Patents

Literature

82results about How to "Uniform slurry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

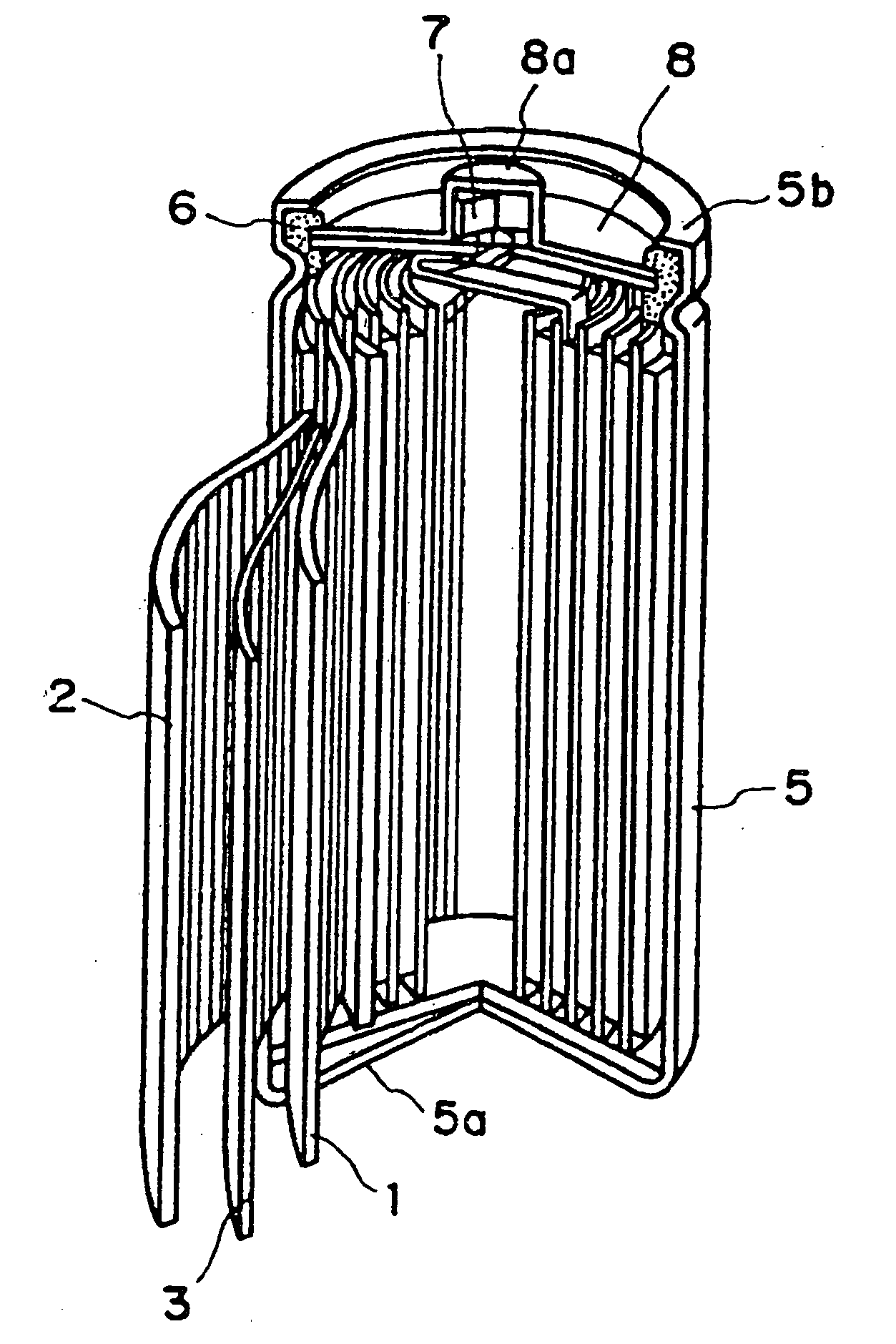

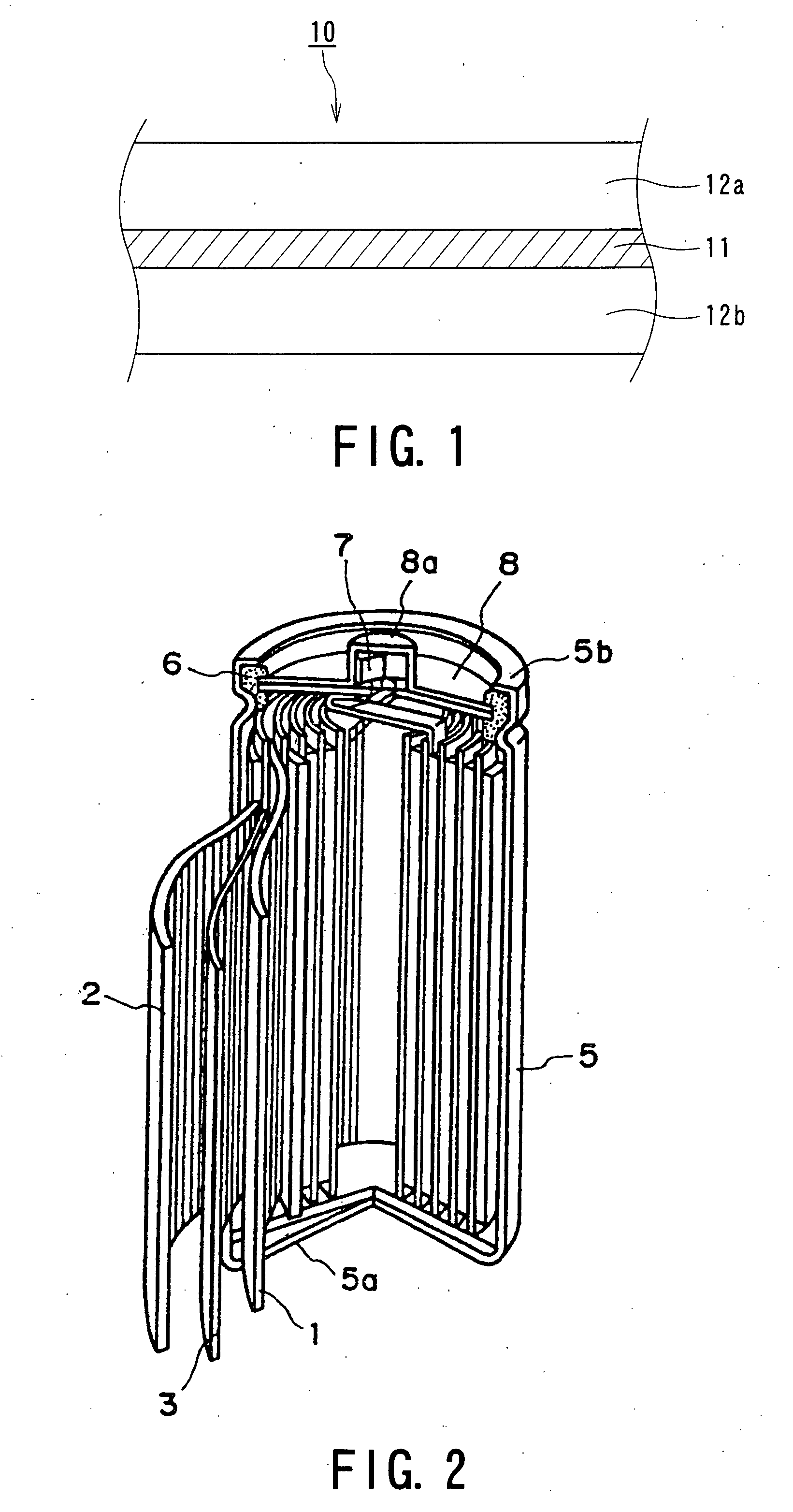

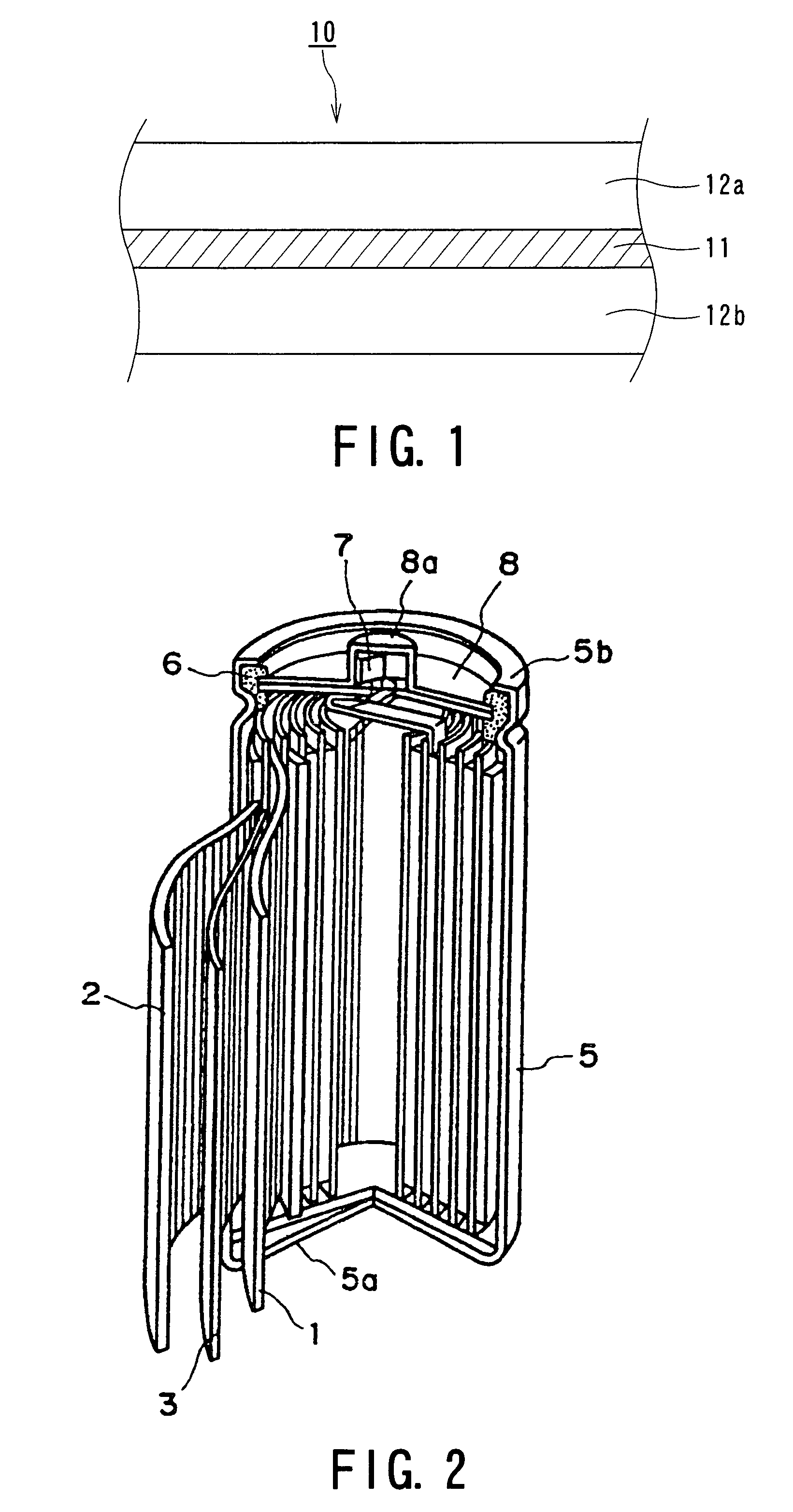

Vinylidene Fluoride Based Core-Shell Type Polymer and Use Thereof in Nonaqueous Electrochemical Device

InactiveUS20080131776A1Increase flexibilityIncrease resistanceNon-aqueous electrolyte accumulatorsHybrid capacitor electrodesComposite electrodePolymer science

A core / shell polymer (A), comprising: a rubbery core comprising a crosslinked vinylidene fluoride copolymer (a) having a vinylidene fluoride content of 30-90 wt. % and a shell comprising a vinylidene fluoride polymer (b) having a vinylidene fluoride content which is larger than in the crosslinked vinylidene fluoride copolymer (a) and at least 80 wt. %, in a weight ratio (a) / (b) of 30 / 70-90 / 10. The vinylidene fluoride-based core / shell polymer (A) is excellent in mechanical properties including flexibility and resistance to nonaqueous electrolytic solutions, is capable of forming a composite electrode layer showing excellent flexibility and adhesion to an electroconductive substrate in combination with a powder active substance and is therefore suitable for use as a binder for nonaqueous electrochemical devices.

Owner:KUREHA KAGAKU KOGYO KK

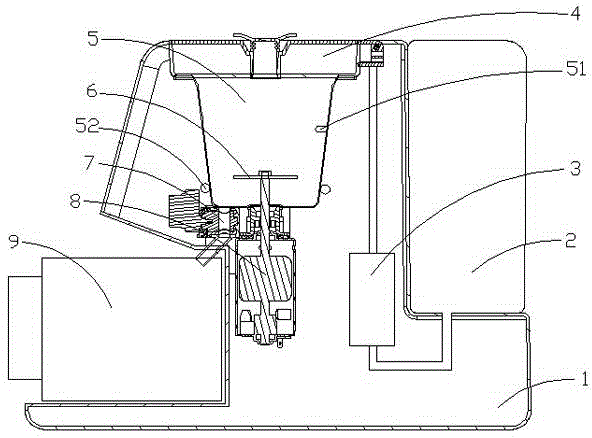

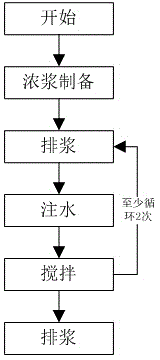

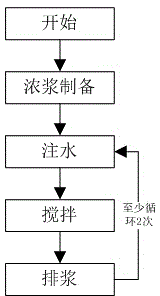

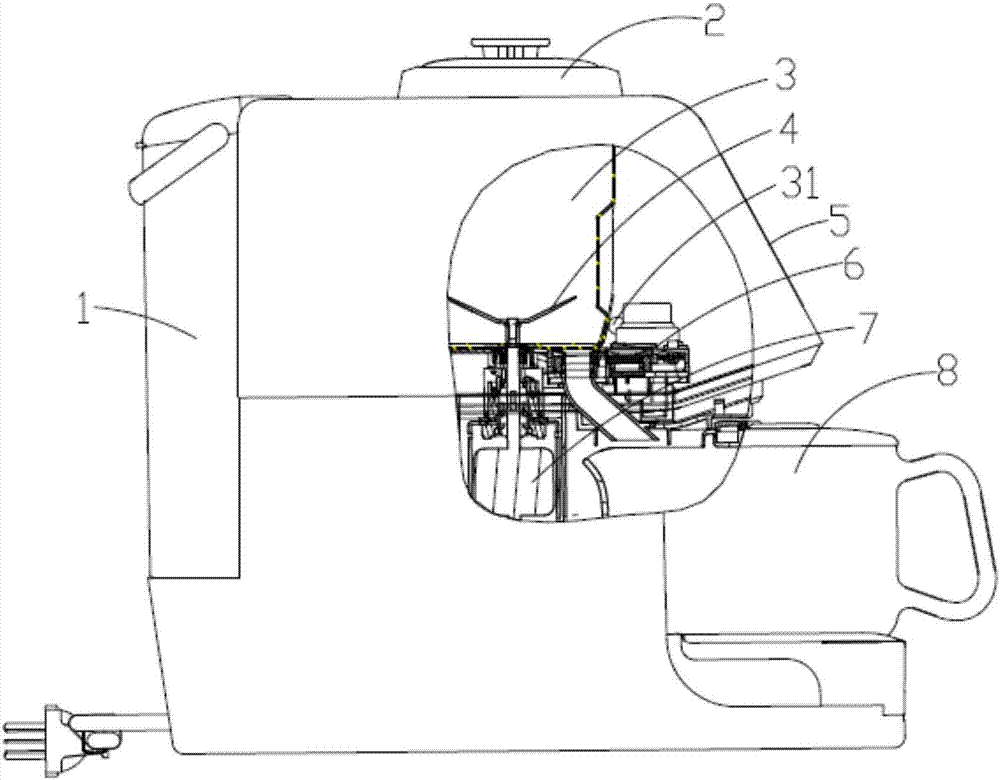

Blending method of small-space crushing soybean milk machine

ActiveCN104543002AReduce concentrationAvoid blending unevenlyBeverage vesselsMilk substitutesEngineeringSlurry

The invention relates to a blending method of a small-space crushing soybean milk machine. The soybean milk machine comprises a small-space crusher for containing materials and crushing the materials, a soybean milk discharging valve for discharging soybean milk in the small-space crusher, a water supplying mechanism, a soybean milk accepting cup and a control unit, wherein soybean milk making of the small-space crushing soybean milk machine comprises a thick soybean milk preparation phase and a blending phase; the blending phase comprises a homogenizing blending step for injecting water into the small-space crusher to dilute the soybean milk and a soybean milk discharging and blending step for discharging the soybean milk in the small-space crusher into the soybean milk accepting cup; the blending phase at least comprises two times of soybean milk discharging and blending steps; and the blending phase is finished when the last time of discharging the soybean milk and blending is finished. Compared with the prior art, the blending effect of the soybean milk is improved; the soybean milk is not blocked and layered; and the quality of the soybean milk is improved and the mouth feel is better.

Owner:JOYOUNG CO LTD

Milk making method of soybean milk machine

ActiveCN107485289AUniform slurryShorten pulping cycleHollow article cleaningCooking vesselsEngineeringSlurry

The invention relates to a milk making method of a soybean milk machine. The milk making method at least comprises the steps that when the selected milk making amount is lower than 0.8V, milk making is completed at a time in smashing cavity by using milk liquid; when the selected milk making amount is higher than 0.8V, blending needs to be conducted at least once to complete milk making, wherein V is the volume of the smashing cavity. Compared with the prior art, the method improves the blending effect of the milk liquid / paste, caking or layering does not happen, the quality of the milk liquid / paste is improved, and the taste is good; meanwhile, the problems are solved that according to soybean milk machines in the prior art, large-volume milk making and self-cleaning cannot be achieved.

