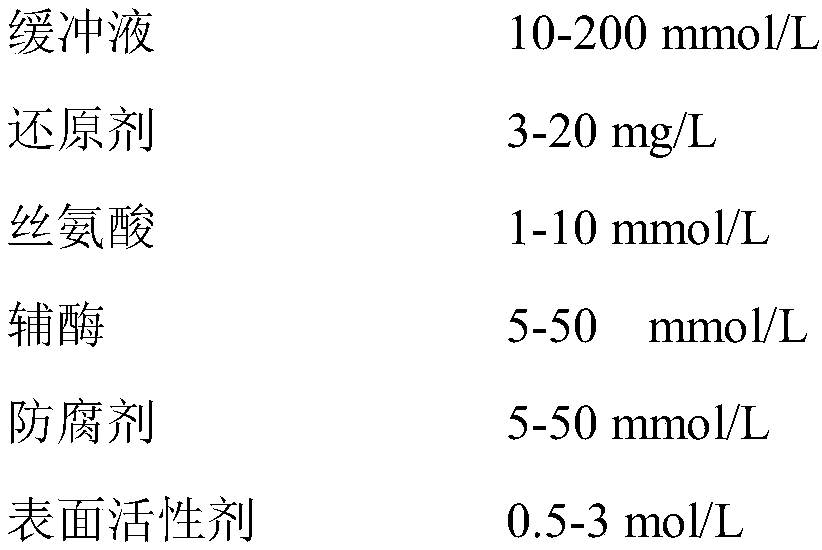

Convenient and stable detection kit for homocysteine and detection method

The invention provides a convenient and stable detection kit for homocysteine and a detection method. The kit comprises a reagent R1, a reagent R2, and a HCY liquid calibration solution. The reagent R1 contains a buffer, a reducing agent, a serine, a coenzyme preservative, and a surfactant. The reagent R2 contains a buffer, a surfactant, a lactate dehydrogenase, a stabilizer, an antioxidant, a preservative, a cystathionine beta-synthase, and a cystathionine beta-lyase. The HCY liquid calibration solution contains a stabilizer, a preservative, and homocysteine. The antioxidant is added into thekit, so that the attenuation of the enzyme under various interference factors is inhibited, and the stability of the kit in the special environment and the validity period is effectively improved.

