Patents

Literature

82results about How to "Meet packaging needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

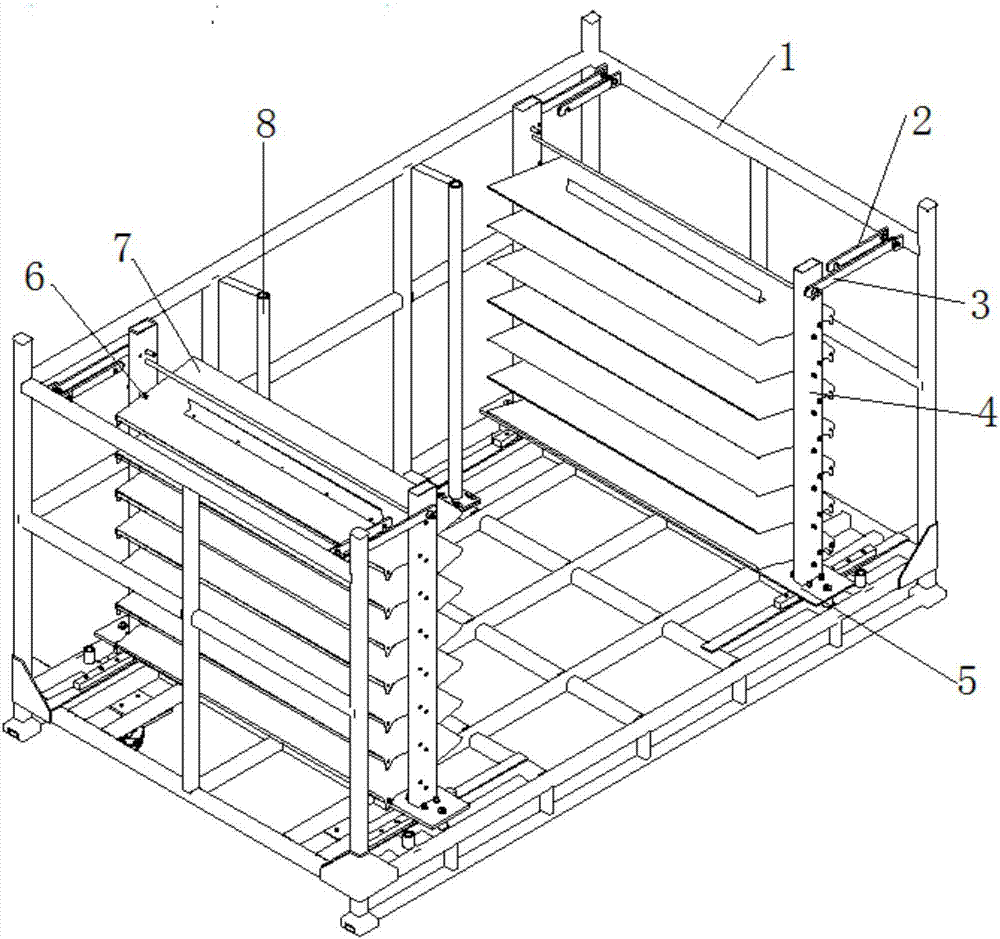

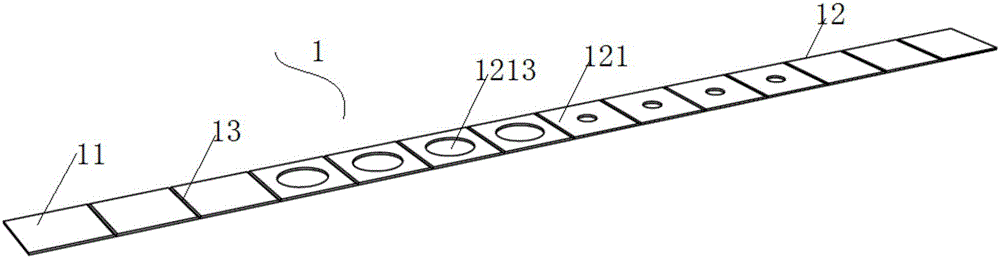

Automatic boxing system for second generation of tetra brik milk bag gift box

ActiveCN105501526AImprove the operating environmentImprove stabilityConveyorsPackagingEngineeringMechanical engineering

