Patents

Literature

30results about How to "Small weight deviation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

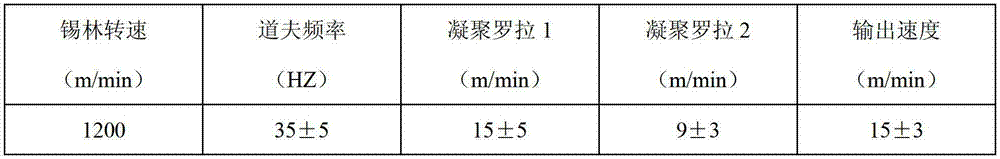

High-intensity low-stretchability polysulfonamide high-temperature-resisting membrane filter material and preparation method thereof

ActiveCN103170183AHigh filtration precisionHigh operabilityFibre typesSynthetic resin layered productsFiberEngineering

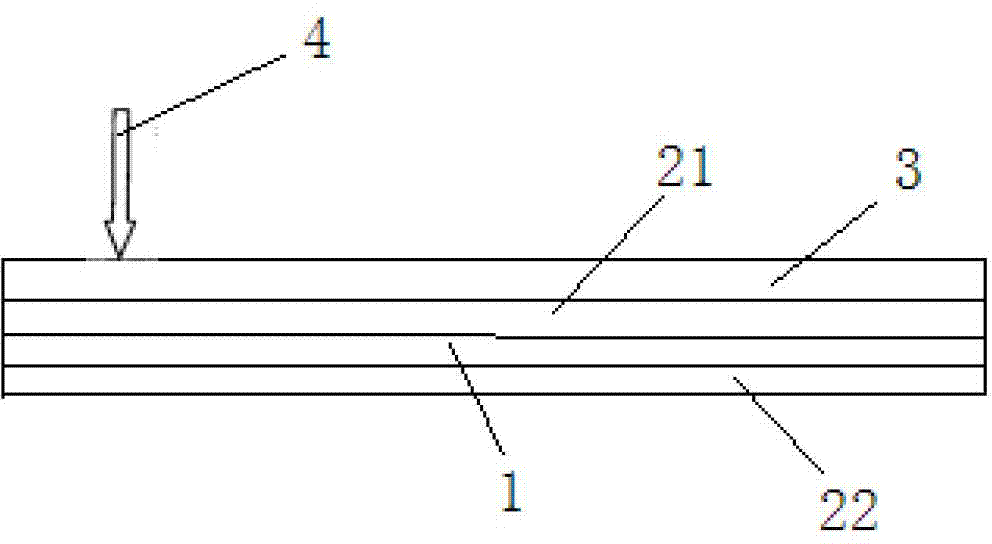

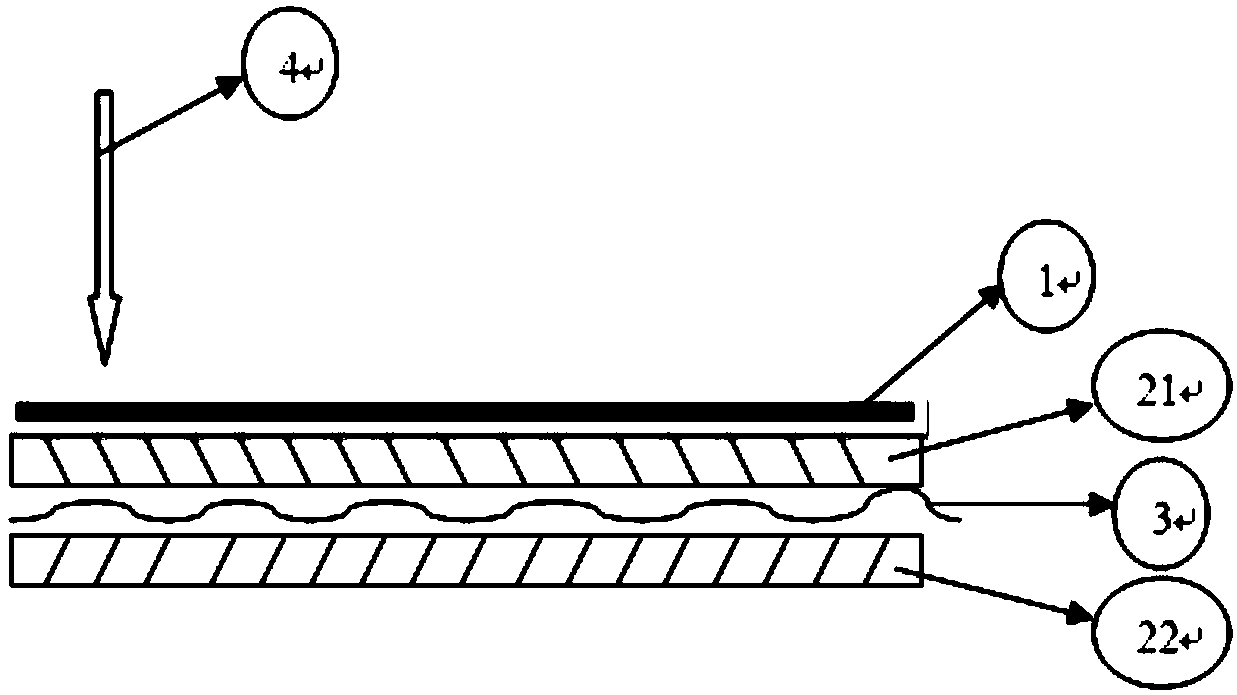

The invention provides a high-intensity low-stretchability polysulfonamide high-temperature-resisting membrane filter material and a preparation method thereof. The filter material disclosed by the invention is formed by compounding a PTFE (Polytetrafluoroethylene) high-compactness microporous membrane layer and a punched felt in sequence from top to bottom. The punched felt is formed by compounding a first polysulfonamide fiber surface layer, a high-intensity low-stretchability base cloth layer and a second polysulfonamide fiber surface layer in sequence from top to bottom. The preparation method comprises steps of: preparation of the punched felt, high-temperature thermoforming, singeing and pressing treatment, full-saturation immersion treatment, predrying, baking curing, and high-temperature high-pressure coating with the PTFE high-compactness microporous membrane. The high-intensity low-stretchability polysulfonamide high-temperature-resisting membrane filter material has high intensity and low stretchability, longitude and latitude strengths are both larger than 3000N / 50mm; the longitude and latitude elongations at break are both smaller than 10%; and the filter material can resist a high temperature grade of 250 DEG C and has high corrosion resistance, good oxidization resistance, smooth surface, high deashing efficiency and wide application range.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

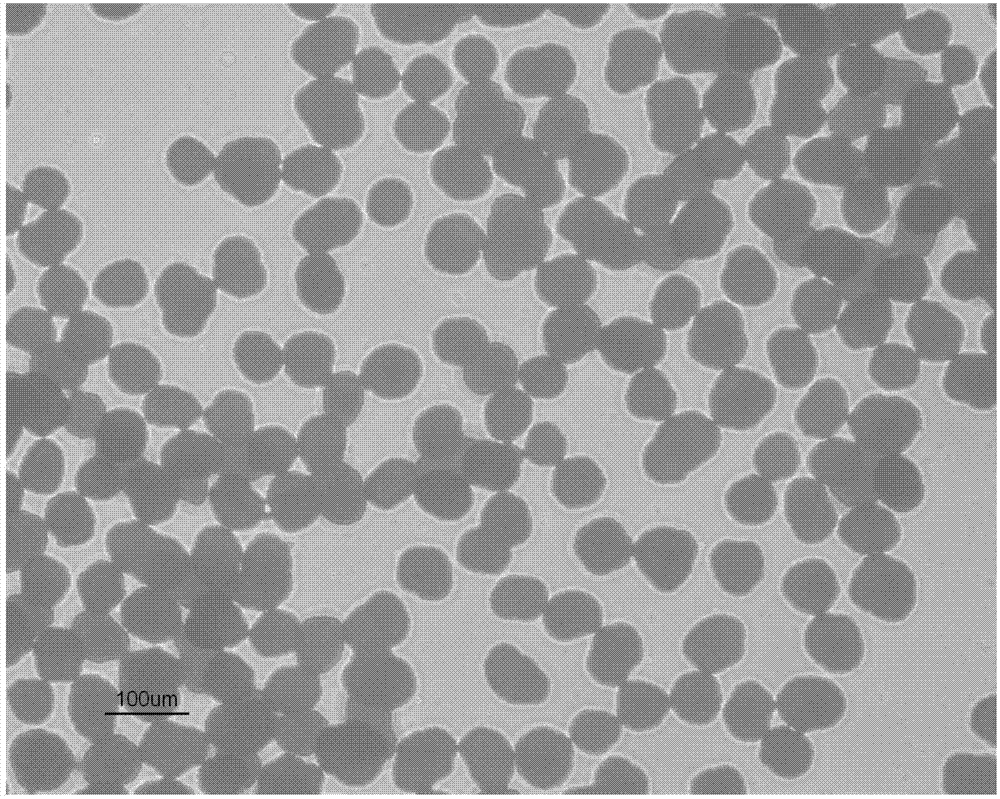

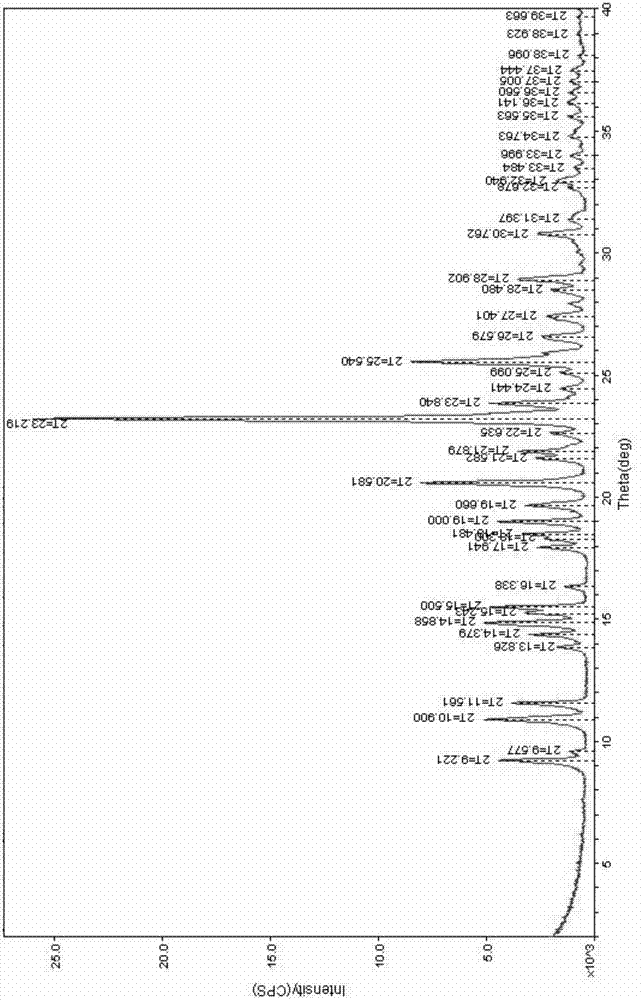

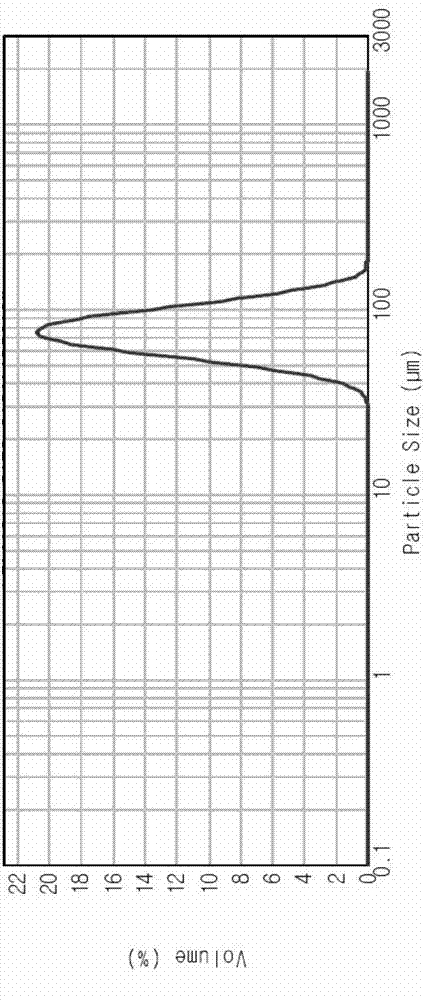

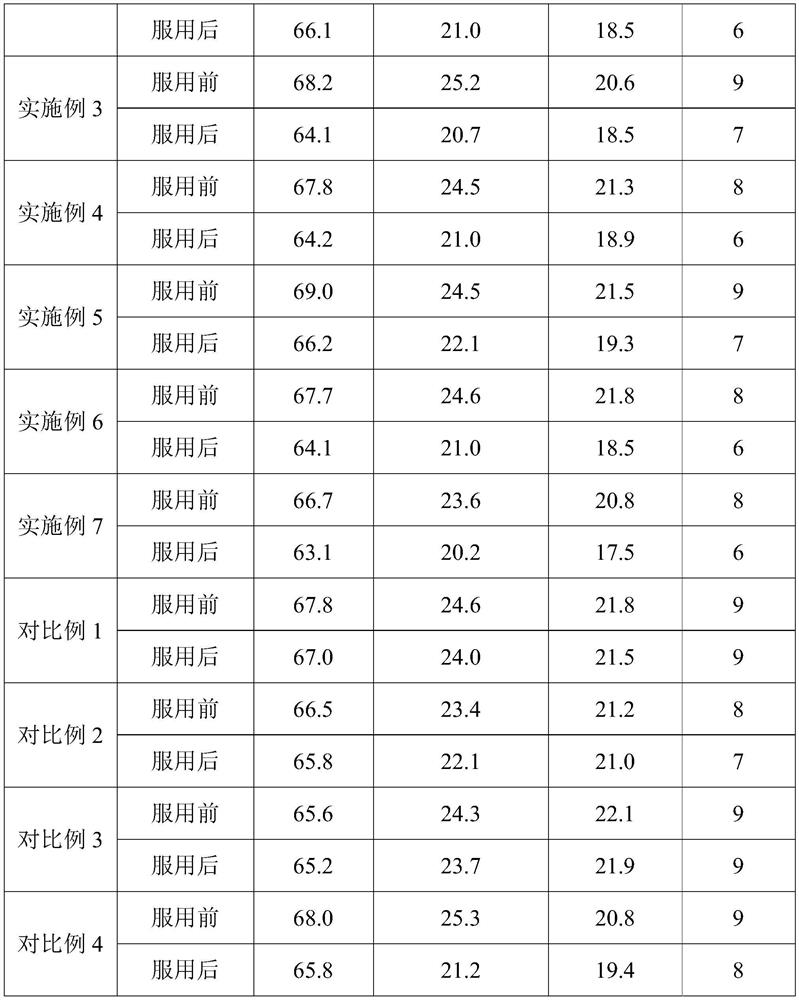

Spherical particles of clopidogrel bisulfate, pharmaceutical composition including same, and method for manufacturing same

InactiveCN103717207AFull strengthEasy to compressOrganic active ingredientsPowder deliveryDrug productUltimate tensile strength

The present invention relates to spherical particles of clopidogrel bisulfate having a 10% volume particle diameter (d0.1) of 30 [mu]m or more and a 50% volume particle diameter (d0.5) in the range of 50 to 200 [mu]m, and to a pharmaceutical composition including same. The spherical particles of the present invention not only significantly improve unfavorable properties in a conventional pharmaceutical preparation of clopidogrel bisulfate, i.e. defective compression and flow and a strong surface electrostatic force, but can also significantly reduce tableting impediments such as weight deviations and sticking during preparation by means of a direct powder compression technique, and the danger of crystalline conversion. Thus, the composition has improved physiochemical stability and, due to anti-clotting effects of the composition, can be effectively used as a therapeutic agent for arteriosclerosis, stroke, myocardial infarction, and atherosclerosis.

