Patents

Literature

163results about How to "Guaranteed coating effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

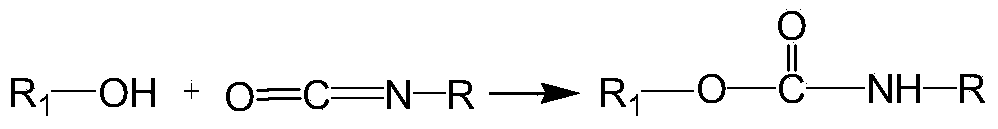

Aqueous two-component wood varnish and application thereof

The invention discloses an aqueous two-component wood varnish and application thereof. The aqueous two-component wood varnish mainly comprises a main agent and a curing agent. The main agent comprises the following components in percentage by mass: 60-80% of emulsion containing hydroxyl polymer, large than 0 and less than or equal to 6% of polycarbodiimide cross-linking agent. The curing agent mainly comprises the following component in percentage by mass: 80-85% of water dispersible polyisocyanate. By adopting double cross-linking, a varnish film with sensory effect and final performance better than that of a one-component aqueous self-crosslinking paint and an ordinary two-component aqueous paint is obtained; the varnish has the advantages of quick varnish film drying speed, quick performance improving speed, excellent varnish film performance and small dosage of aqueous isocyanate. The aqueous two-component aqueous varnish can be used as surface paint in match with the one-component priming paint which is excellent in initial water resisting property and quick in hardness improvement, thereby achieving the coating effect and performance of the conventional two-component aqueous paint at lower cost.

Owner:BAUHINIA PAINTS SHANGHAI CO LTD

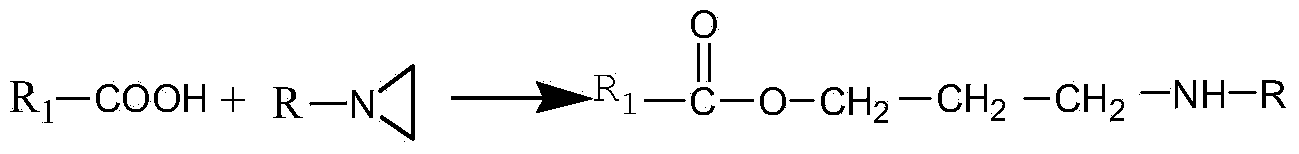

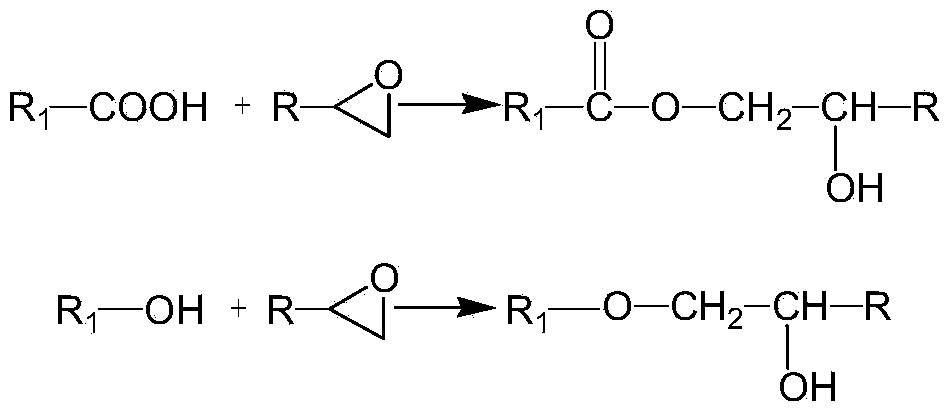

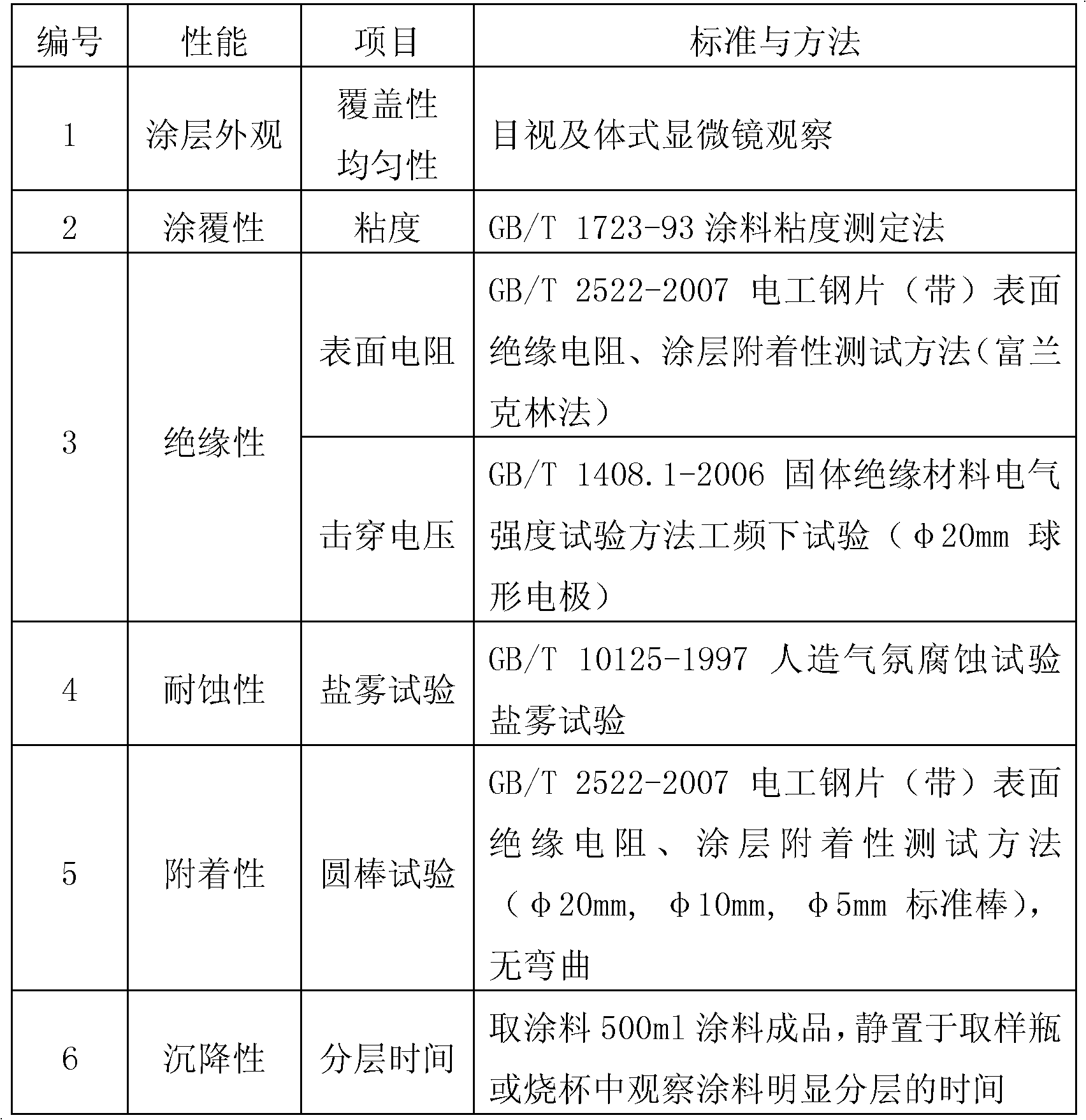

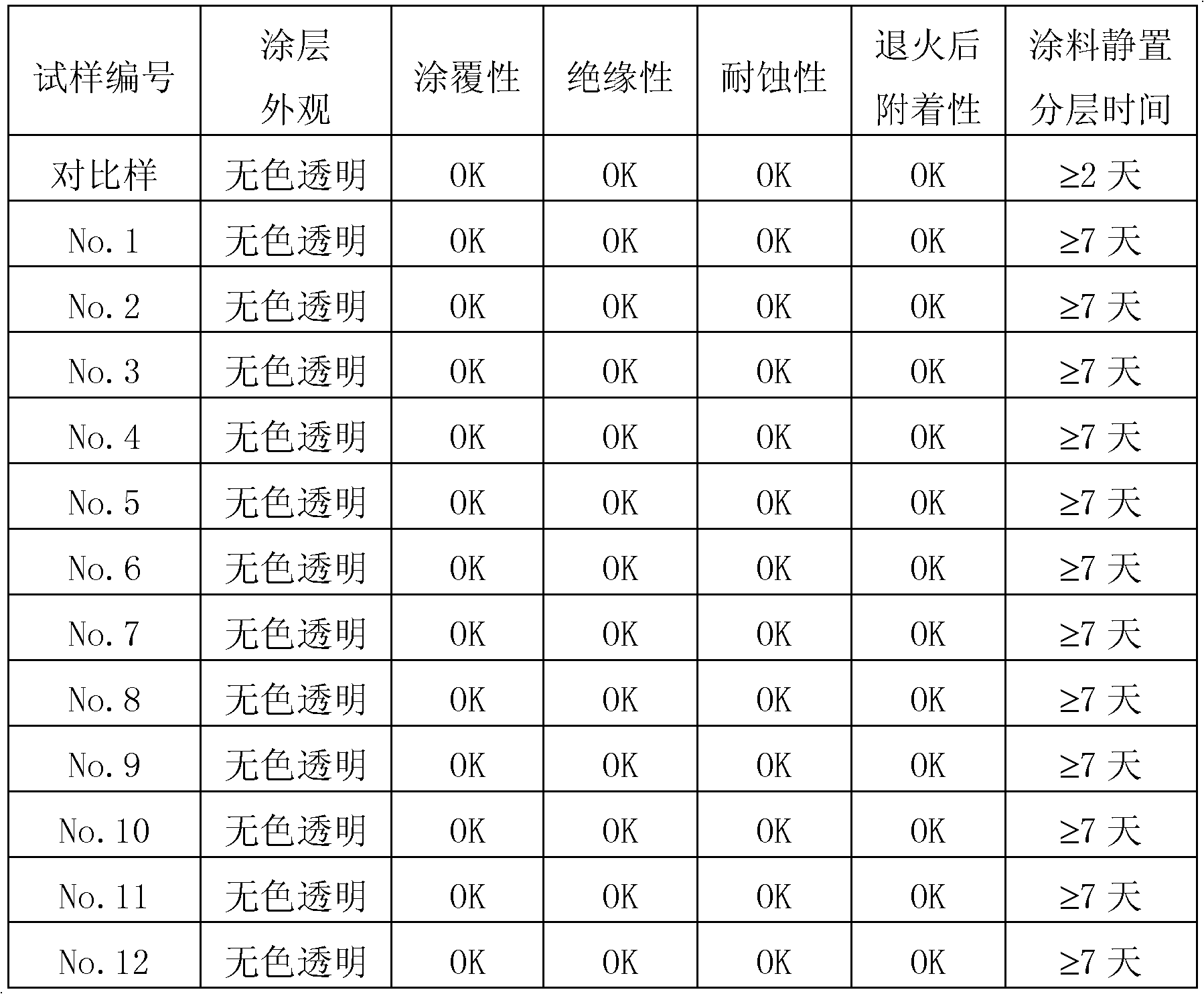

Aqueous environment-friendly insulation coating of anti-settling electric steel and preparation method thereof

InactiveCN102153896AImprove insulation performanceImprove corrosion resistanceMetallic material coating processesDispersityAdditive ingredient

The invention relates to an aqueous environment-friendly insulation coating of anti-settling electric steel and a preparation method thereof. The insulation coating is formulated from the following components by mass percent: 20-60% of aluminium dihydrogen phosphate, 0.5-5% of silica solution, 1-10% of phosphoric acid, 0.3-2% of nitric acid, 1-5% of magnesium oxide, 0.3-5.5% of rare earth-salt blended solution, 0.5-5.5% of silane coupling agents, 3-20% of anti-settling additives, and the balance of solvent water. In the invention, conventional roller painting technology is adopted for coatingand then a film can be made by proper high-temperature solidification. By multiple actions of physical covering, chemical passivation, phosphorization and the like, a surface insulation coating of a cold rolling electric steel plate without orientation has the advantages of good adhesiveness, high insulativity (namely resistance and puncture voltage between high-rises), high corrosion resistance,high temperature resistance and the like, as well as environmental protection without chrome or harmful ions. The insulation coating is widely applicable to the surface coating of the cold rolling electric steel plate without orientation, has a better anti-settling property, better dispersity and a better levelling property, leads coating operation on site to be more convenient and faster, and can effectively avoid the segregation of paint ingredients and the fluctuation of coating performances.

Owner:SHANGHAI QIJIA CHEM

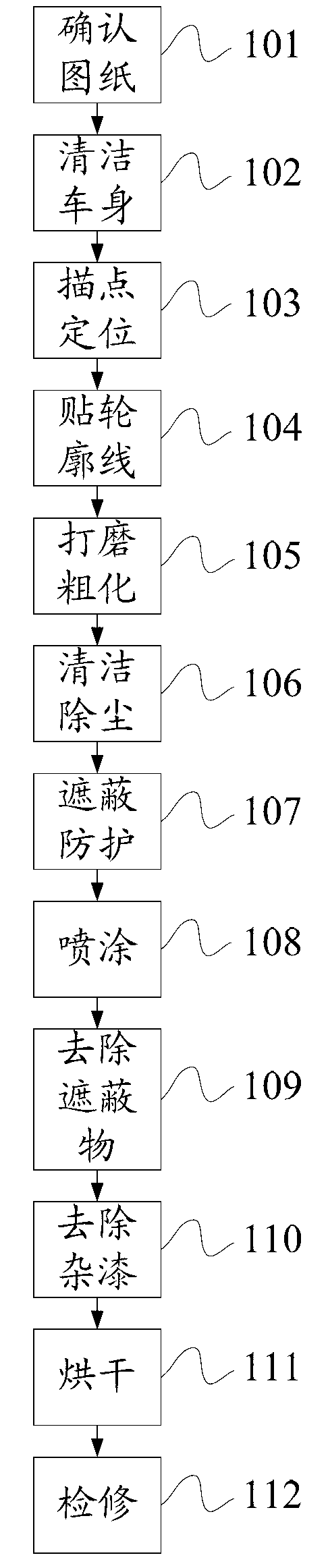

Automobile body color register coating process

InactiveCN103128042AGood coating effectImprove coating qualityPretreated surfacesSpecial surfacesPoint plottingSpray coating

The invention discloses an automobile body color register coating process. By means of the process steps of drawing confirming, automobile body cleaning, point plotting, location, contour line adhesion, polishing, roughening, cleaning, dust removing, shielding, protection, spray coating, shield removing, miscellaneous paint removing, drying and maintaining which are conducted successively, total planning is conducted to coating work by means of drawings before coating work, locating, wire drawing and other process construction processes are accurate and reliable, and the polishing and roughening processes are conducted before an non-color-register area is shielded. Particles produced in a polishing process are effectively prevented from being adsorbed to the shielded part of the non-color-register area, and a total coating effect and coating quality of the automobile body color register coating process are effectively improved.

