Ultra-high performance lightweight concrete taking pottery sand as lightweight aggregate and preparation method thereof

A lightweight concrete, ultra-high-performance technology, applied in climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of complex production process, self-heavy concrete, high production cost, and achieve a significant increase in strength, The effect of reducing cost and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

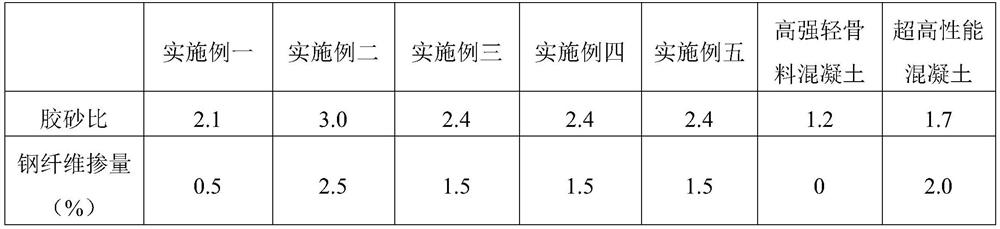

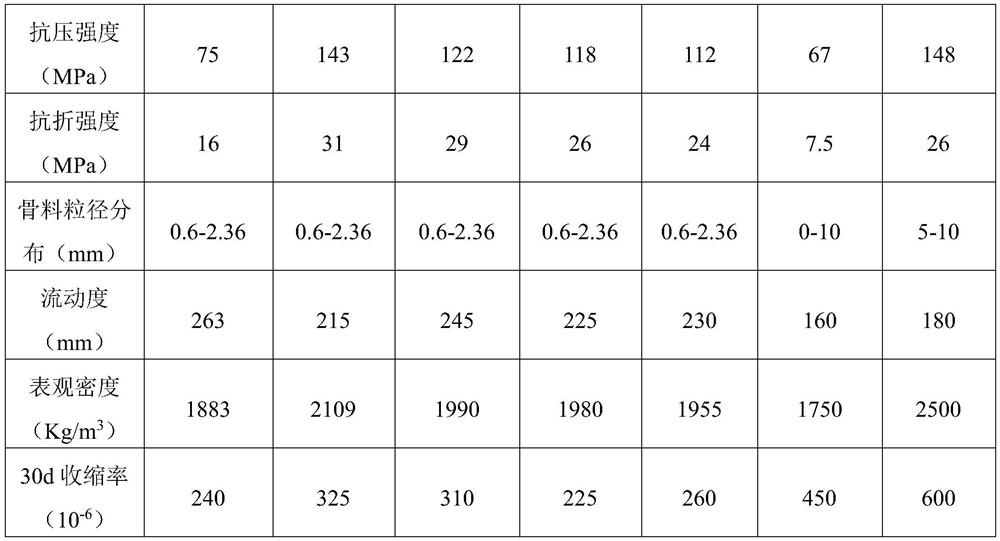

Examples

Embodiment 1

[0035] A kind of ultra-high performance lightweight concrete that uses pottery sand as lightweight aggregate, and the concrete includes the following components in proportion by weight:

[0036] 524 parts of cement, 172 parts of superfine fly ash, 123 parts of microsilica

[0037] Particle size 0.60-1.18mm shale pottery sand 195 parts

[0038] Particle size 1.18-2.36mm shale pottery sand 195 parts

[0039] 15 parts of superplasticizer, 104 parts of steel fiber.

[0040] The cement is PO52.5 ordinary Portland cement.

[0041] Ultrafine fly ash is fly ash with a particle size not greater than 3 μm.

[0042] Silica fume is SiO2 content ≥ 94%, specific surface area ≥ 22000m 2 / kg of silica fume.

[0043] The pottery sand is high-quality shale pottery sand with a density grade of 800, a 1h water absorption rate of 4.0%, and a barrel pressure strength of 6MPa.

[0044] The high-efficiency water reducer is polycarboxylate high-performance water reducer, the liquid has a solid c...

Embodiment 2

[0046] An ultra-high-performance lightweight concrete using clay sand as a lightweight aggregate, the concrete includes the following components in proportion by weight:

[0047] 749 parts of cement, 246 parts of ultra-fine fly ash, 176 parts of silica fume

[0048] Particle size 0.60-1.18mm shale pottery sand 195 parts

[0049] Particle size 1.18-2.36mm shale pottery sand 195 parts

[0050] 21 parts of superplasticizer, 173 parts of steel fiber.

[0051] The cement is PO52.5 ordinary Portland cement.

[0052] Ultrafine fly ash is fly ash with a particle size not greater than 3 μm.

[0053] Silica fume as SiO 2 Content ≥ 94%, specific surface area ≥ 22000m 2 / kg of silica fume.

[0054] The pottery sand is high-quality shale pottery sand with a density grade of 800, a 1h water absorption rate of 4.0%, and a barrel pressure strength of 6MPa.

[0055] High-efficiency water-reducer is polycarboxylate high-performance water-reducer, the liquid has a solid content of 40% and a...

Embodiment 3

[0057] A kind of ultra-high performance lightweight concrete using pottery sand as lightweight aggregate, the concrete includes the following components in proportion by weight:

[0058] 600 parts of cement, 197 parts of superfine fly ash, 140 parts of silica fume

[0059] Particle size 0.60-1.18mm shale pottery sand 195 parts

[0060] Particle size 1.18-2.36mm shale pottery sand 195 parts

[0061] 17 parts of superplasticizer, 138 parts of steel fiber.

[0062] The cement is PO52.5 ordinary Portland cement.

[0063] Ultrafine fly ash is fly ash with a particle size not greater than 3 μm.

[0064] Micro silica fume is SiO2 content ≥ 94%, specific surface area ≥ 22000m 2 / kg of silica fume.

[0065] The pottery sand is high-quality shale pottery sand with a density grade of 800, a 1h water absorption rate of 4.0%, and a barrel pressure strength of 6MPa.

[0066] High-efficiency water-reducer is polycarboxylate high-performance water-reducer, the liquid has a solid content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com