Automatic loading system for lithium battery and application method thereof

An automatic feeding, lithium battery technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of frequent filter cleaning, affecting production line production, easy clogging of filters, etc., to achieve flexible and convenient equipment operation, slurry The material is uniform and not easy to be affected by external conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

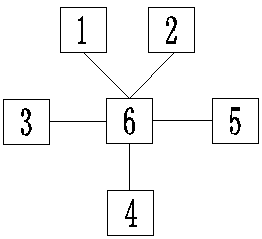

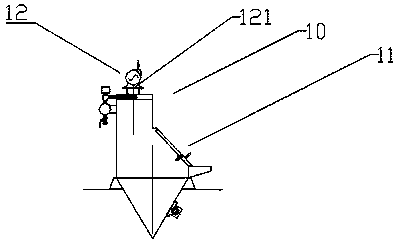

[0047] Such as figure 1 , 2 As shown, the lithium battery automatic feeding system of this embodiment includes a powder feeding system 1, a solvent feeding system 2, a mixer 3, a transfer tank 4, a coating feeding system 5 and control of the powder feeding system 1, solvent feeding system System 2, two mixers 3, transfer tank 4, control system 6 of the coating feeding system 5, the powder feeding system 1 and the solvent feeding system 2 are respectively connected to the mixer 3 in two ways through conveying pipelines, and the mixer 3 It is connected with the transfer tank 4, the transfer tank 4 and the coating feeding system 5 through a delivery pipeline, and the delivery pipeline between the solvent feeding system 2 and the mixer 3, the mixer 3 and the transfer tank 4 is provided with a pump and the discharge valve for controlling the discharge, the delivery pipeline between the powder feeding system 1 and the mixer 3, the transfer tank 4 and the coating feeding system 5 is...

Embodiment 2

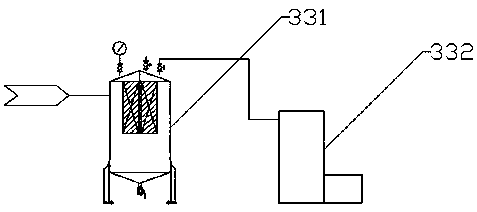

[0050] Such as figure 1 , 3 , 4, 5, and 6, the lithium battery automatic feeding system of this embodiment includes a powder feeding system 1, a solvent feeding system 2, a mixer 3, a transfer tank 4, a coating feeding system 5 and control of the powder Feeding system 1, solvent feeding system 2, two mixers 3, transfer tank 4, control system 6 of coating feeding system 5, the powder feeding system 1 and solvent feeding system 2 are respectively divided into two routes and the mixer 3 passes through the conveying pipeline connection, the mixer 3 and the transfer tank 4, the transfer tank 4 and the coating feeding system 5 are all connected by conveying pipelines, the solvent feeding system 2 and the mixer 3, the mixer 3 and the transfer tank 4 The delivery pipeline is provided with a pump and a discharge valve for controlling discharge, and the delivery pipeline between the powder feeding system 1 and the mixer 3, the transfer tank 4 and the coating feeding system 5 is provide...

Embodiment 3

[0060] Such as figure 1 , 3, 4, 5, and 7, the lithium battery automatic feeding system of the present embodiment includes a powder feeding system 1, a solvent feeding system 2, a mixer 3, a transfer tank 4, a coating feeding system 5 and control of the powder Feeding system 1, solvent feeding system 2, two mixers 3, transfer tank 4, control system 6 of coating feeding system 5, the powder feeding system 1 and solvent feeding system 2 are respectively divided into two routes and the mixer 3 passes through the conveying pipeline connection, the mixer 3 and the transfer tank 4, the transfer tank 4 and the coating feeding system 5 are all connected by conveying pipelines, the solvent feeding system 2 and the mixer 3, the mixer 3 and the transfer tank 4 The delivery pipeline is provided with a pump and a discharge valve for controlling discharge, and the delivery pipeline between the powder feeding system 1 and the mixer 3, the transfer tank 4 and the coating feeding system 5 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com