A high-strength and low-elongation polysulfone fiber high-temperature-resistant film-coated filter material and its preparation method

A technology of film-coated filter material and polysulfone fiber, which is applied in the field of high-strength and low-elongation polysulfone fiber high-temperature-resistant film-coated filter material and its preparation, can solve the problems of low filtration accuracy, poor corrosion resistance, and large elongation, and achieve High filtration efficiency, strong corrosion resistance, smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

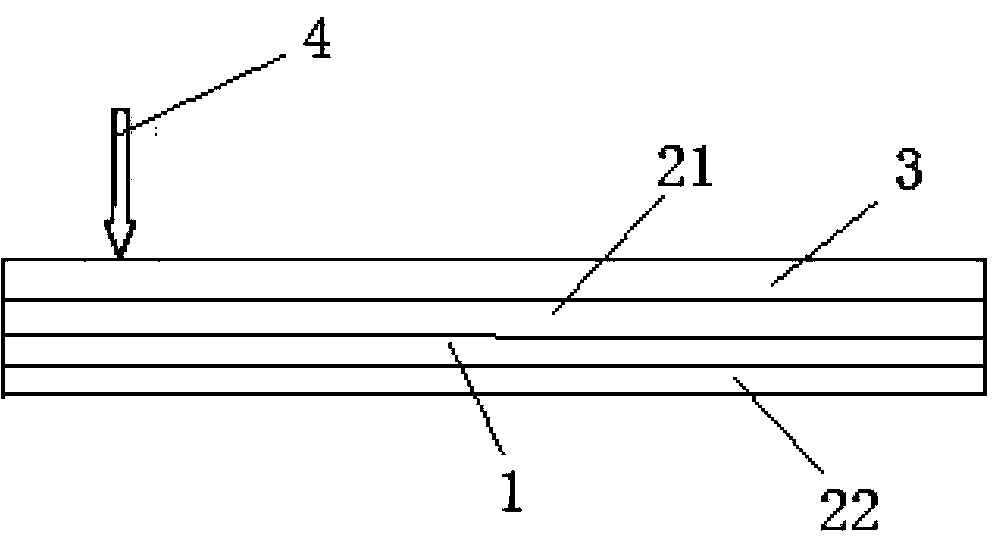

Image

Examples

Embodiment 1

[0031] 1) Selection and preparation of raw materials

[0032] Select sulfonamide fibers with a fineness of 2.0D and 2.8D, both of which have a length of 60 mm; the two fibers are evenly mixed, and the mass ratio of the sulfone fibers with a fineness of 2.0D is: 38% to 50%, and the remaining The weight is 2.8D sulfonamide fiber; the base fabric is glass fiber base fabric, and the weight is 420gsm.

[0033] 2) Temperature and humidity control in the fiber processing area

[0034] The entire production workshop is sealed with a glass cover to effectively prevent the adverse effects of the external climate and the airflow in the processing place. Air conditioning equipment, humidification and dehumidification equipment are installed in the workshop; the temperature of the carding and cross-laying areas is controlled at 20-35 ℃ , the relative humidity is controlled at 50% to 75%.