Owner:QINGDAO HIGHTOP BIOTECH

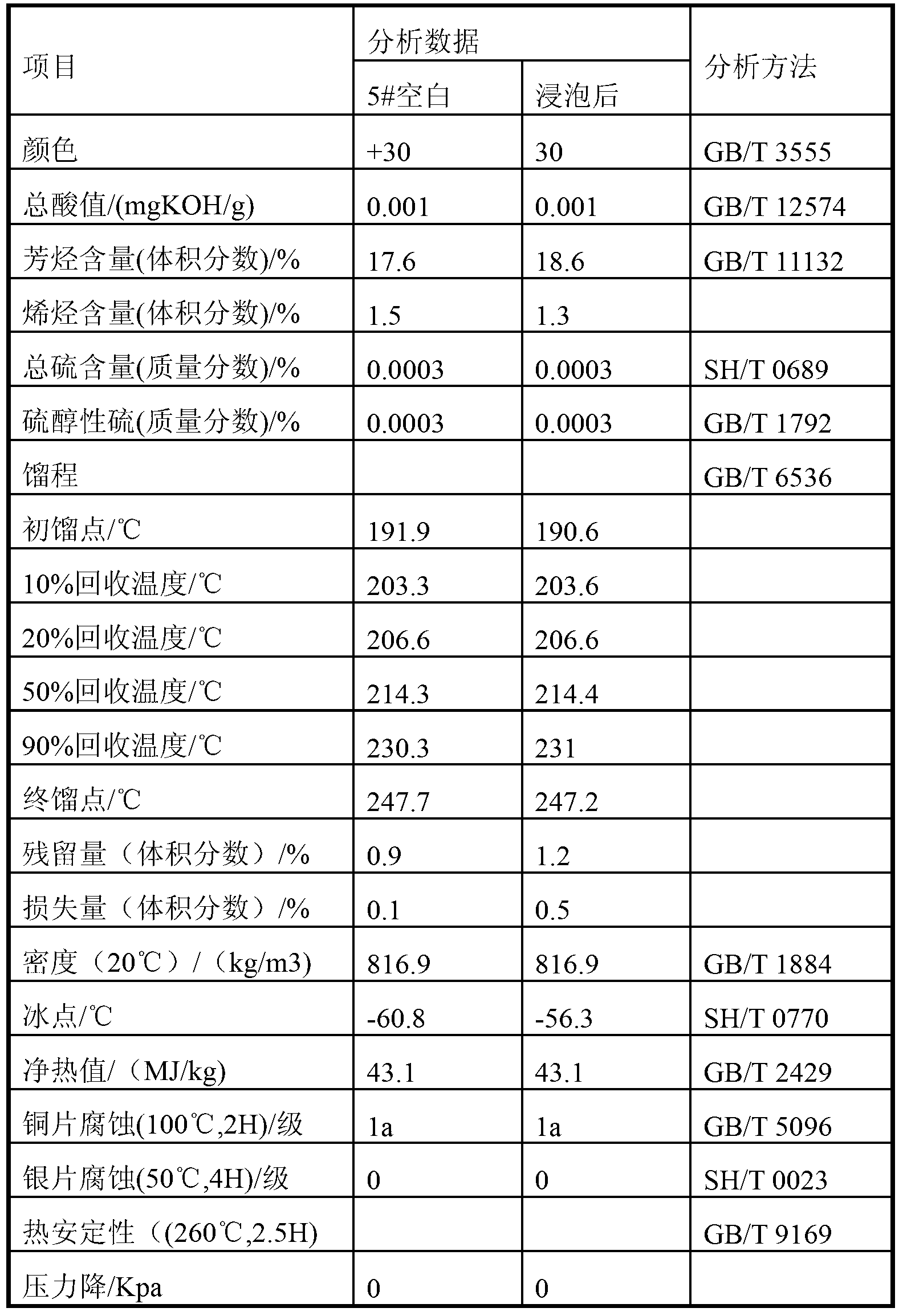

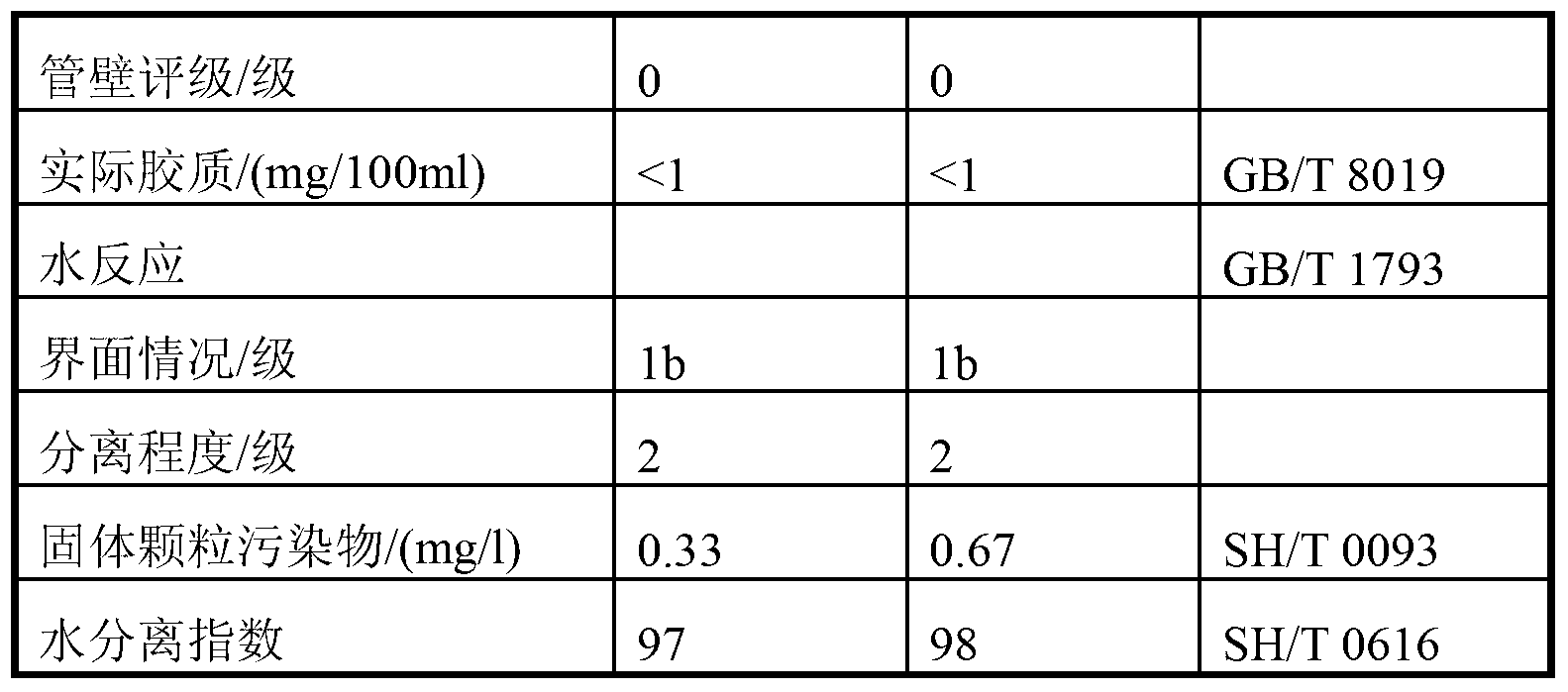

Metal oil tank mould-proof conductive electrostatic anticorrosive coating

InactiveCN103254737AHas anti-mildew effectAntifouling/underwater paintsPaints with biocidesEpoxyLighter fuel

The invention discloses a metal oil tank mould-proof conductive electrostatic anticorrosive coating which comprises a component A and a component B, wherein the component A comprises modified epoxy resin, a solvent, a dispersing agent, a conductive material and a functional filler; and the component B is a composite epoxy curing agent prepared from polyamide resin, a modified amine curing agent and n-butyl alcohol. The metal oil tank mould-proof conductive electrostatic anticorrosive coating is characterized in that the component A comprises a mildew preventive and zinc oxide whiskers; and the conductive material is conductive mica powder. Before use, the component A and the component B are mixed according to a weight ratio of 20:1-1.5. The multiple experiments prove that the coating has excellent mildew resistance, has excellent mold resistance on the specific strains of aircraft fuel, meets the static conductive requirements of light fuel oil, can be widely applied to inner walls of oil tanks, vehicles and oil pipelines and is environment-friendly on the oil.

Owner:REAR SERVICE TECH EQUIP INST NAVY PLA

Environment-friendly high-efficiency wallpaper adhesive

InactiveCN104559850AExtended service lifeHas antibacterial propertiesNon-macromolecular adhesive additivesStarch adhesivesCelluloseEmulsion

The invention discloses an environment-friendly high-efficiency wallpaper adhesive which is prepared from the following raw materials in parts by weight: 20-40 parts of acrylate copolymer emulsion, 10-20 parts of polyvinyl alcohol, 3-8 parts of cellulose, 3-8 parts of urea-formaldehyde resin, 1-5 parts of polysiloxane, 5-10 parts of starch, 0.5-5 parts of anion powder, 0.3-0.8 part of formaldehyde remover, 0.2-0.6 part of antifreezing agent, 1-3 parts of thickener and 30-60 parts of deionized water. Compared with the prior art, the wallpaper adhesive has the advantages of very high binding force, low shedding tendency and short curing time, can not damage the surface of the wallpaper or wall, and prolongs the service life of the wallpaper. The material is environment-friendly, can not generate any pollution to the environment or human body, and has antimicrobial and moldproof effects.

Owner:KUNSHAN YUESHUO BUILDING MATERIALS

Antibacterial and anti-mite organic cotton composite fiber fabric and processing process thereof

InactiveCN111534905AHas anti-mildew effectGuaranteed cleanlinessBiochemical fibre treatmentLiquid/gas/vapor removalPolyesterPolymer science

The invention discloses antibacterial and anti-mite organic cotton composite fiber fabric and a processing process thereof. The antibacterial and anti-mite organic cotton composite fiber fabric is formed by mutually interweaving warp yarns and weft yarns; the warp yarns are made of organic cotton fiber and the weft yarns are made of polyester fiber; the proportion of the organic cotton fiber is 24percent and the proportion of the polyester fiber is 76 percent; antibacterial and anti-mite aids are arranged in the organic cotton fiber and the polyester fiber; the antibacterial and anti-mite aids are fixed in the organic cotton fiber and the polyester fiber and are protected by the organic cotton fiber and the polyester fiber; the antibacterial and anti-mite aid comprises quaternary ammoniumsalt and organic silicon; 10 percent of bamboo fiber is added in the organic cotton fiber; the organic cotton fiber and the bamboo fiber are blended; and the antibacterial and anti-mite cloth can damage the cell walls of bacteria and prevent the metabolic process of microorganisms, so that the microorganisms cannot grow and reproduce. Reproduction of mites is inhibited and peculiar smell caused by the microorganisms is prevented. The antibacterial, mildew-proof and anti-mite agent can effectively resist bacteria and prevent mites and has good anti-mite effect.