Owner:SAMJIN PHARMA +1

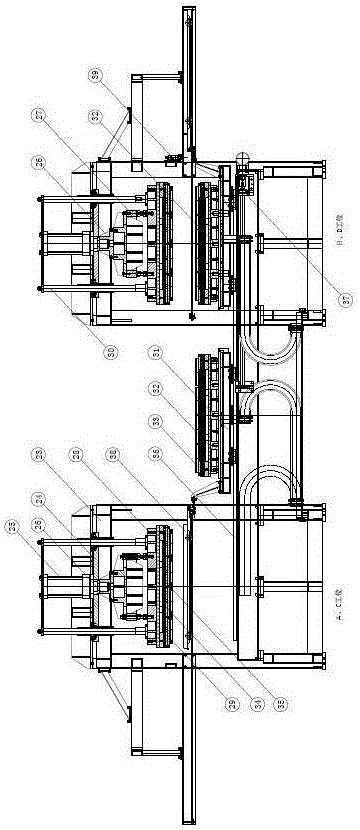

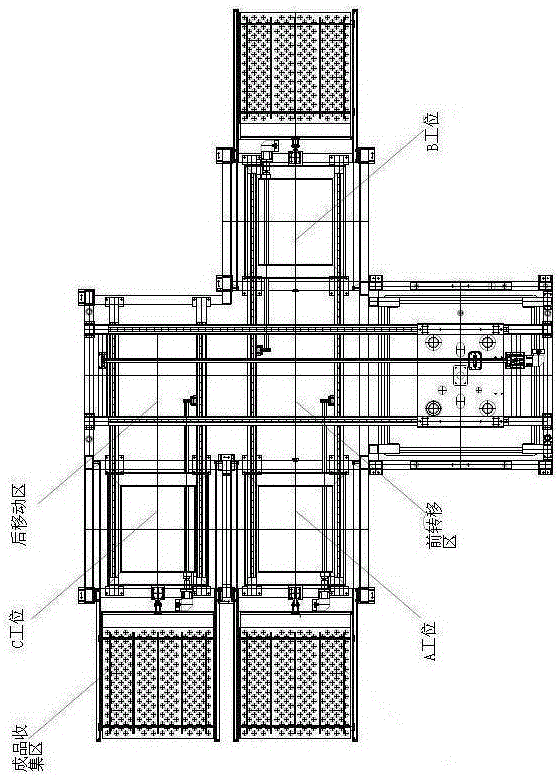

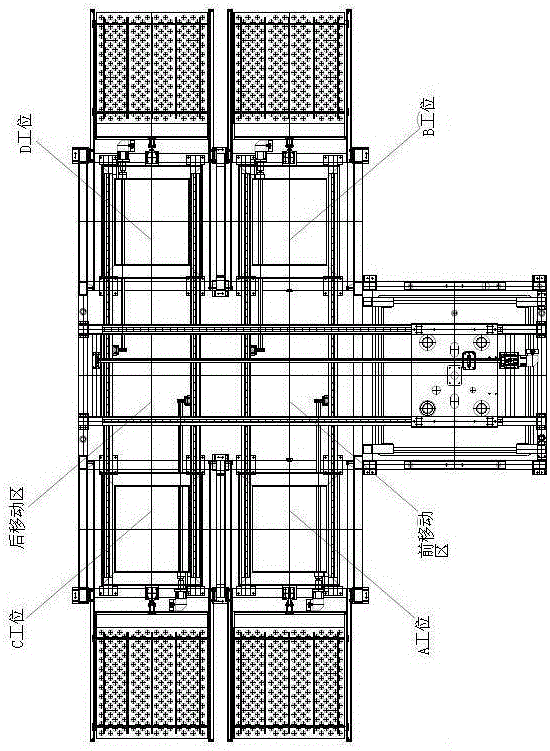

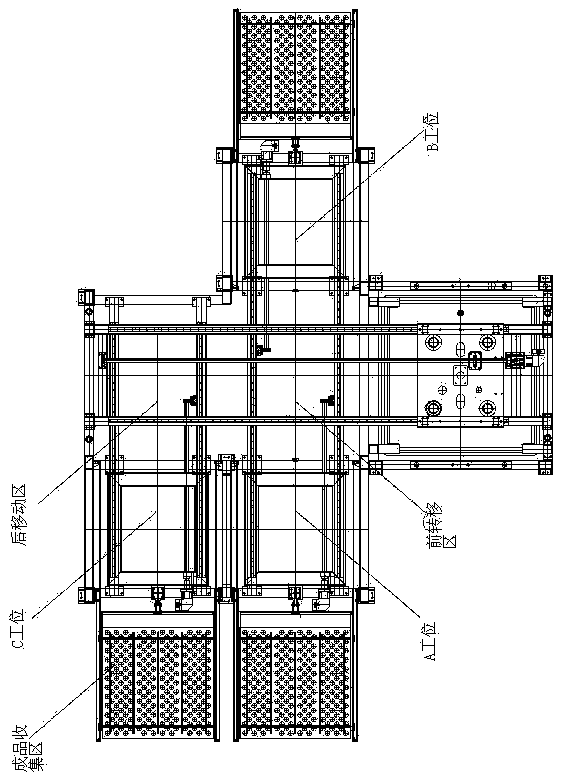

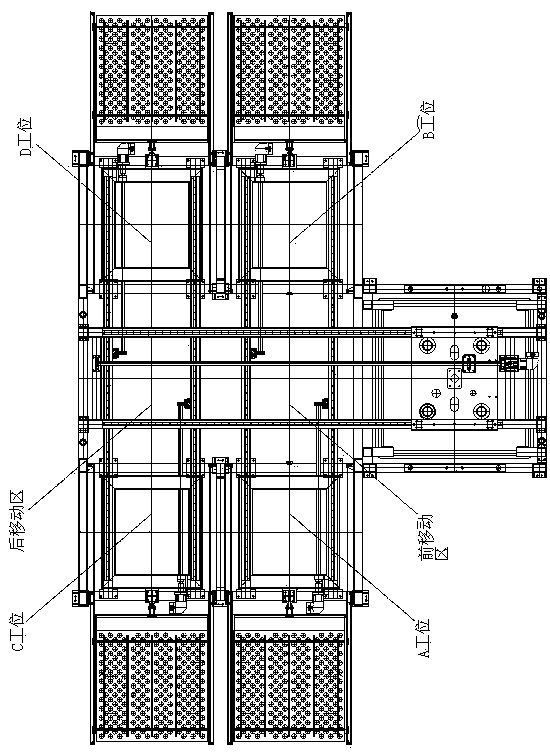

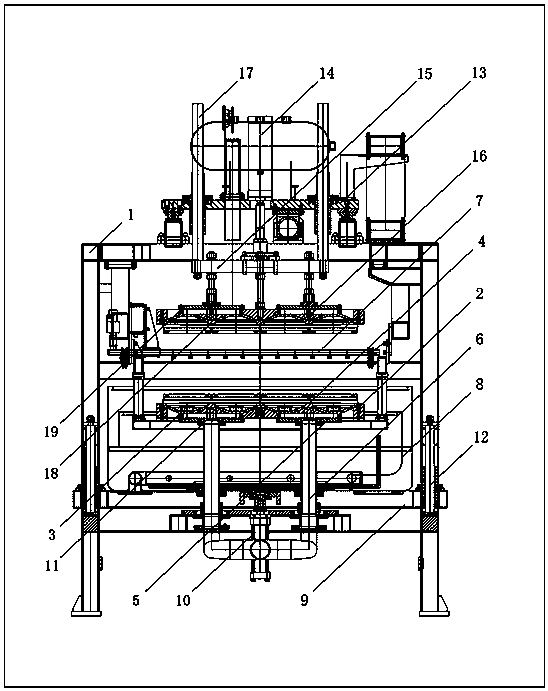

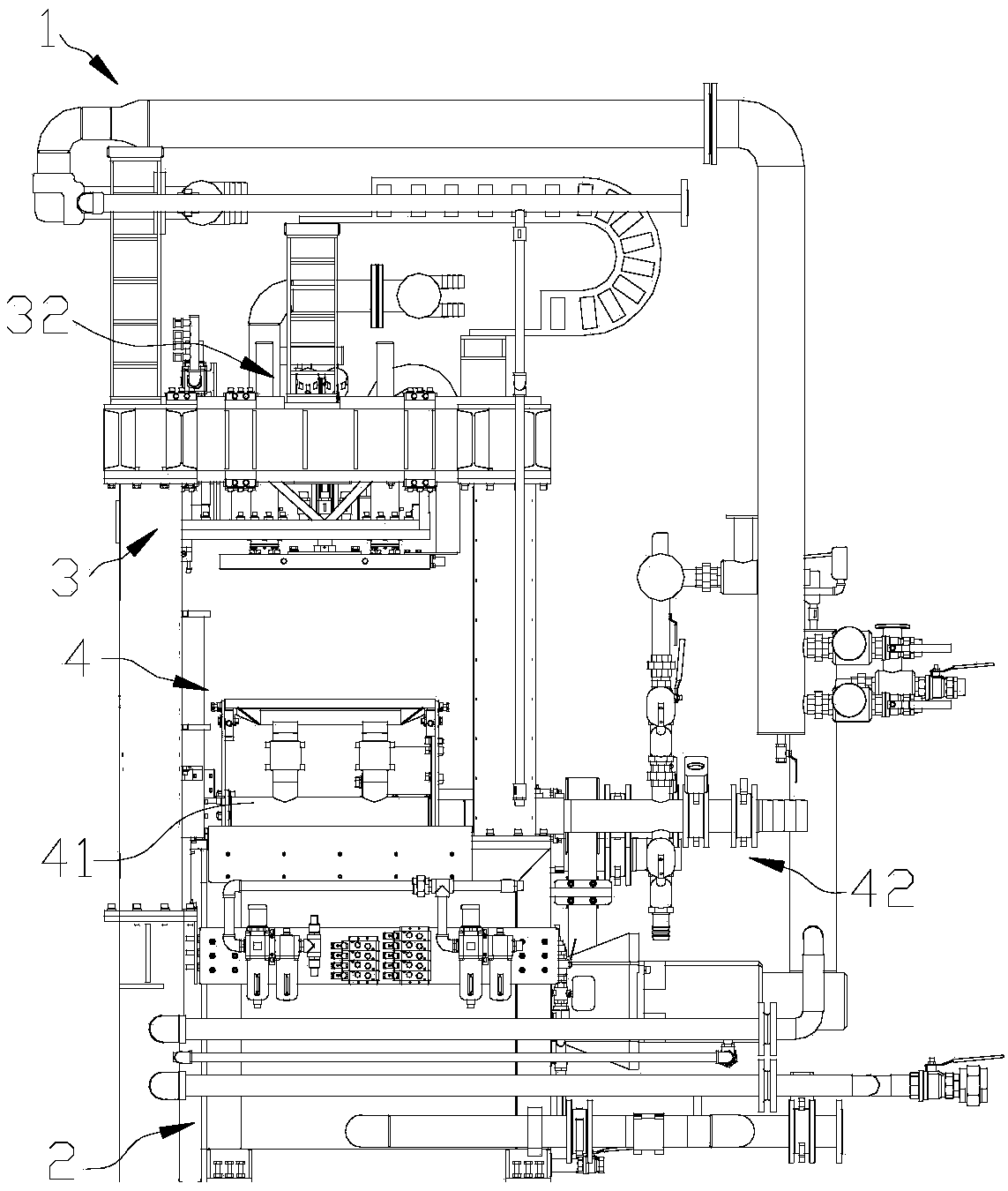

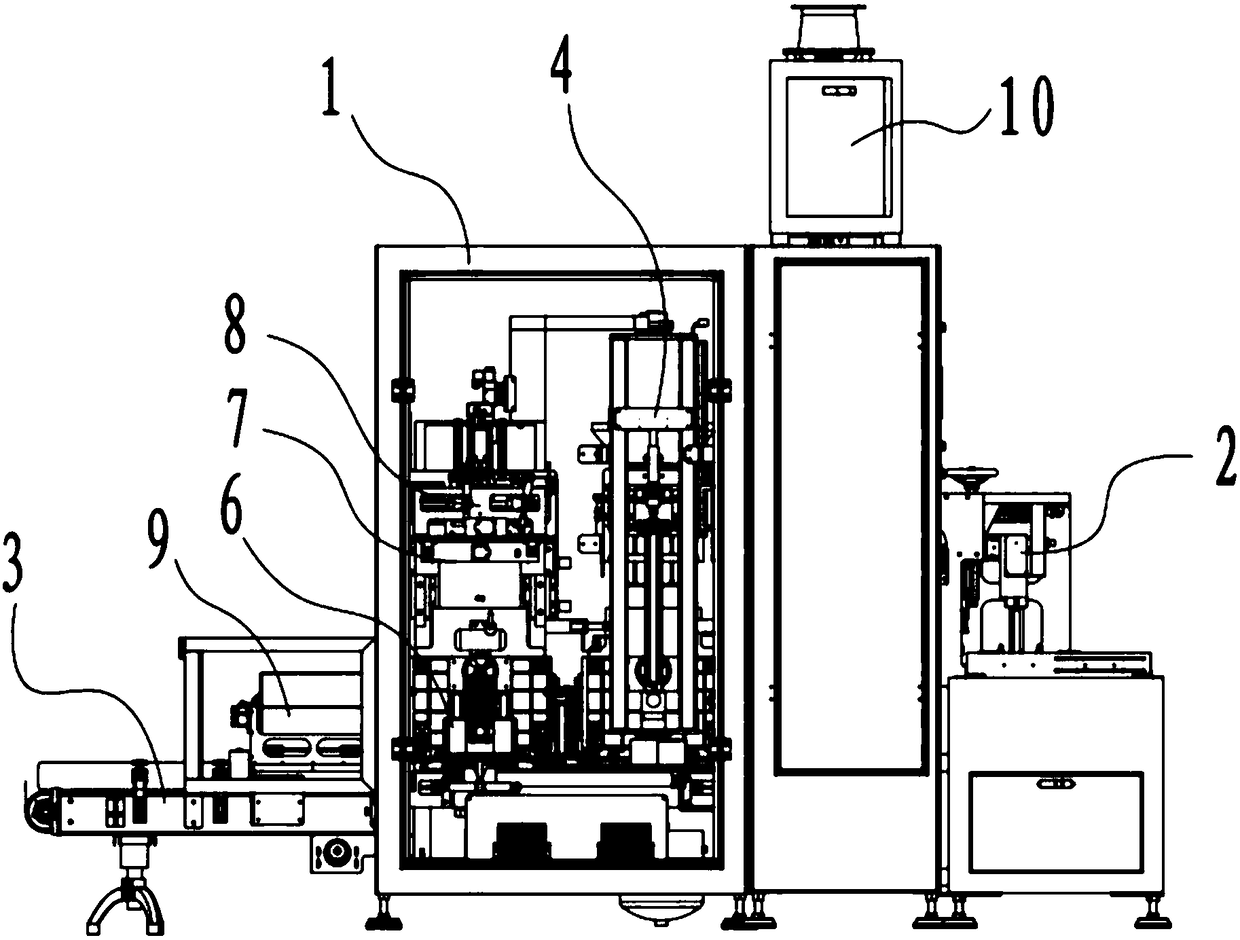

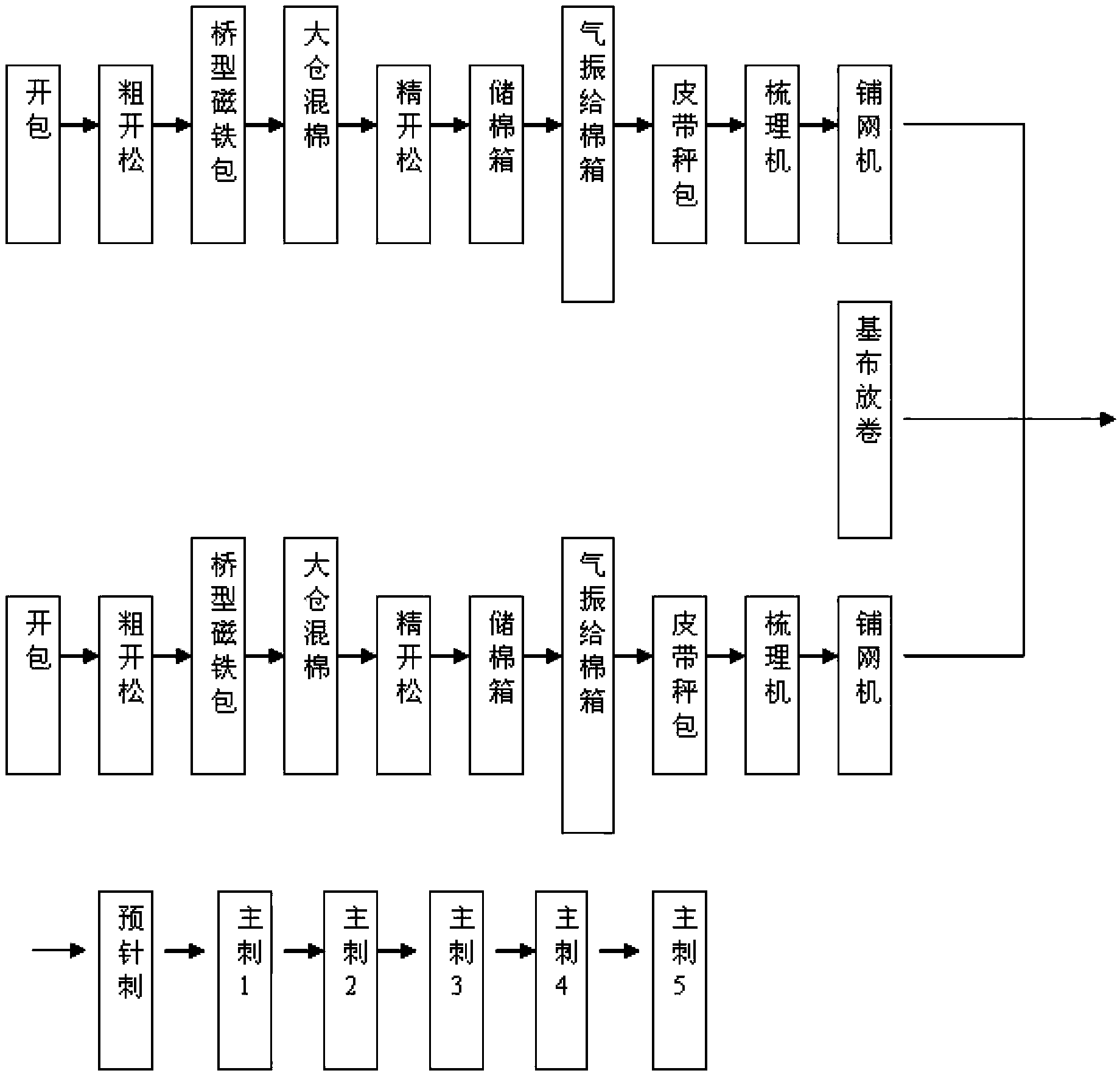

Full-automatic multi-station integrated pulp molding equipment and production technology

ActiveCN106638164AQuality improvementUniform slurryTextiles and paperShell moldingPulp and paper industry

The invention belongs to the field of pulp molding product production equipment in a papermaking technique. Full-automatic multi-station integrated pulp molding equipment comprises an electric-heat conduction oil universal heating device, a steam heating device, a pulp chest homogenizing device, an adsorptive molding device, hot-press sizing devices, a first kind product collection device not needing stacking and a second kind product collection device capable of automatically conducting stacking; a groove is formed in a molding template of the molding device, an airflow dispersion cover plate is installed over the groove, an airflow main pipeline is vertically installed, a deckle edge spraying and template cleaning device is independently installed, heating plates of the molding devices are fixed to an upper molding template and a lower molding template through heat insulation plates, the upper molding template achieves multi-point pressurizing through a pressure stabilizing frame, the lower molding template is fixed to a transverse tackle, and heat deformation of the heating plates is effectively controlled by the molding templates. The equipment is suitable for large-scale production of pulp molding products, few molds are used, and the molds are unified and easy to replace.

Owner:许洪涛 +1

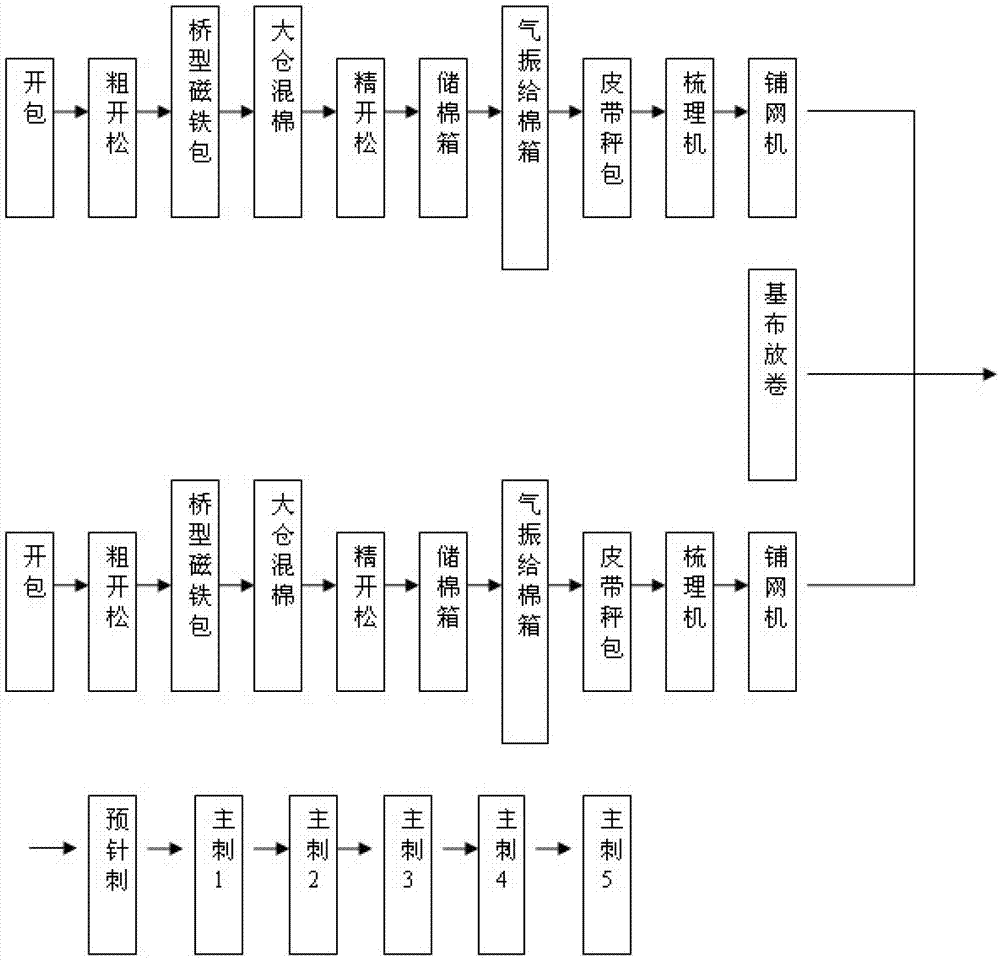

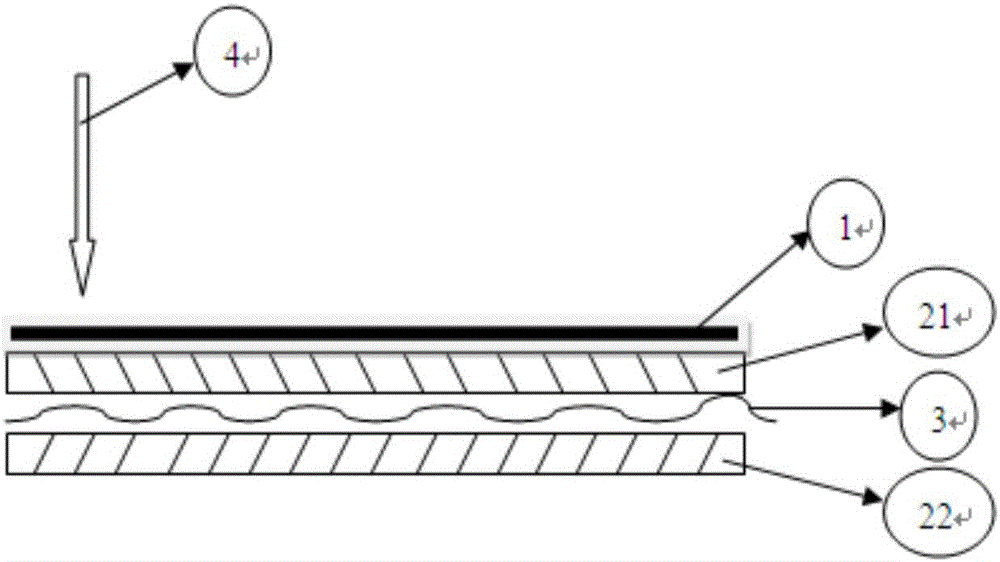

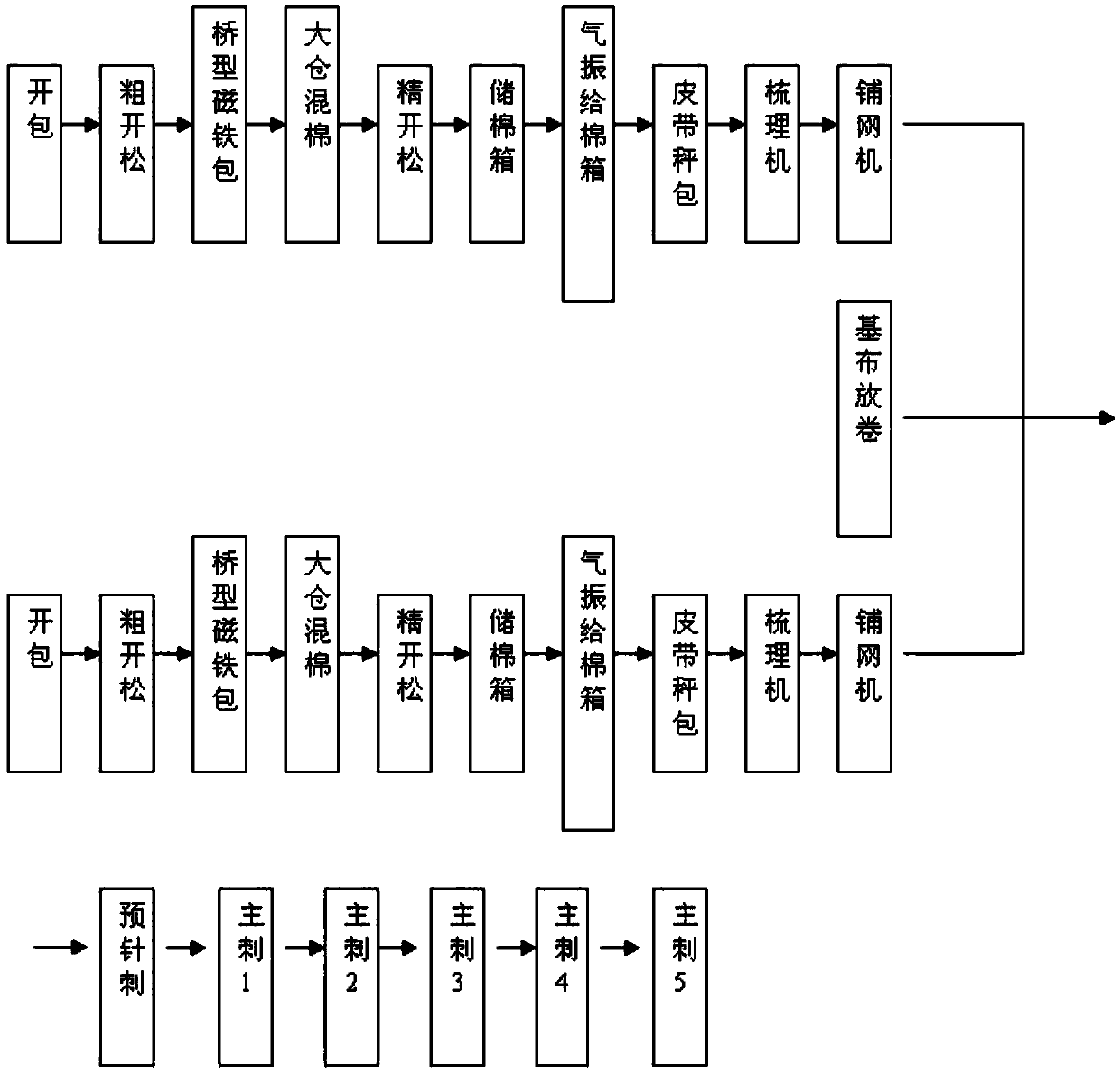

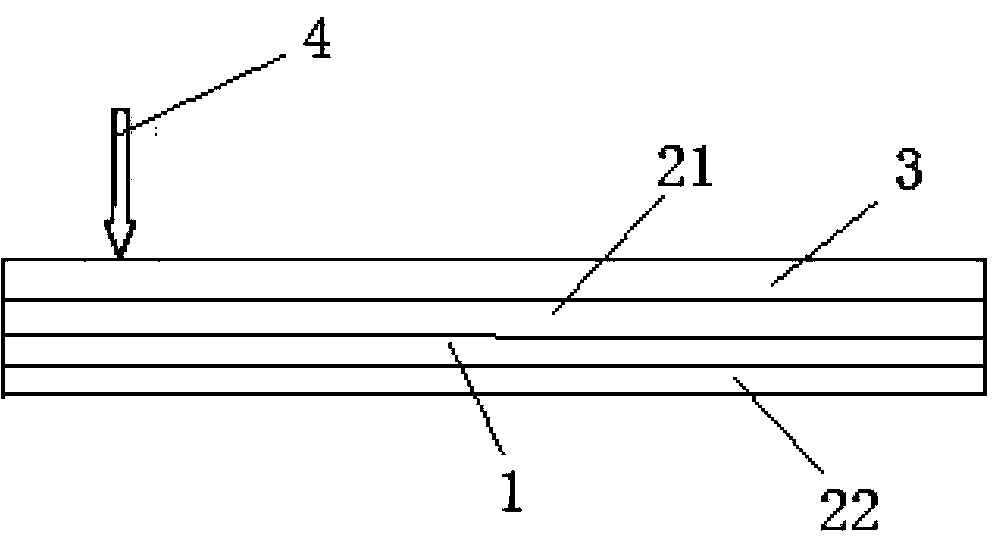

Flue gas purifying filter material for semi-dry desulphurization and preparation method thereof

ActiveCN106582112AGood dimensional stabilityImprove antioxidant capacityHuman health protectionGas treatmentFiltrationCorrosion

The invention discloses a flue gas purifying filter material for semi-dry desulphurization and a preparation method thereof. The flue gas purifying filter material for semi-dry desulphurization is compounded by an expanded polytetrafluoroethylene micropore thin layer and a blended needled felt layer; the blended needled felt is compounded by a blended composite dust facing surface layer, a corrosion resisting enhanced base cloth layer and a blended composite gas cleaning surface layer which are connected in order, wherein the expanded polytetrafluoroethylene micropore thin layer and the blended composite dust facing surface layer are connected. The flue gas purifying filter material for semi-dry desulphurization has warp and weft strength which are higher than 900N / 50mm, warp and weft elongation at break which are less than 15%, and high dimension stability; the filter material can tolerate high temperature which is 250 DEG C or above, and application temperate is wide; corrosion resistance is good, and inoxidizability is good; the polytetrafluoroethylene film has smooth surface, and dust-cleaning efficiency is high and reaches 99.999%; the filter material has the advantages of low friction, flame retardancy, insulating properties, and heat insulation property; the material has long service life; and the material has high filtering efficiency, high filtration accuracy, water resistance and corrosion resistance.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