Owner:LIUZHOU WULING MOTORS +1

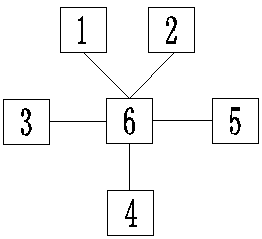

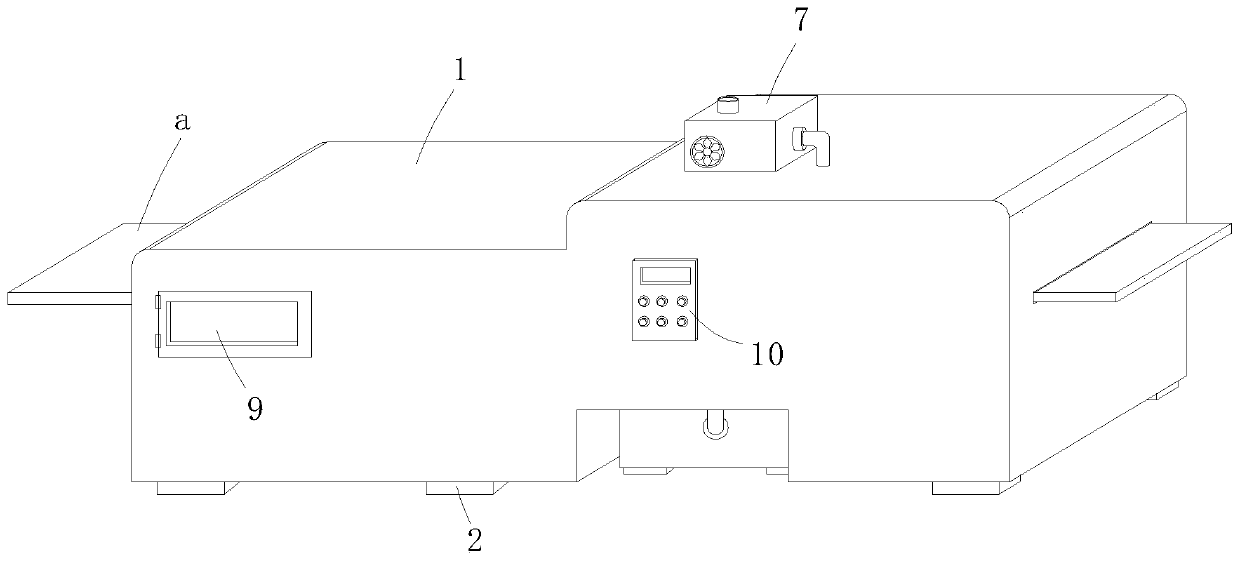

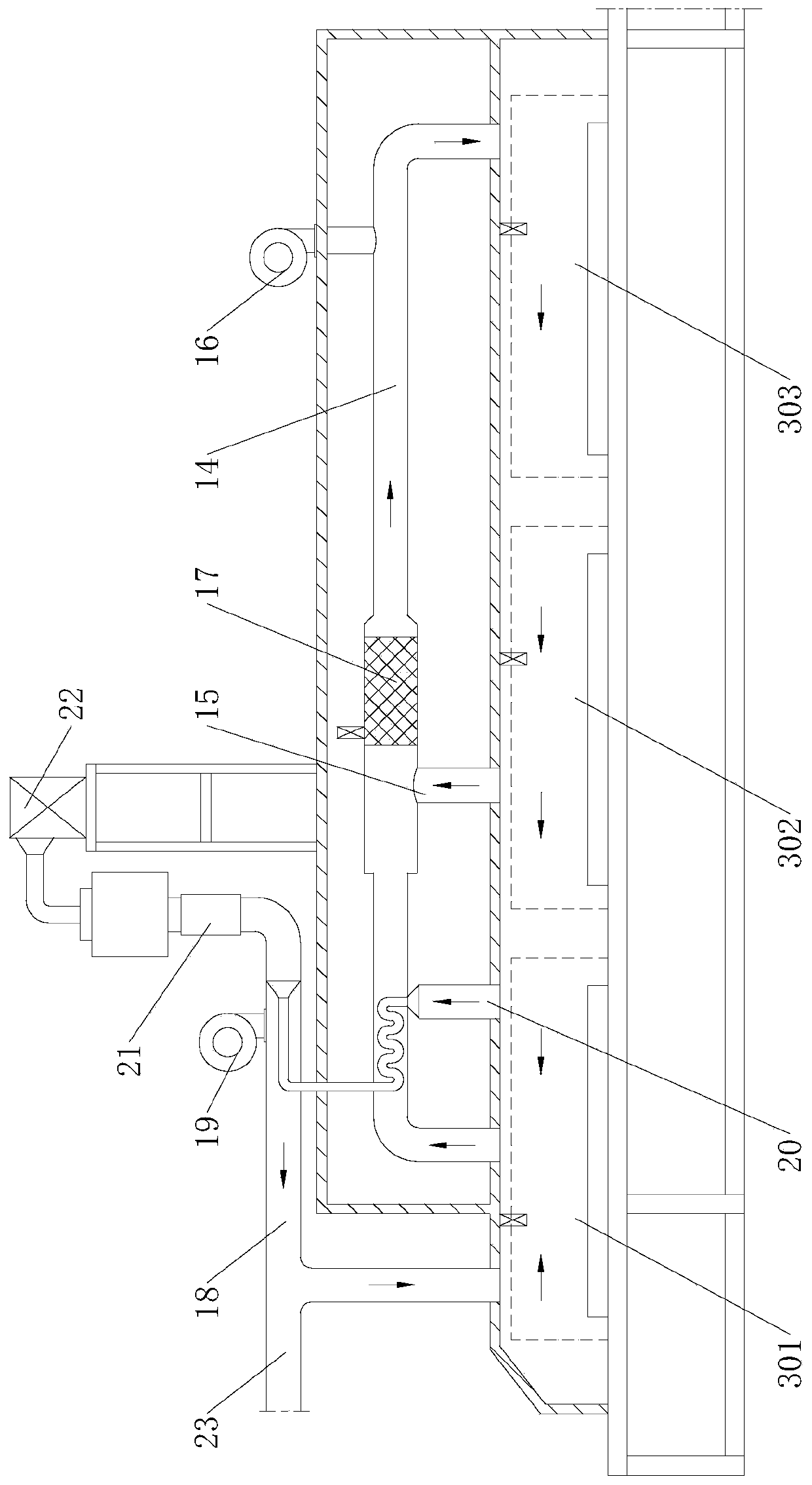

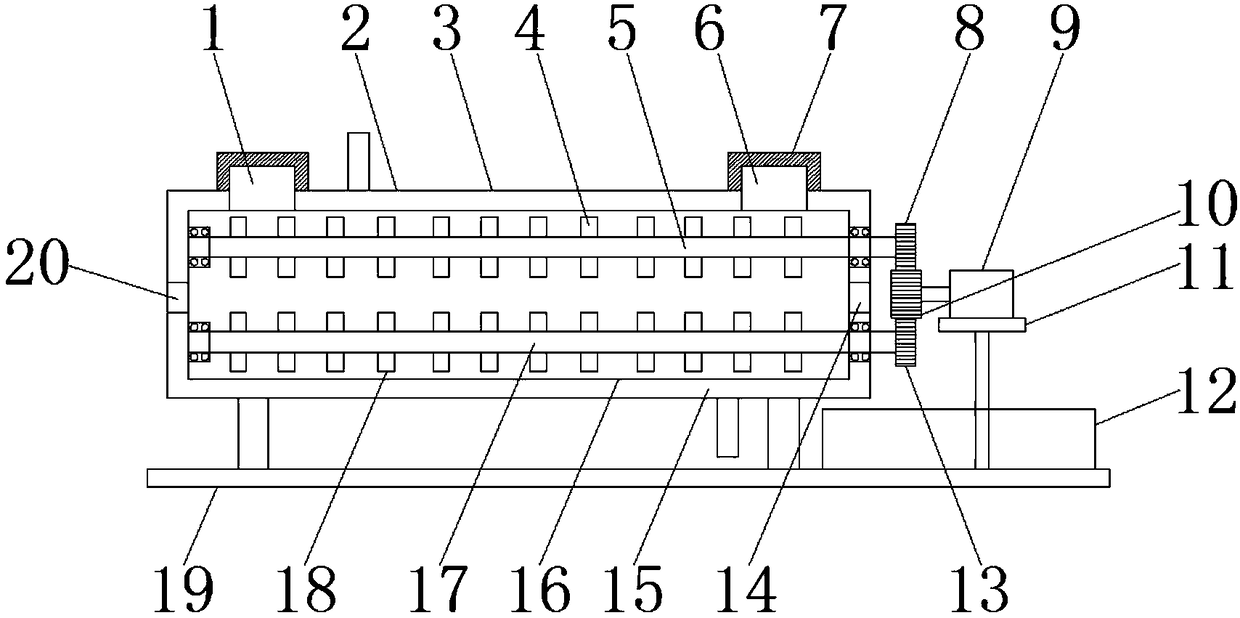

Automatic loading system for lithium battery and application method thereof

ActiveCN108565502AUniform slurryGuaranteed coating effectFinal product manufactureSecondary cellsDiaphragm pumpControl system

The invention discloses an automatic loading system for a lithium battery. The automatic loading system for the lithium battery comprises a powder putting system, a solvent putting system, a stirringmachine, a transferring tank, a coating feeding system and a control system, wherein the coating feeding system comprises a diaphragm pump, an iron removing device, a coating storage tank, a coating die head and a return pipe arranged on the coating storage tank and connected to a pipe between the diaphragm pump and the transferring tank, a return pipe valve is arranged on the return pipe, and thecoating storage tank is provided with a stirring device and a non-contact liquid level sensor. During coating, when the liquid level in the coating storage tank reaches the certain height, a discharging valve of the transferring tank is automatically switched off, the transferring tank is vacuumized, then vacuum breaking and defoaming are carried out, the uniformity of coating slurry is guaranteed, and when the liquid level is lower than the certain height, materials are fed into the coating storage tank; when the system is stopped for a long time, the discharging valve of the transferring tank is automatically switched off, the return pipe valve is automatically switched on, automatic cycling of coating slurry in the transferring tank is achieved, and blocking caused by material accumulation and material drying is prevented.

Owner:江西省汇亿新能源有限公司

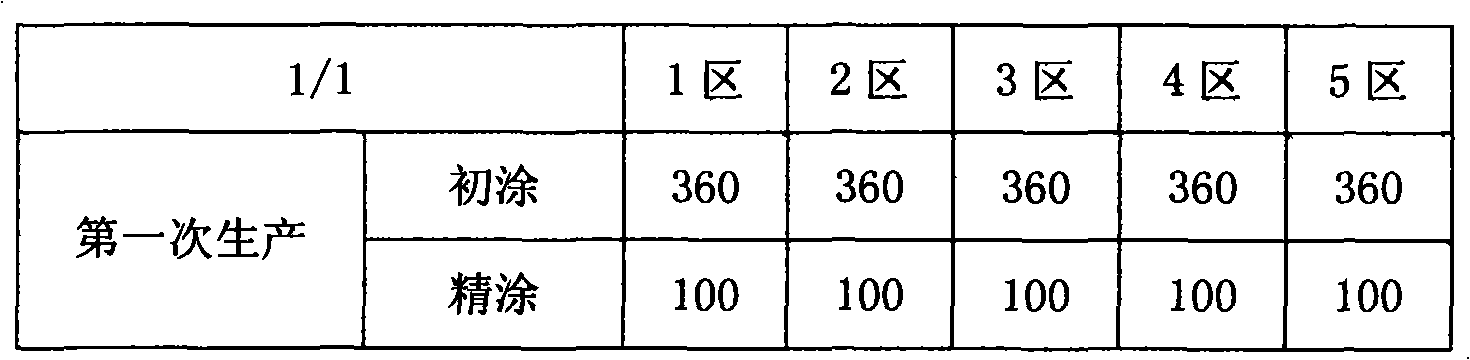

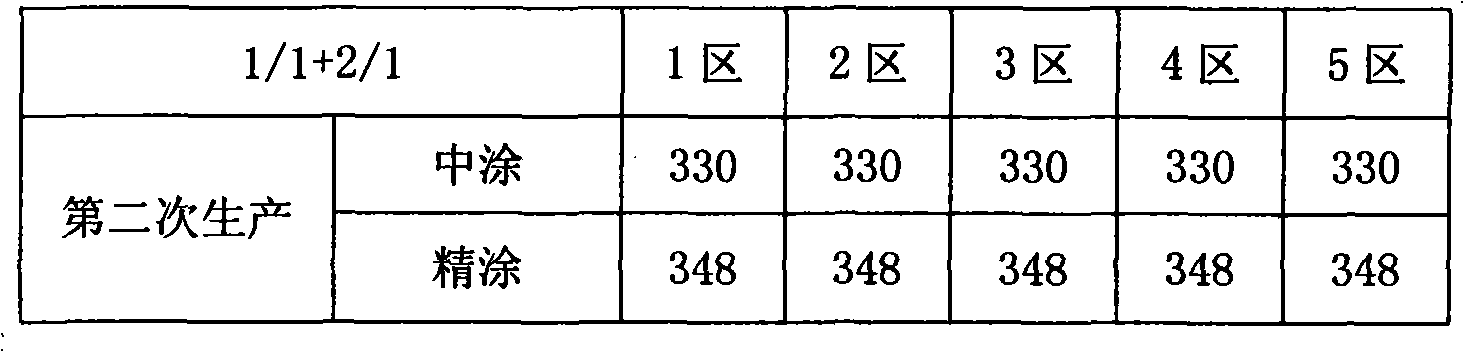

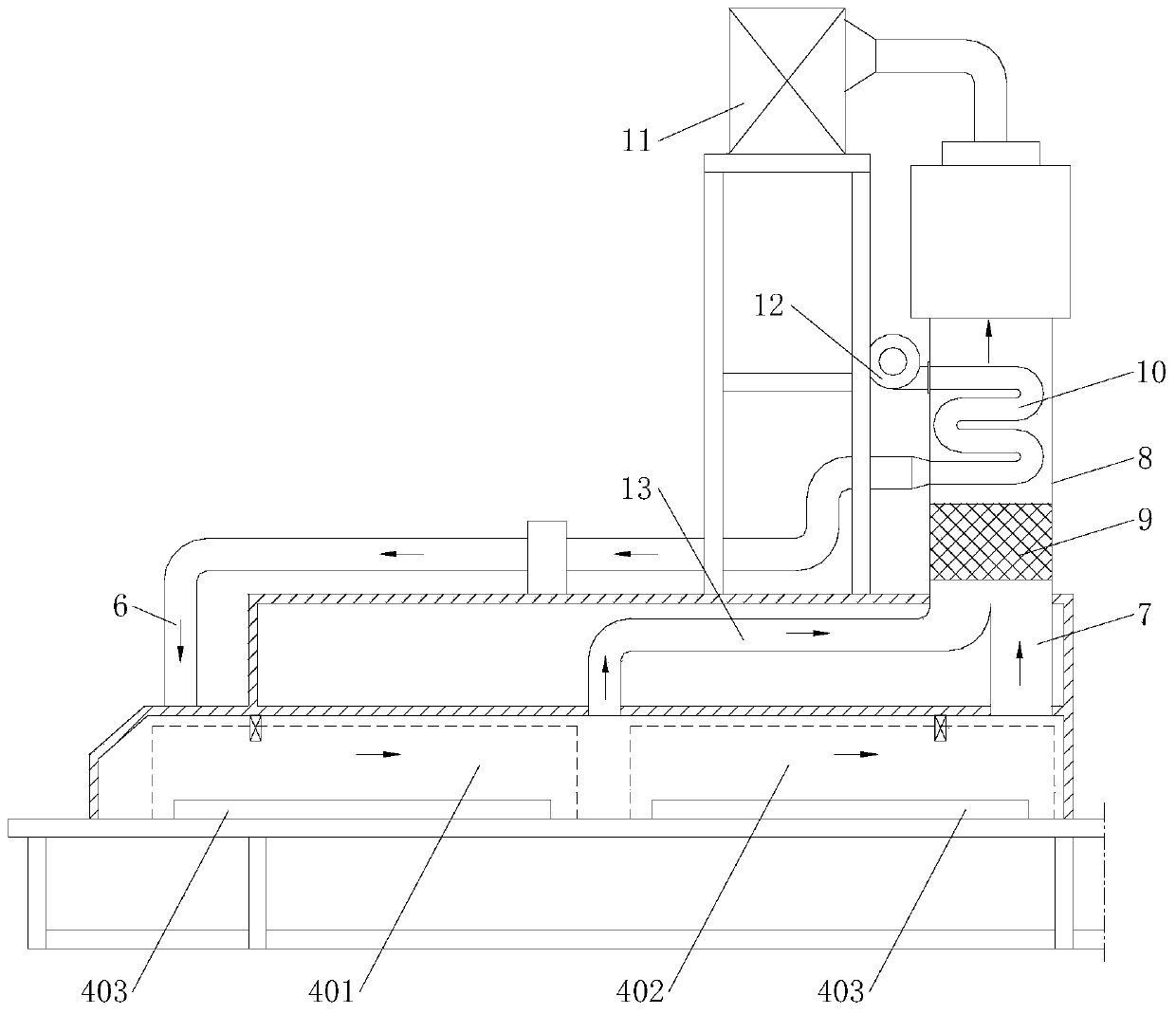

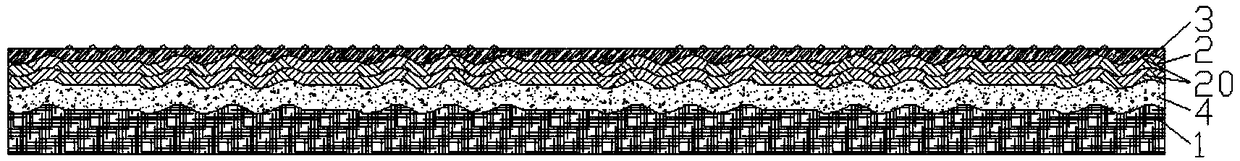

Production technique of three-coat color-coated steel plate

InactiveCN101811114APrecise thickness controlGuaranteed surface qualityLiquid surface applicatorsCoatingsSheet steelPrimary production

The invention provides a production technique of a three-coat color-coated steel plate, which is characterized in that the steel plate is produced through a double-coat double-bake color-coated machine set by the following steps: (1) primary production: uncoiling a basal plate, seaming, degreasing, preprocessing, coating primer, baking, cooling and coiling to complete the primary coat on the front side and the back side of the steel plate; (2) and secondary production: uncoiling, seaming, coating the intermediate paint, baking, cooling, top coating, baking, coiling and coiling to complete the intermediate coat and the surface coat on the front side of the steel plate, and the surface coat on the back side. The invention utilizes the double-coat double-bake machine set to produce the three-coat product, and does not need a special three-coat three-baking machine set, thereby greatly saving equipment and space and reducing the cost; in addition, the technique can accurately control the thickness of the bottom coat, middle coat and face coat, ensure the surface quality and good binding force among the layers during coating the coat, and ensure the comprehensive coat performance after three-coating.

Owner:BAOSHAN IRON & STEEL CO LTD

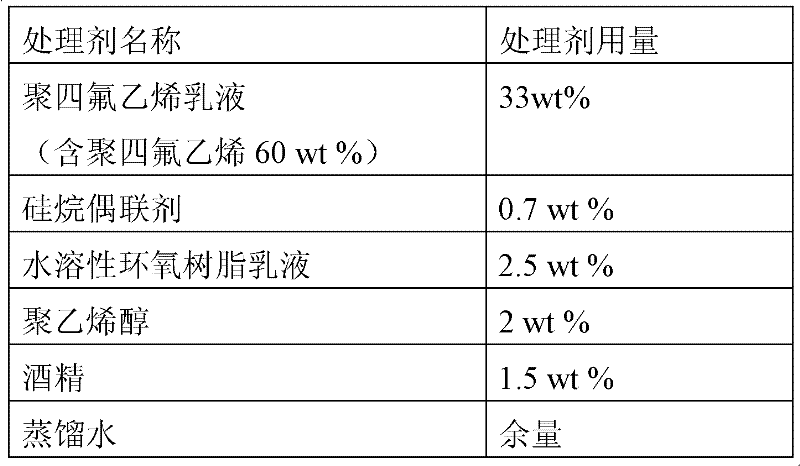

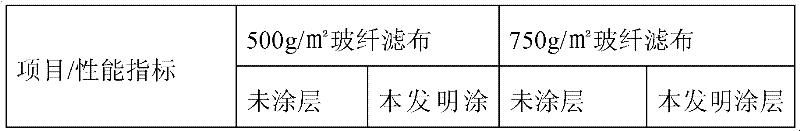

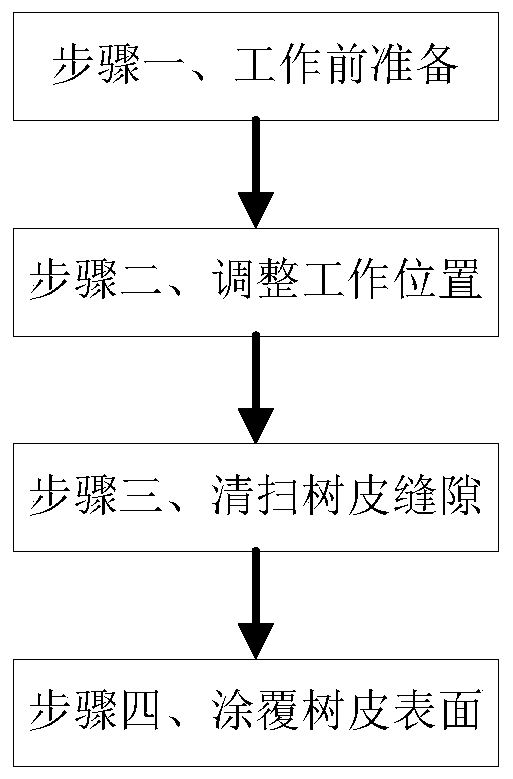

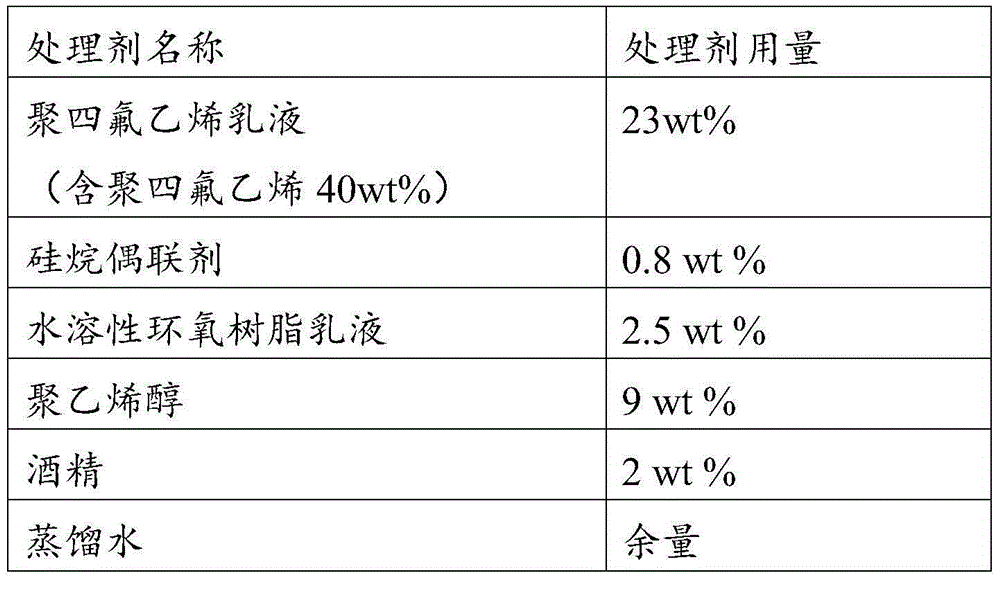

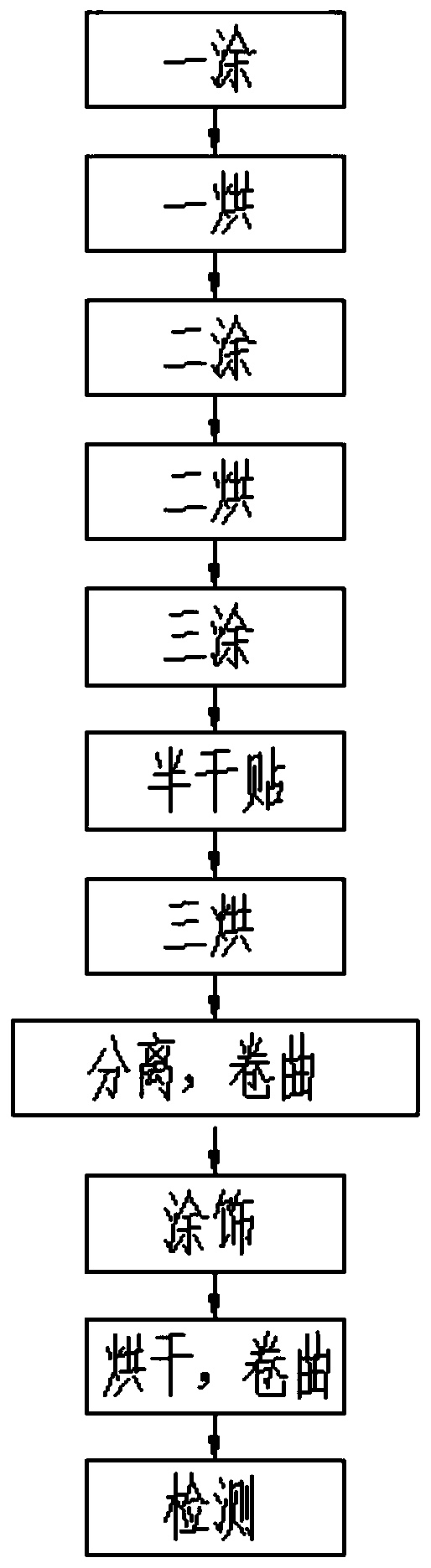

Manufacturing method for high-accuracy coating filter material

InactiveCN102512877AGood acid and alkali resistanceImprove water resistanceSynthetic resin layered productsGlass/slag layered productsFiberLoss strength