Owner:SIMMONS BEDDING&FURNITURE (SUZHOU) LTD

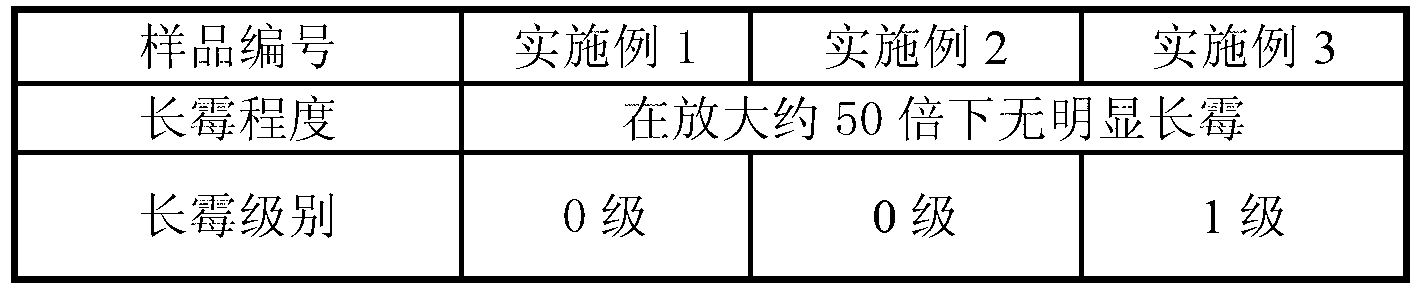

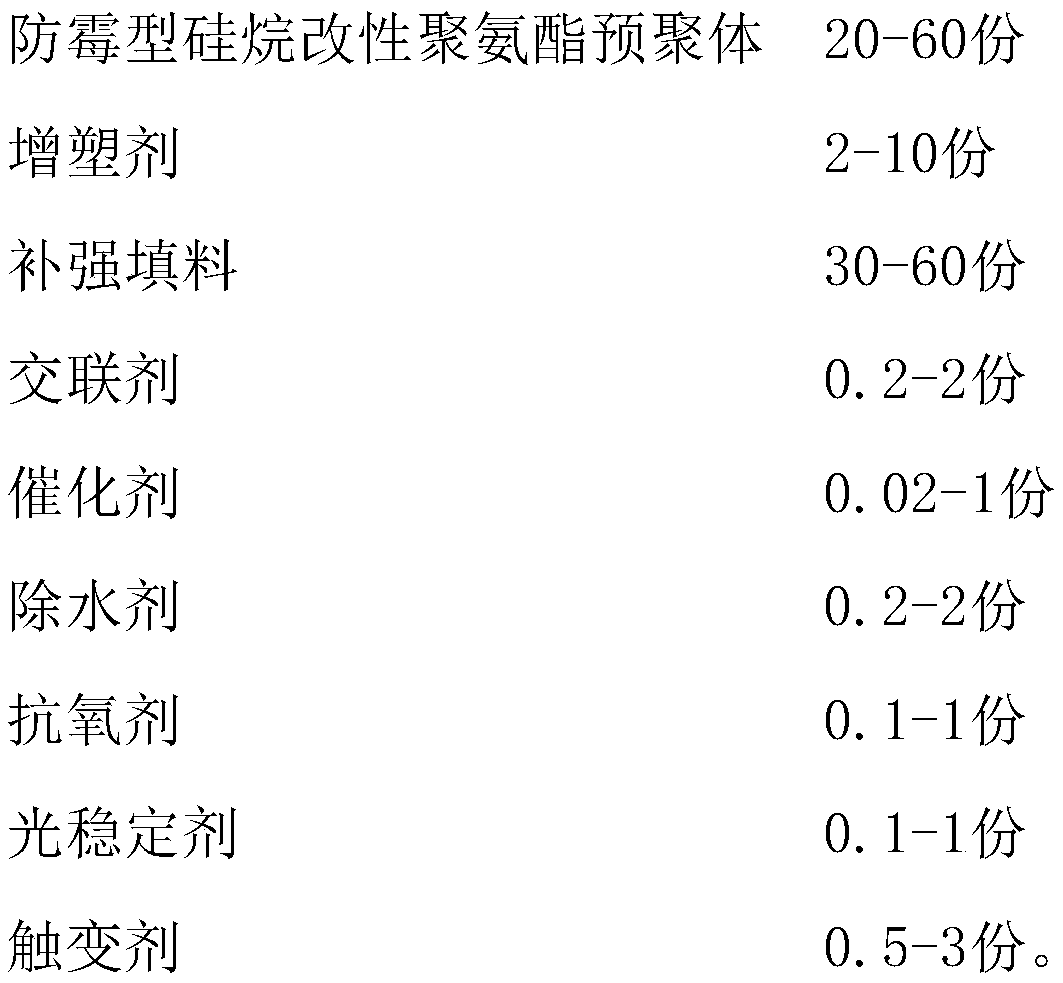

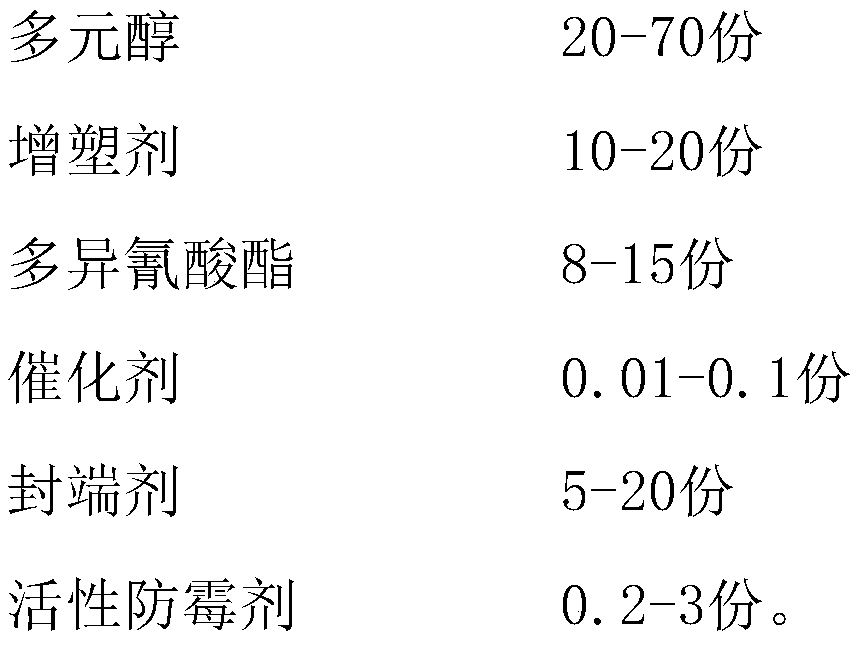

Mildew-proof silane modified polyurethane sealant and preparation method thereof

InactiveCN110655898AGood adhesionNot easy to yellowNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPrepolymerPolymer chemistry

The invention relates to the technical field of sealants, and concretely relates to a mildew-proof silane modified polyurethane sealant and a preparation method thereof. The sealant comprises, by weight, 20-60 parts of a mildew-proof silane modified polyurethane prepolymer, 2-10 parts of a plasticizer, 30-60 parts of a reinforcing filler, 0.2-2 parts of a crosslinking agent, 0.02-1 part of a catalyst, 0.2-2 parts of a water removal agent, 0.1-1 part of an antioxidant, 0.1-1 part of a light stabilizer and 0.5-3 parts of a thixotropic agent. The mildew-proof silane modified polyurethane sealanthas excellent cohesiveness, and is not prone to yellowing; the sealant is prepared by adopting a mildew-proof silane modified polyurethane prepolymer, so that the prepared silane modified polyurethanesealant has a stable and lasting mildew-proof effect, is not prone to yellowing, and is suitable for kitchen and bath decoration; and the preparation method of the polyurethane sealant has the advantages of simplicity in operation, convenience in control, low production cost and high product quality, and is used for large-scale production.

Owner:GUANGDONG PUSTAR SEALED RAYON CO LTD +1

Environment-friendly adhesive

InactiveCN106281210AHigh bonding strengthImprove water resistanceNon-macromolecular adhesive additivesProtein adhesivesAdhesiveBuffering agent

The invention relates to an adhesive and in particular relates to an environment-friendly adhesive. The environment-friendly adhesive is prepared from the following components in parts by weight: 8 to 11 parts of plant starch, 16 to 22 parts of soybean protein powder, 5 to 8 parts of oxidized starch, 2 to 4 parts of a biological enzyme, 6 to 9 parts of microcrystalline cellulose, 4 to 5 parts of an initiator, 5 to 8 parts of a silane coupling agent, 5 to 7 parts of talcum powder, 3 to 5 parts of bentonite, 1 to 2 parts of a preservative, 5 to 6 parts of a thickening agent, 3 to 4 parts of a rosin modifying agent, 2 to 3 parts of a buffering agent, 1 to 3 parts of a mildew-proof agent and 40 to 50 parts of water. The adhesive provided by the invention is green and environmentally friendly and any component polluting the environment is not added; in a utilization process, injuries to health of human bodies are not caused; the environment-friendly adhesive has the advantages of relatively high bonding strength, water resistance and heat resistance, relatively low curing temperature, relatively good anticorrosion protection and the like, belongs to the environment-friendly type adhesive and also has a mildew-proof effect.