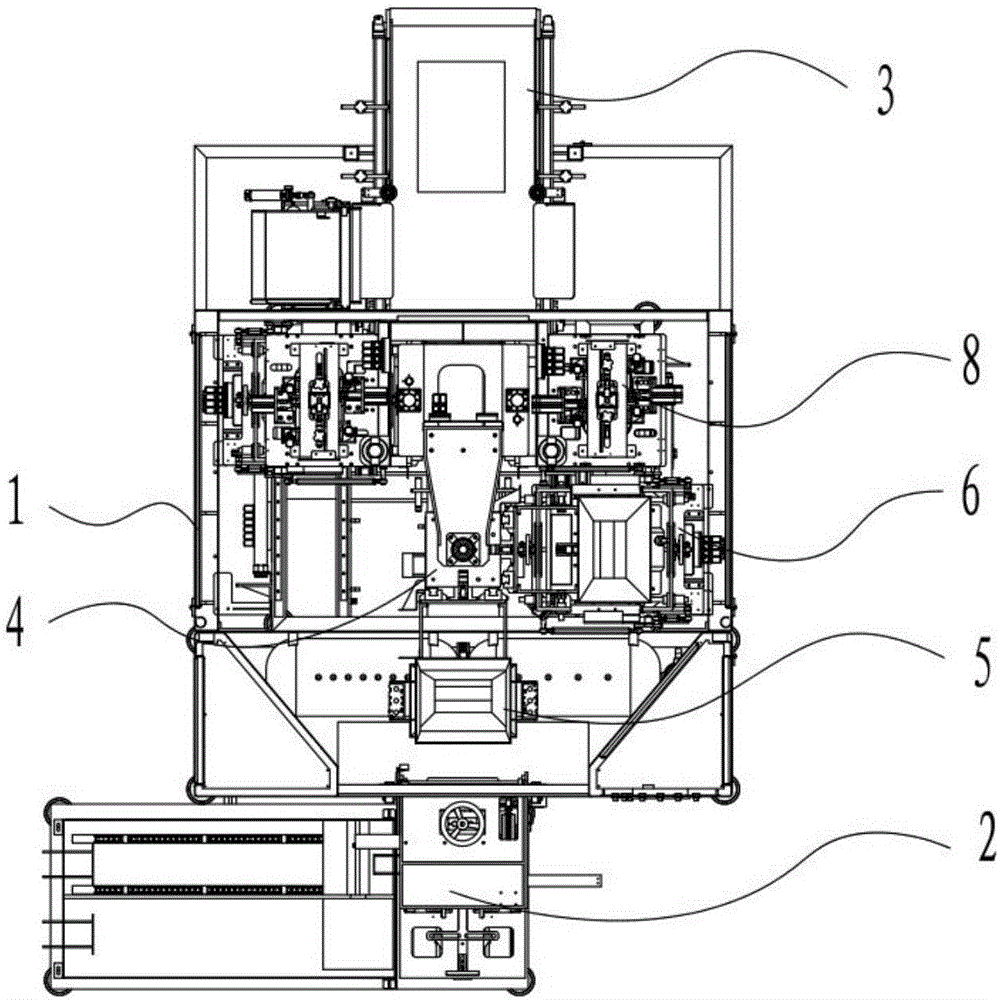

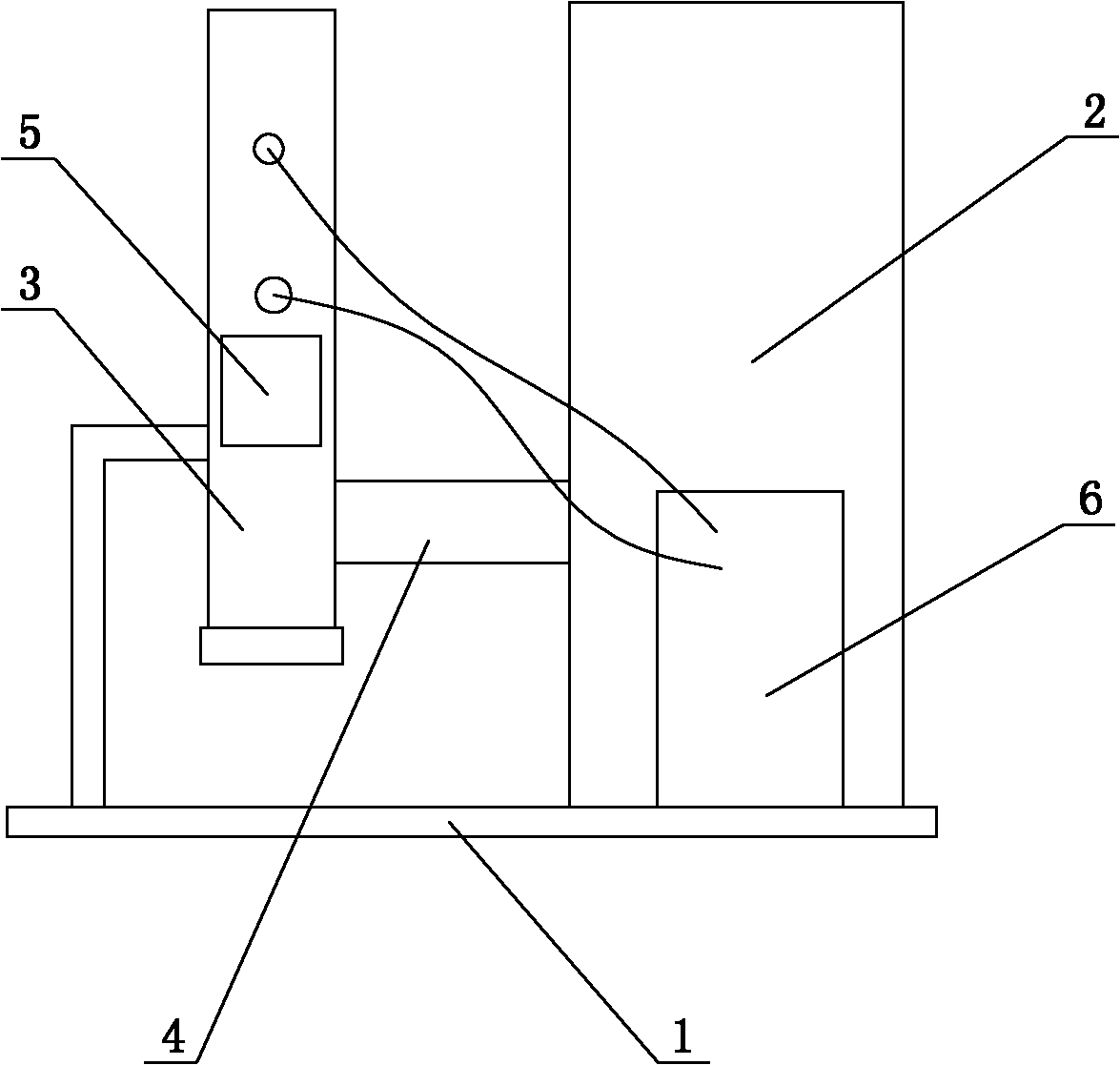

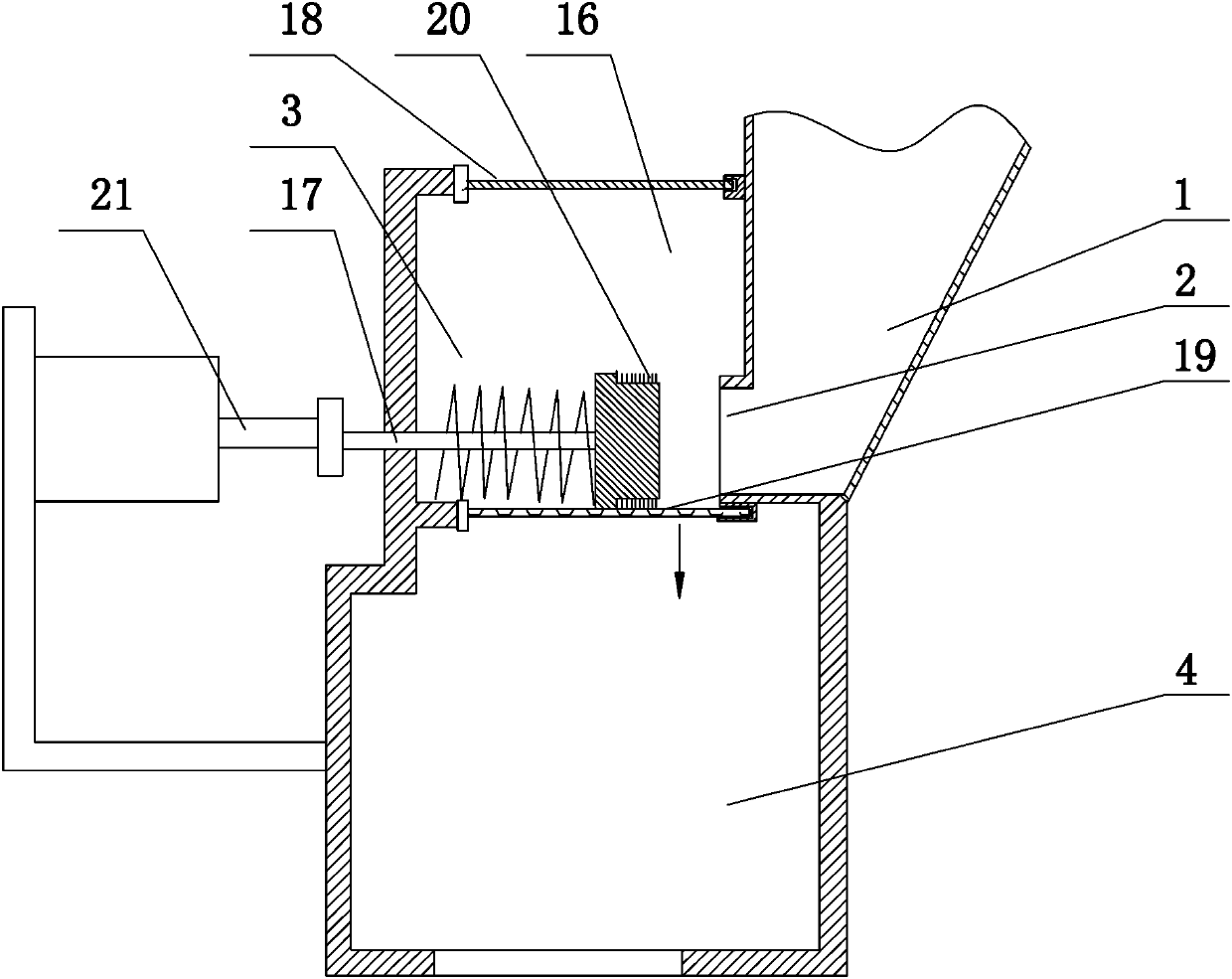

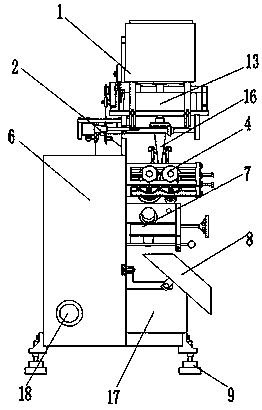

Rotating filling six-sided vacuum shaping packaging machine

InactiveCN106240852ASmall weight deviationIncrease production capacityPackaging by pressurising/gasifyingSolid materialEngineeringElectric control

The invention discloses a rotating filling six-sided vacuum shaping packaging machine. The rotating filling six-sided vacuum shaping packaging machine comprises a machine frame, an electric control box, and a bag feeding mechanism and an output mechanism which are respectively arranged on the two opposite sides of the machine frame; a rotating mechanism, a pair of filling mechanisms, a metering discharging mechanism, and a pair of shaping packaging mechanisms and a pair of vacuumizing mechanisms which are oppositely arranged on the two sides of the metering discharging mechanism are also arranged on the machine frame in the direction from the bag feeding mechanism to the output mechanism; each filling mechanism is driven to perform position exchanging movement between the position above the metering discharging mechanism and the position above the corresponding shaping packaging mechanism through the rotating mechanism; a bag outlet mechanism is also arranged on the machine frame; a packaged finished product is conveyed onto the output mechanism by utilizing the bag outlet mechanism; the electric control box is arranged outside the machine frame and is electrically connected with the bag feeding mechanism, the output mechanism, the rotating mechanism, the filling mechanisms, the metering discharging mechanism, the shaping packaging mechanisms, the vacuumizing mechanisms, a bag poking and sealing mechanism and the bag outlet mechanism; various mechanisms can be subjected to cooperative adjustment conveniently and quickly through the electric control box, so that the packaging efficiency of the packaging machine is higher.

Owner:ZHANGZHOU YUJIE AUTOMATIC PACKING MACHINERY CO LTD

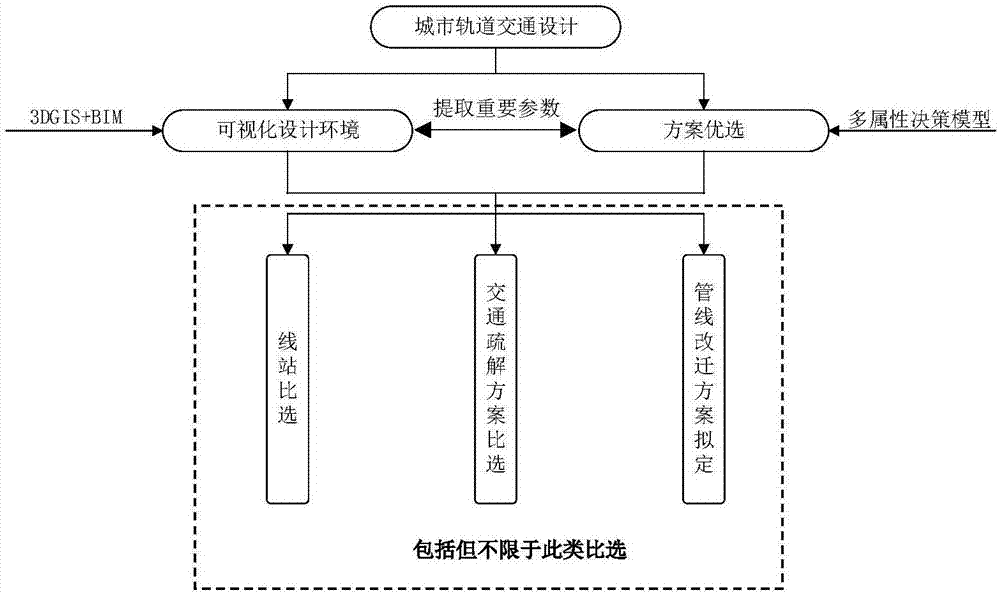

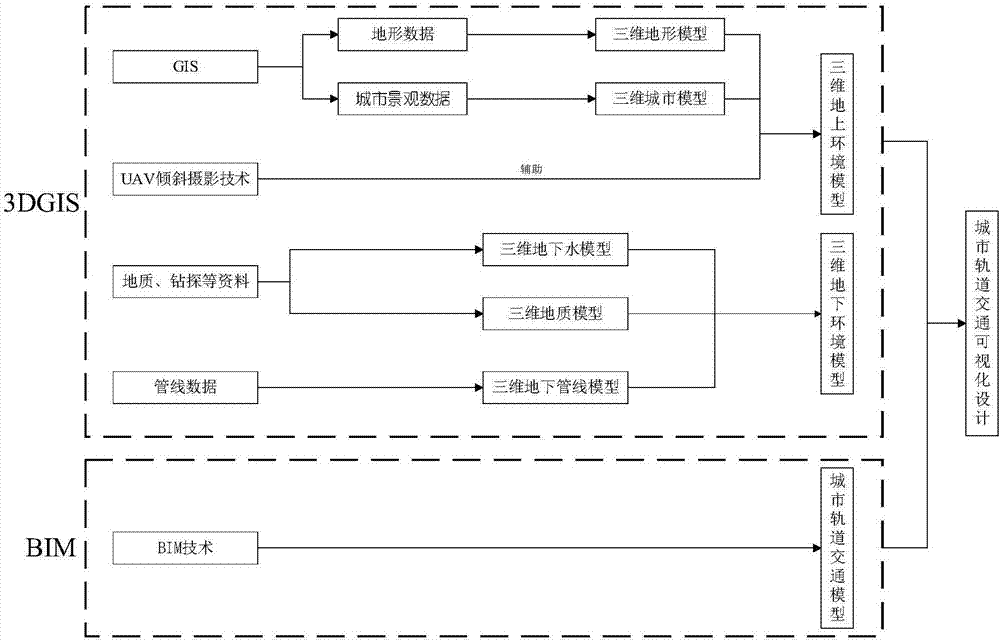

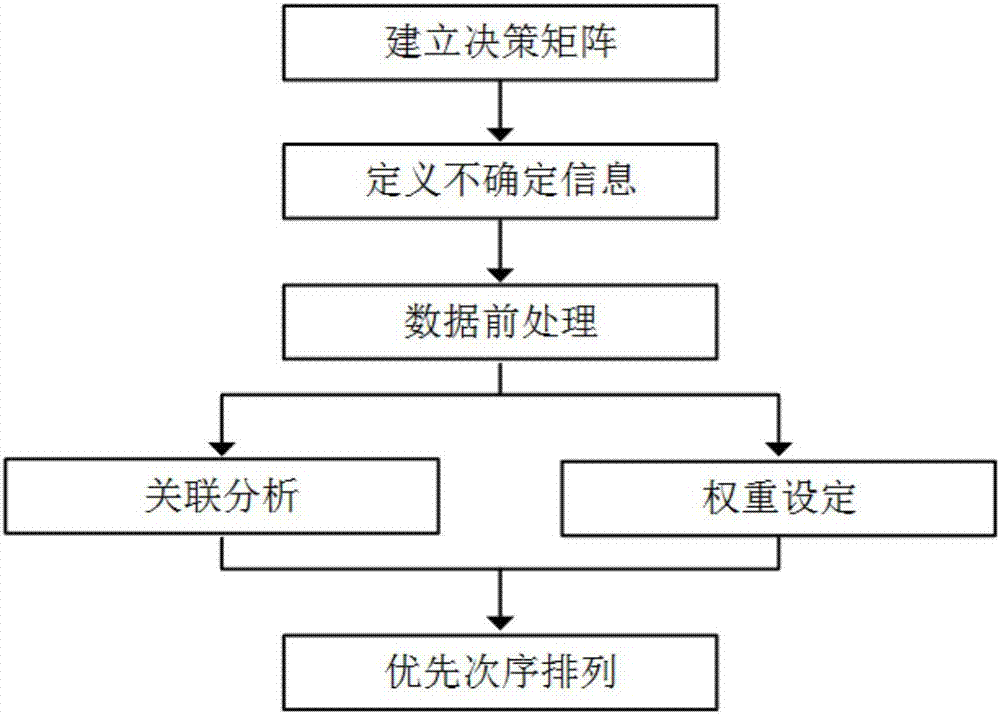

Rail transit solution comparison and selection method based on 3DGIS+BIM technology

InactiveCN107368921ARich relevant informationMake up for the lack of GIS detailsForecastingResourcesDecision modelEngineering

The present invention discloses a rail transit solution comparison and selection method based on the 3DGIS+BIM technology. The main work comprises: carrying out visual design by using the 3DGIS+BIM technology, constructing a multi-attribute decision-making model, and finally selecting the optimal solution. According to the method disclosed by the present invention, the BIM technology is combined with the 3DGIS technology, the BIM technology has characteristics of fine displaying and rich information, makes up for the deficiencies of the lack of GIS details, and provides useful supplement for the more in-depth application of the GIS technology; necessary information data is extracted from the 3DGIS+BIM model as important parameters of the multi-attribute decision-making model; and the multi-attribute decision-making model is constructed, the decision-making model is based on objective weight design rules, the weight is determined through a certain mathematical method, and compared with the weight obtained by the subjective weight assignment method, the deviation is less, so that the decision-making model can better reflect actual importance of multiple evaluation indicators.

Owner:成都亮紫智能科技有限公司

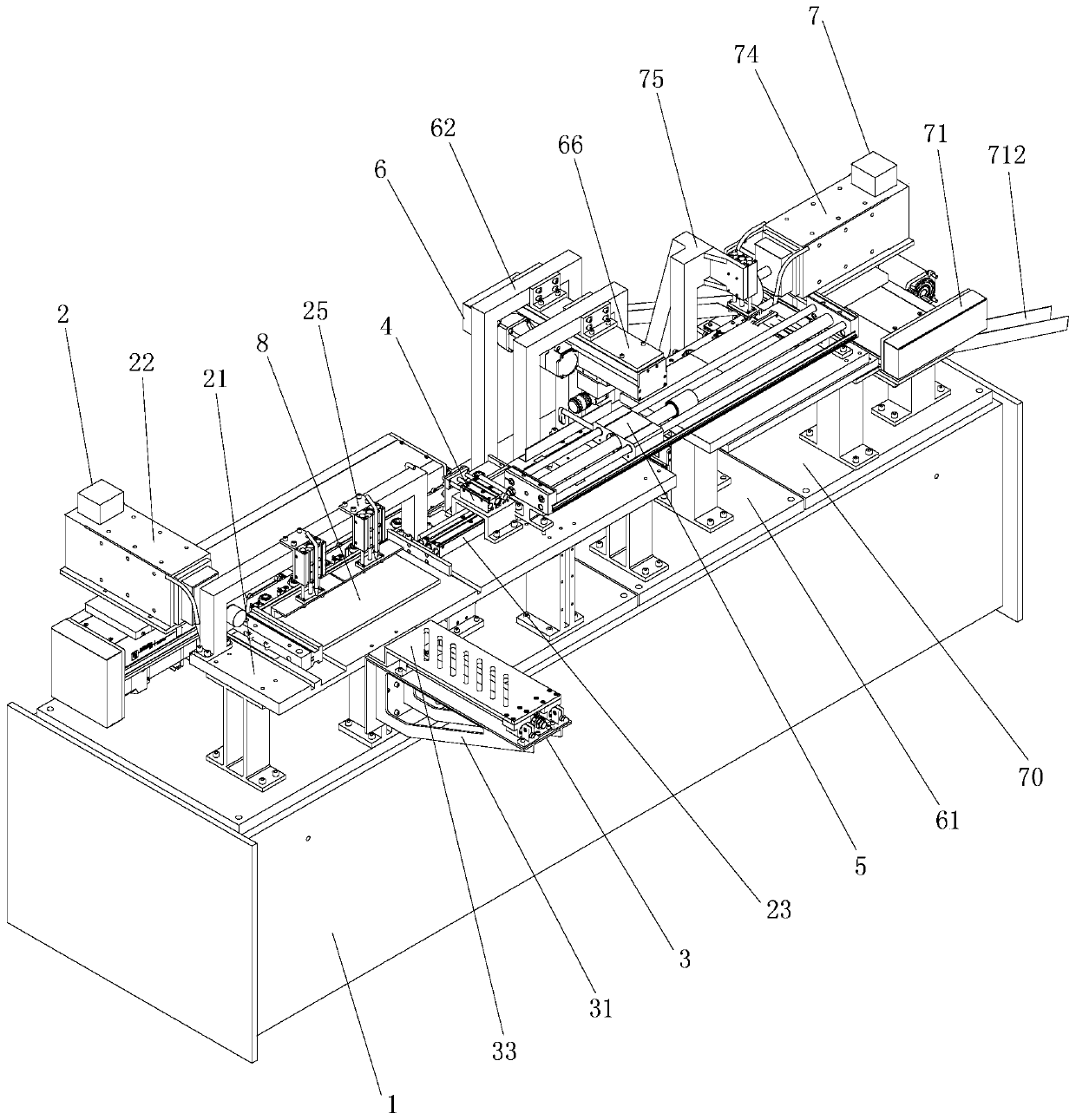

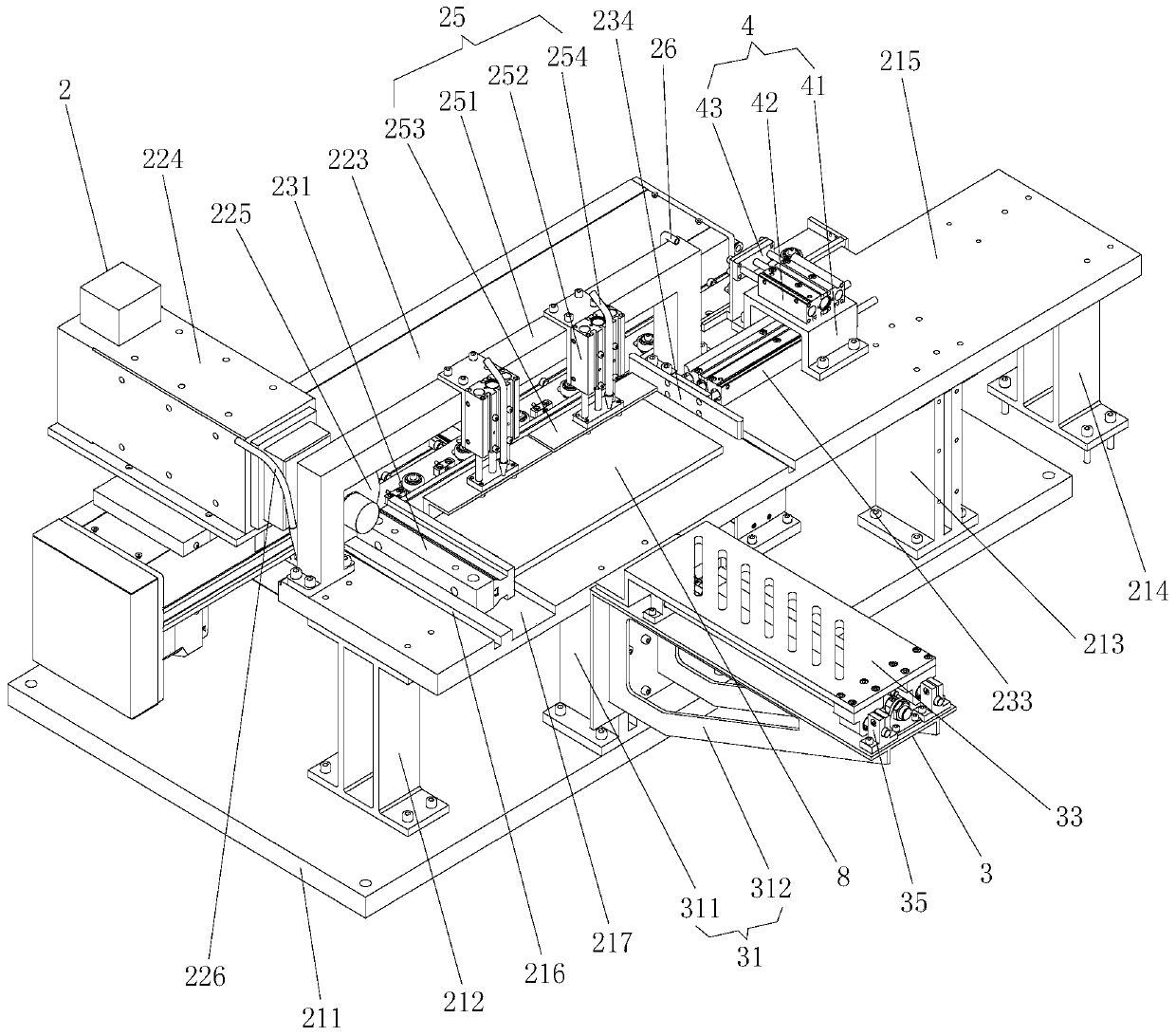

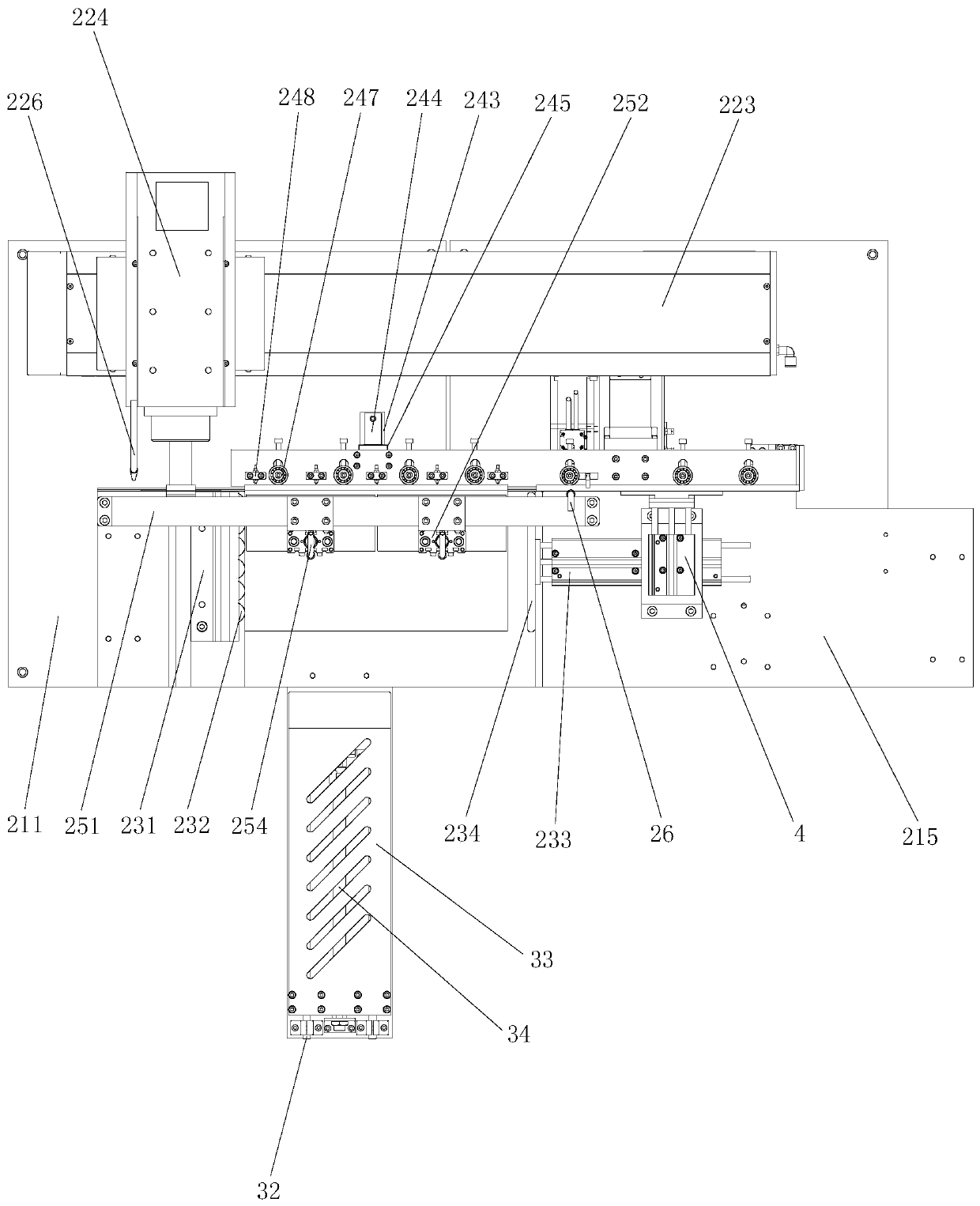

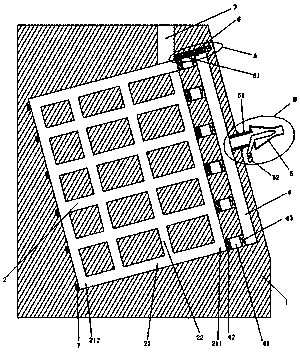

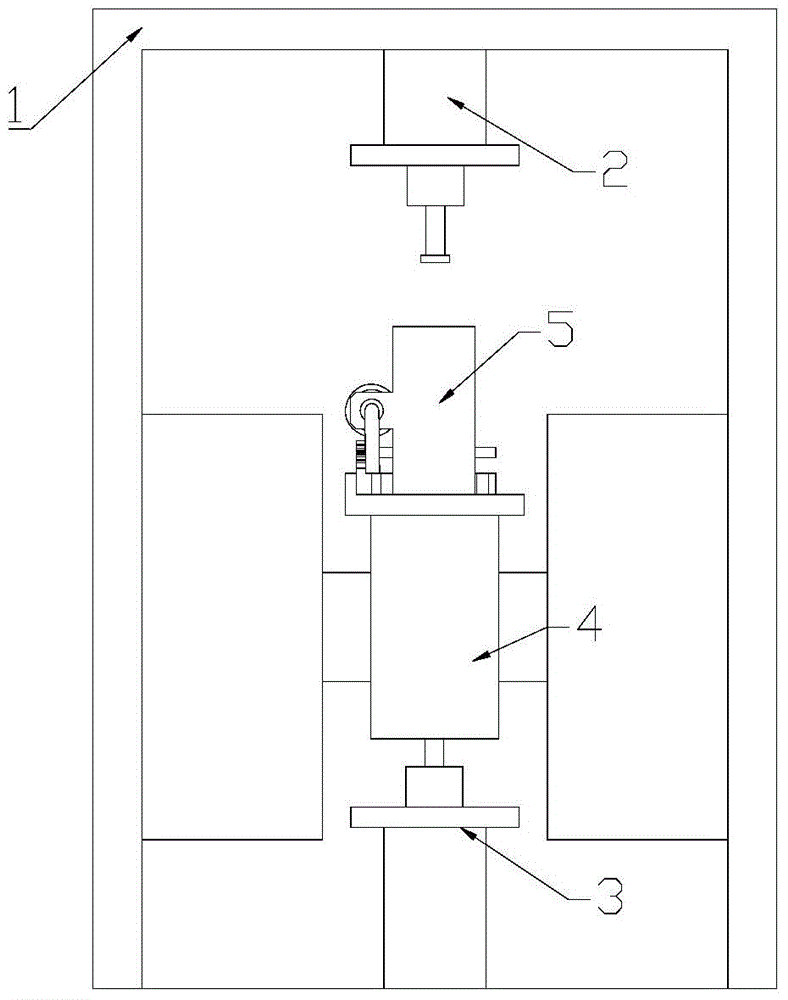

Multi-axis glass cutting apparatus

ActiveCN110156311AReasonable structural designCompact designGlass severing apparatusControl systemEngineering