The invention provides a manufacturing method for a high-accuracy coating filter material, which has the advantages of good binding effect between the filter material and PTFE (Polytetrafluoroethylene) and capability of improving the performance of the filter material. The method comprises the following steps of: (1) thermal cleaning treatment, performing the thermal cleaning treatment on the filter material and removing various auxiliary agents on the surface of the filter material through high temperature; (2) dipping treatment, performing PTFE dipping treatment on the filter material which is subjected to the thermal cleaning treatment; (3) sequentially performing baking, drying and thermal forming treatment on the filter material which is subjected to the dipping treatment; (4) performing coating treatment on the filter material which is subjected to thermal forming; and (5) sequentially performing volatile treatment, baking treatment, sintering treatment and thermal forming treatment on the filter material which is subjected to the coating treatment. In the manufacturing method for the high-accuracy coating filter material, the thermal cleaning treatment is performed before the filter material is subjected to the dipping treatment, so that a wire drawing impregnating agent remained on the surfaces of fibers can be effectively removed, meanwhile, no loss strength of a textile is guaranteed; and the acid and alkali resistance, water resistance, oxidation resistance, wear resistance and folding resistance of the filter material are effectively improved, and the service life of the filter material is prolonged.

Owner:辽宁鸿顺环保新材料有限公司

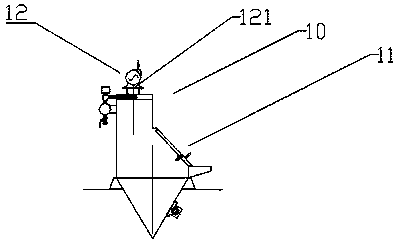

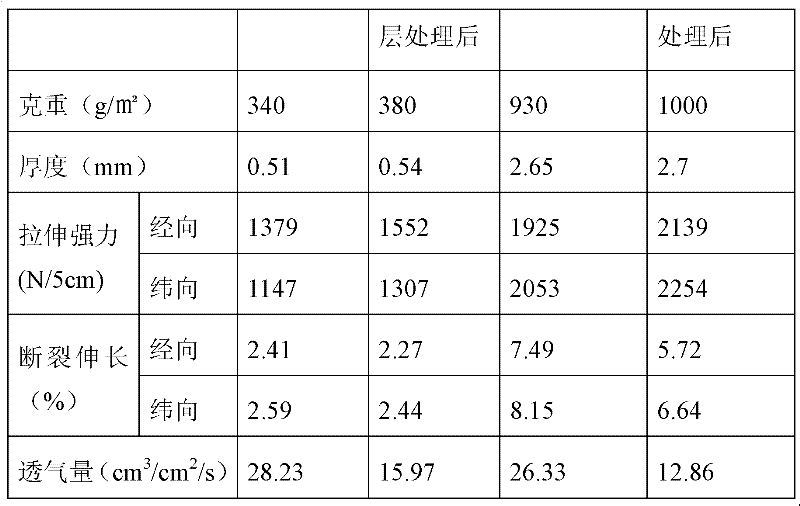

Trunk whitewashing method for road green belt

ActiveCN111151410AImprove cleaning effectImproves sweeping and coating resultsLiquid surface applicatorsCoatingsTrunkEnvironmental geology

The invention belongs to the technical field of greening maintenance, and particularly relates to a trunk whitewashing method for a road green belt. A trunk whitewashing device is adopted for cooperatively implementing the method and comprises a base, wherein idler wheels and a push frame are installed on the base, two installing plates are installed on the base, strip-shaped slide grooves are formed in the side faces of the installing plates, and two first air cylinders are in sliding fit with each other in the strip-shaped slide grooves. Semicircular installing frames are fixedly connected to the ends of the first air cylinders, semicircular slide grooves are formed in the upper surfaces of the semicircular installing frames, and have the identical radius and are matched with each otherin end, vertical n-shaped installing frames are in sliding fit with each other in the semicircular slide grooves, and sweeping mechanisms and brushing mechanisms are installed on the n-shaped installing frames. Before trunks of trees on the green belt are whitewashed by means of the trunk whitewashing method, hairbrush rollers rotating at a high speed conduct annular sweeping on the surface of bark in the vertical direction to clean away moss and other inquilines growing in gaps of the bark, in this way, a whitewashing agent sufficiently enters the gaps of the bark to kill pests hidden in treegaps, and the whitewashing effect is improved.

Owner:福建省鼎贤市政园林工程有限公司

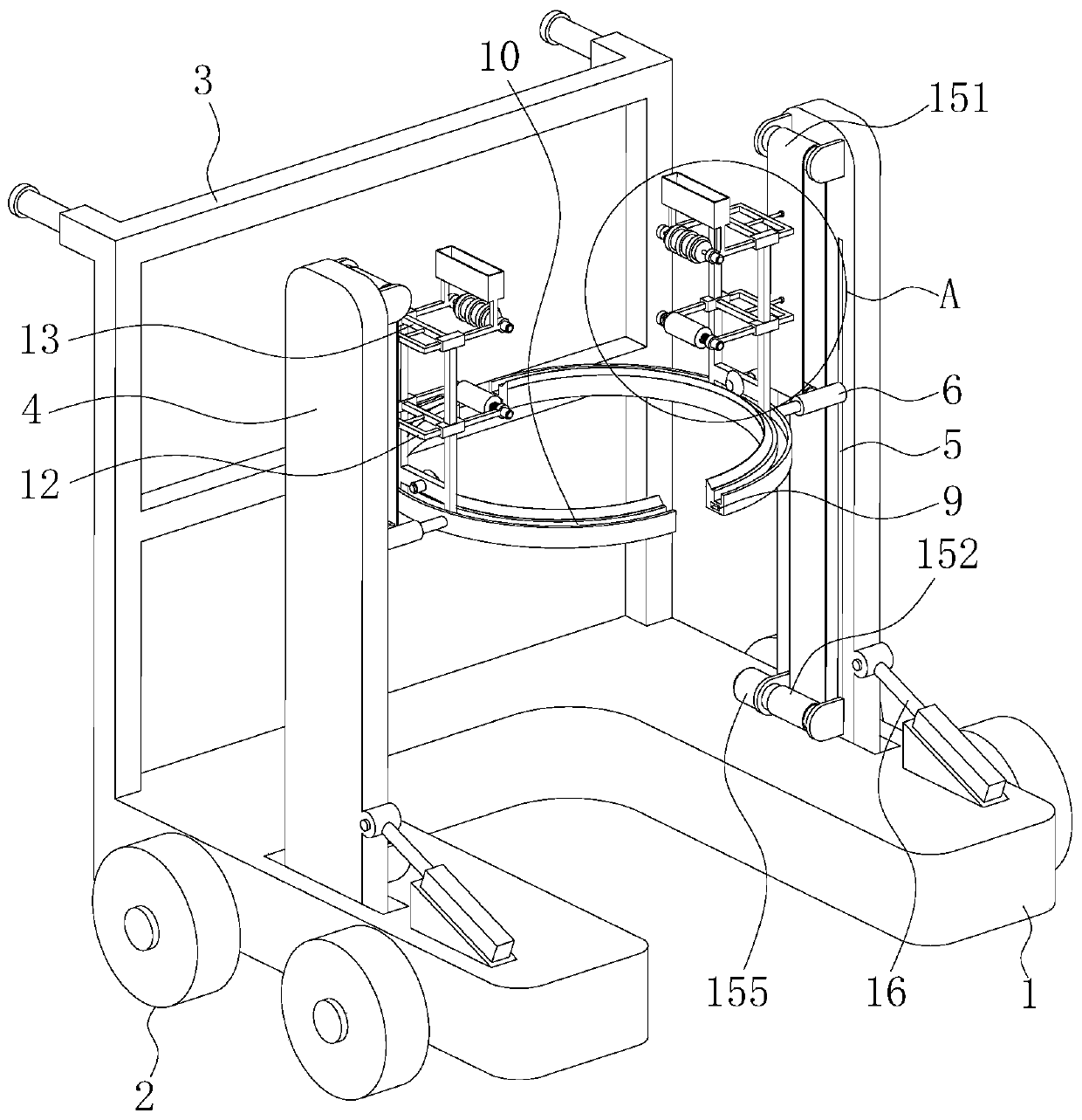

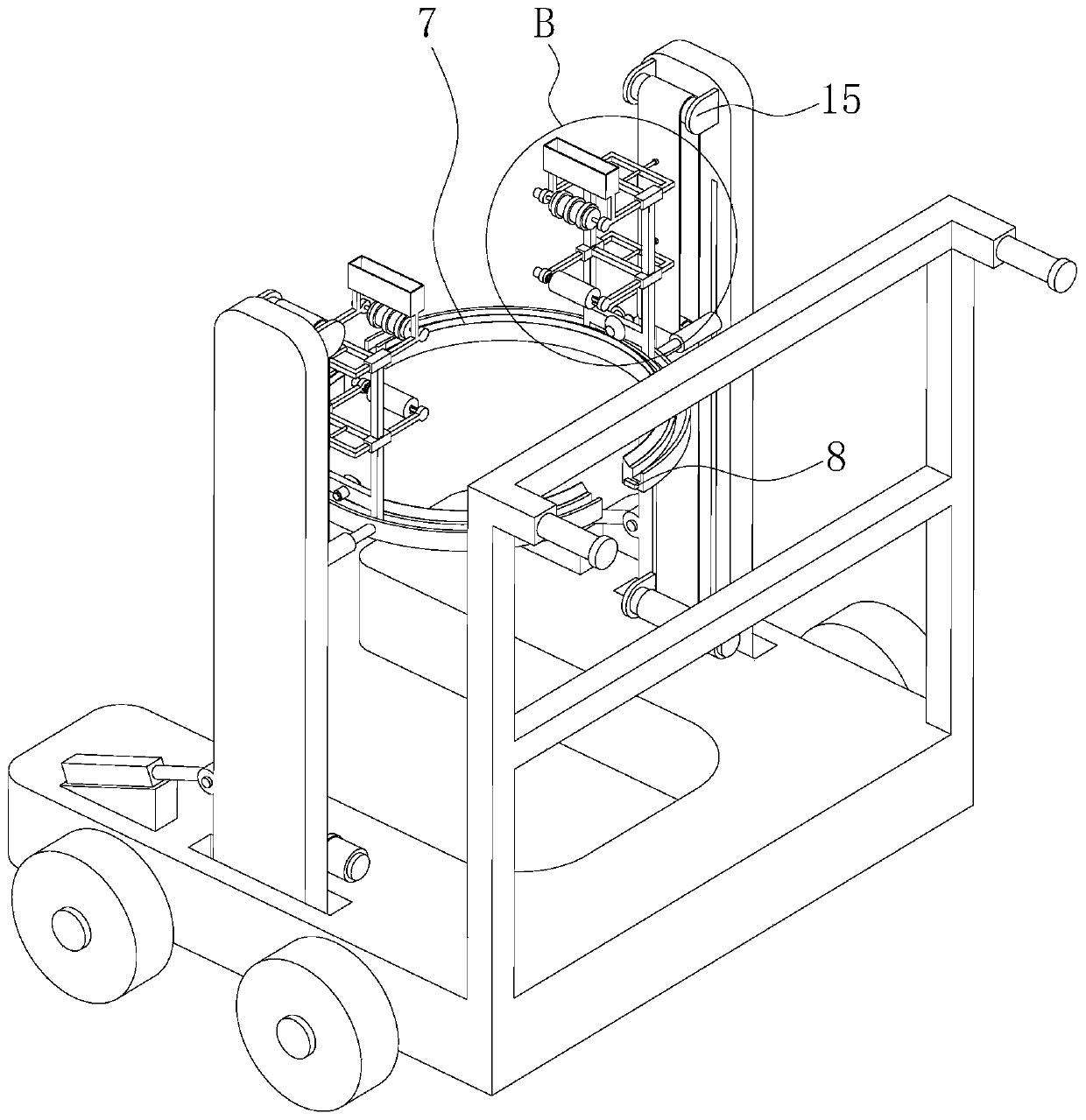

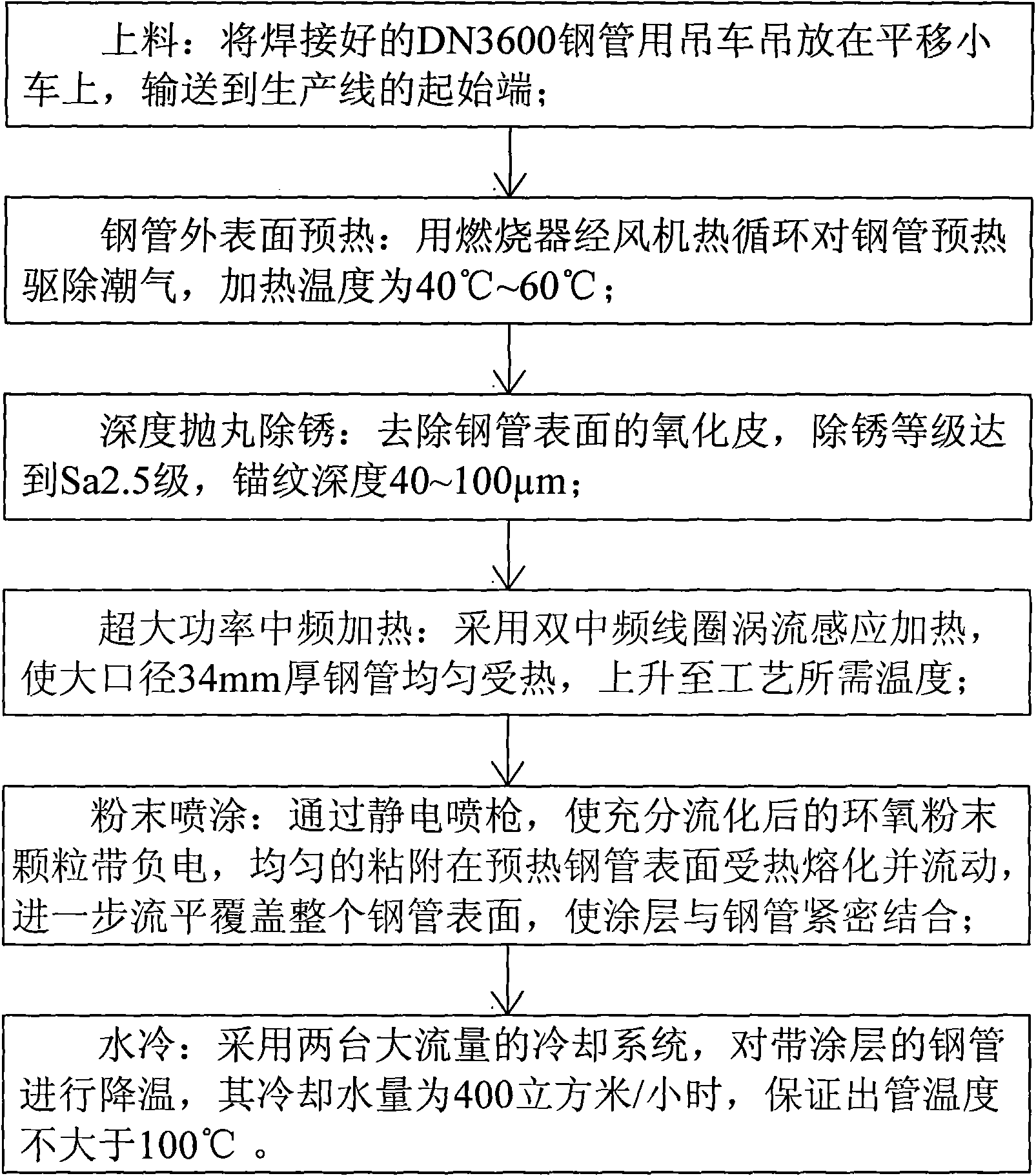

Method for carrying out outer anticorrosion on DN3600 buried steel tube by adopting molten epoxy powder

InactiveCN101602043AGuaranteed coating environmentGuaranteed coating effectPretreated surfacesCoatingsEpoxyMetallurgy

The invention relates to a method for carrying out outer anticorrosion on a DN3600 buried steel tube by adopting molten epoxy powder, and belongs to the field of anticorrosion of tube materials. A coating process comprises material loading, preheating of the outer surface of the steel tube, deep shot blasting and derusting, superlarge power medium-frequency heating, powder spraying and coating and water cooling. Aiming at the characteristics of large diameter and extremely-small rate of the wall thickness to the diameter of a large-diameter buried steel tube with DN3600 millimeter and more than DN3600 millimeter, the method optimizes the whole machining process, controls the velocity of temperature rising, heating and cooling through the control of a moving speed of the steel tube, ensures the coating environment and the coating effect of the steel tube and the adhesion effect of a coating layer and ensures that the quality of an outer anticorrosive coating layer of the large-diameter buried steel tube meets the relevant quality acceptance standards of the state.