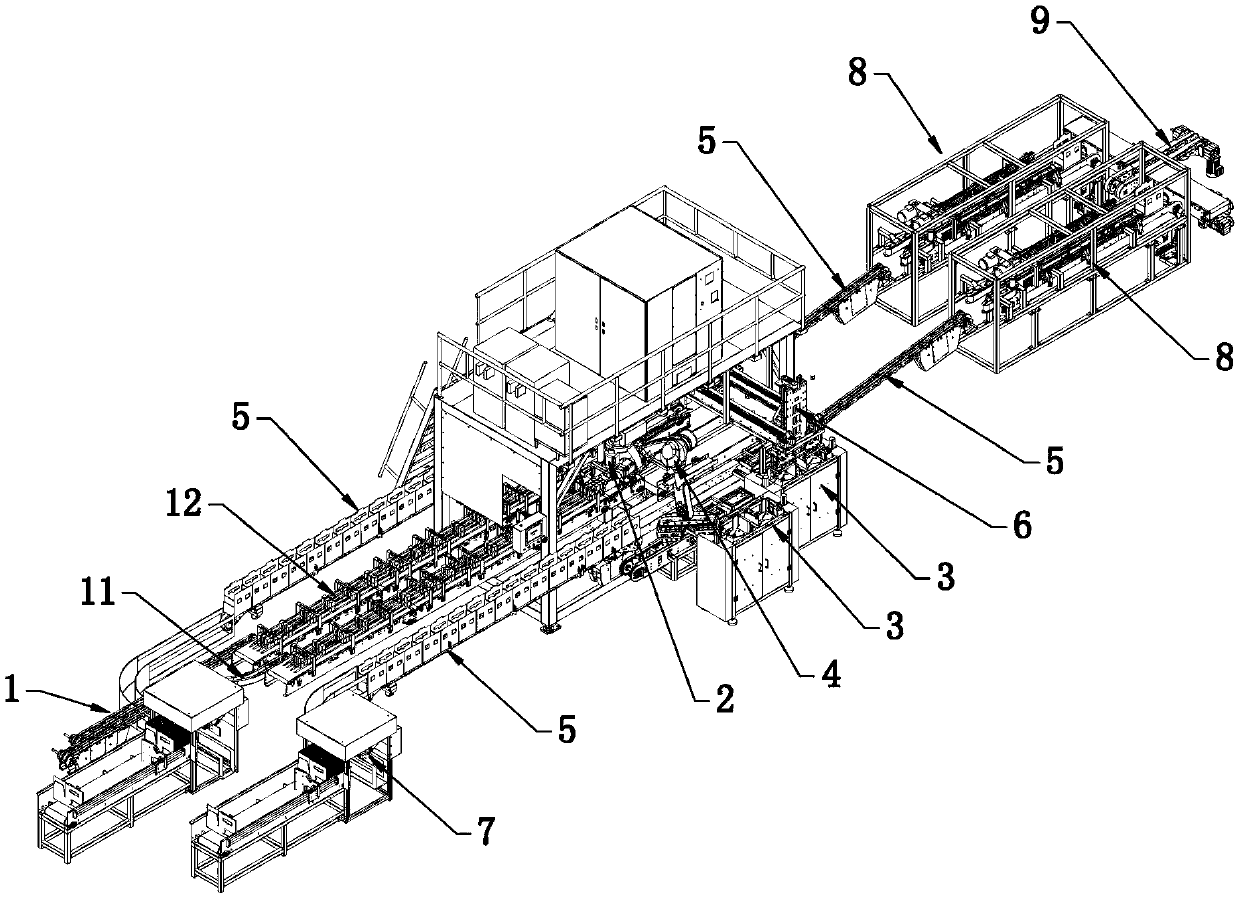

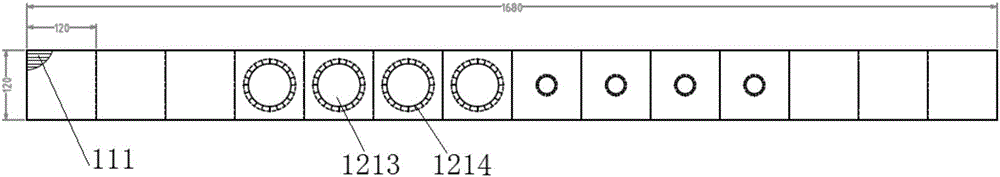

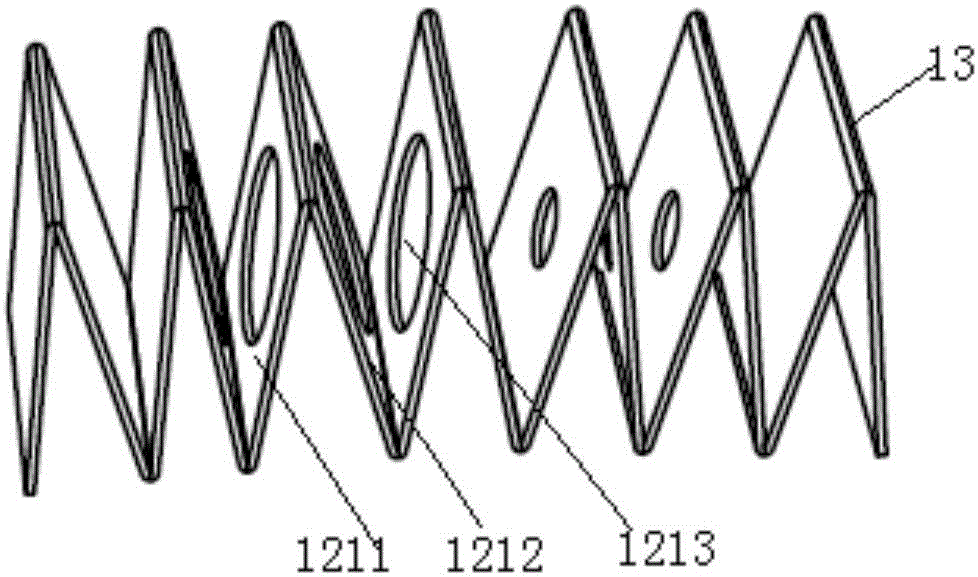

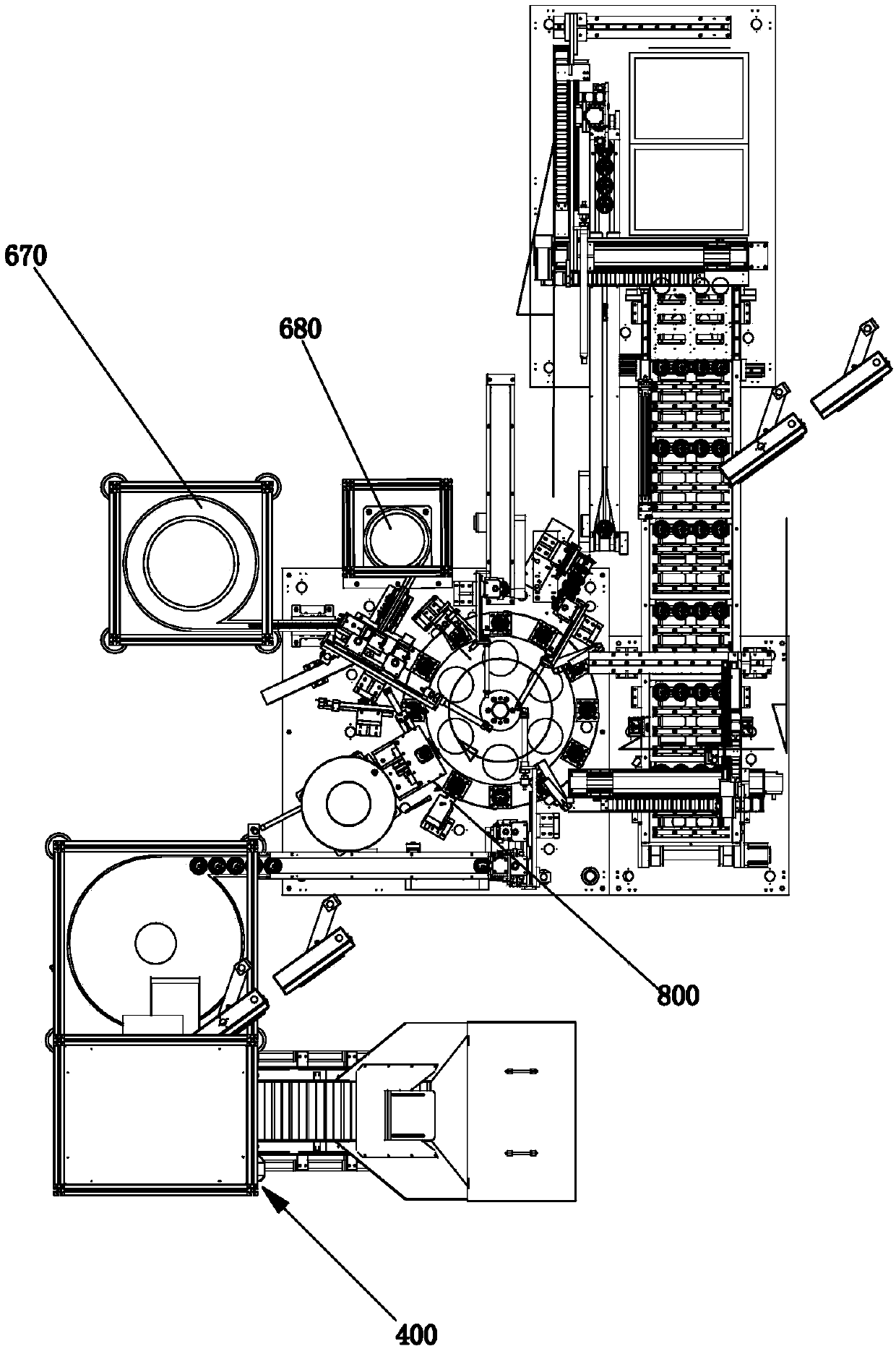

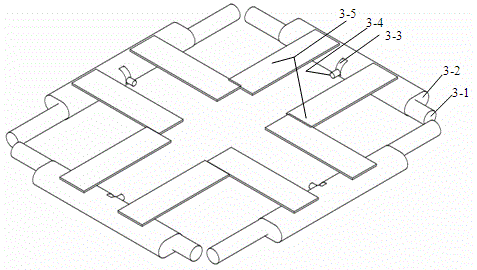

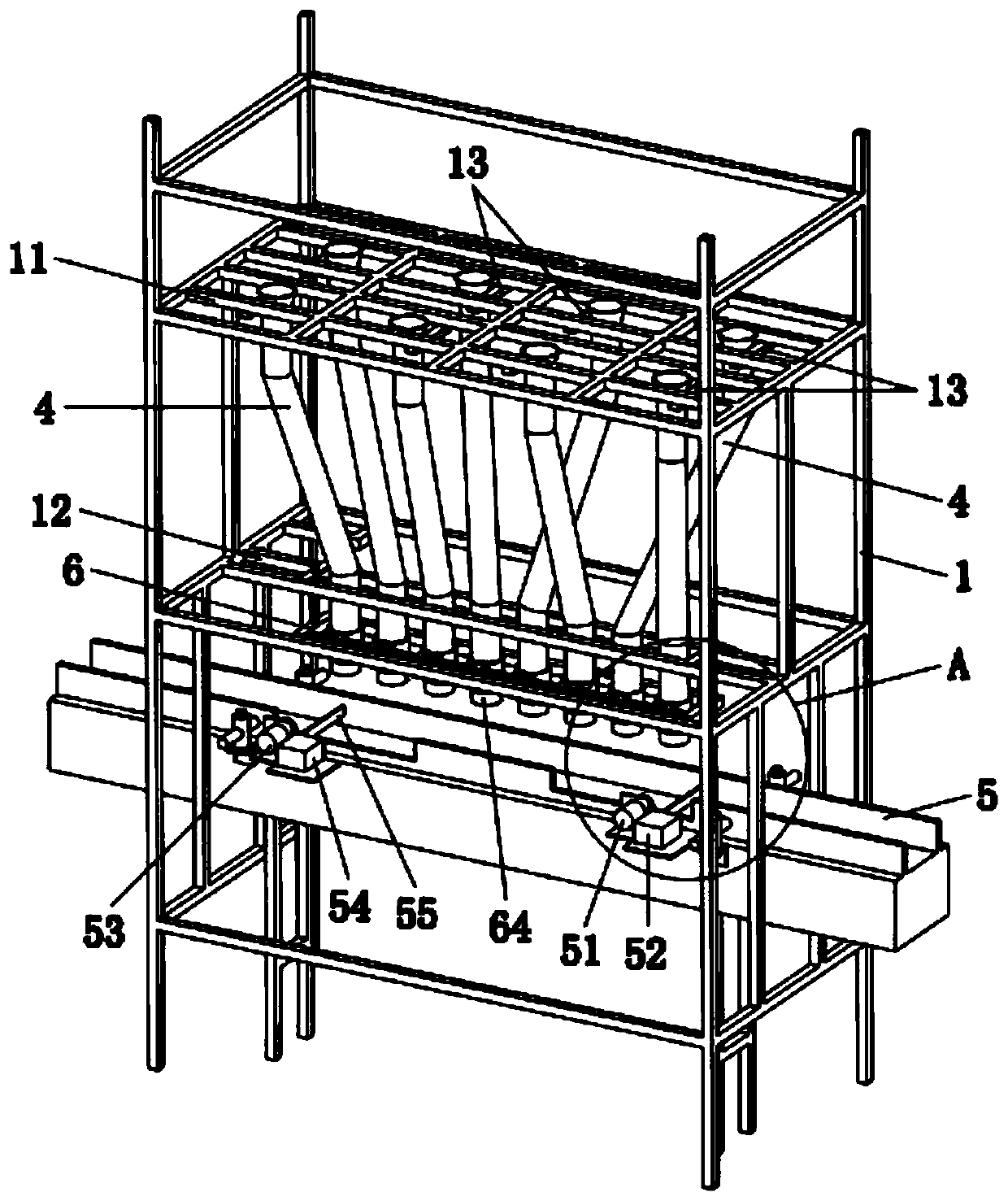

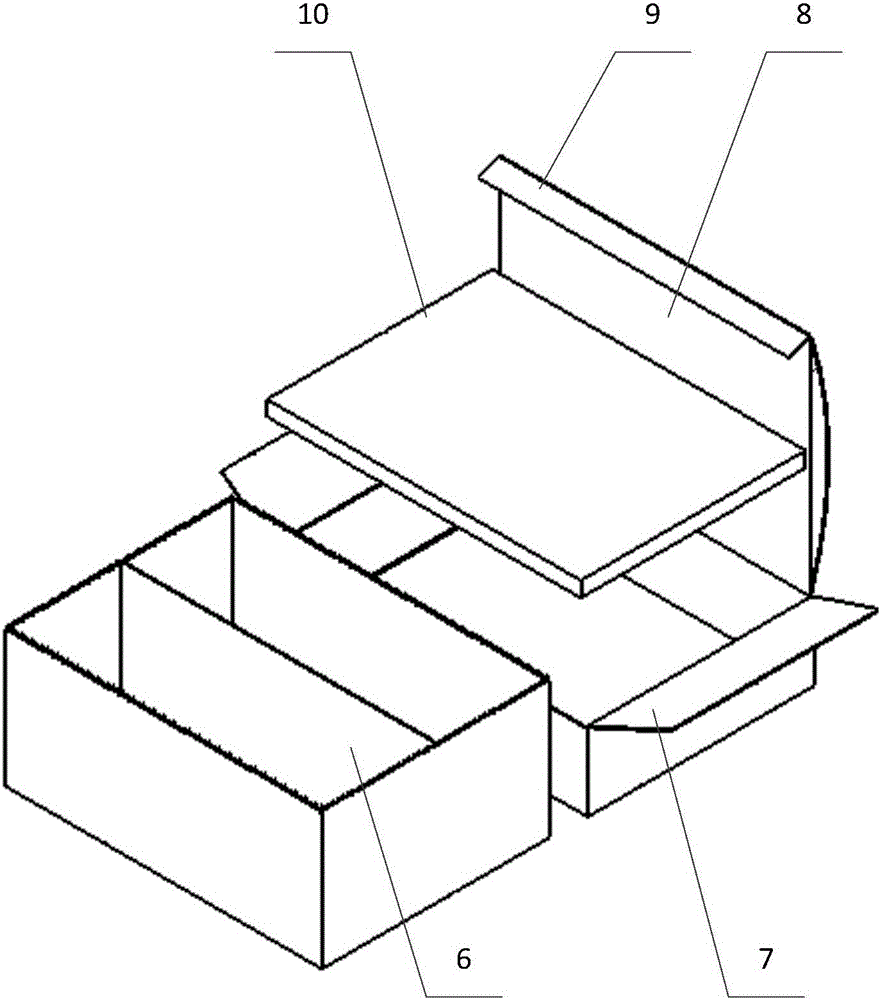

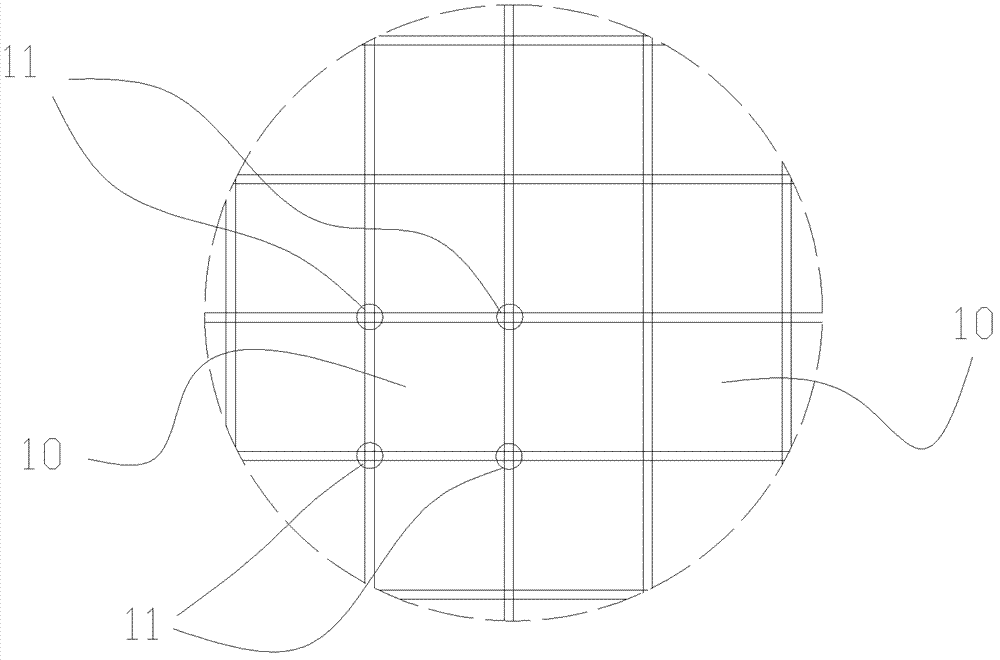

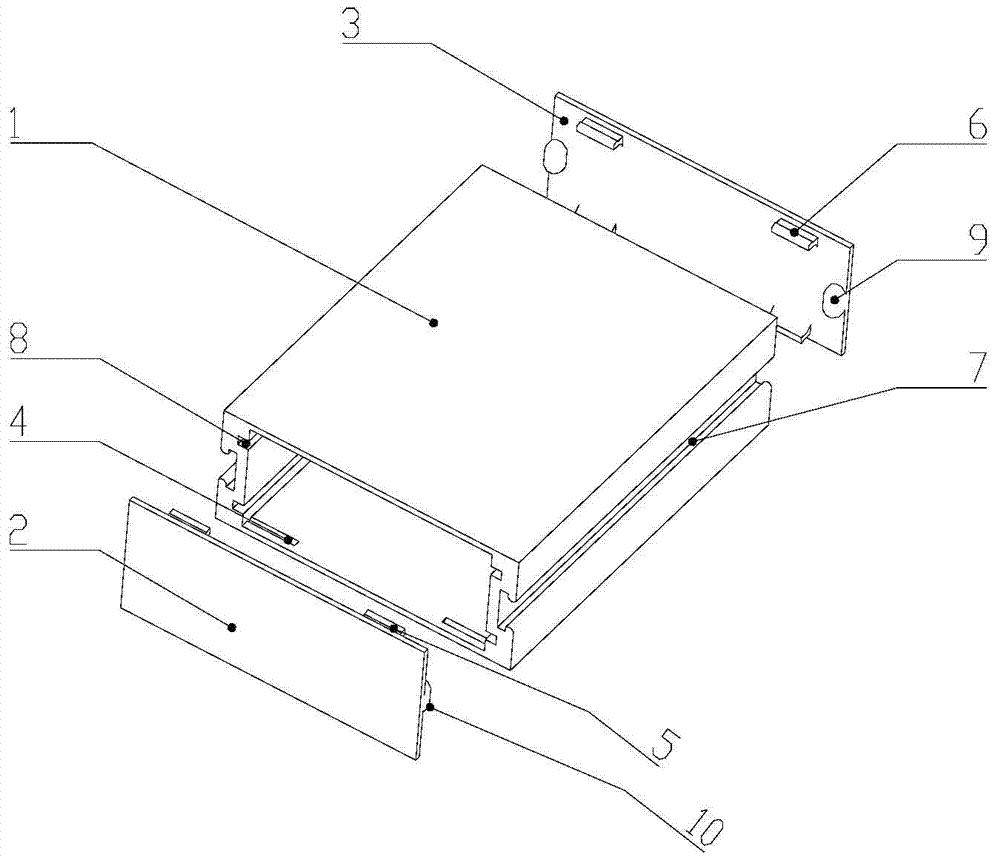

The invention discloses an automatic boxing system for a second generation of tetra brik milk bag gift box. The automatic boxing system comprises a separation mechanism (1), wherein the separation mechanism (1) comprises a primary separation mechanism (11) and two secondary separation mechanisms (12); an integration device (2) is correspondingly arranged at the tail end of each secondary separation mechanism (12), and two groups of partition board feeding mechanisms (3) and a milk box conveying line (5) which are corresponding are arranged beside each integration device (2) successively, the two groups of partition board feeding mechanisms (3) are respectively sleeved with lower partition boards, and a milk bag unit inbox mechanism (4) corresponds to an upper partition board straight-line module (6). A milk box sleeved with the partition board is conveyed to a corresponding lid buckling and box sealing machine (8) for lid buckling and box sealing through the milk box conveying line (5), and a two-in-one conveying mechanism (9) on the rear side of the lid buckling and box sealing machine (8) continues to convey the milk box. The automatic boxing system carries out automatic boxing in a two-in-one way, therefore reducing the speed, reducing links and increasing the output.