The invention relates to a multi-axis glass cutting apparatus. The apparatus comprises a base, a strip cutting mechanism, a detecting mechanism, a dicing mechanism, a feeding mechanism, a cut strip setting mechanism, a PLC control system and a gas source system; the strip cutting mechanism comprises a strip cutting workbench, a strip cutting device, an X-direction positioning device, a Y-directionpositioning device, a Z-direction pressing device and a tail positioning device; the detecting mechanism is mounted at the outer side of an area between the strip cutting workbench and the dicing mechanism; the dicing mechanism is arranged on the top surface of the base at one side of a glass strip pushing mechanism; the feeding mechanism is arranged at one side end of the strip cutting workbenchand is matched with the position of the X-direction positioning device; the cut strip setting mechanism is arranged at the outer side of one end of the X-direction positioning device; and the glass strip pushing mechanism is arranged between the strip cutting workbench at the cut strip setting mechanism side and the dicing mechanism. The apparatus has the advantages of reasonable and compact structure design, simplicity and convenience in operation and use, meeting of the processing needs of different types of glass strips, adjustable cutting tool position, high cutting efficiency and good cutting effect.

Owner:CHENGDU UNIV OF INFORMATION TECH

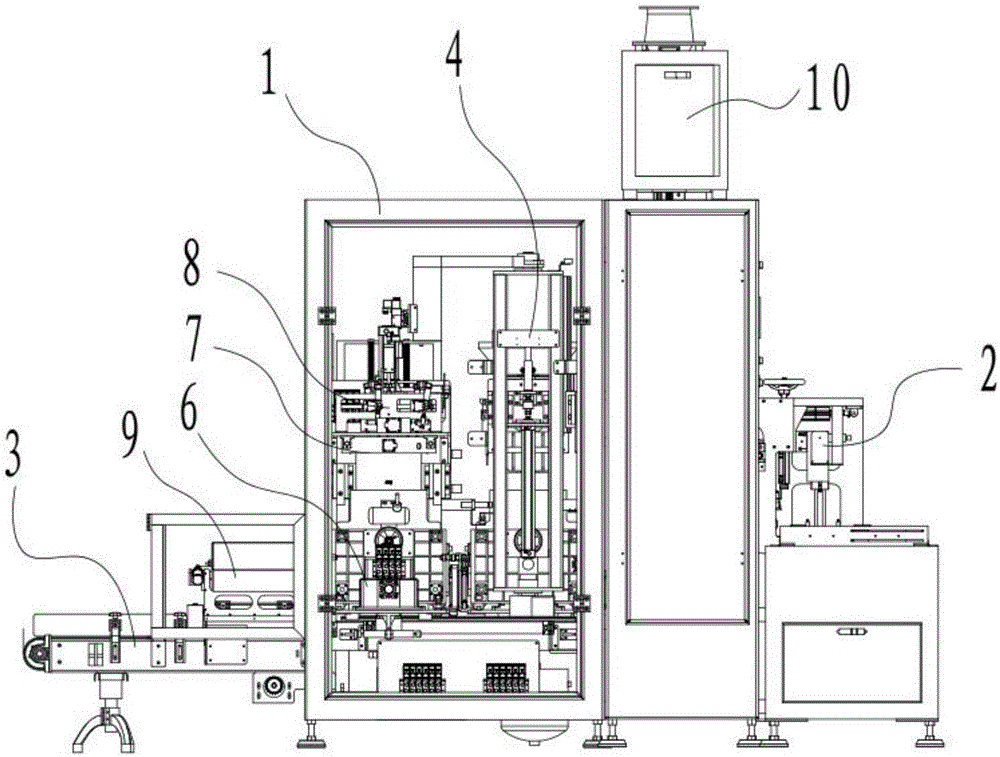

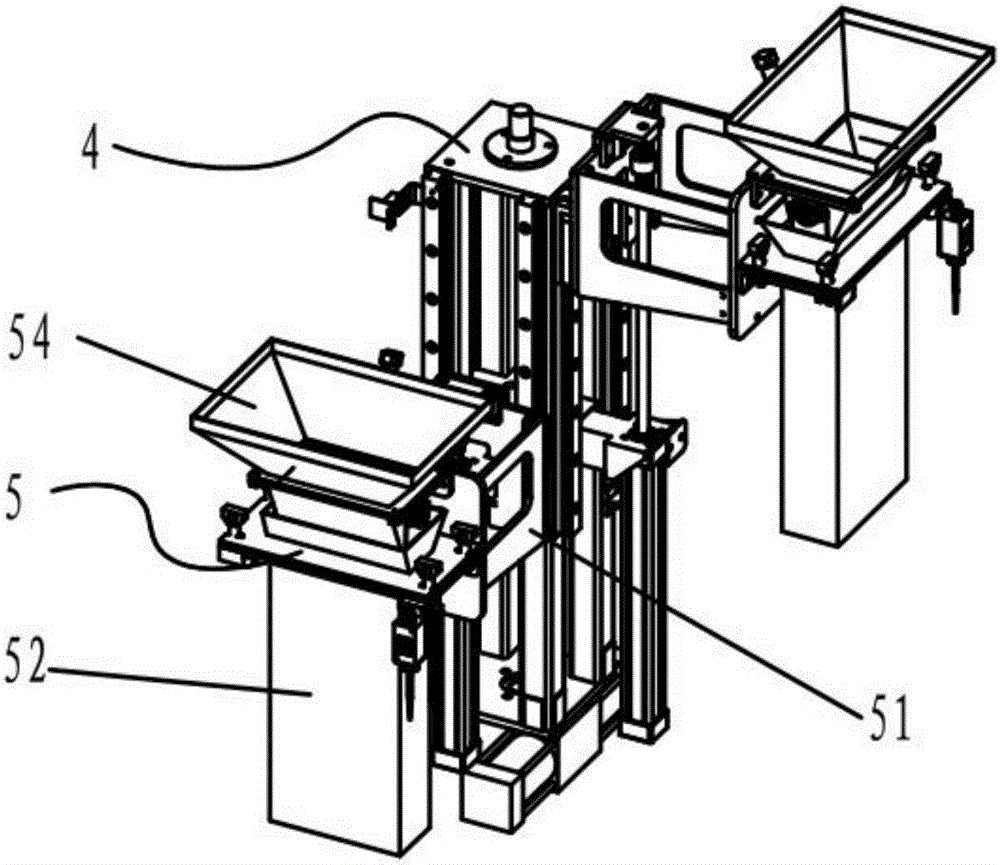

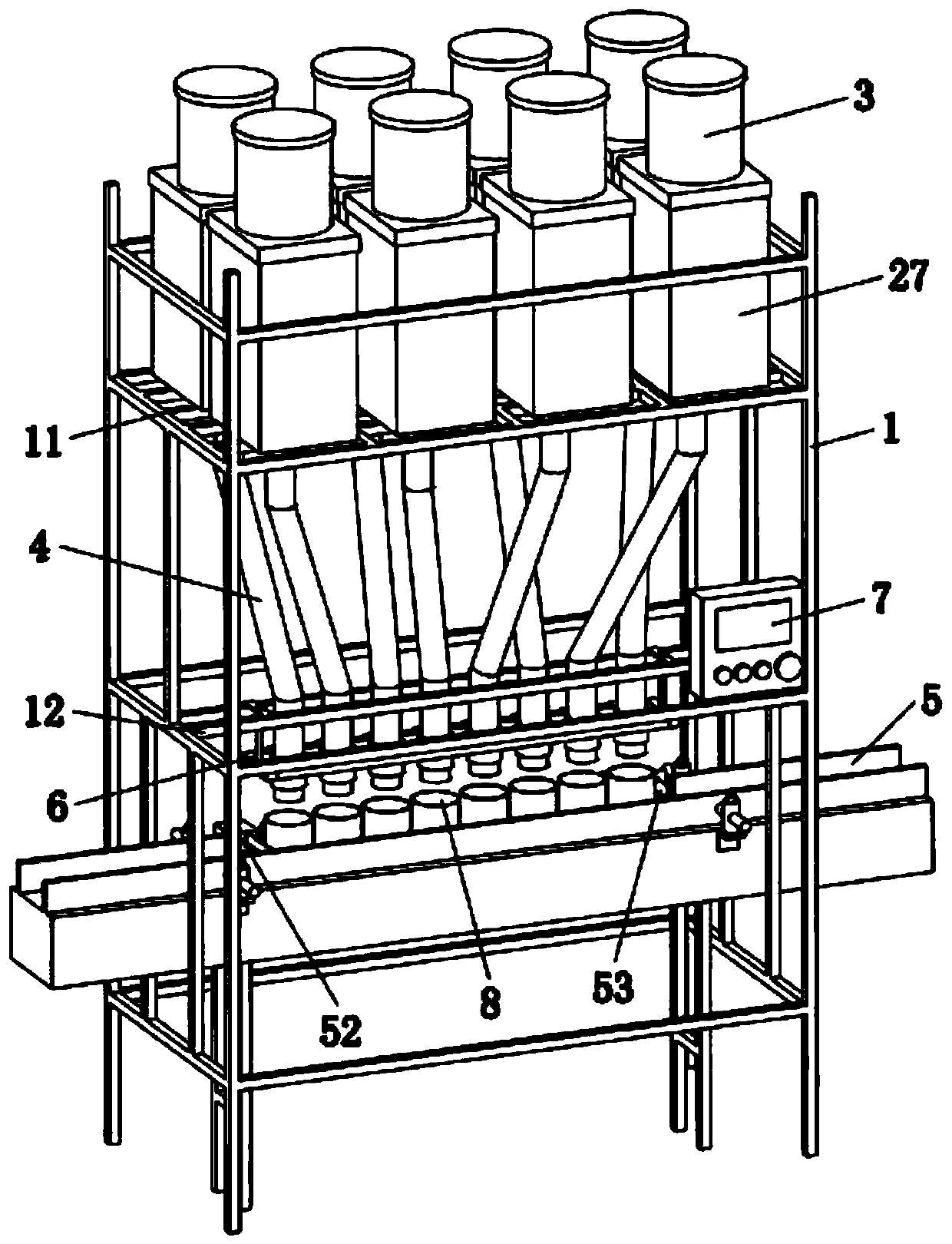

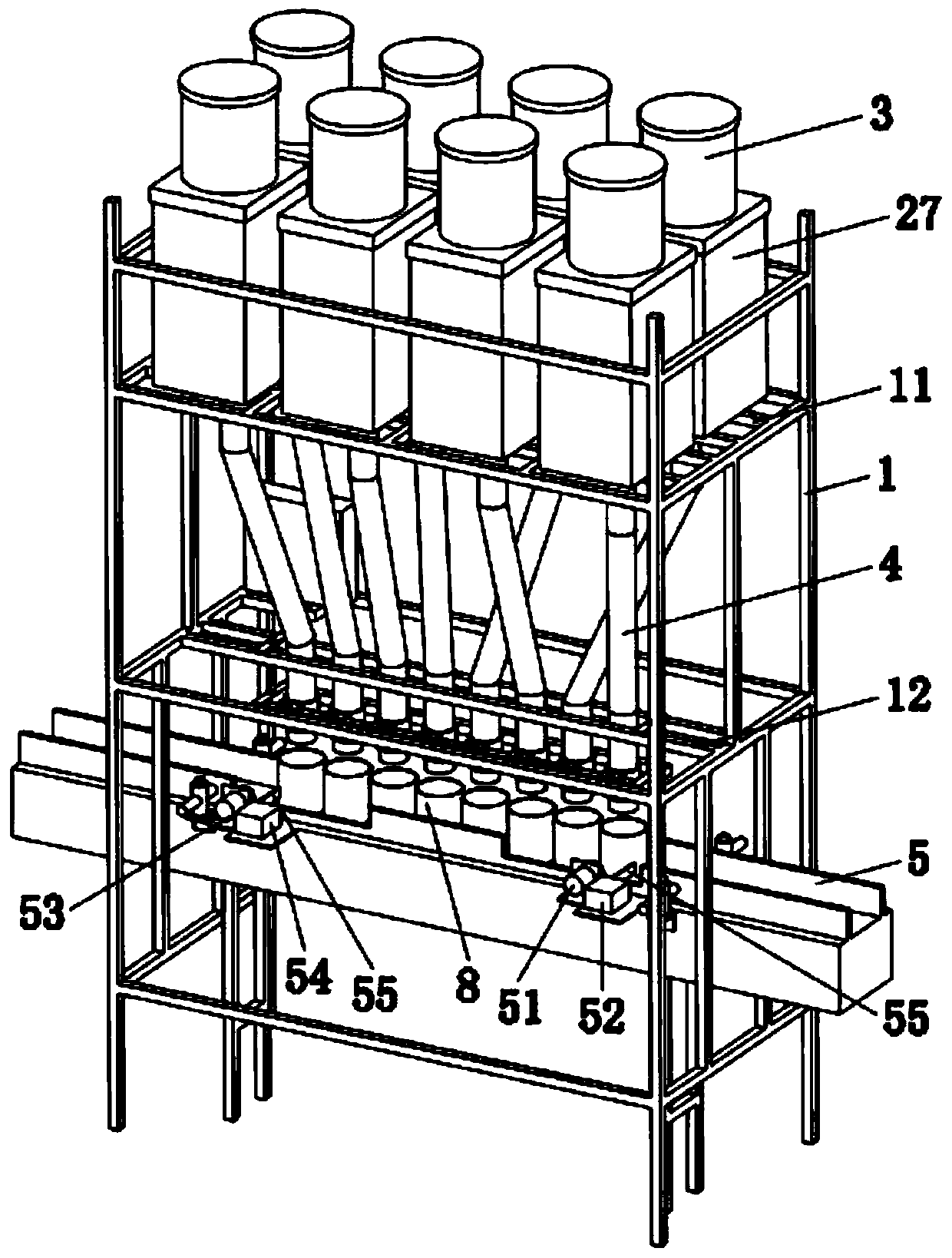

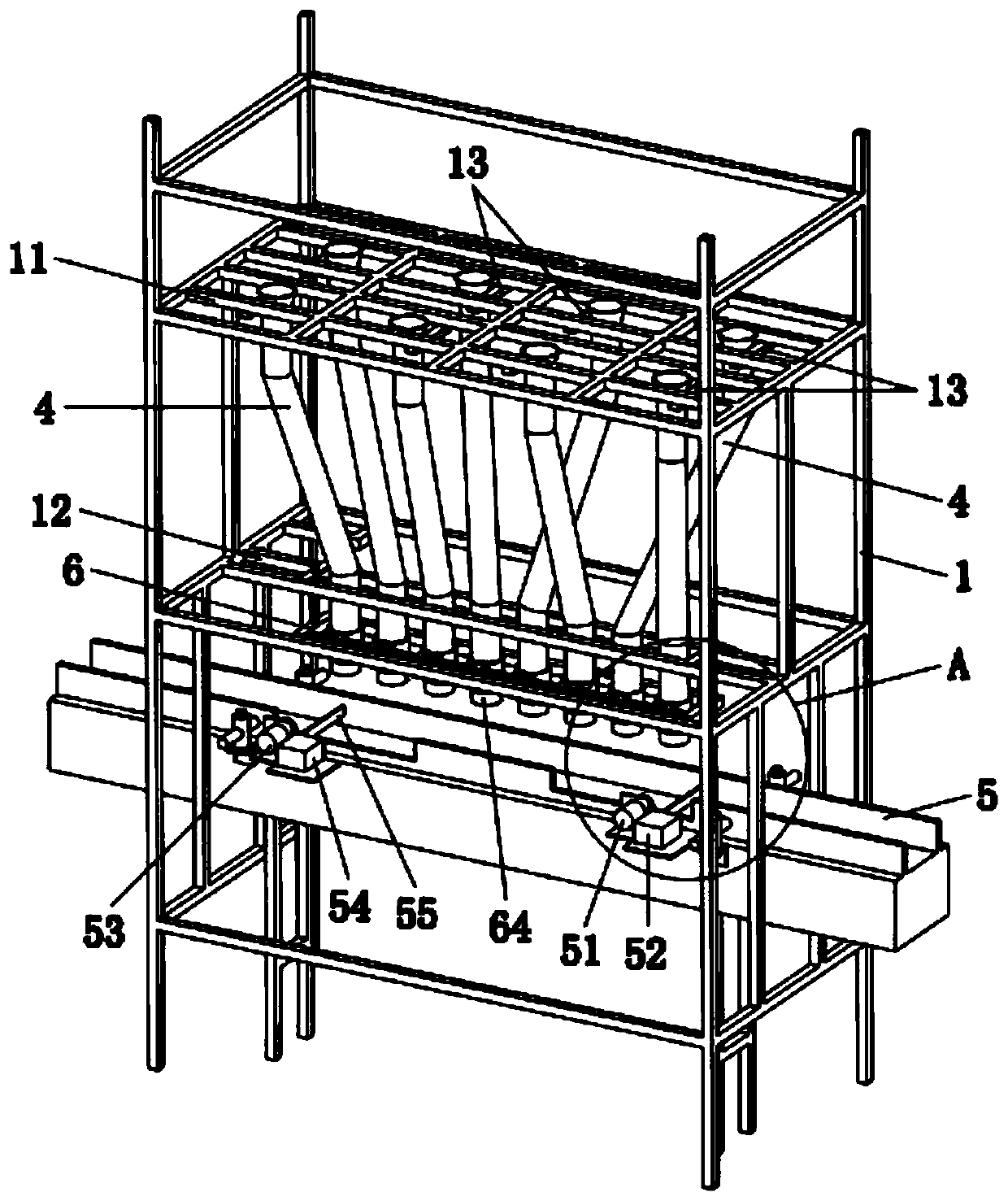

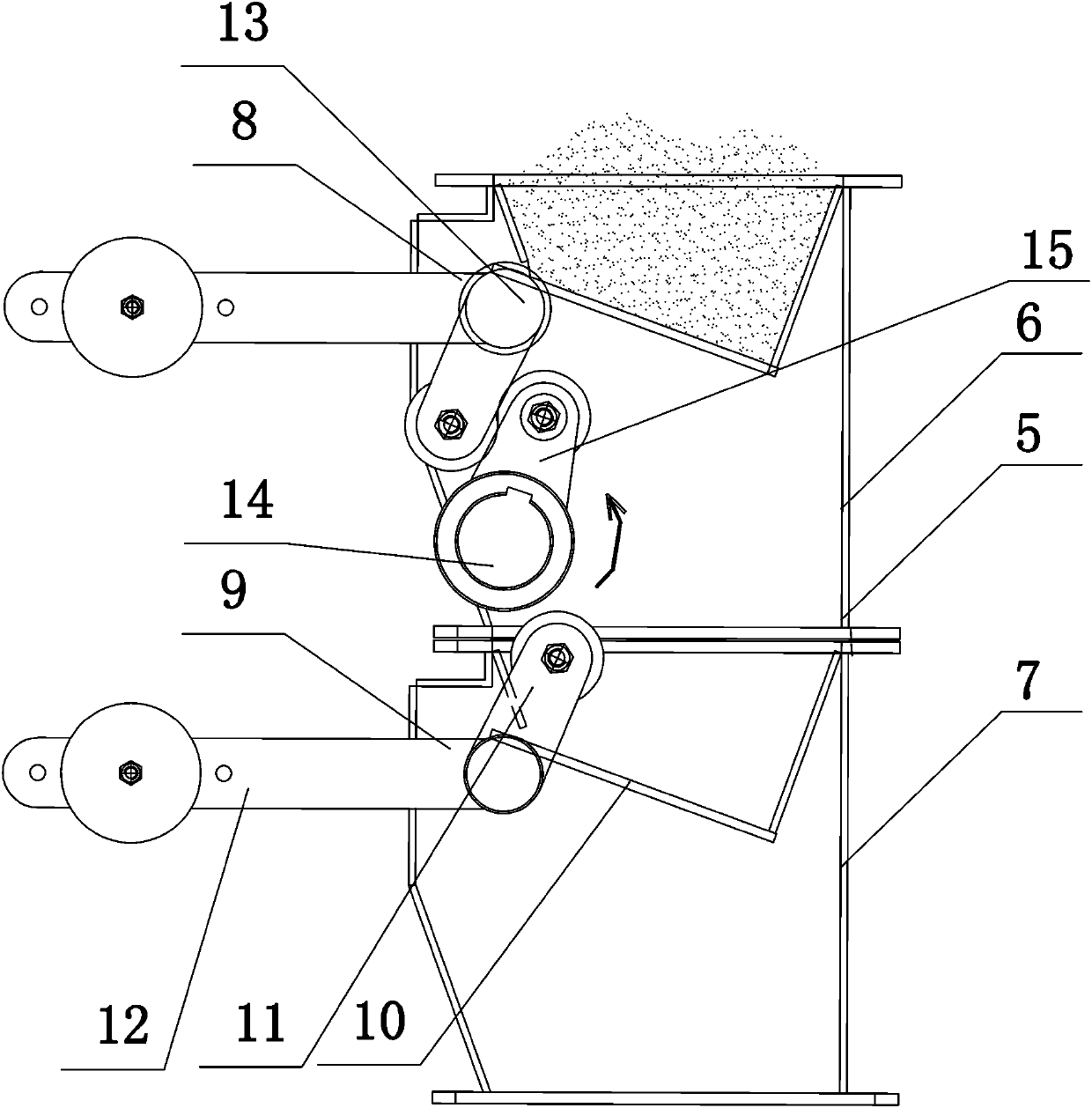

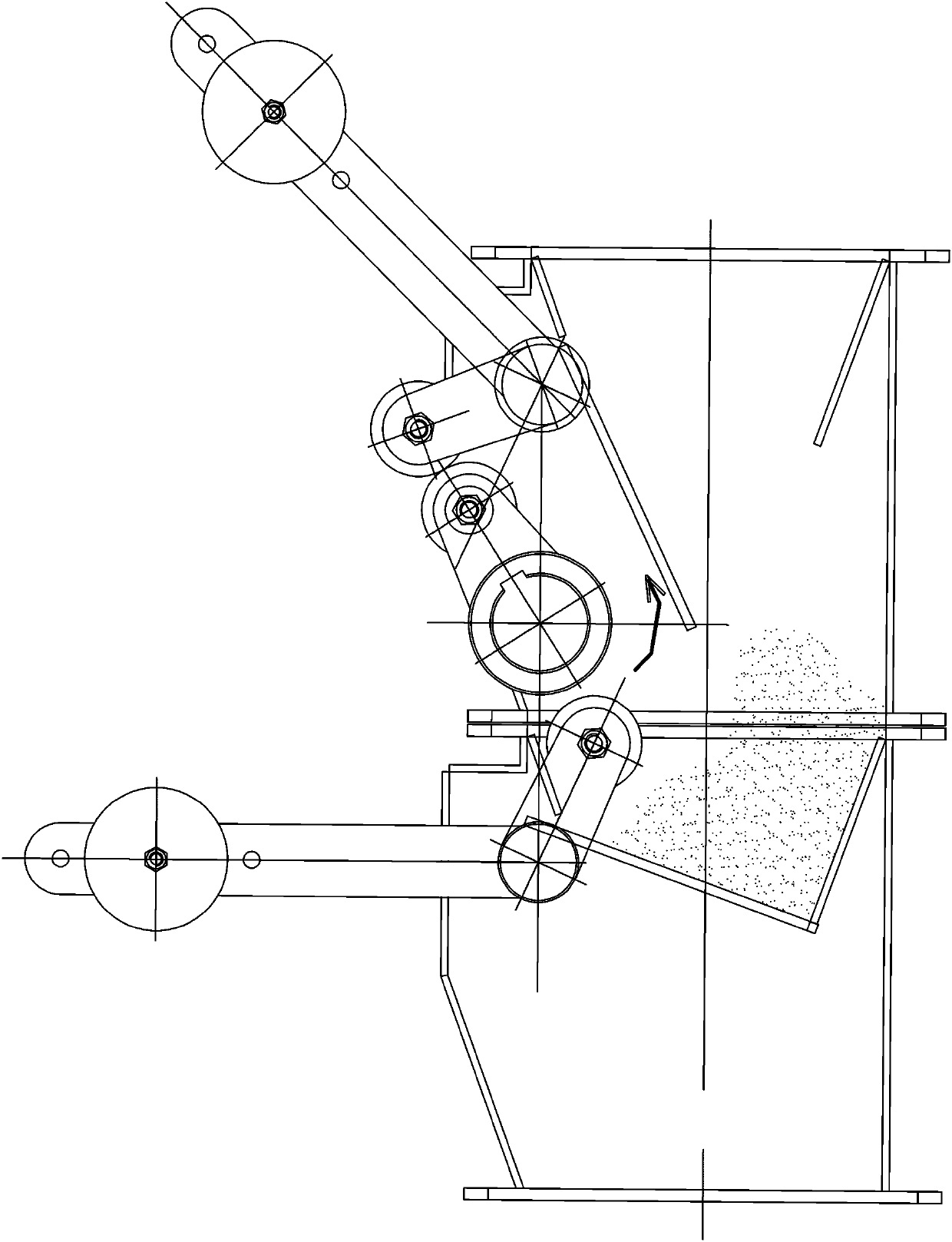

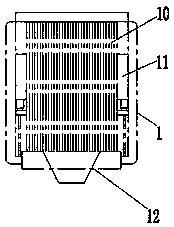

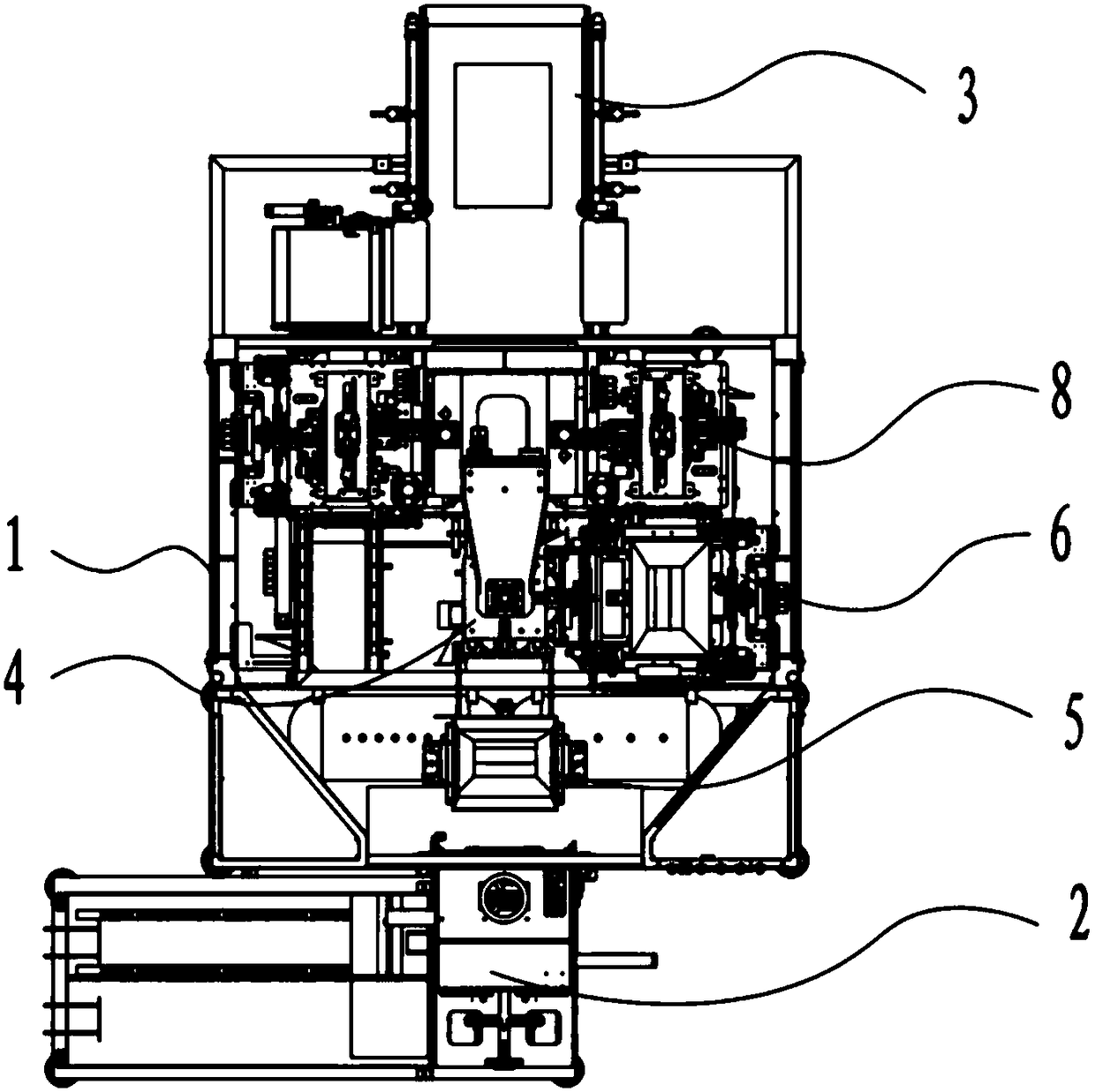

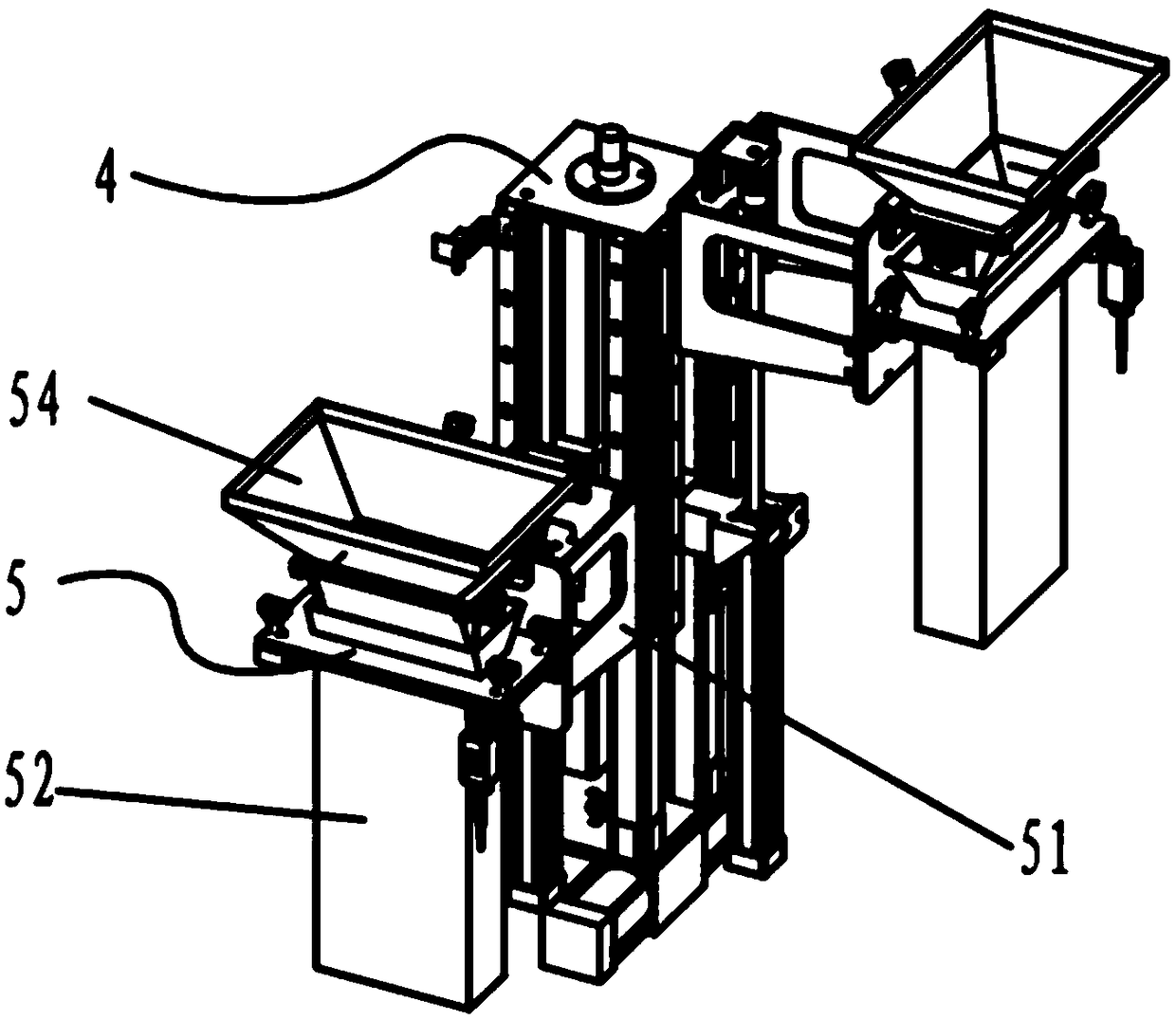

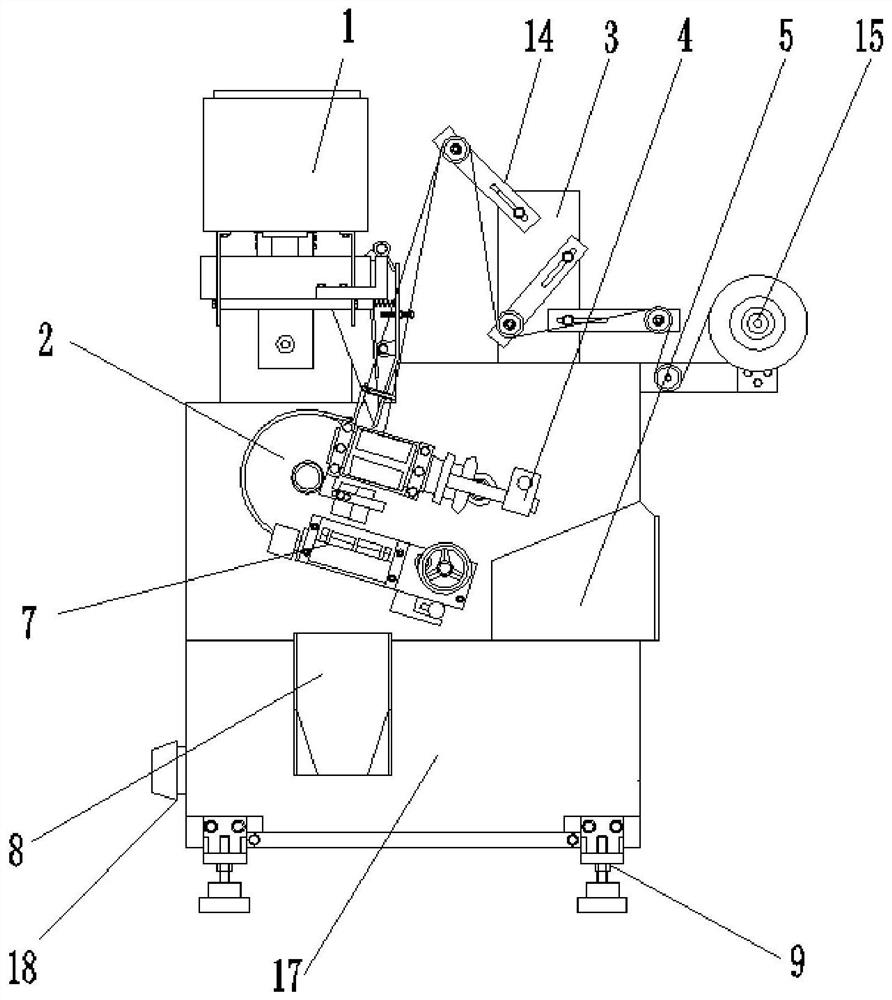

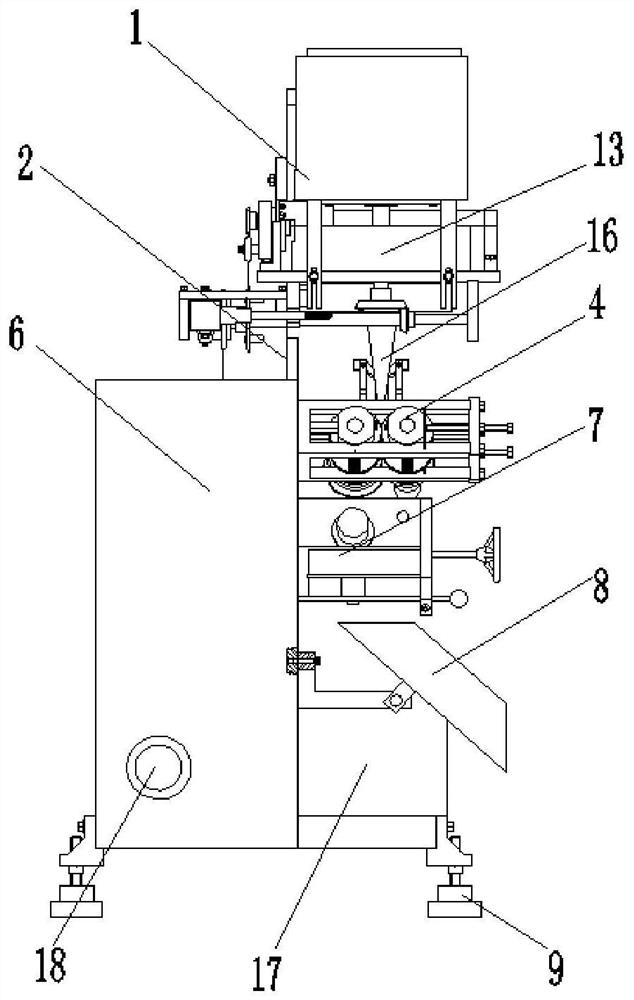

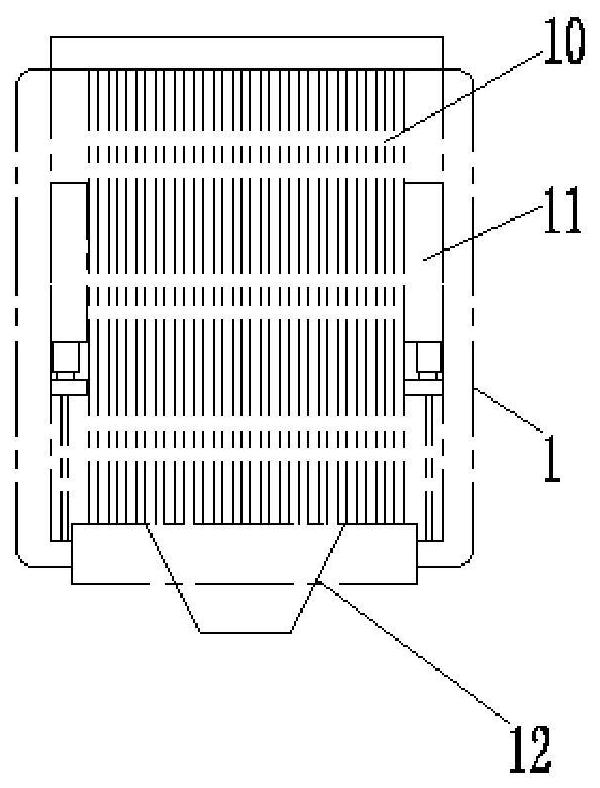

Intelligent split charging machine

PendingCN110294152AImprove packaging efficiencySmall weight deviationPackaging automatic controlSolid materialGramEngineering

The invention discloses an intelligent split charging machine. The intelligent split charging machine comprises a machine frame, a feeding device, a storage cylinder, a material conveying pipe, a conveying line and a control device. The storage cylinder is arranged at the top of the feeding device. The feeding device comprises a first support, a uniforming assembly, a quantitative assembly, a plurality of second supports, weighing sensors and discharging hoppers. The weighing sensors are arranged on the tops of the second supports correspondingly. Each weighing sensor is provided with a discharging hopper. Materials in the storage cylinder are uniformly dispersed by the uniforming assembly and are then conveyed into each discharging hopper by the quantitative assembly to