Intelligent split charging machine

A packing machine and intelligent technology, which is applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of large weight deviation of each material, cannot meet mass production, and the accuracy needs to be improved, so as to improve accuracy, Meet the effect of mass production and small weight deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

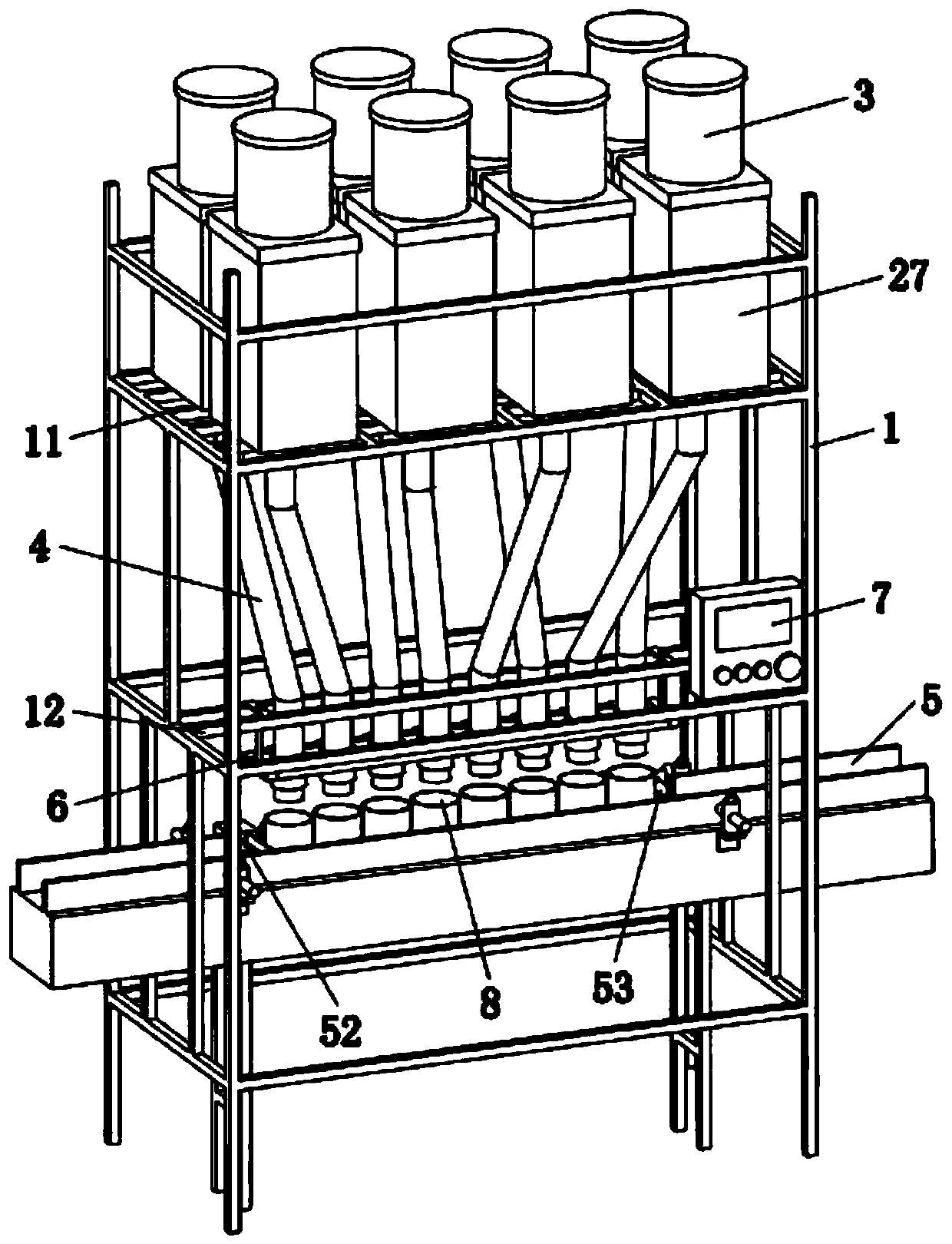

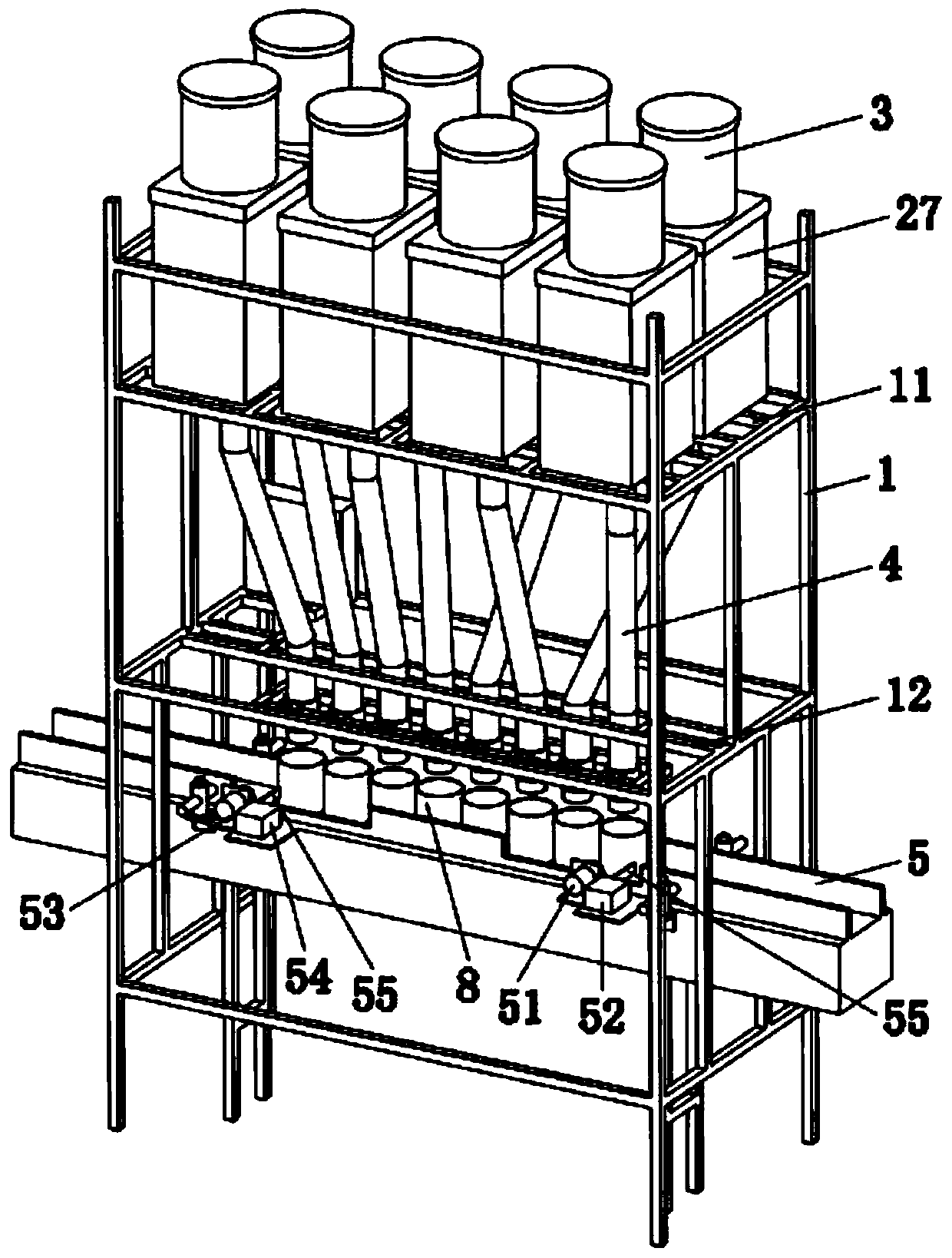

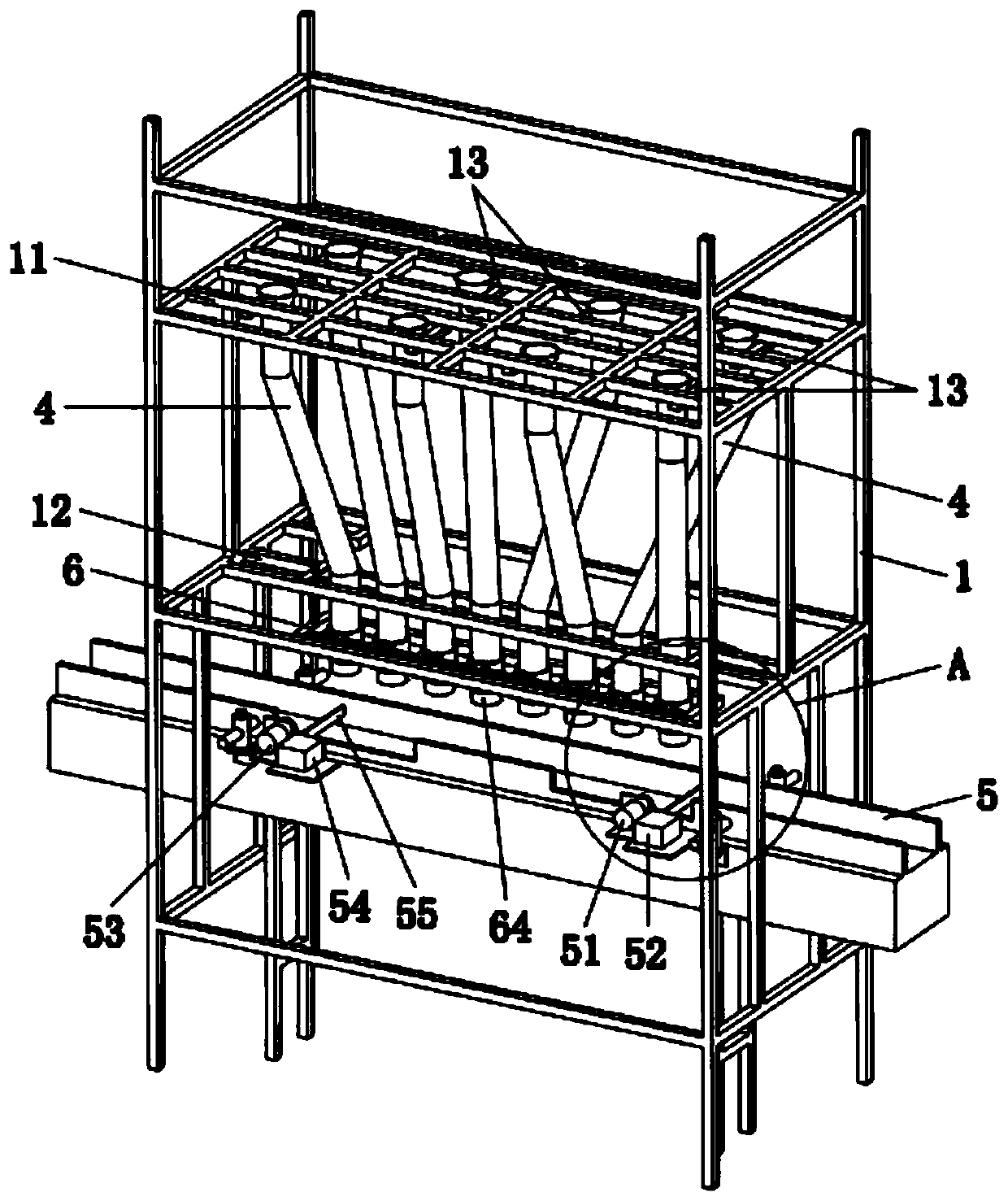

[0042] Cooperate Figure 1 to Figure 3 As shown, the present invention discloses an intelligent dispensing machine, which includes a frame 1 , a feeding device, a storage tank 3 , a feeding pipe 4 , a conveying line 5 , an adjusting frame 6 and a control device 7 .