Owner:林映霞

Method for producing a moisture-keeping fresh-keeping healthy material with Vitamin

ActiveCN1732788APrevent drynessKeep freshOrganic chemistryFruit and vegetables preservationVitamin CWater vapor

Disclosed is a method for producing a moisture-keeping fresh-keeping healthy material with Vitamin, which comprises applying functional substances such as vitamin C onto substrate of porous material, then appending adhesive of inorganic or organic compounds, metallic ions or metallic oxides. The obtained material has water resistance and heat resistance to aqueous vapor.

Owner:SHUNDE APOLLO AIR CLEANER +3

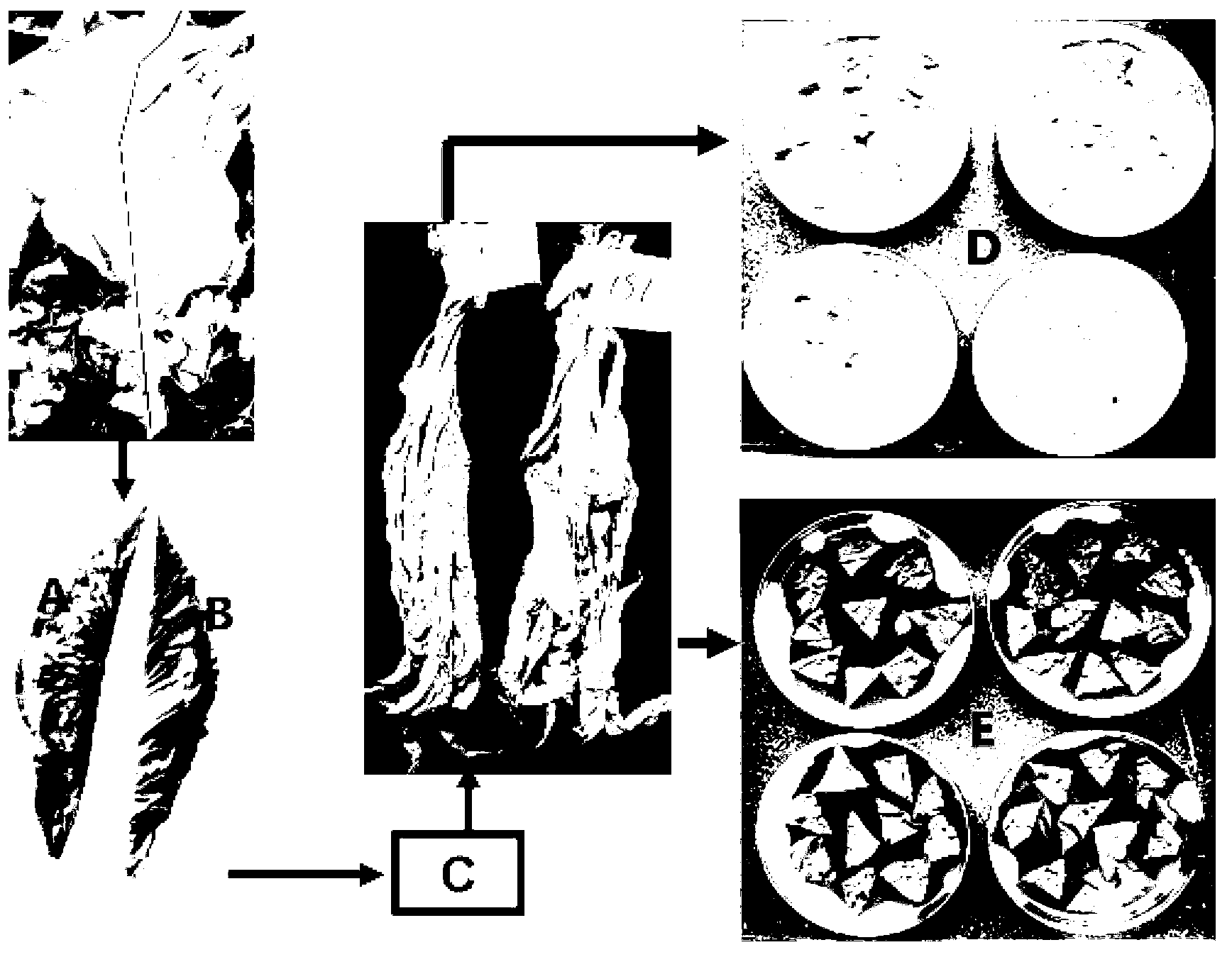

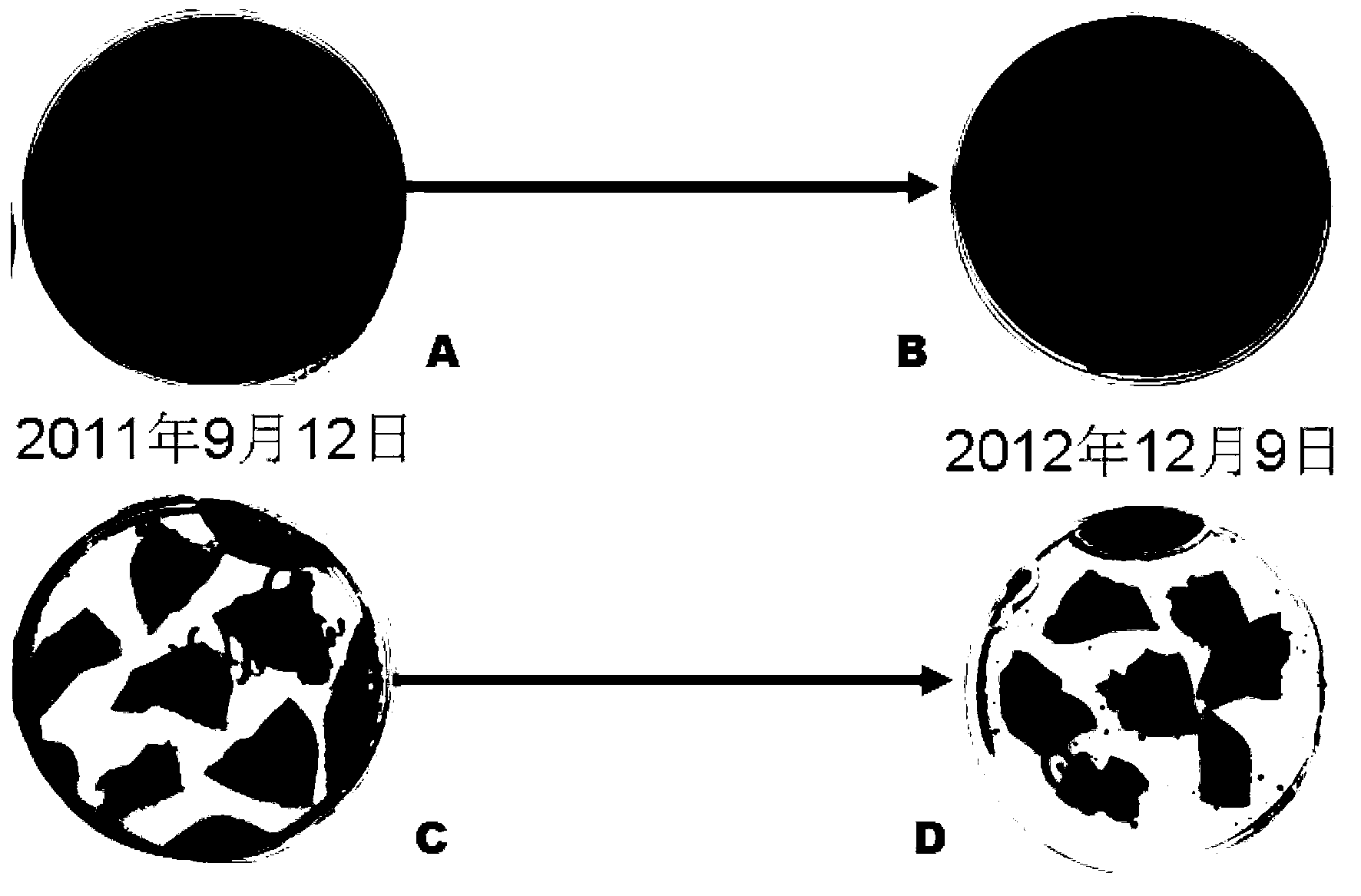

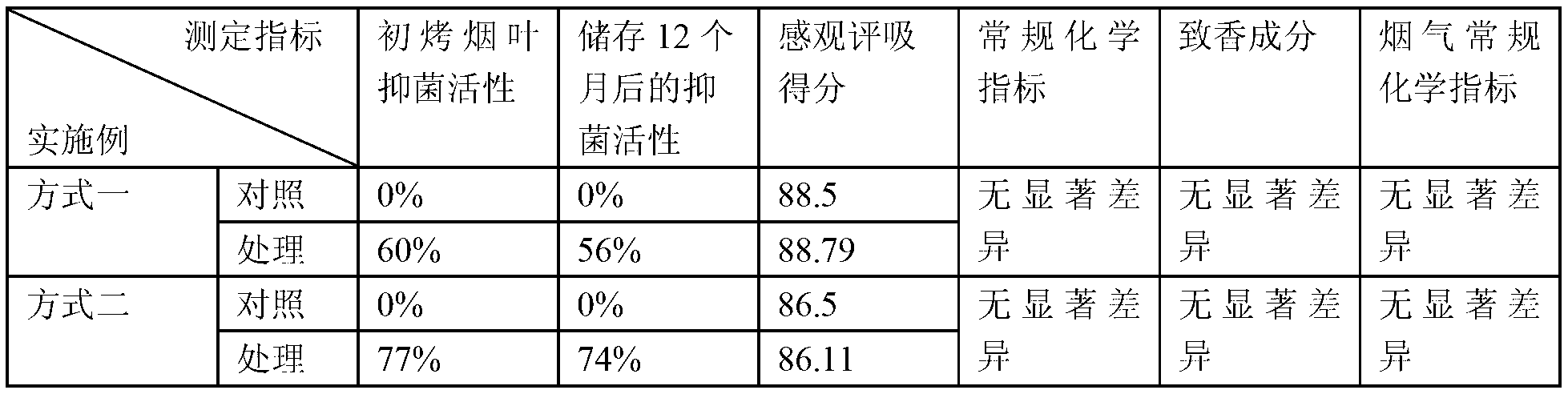

Flue-cured tobacco mildew preventive

The invention discloses flue-cured tobacco mildew preventive. The flue-cured tobacco mildew preventive is prepared from 0.002%-0.2% of natamycin, 0.02%-0.08% of potassium citrate and the balance of water which are uniformly mixed. The flue-cured tobacco mildew preventive is uniformly added to fresh tobacco leaves in a preliminary baking stage by adopting a spraying or soaking method, and the fresh tobacco leaves are preliminarily baked according to a conventional three-step baking technology after being loaded, so that the tobacco leaves has resistance to mildew microorganisms. Experiments prove that the mildew preventive disclosed by the invention has no influence on the tobacco leaves and is non-toxic and non-irritant for human bodies. The mildew preventive the advantages of being simple in technology and low in operating cost, enabling the resistance to the mildew microorganisms of the tobacco leaves to run through the whole process from tobacco leaf braking to storage, preventing the tobacco leaves from mildewing in the processes of preliminary baking, classification, transportation and storage and having good popularization and application value and economic benefits.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD +1

Leather garment stain remover

ActiveCN103666854AHas anti-mildew effectEfficient removalBiocideNon-surface-active detergent compositionsSodium bicarbonatePropanoic acid

The invention relates to a leather garment stain remover which comprises the following components in mass part: 10-22 parts of sodium lauraminopropionate, 10-25 parts of sodium sulfafe decahydrate, 6-15 parts of polyvinyl pyrrolidone-iodine, 1.2-3 parts of alkyldimethylbenzylammonium chloride, 2.5-5 parts of lactic acid, 1-3.5 parts of tetrachloroethylene, 0.3-0.8 part of 2,4-dichlorobenzyl alcohol, 0.2-0.6 part of sodium bicarbonate and 50-70 parts of water. The leather garment stain remover provided by the invention can effectively remove greasy dirt and stains on the surface of the leather garment, and kills bacteria on the surface of the garment; the treated garment has the mildew-proof effect, and the aging speed of the leather is lowered.

Owner:吴美娟