be weighed. A plurality of material conveying pipes are arranged on an upper support. A quantity fixing assembly is arranged in the conveying direction of a conveying line and is used for enabling one empty material bottle to be arranged below each material conveying pipe and completing material conveying of the material bottles. By means of the intelligent split charging machine, split charging of a plurality of materials by part can be completed at one time, so that the material split charging efficiency is greatly improved; and moreover, it can be ensured that the gram-level weight deviation of materials falling into the discharging hoppers is small, and the precision of material split charging is improved.

Owner:大洲新燕(厦门)生物科技有限公司

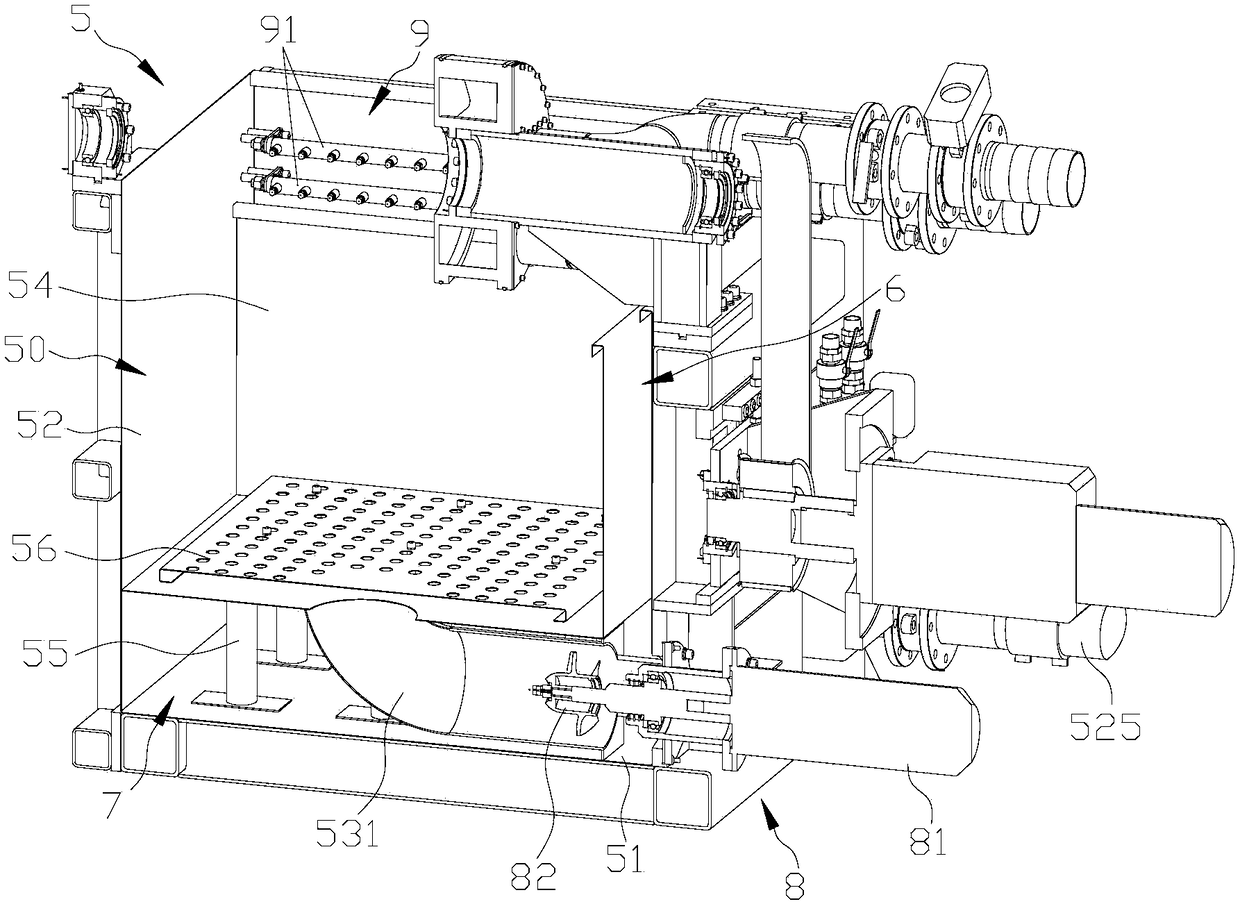

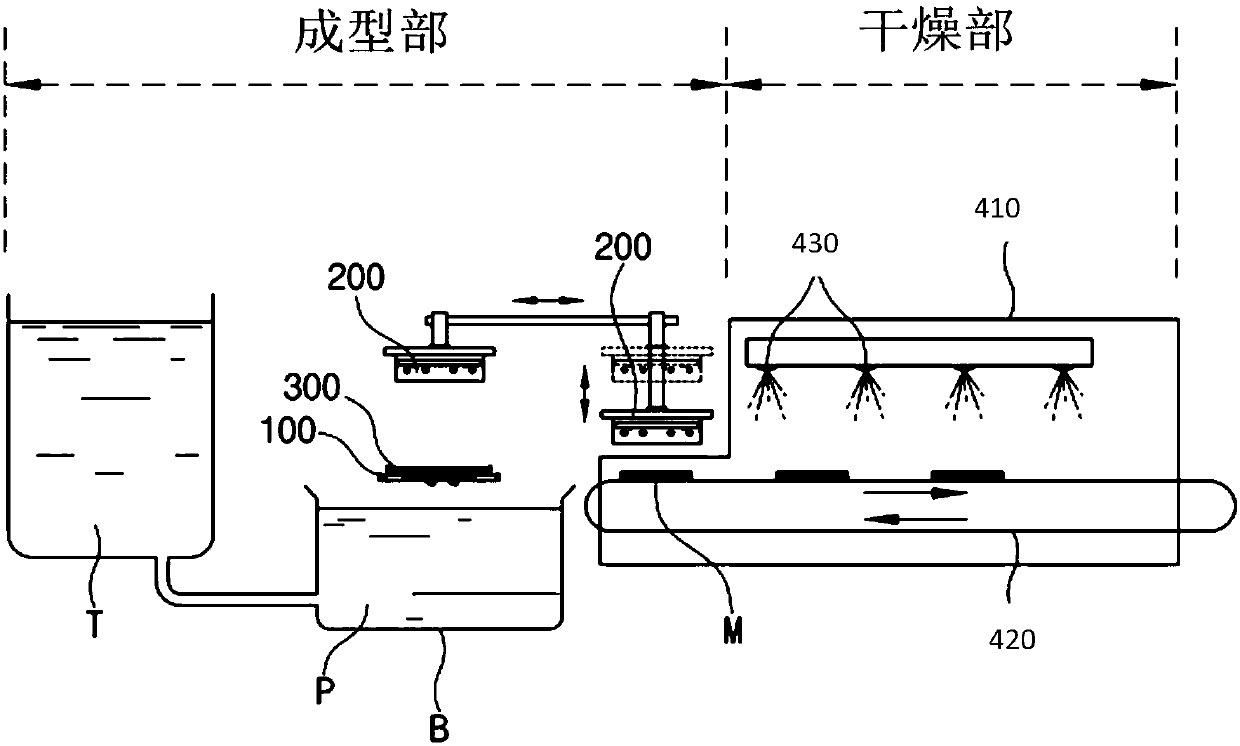

Fully automatic pulp molding multi-station equipment and production process

ActiveCN106638164BSmall weight deviationShorten the timeTextiles and paperMolded pulpThermal deformation

The invention belongs to the field of pulp molding product production equipment in a papermaking technique. Full-automatic multi-station integrated pulp molding equipment comprises an electric-heat conduction oil universal heating device, a steam heating device, a pulp chest homogenizing device, an adsorptive molding device, hot-press sizing devices, a first kind product collection device not needing stacking and a second kind product collection device capable of automatically conducting stacking; a groove is formed in a molding template of the molding device, an airflow dispersion cover plate is installed over the groove, an airflow main pipeline is vertically installed, a deckle edge spraying and template cleaning device is independently installed, heating plates of the molding devices are fixed to an upper molding template and a lower molding template through heat insulation plates, the upper molding template achieves multi-point pressurizing through a pressure stabilizing frame, the lower molding template is fixed to a transverse tackle, and heat deformation of the heating plates is effectively controlled by the molding templates. The equipment is suitable for large-scale production of pulp molding products, few molds are used, and the molds are unified and easy to replace.

Owner:许洪涛 +1

A paint packaging machine

InactiveCN102275639AStable packaging flow rateGuaranteed accuracySolid materialPneumatic valveEngineering

The invention provides a paint packaging machine, which includes a frame, a filter installed on the frame, and a packaging outlet installed on the frame. The filter and the packaging outlet are connected through a connecting pipe, and the packaging outlet is provided There are pneumatic valves. It can ensure the accuracy of the weight of the finished product in paint packaging, so that the weight deviation of the finished product is small, and the packaging efficiency is improved.