Owner:SHANGHAI JIANZHIZHEN ANTI CORROSION TECH DEV

Coating method for non-continuous high-metal-texture film layer

ActiveCN102366742AImprove firmnessGuaranteed coating effectVacuum evaporation coatingPretreated surfacesWeather resistanceSilicon alloy

The invention discloses a coating method for a non-continuous high-metal-texture film layer. The coating method comprises the following steps of: spraying UV (Ultraviolet) priming paint; coating a high-metal-texture nonconductive film layer; and spraying UV finishing paint, wherein the step for coating the high-metal-texture nonconductive film layer is a step for coating a product to be coated by taking an aluminum-silicon alloy of which the length*width*thickness is 1,009 millimeters*124.7 millimeters*8 millimeters as a target material with a magnetron sputtering coating technology. In the invention, a continuous magnetron sputtering coating technology is applied to plastic materials such as mobile phone shells, outer frames of panel computers and the like, the aluminum-silicon alloy is taken as the target material, and a magnetron sputtering target material is precipitated on a substrate in the form of atoms, so that the film layer is dense and firm, and is stable even exposed in the air for a long time after coating. A product obtained with the coating method has ultrahigh metal texture and high weather resistance. The coating method is easy to operate and control, is nontoxic and environmentally-friendly, and is suitable for industrial production.

Owner:DONGGUAN HUAQING OPTICAL TECH

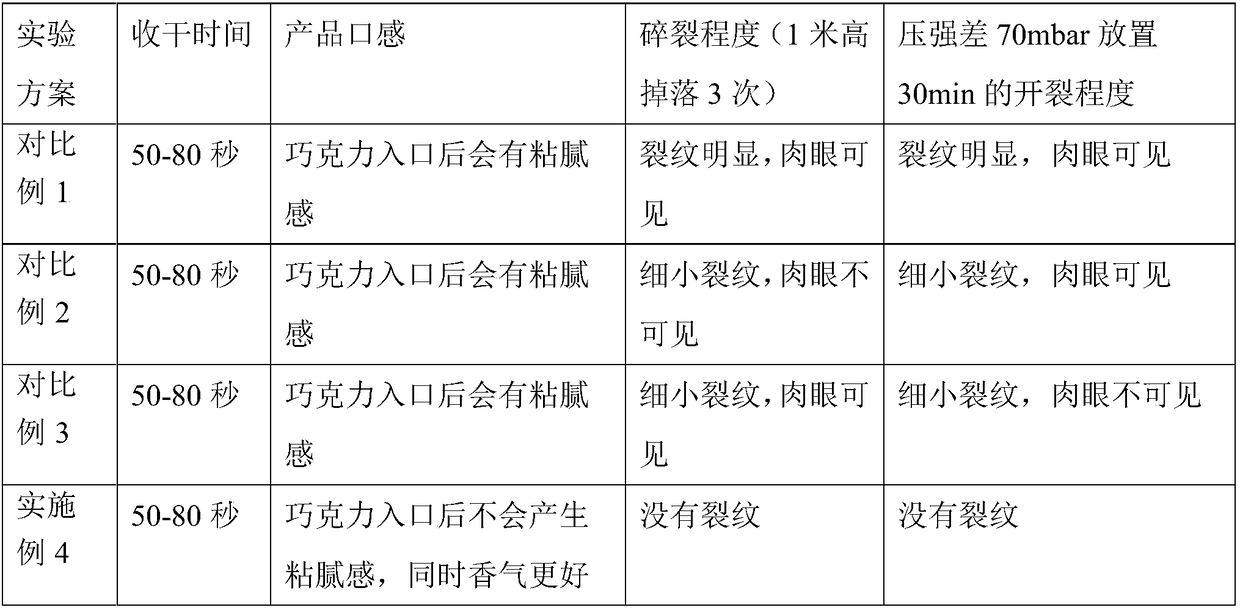

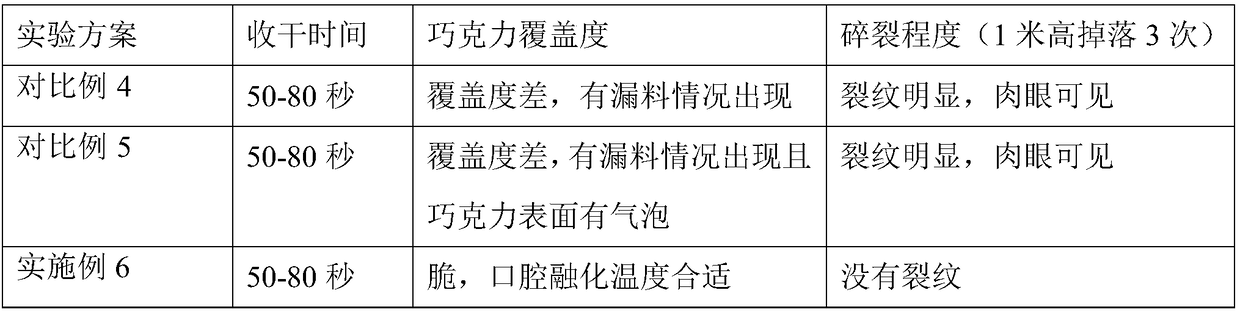

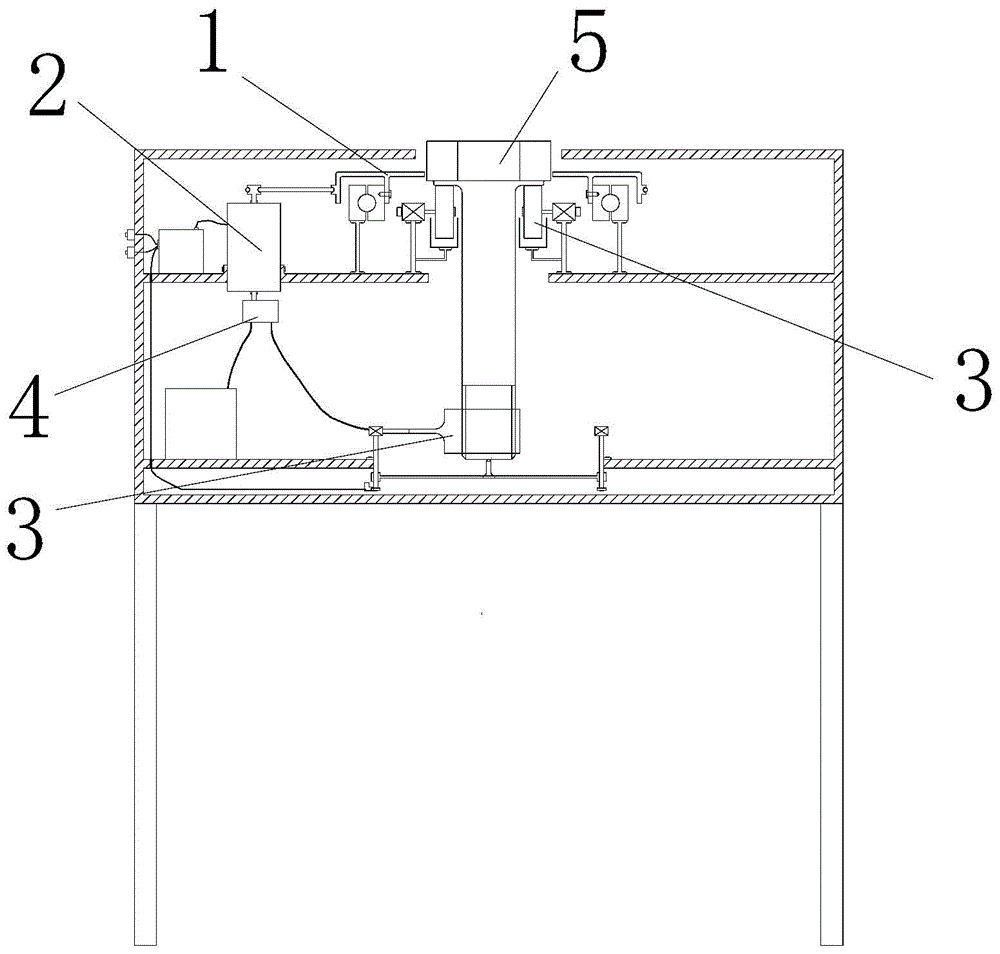

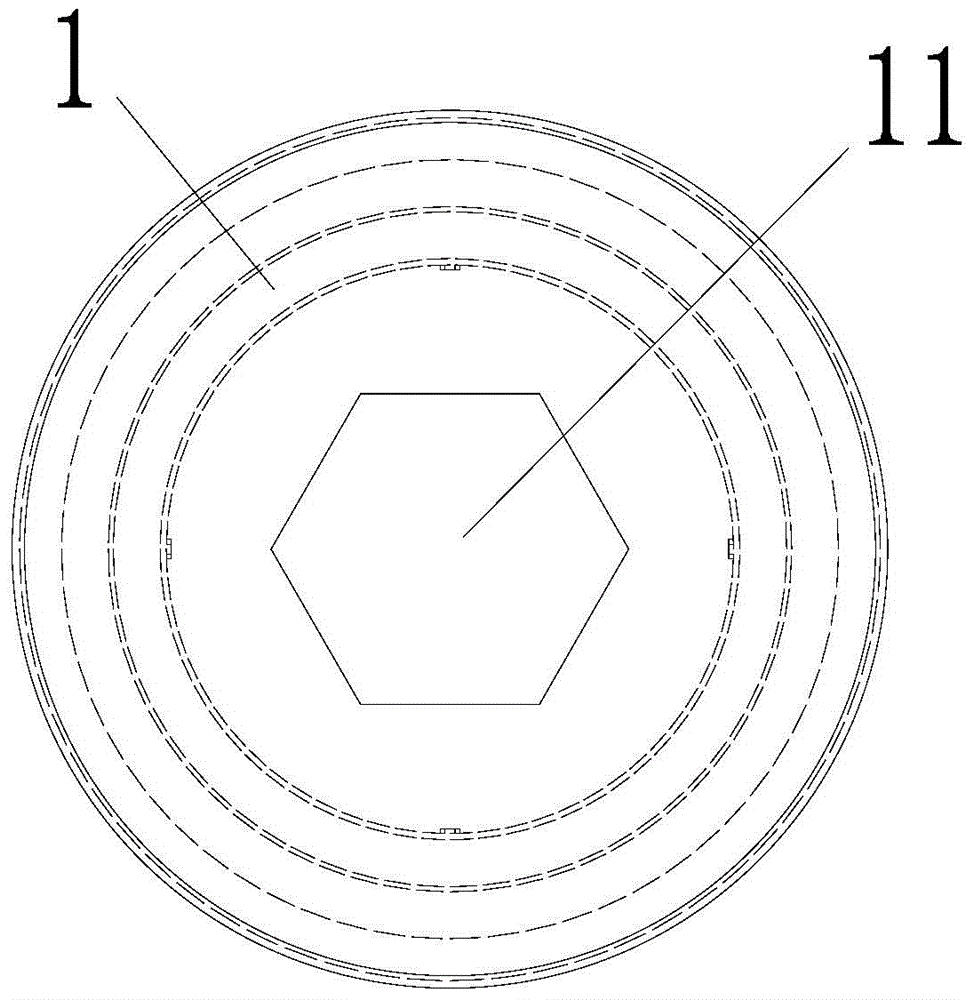

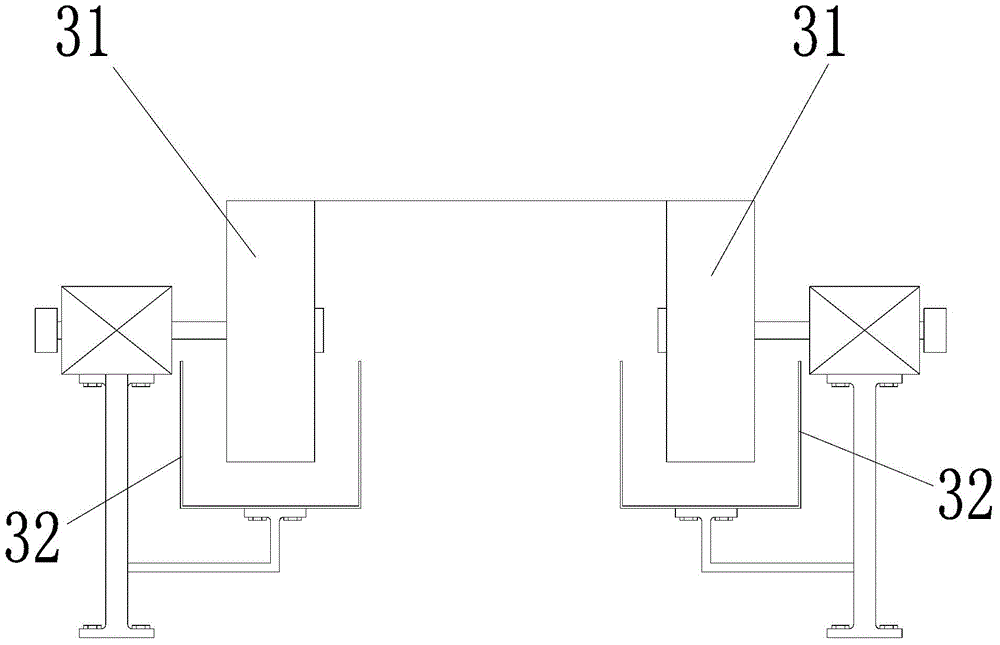

Brittle-failure-resistant chocolate coating and method for coating frozen beverage with brittle-failure-resistant chocolate coating

The invention discloses a brittle-failure-resistant chocolate coating, which comprises the following raw materials by weight: 330-400 parts of white granulated sugar, 130-170 parts of milk powder, 120-160 parts of cocoa liquid block, 40-60 parts of natural anhydrous cream, 260-300 parts of cocoa butter, 1-3 parts of lecithin, and 1-3 parts of polyglyceryl-3 polyricinoleate. The invention further discloses a method for coating a frozen beverage with the brittle-failure-resistant chocolate coating. According to the present invention, by adjusting the ratio of various raw materials of the chocolate coating and optimizing the method for coating the frozen beverage with the chocolate coating, the brittleness of the chocolate coating is ensured, and no cracking is generated within pressure difference of 70 mbar, such that the quality of the product is enhanced, and the market is easily broadened.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

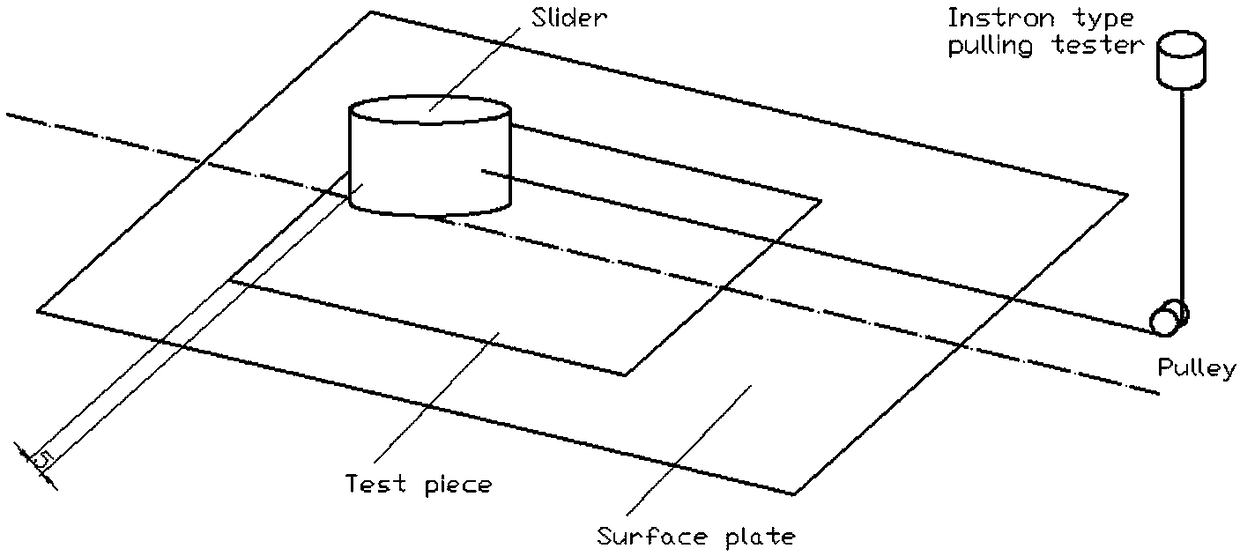

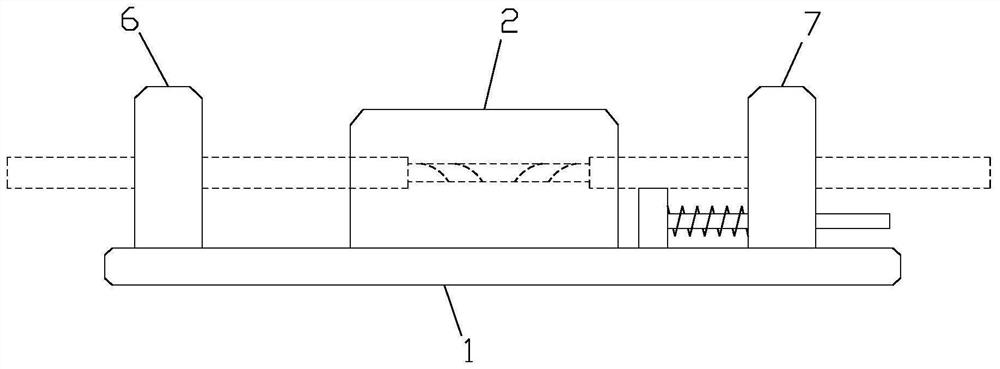

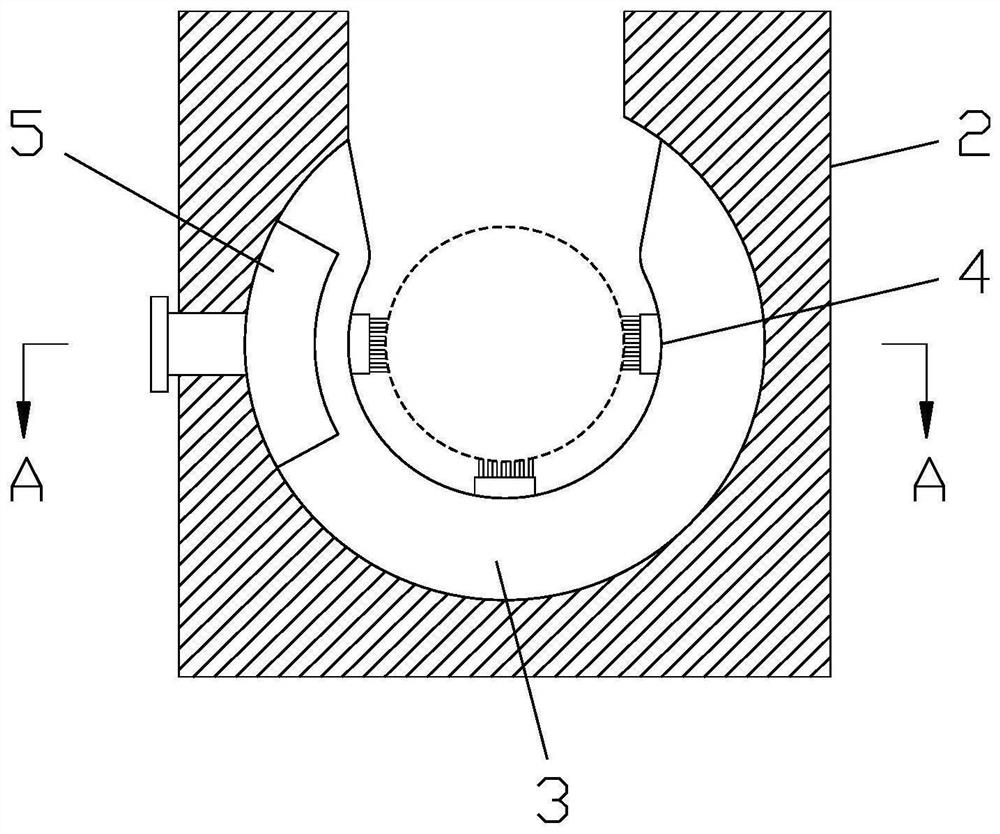

Automatic grease application device and method for bolt

ActiveCN104607351AReduce labor intensityVolume controlLiquid surface applicatorsCoatingsCoated surfaceUltimate tensile strength