Owner:苏州澳昆智能机器人技术有限公司

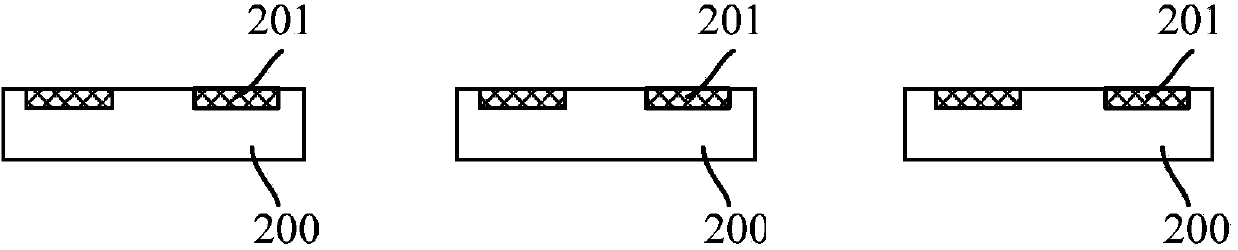

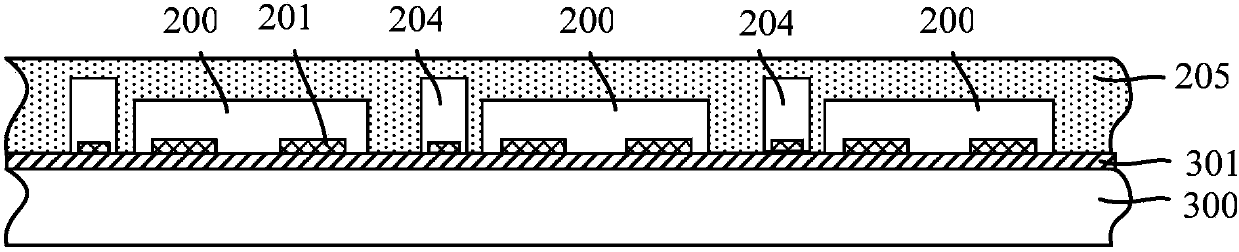

Packaging structure

ActiveCN103745958AImprove efficiencyRealize one packageSemiconductor/solid-state device detailsPrinted circuit aspectsSemiconductor chipInterconnection

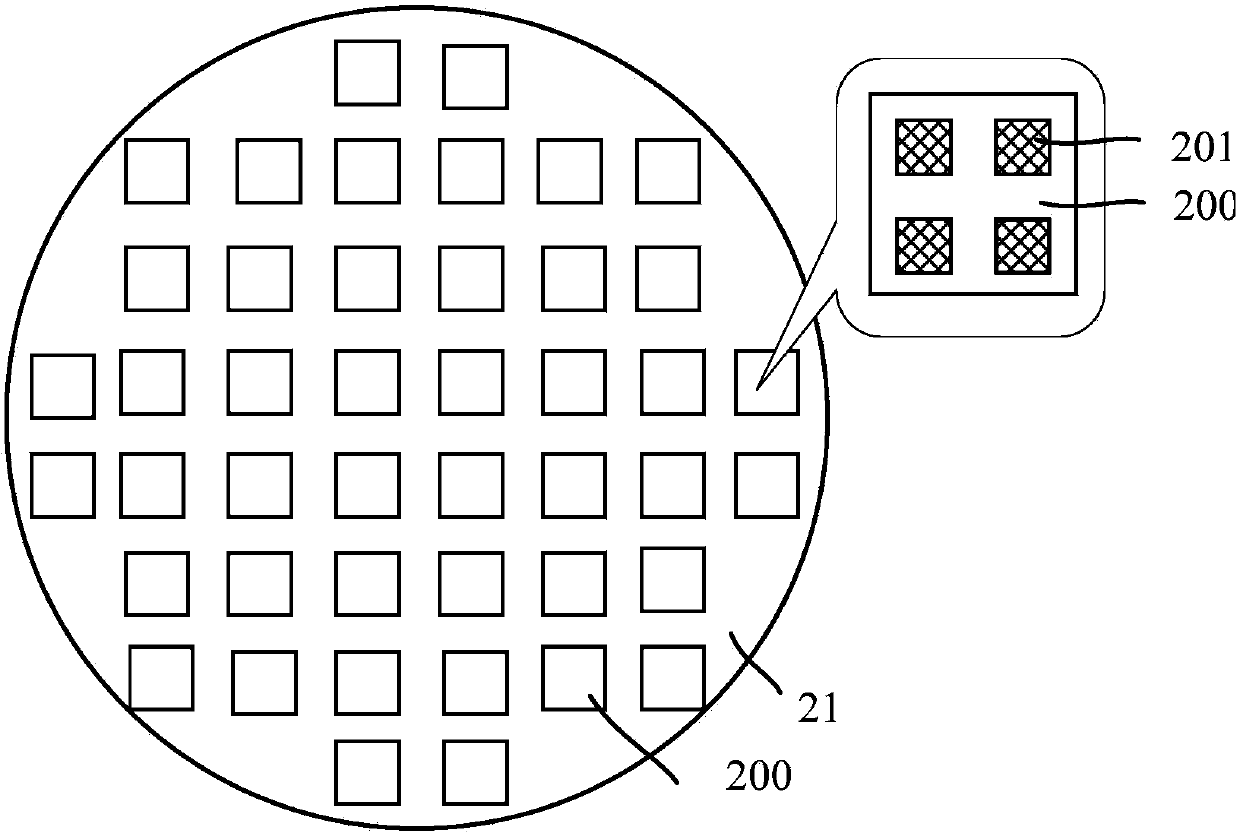

The invention discloses a packaging structure. The packaging structure comprises: a circuit carrier board, wherein the circuit carrier board comprises a first surface and a second surface which is opposite to the first surface, the circuit carrier board is provided with a plurality of bearing units which are arranged in a matrix manner, first surfaces of the bearing units are provided with a plurality of input bonding pads, second surfaces of the bearing units are provided with a plurality of output bonding pads, and the input bonding pads and the output bonding pads are connected through an interconnection structure; a pre-packaged panel, wherein the pre-packaged panel comprises a first plastic packaged layer, a plurality of integrated unit which are arranged in a matrix manner are arranged in the first plastic packaged layer, at least one semiconductor chip is arranged in each integrated unit, surfaces of the semiconductor chips are provided with a plurality of bonding pads, the bonding pads are provided with first metal bumps, the pre-packaged panel is arranged on the first surface of the circuit carrier board in a flipping manner, and the first metal bumps and the input bonding pad are soldered together; a filling layer for filling the space between the first surfaces of the bearing units and the pre-packaged panel; and second metal bumps located on the output bonding pads of the second surfaces of the bearing units. According to the packaging structure of the invention, the integration level is improved.