Owner:JOYOUNG CO LTD

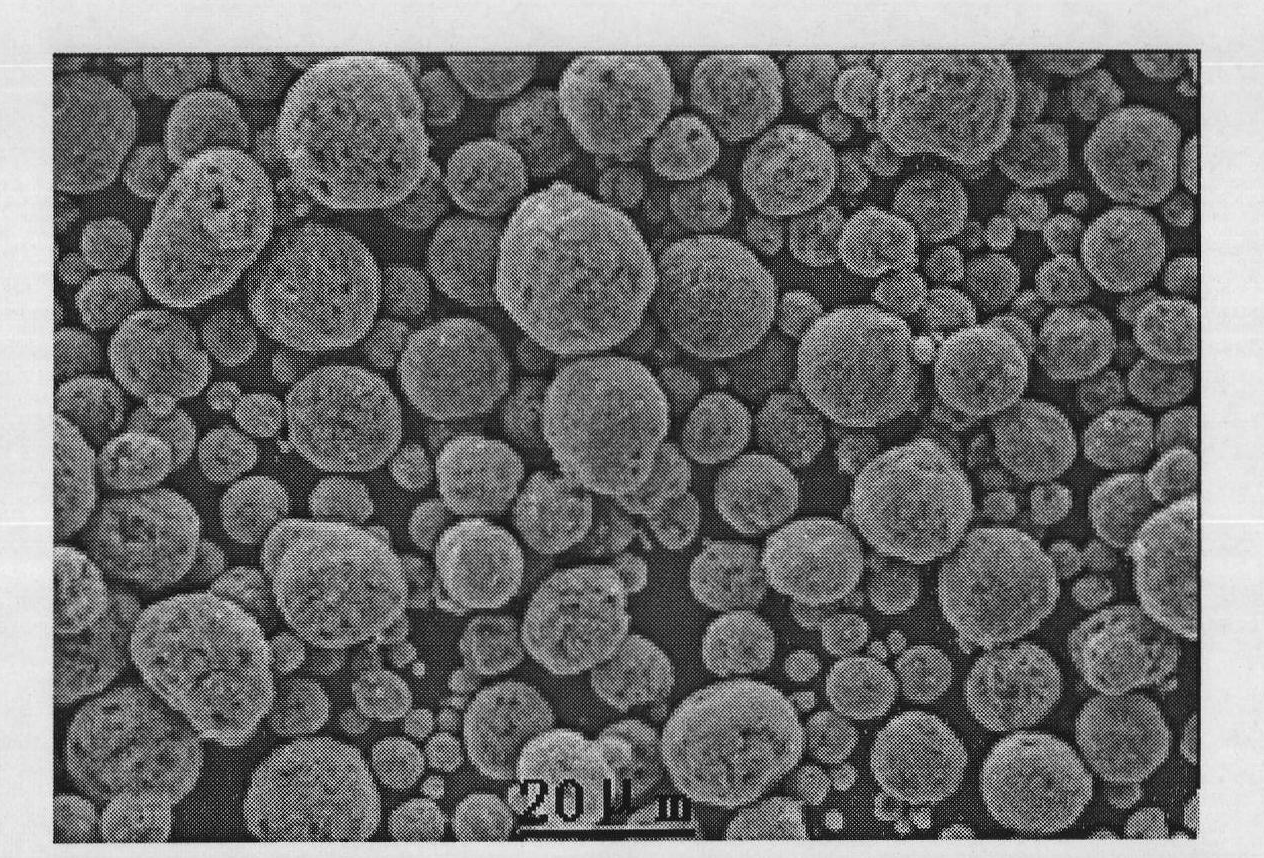

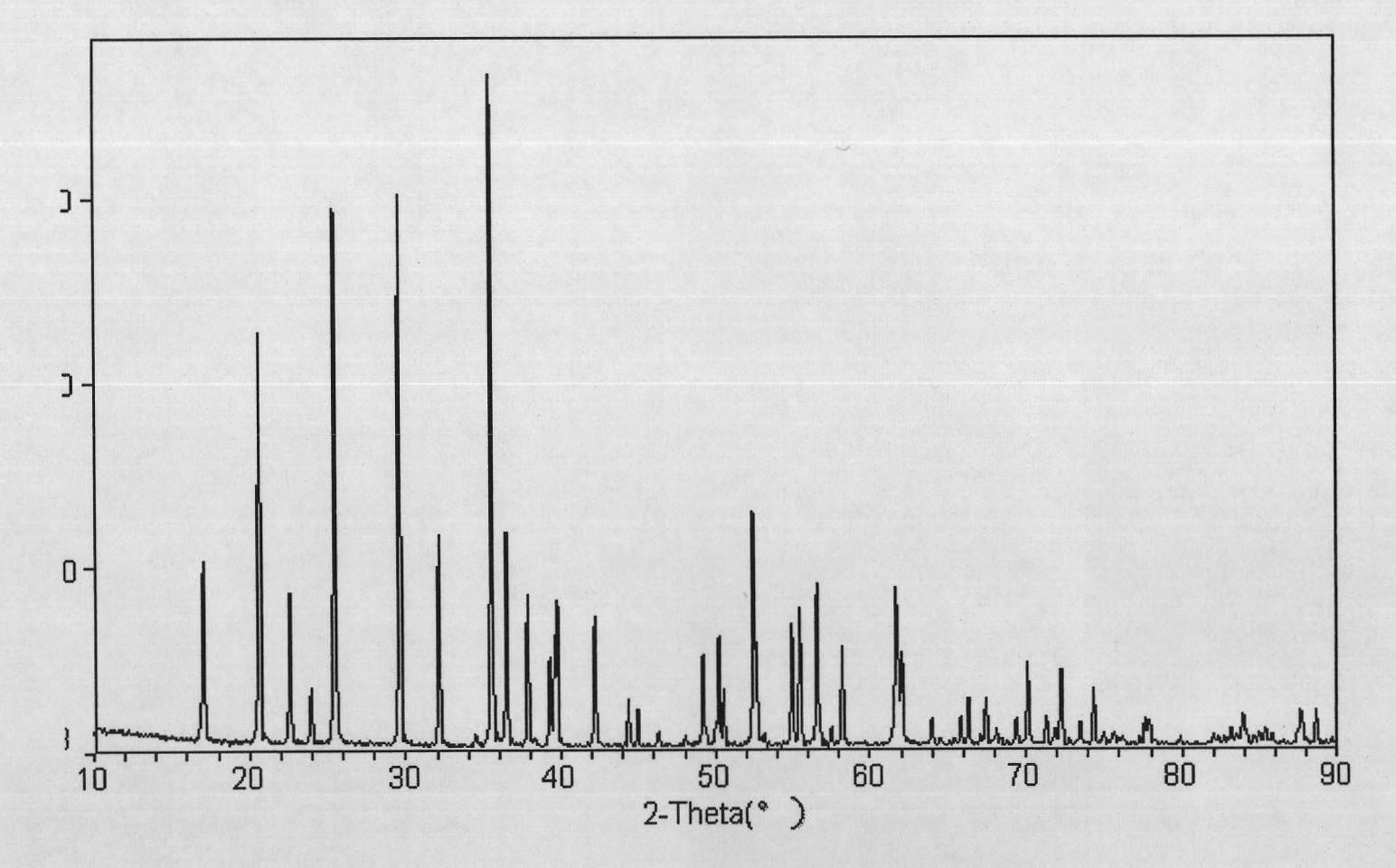

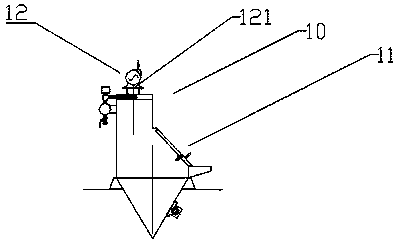

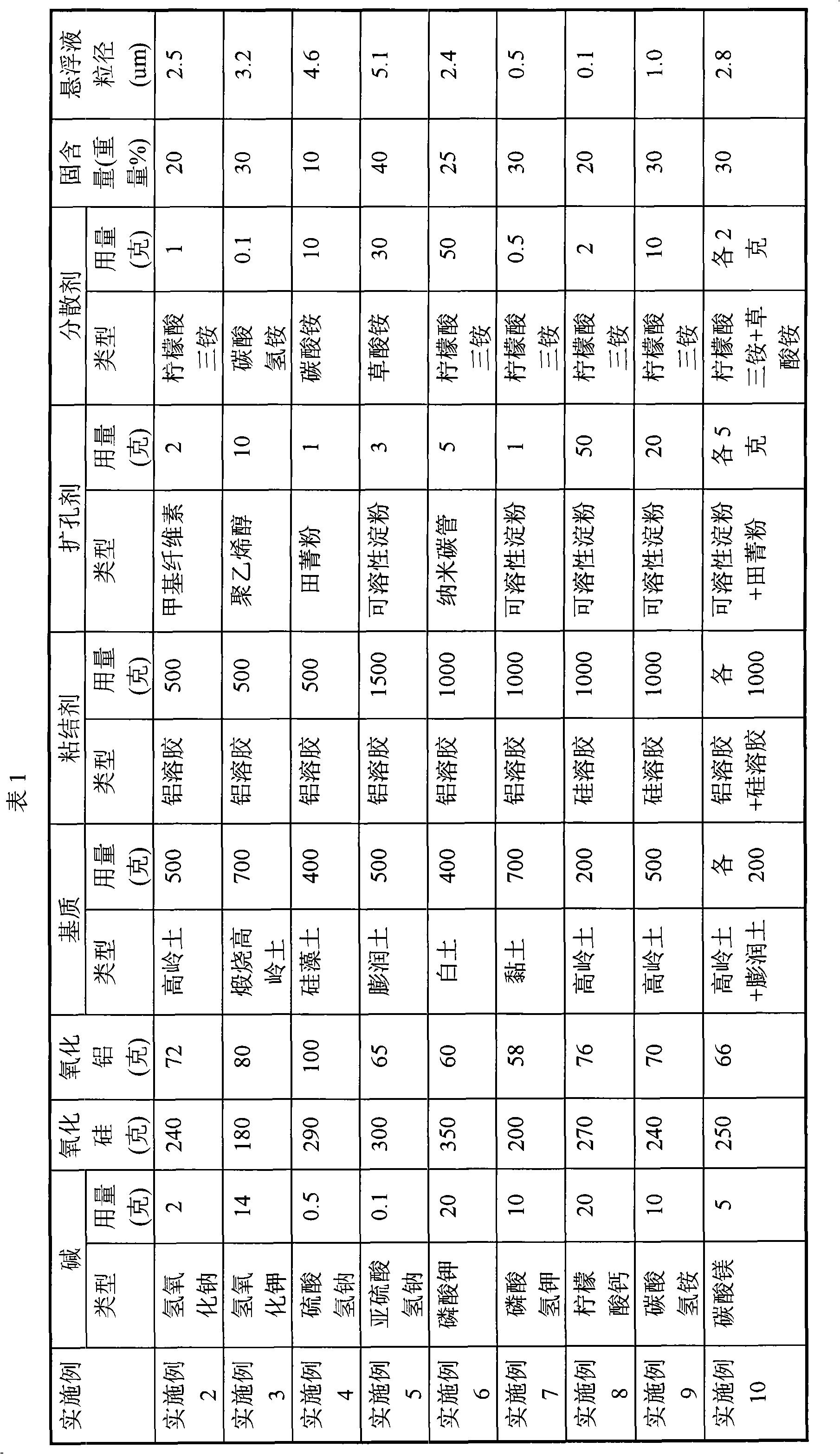

Method for adopting spray pyrolysis technology to prepare spherical anode material lithium iron phosphate

InactiveCN102148374AHigh tap densityIncrease volumetric energy densityCell electrodesPhosphorus compoundsNitrogen gasBall mill

The invention relates to a method for adopting a spray pyrolysis technology to prepare spherical anode material lithium iron phosphate, which comprises the steps which are as follows: a lithium source, a phosphorus source and an organic carbon source soluble in water, and an iron source insoluble in water are mixed in a ball milling-super fine milling way by taking de-ionized water as a dispersing agent according to a certain proportion; then high purity nitrogen is used as a flow carrier gas to atomize the pulp into small drops in a high temperature reaction furnace full of nitrogen protection; finally, the small drops are calcined under the protection of the nitrogen to obtain lithium iron phosphate powder. The spherical anode material lithium iron phosphate prepared by the method has high tap density, uniform size distribution, and excellent electrochemistry performance; moreover, the surfaces of the particles are spherical porous and are suitable for industrial production.

Owner:江西省金锂科技股份有限公司

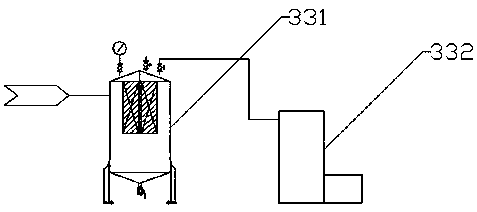

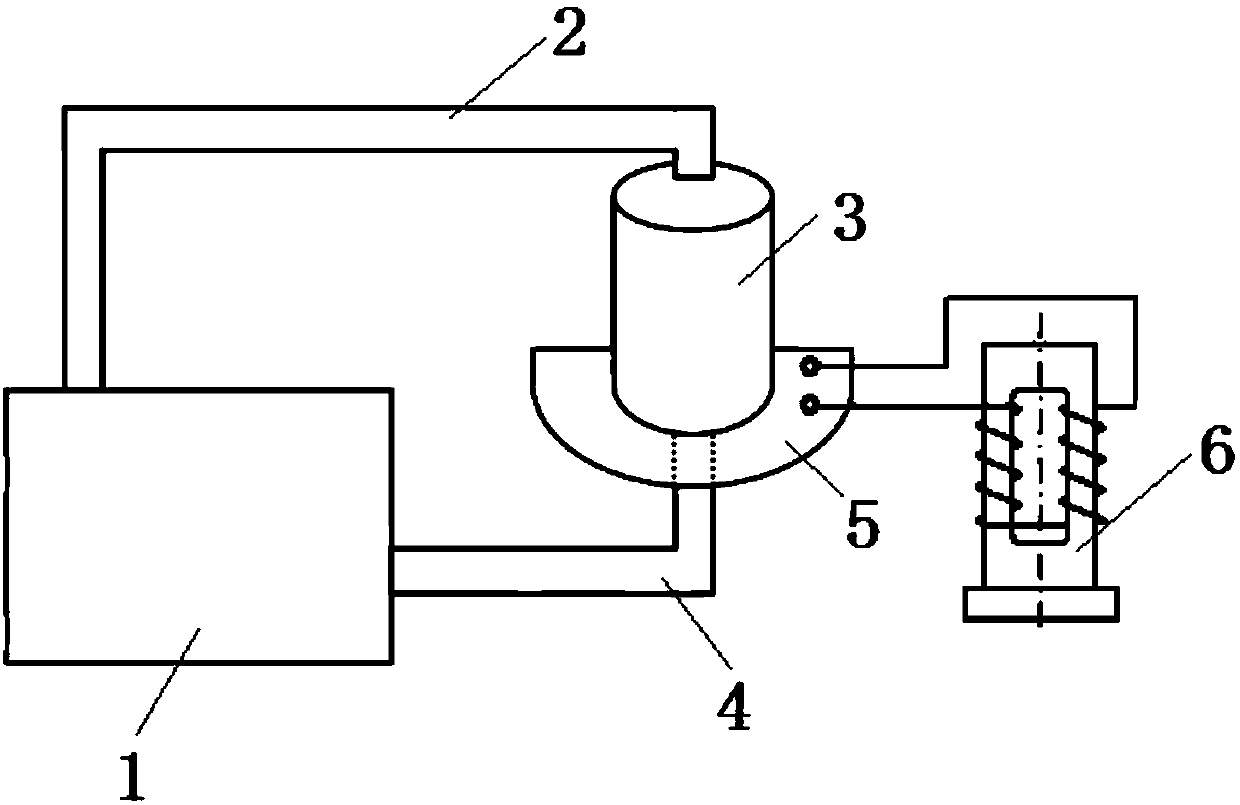

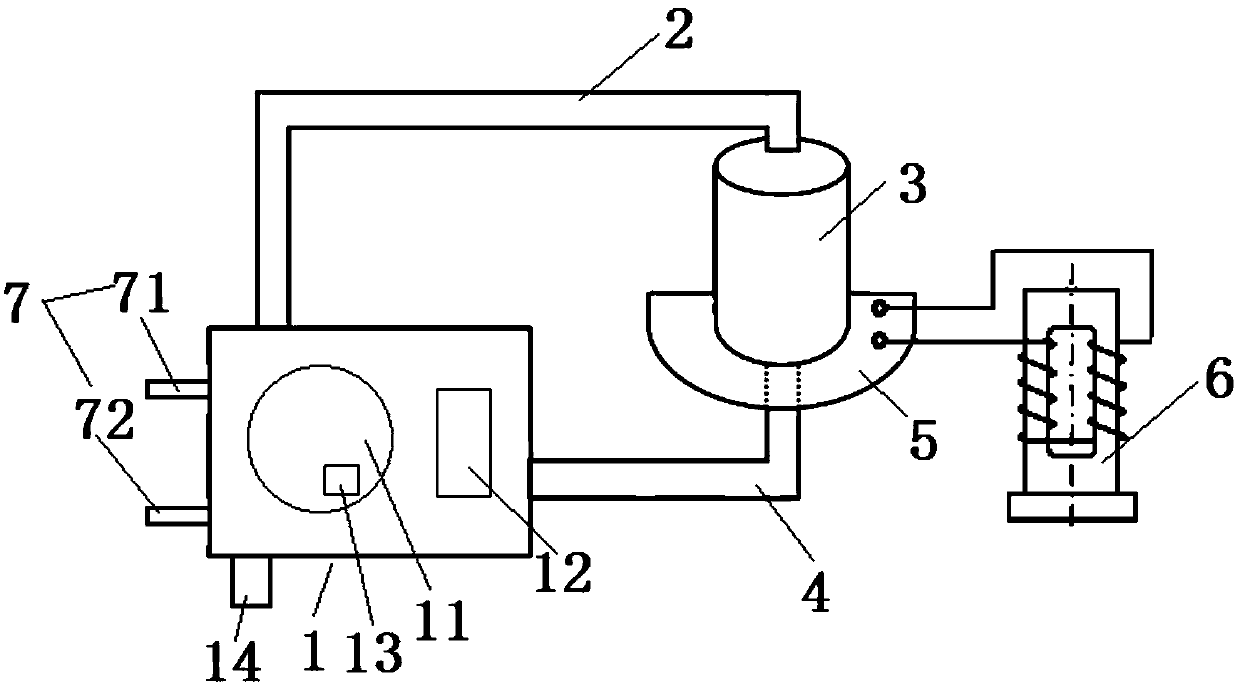

Automatic loading system for lithium battery and application method thereof

ActiveCN108565502AUniform slurryGuaranteed coating effectFinal product manufactureSecondary cellsDiaphragm pumpControl system

The invention discloses an automatic loading system for a lithium battery. The automatic loading system for the lithium battery comprises a powder putting system, a solvent putting system, a stirringmachine, a transferring tank, a coating feeding system and a control system, wherein the coating feeding system comprises a diaphragm pump, an iron removing device, a coating storage tank, a coating die head and a return pipe arranged on the coating storage tank and connected to a pipe between the diaphragm pump and the transferring tank, a return pipe valve is arranged on the return pipe, and thecoating storage tank is provided with a stirring device and a non-contact liquid level sensor. During coating, when the liquid level in the coating storage tank reaches the certain height, a discharging valve of the transferring tank is automatically switched off, the transferring tank is vacuumized, then vacuum breaking and defoaming are carried out, the uniformity of coating slurry is guaranteed, and when the liquid level is lower than the certain height, materials are fed into the coating storage tank; when the system is stopped for a long time, the discharging valve of the transferring tank is automatically switched off, the return pipe valve is automatically switched on, automatic cycling of coating slurry in the transferring tank is achieved, and blocking caused by material accumulation and material drying is prevented.