Preparation method of antibacterial mildew-resistant high-buffer slow-recovery polyurethane soft foam

The invention discloses a preparation method of antibacterial mildew-resistant high-buffer slow-recovery polyurethane soft foam. The antibacterial mildew-resistant high-buffer slow-recovery polyurethane soft foam is prepared by means of a polyurethane soft foam formulation modifying technique; silver-supported mica antibacterial powder is used herein and has good dispersibility and compatibility with raw and auxiliary materials for the production of polyurethane and other plastics; the antibacterial property of the silver-supported mica antibacterial powder can be given to full play so that the prepared foam has antibacterial performance; in addition, copper 8-hydroxyquinoline is used as a mildew preventive so that the prepared antibacterial mildew-resistant MDI memory polyurethane foam can prevent mildew; MDI (diphenylmethane diisocyanate) is used as a raw material to replace existing TDI (toluene diisocynate), and the prepared foam has low cost and is more environmentally friendly.

Owner:FUJIAN YUETE NEW MATERIAL TECH

Foam bacteriostatic liquid soap and production method thereof

InactiveCN107049855AEasy to useTake advantage ofAntibacterial agentsCosmetic preparationsBetaineCuticle

The invention relates to foam bacteriostatic liquid soap and a production method thereof. The foam bacteriostatic liquid soap is characterized by comprising the following components in parts by weight: 5-15 parts of polyoxyethylene fatty alcohol sodium sulfate, 5-10 parts of cocoamidopropyl betaine, 0.1-2 parts of sodium chloride, 0.01-0.1 part of natural essence, 0.5-2 parts of a humectant, 0.1-0.5 part of sodium alginate, 0.1-1.0 part of a plant antibacterial agent and 10-30 parts of deionized water. The foam bacteriostatic liquid soap provided by the invention is safe and non-irritant and convenient to use, has obvious antibacterial effect and small dosage, and can quickly remove peculiar smells and effectively clean various oil stains and blots; the humectant in the liquid soap is beneficial for moisturizing skin and softening cuticles, so that metabolism of skin is accelerated, and the foam bacteriostatic liquid soap further plays a skin moisturizing role.

Owner:黄胜华

Sound-absorbing material for buildings

A sound-absorbing material for buildings comprises the components in parts by mass: 15-20 parts of high-density polyethylene, 10-15 parts of hollow glass micro-beads, 4-7 parts of diatomite, 2-6 parts of silicon carbide, 3-9 parts of zirconium dioxide, 3-7 parts of a wetting agent, 6-10 parts of a mica powder, 6-12 parts of organic silicon modified epoxy resin, 3-8 parts of a mixed solvent, 6-10 parts of xylosma racemosum wood chips, and 5-10 parts of attapulgite. By the technical scheme, the sound-absorbing material for the buildings can absorb most of noise in an environment, has a good effect on bass, and besides, has a certain mouldproof function.