Owner:NANTONG FUJITSU MICROELECTRONICS

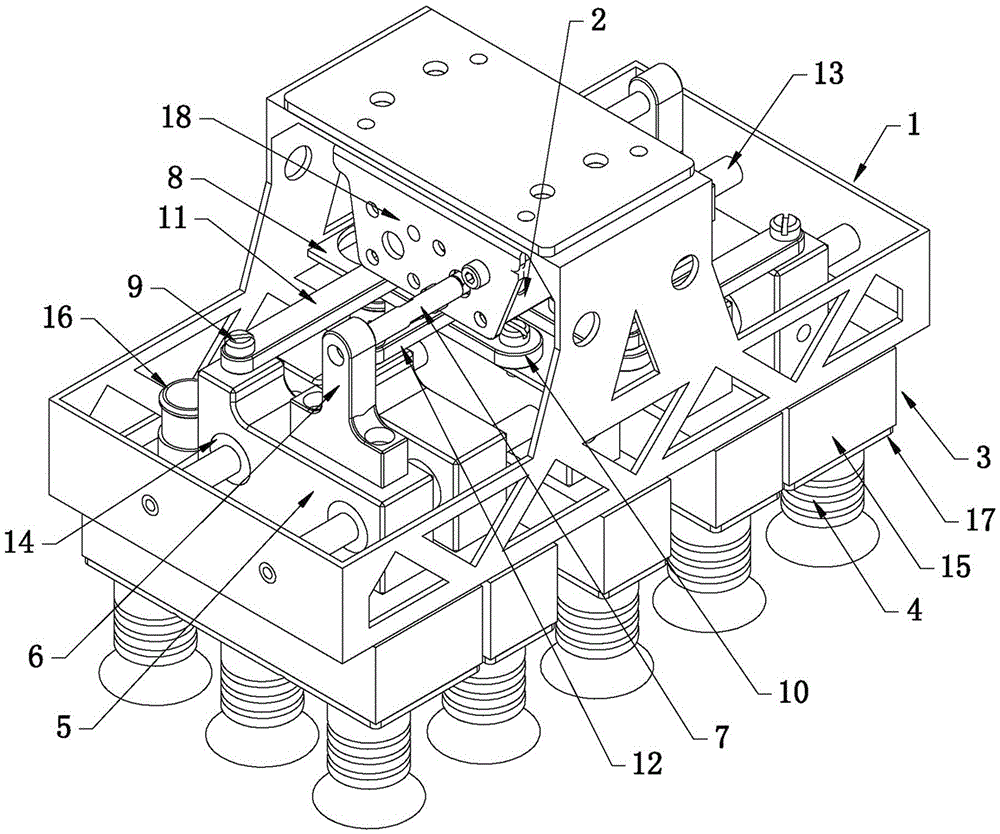

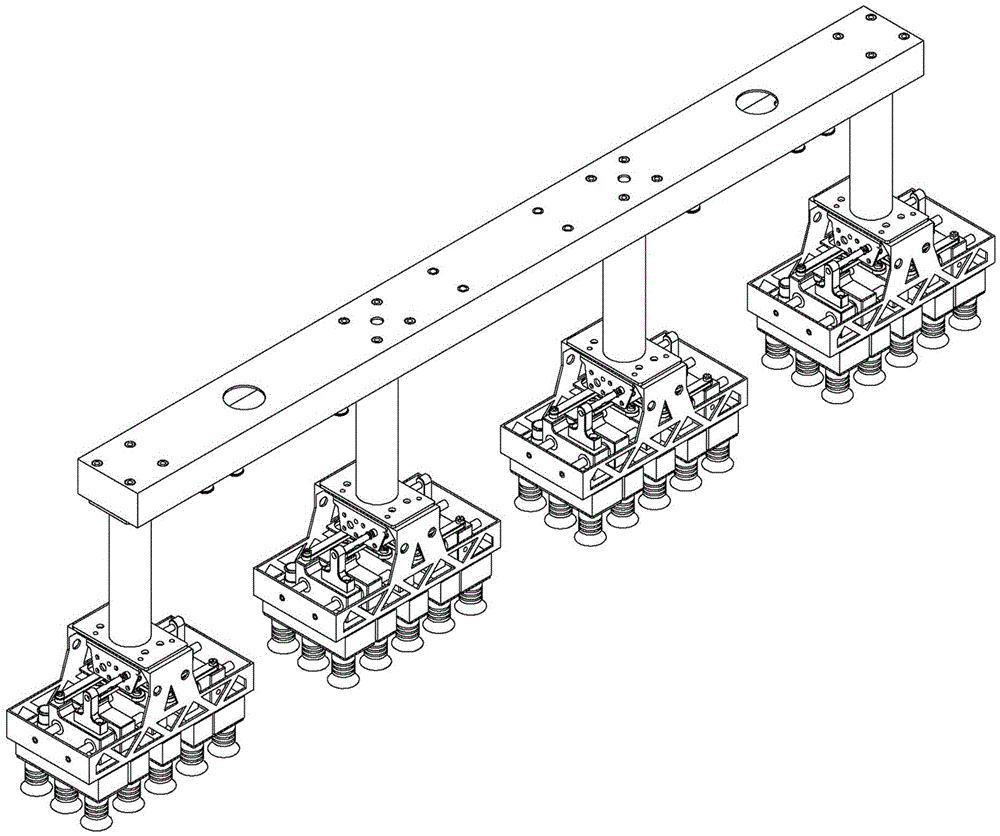

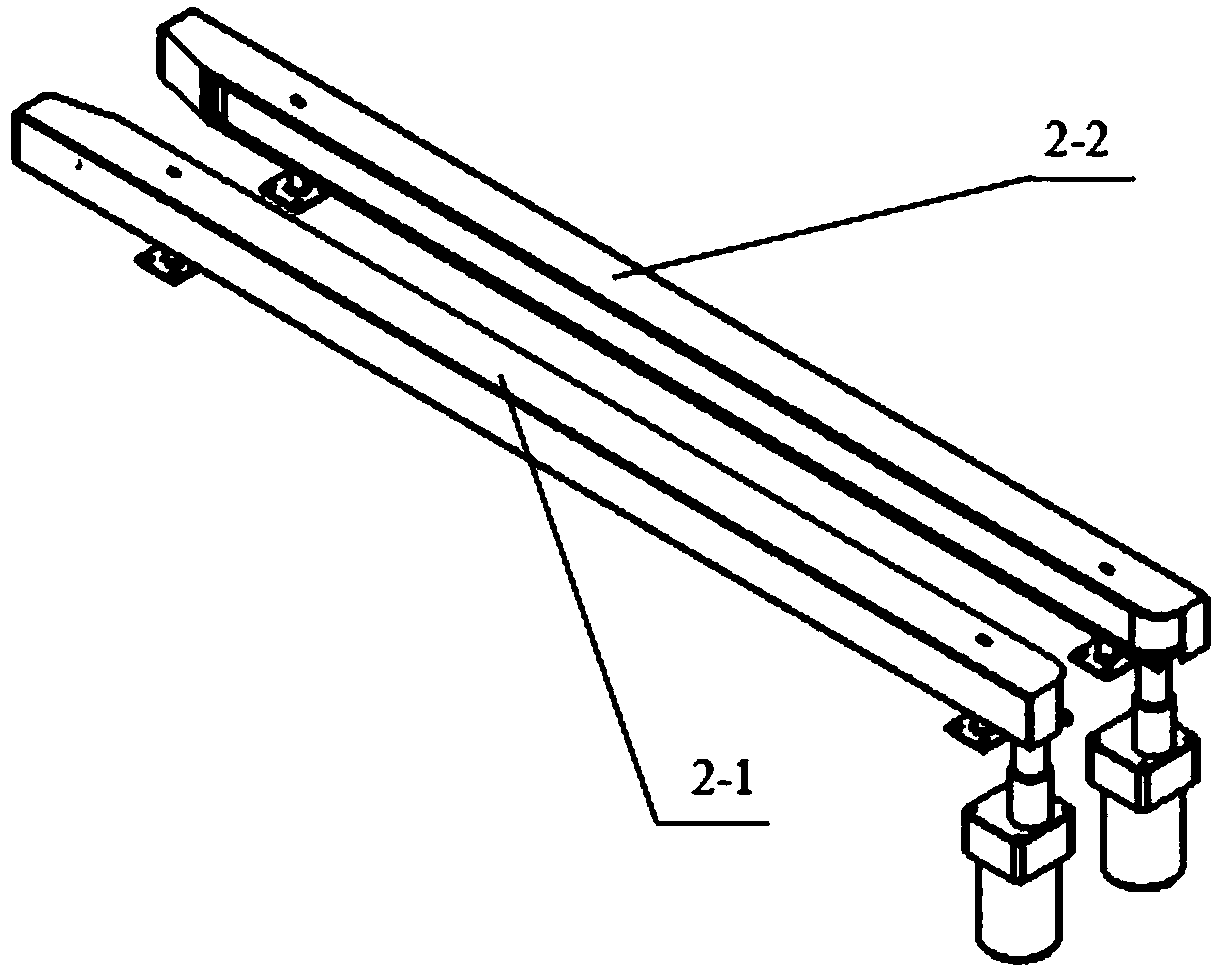

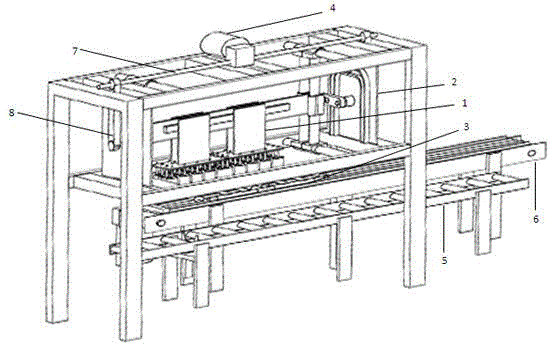

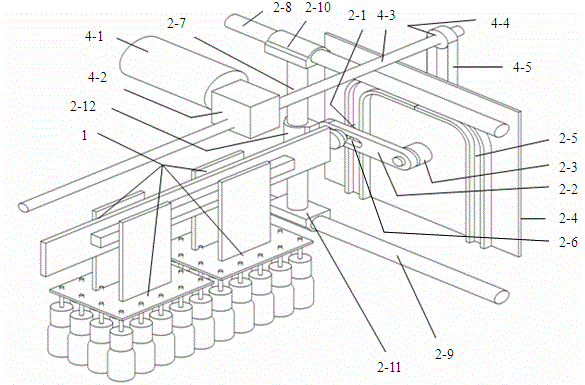

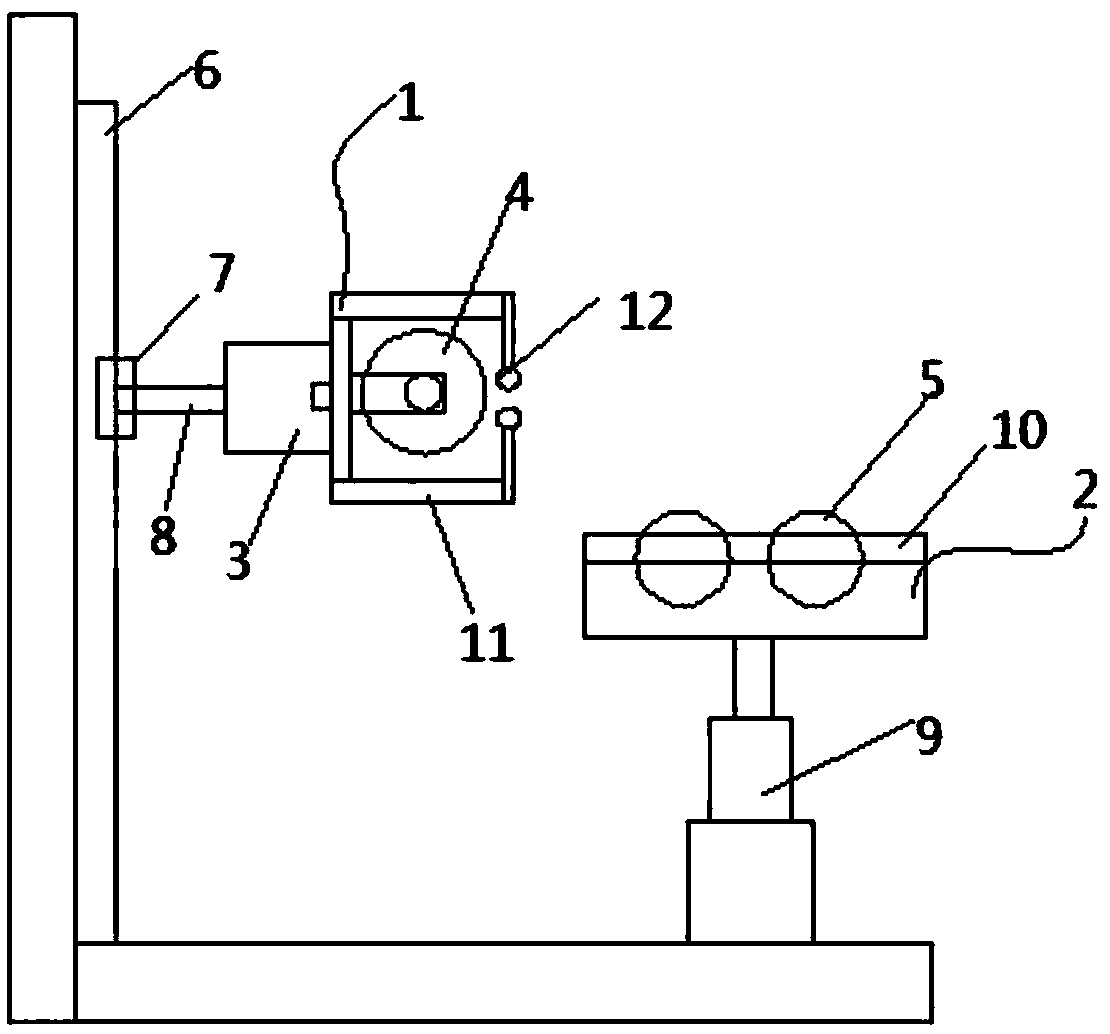

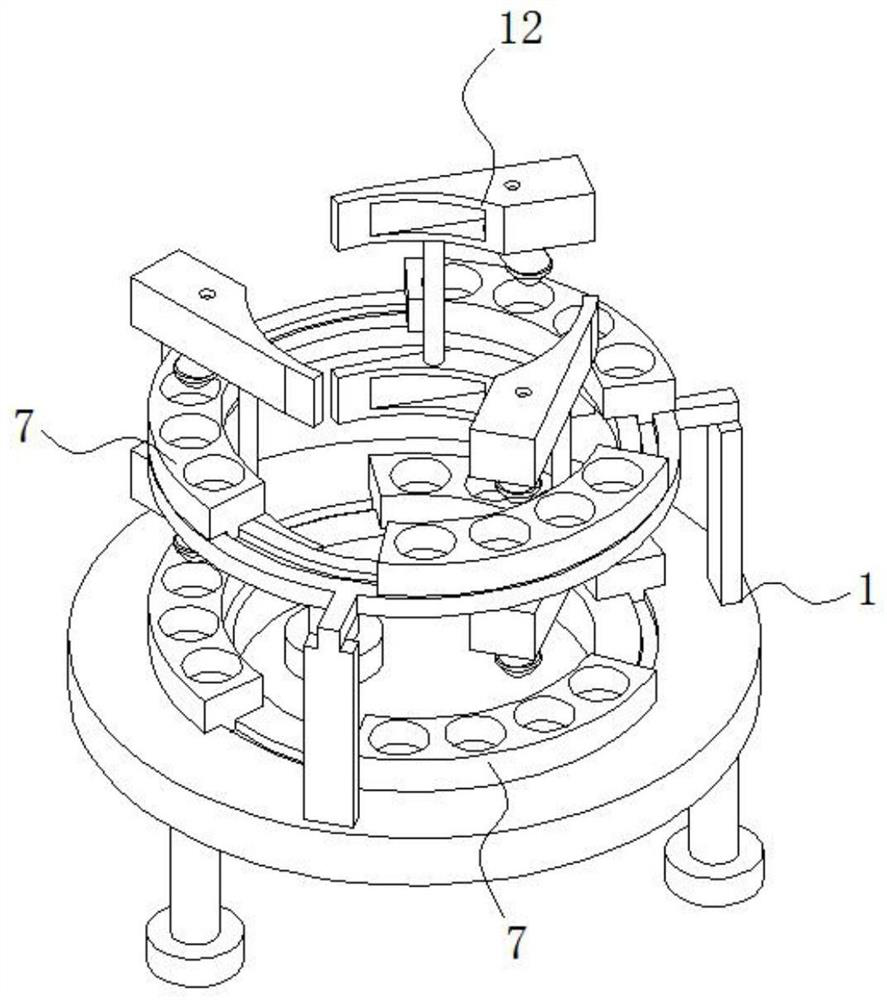

Clamping apparatus of variable-pitch flexible robot

ActiveCN105459087ASimple structureEasy to useProgramme-controlled manipulatorGripping headsEngineeringMechanical engineering

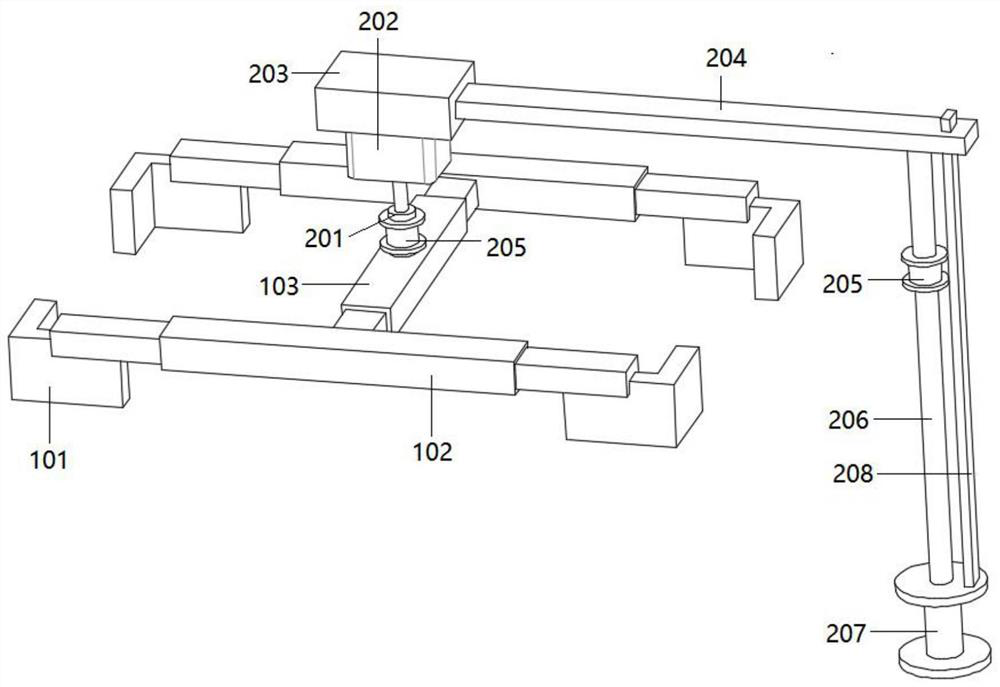

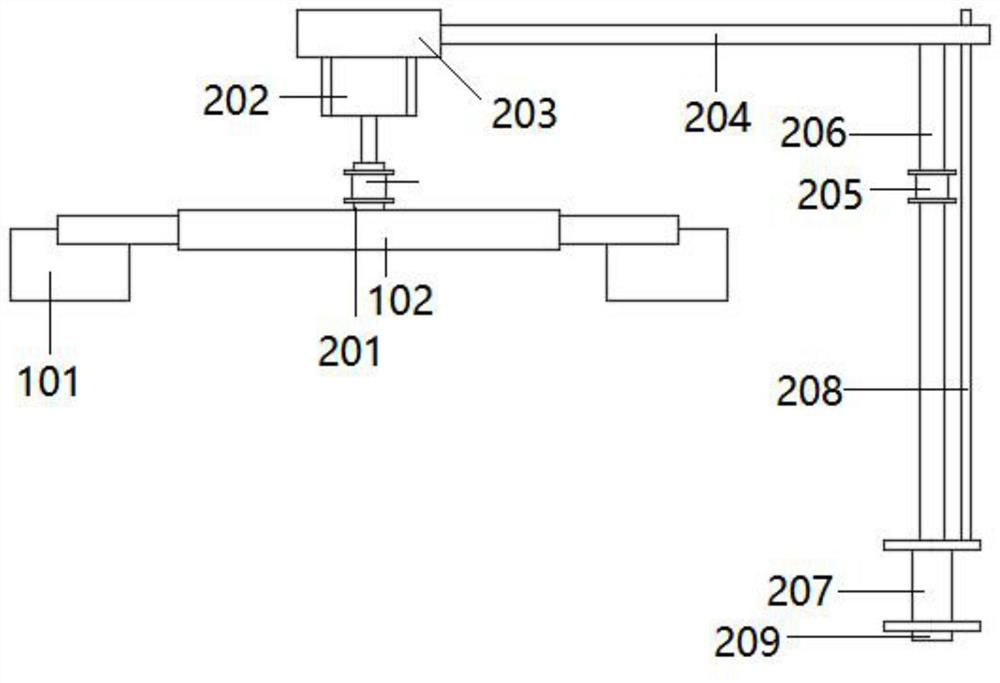

The invention discloses a clamping apparatus of a variable-pitch flexible robot. The clamping apparatus comprises a clamping apparatus framework (1). The bottom of a top plate of the clamping apparatus framework (1) is provided with two cylinders (2) opposite in driving direction. At least two suckers (3) are arranged in the clamping apparatus framework (1). The bottoms of the suckers (3) are provided with sucker flexible joints (4). Connecting blocks (5) are fixedly installed on the suckers (3). Meanwhile, cylinder push blocks (6) are fixedly arranged on the connecting blocks (5) on the sides of the two ends of the clamping apparatus framework (1) in the length direction of the clamping apparatus framework (1) and are connected with piston rods of the cylinders (2) through corresponding cylinder connecting rods (7). When the piston rods of the two cylinders (2) stretch out, the corresponding suckers (3) are far away from each other, and otherwise, the corresponding suckers (3) get close to each other. The clamping apparatus can adjust the distance between the suckers in real time, the binning requirement of ice cream of different kinds and at different intervals is met, and the application range is wide.

