Ultrasonic lapping device

A grinding device and ultrasonic technology, applied in grain processing, etc., can solve the problems of reducing the grinding efficiency, the grinding device cannot meet the grinding requirements, etc., and achieve the effect of improving the grinding efficiency and uniform slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

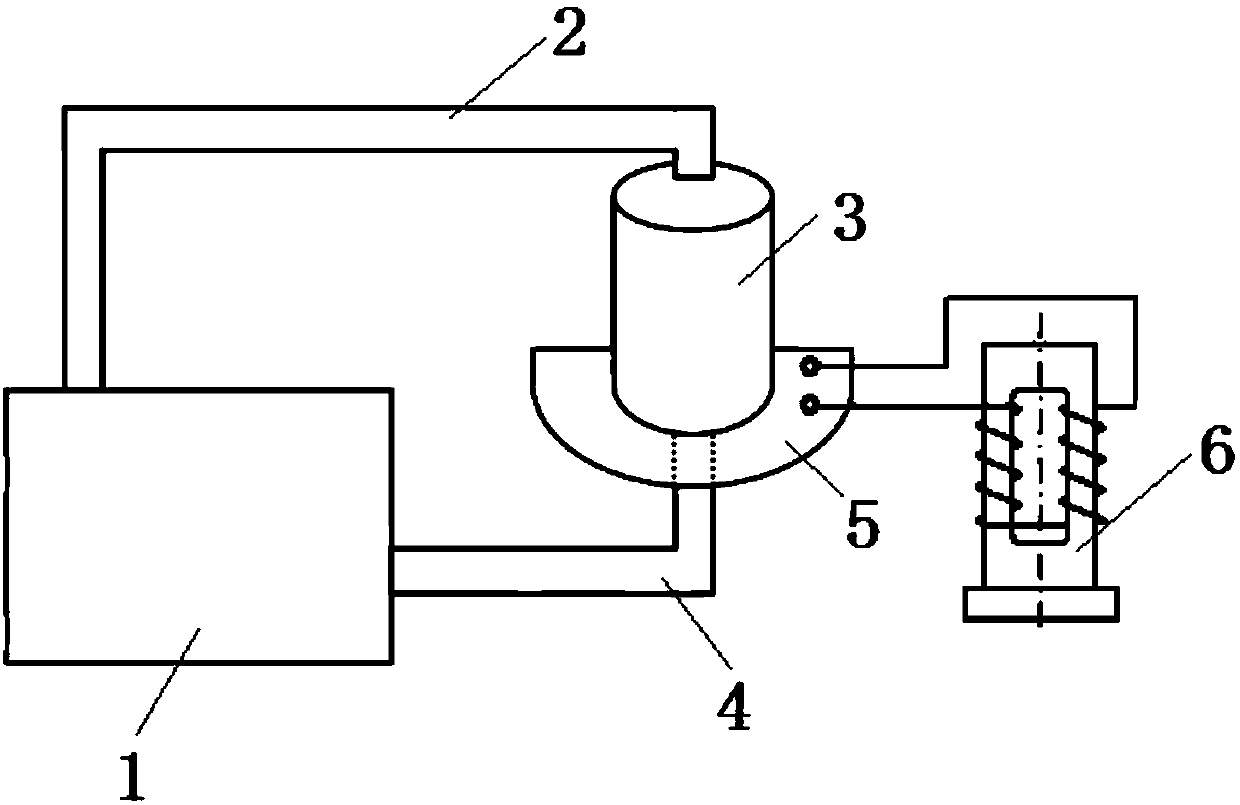

[0016] Embodiment 1 of the present invention provides an ultrasonic grinding device, such as figure 1 As shown, it includes a grinding body 1 with a grinding chamber 11, a discharge pipe 2, a buffer tank 3 and a feeding pipe 4 connected in sequence, and the feeding pipe 4 is connected with the grinding body 1, and the bottom of the grinding body 1 is arranged There is a discharge port 14, which is characterized in that it further includes an ultrasonic generator 5 and a transducer 6, the ultrasonic generator 5 is arranged between the buffer tank 3 and the feed pipe 4 and the lower section of the buffer tank 3 is placed on the ultrasonic generator 5 In the process, the transducer 6 is connected to the ultrasonic generator 5, so that by adding the ultrasonic generator 5 and the transducer 6, the material is ultrasonically dispersed in advance before entering the grinding body again.

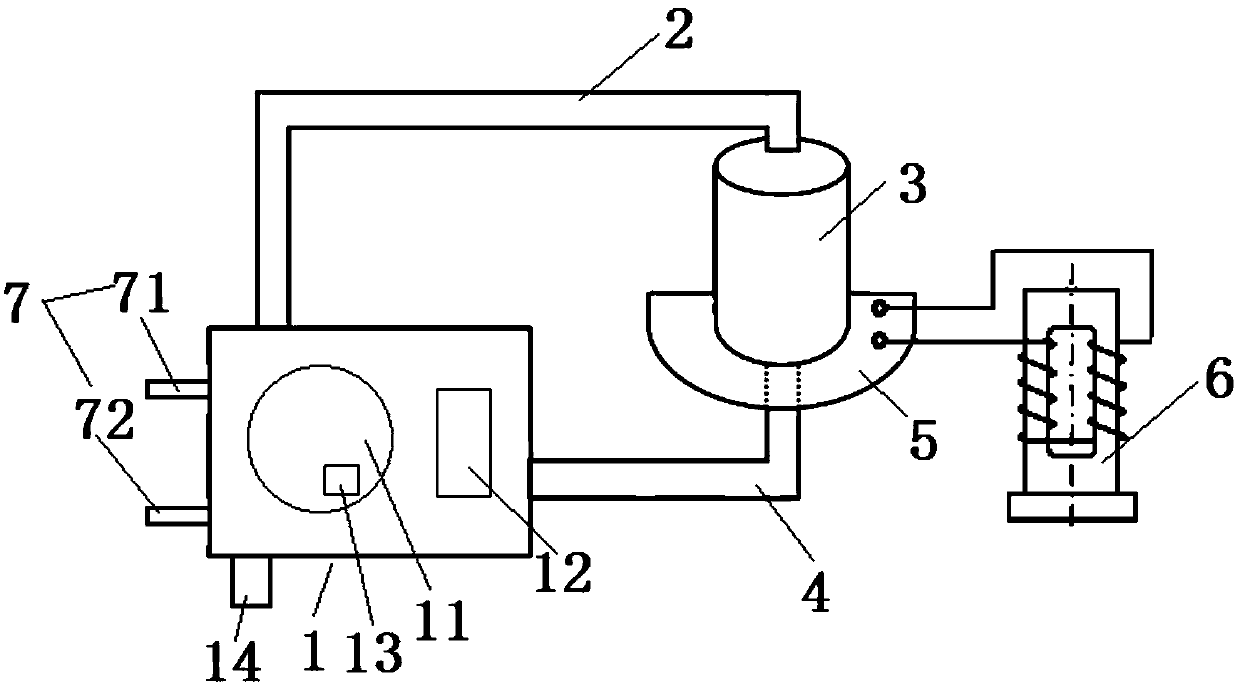

[0017] Embodiment 2 of the present invention provides an ultrasonic grinding device, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com