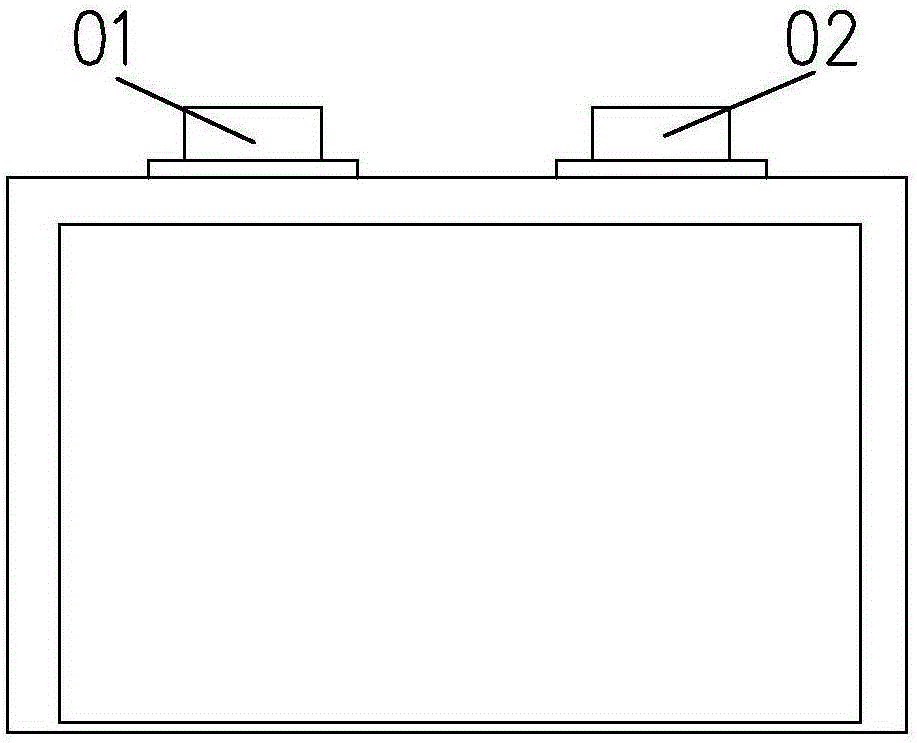

Soft-package lithium iron phosphate battery

A soft-packed lithium iron phosphate and battery technology is applied in secondary batteries, battery pack components, non-aqueous electrolyte batteries, etc. The effect of high performance and large capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

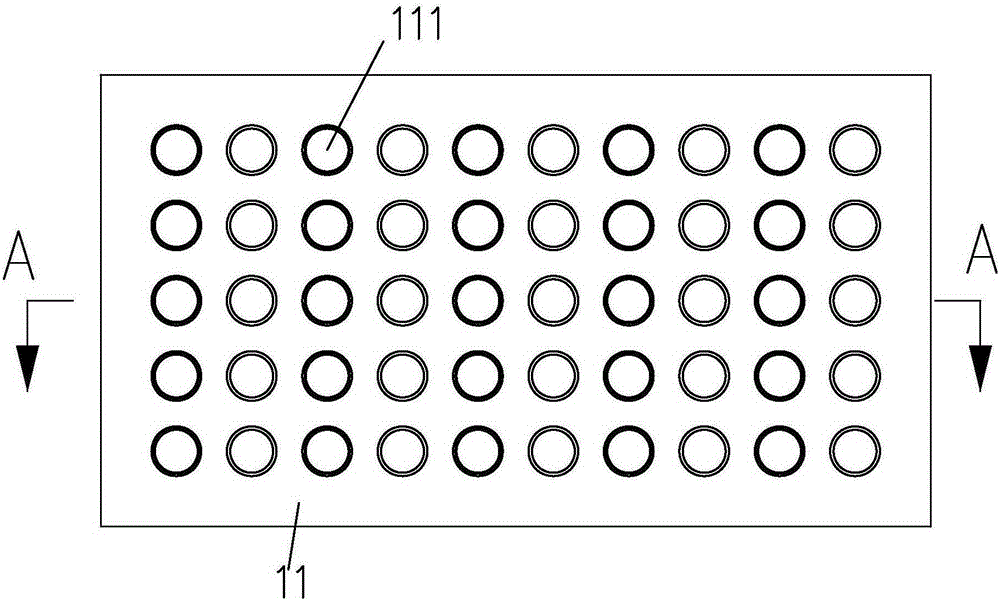

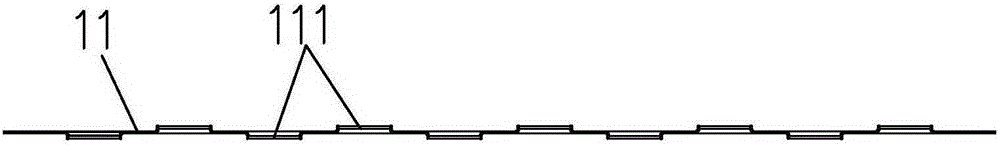

[0031] The preparation method of 3.2V / 65Ah battery comprises the steps:

[0032] Contains Mg 2+ Preparation of lithium iron phosphate: by Li 1-x Mg x FePO 4 The stoichiometric ratio of LiOH·H 2 O, MgO, FePO 4 , add absolute ethanol ball milling mix, and then in N 2 Prepared by roasting at 700°C for 12 hours under atmosphere, where x=0.005-0.02;

[0033] Positive electrode preparation: first dissolve the binder polyvinylidene chloride in nitrogen methyl pyrrolidone, stir for 4 hours at a speed of 50r / min, and disperse at a speed of 1500r / min, then add Mg 2+ The lithium iron phosphate and the conductive agent are continuously stirred, the dispersion speed is 1800r / min, and the time is 5 hours to make the positive electrode material. The viscosity of the positive electrode material is controlled at 5000-10000mPa.s, and then the positive electrode material is coated on the On the positive electrode current collector, the coating surface density of the positive electrode mater...

Embodiment 2

[0038] The preparation method of 3.2V / 80Ah battery comprises the steps:

[0039] Contains Mg 2+ Preparation of lithium iron phosphate: by Li 1-x Mg x FePO 4 The stoichiometric ratio of LiOH·H 2 O, MgO, FePO 4 , add absolute ethanol ball milling mix, and then in N 2 Prepared by roasting at 700°C for 12 hours under atmosphere, where x=0.005-0.02;

[0040] Positive electrode preparation: first dissolve the binder polyvinylidene chloride in nitrogen methyl pyrrolidone, stir for 4 hours at a speed of 50r / min, and disperse at a speed of 1500r / min, then add Mg 2+ Continue to stir the lithium iron phosphate and the conductive agent, the dispersion speed is 1800r / min, and the time is 5h to make the positive electrode material. The viscosity of the positive electrode material is controlled at 5000-10000mPa.s, and then the positive electrode material is coated on the positive electrode assembly On the fluid, the coating surface density of the positive electrode material is 240g / m ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com