Owner:洛阳暖盈电子技术有限公司

Mould-proof wallpaper loaded with medicine-loading chitosan and preparing method of mould-proof wallpaper

ActiveCN106283923AImprove anti-mold and anti-bacterial propertiesEffect of anti-mildew and anti-bacterial performanceCoatings with pigmentsSpecial paperFiberCross-link

The invention discloses a mould-proof wallpaper loaded with medicine-loading chitosan and a preparing method of the mould-proof wallpaper. According to the mould-proof wallpaper, a chitosan / glacial acetic acid mixed solution serves as a carrier, a sodium tripolyphosphate aqueous solution serves as a cross-linking agent, the chitosan / glacial acetic acid mixed solution, the sodium tripolyphosphate aqueous solution and a mould-proof antibacterial agent aqueous solution are mixed with an ion cross-linking method, medicine-carrying chitosan microsphere emulsion is obtained and sprayed to the surface of base paper of PVC wallpaper with plant fiber body paper as a base material, and various chitosan / PVC medicine-carrying mould-proof wallpaper is prepared after drying. The mould-proof wallpaper prepared with the method meets the grade-zero standard of the national standard (GB / T 24346-2009), and the mould-proof effect is excellent. According to the mould-proof wallpaper and the preparing method thereof, the medicine-carrying chitosan microsphere emulsion is obtained through mixing with the ion cross-linking method, an organic solvent does not need to be introduced, and thus the prepared mould-proof wallpaper is environmentally friendly and safe.

Owner:FUJIAN AGRI & FORESTRY UNIV

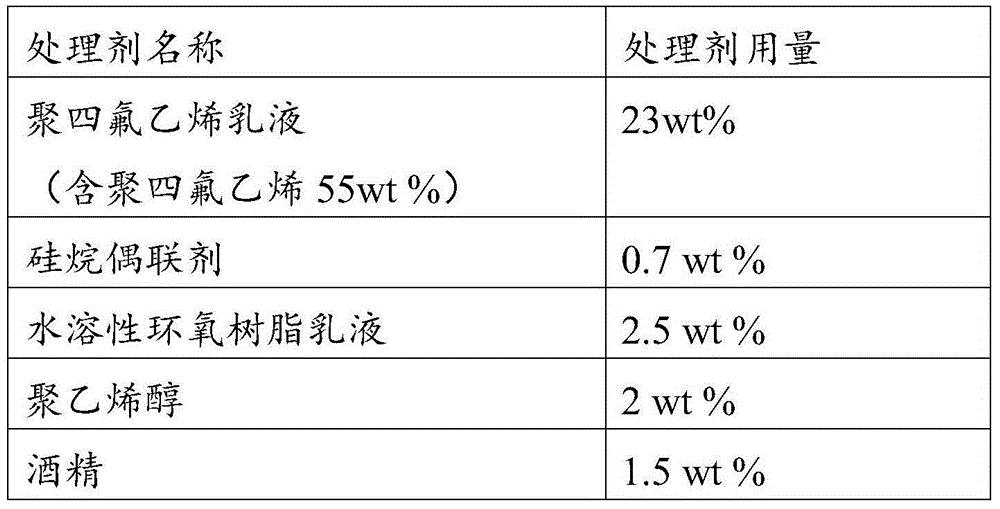

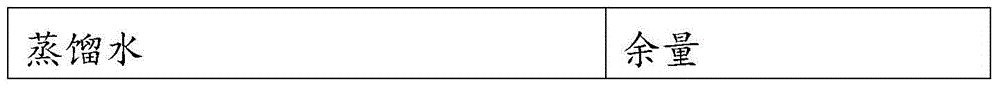

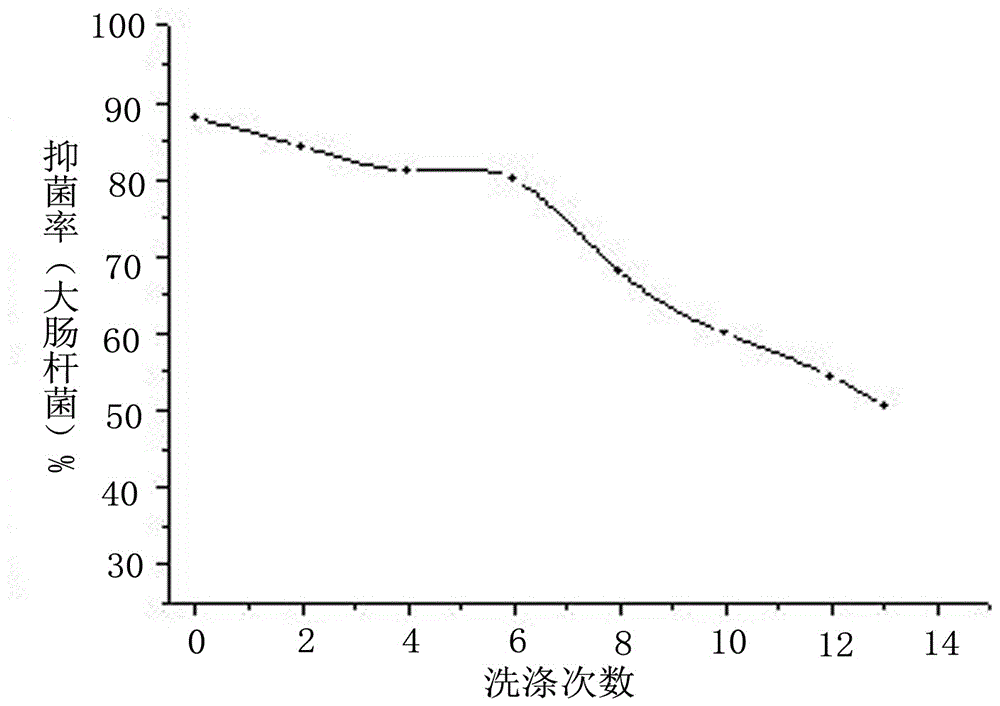

High-molecular-weight polyethylene fiber eight-strand rope

The invention relates to a high-molecular-weight polyethylene fiber eight-strand rope. Eight strands herein include four Z-twist and four S-twist ones subjected to alternate hollow braiding by twisting; in terms of the selection and design of strand material and structure, the strands are composed of a core, a strand body and a surface treatment layer, the core is made by twisting high-molecular-weight polyethylene fibers, an outer layer is made by braiding twisted yarns of the high-molecular-weight polyethylene fibers, and the outer layer of the high-molecular-weight polyethylene is infiltrated with the surface treatment layer with an ethanol or propylene glycol solvent. The high-molecular-weight polyethylene fibers have high specific strength and high specific modulus, so that the rope herein can float on water and is nearly twice as high as aromatic amide fibers in elongation, chemical corrosion resistance and impact absorbing capacity; the cores made with twisted fibers have excellent impact resistance and cutting resistance; the outer layer is made with braided twisted yarns, so that the rope herein is convenient for human hands to hold with rarity of loosening; the high-molecular-weight polyethylene fibers selected herein help reduce the high labor intensity in marine project construction due to high water absorption, and provide improved construction efficiency; the surface treatment layers can soften the rope herein and prevent mildews, so that the life of the rope is extended.

Owner:涂巨丹

Preparation method of antibacterial and mildew-proof TDI (toluene diisocyanate) memory polyurethane foam

The invention discloses a preparation method of antibacterial and mildew-proof TDI (toluene diisocyanate) memory polyurethane foam. The preparation method comprises the following steps of: 1) impregnating white mica powders in hydrogen peroxide to obtain expansion white mica powders after treatment; 2) adding the expansion white mica powders from the step 1 to trisodium phosphate solution to obtain a solid product after treatment; 3) adding the solid product from the step 2 to AgNO3 solution to obtain a solid-supported silver mica antibacterial agent after stirring and post-treatment; 4) adding the product from the previous step to the mixed solution of a diluting agent and a coupling agent for mixing, and then stirring to obtain a plastic antibacterial agent; and 5) adding the plastic antibacterial agent and a mildew-proof agent to a reaction kettle of butter PPG (Polypropylene Glycol) to realize dissolution by stirring, then adding a variety of accessories and TDI, stirring at high speed and then pouring the mixture into a reaction tank, and finally, naturally aging to obtain the product. According to the invention, the solid-supported silver mica antibacterial agent and the 8-hydroxyquinolinate mildew-proof agent are employed to result in antibacterial property and mildew-proof effect in the prepared product.