Owner:苏州澳昆智能机器人技术有限公司

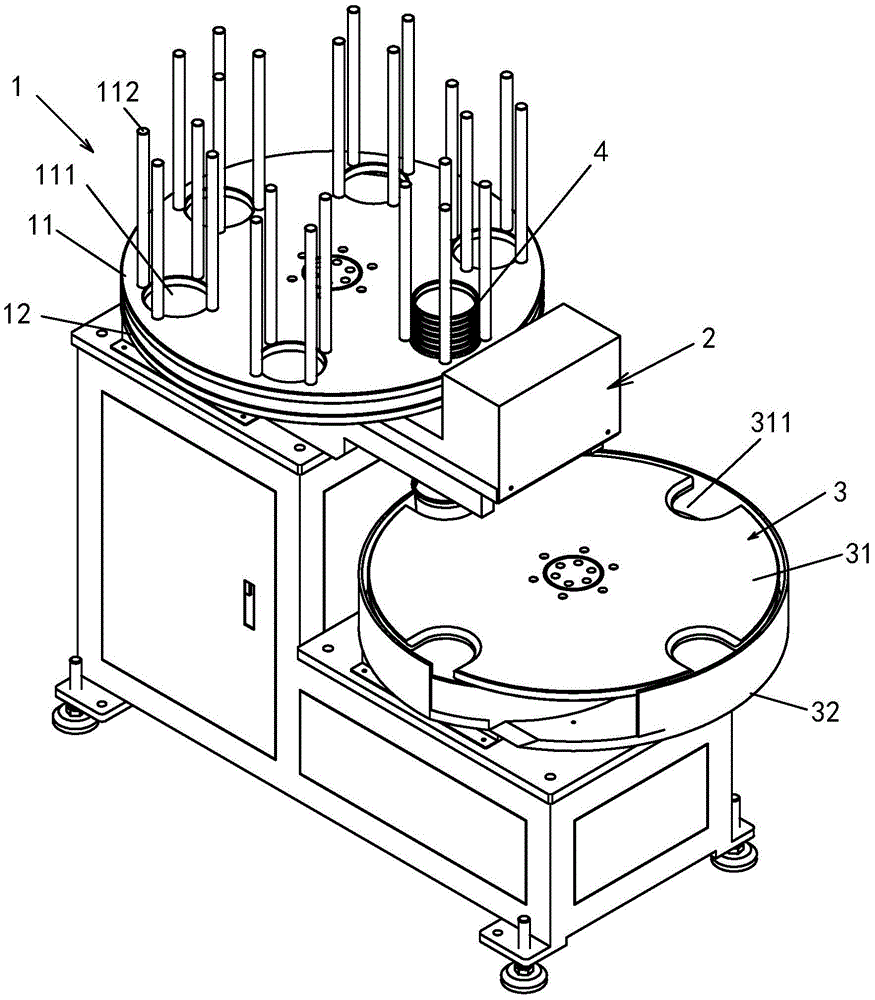

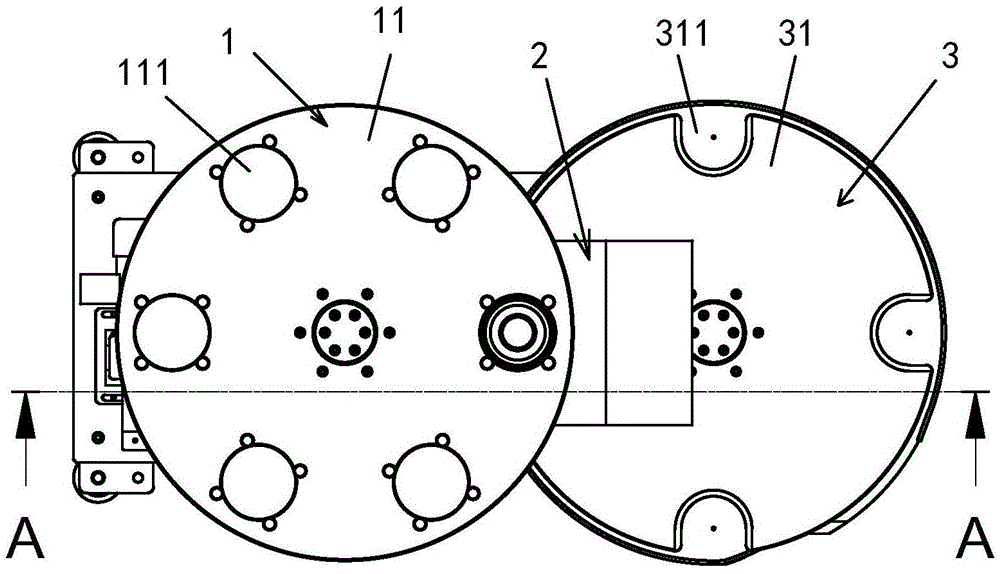

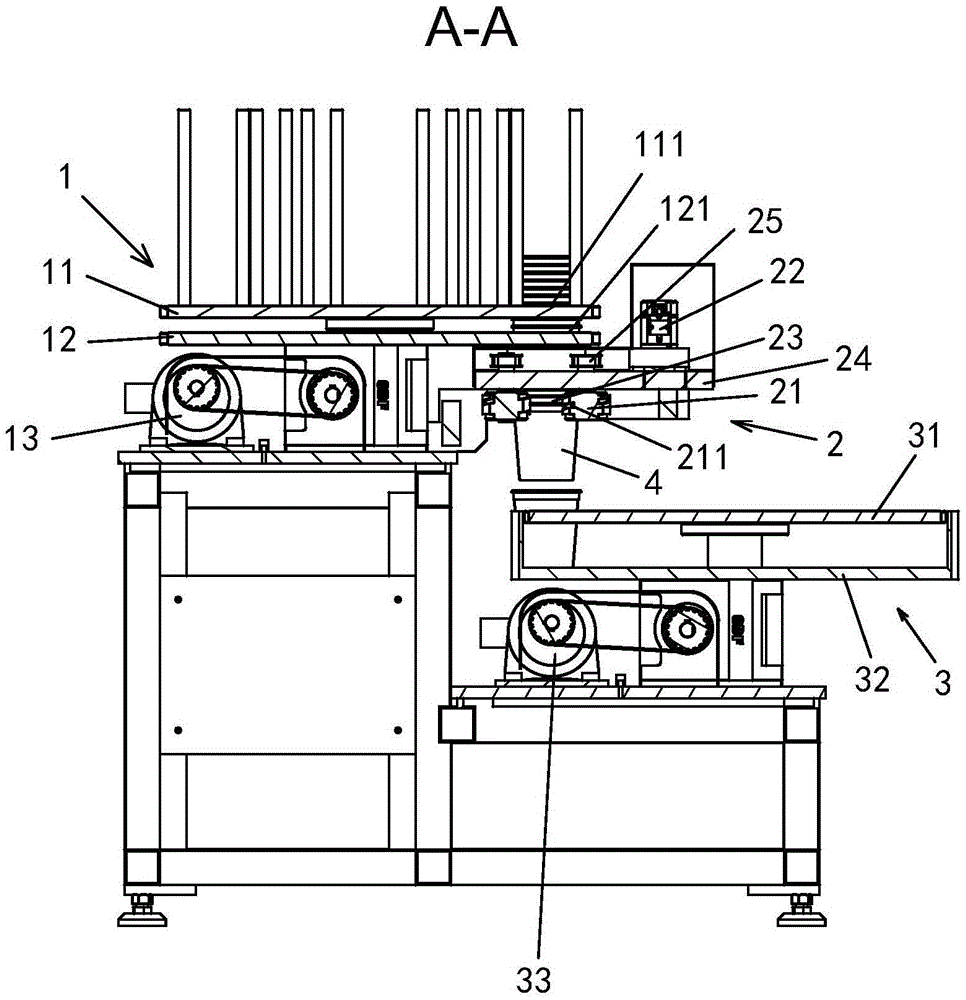

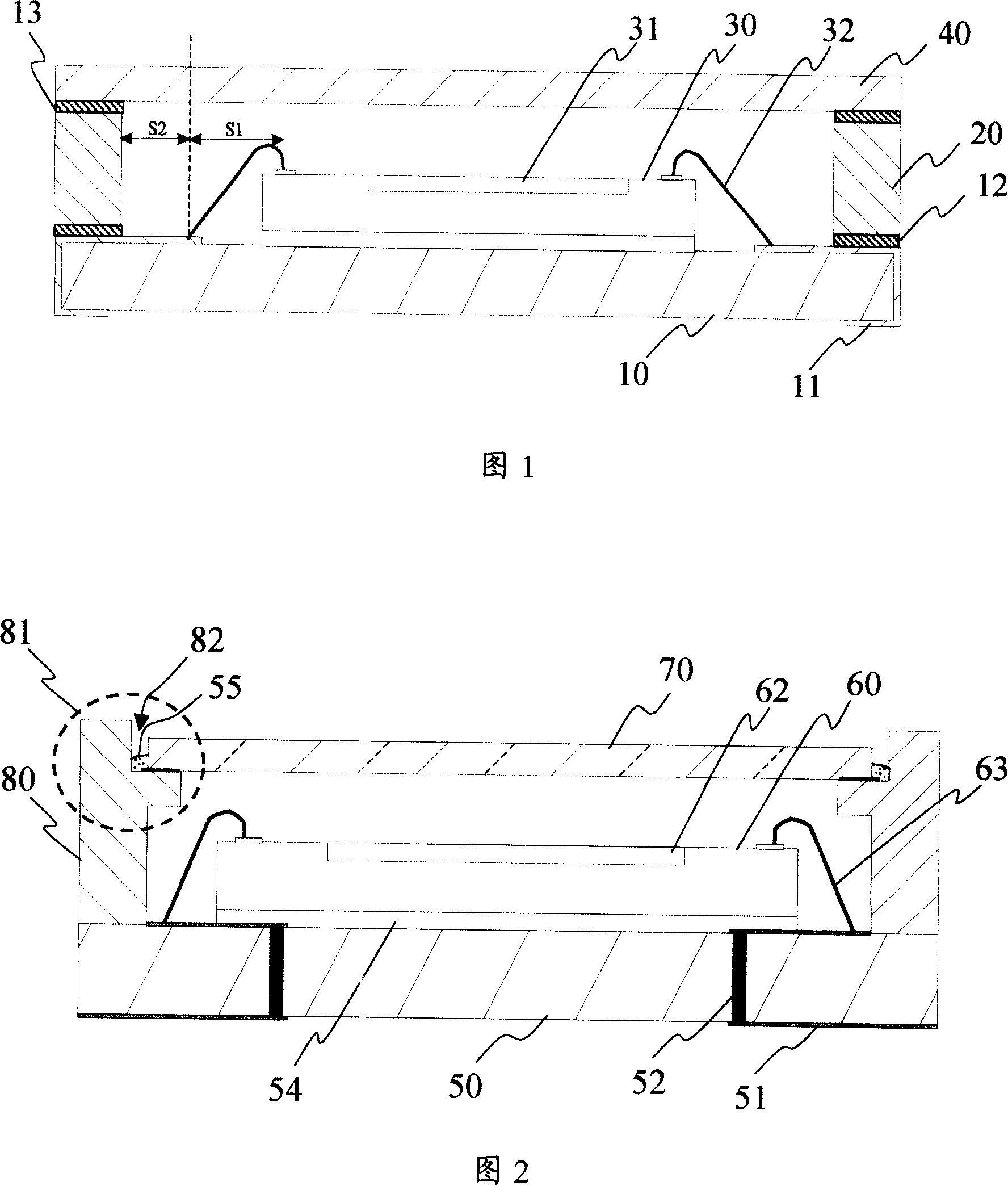

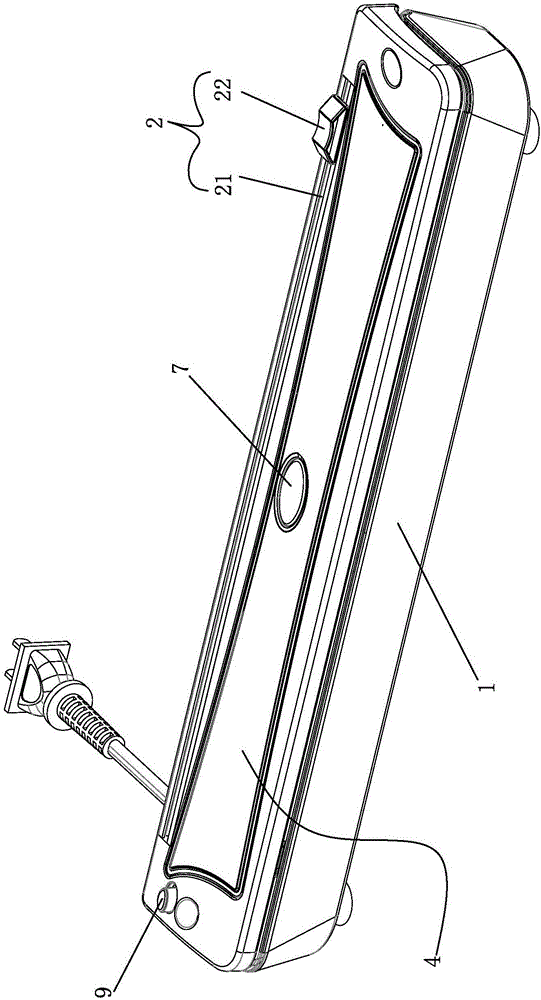

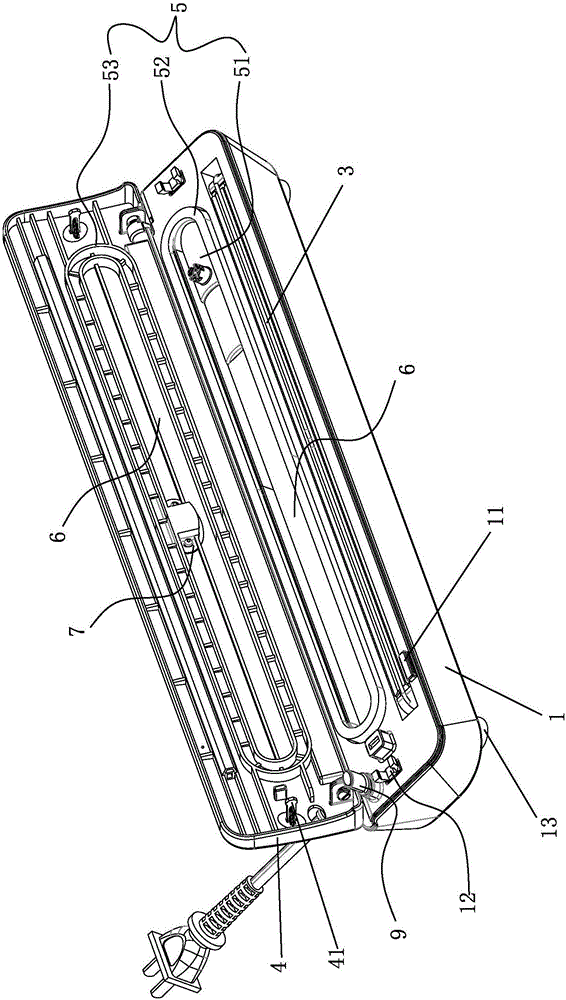

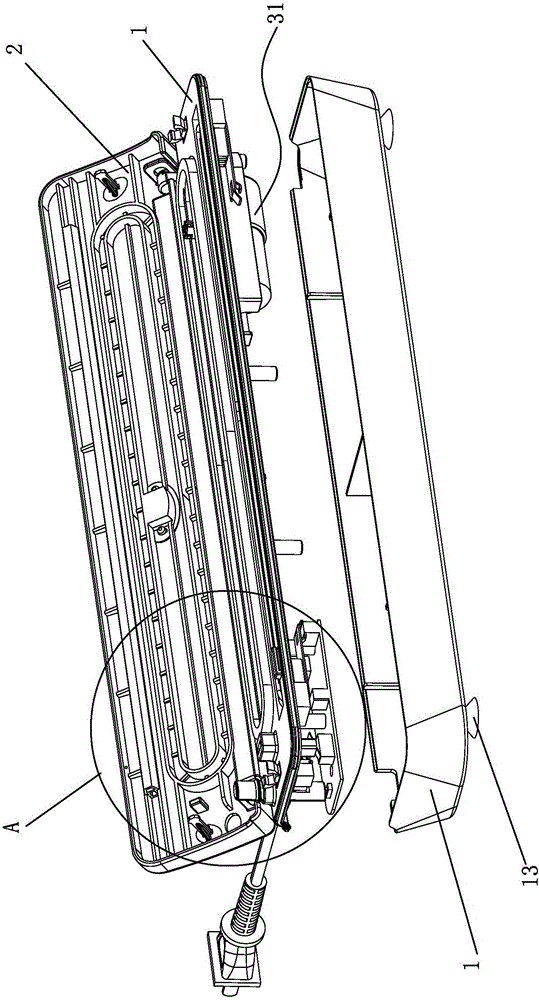

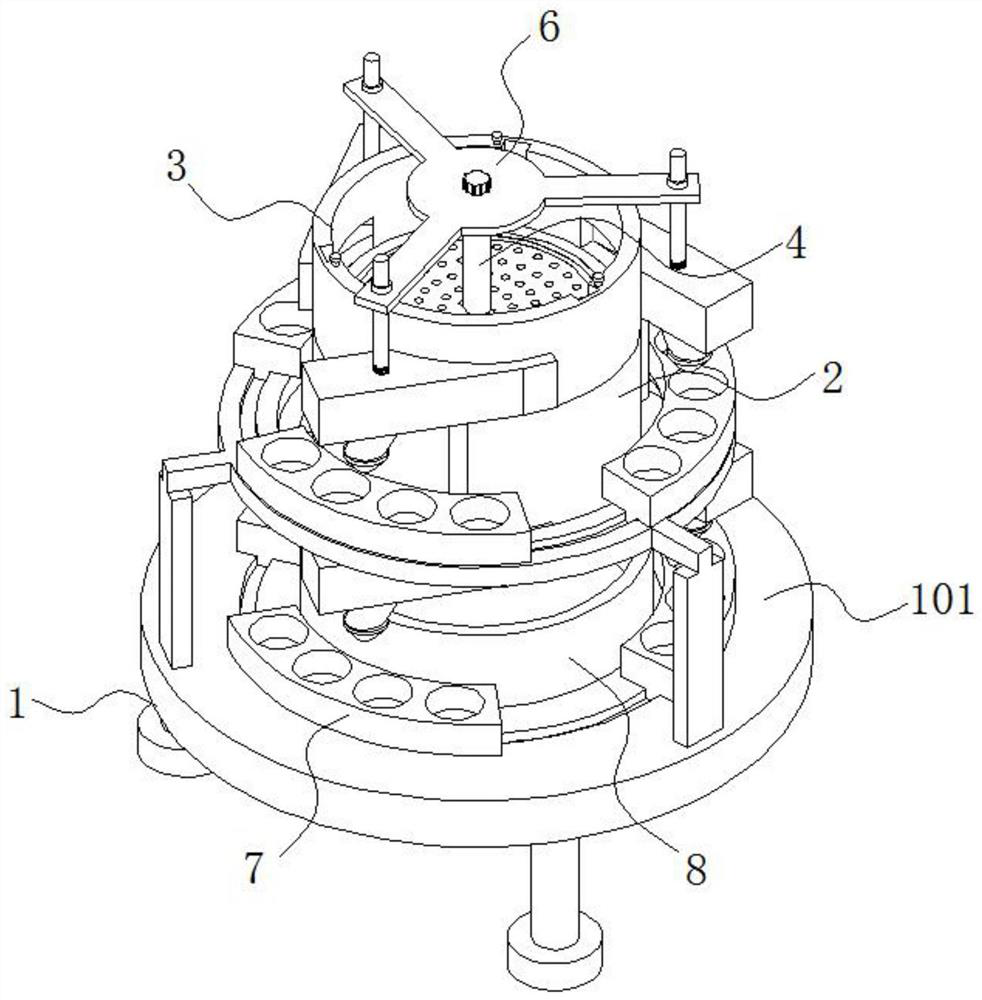

Packaging barrel supply mechanism of automatic punching packaging production line

The invention discloses a packaging barrel supply mechanism of an automatic punching packaging production line. The packaging barrel supply mechanism is characterized by being composed of a storage barrel rotary disc mechanism (1), a barrel separating mechanism (2) and a barrel feeding rotary disc mechanism (3); the storage barrel rotary disc mechanism (1) comprises a storage barrel rotary disc (11), a fixed bottom plate (12) and a storage barrel driving device (13) used for driving the storage barrel rotary disc (11) to rotate; the barrel separating mechanism (2) comprises at least three barrel separating action wheels (21) and a barrel separating driving device (22) used for driving the barrel separating action wheels (21) to rotate; barrel separating spiral grooves (211) are formed in the barrel separating action wheels (21), and the barrel separating action wheels (21) are evenly arranged below lower end openings of barrel discharging through holes (121) in a manner of being around the center axes of the barrel discharging through holes (121); a barrel separating action space (23) is formed among the barrel separating action wheels (21), and the diameter of the barrel separating action space (23) is smaller than the outer diameter of the edge of a barrel opening of one packaging barrel (4); and the barrel feeding rotary disc mechanism (3) comprises a barrel feeding rotary disc (31), a barrel supporting bottom plate (32) and a barrel feeding driving device (33) used for driving the barrel feeding rotary disc (31) to rotate.