Owner:ZHEJIANG HUABAO INK

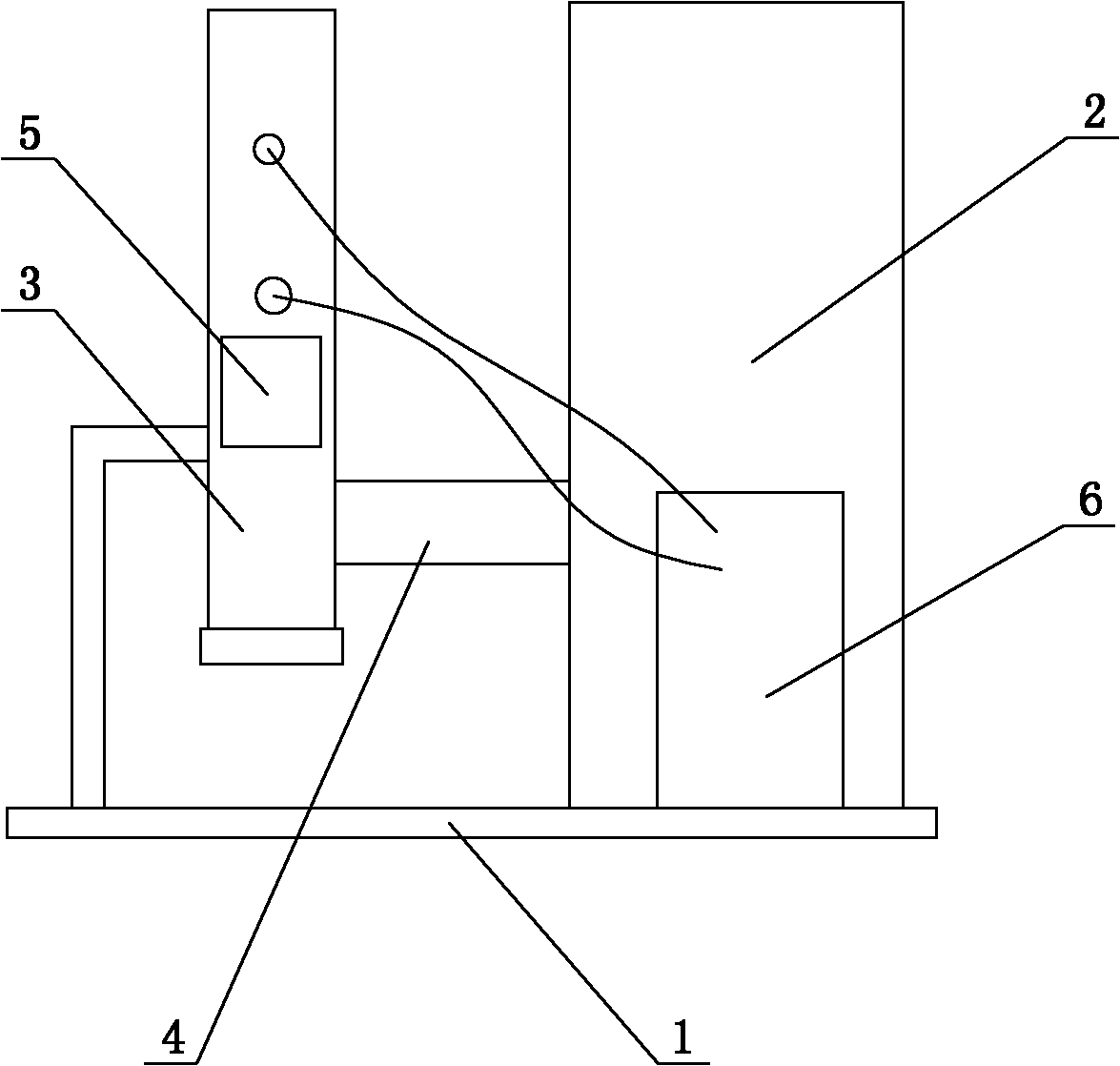

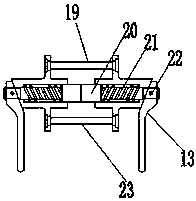

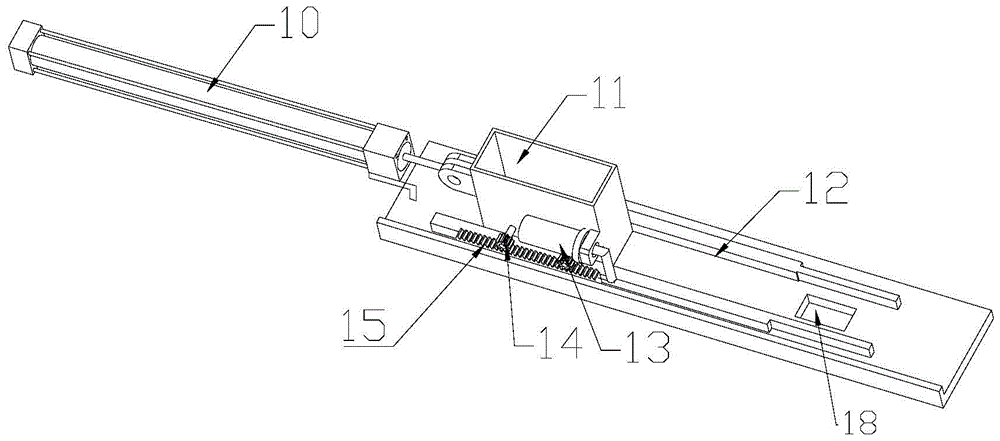

Rice dumpling raw material discharging mechanism

InactiveCN110510384ASmall weight deviationMeet the basic needs of productionConveyorsConveyor partsEngineeringUpper floor

The invention discloses a rice dumpling raw material discharging mechanism. The rice dumpling raw material discharging mechanism comprises a hopper, a discharging port is arranged on one side of the hopper, an adjusting valve is arranged on one side of the discharging port, and connection or disconnection between the hopper and a falling bin is adjusted through the adjusting valve; an outlet formed in the lower end of the falling bin communicates with an adjusting bin; the adjusting bin comprises an upper containing cavity and a lower containing cavity, an upper-layer valve plate and a lower-layer valve plate are arranged in the upper containing cavity and the lower containing cavity respectively, the upper-layer valve plate and the lower-layer valve plate each comprise a turning plate, apushing rod and a balancing weight, each turning plate, the corresponding pushing rod, the corresponding balancing weight and a rotation shaft form an entirety, and the rotation shafts are rotatably installed on the upper containing cavity and the lower containing cavity separately; a transmission shaft is arranged between the upper-layer valve plate and the lower-layer valve plate, and a crank isinstalled on the transmission shaft; the crank is used for pushing the upper pushing rod and the lower pushing rod, when the upper-layer turning plate is opened, the lower-layer turning plate is closed, and materials enter a middle cavity; and when the upper-layer turning plate is closed, the lower-layer turning plate is opened, and the materials pass through the middle cavity. According to the rice dumpling raw material discharging mechanism, rice dumpling raw materials can be quickly discharged, and subsequent production is convenient.

Owner:ZIGUI COUNTY QUGU FOOD

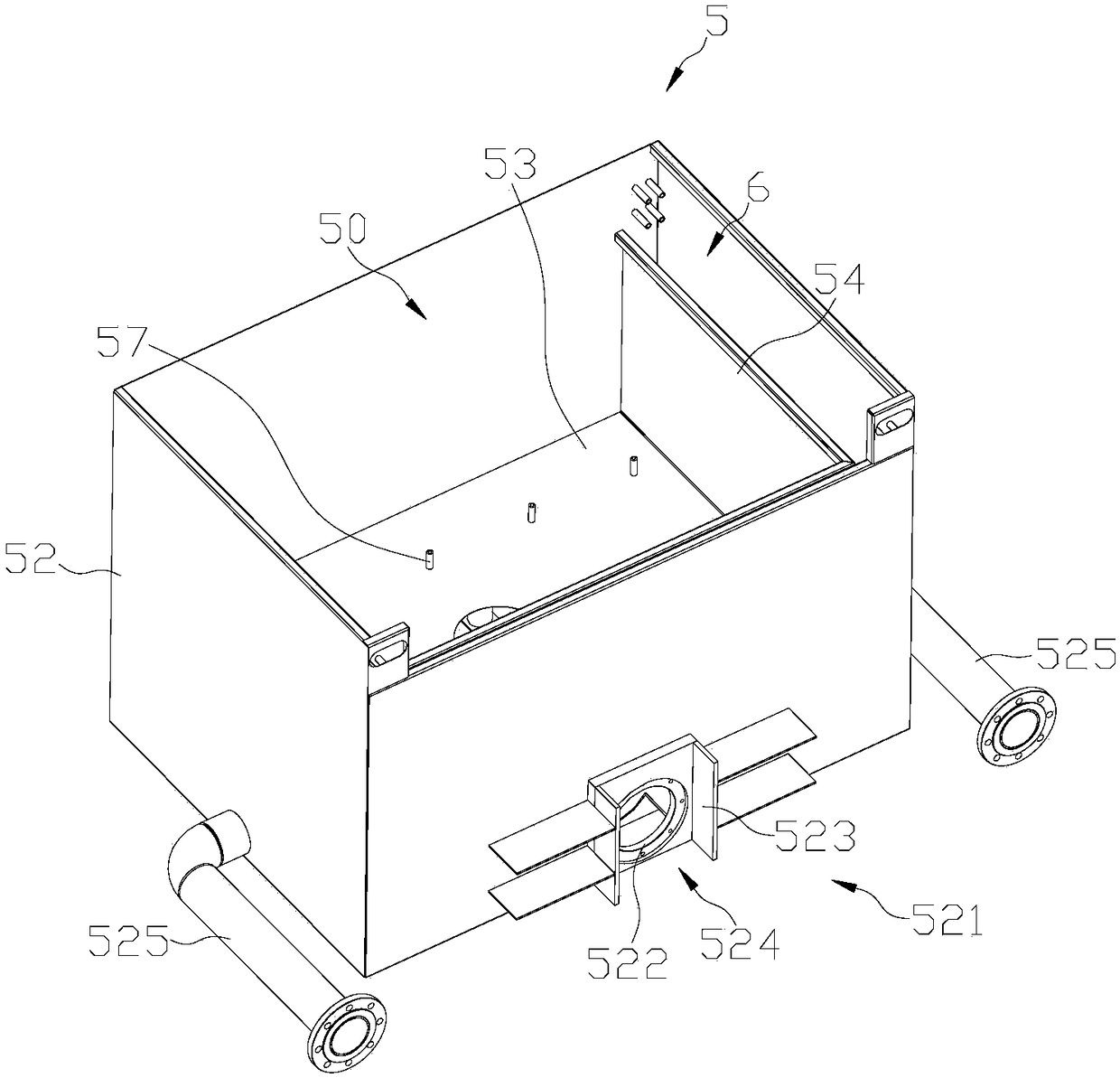

Pulp box and paper-form wet base forming equipment

PendingCN108193566AUniform concentrationSmall weight deviationTextiles and paperHigh volume manufacturingSlurry

Owner:FOSHAN BESURE TECH

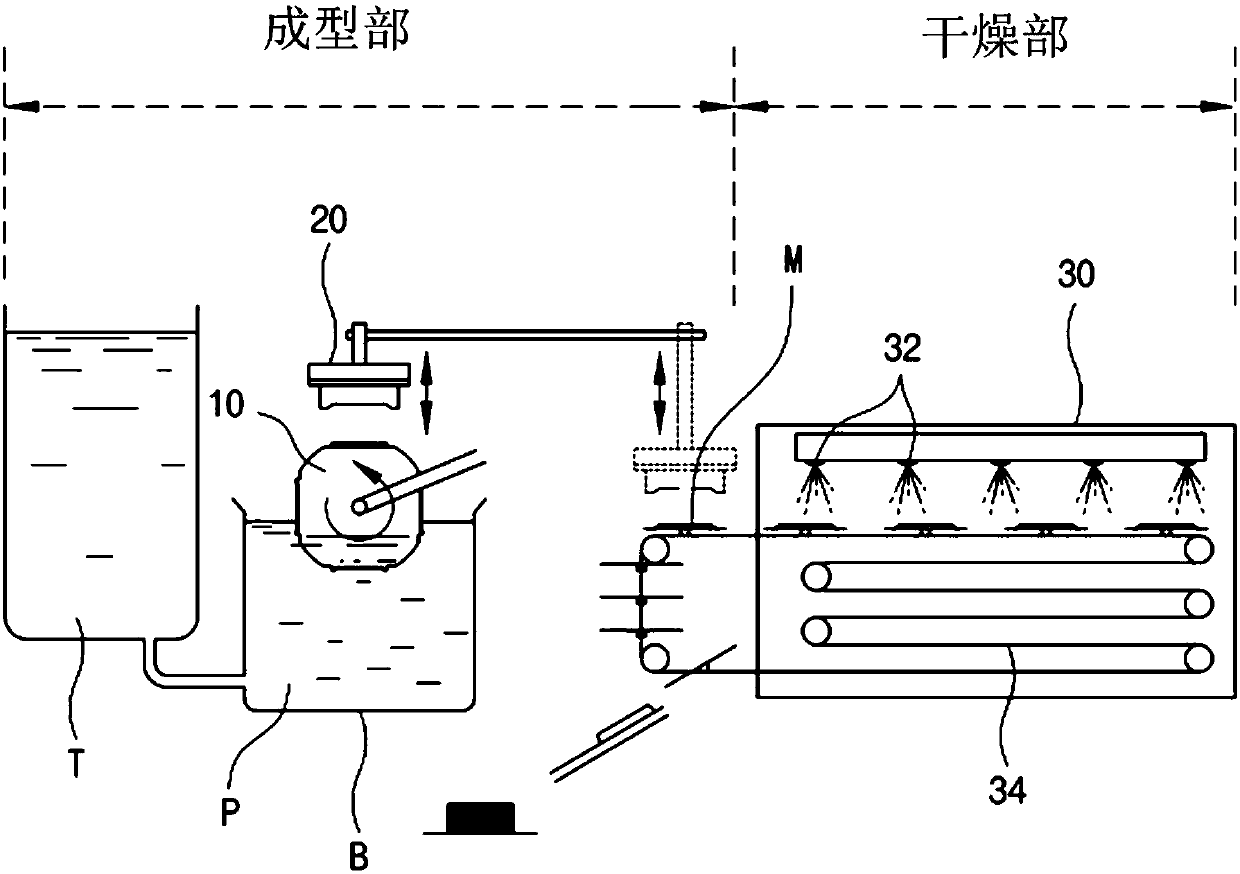

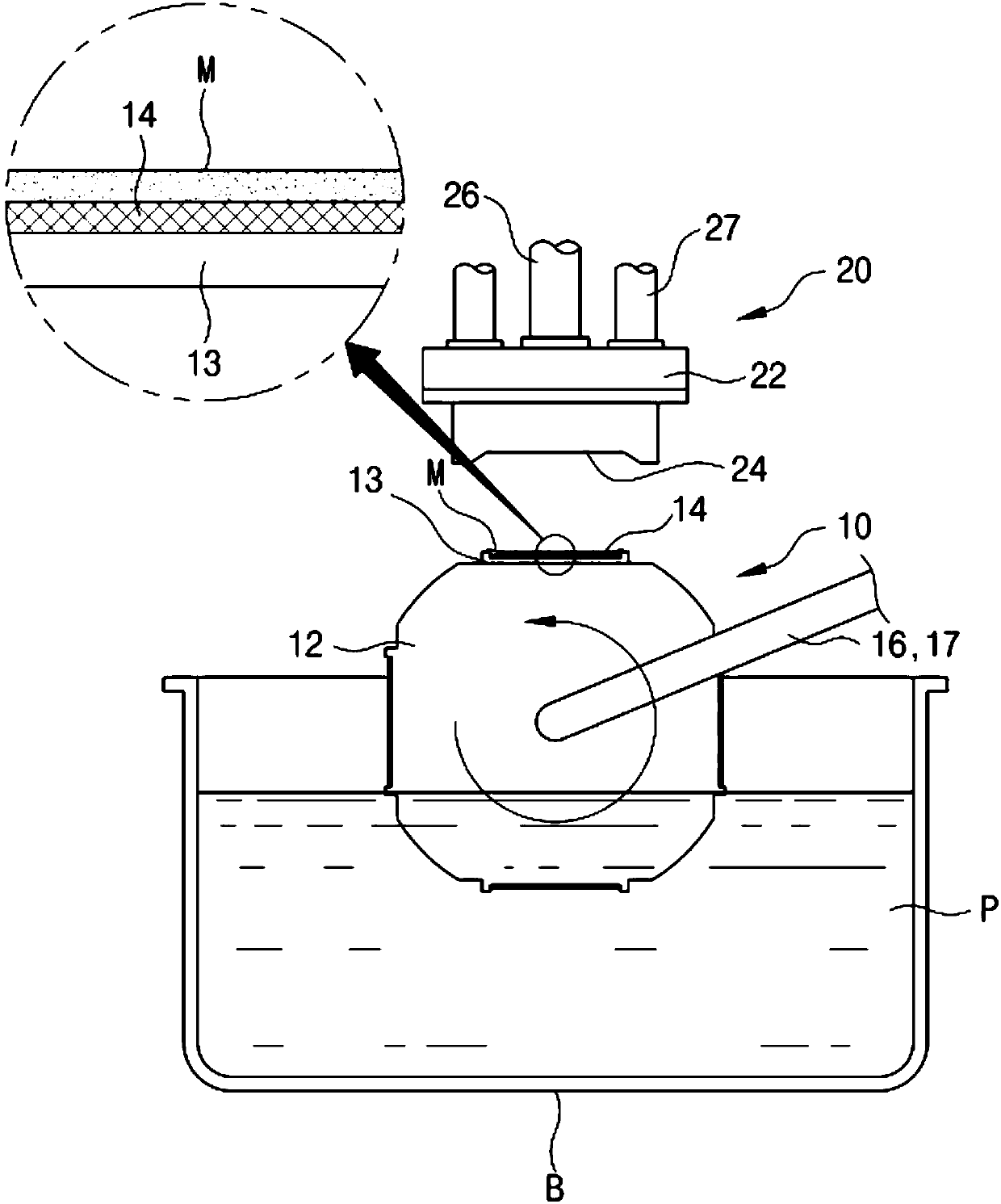

Pulp Molding Manufacturing System

InactiveCN106996060BThickness is easy to adjustReduce molding weight deviationFibreboardMolding machineShell molding

Disclosed is a pulp mold manufacturing system. The present invention relates to a pulp mold molding system, comprising a molding unit and a drying unit, in which a molding machine or a raw material container is additionally provided with a water blocking member in the molding unit where pulp is vertically moved up and down to be submerged in the raw material container and then raised to be molded. As such, a vortex of the pulp inside the raw material container due to the up-and-down movement of the molding machine is alleviated, such that it is possible to produce a satisfactory product having a uniform thickness.

Owner:株式会社利智技术

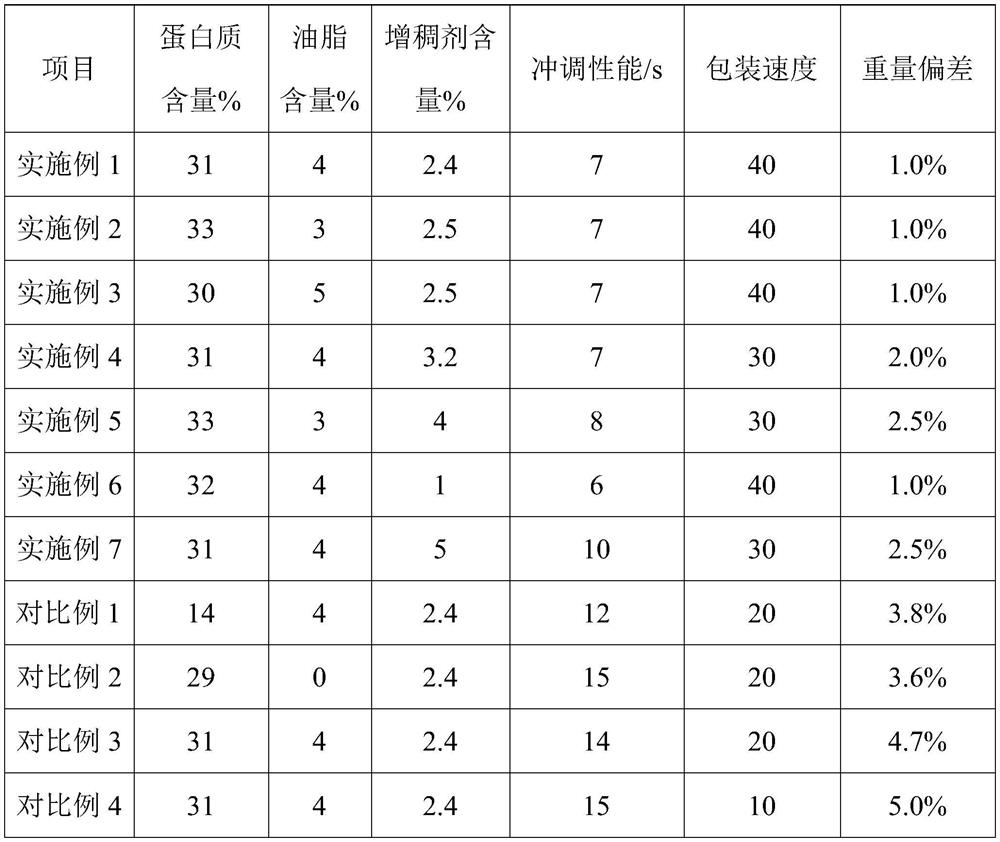

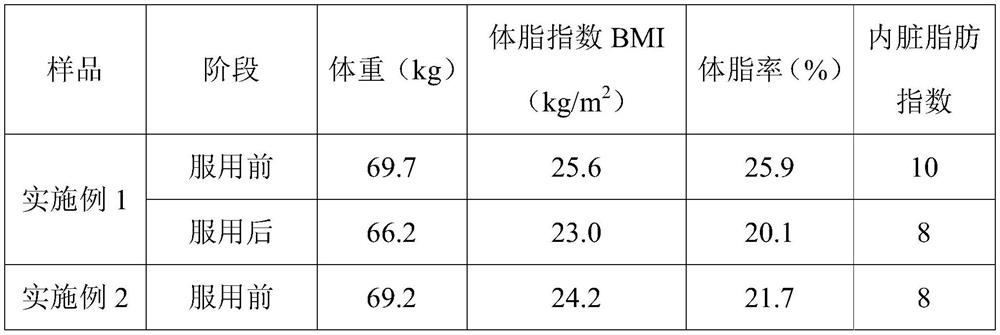

Brewing type sports nutritional meal replacement powder and preparation method thereof

PendingCN111758962ANutritional balanceNutritious and deliciousLipidic food ingredientsFood ingredient functionsBiotechnologyPhenolic content in tea

The invention provides brewing type sports nutritional meal replacement powder and a preparation method thereof. The brewing type sports nutritional meal replacement powder comprises skim milk powder,maltodextrin, soy isolate protein, coconut oil powder, tea polyphenol, a nutrition enhancer, a thickener and an anti-caking agent. The brewing type sports nutritional meal replacement powder has thecharacteristics of high protein and low grease, and meanwhile, the problems of non-uniform blanking, large weight deviation and poor brewing property of a finished product in the automatic packaging process of the product are solved.