The invention provides an automatic grease application device and method for a bolt. The automatic grease application device for the bolt comprises a driving disc, a power mechanism and an application mechanism, wherein the power mechanism is in driving connection with the driving disc, a to-be-coated bolt is mounted on the driving disc, and the power mechanism drives the driving disc to drive the to-be-coated bolt to rotate around the own axis; the application mechanism comprises application wheels and lubricating grease storage tanks, and the application wheels are arranged in the corresponding lubricating grease storage tanks, are propped against the to-be-coated surface of a bolt head of the to-be-coated bolt, roll relative to the to-be-coated surface of the bolt head and are used for applying lubricating grease in the lubricating grease storage tanks onto the to-be-coated surface of the bolt head. The automatic grease application device and method have the advantages as follows: the design is reasonable, the structure is simple, the automation degree is high, the application effect is good, the labor intensity of an operator can be reduced, and the working efficiency can be increased.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

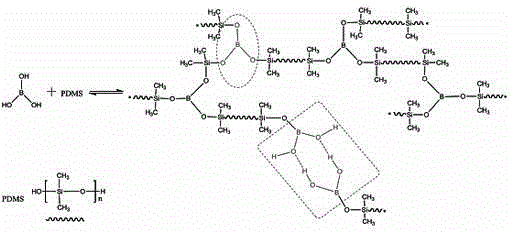

Silica gel composition for itching relieving and repairing of scars

InactiveCN104784104AGuaranteed water vapor barrier performanceGuaranteed breathabilityHeavy metal active ingredientsAerosol deliveryCross-linkSilicone Gels

Silica gel composition for itching relieving and repairing of scars comprises cross-linked PDMS (polydimethylsiloxane), PDMS, volatile annular siloxane and gaseous-phase silicon dioxide particles and is characterized by further comprising boronized polysiloxane. The silica gel is formed by compositing the cross-linked PDMS, the PDMS, the volatile annular siloxane, a reaction product of boric acid and hydroxy-terminated polydimethylsiloxane, the gaseous-phase silicon dioxide particles and the like. Through adjustment of the ratio of the cross-linked PDMS to the PDMS to the volatile annular siloxane to the reaction product of the boric acid and the hydroxy-terminated polydimethylsiloxane to the gaseous-phase silicon dioxide particles, the water vapor blocking performance, the air permeability, the paintability and the itching relieving performance of the composition are guaranteed.

Owner:ZHEJIANG PROVINCE ZHUJI CITY ZHULISHEN MEDICAL SUPPLIES CO LTD

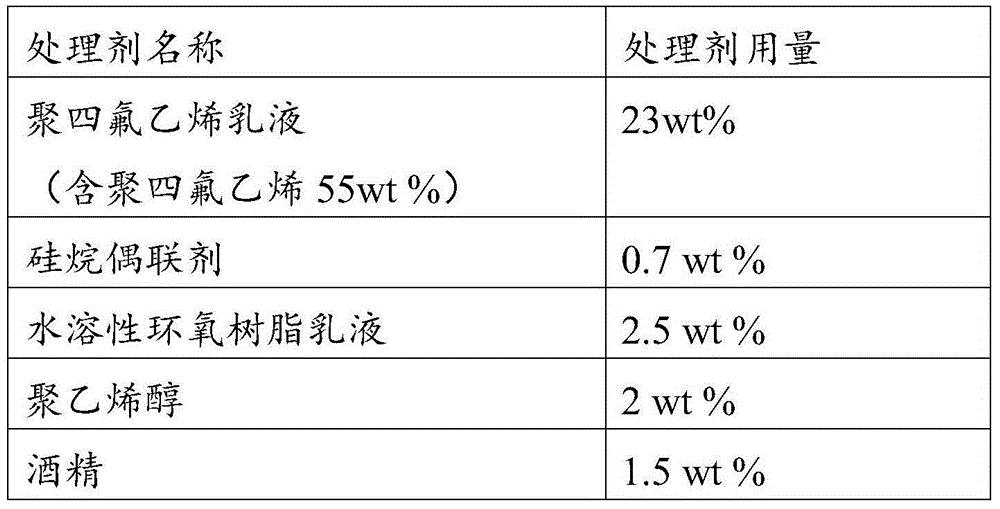

Preparation method of high-precision coating filter material

ActiveCN104436861AImprove acid and alkali resistanceExtended service lifeSynthetic resin layered productsGlass/slag layered productsPolytetrafluoroethyleneFilter material

The invention provides a preparation method of a high-precision coating filter material. According to the preparation method, the filter material can be well combined with PTFE (Polytetrafluoroethylene), and the performances of the filter material can be improved. The method comprises the following steps: (1) carrying out heat cleaning treatment, namely, performing the heat cleaning treatment on the filter material and removing various assistants on the surface of the filter material at high temperature; (2) performing immersion treatment, that is, performing PTFE immersion treatment on the filter material after heat cleaning treatment; (3) baking, drying, and carrying out heat setting on the filter material after immersion treatment sequentially; (4) coating the filter material after heat setting; and (5) performing volatilization, drying, sintering and heat setting on the filter material after coating treatment sequentially. According to the preparation method of the high-precision coating filter material, the filter material is subjected to heat cleaning treatment before immersion treatment, thus, wiredrawing impregnating compound remained on the surface of the fiber can be effectively removed, and the fabric strength can be ensured not to be lost; the acidic and alkali resistances, the water resistance, the oxidation resistance and the abrasion and folding resistances of the filter material can be effectively improved, and the service life of the filter material can be prolonged.

Owner:辽宁新洪源环保材料有限公司

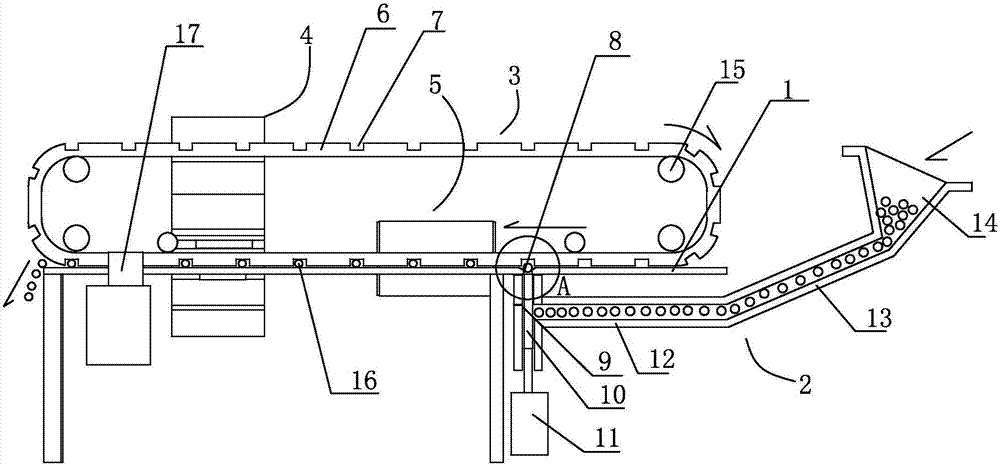

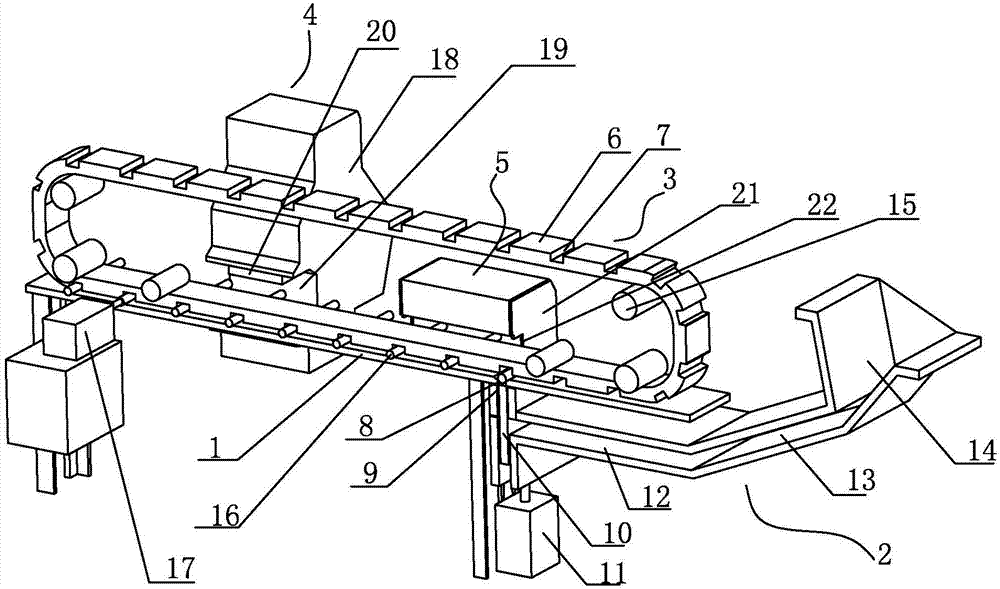

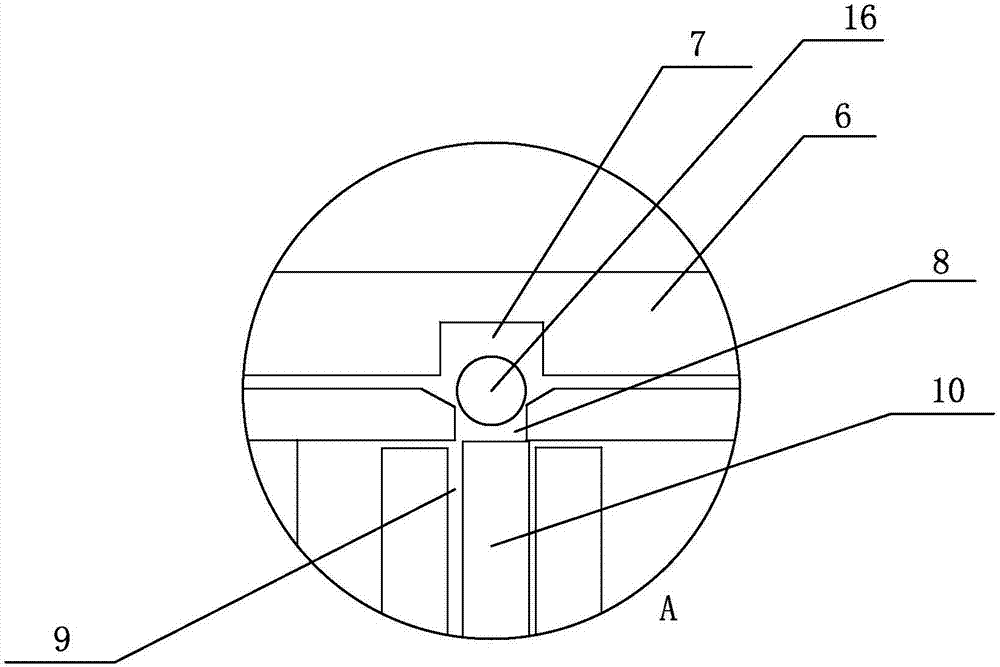

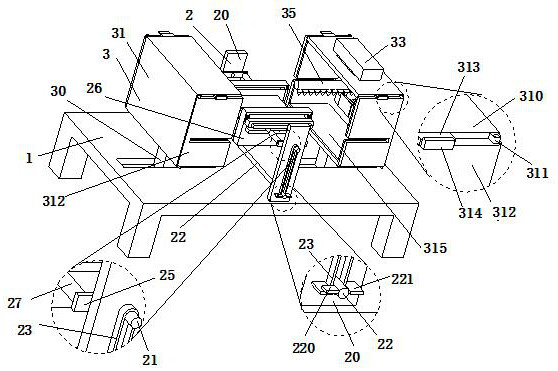

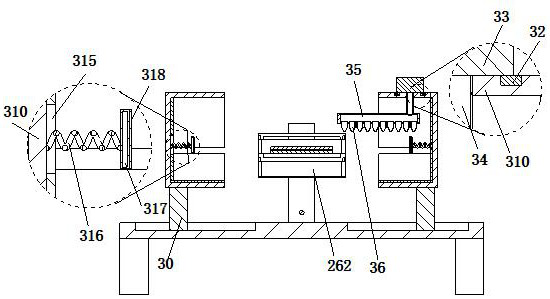

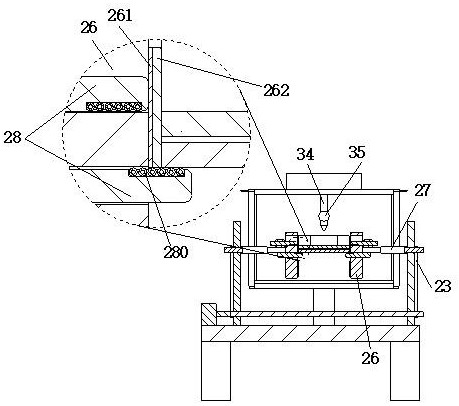

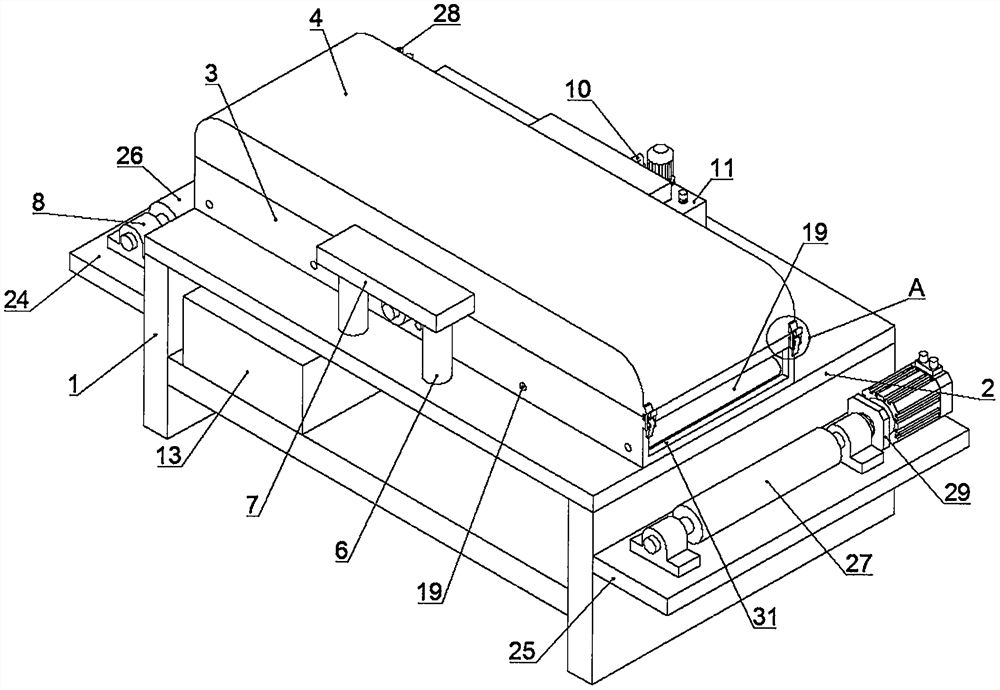

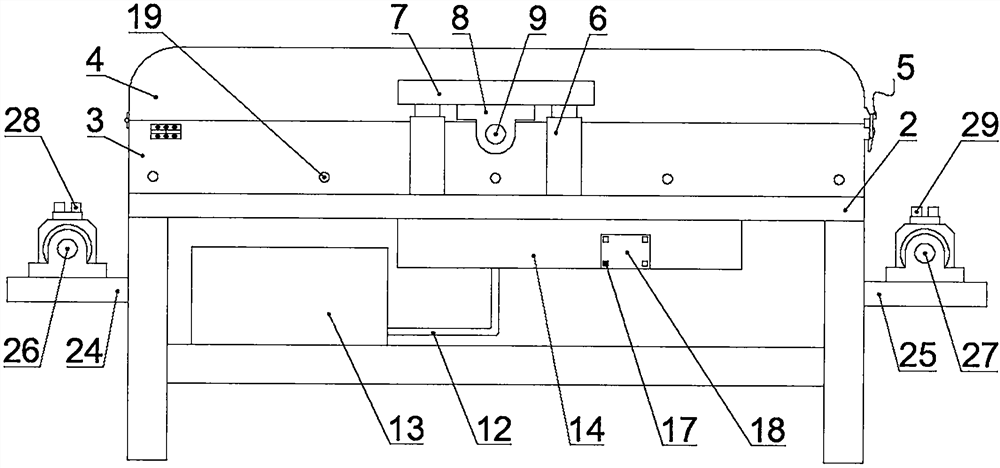

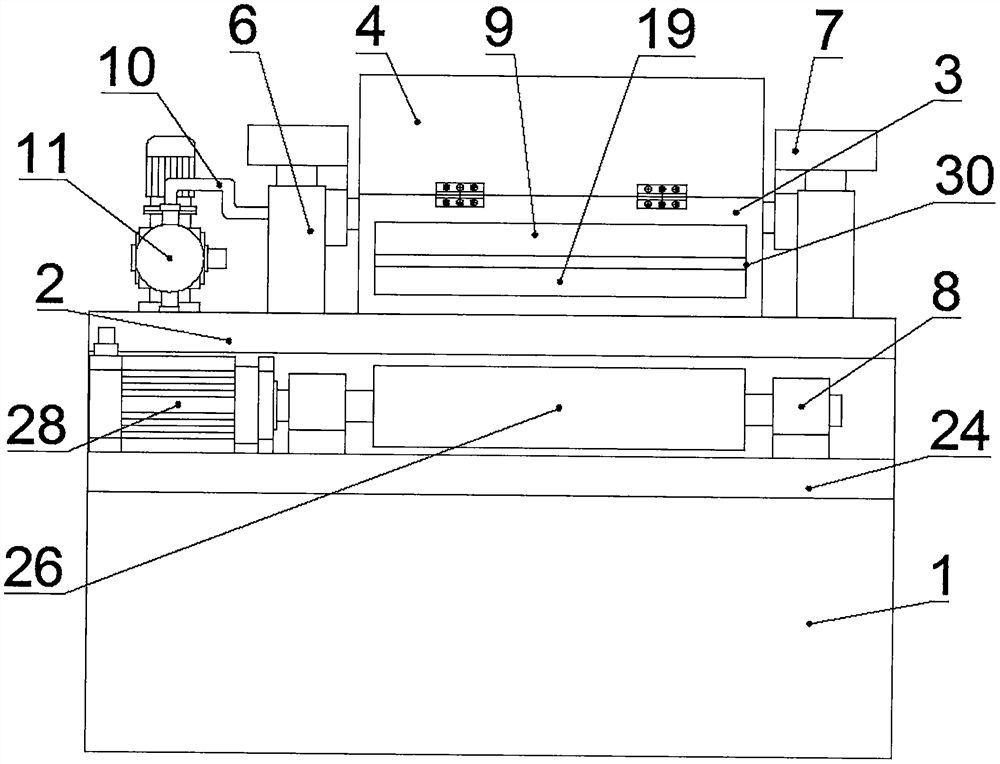

Welding quality detection device of ceramic tile drilling bit

ActiveCN107024538AReduce labor intensityAvoid missing detectionAnalysing solids using sonic/ultrasonic/infrasonic wavesDrive motorEngineering

The invention discloses a welding quality detection device of a ceramic tile drilling bit. The welding quality detection device comprises a worktable, an automatic feeding mechanism, a material conveying mechanism, a coupling agent coating mechanism and an ultrasonic detection mechanism, wherein a feeding hole is formed in the worktable; the material conveying mechanism comprises an annular material conveying belt, a driving motor and driving wheels for driving the material conveying belt to transmit; a plurality of clamping grooves are formed in an outer side wall of the material conveying belt; the bottom of the material conveying belt is fitted to the top of the worktable; when the clamping grooves in the outer side wall of the material conveying belt are aligned to the feeding hole in the worktable, the automatic feeding mechanism is used for jacking drilling bits to be detected into the clamping grooves; the ultrasonic detection mechanism is arranged at one side of the worktable and stretching-out end welding parts of the drilling bits to be detected in the clamping grooves on the material conveying belt are located in a detection opening of the ultrasonic detection mechanism. By adopting the welding quality detection device of the ceramic tile drilling bit, missed detection and erroneous detection, caused by anthropic factors, can be effectively avoided; the detection efficiency and accuracy of a product are improved and the labor intensity of detectors is reduced.