Owner:江西省汇亿新能源有限公司

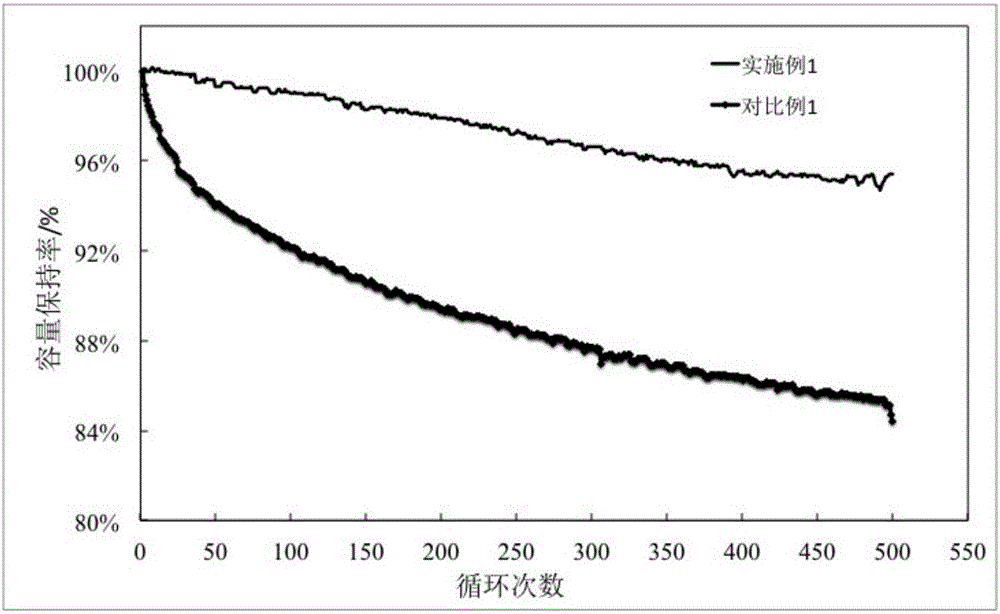

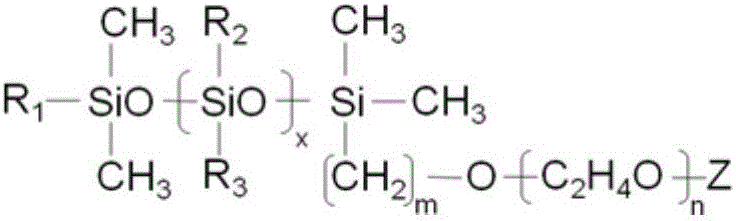

Method for preparing lithium ion battery negative pole piece

The invention relates to a method for preparing a lithium ion battery negative pole piece. The method comprises the following steps: (1) performing dry mixing on a negative active material and a conductive agent so as to obtain a dry mixture; (2) adding a negative additive, a thickening agent and a first solvent into the dry mixture so as to obtain a first mixture; (3) adding an adhesive and a second solvent into the first mixture so as to obtain a second mixture; and (4) adding a third solvent into the second mixture so as to obtain precast pulp, coating the precast pulp, thereby obtaining the lithium ion battery negative pole piece, wherein the negative additive is polyether-modified organic silicone oil. Due to the added polyether-modified organic silicone oil, bubbles can be effectively removed, and an emulsifying effect is achieved, so that the uniform lithium ion battery negative pole piece can be obtained, and the safety of a lithium ion battery is further improved. Colloid does not need to be prepared in advance in the preparation method, the whole pulping process can be completed in the same equipment, the production efficiency is high, and the cost is low.

Owner:ZHEJIANG MEIDARUI NEW MATERIAL TECH CO LTD

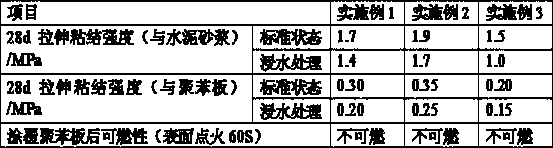

Interface mortar with ardealite-based hydraulicity composite cementing material as cementing material

The invention belongs to the technical field of building materials and particularly relates to interface mortar with an ardealite-based hydraulicity composite cementing material as a cementing material. The interface mortar is composed of ardealite, a slag powder, coal ash, metakaolin, a copper tailing slag powder, red mud, ordinary Portland cement, aluminate cement, quartz sand, a quartz powder,chesterite, calcium bentonite, a polycarboxylate-type water reducing agent, cellulose ether and latex powder. By adopting the interface mortar, the binding property of a base wall and a heat preservation layer in a wall heat preservation system can be effectively improved, the peeling risk of the heat preservation layer of a building wall can be reduced, and environment security problems caused bypiling of industrial ardealite can be also solved. When the interface mortar is produced, a great amount of industrial solid wastes such as non-calcined ardealite, coal ash, copper tailing slag powder and red mud are used, so that the interface mortar has the outstanding advantages of being low in energy consumption, low in cost, low in emission, and the like. The interface mortar is applied to heat preservation systems of various building walls, and the like.

Owner:TONGJI UNIV

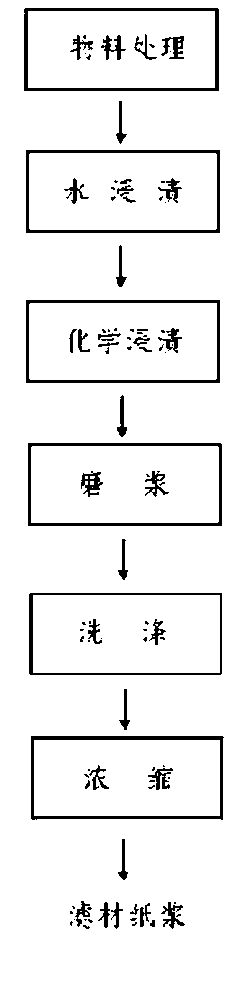

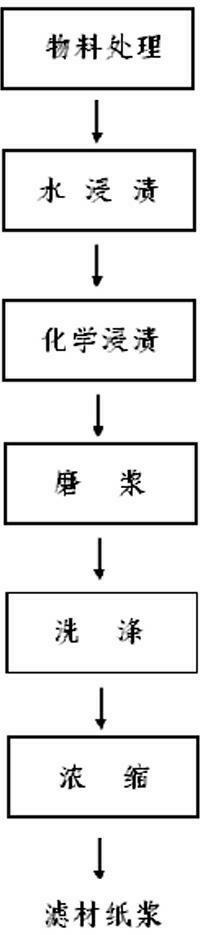

Method for reproducing paper pulp used for filter stick core paper by utilizing filter stick waste

ActiveCN102704300AIncrease profitImprove overall utilizationWashing/displacing pulp-treating liquorsContinuous pulping processFiberWaste material

The invention discloses a method for reproducing paper pulp used for filter stick core paper by utilizing filter stick waste, which includes procedures of material treatment, impregnation, defibrination, washing and concentration. Impurities in the filter stick waste are eliminated, and the filter stick waste is cut off into particles of 1-150 mm; the particles are impregnated by 4-10 times of water for 5-30 minutes under 70-100 degree C; inorganic base with weight being 0.5%-6% of dry weight of the particles is added into the impregnation liquid, so that the chemical concentration of the impregnation liquid is 0.25g-3g / L; the pulp liquid is concentrated to 10%-30%, and then pan-grinding defibrination is performed; and finally, the pulp liquid is washed and concentrated to 20-30%, so that the paper pulp used for wet process papermaking cigarette filter stick filter material can be obtained. The method disclosed by the invention has low treatment requirement for the impurities in the raw material, dispenses with molding paper stripping procedure, uses no toxic solvent, has high paper pulp yield, is excellent in fiber evenness, has centralized length distribution and uniform pulp, has no paper fragments and fiber beams, has excellent dispersion property, and is very suitable for making the filter stick core paper.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

