Rice dumpling raw material discharging mechanism

A technology of raw materials and zongzi, which is applied in the field of zongzi raw material cutting mechanism, which can solve the problems of high equipment cost, large power consumption, troubles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

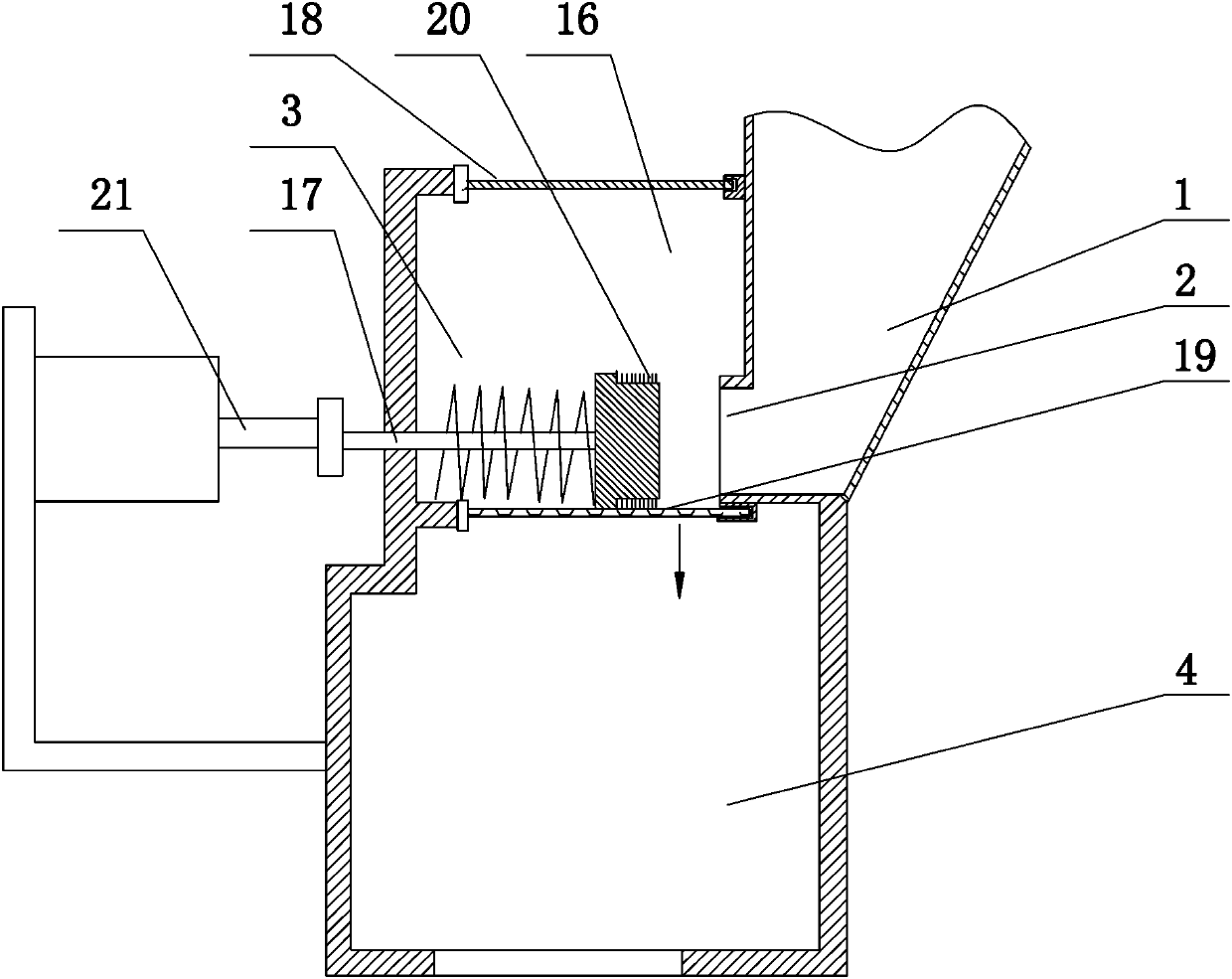

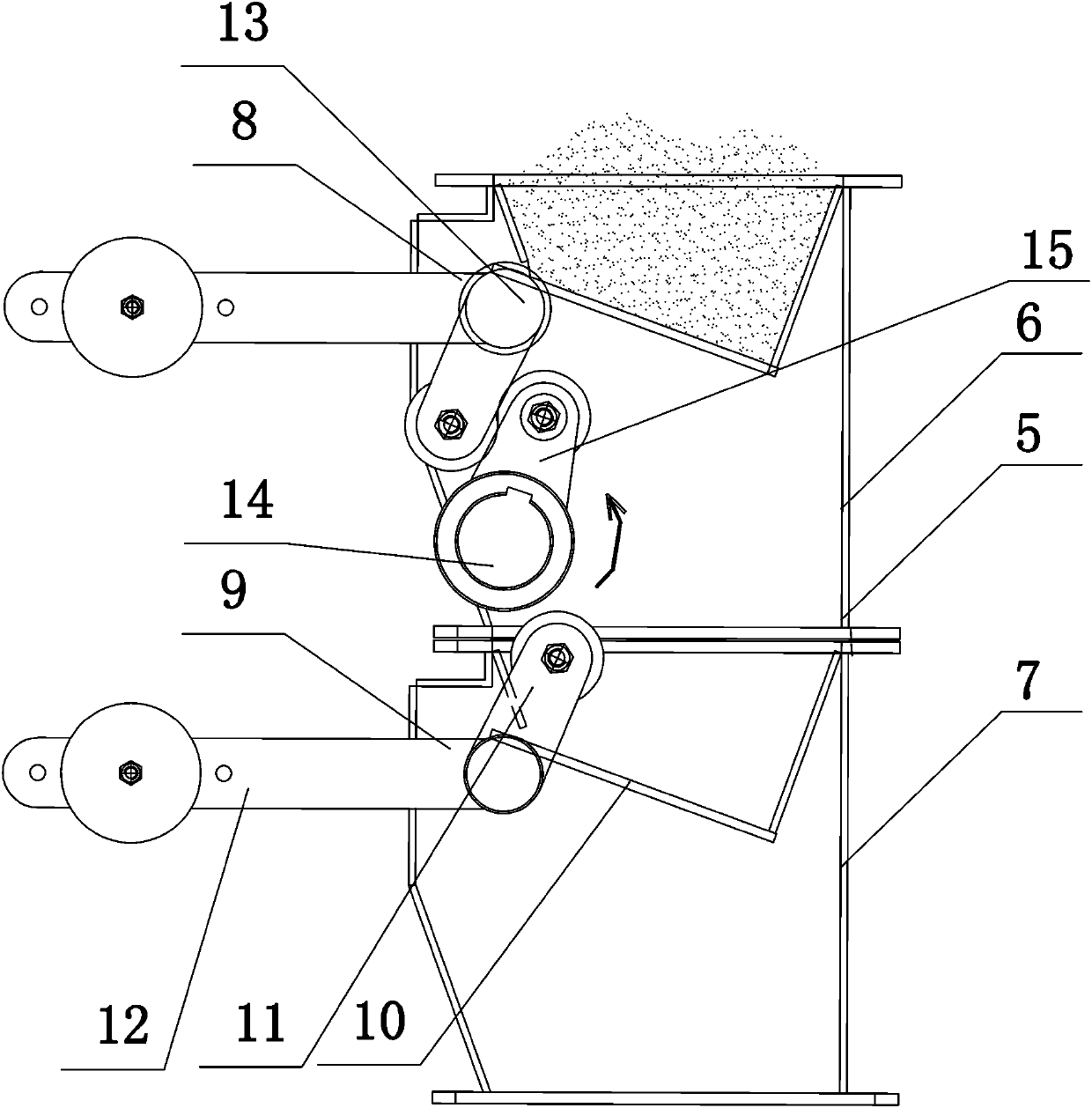

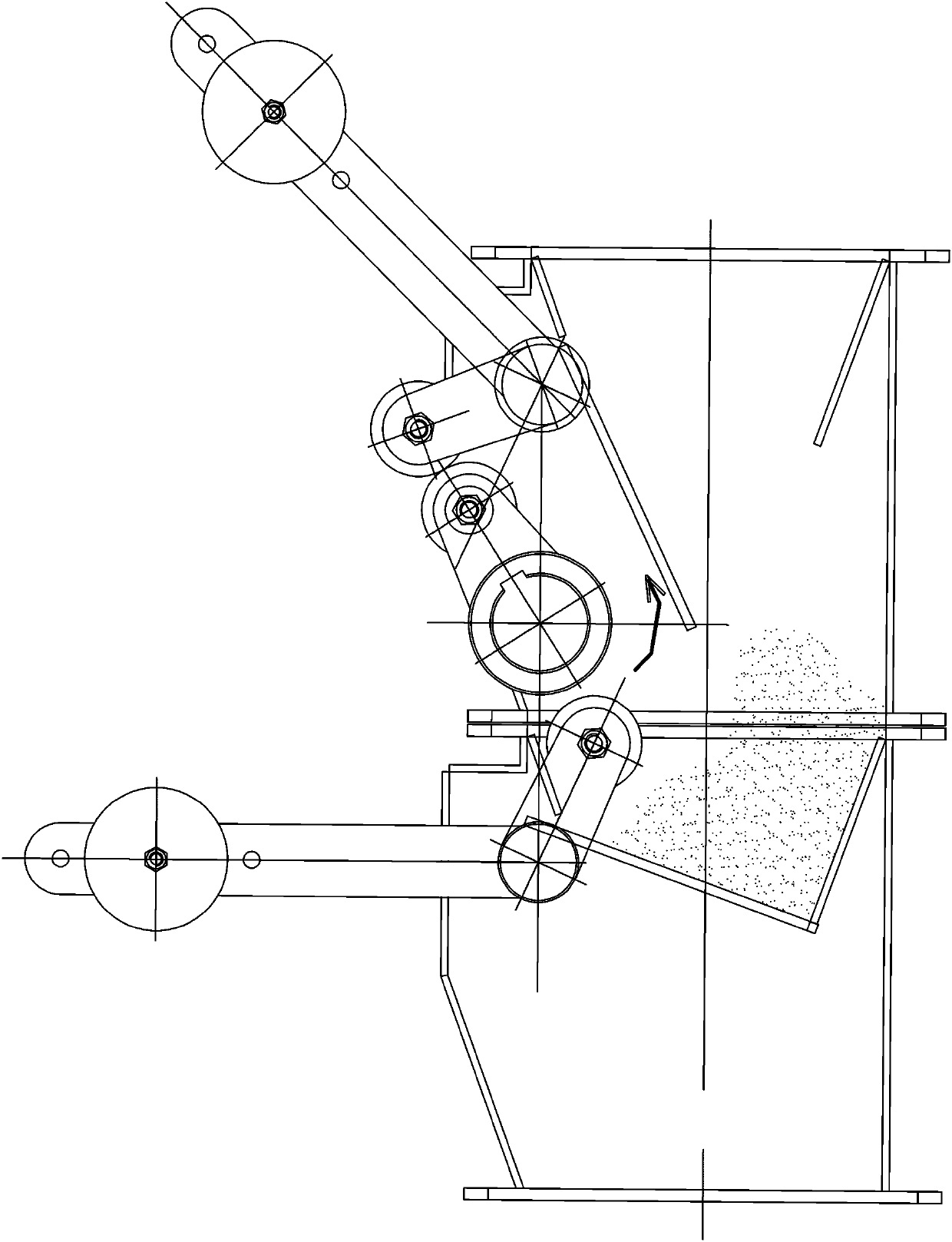

[0017] Such as Figure 1-4 As shown, a raw material feeding mechanism for zongzi includes a hopper 1. The hopper 1 is a funnel-type hopper with a thick upper end and a thinner end. A discharge port 2 is provided on the bottom side of the hopper 1, and the discharge port 2 extends into the volume cavity 16. Inside. The volume cavity 16 is provided with a piston rod 17 with a spring, the piston rod 17 includes a piston and a connecting rod, and the other end of the connecting rod extends out of the volume cavity 16 and is connected with the cylinder 21 . When the cylinder 21 is stretched out, the piston can block the discharge port 2, and the material cannot enter the volume cavity 16 from the hopper 1, and when the cylinder 21 is retracted, the material enters the volume cavity 16 by gravity. A baffle 18 and a screen 19 are respectively hinged on the upper and lower sides of the volume chamber 16 through pin shafts, and the other ends of the baffle 18 and the screen 19 are eng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com