Owner:宁波神钻工具有限公司

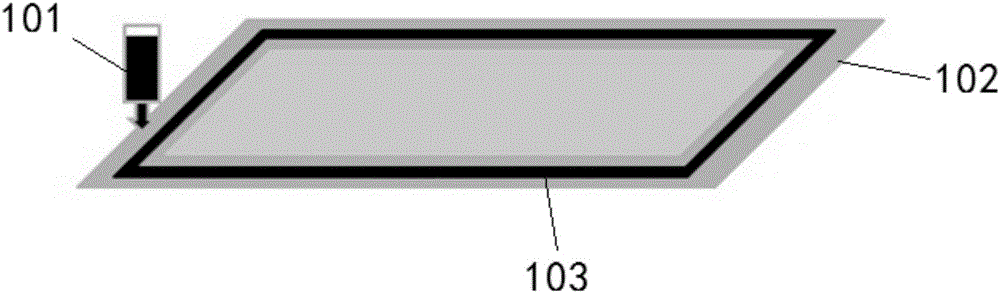

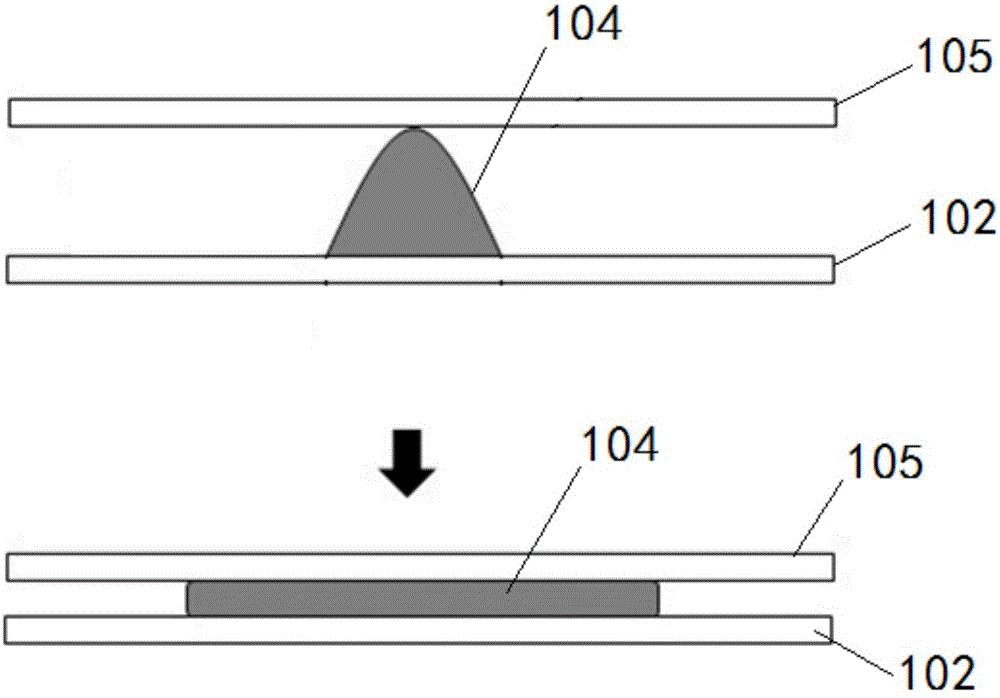

Bonding glue mixture, bonding glue detecting device, display panel and preparation method of display panel

InactiveCN105907329APrevents the problem of poor coating effectGuaranteed coating effectNon-macromolecular adhesive additivesElectric/magnetic position measurementsEngineeringGenerating unit

The invention provides a bonding glue mixture, a bonding glue detecting device, a display panel and a preparation method of the display panel. The bonding glue mixture comprises bonding glue and a plurality of filling particles which are distributed in the bonding glue, wherein the distribution range of the filling particles can be detected and differentiated by virtue of a matched detecting instrument at a set detection environment. The bonding glue detecting device comprises a magnetic field generating unit and a magnetic field range detecting unit. The display panel comprises a first substrate and a second substrate, wherein the first substrate and the second substrate are closed together and are bonded together through the bonding glue. The preparation method comprises the following steps: coating the first substrate with the bonding glue mixture; closing the second substrate and the first substrate together; precuring the bonding glue mixture, detecting the distribution range of the filling particles by virtue of the matched detecting device, and acquiring the coverage range of the bonding glue according to the distribution range of the filling particles, so as to judge the coating effect.

Owner:BOE TECH GRP CO LTD +1

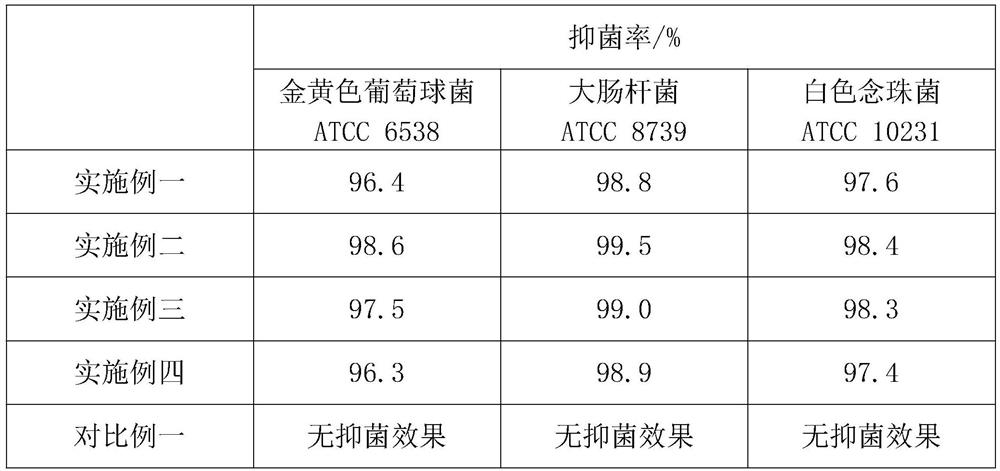

Nonwoven fabric for protective clothing and preparation method of non-woven fabric

PendingCN111749009ABiodegradableBacteriostaticBiochemical fibre treatmentFibre typesCellulosePolymer science

The invention relates to the technical field of non-woven fabrics, and provides a non-woven fabric for protective clothing and a preparation method of the non-woven fabric. The non-woven fabric comprises a non-woven fabric substrate, and the non-woven fabric substrate can be applied to the protective clothing after being treated by microcapsule finishing liquid, wherein the microcapsule finishingliquid is prepared from the following raw material in parts by weight: 35 to 60 parts of microcapsule emulsion, 6 to 12 parts of cross-linking agent, 2 to 4 parts of carboxymethyl cellulose and 1.5 to2.5 parts of fatty alcohol-polyoxyethylene ether; the microcapsule emulsion is prepared by taking chitosan and sodium alginate as wall materials and xylitol, N-ethyl-L-menthyl formamide and ammoniumnitrate as core materials by using a complex coacervation method, and the non-woven fabric substrate treated by the microcapsule finishing liquid solves the problems that in the prior art, the medicalprotective clothing non-woven fabric is single in function, a cool feeling cannot be generated, and stuffiness and discomfort are easily caused when a large amount of sweat is sweated.

Owner:FUJIAN HENGAN HLDG CO LTD +2

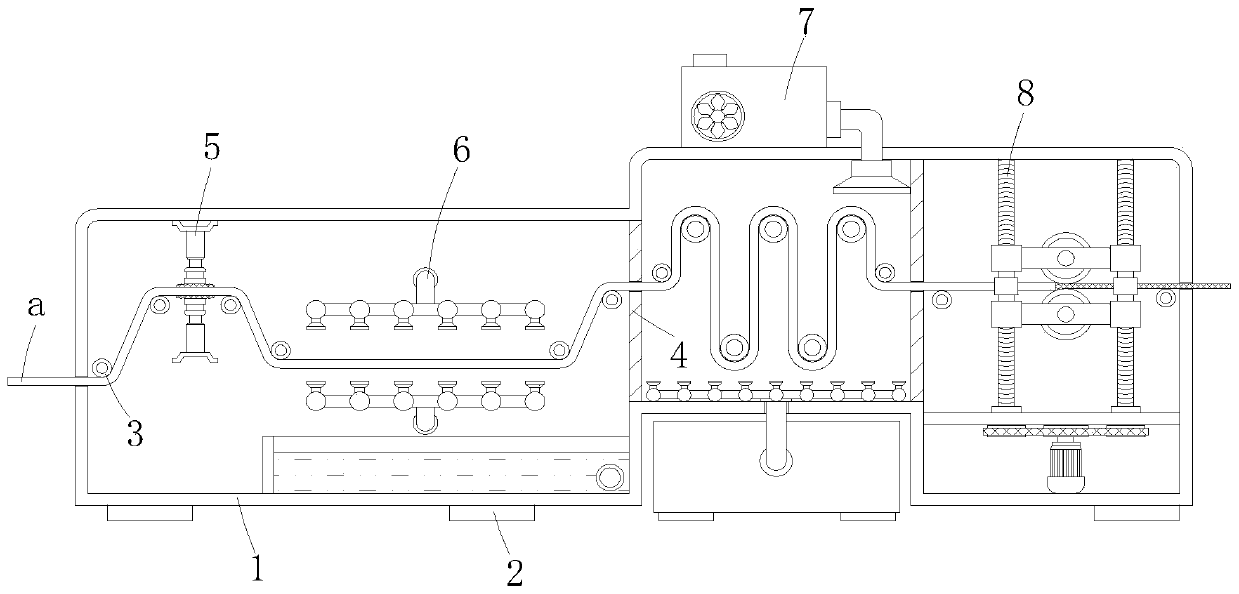

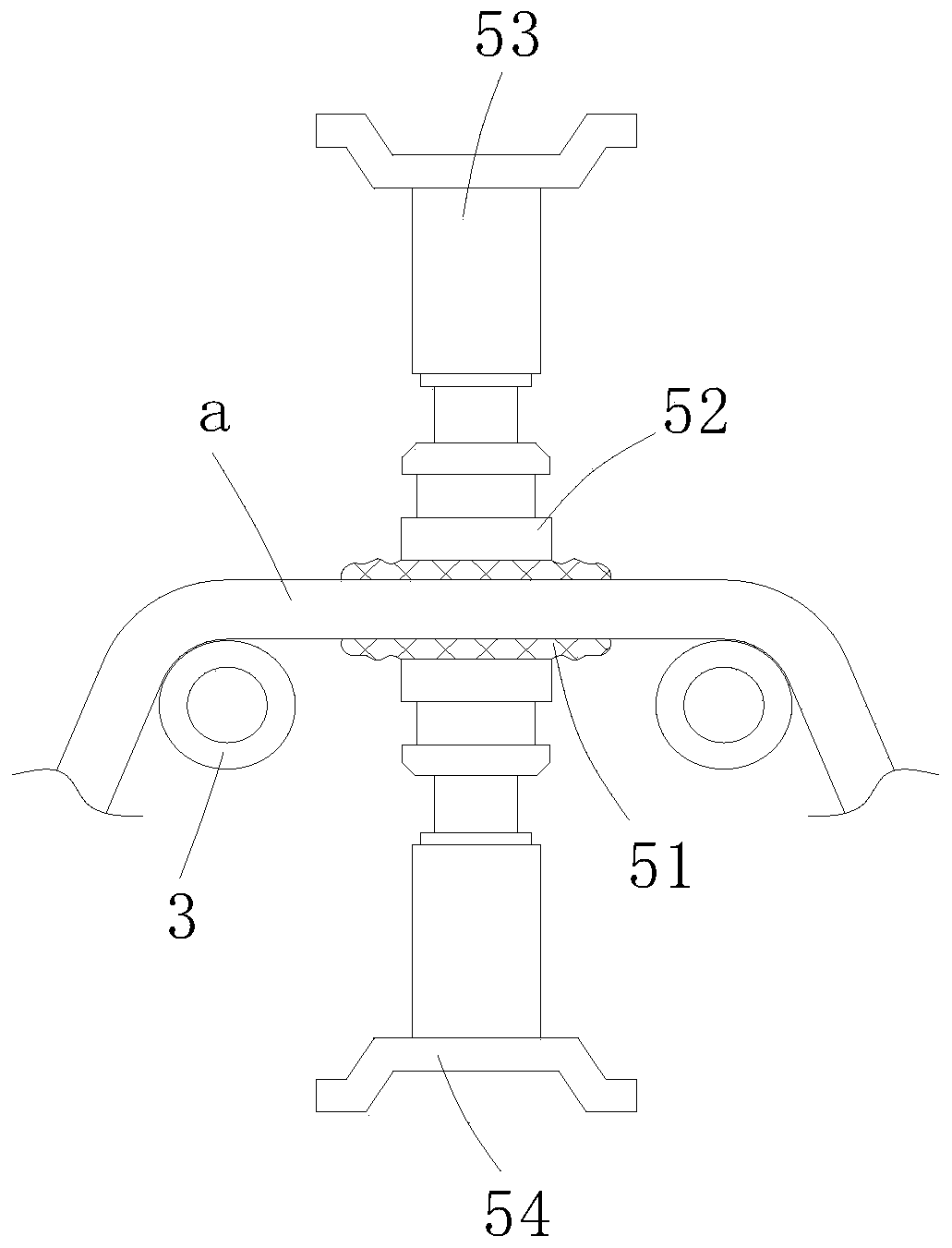

Coating and rolling device for battery production

InactiveCN111495656AIncrease productivityGuaranteed moldingPretreated surfacesCleaning using toolsEngineeringPole piece

The invention relates to the technical field of battery production equipment, and provides a coating and rolling device for battery production. The coating and rolling device aims to solve the problems that a traditional battery pole piece coating and rolling processing production efficiency is low, meanwhile, a pole piece is exposed in air for a long time, and the controllability of the product quality is extremely poor. The coating and rolling device comprises a device outer shell and a plurality of supporting legs installed at the lower end of the device outer shell; a feeding port and a discharging port are formed in the opposite side walls of the device outer shell respectively, a plurality of rotating rollers used for current collector transmission and tension are installed on the inner wall of the device outer shell, two partition plates are vertically installed in an inner cavity of the device outer shell, the two partition plates sequentially divide the inner cavity of the device outer shell into a coating cavity, a drying cavity and a rolling cavity from left to right in the movement direction of the current collector, a coating mechanism is arranged in the coating cavity, a drying mechanism is arranged in the drying cavity, and a rolling mechanism is arranged in the rolling cavity. The device is particularly suitable for coating and rolling processing of the batterypole piece, and has higher social use value and application prospect.

Owner:安徽奥邦科技有限公司

Weather-resistant and environmentally-friendly powder coating for household appliances

InactiveCN103205182AImproved yellowing resistanceGuaranteed coating effectPowdery paintsPolyester coatingsPolyesterEnvironmentally friendly

The invention discloses weather-resistant and environmentally-friendly powder coating for household appliances, relates to a novel coating in the field of new chemical materials and particularly relates to the technical field of energy-saving, weather-resistant and environmentally-friendly powder coatings for household appliances. The weather-resistant and environmentally-friendly powder coating is composed of resin, a curing agent, a pigment, stuffing and an assistant, wherein the mass percents of the resin, the curing agent, the pigment, the stuffing and the assistant in the total mass percent of the coating are respectively 60-65%, 3-5%, 27-32% and 3-5%. According to the invention, the defect of easy pinhole generation in the film coating process of HAA cured polyester powder coating is perfected, and no pinhole phenomenon is generated within a film coating thickness of 120 microns, so that the coating effect is guaranteed.

Owner:徐伟箭

Liquid crystal screen glass coating automatic processing device and coating process

ActiveCN113385328AImplement automatic conversionAvoid pollutionSpraying apparatusPhysical chemistryWorking environment

The invention provides a liquid crystal screen glass coating automatic processing device and a coating process, an adopted clamping and fixing mechanism can adaptively clamp and fix a screen plate according to the size of the screen plate, meanwhile, automatic switching of the spraying face of the screen plate can be achieved, so that fingerprints, oil stains and the like are prevented from being left on the surface of the screen plate due to the fact that workers make contact with the screen plate many times, and the forming effect of a coating agent on the surface of the screen plate is further improved. A relatively closed space formed by a spraying mechanism can play a role in blocking the splashed coating agent in the coating period of the screen plate, so that the situation that the working environment is polluted and the body of a worker is injured due to the fact that the coating agent is scattered all around is avoided.

Owner:江苏二五七特显科技集团有限公司

Coating device with tail recovery and protective housing mechanism

InactiveCN111701766AAvoid pollutionReduce pollutionLiquid surface applicatorsSpraying apparatusAdhesion processElectric machinery

The invention discloses a coating device with a tail recovery and protective housing mechanism. The coating device with the tail recovery and protective housing mechanism comprises a frame, a workbench, a protective frame, a protective housing, a latch fastener, a lifting column, a lifting plate, a bearing seat, a coating roller, a material injection pipe, a plunger pump, a material pumping pipe,a coating tank, a recovery groove, a collection opening, a cotterway, a square cottar, a sealing cover, a traction roller, a tool holder, a scraping knife, a lead screw, an adjusting nut, a first suspension platform, a second suspension platform, an unwinding roller, a winding roller, an unwinding motor, a winding motor, a first through window and a second through window. According to the coatingdevice with the tail recovery and protective housing mechanism, by covering the protective housing above the protective frame, the problem that a coating is polluted by impurities such as dust in theadhesion process is solved, the coating effect of the device is guaranteed, and the product quality is improved; by shoveling tails remaining on the coating roller and the scraping knife into the recovery groove and opening the sealing cover to take out the tails from the collection opening, an effect of recovering the tails is achieved, unnecessary resource wastes and environment pollution are reduced, and the production cost is saved.

