Ceramic membrane blade-coating device

A technology of ceramic membrane and scraping membrane, which can be applied to the device for coating liquid on the surface, pretreatment surface, coating and other directions, which can solve the problem of high manufacturing cost of scraper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings by means of specific embodiments:

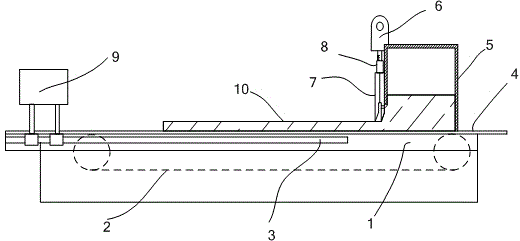

[0012] Such as figure 1 The ceramic diaphragm scraping device shown includes a worktable 1, a transmission belt 2 and a scraping film substrate 4, the scraping film substrate 4 is fixed on the transmission belt 2, and both ends of the transmission belt 2 are fixed on the worktable 1 by rotating rollers. A film scraping device is erected above the conveyor belt 2. The film scraping device includes a material box 5, a scraper bracket 6 and a scraper 7. The scraper bracket 6 is fixed on one side of the material box 5, and the bottom edge of the other side of the material box 5 is connected to the scraping film substrate 4. For contact, a plurality of scrapers 7 are fixedly arranged under the scraper bracket 6 , the lower ends of the blades of the scrapers 7 are flush, and a screw regulator 8 is arranged between the scraper bracke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com