Storage battery grid casting die

A battery and mold technology, applied in the field of casting molds, can solve problems such as grid collision damage, casting liquid waste, grid failure, etc., and achieve the effects of increased yield, thin interlayer, and small weight deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

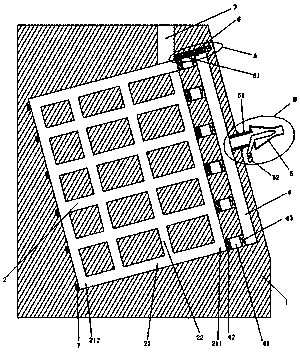

[0009] The present invention will be further described below in conjunction with accompanying drawing.

[0010] see figure 1 , the battery grid casting mold of the present invention includes a mold body, a mold cavity is arranged in the mold body, a sprue communicating with the mold cavity is arranged on the mold body, and a material breaking device is arranged in the mold body near the sprue , one side of the mold body is provided with an exhaust passage, and the mold cavity communicates with the exhaust passage through the exhaust port. The exhaust passage is provided with an air outlet, and a negative pressure generator is arranged in the air outlet. The cavity is provided with a temperature detector, the material cutting device is provided with a slider, the mold body is provided with a slide rail, and the material cutting device is slidably connected with the mold body through the slider and the slide rail.

[0011] The invention is simple in structure, easy to operate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com