Owner:深圳市鼎泰祥新能源科技有限公司

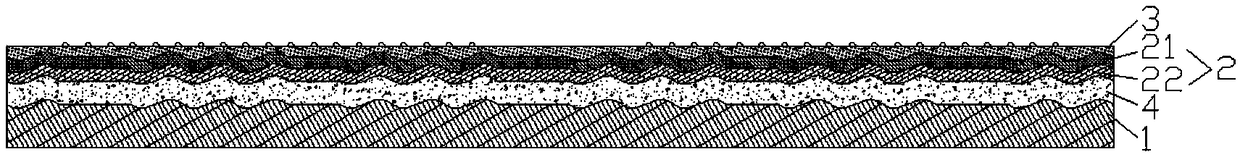

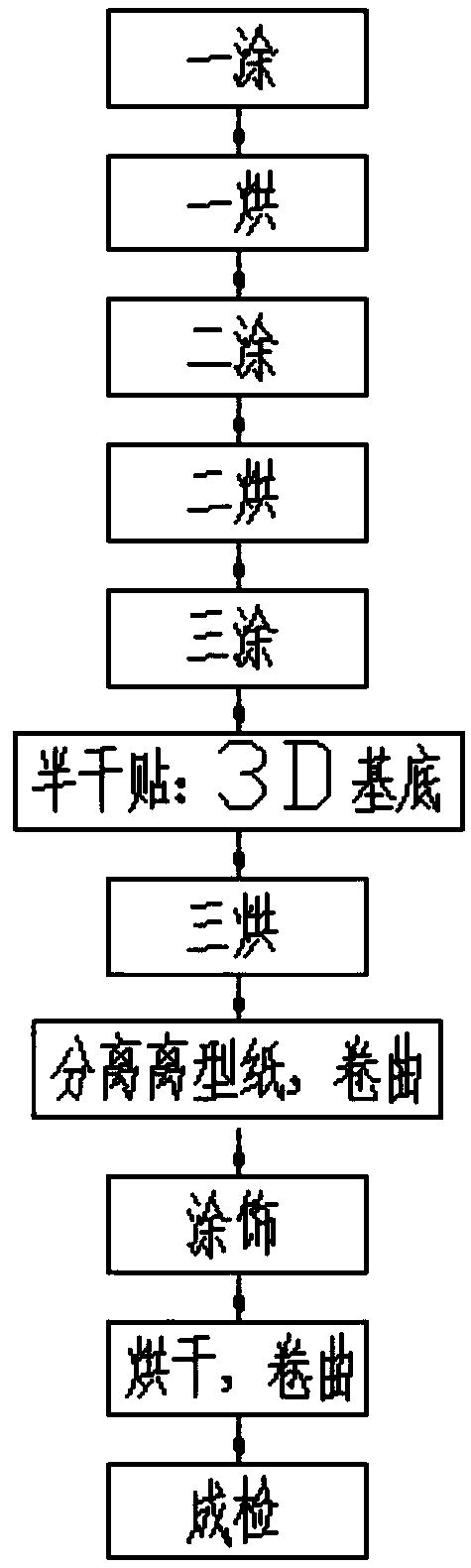

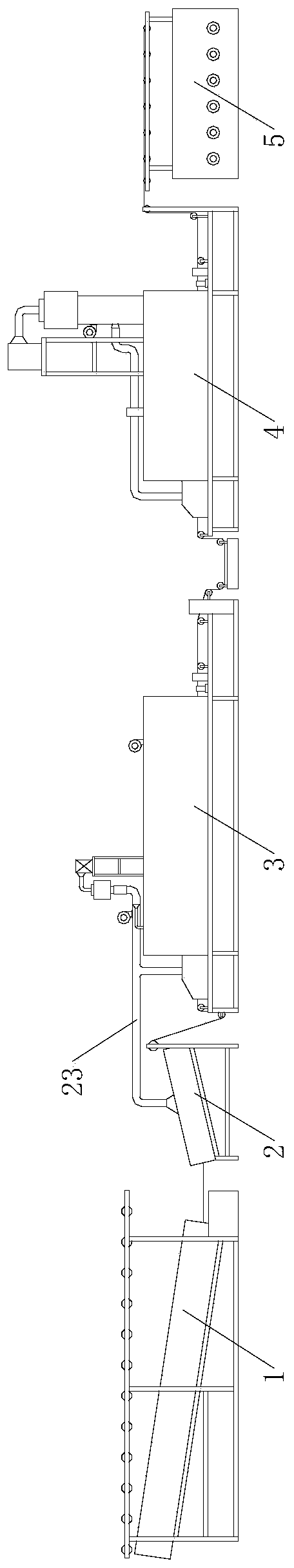

PU (polyurethane) composite leather with 3D effect and preparation method of PU composite leather

InactiveCN108729252AHigh degree of bonding integrationDurableVehicle componentsTextiles and paperSolvent freeFire retardant

The invention discloses PU (polyurethane) composite leather with a 3D effect. The leather successively comprises a 3D basal layer, a PU composite layer and a finishing layer, a bonding agent layer isarranged between the 3D basal layer and the PU composite layer, a solvent-free PU bonding agent serves as the raw material of the bonding agent layer, the finishing layer is a waterborne finishing layer, the PU composite layer comprises a PU monolayer and a high solid layer, and the PU monolayer is prepared from the following raw materials in parts by weight: 95-105 parts of PU resin, 62-70 partsof DMF (dimethyl formamide), 13-16 parts of acetic ether and 7.5-9 parts of color paste; the high solid layer is prepared from the following raw materials in parts by weight: 95-105 parts of high solid resin, 6-7.5 parts of cross-linking agent, 2.5-4 parts of propylene glycol methyl ether acetate, 12-16 parts of fire retardant, 0.55-0.7 part of flatting agent, 0.25-15 parts of color paste and 0.6-1 part of foaming agent. According to the PU composite leather with the 3D effect and the preparation method of the PU composite leather, base cloth is removed compared with previous PU composite materials, the materials are lighter, and the supporting performance is strong; before the process of automotive trim forming, the process in which PU leather is combined with 3D is left out, and the costis reduced when the PU composite leather has a prominent 3D effect.

Owner:SUZHOU RUIGAO NEW MATERIAL CO LTD

Processing technology of special self-adhesive enameled wire for household motor and device

ActiveCN110310782AImprove processing stabilityGood coating effectInsulating conductors/cablesCopper wireSelf adhesive

The invention discloses a processing technology of a special self-adhesive enameled wire for a household motor and a device. The processing technology comprises the steps of softening a copper bare wire through an annealing oven to obtain a copper wire A; sensing the copper wire A into a drying furnace for drying to obtain a copper wire B; coating the surface of the copper wire B with primer, sending the copper wire B into a first enamelling furnace, and drying the copper wire B for the first time in different temperature environments through the first enamelling furnace to obtain an enameledwire C; coating the surface of the enameled wire C with finish paint, then sending the enameled wire C into a second enamelling furnace, and drying the enameled wire C for the second time in differenttemperature environments through the second enamelling furnace to obtain an enameled wire D; and winding the enameled wire D to obtain a finished enameled wire. The working stability and the bondingeffect of the self-adhesive paint after being coated can be effectively improved according to the invention.

Owner:浙江郎立电工器材有限公司

Silencing and noise-reducing PU leather and preparation method thereof

The invention discloses silencing and noise-reducing PU leather which successively comprises a base cloth layer, a PU layer and a coating layer. An adhesive layer is arranged between the base cloth layer and the PU layer, the adhesive layer is made from a solvent-free PU adhesive, the coating layer is an aqueous coating layer, the PU layer comprises two PU single layers, and the PU layer is prepared from the following raw materials in parts by weight: 85-110 parts of PU resin, 60-70 parts of DMF, 12-18 parts of acetic ether and 20-32 parts of color paste. According to the silencing and noise-reducing PU leather and a preparation method thereof, the noise problem of the PU leather and other trim materials in a using process can be alleviated, so that a passenger has a high-end layered texture and silent comfort experience.

Owner:SUZHOU RUIGAO NEW MATERIAL CO LTD

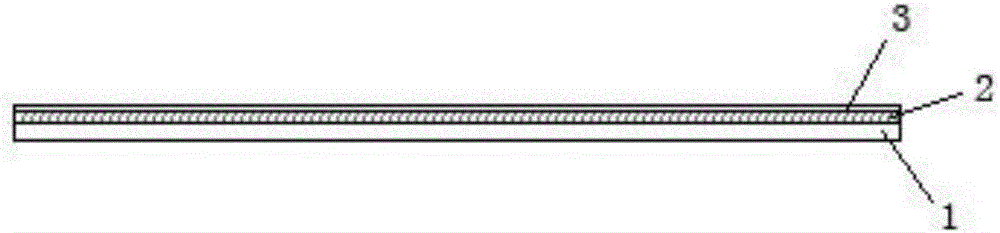

Adjustable paste box

ActiveCN110653121AGuaranteed tightnessGuaranteed liquid levelLiquid surface applicatorsCoatingsStructural engineeringMechanical engineering

The invention discloses an adjustable paste box, and belongs to the field of coating method research. The adjustable paste box comprises a shell, material collecting mechanisms, two rubber pads, an adjusting mechanism and two scrapers; the shell is in a cuboid shape, a concave cavity is formed in the top surface of the shell, the shell comprises two identical sub-shells, each sub-shell comprises abottom plate, side plates and two mutual paralleled vertical plates, wherein the side plates and the two vertical plates are vertically arranged on the bottom plate, the side plates are vertically connected with any vertical plate, and a clamping mechanism is arranged between the two vertical plates forming the side faces of the shell; the material collecting mechanisms are arranged inside the shell; the two rubber pads are arranged, the cross sections of the rubber pads are in U shapes, and the two rubber pads are arranged between the two sub-shells; the adjusting mechanism is provided withguide rails and sliding blocks, and the guide rails are fixedly arranged at the top of the shell; and the two scrapers are symmetrically arranged on two sliding blocks, and the scrapers are arranged in parallel with the middle section parts of the rubber pads. The adjustable paste box is simple in structure and convenient to operate, the contact area between paste liquid and a pole piece can be ensured, and then the coating quality of the pole piece is guaranteed.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