Owner:GUANGZHOU YABO BIOTECH

Cavity casting and liner removing technique

InactiveCN101559473BSmall weight deviationCost controlFoundry moulding apparatusEngineeringMechanical engineering

Owner:长沙水泵厂有限公司

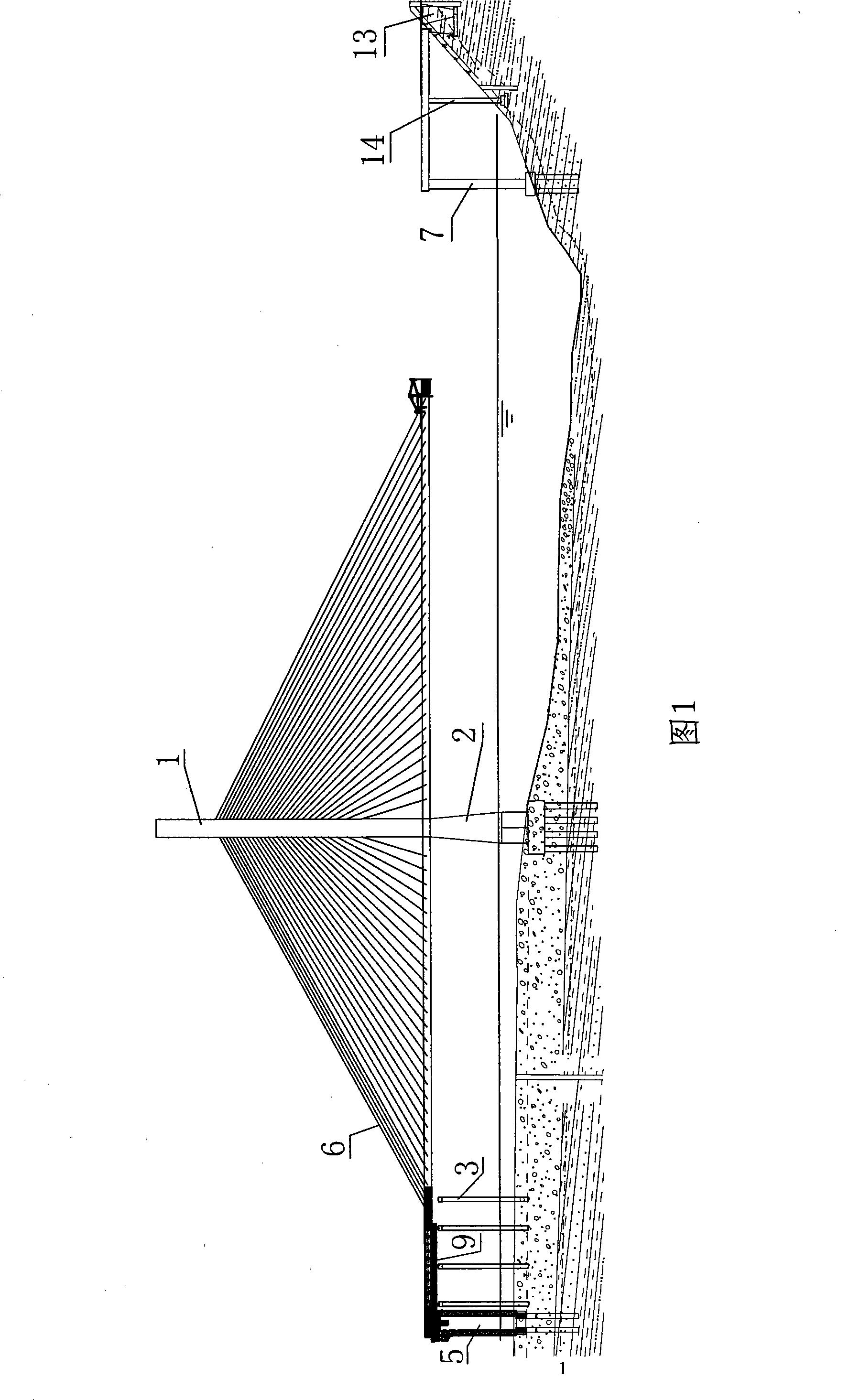

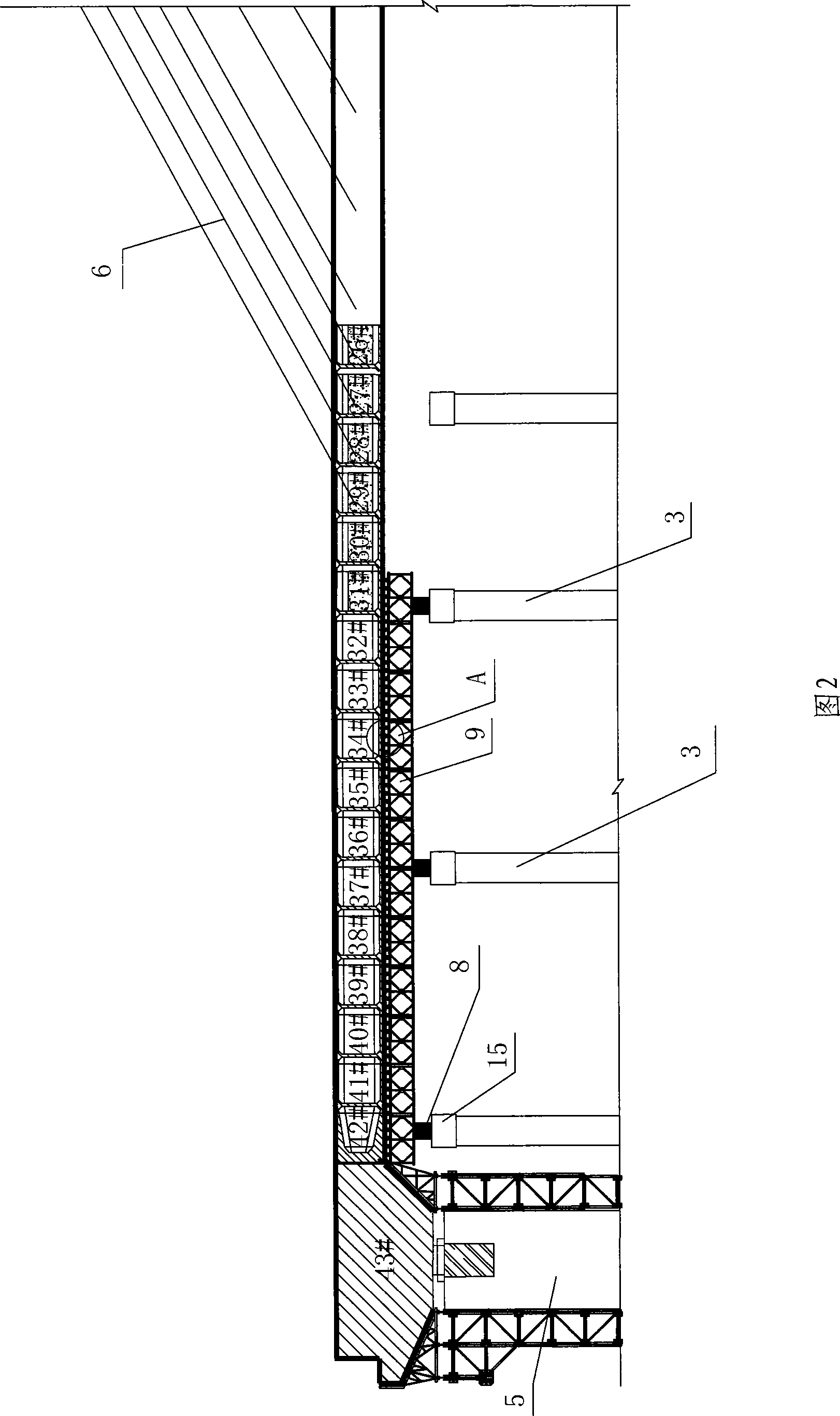

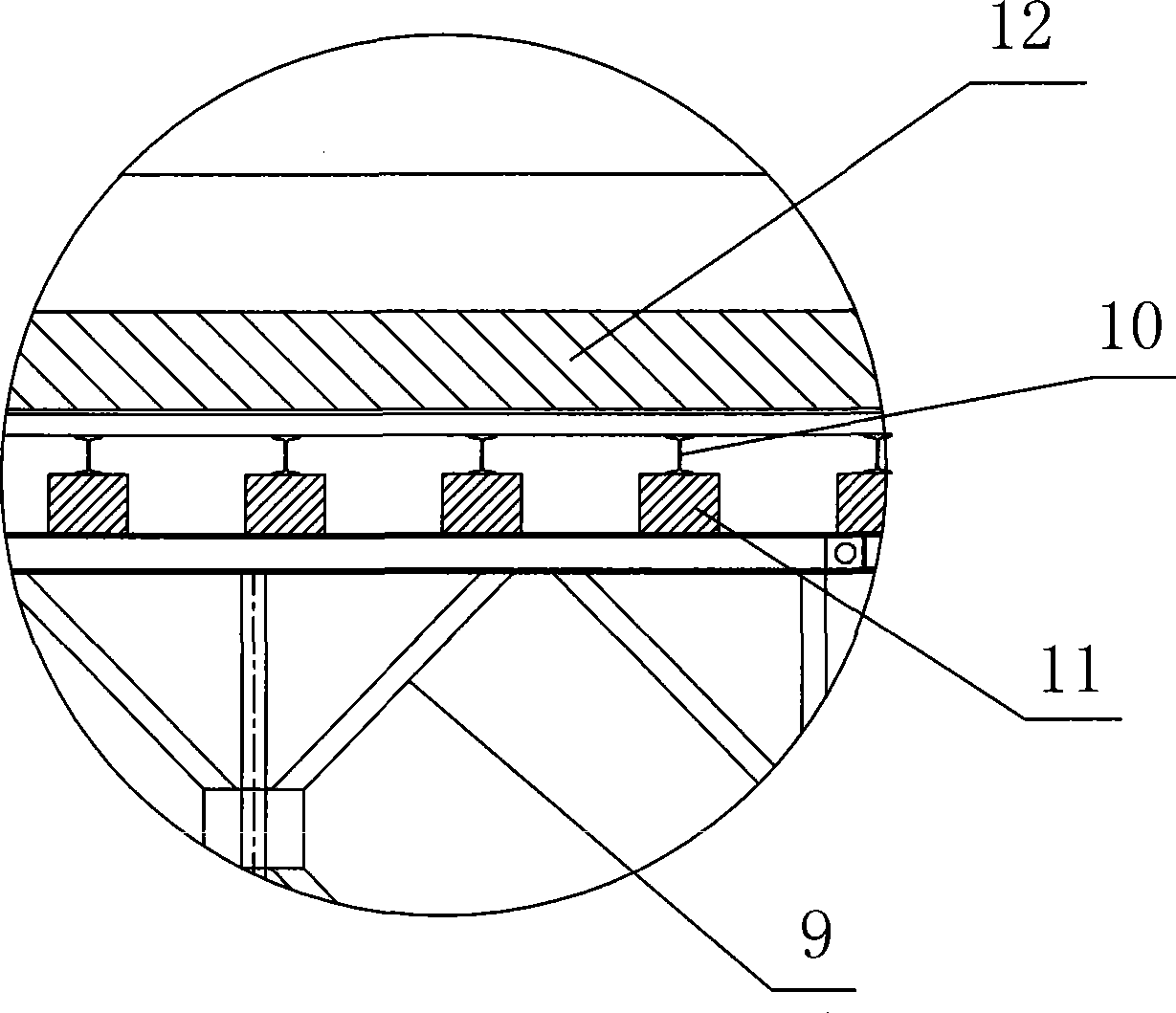

Counter weight control construction method for large span un-symmetric segment stayed-cable bridge

ActiveCN101424072BImprove structural rigidityImprove structural safetyCable-stayed bridgeBridge erection/assemblyNon symmetricCable stayed

The invention discloses a method for controlling and constructing a balance weight for a large-span asymmetric section of a cable-stayed bridge, which comprises the following steps: constructing a cantilever girder section of a main span and a side span symmetrically with a guyed traveler; constructing a side span support cast-in-place girder section until the side span is joined; continuously constructing the cantilever girder section of the main span with the guyed traveler, which comprises the following sub-steps: determining a balance weight girder section to be constructed with a balanceweight, casting the balance weight girder section with concrete as a balance weight material, thoroughly measuring the marked elevation of the whole bridge and measuring the offset on the top of a cable support tower to make sure a dismountable balance weight support and dismount the balance weight support, casting the constructed cantilever girder section of the main span, and then mounting stayed cables; and repeating the previous step until the main span is joined. The method can overcome the problems that line shapes of the girders, the offset on the top of the tower, and the safety of a balance weight bearing support cannot be well controlled in the prior process for controlling and constructing the balance weight for the large-span asymmetric section.

Owner:CHINA RAILWAY FIRST GRP CO LTD

Packaging device used for fine dried noodle production

ActiveCN110065661ASmall weight deviationSame lengthWrapping material feeding apparatusConveyor wrappingSlagPoor quality

The invention belongs to the technical field of fine dried noodle production, and particularly relates to the packaging device used for the fine dried noodle production. The packaging device aims to solve the problems that manual packages vary in tightness and mechanical packages are in poor quality. The packaging device comprises a machine cabinet and a slag collecting box, wherein one side of the outer wall of the top of the machine cabinet is fixedly provided with a cutting structure through a bolt, and the outer wall of the top of the cutting structure is fixedly provided with a feeding box through a bolt. A through groove is formed in the outer wall of one side, close to the slag collecting box, of the machine cabinet, the inner wall of the through groove is fixedly provided with a rotary motor through a bolt, and an output shaft of the rotary motor is connected with a rotary disc in a sleeve joint mode. According to the packaging device used for the fine dried noodle production,by means of bundle splitting, truncating, paper sealing, plastic packaging and discharging, packaging papers and packaging films are simultaneously fed and synchronously packaged, thus packages are more compact; both steps of bundle splitting and the truncating can allow the weight deviation of the whole fine dried noodle finished product package to become small, and a packaging machine cooperatesthe feeding box through the rotating of a bundling cylinder, accordingly the vertical material placing, horizontal bundle pressing and horizontal plastic packaging can be achieved, and the whole process is more compact.

Owner:安徽冠淮食品有限公司

Storage battery grid casting die

InactiveCN109746423AImprove patencyImprove liquidityElectrical and Electronics engineeringEngineering

The invention discloses a storage battery grid casting die which comprises a die body. A die cavity is formed in the die body. The die body is provided with a casting opening communicating with the die cavity. A breaking device is arranged at the position, close to the casting opening, in the die body. An exhausting channel is formed in one side of the die body. The die cavity communicates with the exhausting channel through an exhausting opening. An air outlet is formed in the exhausting channel. A negative pressure generator is arranged in the air outlet. The storage battery grid casting dieis simple in structure and convenient to operate, the negative pressure generator is arranged, the smoothness in the exhausting process of a grid and mobility of lead liquid can be improved, a special-shaped grid difficult to cast at ordinary times can be cast and formed smoothly, the production efficiency is improved, and the phenomenon of generating grid air holes is avoided.

Owner:黄玉春

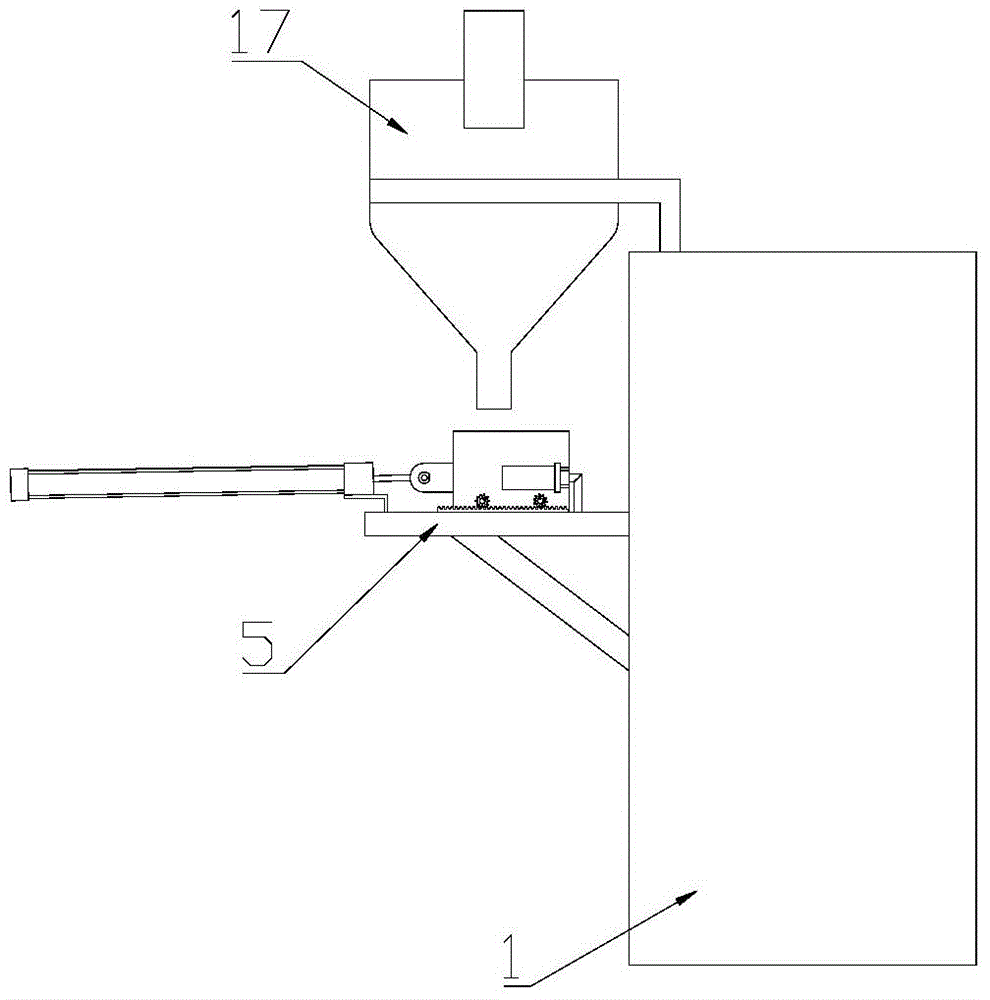

Feeding system for magnet rotor pressing process

ActiveCN104117671BIncrease production capacityIncrease productivityInductances/transformers/magnets manufactureRotor magnetsMachining process

Owner:HANYU GRP CO LTD

A kind of easy-to-use encapsulation block and preparation method thereof

ActiveCN108929644BSmall weight deviationNice appearanceMineral oil hydrocarbon copolymer adhesivesRosin adhesivesAdhesive cementPolymer science

Owner:RUGAO JIAHAO HOT MELT ADHESIVE

Encapsulated rubber block convenient for use and preparation method thereof

ActiveCN108929644ASmall weight deviationNice appearanceMineral oil hydrocarbon copolymer adhesivesRosin adhesivesPolymer scienceAdhesive

Owner:RUGAO JIAHAO HOT MELT ADHESIVE

A semi-dry desulfurization flue gas purification filter material and its preparation method

ActiveCN106582112BGood dimensional stabilityImprove antioxidant capacityHuman health protectionGas treatmentFiltrationCorrosion

The invention discloses a flue gas purifying filter material for semi-dry desulphurization and a preparation method thereof. The flue gas purifying filter material for semi-dry desulphurization is compounded by an expanded polytetrafluoroethylene micropore thin layer and a blended needled felt layer; the blended needled felt is compounded by a blended composite dust facing surface layer, a corrosion resisting enhanced base cloth layer and a blended composite gas cleaning surface layer which are connected in order, wherein the expanded polytetrafluoroethylene micropore thin layer and the blended composite dust facing surface layer are connected. The flue gas purifying filter material for semi-dry desulphurization has warp and weft strength which are higher than 900N / 50mm, warp and weft elongation at break which are less than 15%, and high dimension stability; the filter material can tolerate high temperature which is 250 DEG C or above, and application temperate is wide; corrosion resistance is good, and inoxidizability is good; the polytetrafluoroethylene film has smooth surface, and dust-cleaning efficiency is high and reaches 99.999%; the filter material has the advantages of low friction, flame retardancy, insulating properties, and heat insulation property; the material has long service life; and the material has high filtering efficiency, high filtration accuracy, water resistance and corrosion resistance.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

Rotary-filling hexahedral vacuum shaping and packaging machine

InactiveCN108423233ASmall weight deviationIncrease production capacityPackaging under vacuum/special atmosphereWrapper twisting/gatheringVacuum pumpingEngineering

The invention discloses a rotary-filling hexahedral vacuum shaping and packaging machine. The rotary-filling hexahedral vacuum shaping and packaging machine comprises a rack, an electric control box,and a bag loading mechanism and an output mechanism which are separately arranged on opposite two sides of the rack, wherein the rack is further sequentially equipped with a rotary mechanism, a pair of filling mechanisms, a metering and unloading mechanism as well as a pair of shaping and packaging mechanisms and a pair of vacuum-pumping mechanisms, which are oppositely arranged at the two sides of the metering and unloading mechanism, in a direction from the bag loading mechanism to the output mechanism; the rotary mechanism drives the filling mechanisms to perform position changing motion between the metering and unloading mechanism and the upper portion of the shaping and packaging mechanisms; a bag discharge mechanism is further arranged on the rack for conveying packaged finished products onto the output mechanism; the electric control box is arranged outside the rack, and is electrically connected with the bag loading mechanism, the output mechanism, the rotary mechanism, the filling mechanism, the metering and unloading mechanism, the shaping and packaging mechanisms, the vacuum-pumping mechanisms, a bag-pulling and sealing mechanism and the bag discharge mechanism; and theelectric control box can conveniently and quickly regulate each mechanism in a matched mode, so that packaging efficiency of the packaging machine is higher.

Owner:霍梅芳

A high-strength and low-elongation polysulfone fiber high-temperature-resistant film-coated filter material and its preparation method

ActiveCN103170183BHigh filtration precisionHigh operabilityFibre typesSynthetic resin layered productsFiberPolymer science

The invention provides a high-intensity low-stretchability polysulfonamide high-temperature-resisting membrane filter material and a preparation method thereof. The filter material disclosed by the invention is formed by compounding a PTFE (Polytetrafluoroethylene) high-compactness microporous membrane layer and a punched felt in sequence from top to bottom. The punched felt is formed by compounding a first polysulfonamide fiber surface layer, a high-intensity low-stretchability base cloth layer and a second polysulfonamide fiber surface layer in sequence from top to bottom. The preparation method comprises steps of: preparation of the punched felt, high-temperature thermoforming, singeing and pressing treatment, full-saturation immersion treatment, predrying, baking curing, and high-temperature high-pressure coating with the PTFE high-compactness microporous membrane. The high-intensity low-stretchability polysulfonamide high-temperature-resisting membrane filter material has high intensity and low stretchability, longitude and latitude strengths are both larger than 3000N / 50mm; the longitude and latitude elongations at break are both smaller than 10%; and the filter material can resist a high temperature grade of 250 DEG C and has high corrosion resistance, good oxidization resistance, smooth surface, high deashing efficiency and wide application range.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

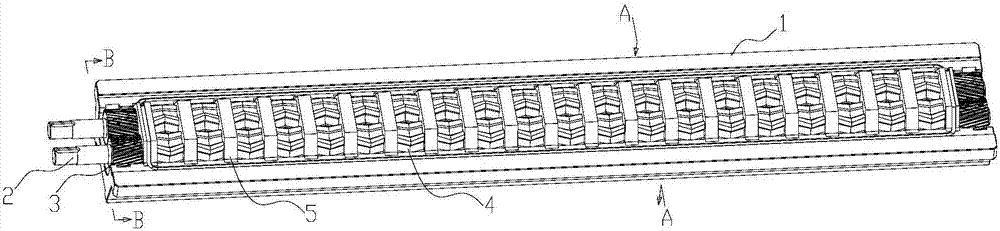

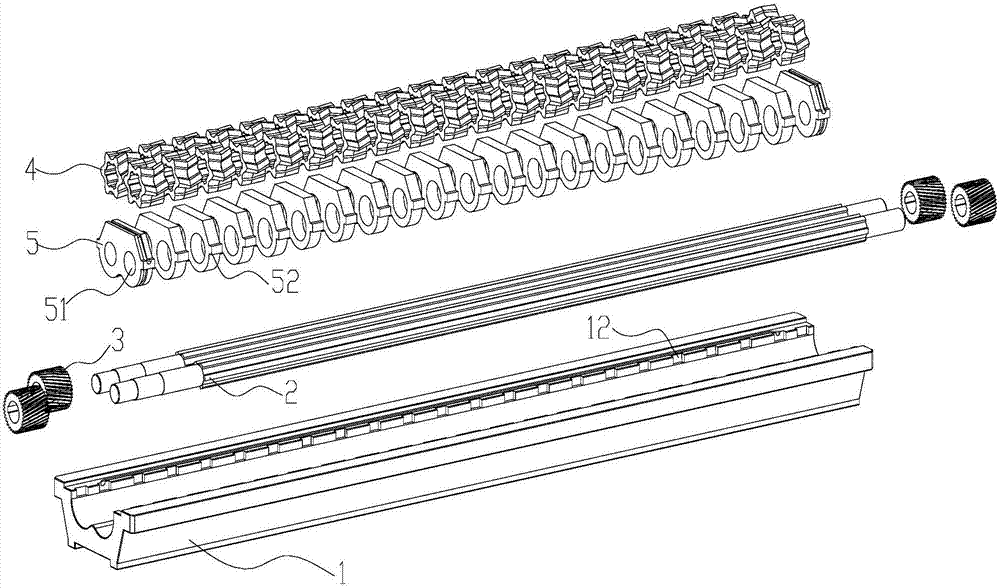

Inverted-V-shaped arc gear metering pump

InactiveCN107100835AFew teethSmall pressure angleRotary piston pumpsRotary piston liquid enginesMetering pumpGear tooth

The invention discloses an inverted V-shaped arc gear metering pump, and belongs to the technical field of gear metering pumps. The inverted V-shaped arc gear metering pump comprises a gear case, two splined shafts, a plurality of transmission bevel gears and a plurality of inverted V-shaped arc gear sets; the driving spiral gears are arranged on the end portions of the two splined shafts, and the two splined shafts are arranged in the gear case side by side and enable the two driving spiral gears on the end portions of the two splined shafts to be engaged with each other; the multiple inverted V-shaped arc gear sets are arranged on the two splined shafts and located between the transmission bevel gears at two ends of the splined shafts; and a baffle is arranged between every two adjacent inverted-V-shaped arc gear sets to enable an independent cavity body to be formed between each inverted-V-shaped arc gear set and the gear case. The metering pump has less gear teeth, and high flow quantity, is stable to rotate, cannot result in the phenomena of flow fluctuation and material being trapped, can achieve quantitative material extrusion, and is very low in weight deviation.