Owner:SUZHOU TONGJIN PRECISION IND

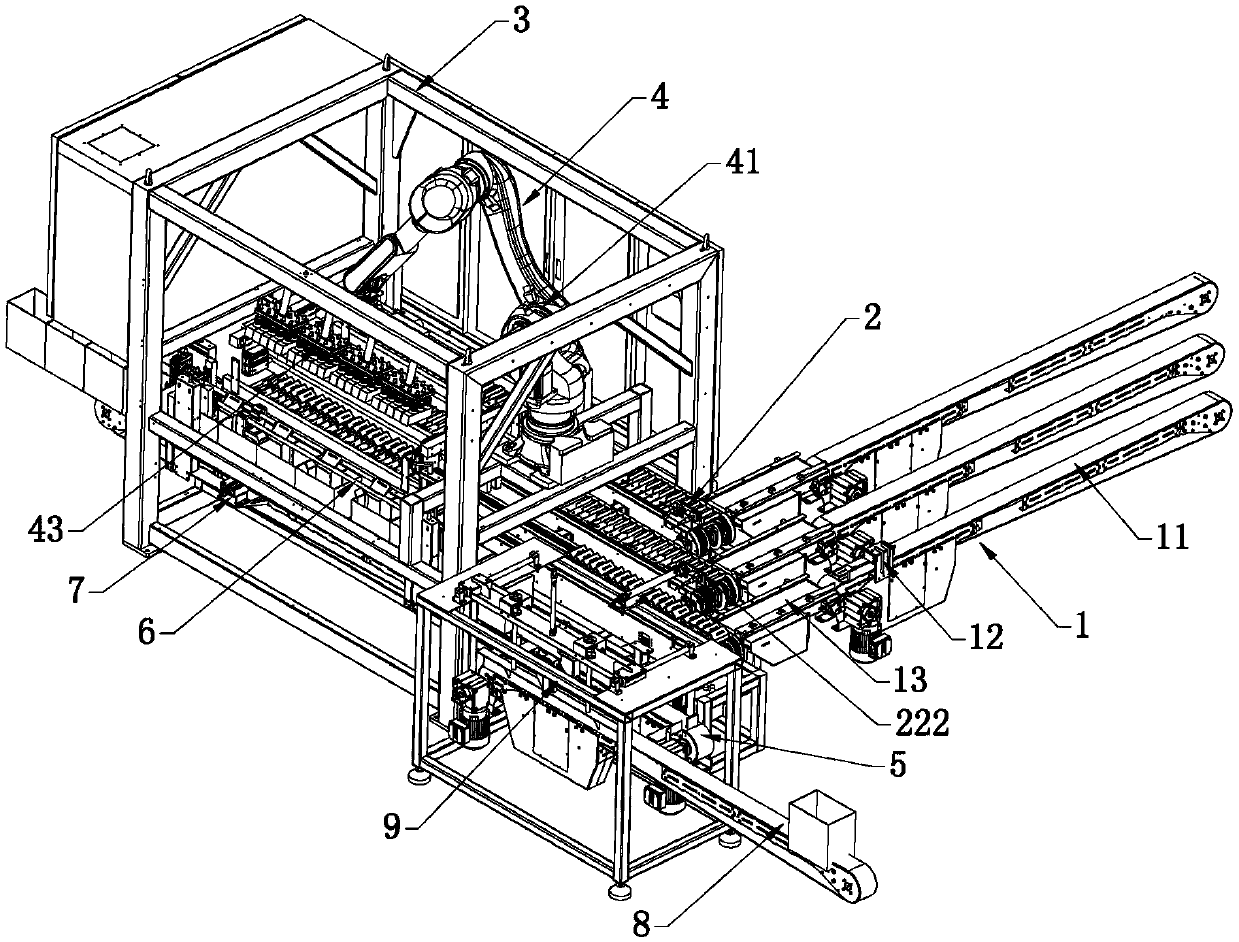

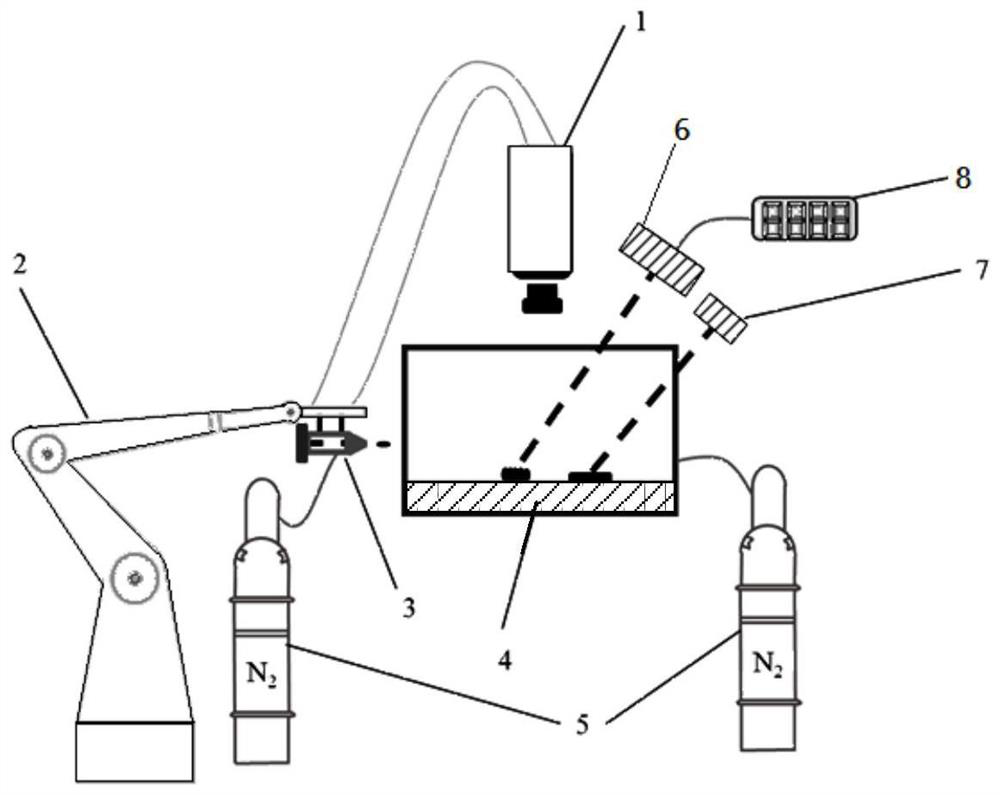

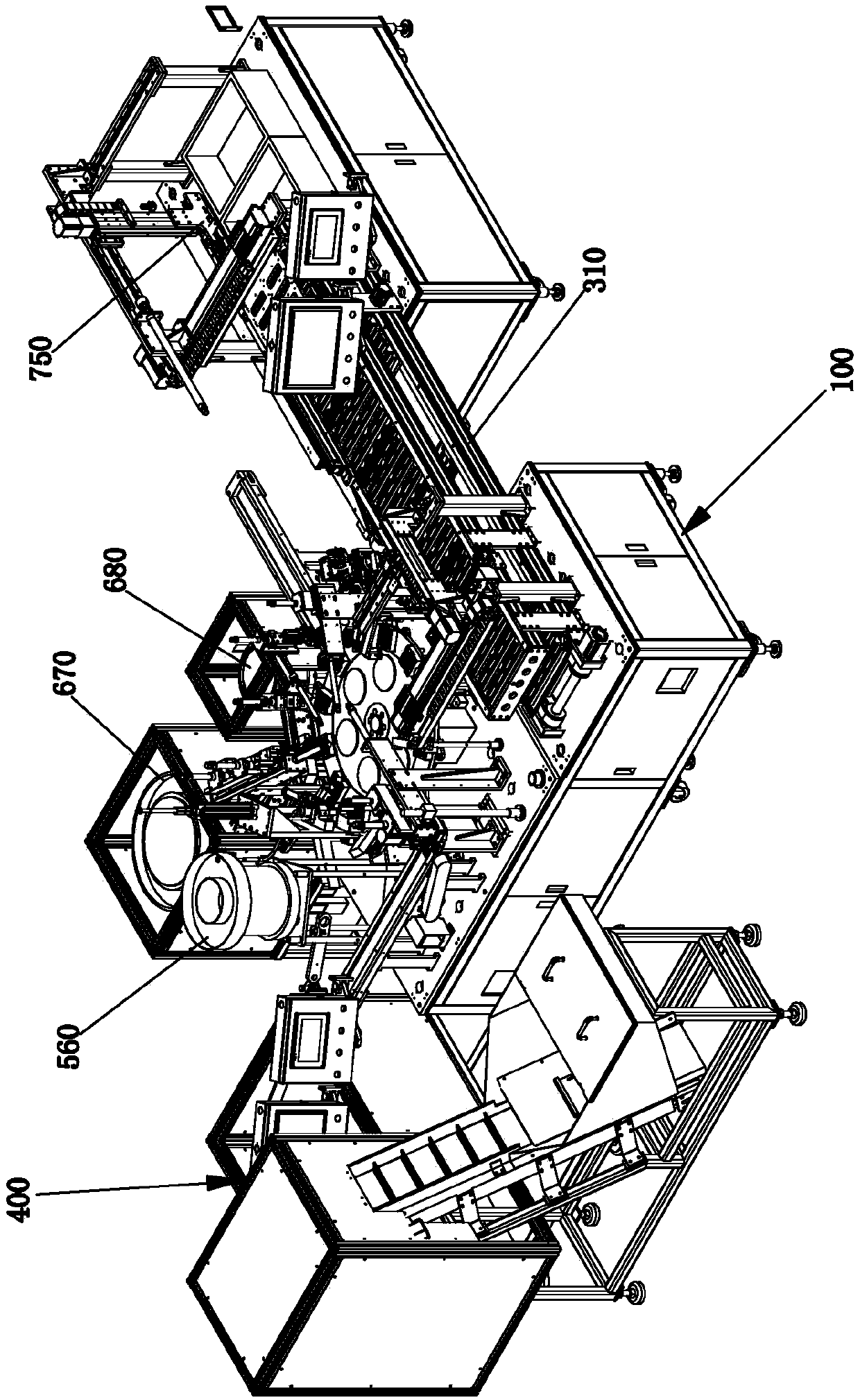

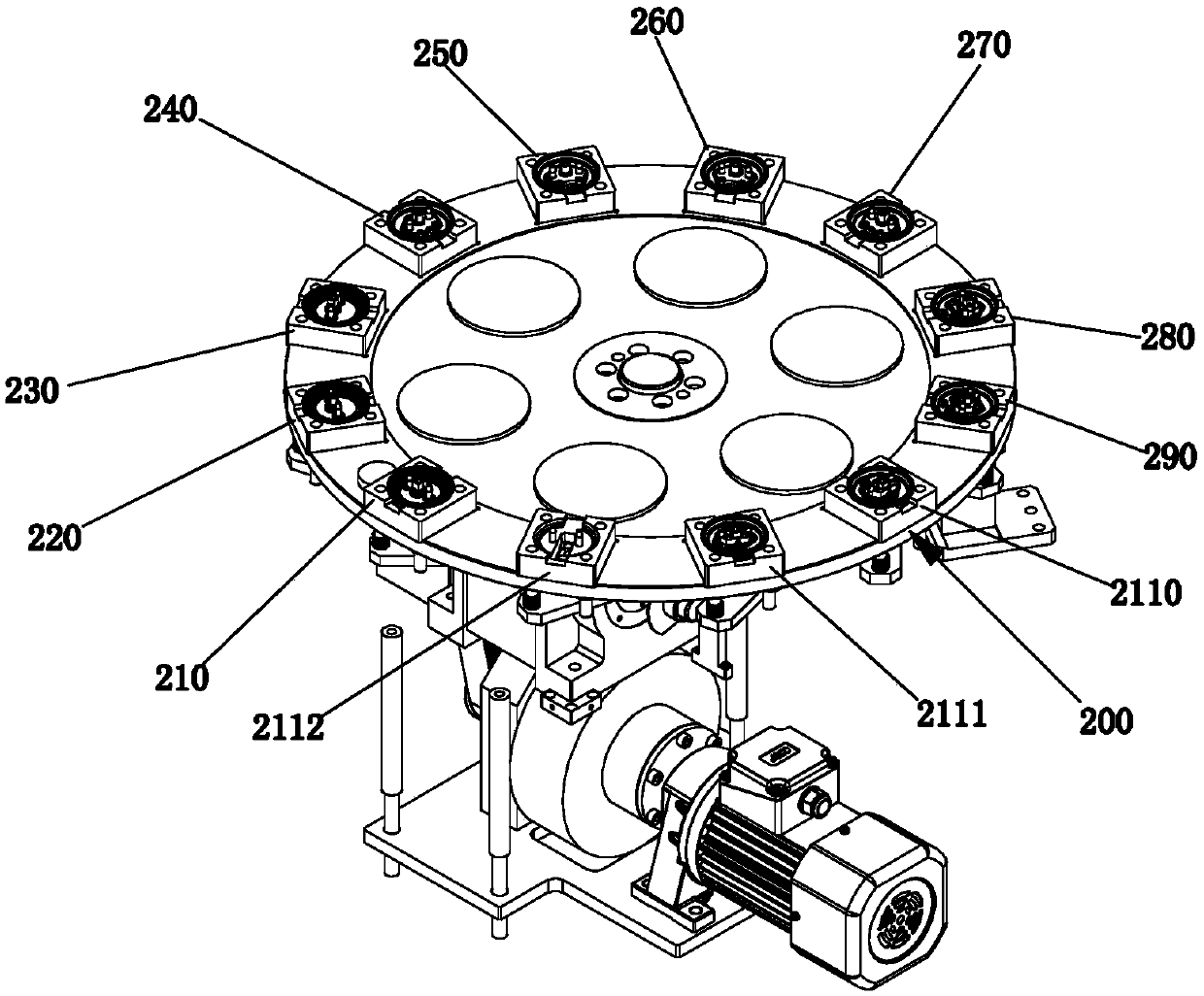

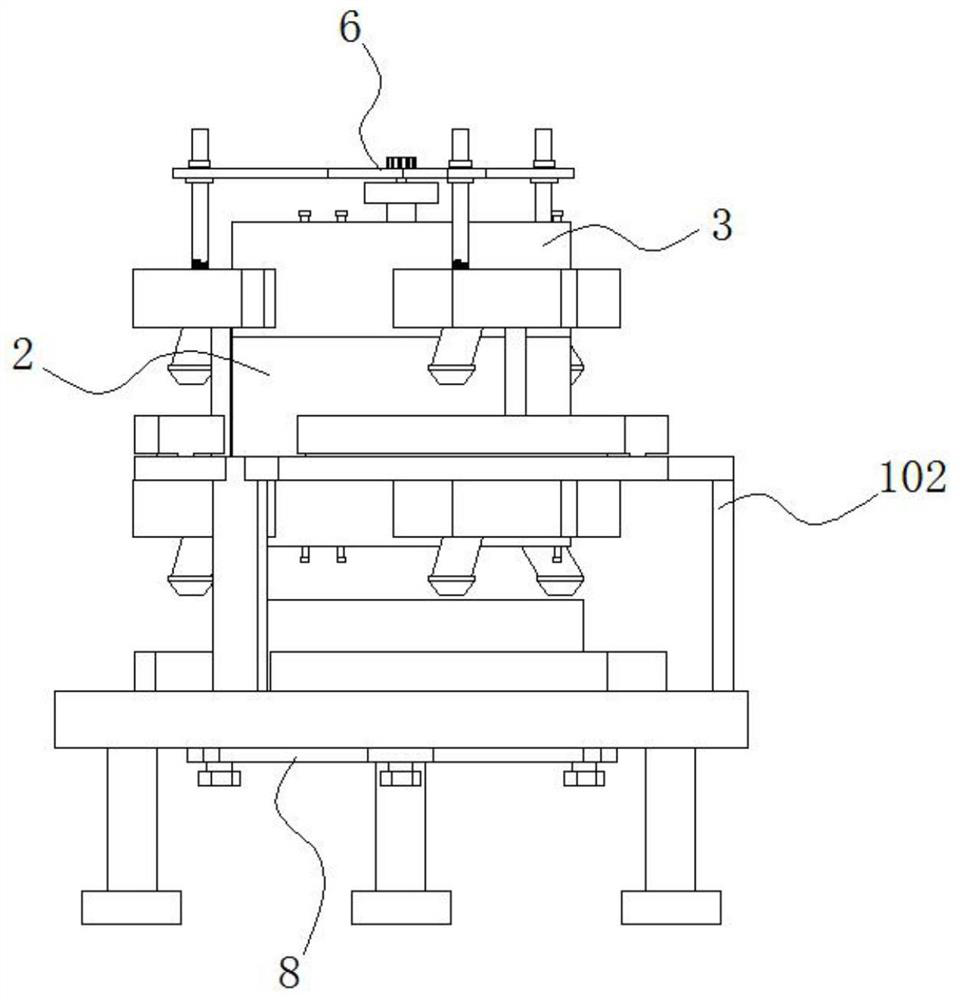

Automatic ice cream packaging system

ActiveCN105501544ASimple and fast deliveryImprove packaging efficiencyShock-sensitive articlesPackaging machinesElectric machineryEngineering