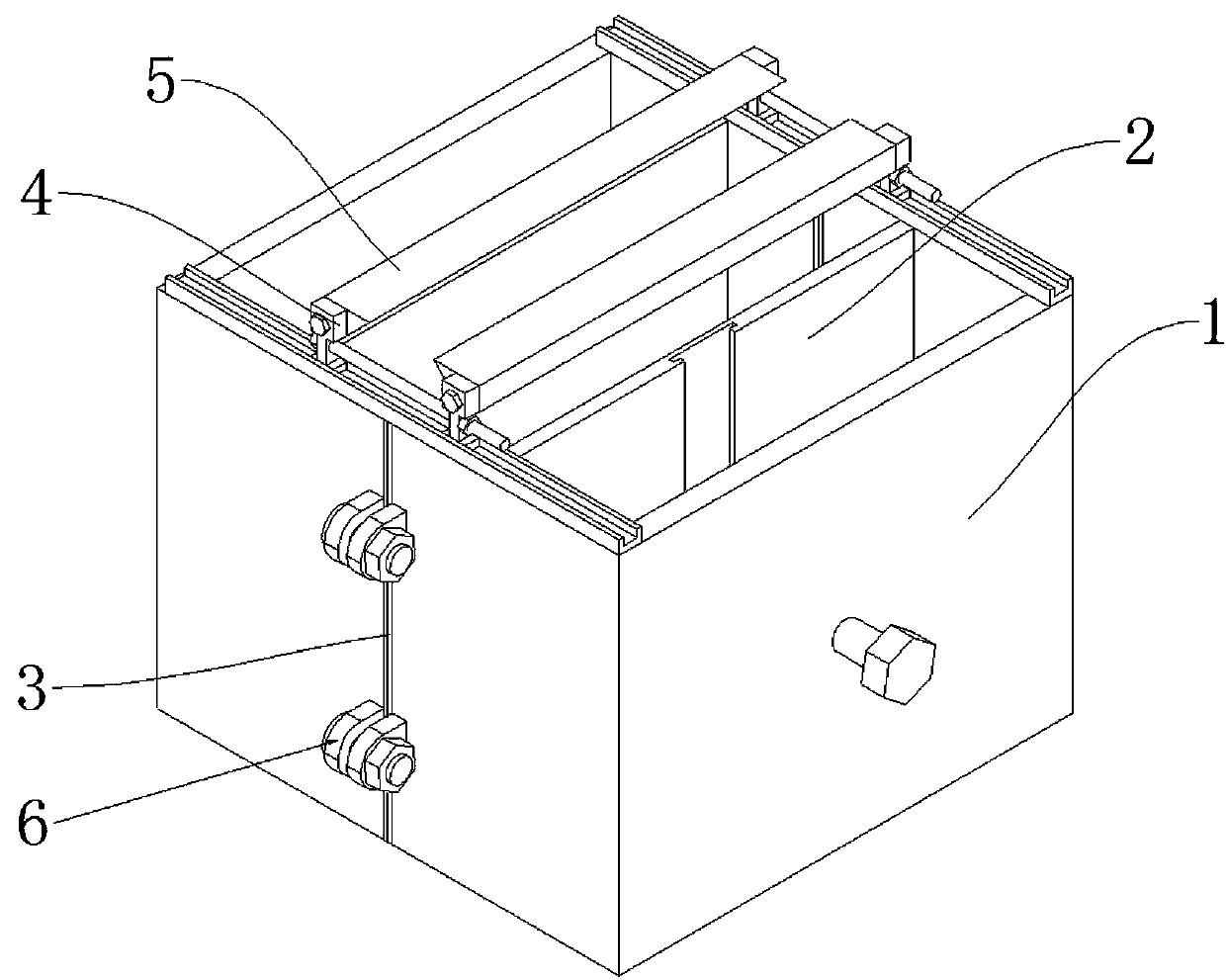

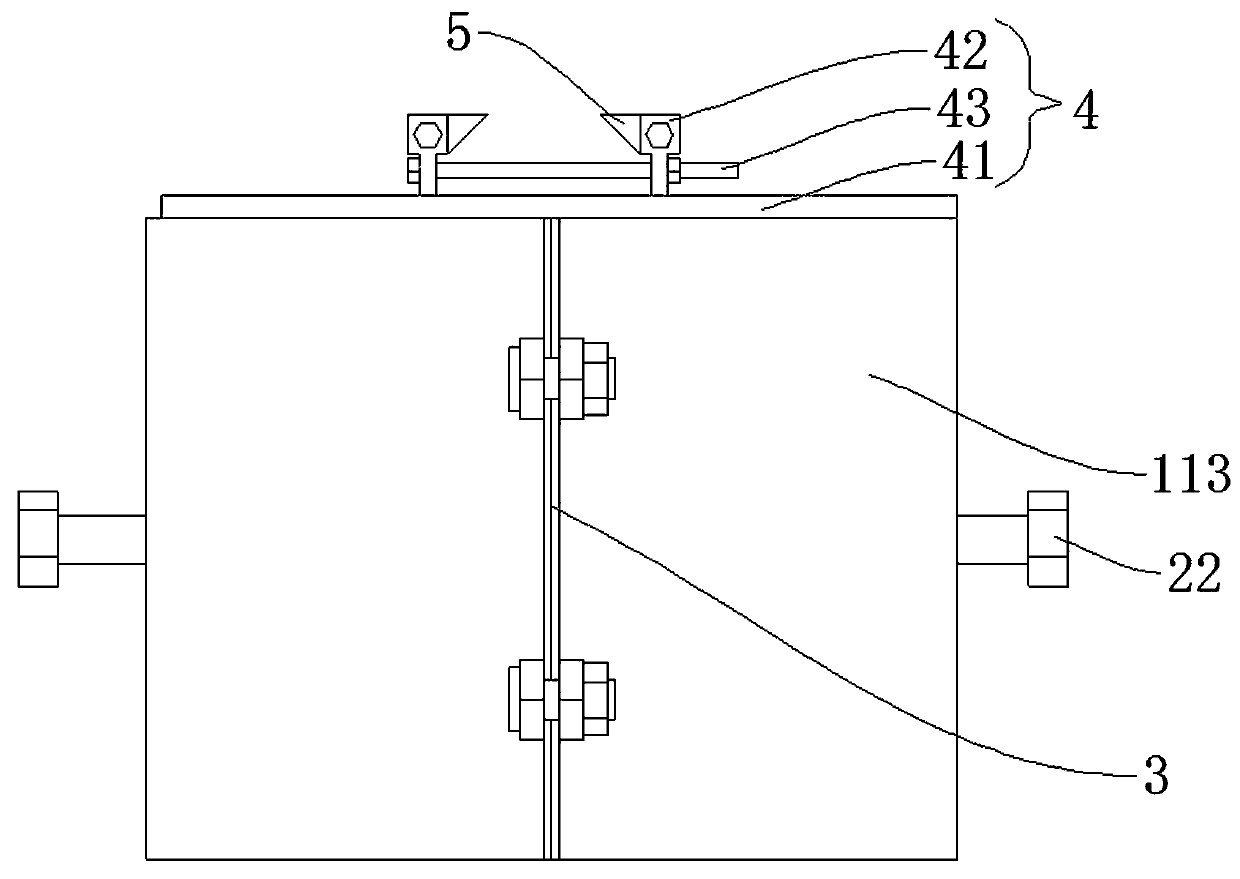

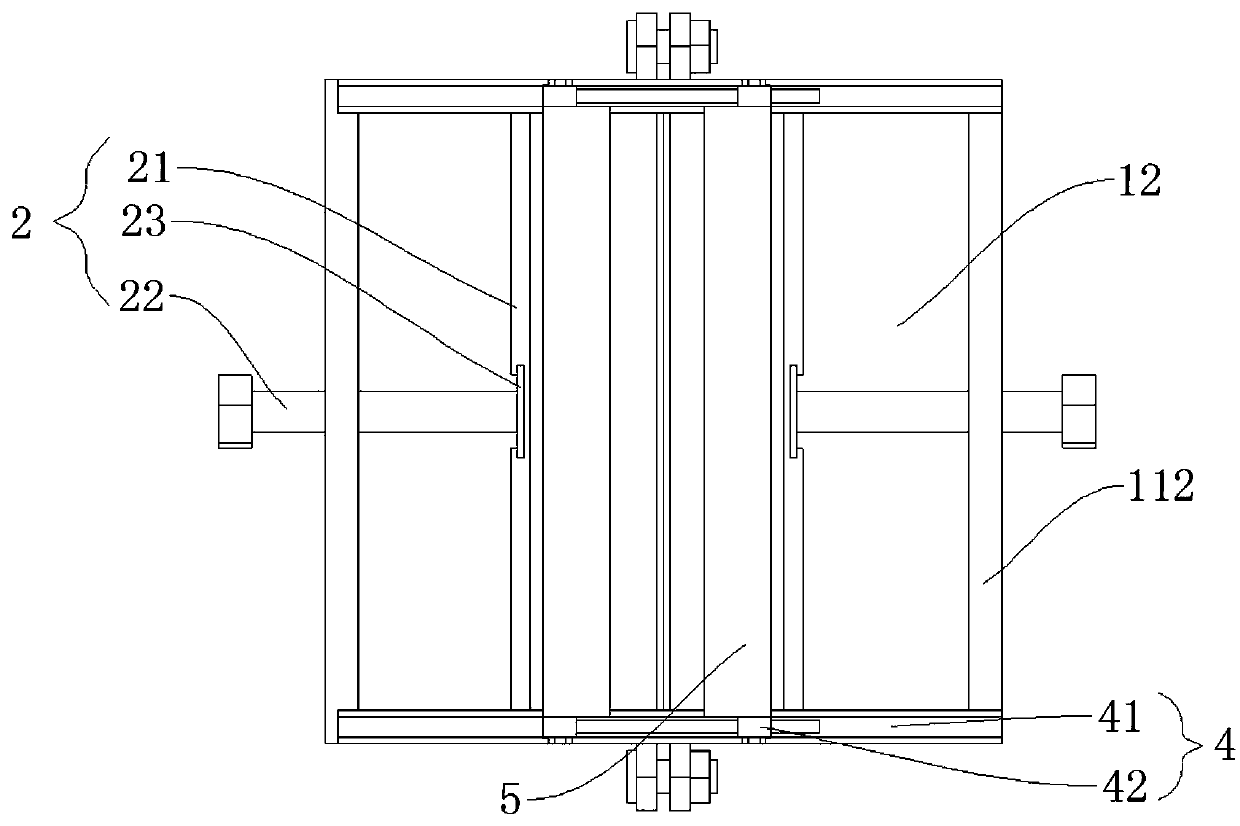

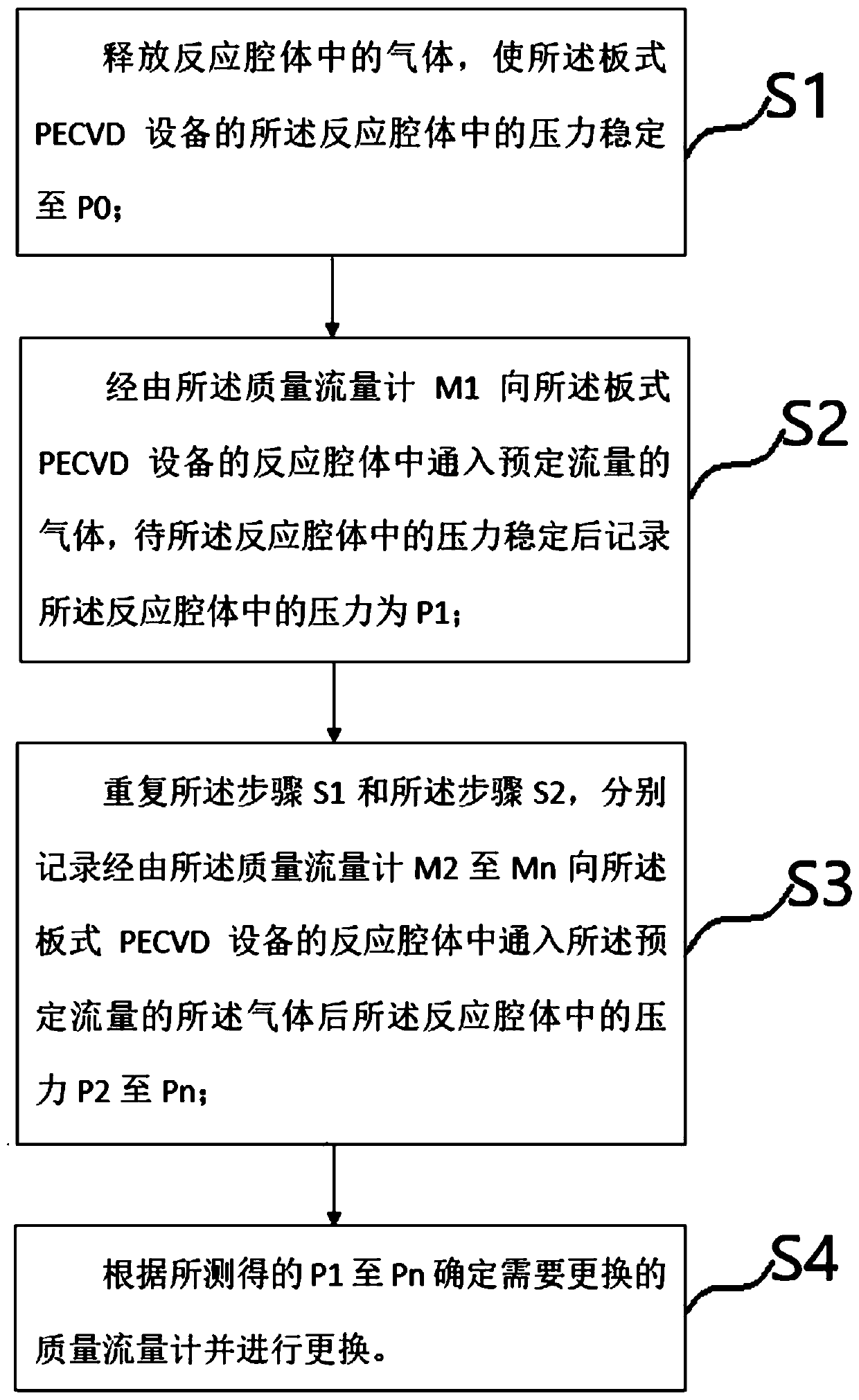

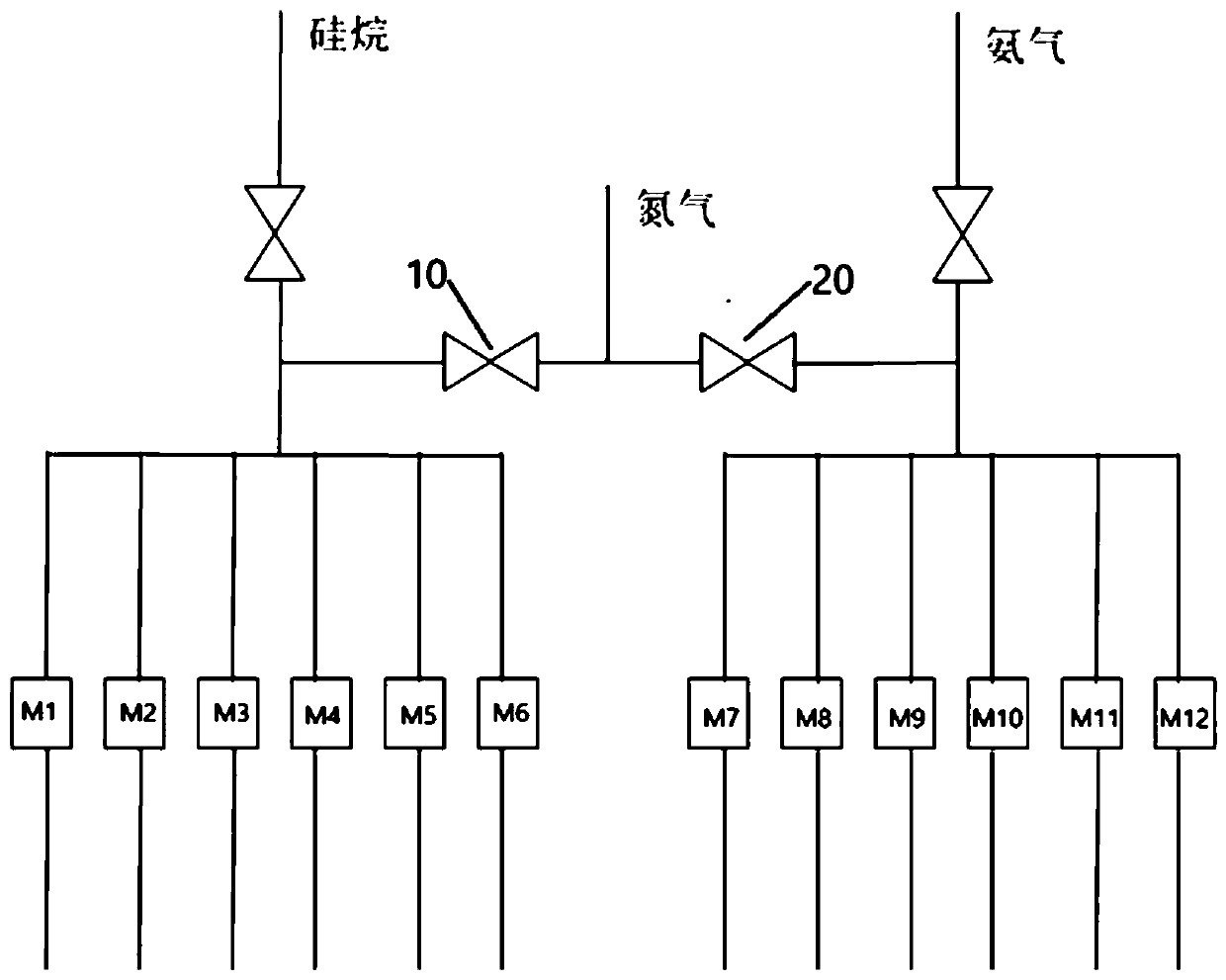

Calibration method for mass flow meters of plate PECVD equipment

ActiveCN110299300AControl thicknessGuaranteed coating effectSemiconductor/solid-state device testing/measurementFinal product manufactureEngineeringStreamflow

The invention relates to a calibration method for mass flow meters of plate PECVD equipment. The plate PECVD equipment includes mass flow meters M1 to Mn, wherein n is a natural number greater than 3.The calibration method includes the following steps: S1, releasing the gas in a reaction chamber to stabilize the pressure in the reaction chamber of the plate PECVD equipment to P0; S2, introducinggas of a predetermined amount of flow into the reaction chamber of the plate PECVD equipment via the mass flow meter M1, and recording the pressure in the reaction chamber as P1 after the pressure inthe reaction chamber is stabilized; S3, repeating S1 and S2, and recording the pressure in the reaction chamber as P2 to Pn after the gas of a predetermined amount of flow is introduced into the reaction chamber of the plate PECVD equipment via the mass flow meters M2 to Mn; and S4, determining mass flow meters needing to be replaced according to the measured P1 to Pn and replacing the mass flow meters. By using the calibration method of the embodiment of the invention, abnormal mass flow meters can be judged accurately and replaced, the coating effect is ensured, and the operation is simple and convenient.

Owner:JA SOLAR +1

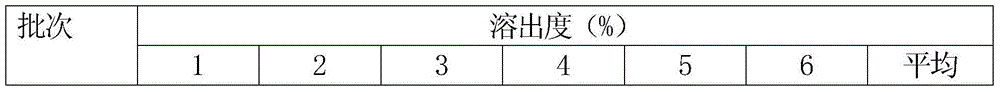

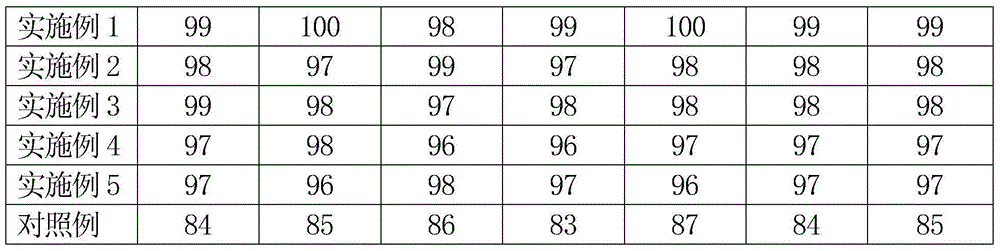

Mini-pill type nicergoline capsule and preparation method thereof

InactiveCN104622850AImprove solubilityWidely distributedSenses disorderNervous disorderSide effectBiomedical engineering

The invention discloses a mini-pill type nicergoline capsule and a preparation method thereof. The mini-pill type nicergoline capsule is a sustained-release preparation and is prepared from a capsule shell and a nicergoline mini-pill accommodated in the capsule shell, wherein the nicergoline mini-pill sequentially comprises an empty pill core, a main drug layer and a pigmented layer from inside to outside; the main drug layer accounts for 15-60 percent of the empty pill core, and the pigmented layer accounts for 0.5-1 percent of the total weight of the empty pill core and the main drug layer. The mini-pill type nicergoline capsule has the advantages of small stimulation to intestines and stomach, high utilization rate, high stability, less toxic or side effects and capability of fully releasing effective components in time.

Owner:ZHEJIANG CHANGDIAN PHARMA +1

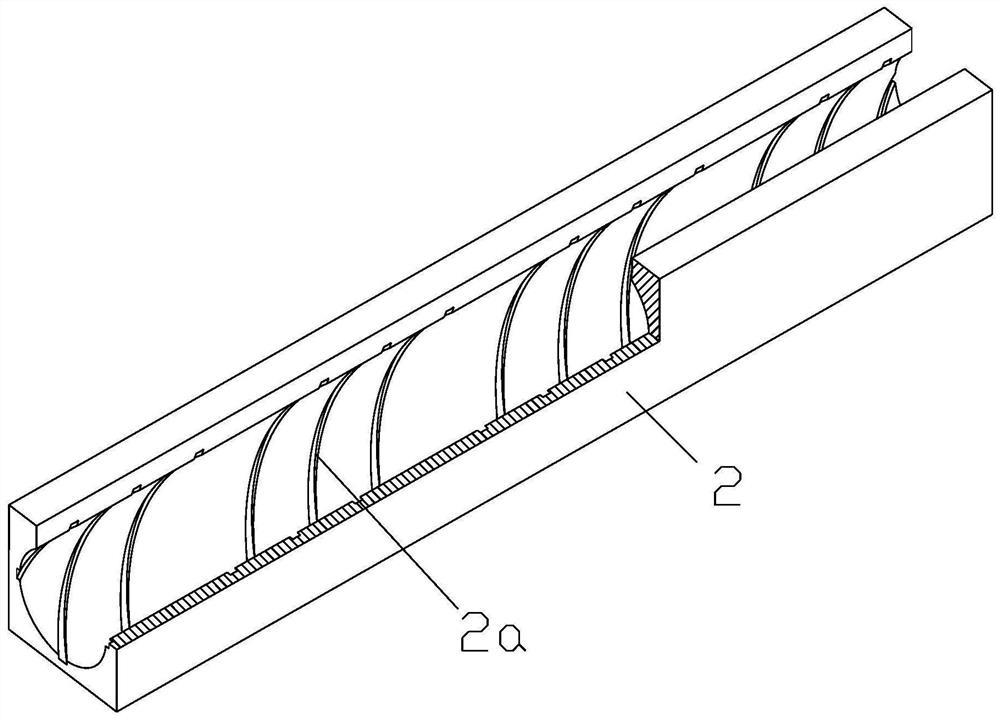

Wire insulation coating device

PendingCN111834959AGuaranteed coating effectLiquid surface applicatorsApparatus for repairing insulation/armouring cablesStructural engineeringElectric wire

The invention provides a wire insulation coating device, which comprises a base, a fixed support, a movable support and a hair brush, wherein the fixed support is fixedly mounted on the base, a mounting groove with a first opening part at the top end is transversely formed in the fixed support, and a spiral sliding rail is arranged on the inner wall of the mounting groove; the movable support is arranged in the mounting groove, a sliding block is arranged on the movable support, a coating groove and a liquid storage cavity are transversely formed in the movable support, and the liquid storagecavity is provided with a liquid leakage hole communicated to the coating groove; the hair brush is connected to the liquid leakage hole; and the movable support moves in the mounting groove in a spiral mode so as to enable the hair brush to brush the exposed part of a wire in a spiral manner. Through cooperation of the spiral sliding rail and the sliding block, the movable support moves along themounting groove and rotates at the same time, so that the movable support is driven to move forwards in a spiral mode, the hair brush mounted on the movable support can coat the exposed wire in an all-around mode, and the coating effect is guaranteed.

Owner:HUZHOU ELECTRIC POWER SUPPLY CO OF STATE GRID ZHEJIANG ELECTRIC POWER CO LTD

Production method for leather-like paper

InactiveCN106560547AReach the touchTo achieve tactile effectPaper coatingCoatingsWhiteboardSlurry coating

The invention provides a production method for leather-like paper. The leather-like paper comprises, from bottom to top, a white board layer, a carboxylic butadiene-styrene latex layer and a polyurethane synthetic leather layer. According to the method, a white board is used as a bottom layer and coated with carboxylic butadiene-styrene latex; a carboxylic butadiene-styrene latex coating is heated and dried so as to form a film; the obtained carboxylic butadiene-styrene latex film is coated with polyurethane synthetic leather slurry; and a polyurethane synthetic leather slurry coating is dried so as to obtain the leather-like paper. The leather-like paper provided by the invention uses the white board easily available on a common market as the bottom layer; the carboxylic butadiene-styrene latex coats the white board at first, and the carboxylic butadiene-styrene latex film obtained after drying functions as a bridge; the carboxylic butadiene-styrene latex has high bonding force with the surface of the white board and with polyurethane synthetic leather, so the white board, the carboxylic butadiene-styrene latex film and polyurethane form a firm bonded body; and the carboxylic butadiene-styrene latex film and polyurethane can protect a printed pattern and improve hardness and rub resistance, enable the touch of leather to be obtained, enhance the beauty of the leather-like paper and elevate the comfort level of the leather-like paper in usage.

Owner:ZHEJIANG TIANCHEN PLASTIC IND

Gold crispy wrap powder and application method thereof

The invention discloses gold crispy wrap powder comprising a main ingredient and an additive. The main ingredient comprises wheat flour, corn flour, corn starch and modified starch. The additive comprises a composite leavening agent and a food coloring. The main ingredient and the additive include, by weight parts, 35-50 parts of wheat flour, 15-25 parts of corn flour, 15-25 parts of corn starch,10-25 parts of modified starch, 0.5-1.5 parts of composite leavening agent and 0.01-0.3 part of food colorant. A method for application of the gold crispy wrap powder comprise the following steps: weighing the golden crispy wrap powder and water separately according to the proportion; slowly adding the water into the wrap powder, continuously stirring to form uniform slurry; placing pickled meat loaves, chicken wings or chicken legs in the slurry, so that the surface is evenly smeared with the slurry, taking out the products, and placing the products in a frying pan for frying. According to the gold crispy wrap powder and the application method thereof, the golden color and crisp taste of the wrap powder are increased, the use of the coloring is reduced, the oil absorption features are reduced, and oil intake is reduced.

Owner:苏州闻达食品配料有限公司

Talcum powder coating device for cable

PendingCN108525962APrevent leakageAvoid pollutionLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention provides a talcum powder coating device for a cable. According to the device, by arranging a sealing cover for sealing a first feeding inlet and a second feeding inlet, talcum powder ina powder box is prevented from leaking out through the first feeding inlet and the second feeding inlet, the practicability of the device is improved, by arranging a receiving trough for receiving talcum powder overflowing from a cable outlet along with the cable, the situation that talcum powder falls around and pollutes the environment is avoided, and the environment protection property of the device is improved; and when the cable needs to be coated with talcum powder, the cable is extended into the powder box through a cable inlet and further extended out through the cable outlet, thus, the purpose of coating the cable with talcum powder is achieved, operation is simple, through rotation of a motor, a driving gear is driven to rotate, then a first driven gear and a second driven gear are driven to rotate, first stirring blades on a first stirring rotary shaft and second stirring blades on a second stirring rotary shaft are further driven to rotate so as to stir talcum powder in thepowder box, and the cable coating effect is ensured.

Owner:GUANGDONG POWER GRID CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com