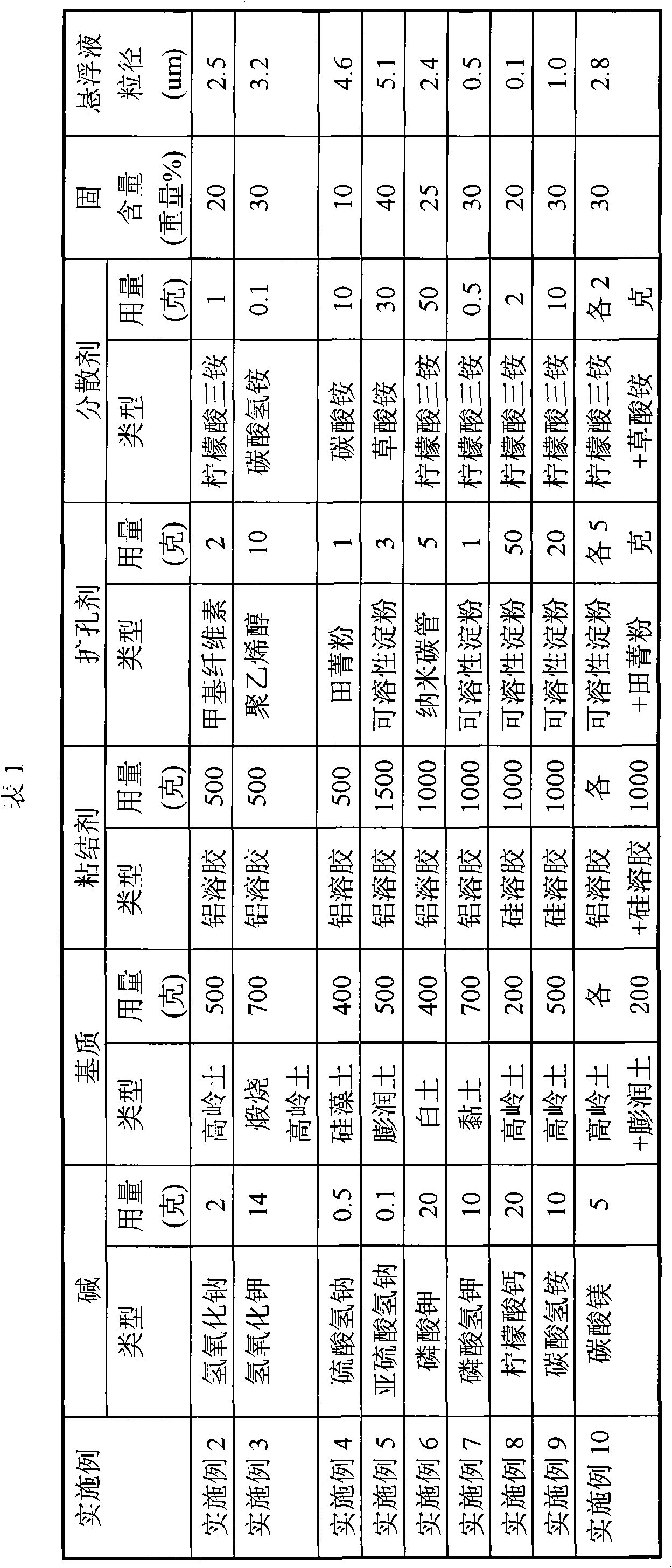

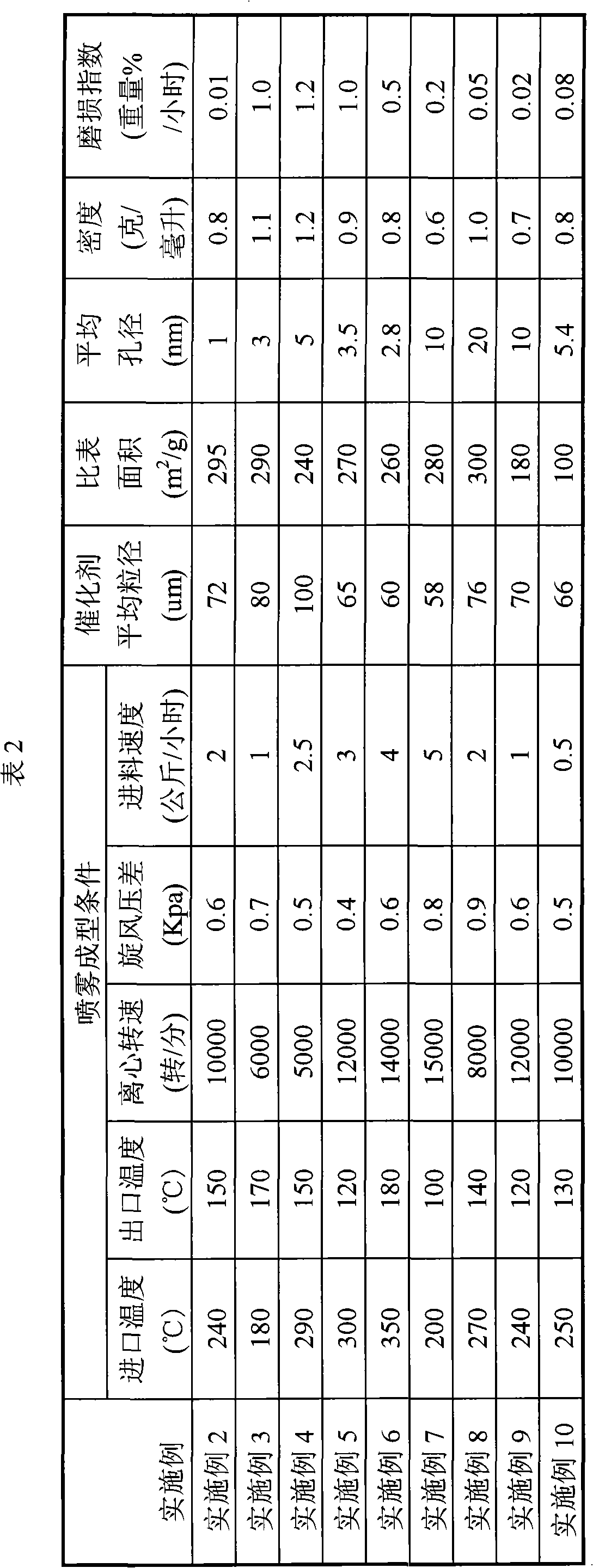

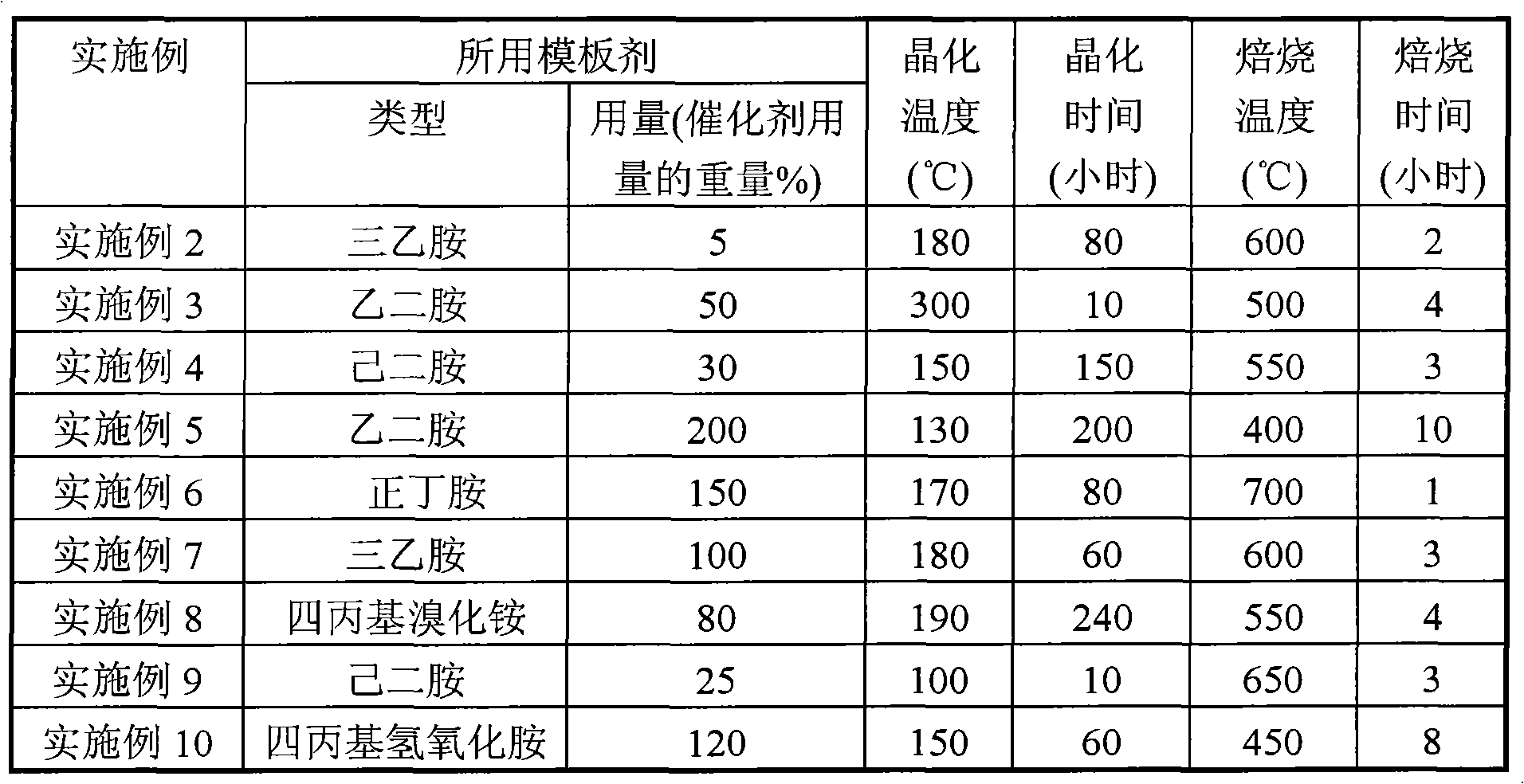

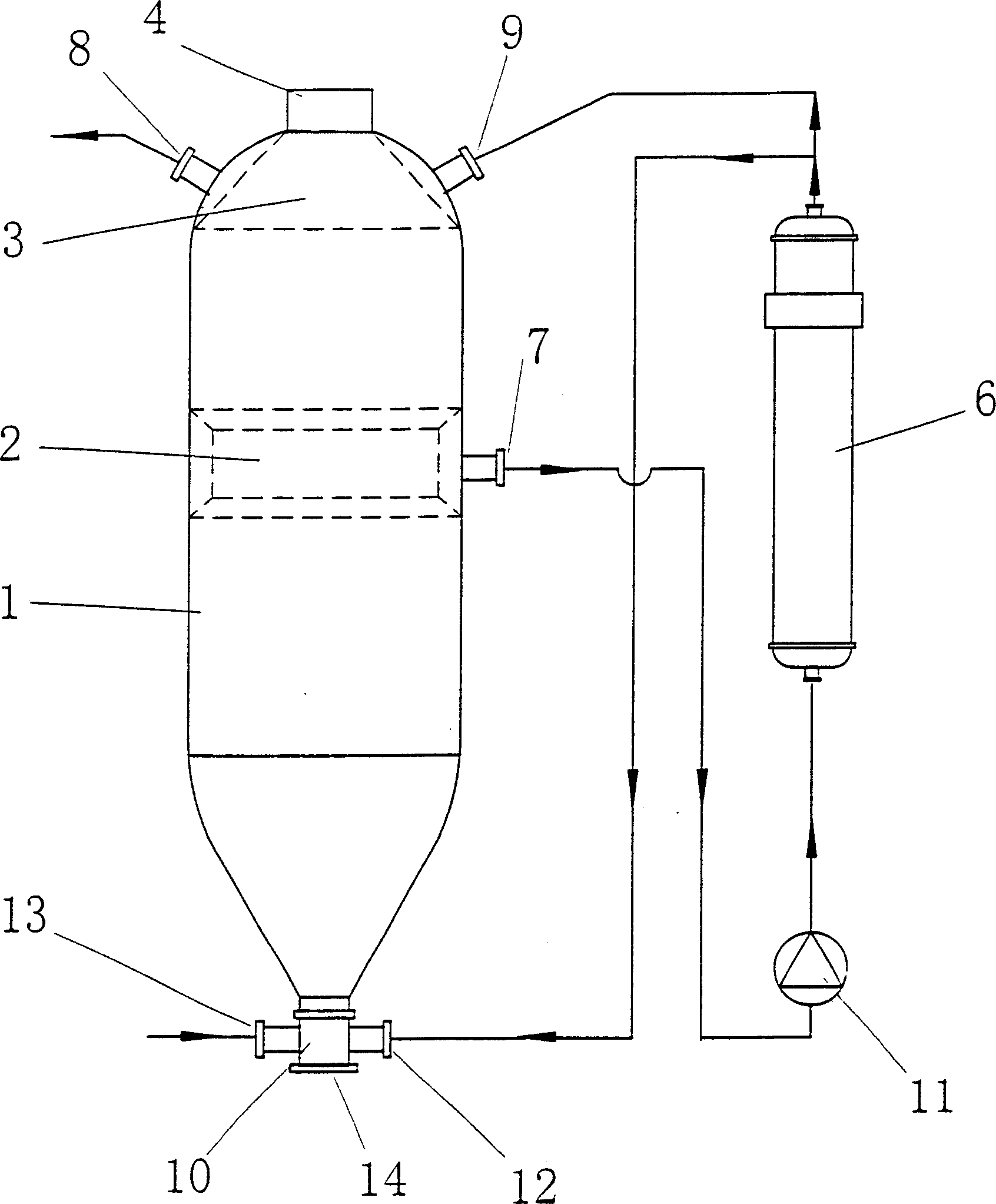

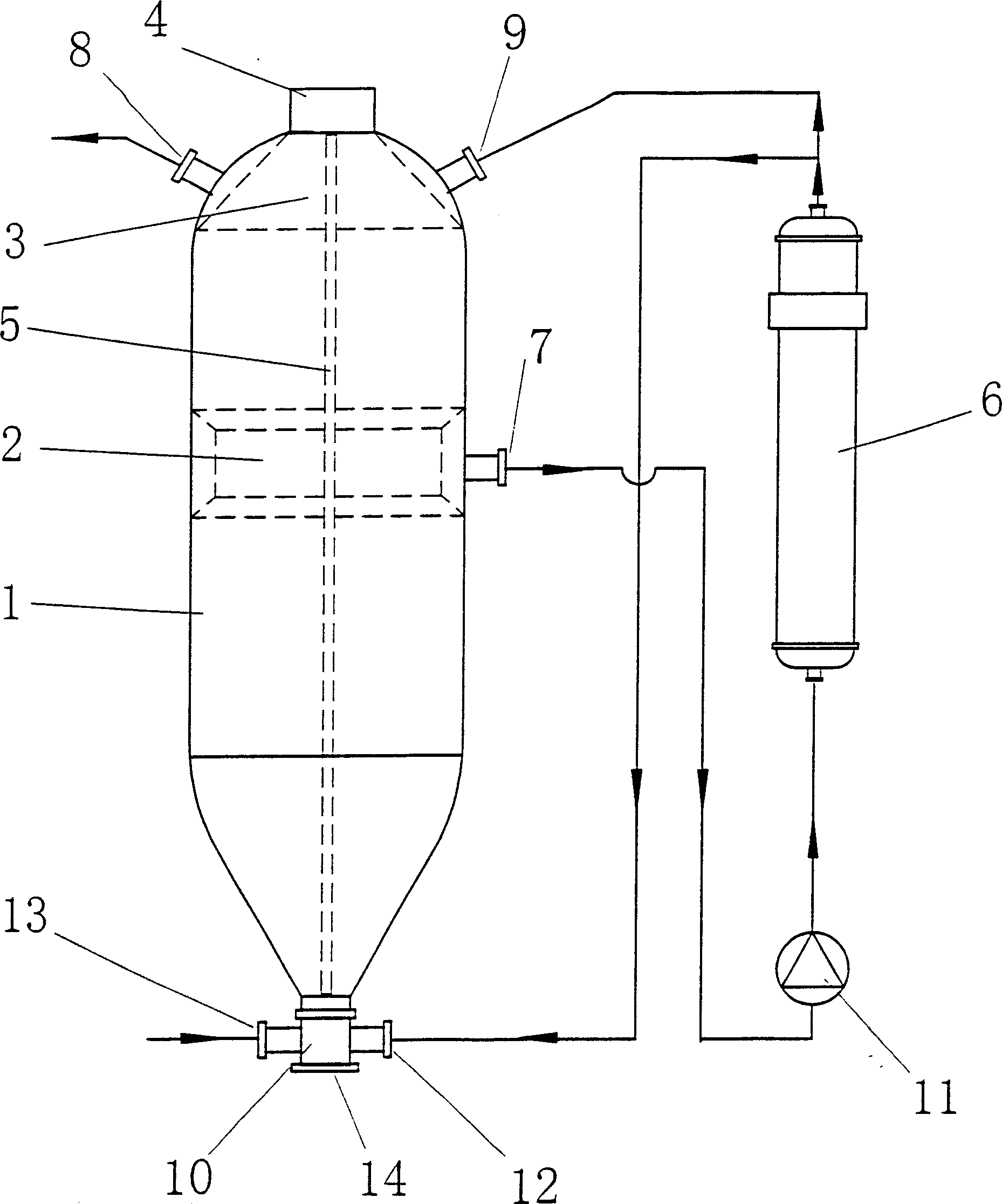

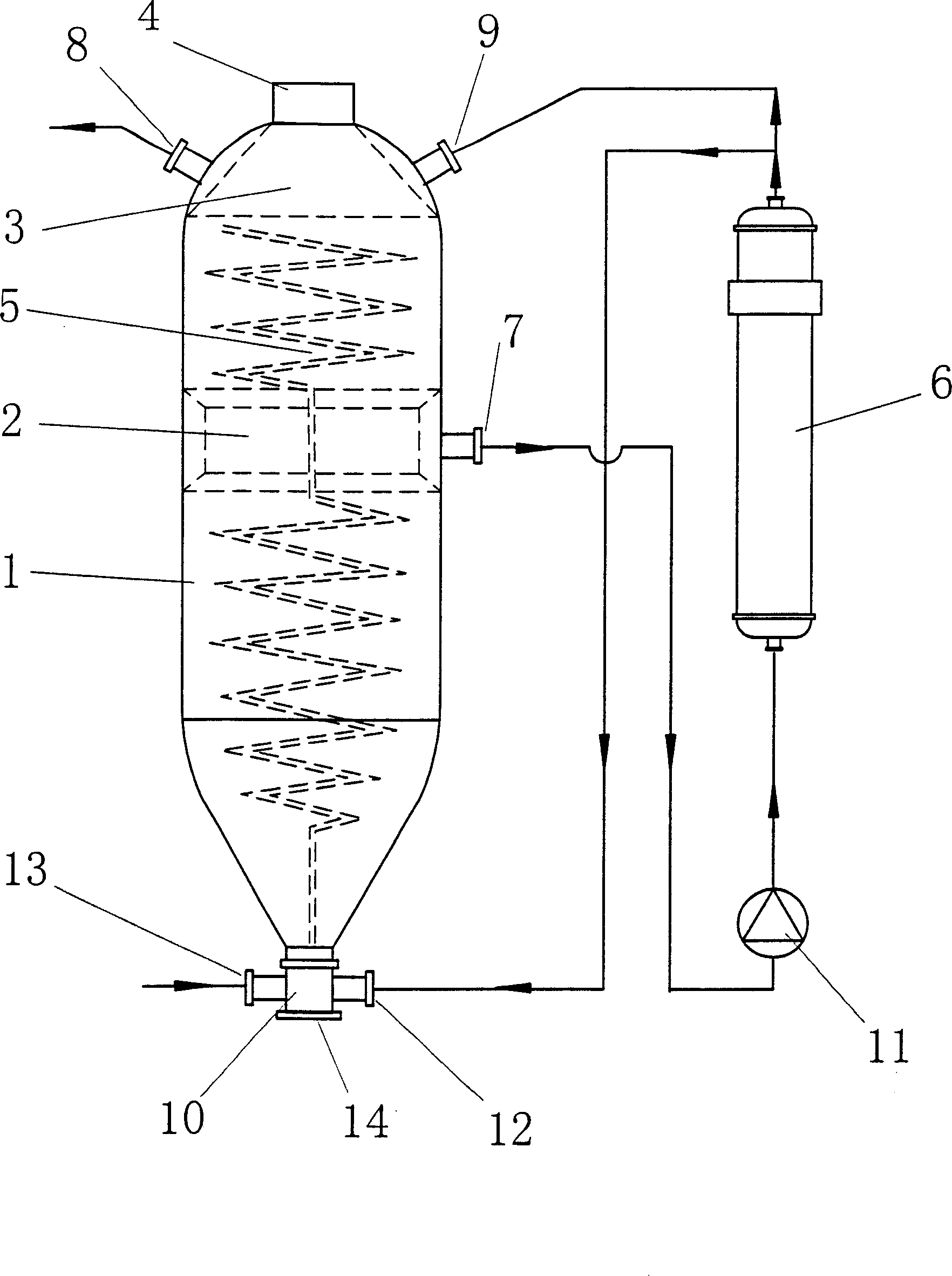

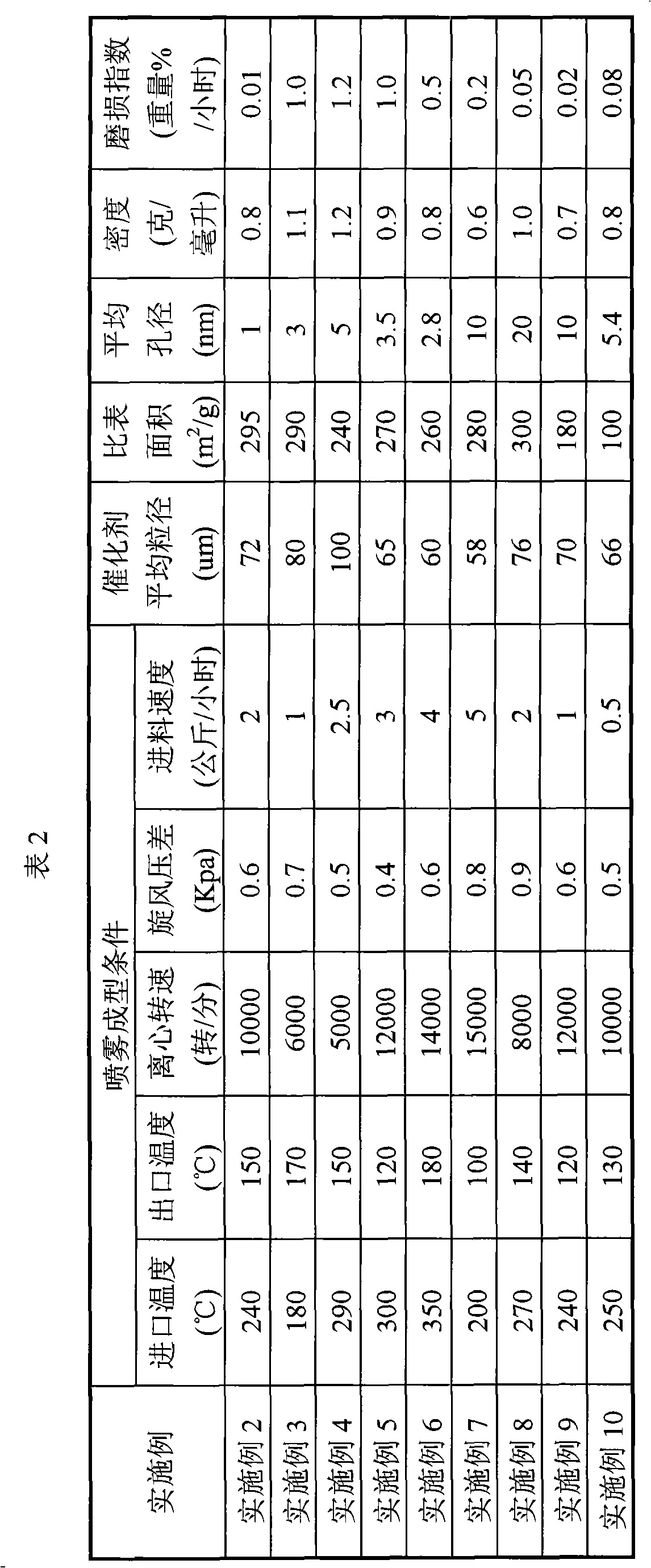

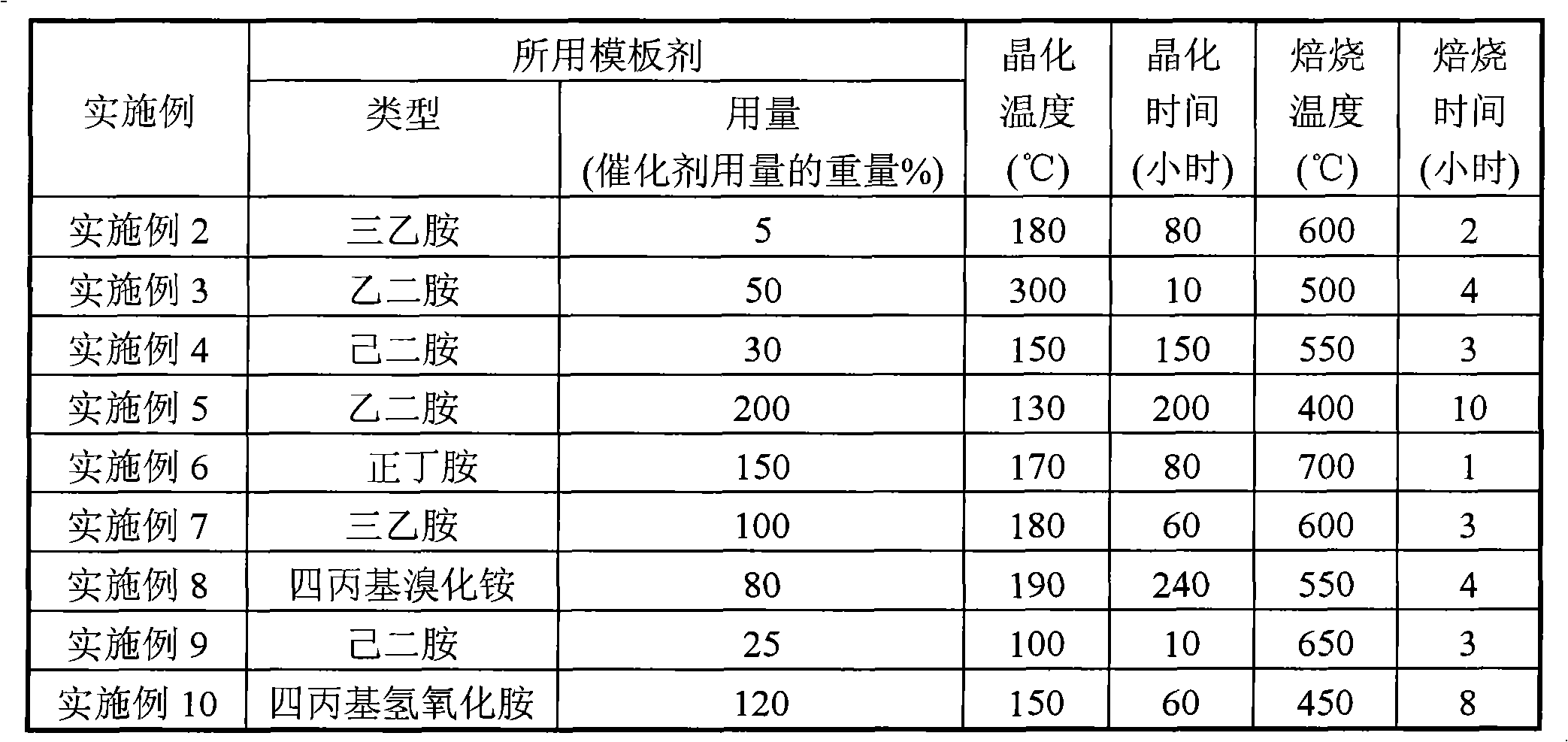

Method for producing propylene by oxygen-containing compound conversion

ActiveCN102372571AHigh sphericityImprove diffusivityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveFluidized bed

The invention relates to a method for producing propylene by oxygen-containing compound conversion and mainly solves the problem of poor wear resistance of a fluidized bed catalyst during present technologies for producing propylene by oxygen-containing compound conversion. According to the invention, methanol or dimethyl ether is used as a raw material, and the raw material contacts with a binder-free ZSM-5 molecular sieve fluidized bed catalyst through a catalyst bed so as to generate light olefin while the reaction temperature is 400-600 DEG C, the reaction surface pressure is 0.001MPa-0.5MPa, the reaction weight space velocity is 0.1-4 h<-1>, and the weight ratio of water / methanol or dimethyl ether is 0.1-3: 1. The method for producing propylene by oxygen-containing compound conversion is adopted to greatly solve the problem and can be used in the industrial production of propylene by oxygen-containing compound conversion.

Owner:CHINA PETROLEUM & CHEM CORP +1

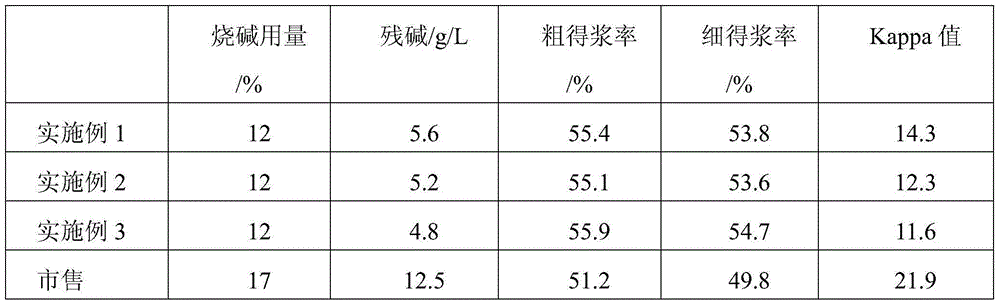

Cooking auxiliary agent for papermaking and pulping

ActiveCN104099792AGood emulsifying effectImprove diffusivityCellulose material pulpingSodium acetateKappa number

The invention relates to a cooking auxiliary agent for papermaking and pulping, belongs to the field of papermaking, and aims to solve the problems that the existing cooking auxiliary agent is high in toxicity and severe in environmental pollution. The cooking auxiliary agent for papermaking and pulping comprises the following components in percentage by weight: 8-12% of primary alcobol ethoxylate, 10-20% of linear alkylbenzene sulfonates, 3-8% of alkyl sulfonate sodium acetate, 3-8% of alkyl phenyl polyoxyethylene ether, 2-5% of sodium nonylphenol polyoxyethylene ether sulfonate, 1-3% of methyl sulfone, 2-5% of carboxymethyl cellulose, 0.5-1.2% of oleamide, 0.1-0.5% of sodium pyrophosphate and the balance of deionized water. The cooking auxiliary agent is mainly applicable to the papermaking field, can reduce environmental pollution, improve the screened pulp yield and reduce Kappa number.

