TPR soft rubber insole and manufacturing method thereof

A technology of insole and soft rubber, which is applied in the field of TPR soft rubber insole and its manufacturing, can solve the problems of sweat absorption, sterilization and shock absorption, etc., and achieve the effects of easy promotion and use, low production cost and improved usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

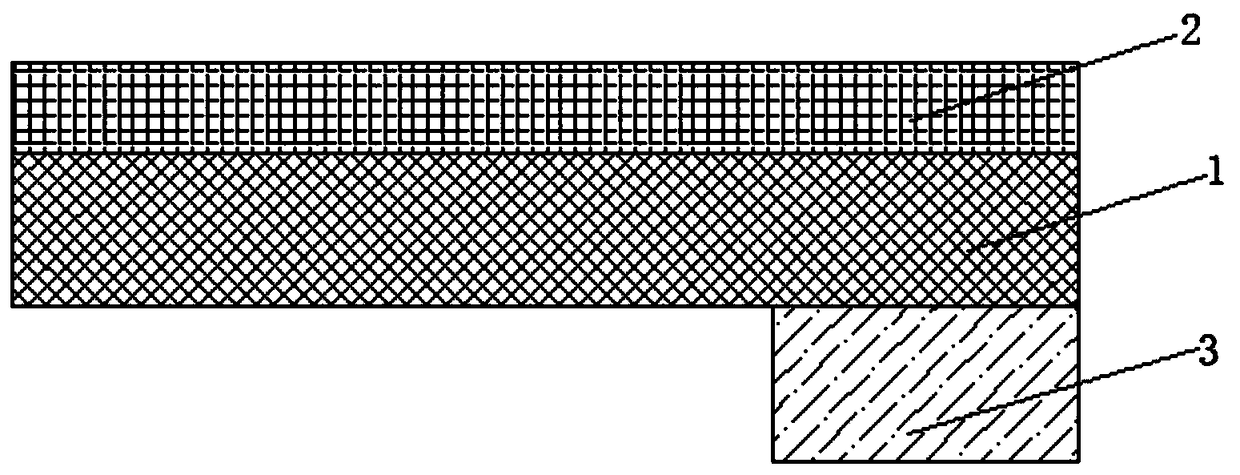

[0023] Embodiment one: refer to figure 1 , a TPR soft rubber insole, comprising a shoe-pad body layer 1, an anti-odor antibacterial layer 2 and a shock-absorbing layer 3, the shoe-pad body layer 1 comprising the following raw materials in parts by weight: 40 parts of styrene-butadiene copolymer, 15 parts of phenolic resin, 12 parts of ethylene-vinyl acetate copolymer, 70 parts of polystyrene, 3 parts of 2,6-tertiary butyl-4-methylphenol, 5 parts of 8-hydroxyquinoline copper, bis(3,5-tertiary butyl 2 parts of 4-hydroxyphenyl) sulfide, 3 parts of polydimethylsiloxane, 5 parts of fatty acid amide, 5 parts of zinc stearate, 1 part of toluidine, 3 parts of sodium hexametaphosphate, deodorant and antibacterial Layer 2 includes the following raw materials in parts by weight: 32 parts of polyester resin, 3 parts of macroporous adsorption resin, 2 parts of hydroxypropyl cellulose, 5 parts of 4-chloro-3,5-dimethylphenol, 1,2-benzene 3 parts of isothiazolin-3-one, 4 parts of activated c...

Embodiment 2

[0029] Embodiment two: refer to figure 1 , a kind of TPR soft rubber insole, comprises shoe-pad body layer 1, deodorant antibacterial layer 2 and shock-absorbing layer 3, shoe-pad body layer 1 comprises the raw material of following weight portion: styrene-butadiene copolymer 42 parts, phenolic resin 16 parts, 13 parts of ethylene-vinyl acetate copolymer, 74 parts of polystyrene, 5 parts of 2,6-tertiary butyl-4-methylphenol, 6 parts of 8-hydroxyquinoline copper, bis(3,5-tertiary butyl 2 parts of 4-hydroxyphenyl) sulfide, 3 parts of polydimethylsiloxane, 5 parts of fatty acid amide, 6 parts of zinc stearate, 1 part of toluidine, 4 parts of sodium hexametaphosphate, deodorant and antibacterial Layer 2 includes the following raw materials in parts by weight: 33 parts of polyester resin, 4 parts of macroporous adsorption resin, 2 parts of hydroxypropyl cellulose, 6 parts of 4-chloro-3,5-dimethylphenol, 1,2-benzene 4 parts of isothiazolin-3-one, 5 parts of activated carbon, 2 part...

Embodiment 3

[0035] Embodiment three: refer to figure 1 , a kind of TPR soft rubber insole, comprises shoe-pad body layer 1, deodorant antibacterial layer 2 and shock-absorbing layer 3, shoe-pad body layer 1 comprises the raw material of following weight portion: styrene-butadiene copolymer 45 parts, phenolic resin 18 parts, 14 parts of ethylene-vinyl acetate copolymer, 78 parts of polystyrene, 5 parts of 2,6-tertiary butyl-4-methylphenol, 6 parts of 8-hydroxyquinoline copper, bis(3,5-tertiary butyl 2 parts of 4-hydroxyphenyl) sulfide, 4 parts of polydimethylsiloxane, 5 parts of fatty acid amide, 6 parts of zinc stearate, 1 part of toluidine, 4 parts of sodium hexametaphosphate, deodorant and antibacterial Layer 2 includes the following raw materials in parts by weight: 33 parts of polyester resin, 4 parts of macroporous adsorption resin, 2 parts of hydroxypropyl cellulose, 6 parts of 4-chloro-3,5-dimethylphenol, 1,2-benzene 4 parts of isothiazolin-3-one, 5 parts of activated carbon, 2 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com