[0043] The frame 1 is provided with an upper bracket 11 and a lower bracket 12, and the upper bracket 11 is provided with a feeding device, and the upper bracket 11 is provided with several feeding pipes 4 below the feeding device, and the top of the feeding device is provided with a storage tank 3 , The lower bracket 12 is provided with an adjustment frame 6 . The upper end of the feeding pipe 4 is trumpet-shaped, and it is fixed on the upper bracket 11 by the upper adjusting piece 13. The lateral position of the feeding pipe 4 is adjustable, and the feeding can be adjusted by adjusting the position of the upper adjusting piece 13 fixed on the upper bracket 11. The position of the upper end of the feed pipe 4. ...

Embodiment 2

[0054] Cooperate Figure 9 to Figure 12 As shown, the difference between this embodiment and Embodiment 1 is:

[0055] Feeding device also comprises material warehouse 27, and the quantity of material warehouse 27 is one, is provided with first support 21, even material assembly, quantitative assembly, the second support 24, load cell 25 and discharge hopper 26 in material warehouse 27, material warehouse The bottom of 27 is provided with a plurality of discharge ports (not shown) corresponding to discharge hopper 26, is provided with the discharge door 261 that can open and close automatically on the discharge port, and the upper end nozzle of each feeding pipe 4 is respectively Align each discharge port.

[0056] The top of the first bracket 21 is provided with a leveling assembly and several quantitative components, and the leveling assembly includes a front chute 221 and a front vibrator 222 located at the bottom of the front chute 221, and the front chute 221 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com