Owner:刘建国

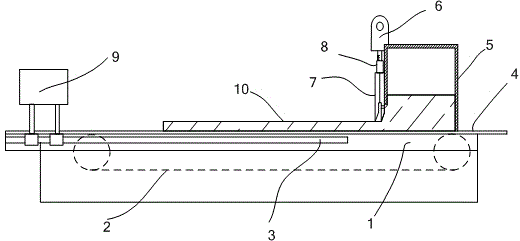

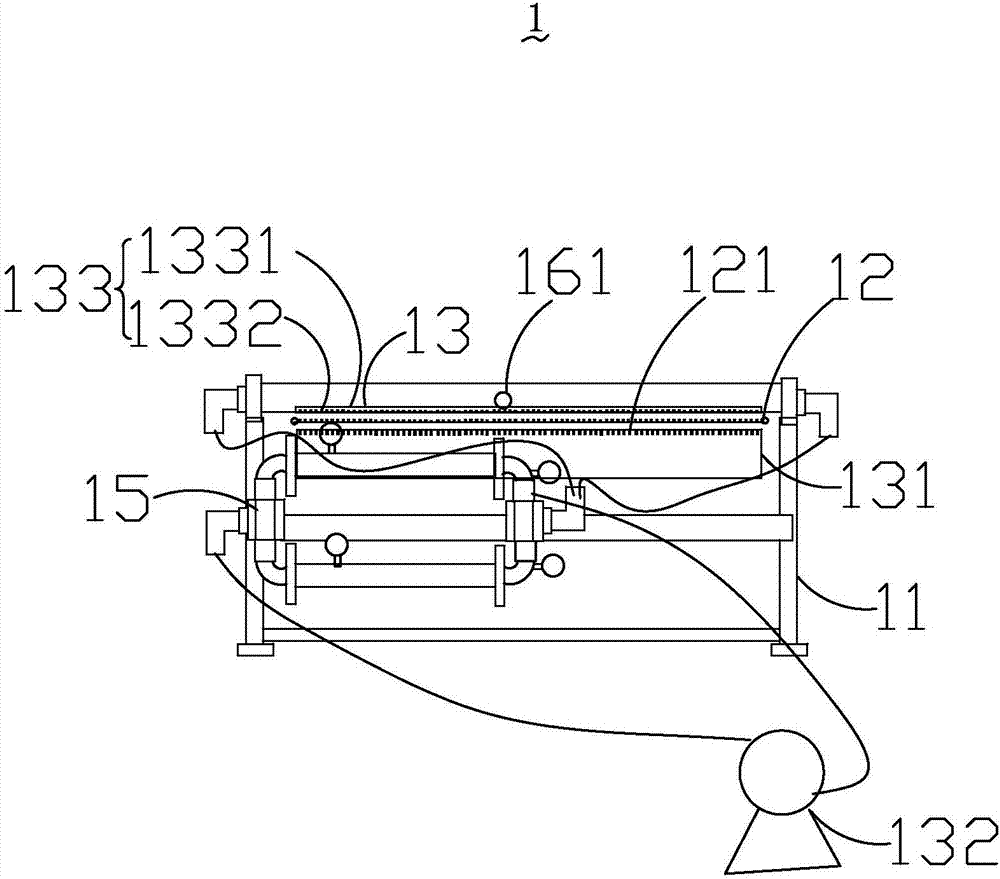

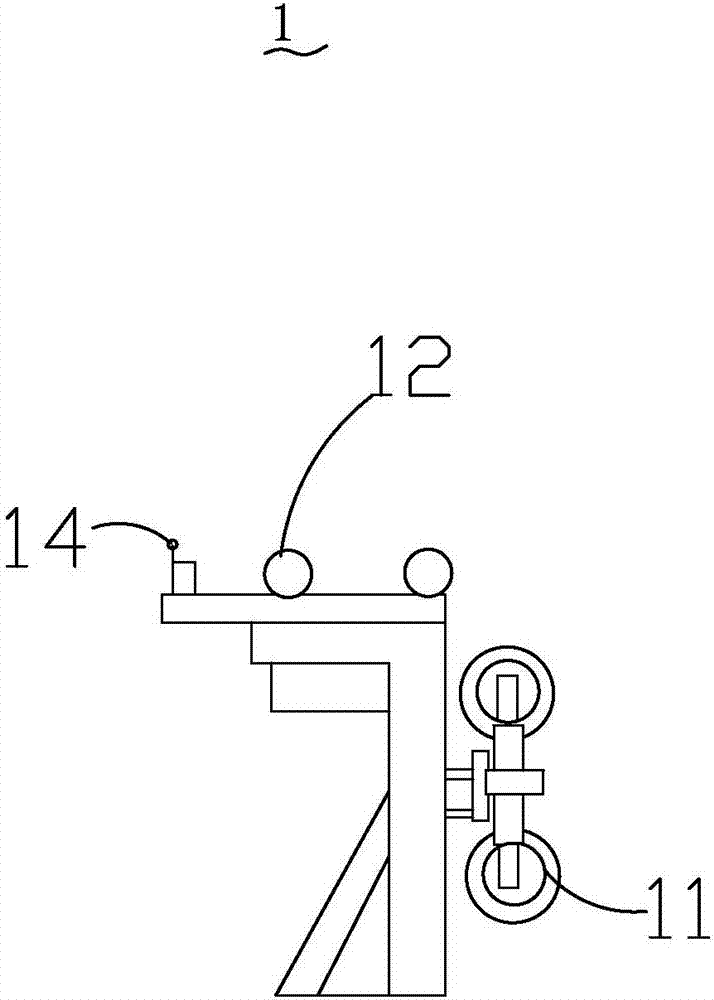

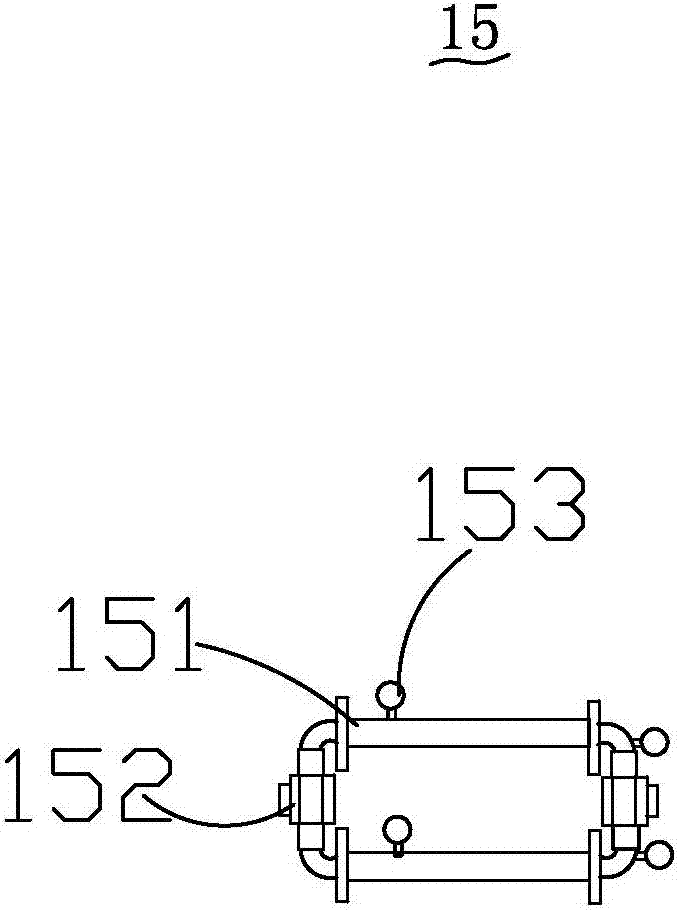

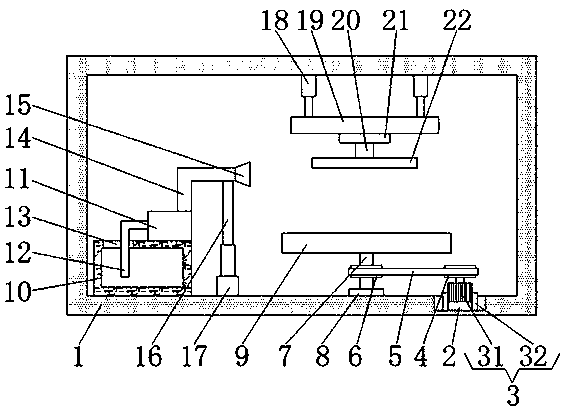

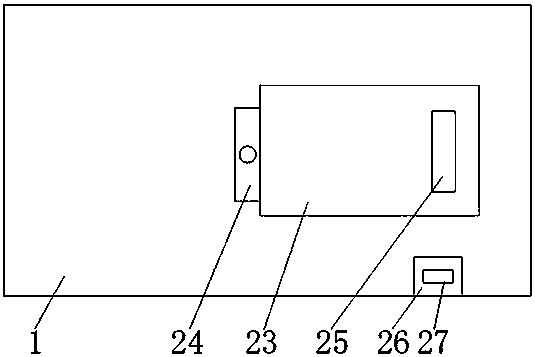

Ceramic membrane blade-coating device

InactiveCN105710002AAvoid stickingUniform slurryPretreated surfacesCoatingsTransmission beltCeramic membrane

The invention relates to the field of electronic material manufacture and concretely relates to a ceramic membrane blade-coating device. The device comprises a workbench, a transmission belt and a membrane blade-coating base plate. The membrane blade-coating base plate is fixed to the transmission belt. Two ends of the transmission belt are fixed to the workbench through rotating rollers. A membrane blade-coating device is erected above the transmission belt. The membrane blade-coating device comprises a material tank, a scrapping blade support and scrapping blades. The scrapping blade support is fixed to one side of the material tank and the bottom edge of the other side of the material tank contacts with the membrane blade-coating base plate. The multiple scrapping blades are fixedly arranged below the scrapping blade support. Lower ends of the edges of the scrapping blades align. Spiral regulators are arranged between the scrapping blade support and the scrapping blades. The device is used for ceramic membrane manufacture and realizes finish machining blade effects only through the common scrapping blades.

Owner:CHONGQING KUGEER ELECTRONICS

Vertical boiling pot for paper pulp

The vertical paper pulp boiling pot has steam heating pipe with steam inlet on its one end and steam pores on its wall. By means of the steam heating pipe and the circular heating, the paper pulp boiling pot has homogeneous pulping, raised boiling speed, raised straw pulp quality and yield. The prepared straw pulp may be used to replace wood pulp, and hw light color, high whiteness, low hardness, high strength and other advantages. In addition, the black liquor may be reused to reduce drainage and save water.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

Method for producing olefin by catalytically cracking

ActiveCN102372553AHigh sphericityImprove diffusivityCatalytic crackingMolecular sieve catalystsPolymer sciencePtru catalyst

The invention relates to a method for producing olefin by catalytically cracking, which mainly solves the problem of low activity of a fluid catalyst in a current method for producing olefin by catalytically cracking. According to the method for producing olefin by catalytically cracking, C4-C12 olefins are taken as a raw material, under the condition that the reaction temperature is 550-750 DEG C, the reaction gauge pressure is 0.001MPa-0.5MPa, the weight space velocity of the reaction is 0.05-4 hours<-1> and the weight ratio of water to light oil is 0-4:1, the raw material is contacted withthe catalyst through a catalyst bed layer for reacting to generate light olefin, the catalyst is a binderless ZSM-5 / a mordenite fluid catalyst. The technical scheme better solves the problem, and thepresent invention can be used in industrial production for producing olefin by catalytically cracking.

Owner:CHINA PETROLEUM & CHEM CORP +1

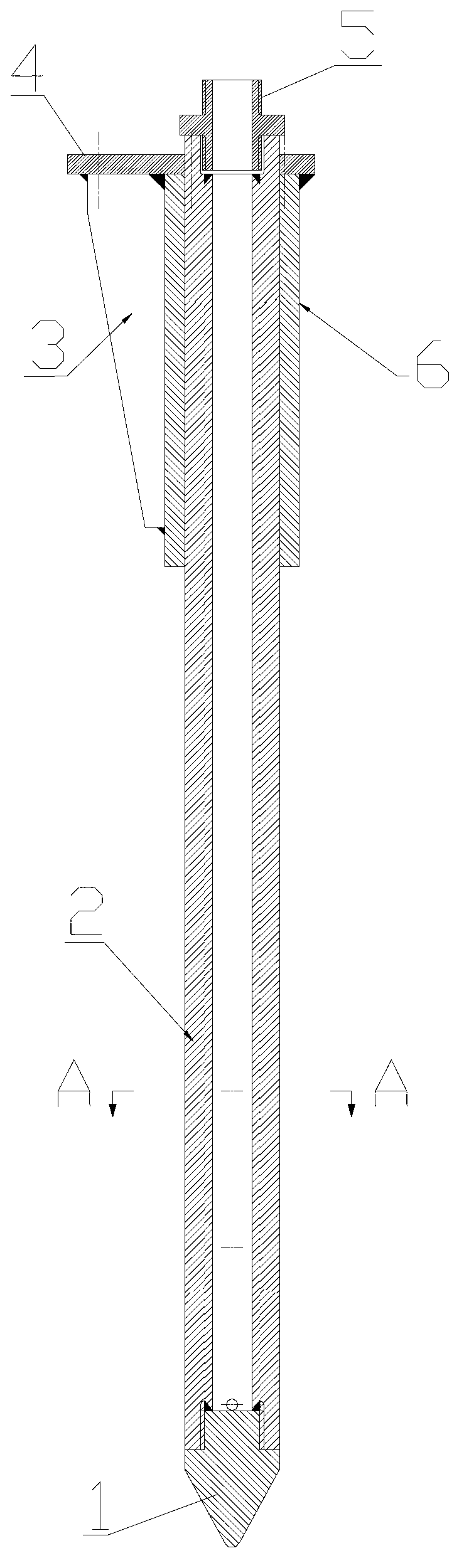

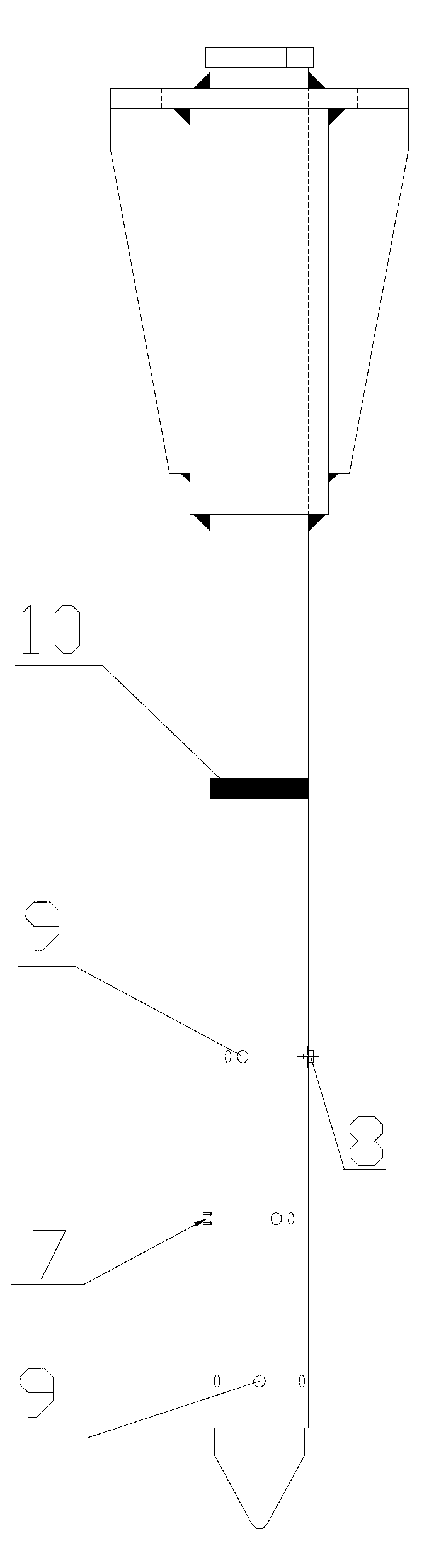

Adjustable plug-in slurry injector

InactiveCN103174145AAdjust apertureEasy to fill evenlyFoundation engineeringStructural engineeringSlurry

The invention discloses an adjustable plug-in slurry injector, and belongs to a slurry injector in the filed of distorted concrete slurry injection construction. The adjustable plug-in slurry injector comprises a slurry injection pipe, a conical head and a connector, wherein a slurry inlet of the slurry injection pipe is connected with the connector, a slurry outlet of the slurry injection pipe is connected with the conical head, slurry injection holes are formed at the lower portion of the slurry injection pipe and are arranged into a plurality of layers, the slurry injection holes of each layer are distributed evenly, and the layers are arranged in a staggered mode. The adjustable plug-in slurry injector is characterized in that the slurry injection holes are threaded holes, slurry outlet heads of different inner diameters are arranged on the slurry injection holes, or plugs are arranged on the slurry injection holes. The adjustable plug-in slurry injector has the advantages that the slurry injection holes are the threaded holes, the slurry outlet heads of different inner diameters are arranged on the slurry injection holes, and the hole diameters of the slurry injection holes can be adjusted as needed. The plugs are arranged on the slurry injection holes, the height and the quantity of the slurry injection holes can be adjusted as needed, the hole diameters of the slurry injection holes can be adjusted freely, so that distorted concrete slurry is injected conveniently and evenly, and construction quality is guaranteed.

Owner:SINOHYDRO BUREAU 7 CO LTD +1

Energy-saving kiln material and preparation method thereof

The invention discloses an energy-saving kiln material and a preparation method of the energy-saving kiln material. The energy-saving kiln material is prepared from the following intergradient in proportioning: 35-42% of alumina, 50-58% of silicon oxide and 6.5-8.5% of magnesium oxide. The preparation method comprises the following steps of ball-milling, screening, further ball-milling, casting molding, sintering and the like so as to obtain the energy-saving kiln material ultimately. The kiln material is high in normal temperature breaking strength and strong in high temperature non-deformability, and can be widely used in kiln furnaces with large bearing quantity and long service life; by utilizing the product, the output can be improved, and the consumption of raw materials and energy is reduced with high efficiency, energy conservation and production cost conservation; and the production process is simple, so that the energy-saving kiln material is applicable to large-scale production.

