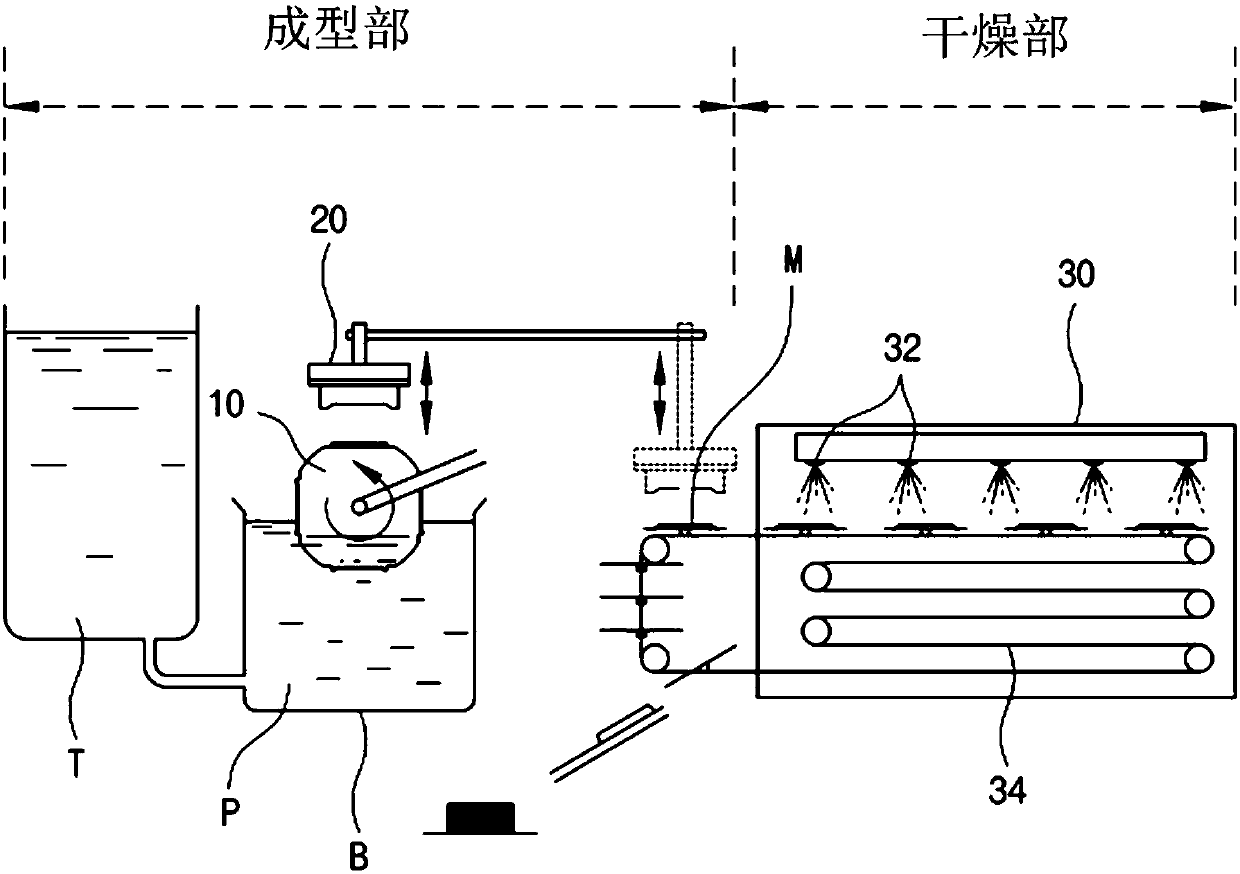

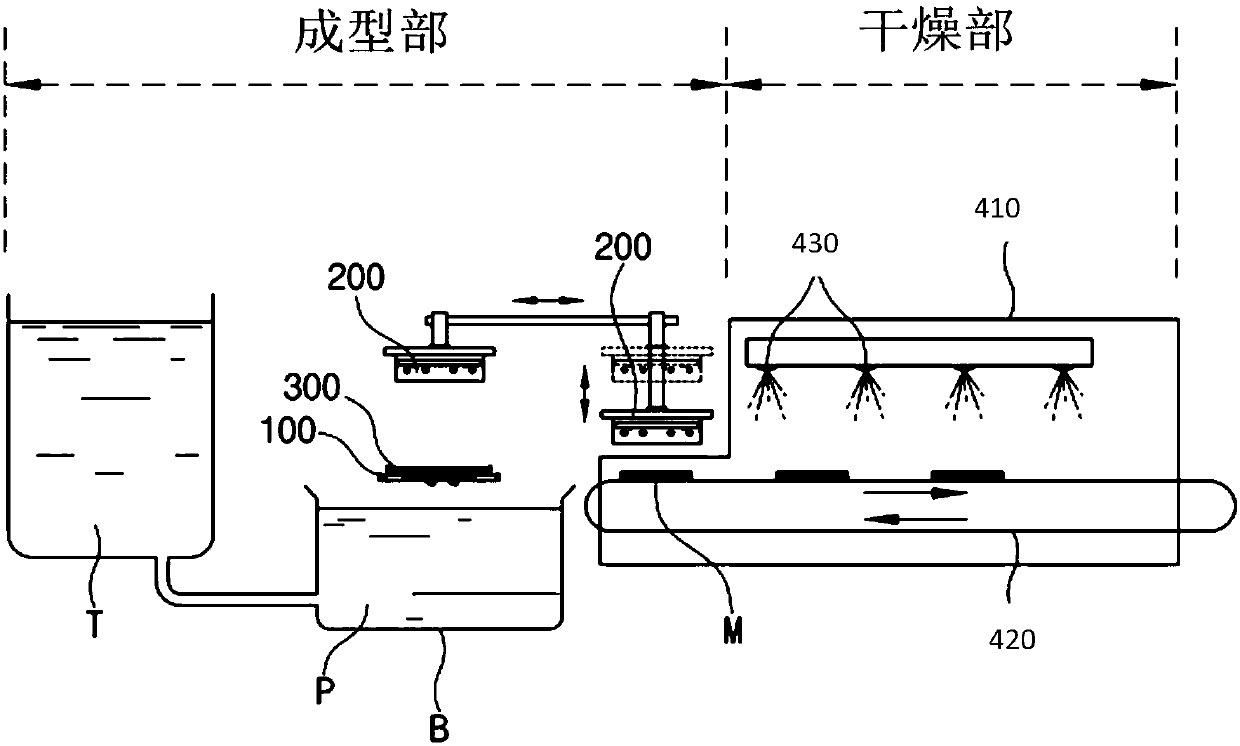

Pulp Molding Manufacturing System

A manufacturing system and pulp molding technology, applied in textiles and papermaking, etc., can solve the problems of low marketability of pulp molding products and different thicknesses of pulp moldings, and achieve excellent drying efficiency, easy product thickness, and product thickness adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

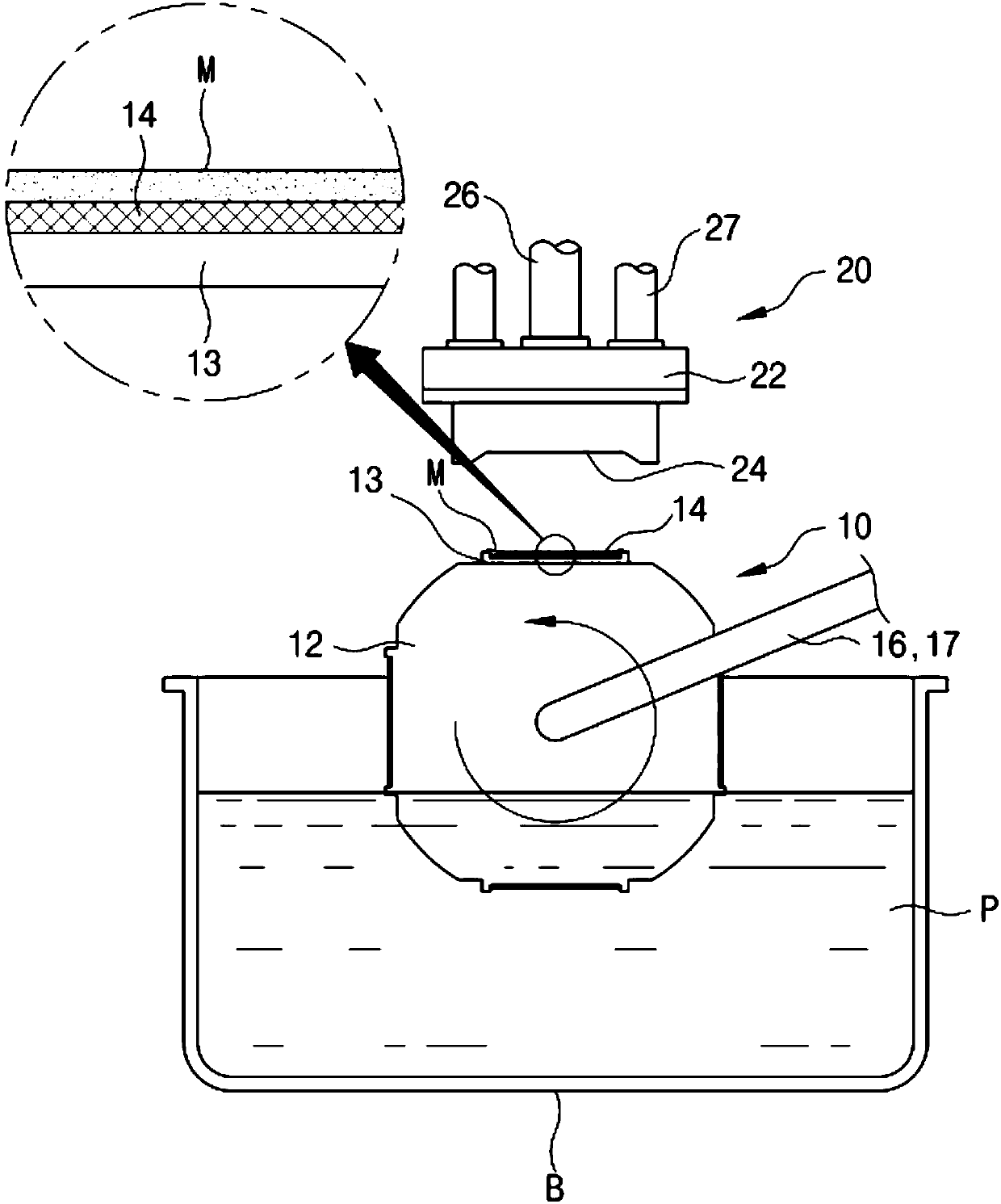

Embodiment Construction

[0050] In order to facilitate a full understanding of the present invention, preferred embodiments of the present invention will be described with reference to the accompanying drawings. The embodiments of the present invention can be modified into various forms, and the scope of the present invention should not be interpreted as being limited to the embodiments described in detail below. This embodiment is provided to more fully describe the present invention to those skilled in the art. Therefore, the shapes of elements in the drawings and the like are displayed exaggeratedly in order to more clearly describe the shapes of the elements in the drawings. It should be noted that in the respective drawings, there are cases where the same components are shown with the same reference numerals. In addition, specific descriptions of well-known functions and configurations that are judged to be unnecessary and obscure the gist of the present invention are omitted.

[0051] First of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com