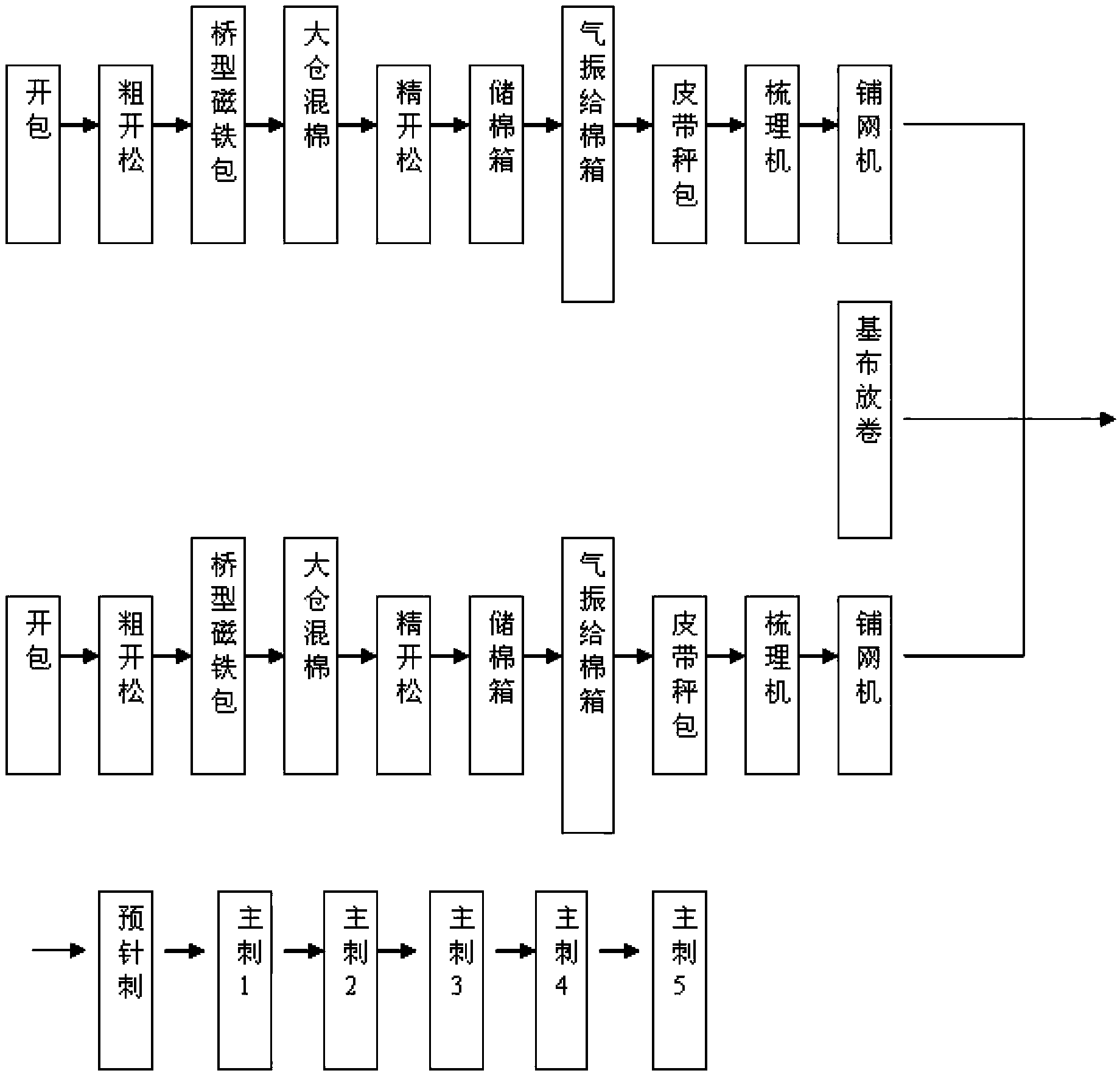

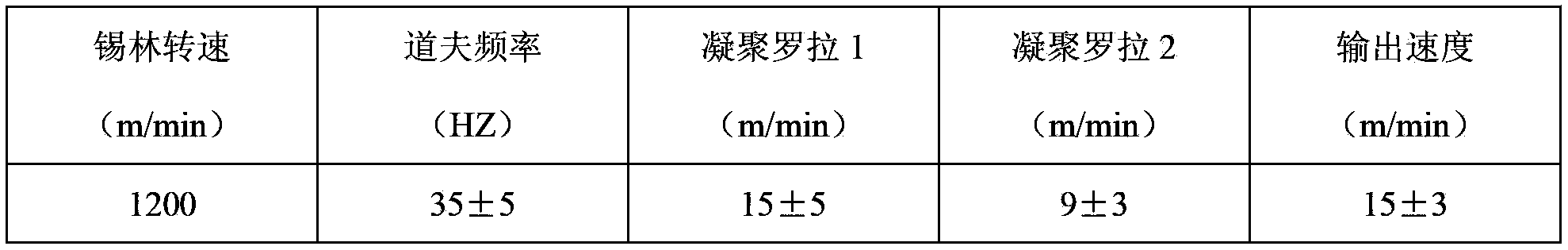

[0035] 3) Carding and cross-lapping

[0036] The evenly mixed sulfonamide fiber layer is fed into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com