Owner:GUANGDONG SHUNXIANG PORCELAIN

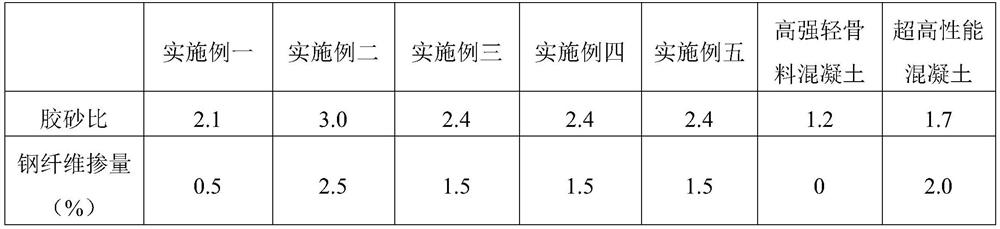

Ultra-high performance lightweight concrete taking pottery sand as lightweight aggregate and preparation method thereof

InactiveCN112125603AImprove workabilityMeet the fluidity construction requirementsSolid waste managementSuperplasticizerUltimate tensile strength

The invention relates to ultra-high performance lightweight concrete taking pottery sand as a lightweight aggregate. The concrete comprises the following components in parts by weight: 524-749 parts of cement, 140-246 parts of ultrafine fly ash, 123-176 parts of micro silicon, 190-200 parts of shale pottery sand with the particle size of 0.60-1.18 mm, 190-200 parts of shale pottery sand with the particle size of 1.18-2.36 mm, 15-21 parts of a superplasticizer, and 104-173 parts of steel fiber. According to the ultra-high-performance lightweight concrete taking the pottery sand as the lightweight aggregate and the preparation method of the ultra-high-performance lightweight concrete, the problems that concrete is large in dead weight, large in shrinkage deformation, high in production cost,complex in production process and the like can be solved. The working performance of the concrete is improved while the ultrahigh strength is realized, and the construction requirement of self-leveling is met.

Owner:CHINA THREE GORGES UNIV

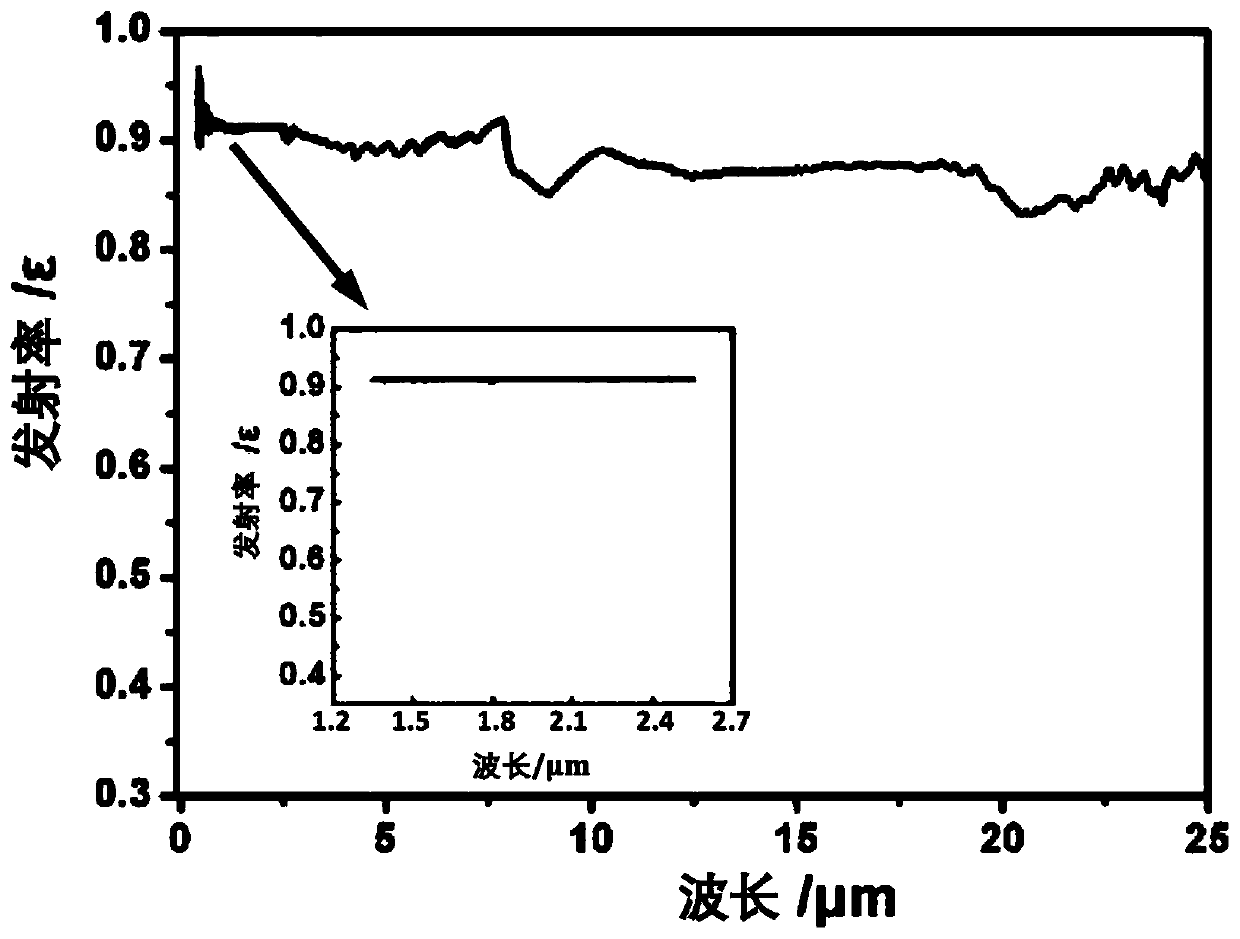

Multi-pore fiber-shaped carbon-based insulation material surface anti-oxidation high-emissivity coating and manufacturing method thereof

ActiveCN110653136AImprove temperature resistanceImprove antioxidant capacityPretreated surfacesCoatingsBorideMetal silicide

The invention discloses a multi-pore fiber-shaped carbon-based insulation material surface anti-oxidation high-emissivity coating and a manufacturing method thereof. The multi-pore fiber-shaped carbon-based insulation material surface anti-oxidation high-emissivity coating comprises an inner layer transition coating, a middle-layer anti-oxidation coating and a surface-layer high-emissivity coating; the inner layer transition coating comprises 35-55% of glass, 2-4% of one or two of silicon hexaboride or silicon tetra-boride and 41-63% of high-emissivity indissolvable metal silicide; the middle-layer anti-oxidation coating comprises 50-70% of glass, 2-4% of one or two of silicon hexaboride or silicon tetra-boride and 26-48% of high-emissivity indissolvable metal silicide; and the surface-layer high-emissivity coating comprises 30-40% of glass, 2-4% of one or two of silicon hexaboride or silicon tetra-boride and 56-68% of high-emissivity indissolvable metal silicide. According to the coating, interface combination force between the coating and a matrix is improved through the transition-layer connection coating and the matrix material; the problem that thermal expansion coefficients of the coating and the matrix are not compatible is alleviated; and therefore the coating can meet space or near space aerocraft surface insulation requirements.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Mass flow plastic coating slot

The invention provides a mass flow plastic coating slot. The mass flow plastic coating slot comprises a plastic coating slot bracket, a module bracket, a slurry coating system and a glass fiber yarn guiding device; the module frame and the slurry spraying system are arranged at the plastic coating slot bracket; the glass fiber yarn guiding device is erected at the module frame and the plastic coating slot bracket; the slurry spraying system is connected with the module frame; the slurry spraying system comprises a slurry slot, a rotor pump and a slurry spraying pipe; the slurry slot is arranged beneath the module frame; the slurry spraying pipe is arranged on the module frame, and connected with the slurry slot through the rotor pump. The mass flow plastic coating slot adopts the lower sprouting and other ways for improving the sprouting amount, thus the glass fiber yarn moved at high speed can be fully immersed by slurry within a short time, thus the coating effect is improved.

Owner:淄博卓意玻纤材料有限公司

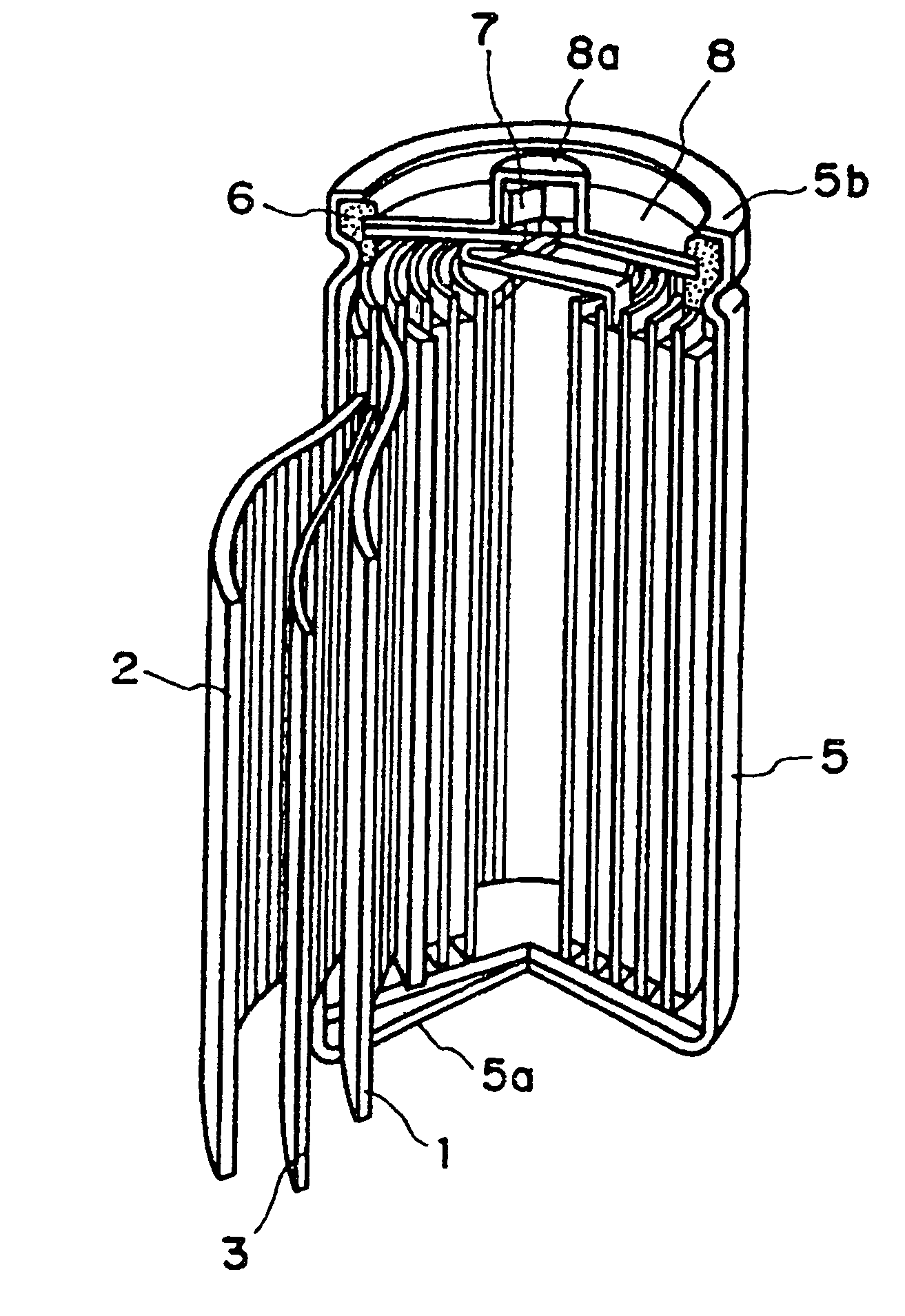

Vinylidene fluoride based core-shell type polymer and use thereof in nonaqueous electrochemical device

InactiveUS7851084B2Increase flexibilityIncrease resistanceNon-aqueous electrolyte accumulatorsHybrid capacitor electrodesComposite electrodePolymer science

A core / shell polymer (A), comprising: a rubbery core comprising a crosslinked vinylidene fluoride copolymer (a) having a vinylidene fluoride content of 30-90 wt. % and a shell comprising a vinylidene fluoride polymer (b) having a vinylidene fluoride content which is larger than in the crosslinked vinylidene fluoride copolymer (a) and at least 80 wt. %, in a weight ratio (a) / (b) of 30 / 70-90 / 10. The vinylidene fluoride-based core / shell polymer (A) is excellent in mechanical properties including flexibility and resistance to nonaqueous electrolytic solutions, is capable of forming a composite electrode layer showing excellent flexibility and adhesion to an electroconductive substrate in combination with a powder active substance and is therefore suitable for use as a binder for nonaqueous electrochemical devices.

Owner:KUREHA KAGAKU KOGYO KK

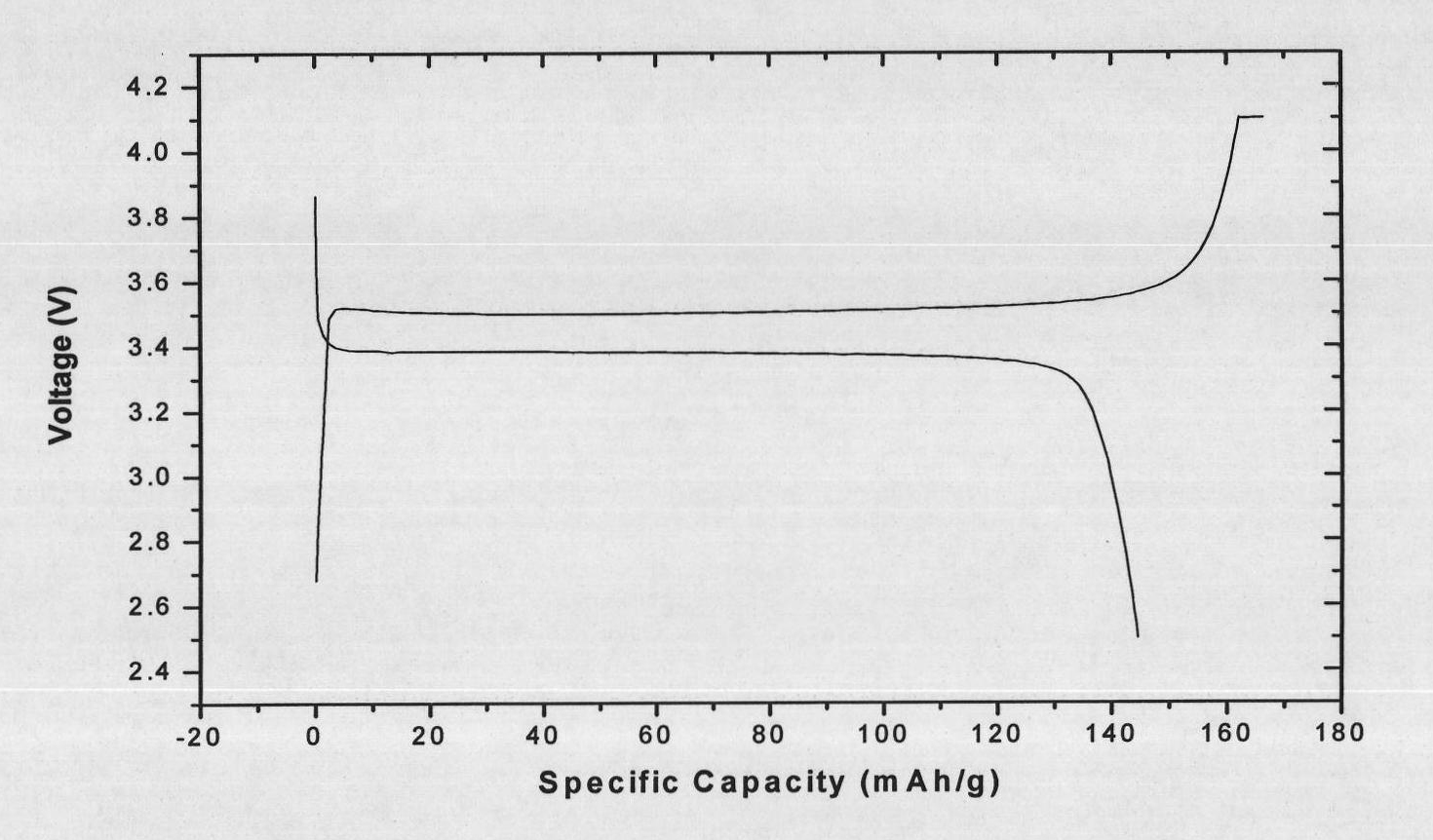

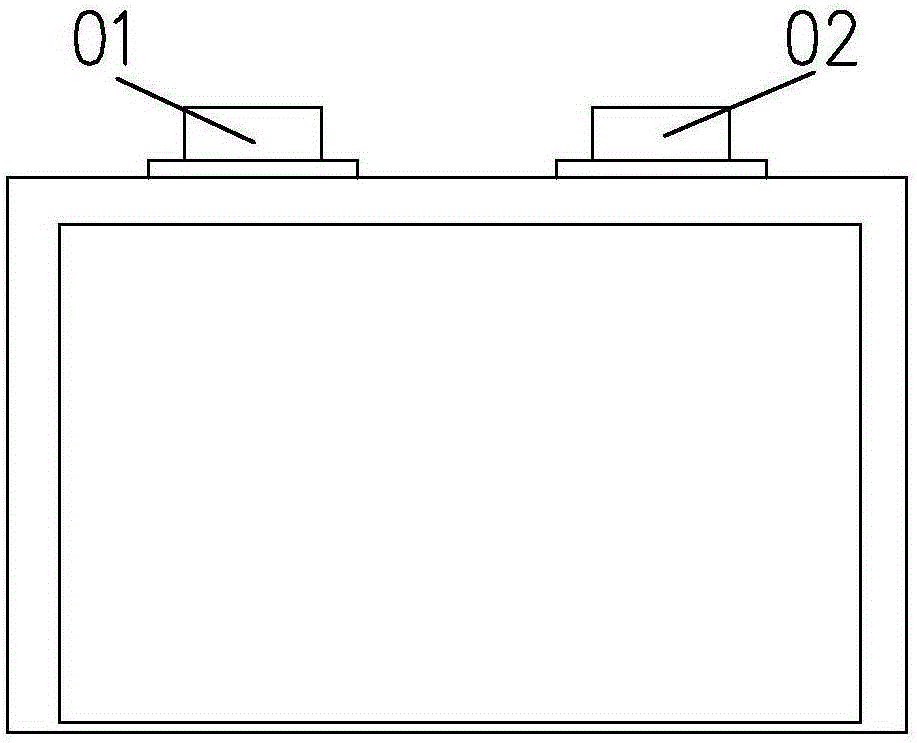

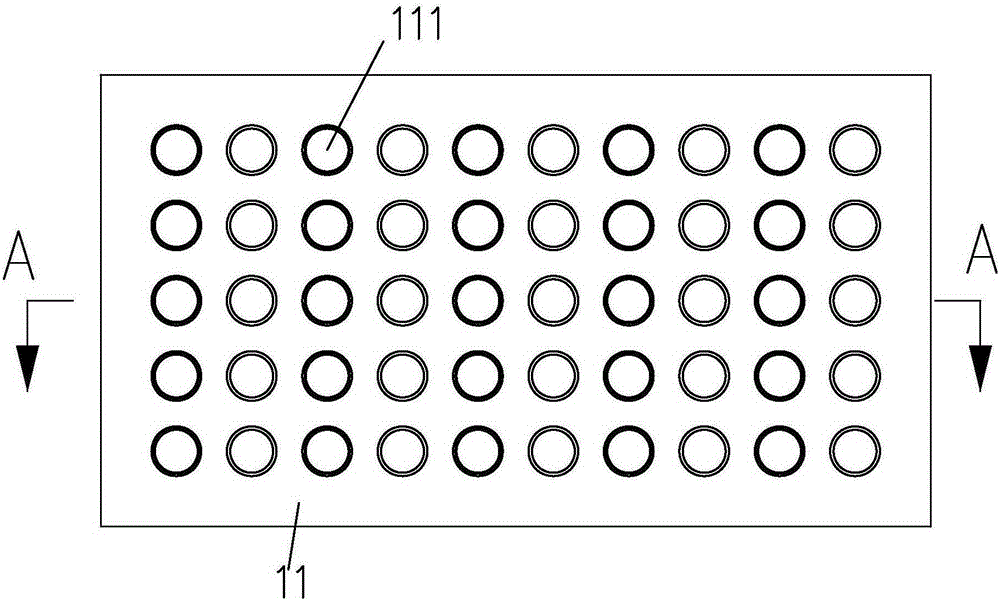

Soft-package lithium iron phosphate battery

InactiveCN105304857ALarge capacityImprove rate discharge performanceElectrode manufacturing processesFinal product manufactureLithium iron phosphateMaterials science

The invention discloses a soft-package lithium iron phosphate battery and a preparation method thereof. The soft-package lithium iron phosphate battery comprises an anode, a cathode, a membrane, electrolyte and a shell, wherein the anode comprises an anode pole lug, an anode current collector and an anode material coating on the surface of the anode current collector; the cathode comprises a cathode pole lug, a cathode current collector and a cathode material coating on the surface of the cathode current collector; the anode current collector is a sheet-plate-shaped base material; overturning edge concave pits are uniformly distributed on the two side faces of the sheet-plate-shaped base material; the cathode current collector is a sheet-plate-shaped base material; overturning edge concave pits are uniformly distributed on the two side faces of the sheet-plate-shaped base material of the cathode. With the adoption of the soft-package lithium iron phosphate battery, the condition that the multiplying power of a lithium iron phosphate battery in the prior art is low so that the use requirements cannot be met is solved and the multiplying power is greatly improved.