Owner:珠海市洪富食品机械制造有限公司

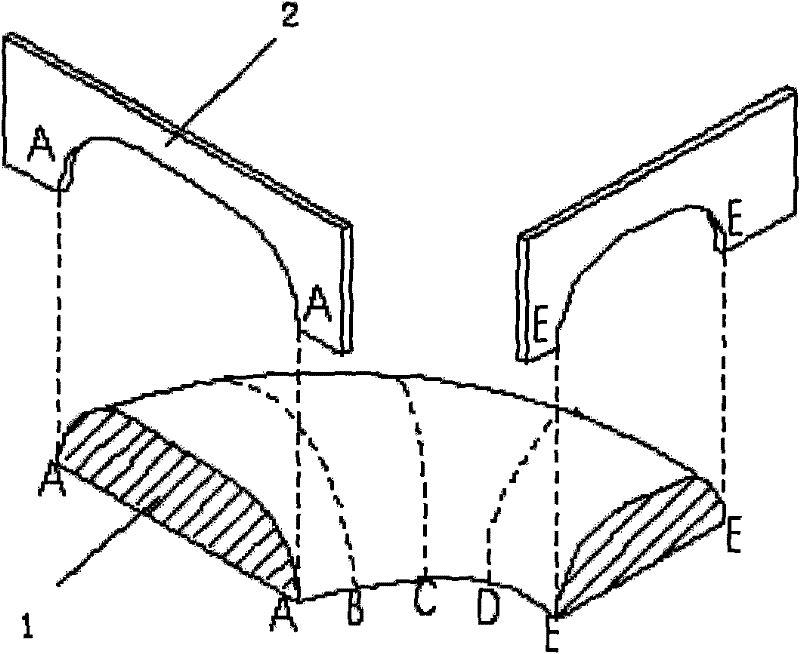

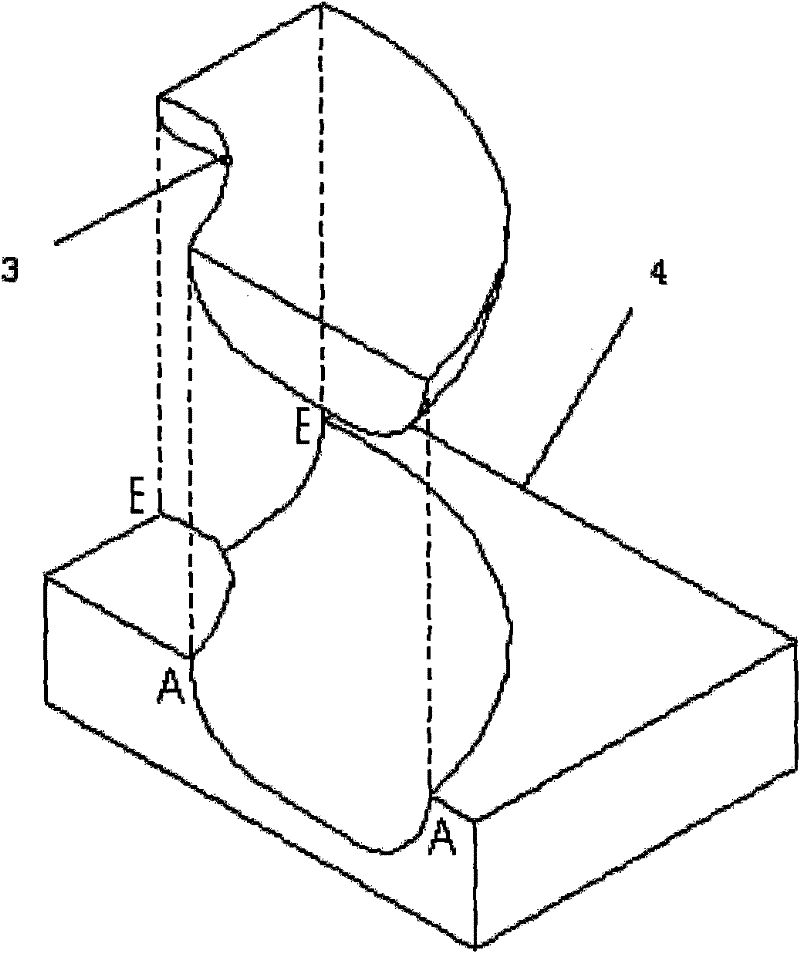

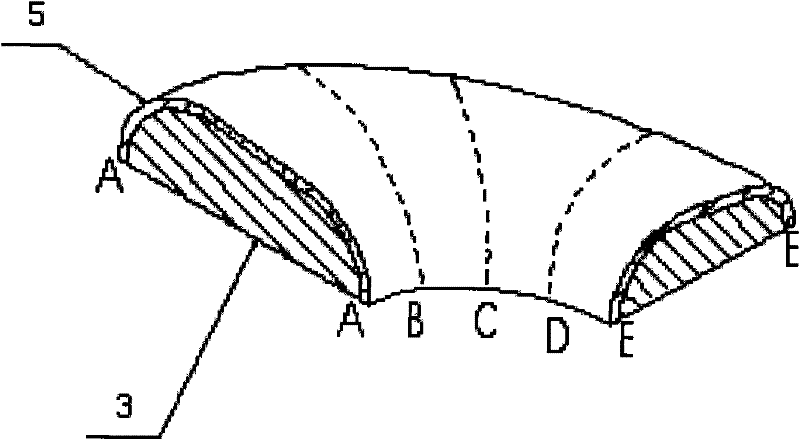

Cavity casting and liner removing technique

InactiveCN101559473ASmall weight deviationCost controlFoundry moulding apparatusEngineeringMechanical engineering

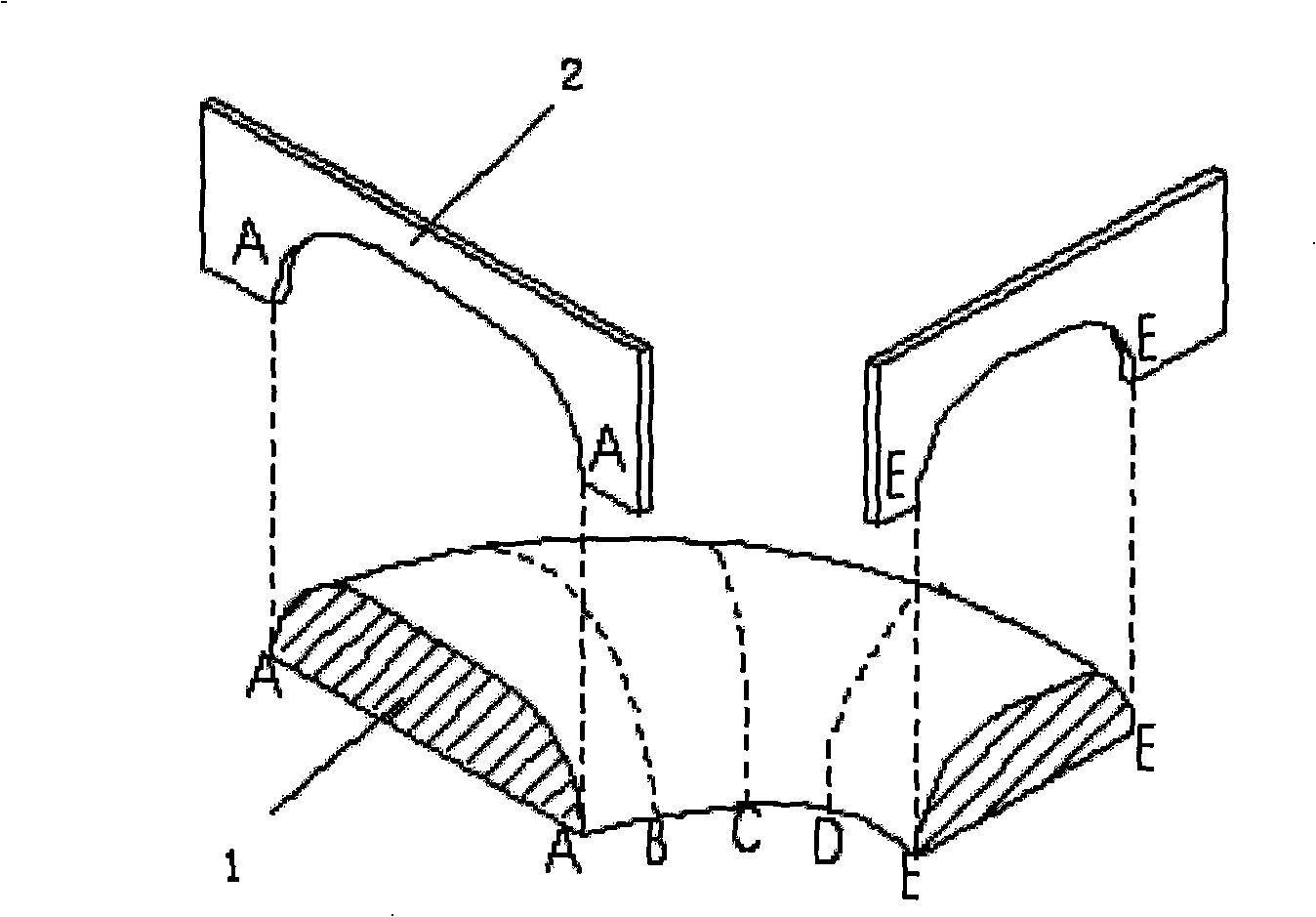

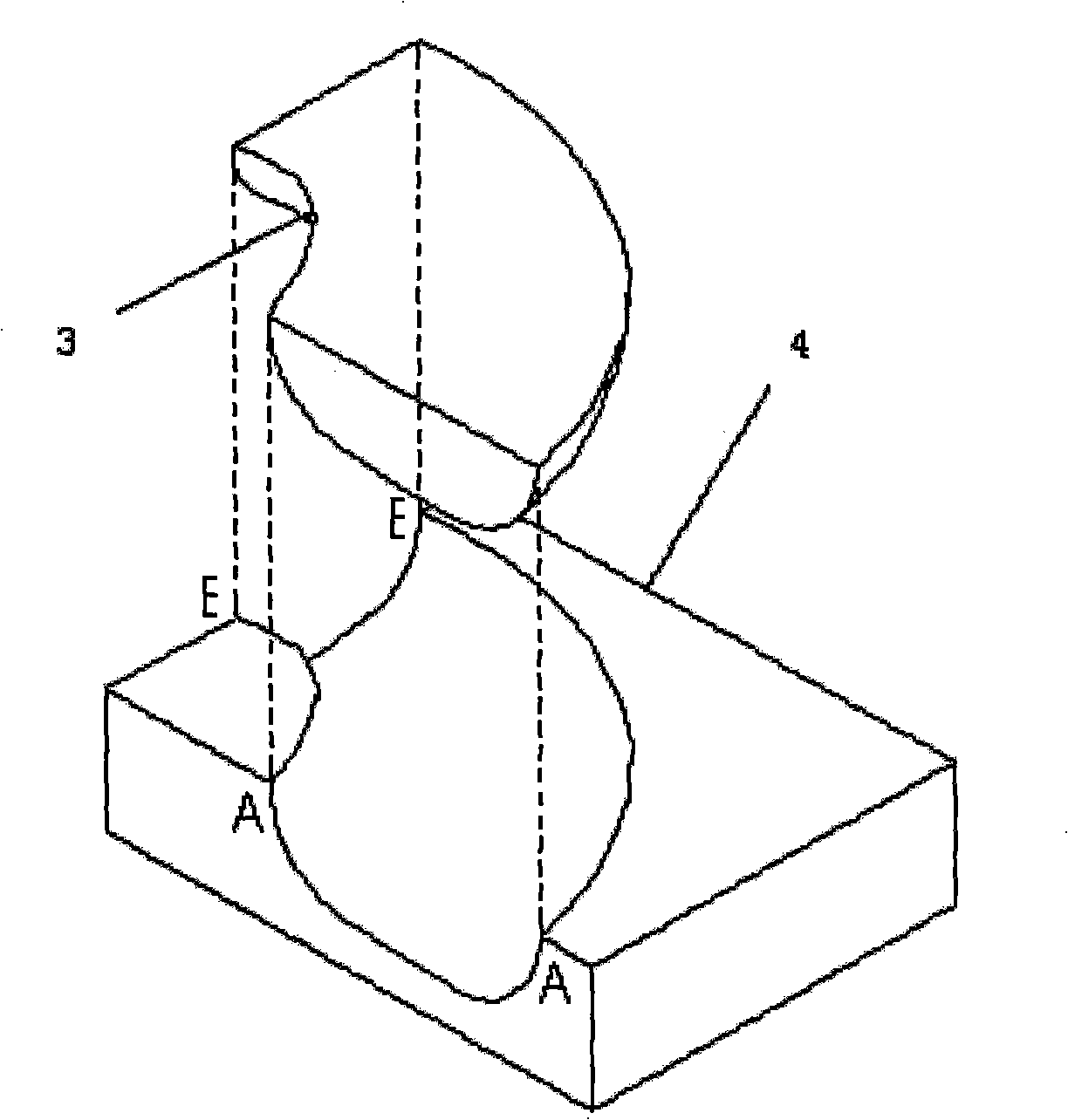

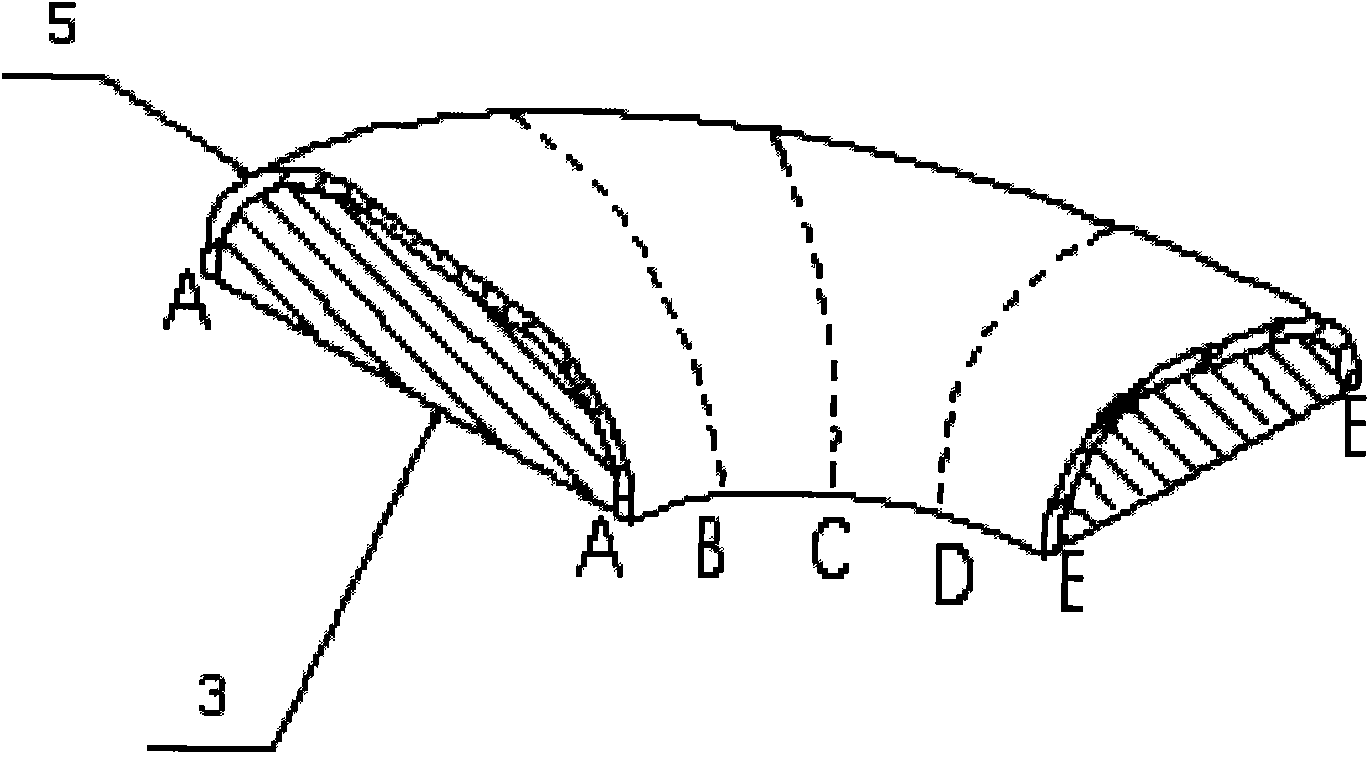

The invention discloses a cavity casting and liner removing technique which comprises the following steps: (1) first, a set of A-E templates with concave cross sections are manufactured according to the shapes of inner cavities of the parts which are needed to be casted and positioned according to the direction of drawing size of the parts, the shapes of all the cross sections are shoveled and scraped by the templates on the dry wood, and all the cross sections are smoothly connected with each other to form a wooden entity; (2) the wooden entity is used for making a female die in a plastic core box, then a plastic entity is made on a female die; (3) the material with the same thickness as the thickness of the parts needing to be casted is nailed up on the plastic entity and smoothly connected by plastics to form the appearance of an external die.

Owner:长沙水泵厂有限公司

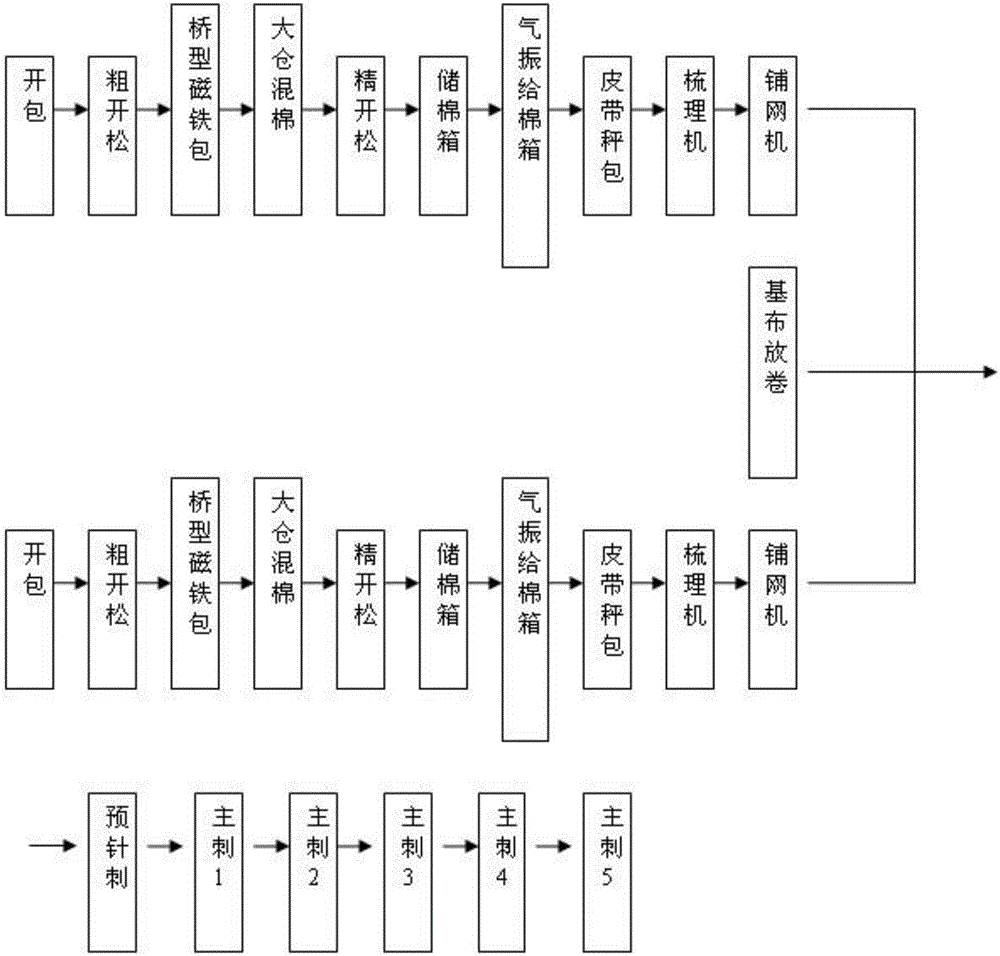

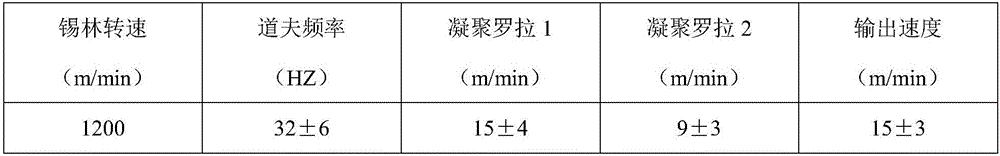

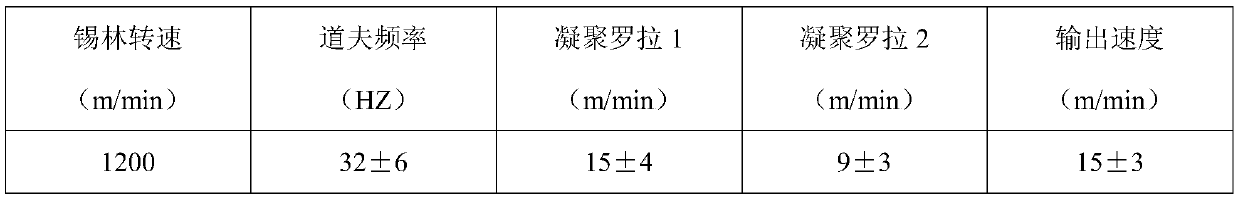

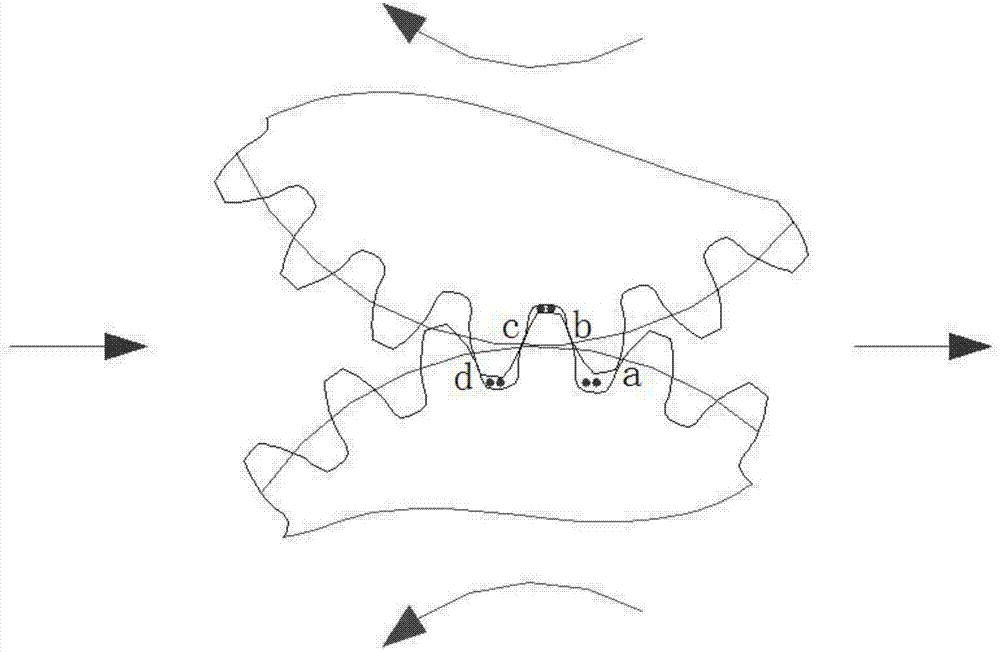

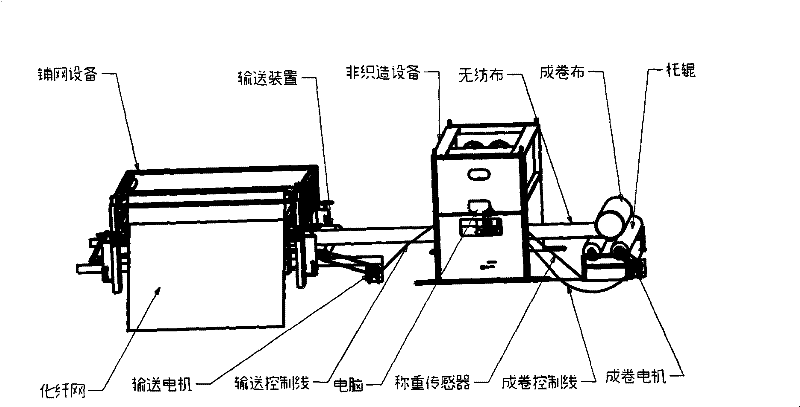

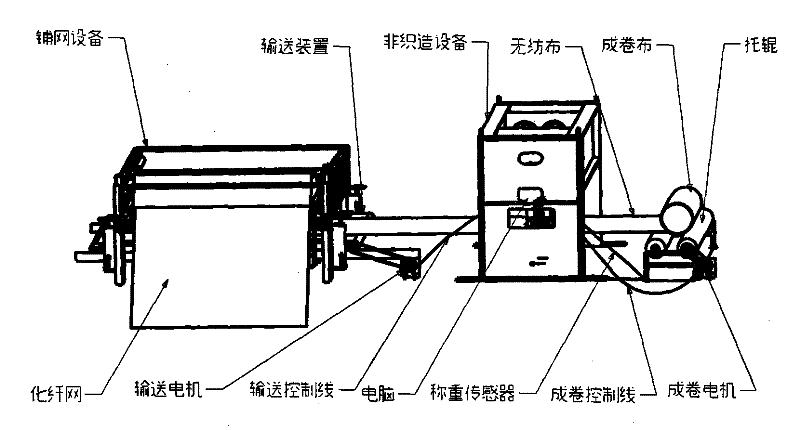

Non-woven on-line weighing control device

The invention relates to a non-woven on-line weighing control device. Chemical fiber nets are overlapped on a conveyer device through a net laying device, are processed into non-woven fabrics by a non-weaving machine under the driving of a conveying motor; the non-woven fabrics are arranged on a supporting roller, is driven by a supporting roller motor and rolled automatically; a weighing sensor is connected with a computer; a computer output wire is connected with each motor required to be controlled; and the weight (gram) per square meter can be controlled automatically and also can be controlled manually. The device provided by the invention has the beneficial effects that the weight (gram) per unit area has small deviation, an automatic effect is realized, and materials and time are saved.

Owner:杨森

Automatic glaze spraying technology for electronic vacuum metallized ceramic surface

Owner:湖南湘瓷科艺有限公司

A packaging device for noodle production

ActiveCN110065661BSmall weight deviationSame lengthWrapping material feeding apparatusConveyor wrappingElectric machineIndustrial engineering

The invention belongs to the technical field of noodle production, in particular to a packaging device for noodle production. Aiming at the problems of uneven tightness of manual packaging and poor quality of mechanical packaging, the following scheme is proposed, including a cabinet and a slag collection box. The top of the cabinet is One side of the outer wall is fixed with a truncated structure by bolts, and the top outer wall of the truncated structure is fixed with a discharge box by bolts, the outer wall of the cabinet close to the slag collection box has a through groove, and the inner wall of the through groove is fixed with a rotating motor by bolts , the output shaft of the rotary motor is sleeved with a rotary disc. The present invention through beam splitting, truncation, paper sealing, plastic sealing and discharging, simultaneously feeds through wrapping paper and wrapping film, synchronously packs, and the packing is more compact, and the beam splitting step and the truncation step can make the weight deviation of the finished dried noodle package of the whole Small, the packaging machine cooperates through the rotation of the bundle drum and the discharge box, vertical discharge, horizontal bundle paper, horizontal plastic sealing, and the overall process is more compact.

Owner:安徽冠淮食品有限公司

Automatic glaze spraying technology for electronic vacuum metallized ceramic surface

The invention relates to an automatic glaze spraying technology for an electronic vacuum metallized ceramic surface, which has the key points of filtering raw glaze slip by a 200-mesh screen to remove iron; stirring and mixing 2-20% of suspending agent, 0-0.3% of water glass and 0-0.4% of sodium polyacrylate to form glaze slip additive; adding the glaze slip additive into 79.3-98% of glaze slip which is treated by deironing, and stirring to prepare glaze slip spraying agent with 50-70 o Be and the moisture content of 30-45%; setting the operating parameters of a glaze spraying machine, and spraying glaze for 4-10 times; and naturally drying for 1-2h at the room temperature. The automatic glaze spraying technology is simple in glaze spraying technology, and the prepared glaze slip spraying agent is proper in fluidity on the surface of a workpiece; the technology is convenient to operate and control; the glaze slip sprayed on the surface of the workpiece is good in compactness and smoothness; a glaze layer stuck on the surface of the workpiece is even in thickness; the produced metallized ceramic can be welded with metal, so that a composite ceramic part with firm connection, good air tightness, reliable quality and stable performances can be formed; and product quality and production efficiency are improved, and the production cost and energy consumption are reduced.

Owner:湖南湘瓷科艺有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com