Owner:FUJIAN YUETE NEW MATERIAL TECH

Green, environmentally-friendly, waterproof, antibacterial and mildew-resistant decoration coating and preparation method thereof

InactiveCN108395745AExcellent waterproof performanceUniform natureAntifouling/underwater paintsPaints with biocidesFiberPolyvinyl alcohol

The invention discloses a green, environmentally-friendly, waterproof, antibacterial and mildew-resistant decoration coating and a preparation method thereof. The decoration coating comprises, by weight, 30-40 parts of polyamine resin, 15-25 parts of butyl acrylate, 10-16 parts of polyvinyl alcohol, 4-8 parts of a modified nano-additive, 8-10 parts of ore powder, 2-4 parts of a mildew inhibitor, 1-3 parts of a botanical bactericide, 4-6 parts of hollow ceramic microbeads, 2-4 parts of reinforced fibers, 1-3 parts of titanium dioxide, 5-7 parts of a flame retardant additive, 6-9 parts of a processing enhancing additive and 18-24 parts of deionized water. The coating has the advantages of excellent hydrophobic and impermeable performances, good film forming performance, smooth and fine surface, certain sterilizing, bacterium-killing and mildew-resisting effects, realization of greenness and environmental protection due to the use of the botanical antibacterial and mildew-resistant additives, safe and reliable raw material components, no toxic or harmful volatile substances, low cost, simple process, high practical values and good application prospect.

Owner:HEFEI FANTENG ENVIRONMENTAL PROTECTION TECH CO LTD

TPR soft rubber insole and manufacturing method thereof

InactiveCN109206767AImprove antibacterial propertiesIncrease the shock absorption functionInsolesSynthetic resin layered productsAdhesivePolystyrene

The invention discloses a TPR soft rubber insole and a manufacturing method thereof, and the TPR soft rubber insole comprises an insole body layer, a deodorizing antibacterial layer and a shock absorbing layer, wherein the insole body layer comprises the following raw materials by weight: styrene butadiene copolymer, phenolic resin , ethylene-vinyl acetate copolymer, polystyrene, 2,6-tert-butyl-4-methylphenol, 8-Hydroxyquinoline copper(II) salt, and the like, and the deodorizing antibacterial layer comprises the following parts by weight of raw materials: a film-forming resin, and the like. The manufacturing method comprises the following steps: S1, processing the insole body layer; S2, processing the deodorizing antibacterial layer; S3, processing the shock absorbing layer; and S4, bonding the deodorizing antibacterial layer with an adhesive to the upper end of the insole body layer, and bonding the shock absorbing layer to the lower end of the insole body layer to obtain the TPR softrubber insole. The deodorizing antibacterial layer is arranged on the upper end of the insole body layer, and the shock absorbing layer is arranged on the lower end of the insole body layer, so thatthe deodorizing antibacterial effect and the shock absorption function of the TPR soft rubber insole can be improved, and the TPR soft rubber insole works well.