Owner:河南环宇赛尔新能源科技有限公司

High-strength ultrathin heat-insulation paper, preparation method and application thereof

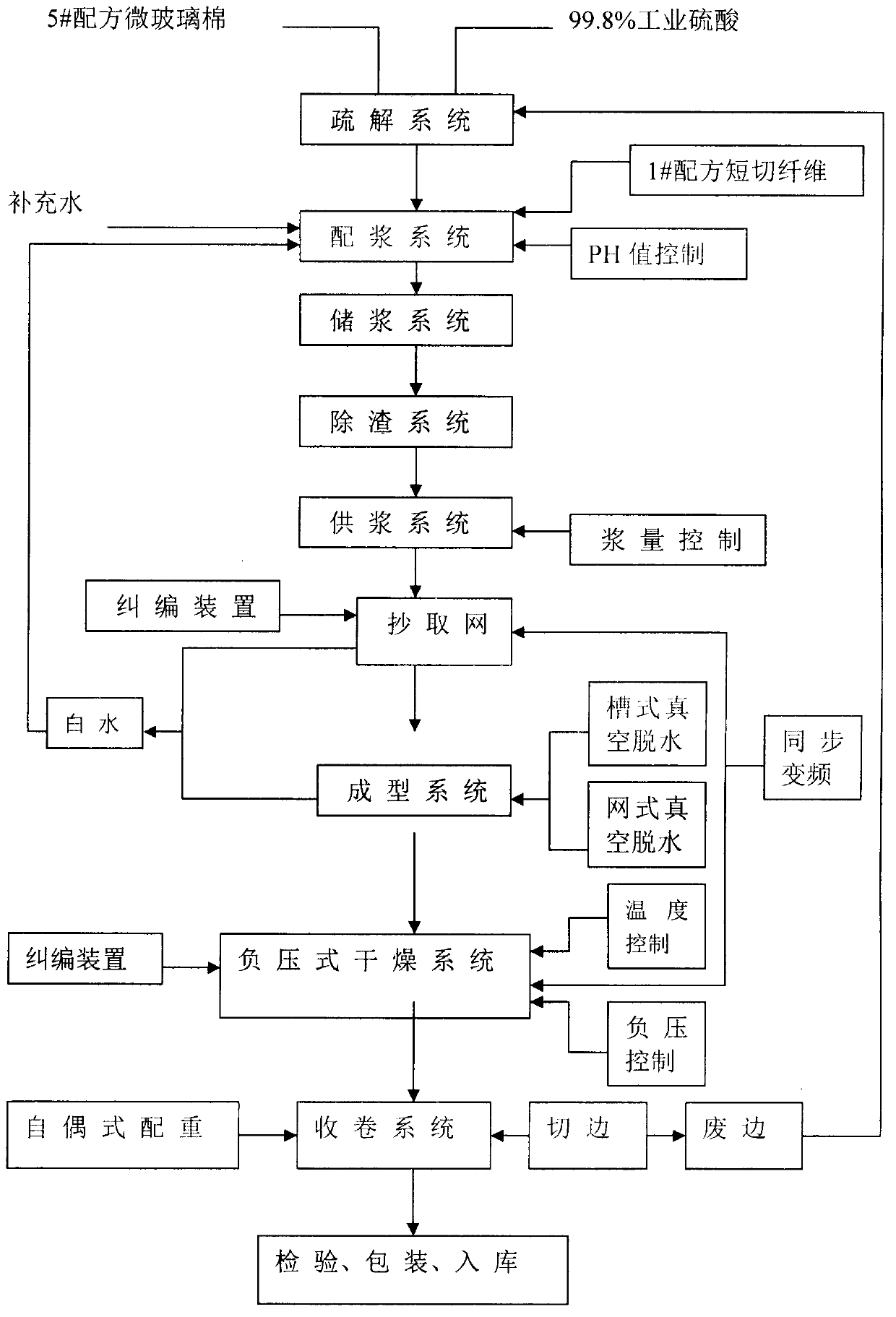

InactiveCN103866602AReduce thicknessIncreasing the thicknessSynthetic cellulose/non-cellulose material pulp/paperRaw material divisionGlass fiberFiber

The invention discloses high-strength ultrathin heat-insulation paper, a preparation method and application thereof. The low-temperature heat-insulation paper is prepared by mixing micro glass wool and alkali-free short cut fiber according to a ratio of 100:2-3. The preparation method of the high-strength ultrathin heat-insulation paper comprises: mixing micro glass wool and alkali-free short cut fiber according to a ratio of 100:2-3, and then performing defibering, pulp preparing, pulp storage, slag removing, pulp supply, beater-addition, dewatering, negative-pressure drying and rolling. The finished product has the thickness of 0.04-0.06 mm and the gram weight of 9-10 m<2>, and is relatively high in tensile strength. Also the finished product is good in heat insulation performance, small in outgassing rate in vacuum, relatively reliable in performances and relatively environment-friendly, is applicable to deep-cold liquid storage and transportation containers, low-temperature pressure containers, and vacuum multi-layer heat-insulation structures of matched pipelines, and is relatively wide in application.

Owner:CHANGZHOU JUNENG COMPOUND NEW MATERIAL

Preparation method of aqueous composite carbon nanotube conductive slurry

PendingCN111129500AUniform slurryGood uniformityMaterial nanotechnologyCell electrodesElectrically conductiveBall mill

The invention discloses a preparation method of aqueous composite carbon nanotube conductive slurry. The preparation method comprises the following steps: (1) carrying out ball milling on powdered carbon nanotubes, a dispersing agent and a water-based solvent in a ball mill until the particle size D50 is 10-15 microns, and then putting the obtained slurry into a sand mill for sand milling until the particle size D50 is 3.5-4 microns to obtain carbon nanotube slurry; 2) carrying out ball milling on powdered graphite, a dispersant and an aqueous solvent in a ball mill until the particle size D50is less than 50 microns, and putting the obtained slurry into a grinding device for treatment until the particle size D50 is less than 2 microns to obtain graphene slurry; 3) carrying out high-speedstirring on the carbon nanotube slurry and the graphene slurry to obtain the aqueous composite carbon nanotube conductive slurry. The preparation method solves the problems of high cost of carbon nanotube conductive slurry produced in factories, water and soil pollution caused by oil solvents and the like, and is simple in process, sufficient in raw materials, low in cost and suitable for industrial production.

Owner:哈尔滨万鑫石墨谷科技有限公司

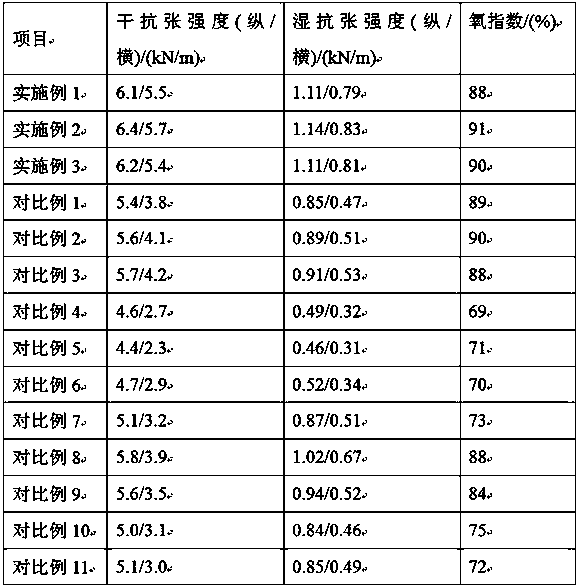

High strength flame retardant environmentally friendly packing paper

InactiveCN109208387AHigh strengthReduced risk of burnsFlexible coversWrappersCelluloseSilicon dioxide

The invention mainly relates to the technical field of packing paper processing, and discloses a high strength flame retardant environmentally friendly packing paper, which is prepared from followingraw materials in parts by weight: 45 to 47 parts of cotton straw, 36 to 38 parts of corn straw, 21 to 23 parts of wheat straw, 9 to 11 parts of glass fiber, 5 to 7 parts of nano silicon dioxide, 4 to6 parts of nano zinc oxide, 0.21 to 0.23 part of polylactic acid, and 0.02 to 0.03 part of composite enzyme. The provided packing paper has high strength, can be used to prepare multiple packing materials, is green and environmentally friendly, and has a flame retardant rating of V-1 grade. The risk of burning is largely reduced during the process of production, storage, and use. The cotton straw,corn straw, and wheat straw are taken as the main raw materials, the waste is converted into valuable resources, the raw material source is wide, the environment is protected, the raw materials are cheap, after raw materials are grinded, composite enzymes are added into raw materials to carry out fermentation to decompose impurities in the raw materials rapidly, and the cellulose extraction is promoted.

Owner:马鞍山市康辉纸箱纸品有限公司

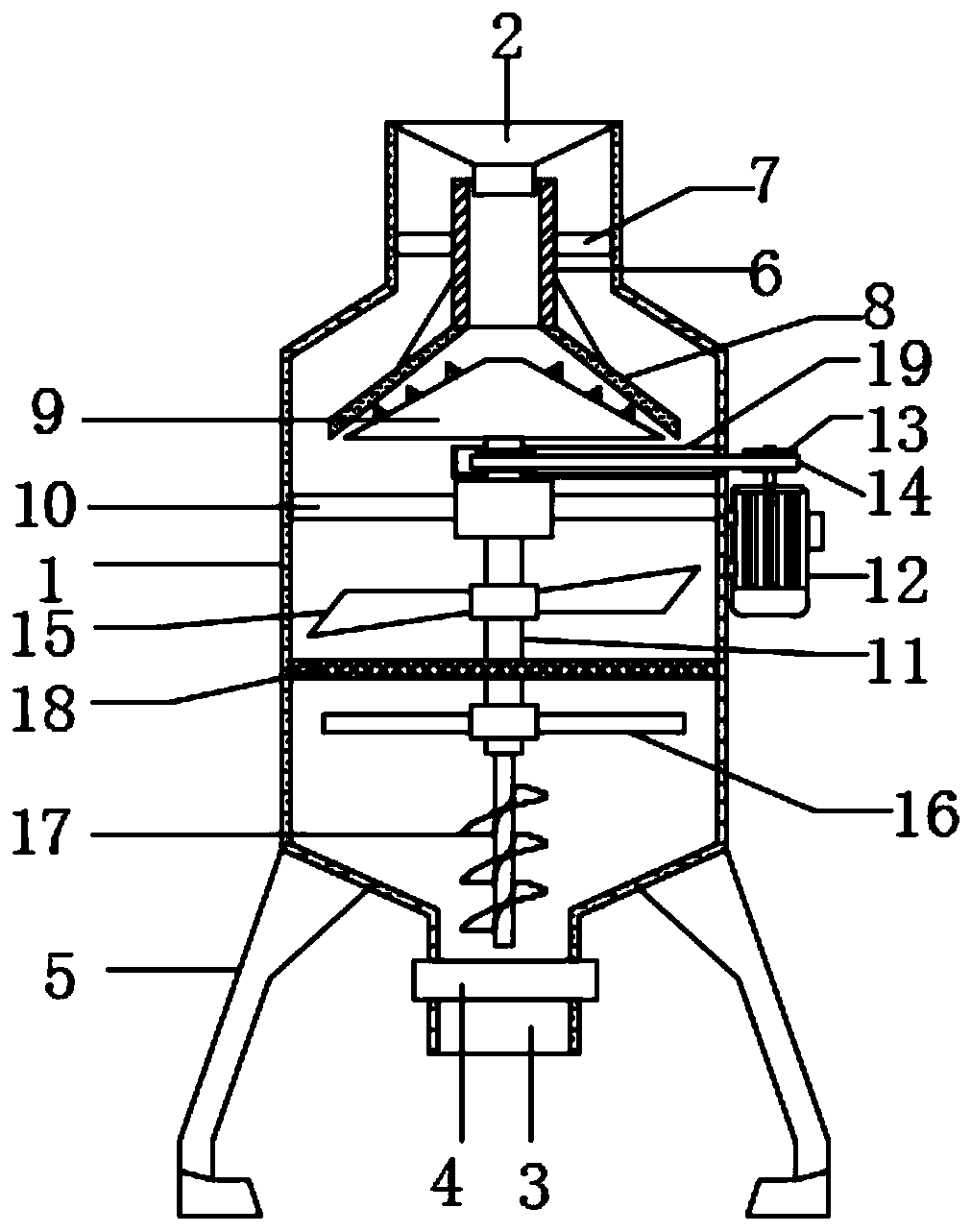

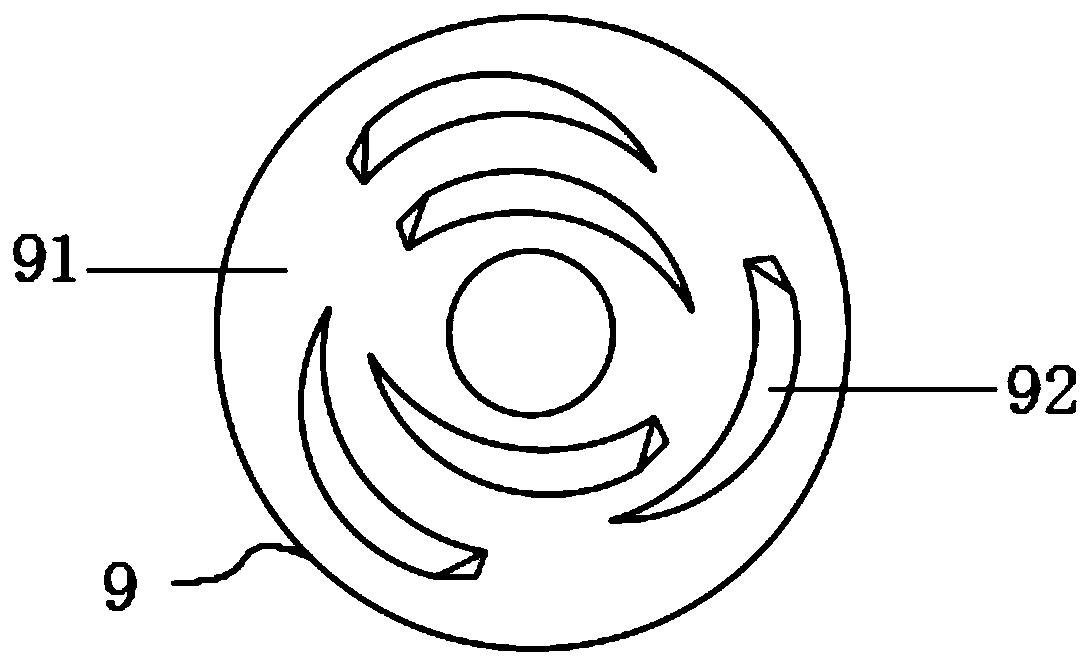

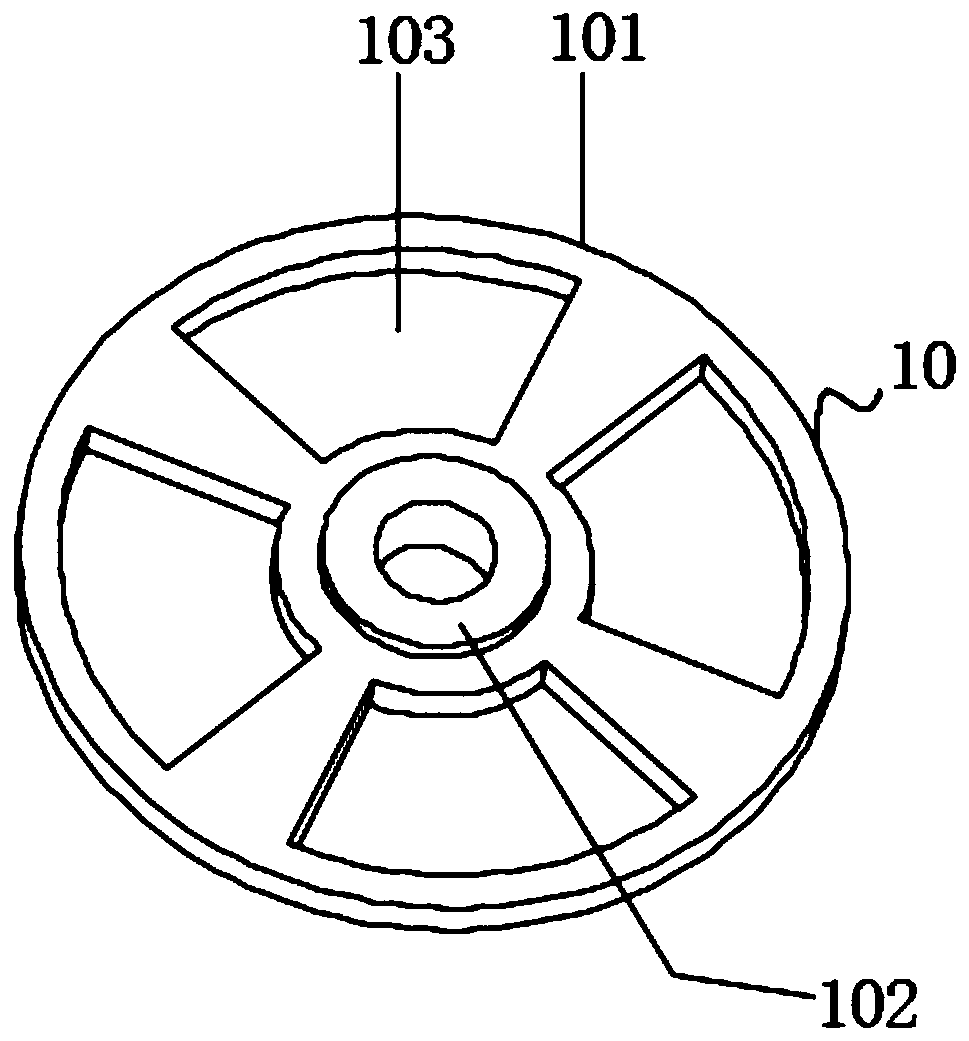

Environment-friendly scrapped printed matter recovery device

InactiveCN110952361ARapid pulpingUniform slurryPaper recyclingRaw material divisionPaper dustStructural engineering

The invention discloses an environment-friendly scrapped printed matter recovery device in the technical field of environmental protection. The device comprises a recovery frame. The top of the recovery frame is fixedly connected with a feeding hopper. A discharge opening is formed in the bottom of the recovery frame. A valve is mounted on the discharge opening. Supporting legs are evenly and fixedly connected to the outer wall of the lower portion of the recovery frame. A sleeve which sleeves the lower end of the feeding hopper is arranged at the upper part of an inner cavity of the recoveryframe. A connecting block is fixedly connected between the sleeve and the inner cavity wall of the recovery frame. The bottom of the sleeve is fixedly connected with a horn block in a communicated mode. A cutting disc is arranged in the middle of an inner cavity of the horn block. A fixing block is arranged below the cutting disc. The device is suitable for fine pulping of scrapped printing paperproducts. The scrapped printing paper products falling on the cutting disc can be rapidly and efficiently cut up through rotation of the cutting disc, the rotating smashing blades can cut up paper scraps in smashed paper mixed liquid again and has a stirring function, and therefore, the paper scraps can be rapidly pulped.

