Non-woven on-line weighing control device

A technology of control equipment and non-woven fabrics, which is applied in the direction of sending objects, thin material handling, transportation and packaging, etc., which can solve the problems of inability to adjust and control the weight deviation, and achieve the effect of saving materials and time, and small weight deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

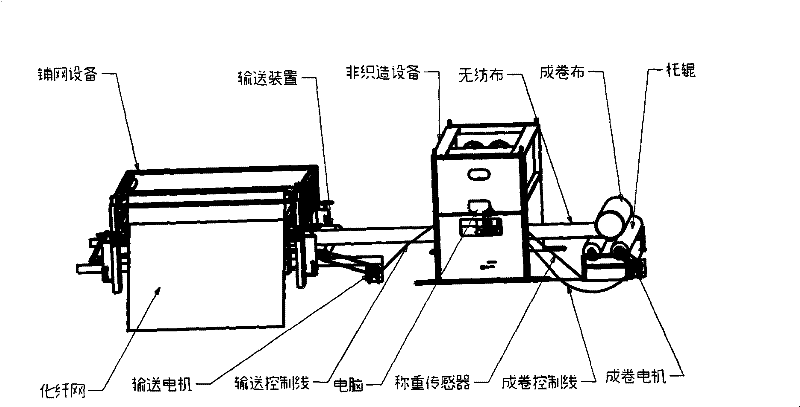

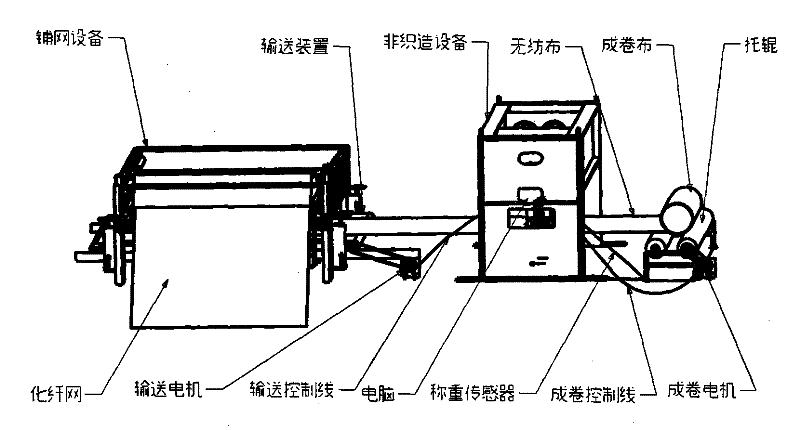

[0008] exist figure 1 Among them, the chemical fiber web (1) is overlapped on the conveying device (3) through the web-laying equipment (2), and driven by the conveying motor (13), it enters the non-woven equipment (4) and is processed into a non-woven fabric (5) into a roll The cloth (6) is on the top of the two supporting rollers (7), driven by the roll-forming motor (8), and the load cell (10) below the roll-forming control line (9) and the conveying control line (12) are respectively connected with the computer ( 11) Connect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com