Owner:扬州朗劲塑胶实业有限公司

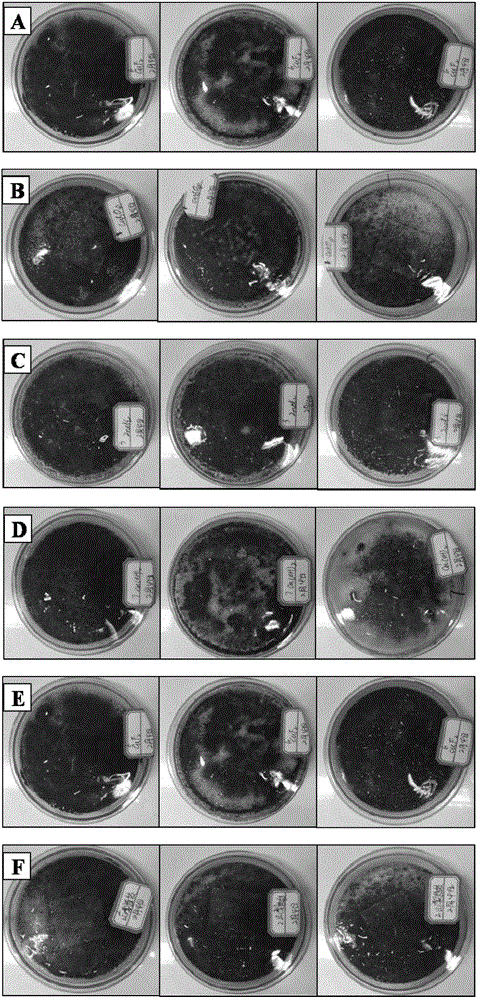

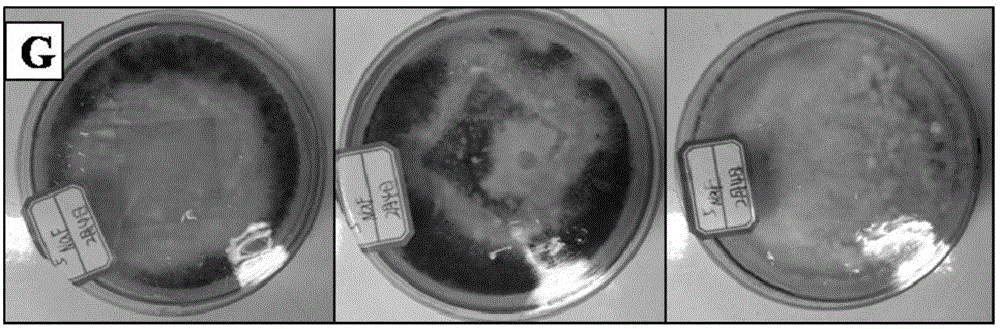

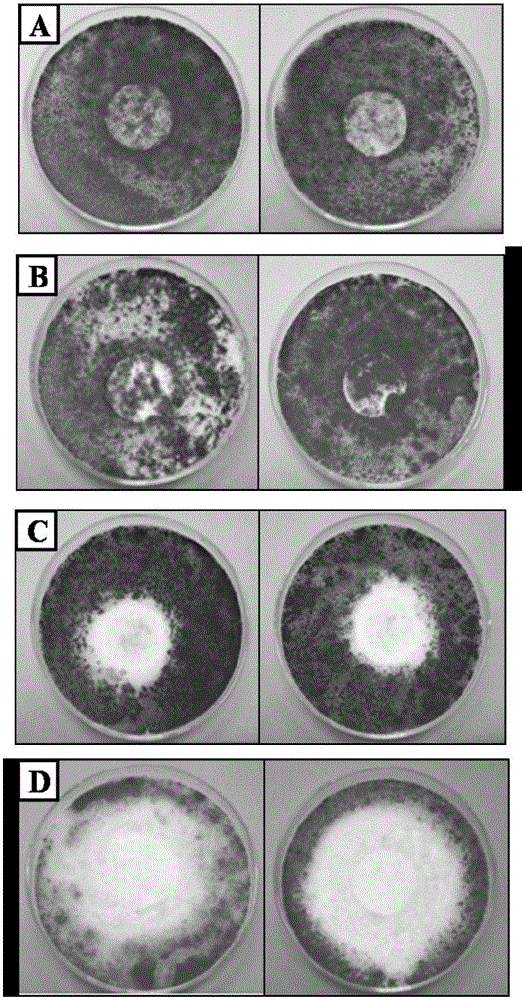

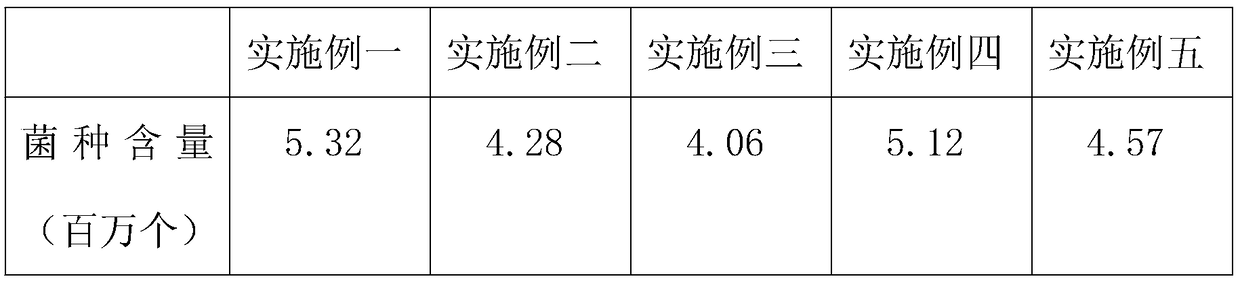

Bacillus pumilus with anti-mildew function

The invention discloses a bacterial strain for preventing mildew of stored flue-cured tobacco strips, and belongs to the field of biological control of plant diseases. The strain has been collected in China General Microbiological Culture Collection Center on August 23, 2010 with the collection number of CGMCC No.4116, and is classified and named Bacillus pumilus. The strain can inhibit the growth of mould of the flue-cured tobacco strips, has good control effect on the mildew caused by the mould, and comprises an active ingredient of a whole culture solution culture or spores of the Bacilluspumilus LZ-7. The bacterial strain has the advantages of low production and use cost, convenience in use, good anti-mildew effect, promotion of alcoholization of the flue-cured tobacco strips and thelike, and overcomes the defects that a chemical mildewproof agent easily influences the quality of the flue-cured tobacco strips, easily causes residue and the like.

Owner:TOBACCO RES INST CHIN AGRI SCI ACAD +1

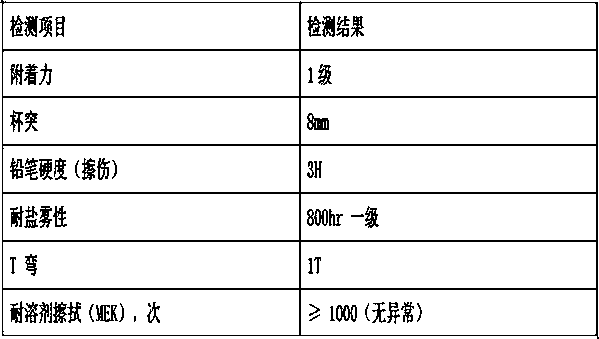

Coil coating and production method thereof

ActiveCN109233568AGood outdoor weather resistanceGood gloss and color retentionEpoxy resin coatingsEpoxyChemical reaction

The invention relates to the field of coating, in particular to coil coating and a production method thereof. The coil coating comprises the following raw materials in parts by weight: 80-120 parts ofepoxy resin, 50-70 parts of acrylic resin, 15-20 parts of polyvinylidene fluoride, 3-5 parts of garnet, 10-15 parts of glass fiber, 5-10 parts of titanium dioxide, 5-10 parts of zinc oxide, and 0.5-2parts of auxiliary agent. The prepared coil coating has a reflection effect on ultraviolet light, prevents the aging, powdering, cracking and other damage of a formed film caused by the photochemicalreaction of the ultraviolet light on a coating, and enhances the weather resistance of the coating; and the coil coating has excellent comprehensive mechanical properties, high storage stability, good decorativeness, protectiveness, durability, stamping resistance, abrasion resistance, light resistance, weather resistance, scratch resistance, physical hardness and the like, fine texture, smooth appearance, no dust accumulation, gloss and color retention and excellent adhesiveness, and is not easy to yellow.

Owner:广西南宁维一防腐科技有限公司

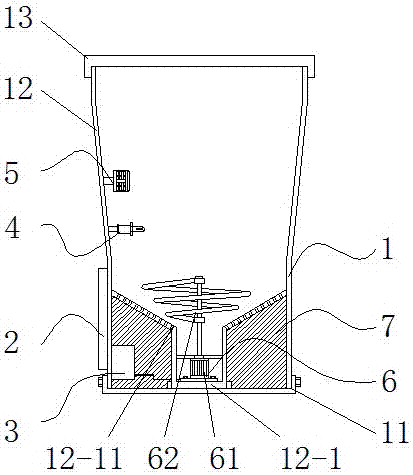

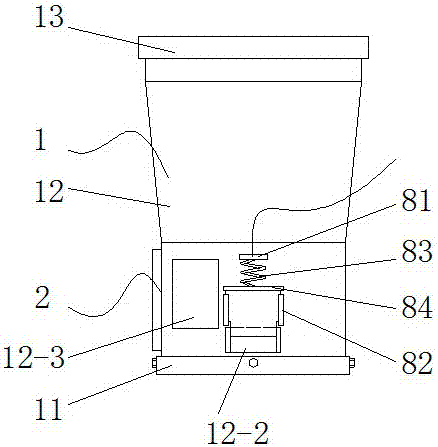

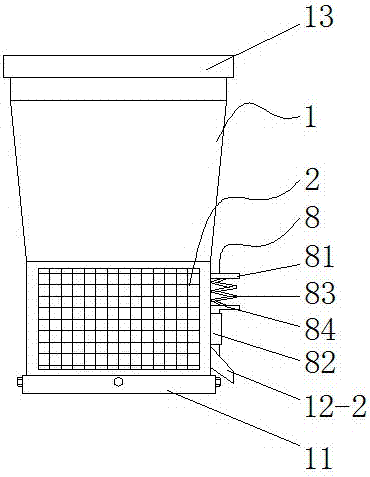

Novel rice storage bucket

InactiveCN107380746APrevent long-term depositionWith purification and anti-mildewPowdered material dispensingBio-packagingClamp connectionEngineering

The invention discloses a novel rice storage bucket, and relates to the field of rice storage devices. The novel rice storage bucket comprises a rice bucket body, a solar photovoltaic panel, a battery, a temperature sensor, a humidity sensor, a motor assembly, high-temperature activated bamboo charcoal bags and a rice taking opening baffle assembly. The rice bucket body is composed of a bottom cover, a bucket body and a bucket cover, wherein the bottom cover is fixedly connected with the lower end of the bucket body, the bucket cover is in clamped connection with the upper end of the bucket body, and the solar photovoltaic panel is fixedly connected with the side wall of the bucket body. The battery, the temperature sensor and the humidity sensor are all fixedly connected with the inner wall of the bucket body. A funnel-shaped partition plate is arranged inside the bucket body; the motor assembly and the funnel-shaped partition plate are fixedly connected; the high-temperature activated bamboo charcoal bags are placed in two side cavities formed by the bottom cover and the funnel-shaped partition plate; and the rice taking opening baffle assembly is fixedly connected with the side wall of the bucket body. The novel rice storage bucket enables rice to be fed from the upper portion and discharged from the lower portion, the temperature and humidity in the bucket can be monitored in real time, and the advantages of damp prevention, mildew prevention and insect inhibition are achieved.

Owner:HUAIAN YUETA RICE IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com