Owner:福清市迪川包装有限公司

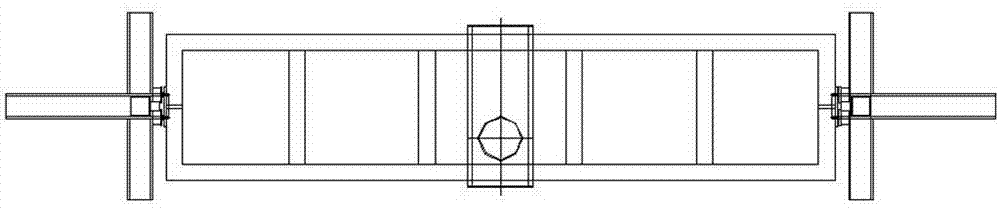

Slurry treating device facilitating spray coating

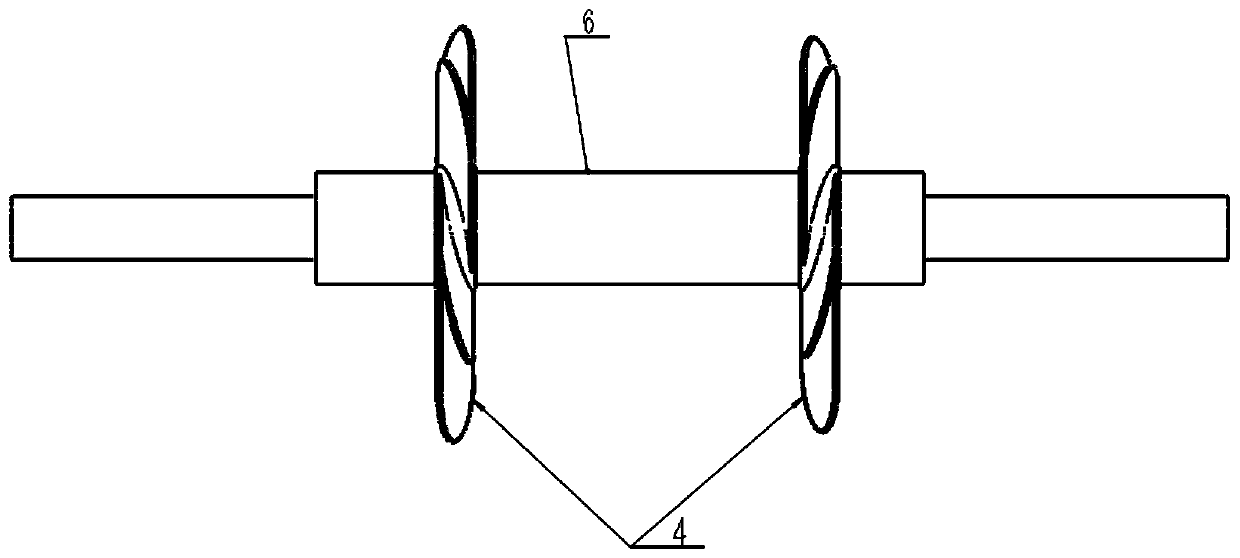

ActiveCN108221239AEasy to sprayReduce work intensityTextile treatment machine arrangementsTextile treatment by spraying/projectingDrive wheelSpray coating

The invention discloses a slurry treating device facilitating spray coating. The device comprises a box; a groove is formed in the lower surface of the inner wall of the box, the upper surface of theinner wall of the groove is fixedly connected with the bottom end of a driving device, the top end of the driving device is clamped to the inner surface of a driving wheel, the outer surface of the driving wheel is in transmission connection with a driven wheel through a belt, a first rotating shaft is clamped to the inner surface of the driven wheel, the outer surface of the first rotating shaftand the inner surface of a first bearing are sleeved, the first bearing is clamped to the lower surface of the inner wall of the box, the top end of the first rotating shaft is fixedly connected withthe lower surface of a bearing plate, and the lower surface of the inner wall of the box is fixedly connected with the lower surface of a slurry box. According to the slurry treating device facilitating spray coating, due to cooperation of a motor, the driving wheel, the belt, the driven wheel, the bearing plate, an extrusion plate, a second electric push rod and a slurry spraying gun, the labor intensity of workers is lowered, and slurry on the surface of an object is more uniform.

Owner:绍兴国泰印染有限公司

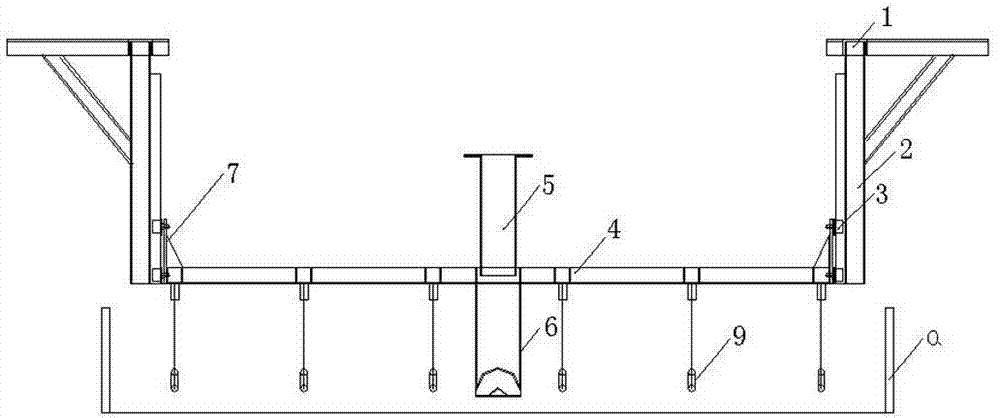

Pouring/vibrating/entraining automatic lifting device

The invention provides a pouring / vibrating / entraining automatic lifting device and relates to the technical field of building material processing. The pouring / vibrating / entraining automatic lifting device comprises a fixed frame (1), a guide rail (2), guide wheels (3), a lifting frame (4), a pouring pipe (5), a fastening rack (6), a hanging spring (7) and vibrating rods (9); the fixed frame (1) is fixedly arranged above the guide rail (2); the guide wheels (3) are arranged on the inner side under the guide rail (2); the two guide wheels (3) are connected by use of the hanging spring (7); the bottom of the guide rail (2) is connected with the lifting frame (4); a pouring tube (5) is arranged in the middle position of the lifting frame (4); the fastening rack (6) is arranged under the pouring tube (5); a plurality of vibrating rods (9) are evenly arranged under the lifting frame (4). The pouring / vibrating / entraining automatic lifting device is simple in structure, reasonable in design, convenient to use, and capable of reducing the pouring height, preventing the slurry from splashing all around, homogenizing the slurry and reducing bubbles; besides, small bubbles are distributed evenly to enhance the strength of the material and reduce the weight of the material.

Owner:邓孝明

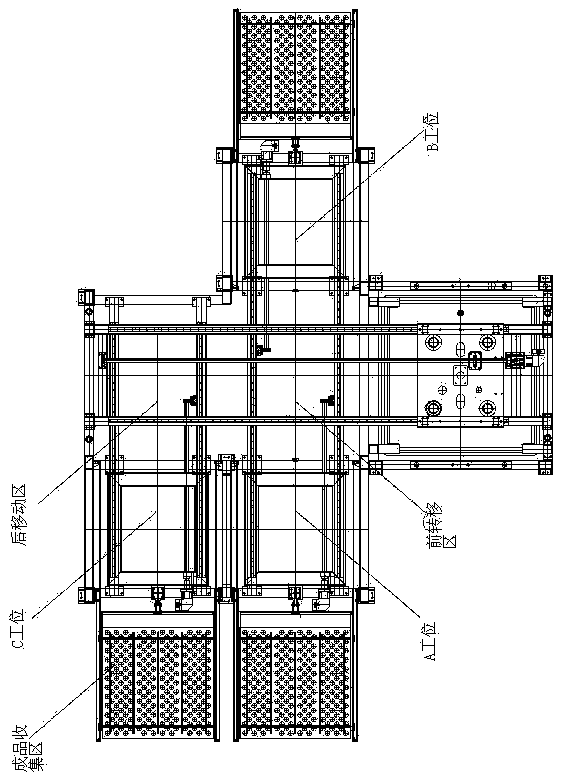

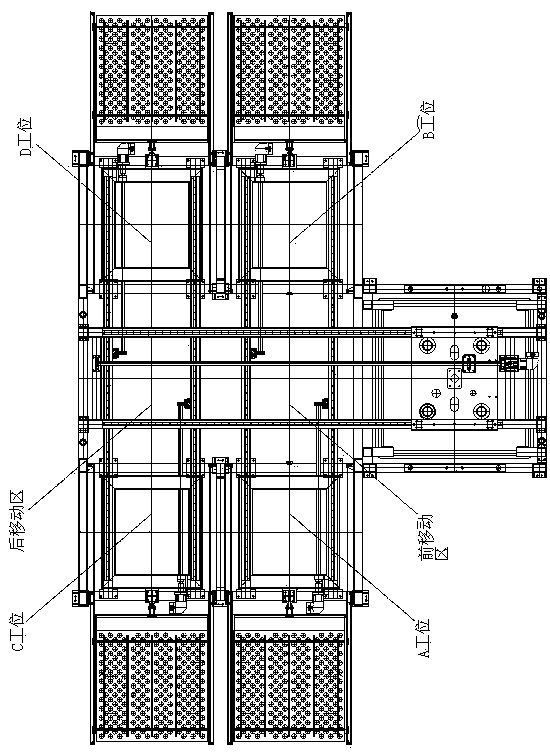

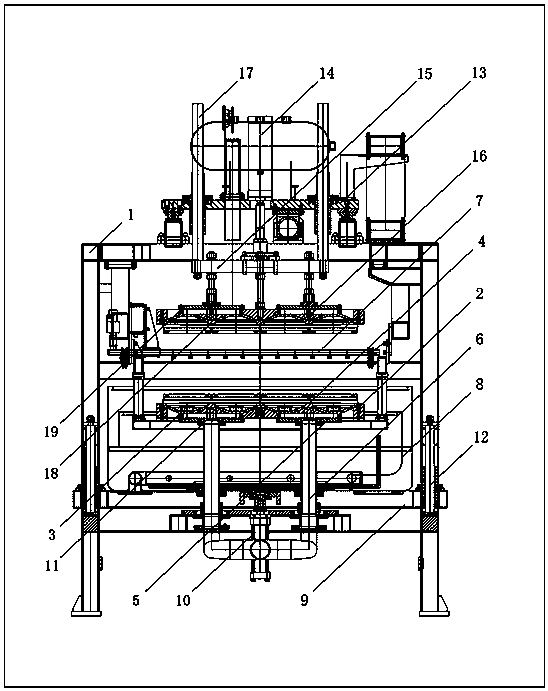

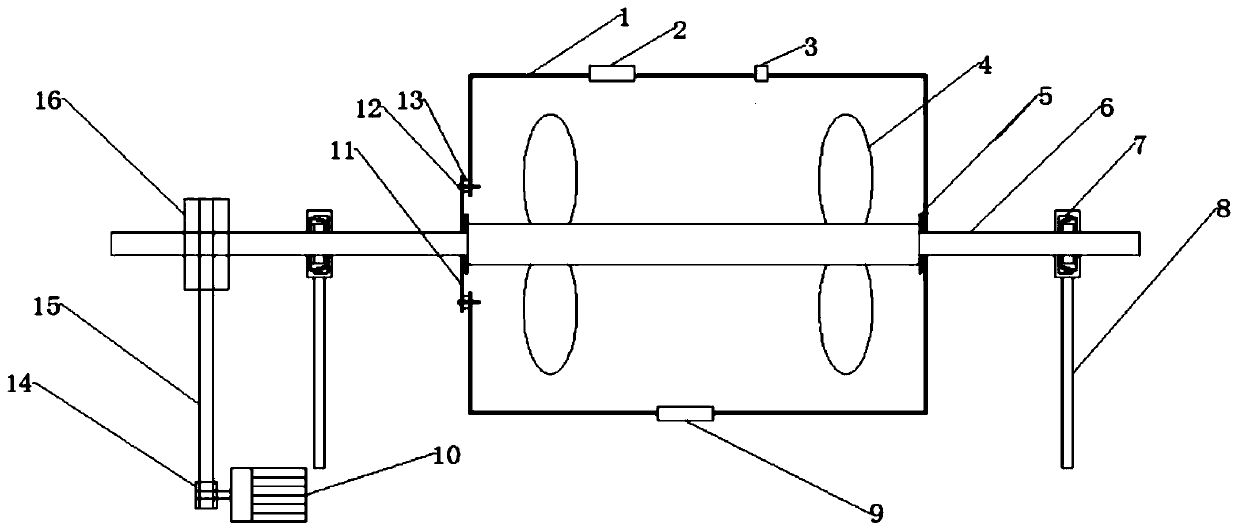

Fully automatic pulp molding multi-station equipment and production process

ActiveCN106638164BSmall weight deviationShorten the timeTextiles and paperMolded pulpThermal deformation

The invention belongs to the field of pulp molding product production equipment in a papermaking technique. Full-automatic multi-station integrated pulp molding equipment comprises an electric-heat conduction oil universal heating device, a steam heating device, a pulp chest homogenizing device, an adsorptive molding device, hot-press sizing devices, a first kind product collection device not needing stacking and a second kind product collection device capable of automatically conducting stacking; a groove is formed in a molding template of the molding device, an airflow dispersion cover plate is installed over the groove, an airflow main pipeline is vertically installed, a deckle edge spraying and template cleaning device is independently installed, heating plates of the molding devices are fixed to an upper molding template and a lower molding template through heat insulation plates, the upper molding template achieves multi-point pressurizing through a pressure stabilizing frame, the lower molding template is fixed to a transverse tackle, and heat deformation of the heating plates is effectively controlled by the molding templates. The equipment is suitable for large-scale production of pulp molding products, few molds are used, and the molds are unified and easy to replace.

Owner:许洪涛 +1

Cement stirring machine

InactiveCN109849180APrevent splashWell mixedDischarging apparatusMixing operation control apparatusPulp and paper industryCement

The invention designs a cement stirring machine. The cement stirring machine comprises a cylindrical hollow stirring barrel, wherein a feeding opening, a water inlet and a discharging opening are formed in the side surfaces of the stirring barrel; a dismountable end surface cover is mounted on one of the end surfaces of the stirring barrel; a stirring shaft is arranged in the stirring barrel; blades are fixed on the stirring shaft; sealing rings are arranged at positions where the stirring shaft is in contact with the end surface and the end surface cover of the stirring barrel; and bearings are respectively arranged at two ends extending out of the stirring barrel, of the stirring shaft. The cement stirring machine disclosed by the invention is a horizontal type cement pulping machine with a simple supporting beam structure; and the simple supporting beam structure is adopted, so that materials can be sufficiently mixed, the mixing uniformity and the production efficiency are notablyimproved, and the stirring effect of cement is greatly improved.

Owner:WUHAN UNIV OF TECH

Manufacturing method for mung bean powder

InactiveCN108617963AThe color is green and lustrousUniform slurryFood homogenisationFood mechanical treatmentMung bean

A Manufacturing method for mung bean powder overcomes the prejudice that mung beans must be thoroughly cooked before grinding, and eliminates a thoroughly cooked process in the prior art, and only utilizes the accumulation of temperature rising of the mung beans in subsequent process to make the mung beans cooked. A result of process adjustment is that produced mung bean powder maintains natural color of the mung beans and does not stratify when the mung bean powder is brewed.

Owner:徐小芹

Ultrasonic lapping device

The invention discloses an ultrasonic lapping device comprising a lapping body with a lapping cavity, a discharging pipe, a buffer tank and a feeding pipe which are connected with each other in sequence; the feeding pipe is connected with the lapping body, and the bottom of the lapping body is provided with a discharging port; the ultrasonic lapping device further comprises an ultrasonic generatorand a transducer; the ultrasonic generator is arranged between the buffer tank and the feeding pipe, and the lower section of the buffer tank is arranged in the ultrasonic generator; and the transducer is connected with the ultrasonic generator. According to the ultrasonic lapping device, the lower section of the buffer tank is arranged in the ultrasonic generator, so that materials are subjectedto ultrasonic dispersion through the dispersion function of the ultrasonic generator in advance before reentering the lapping body; and thus, slurry is more uniform, and the lapping efficiency is improved.

Owner:NORTHERN ALTAIR NANOTECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com