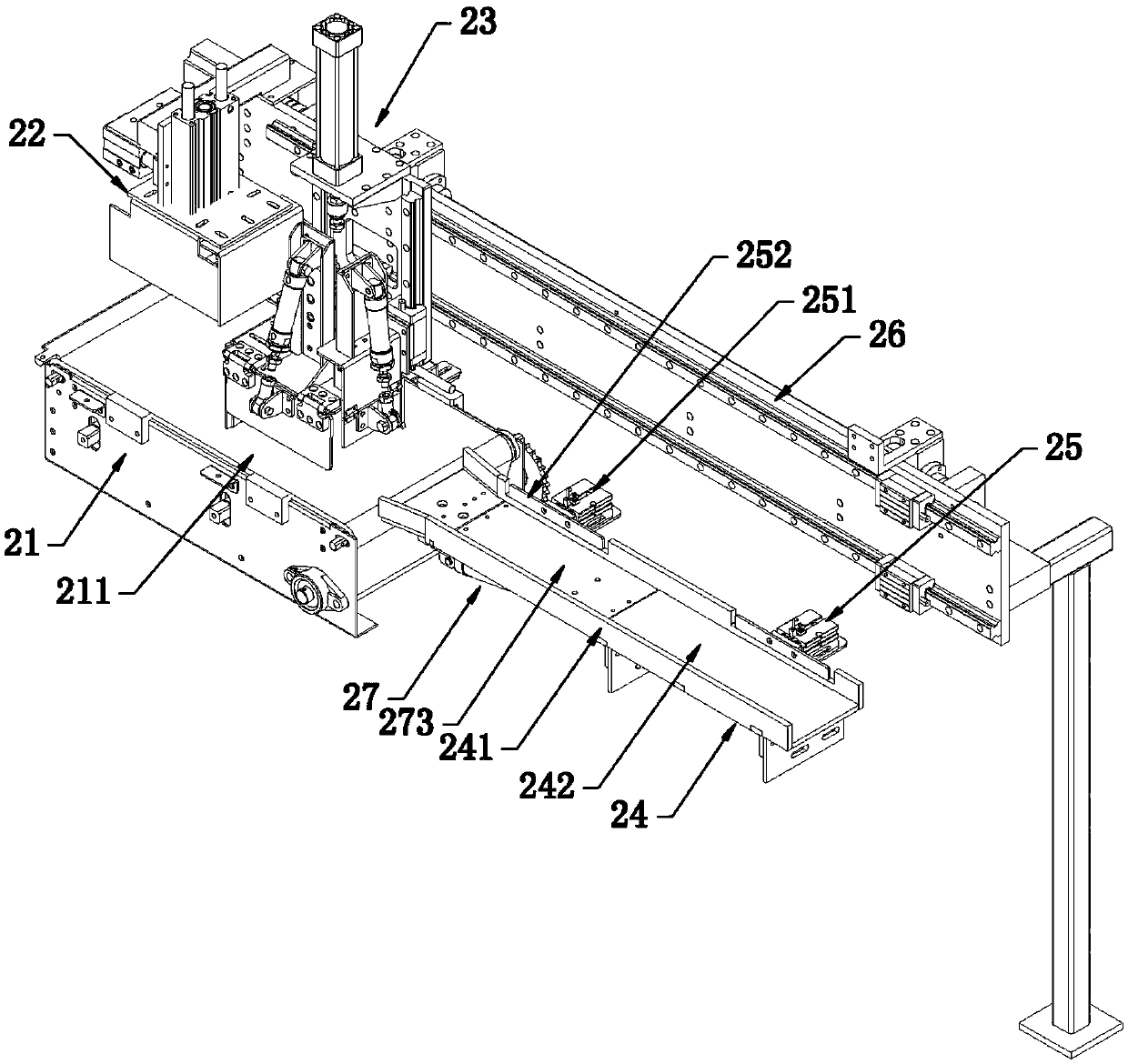

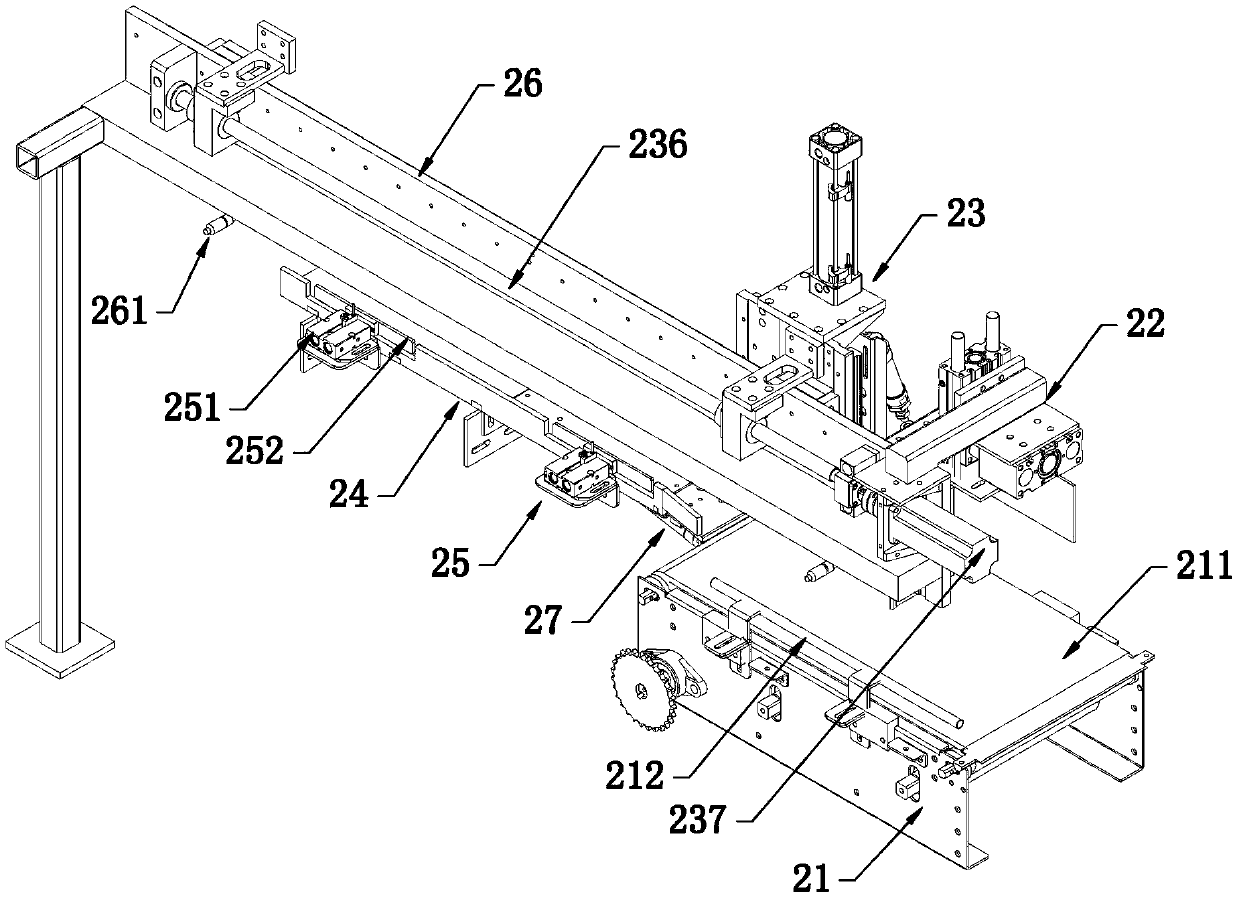

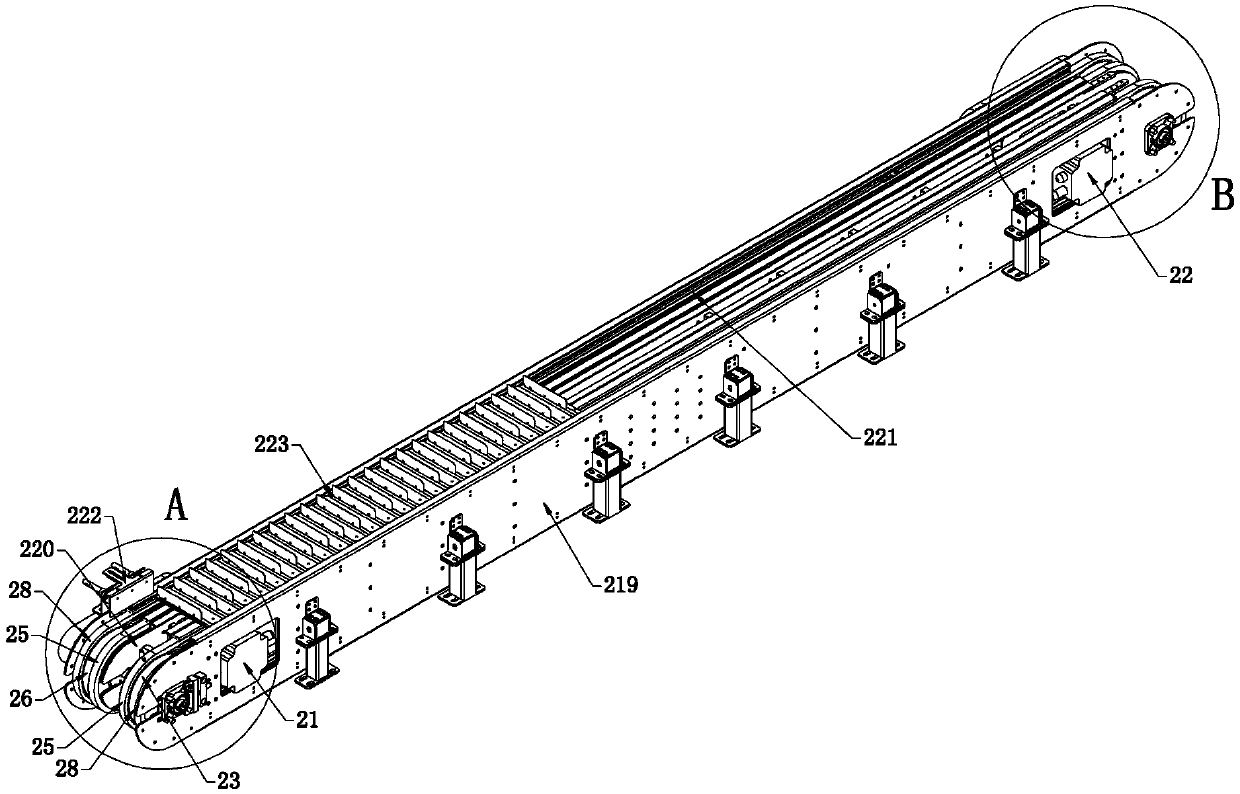

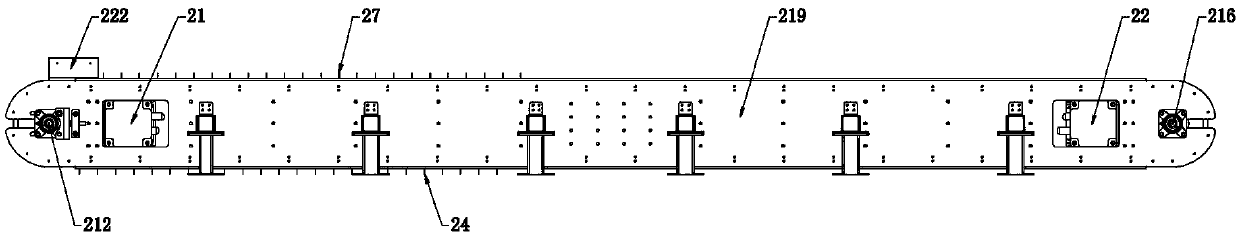

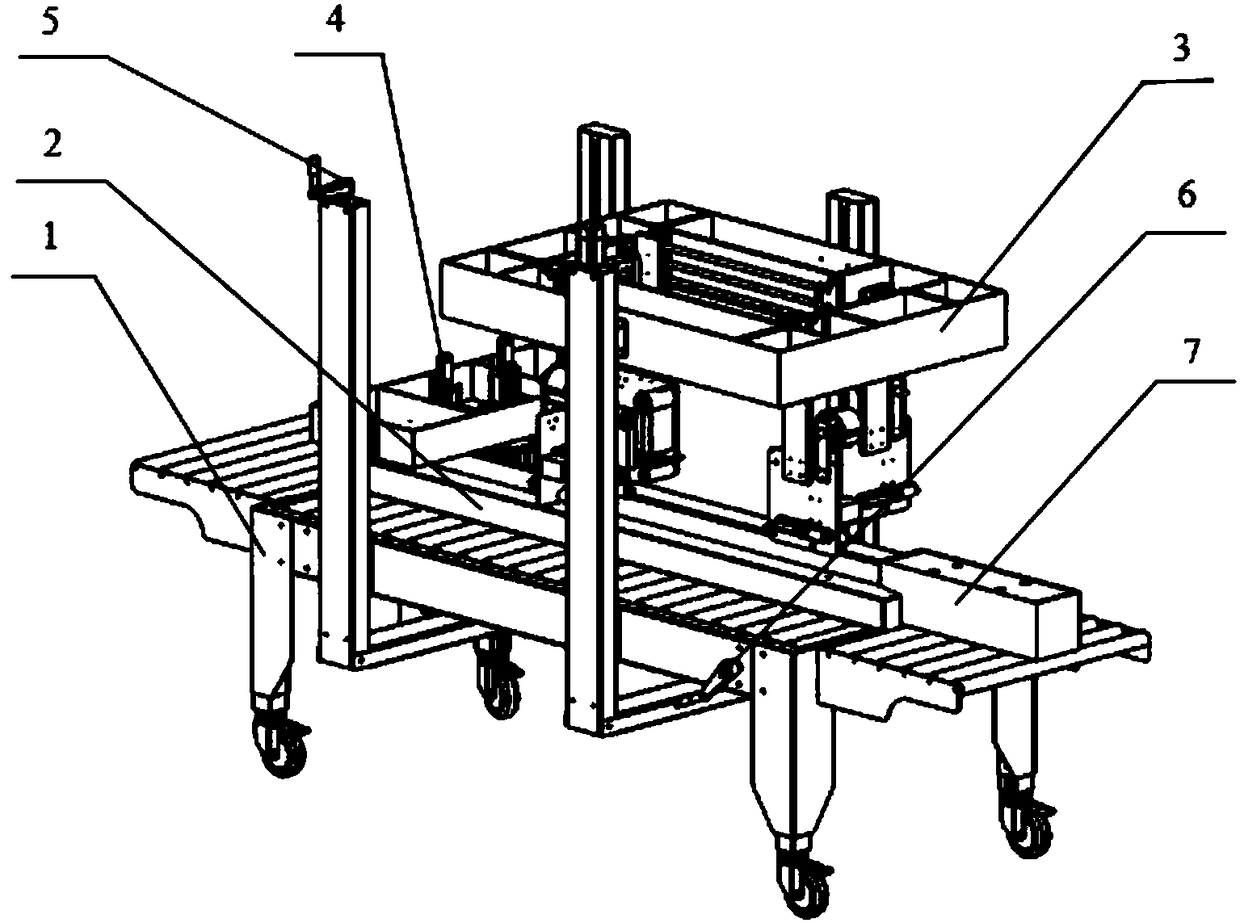

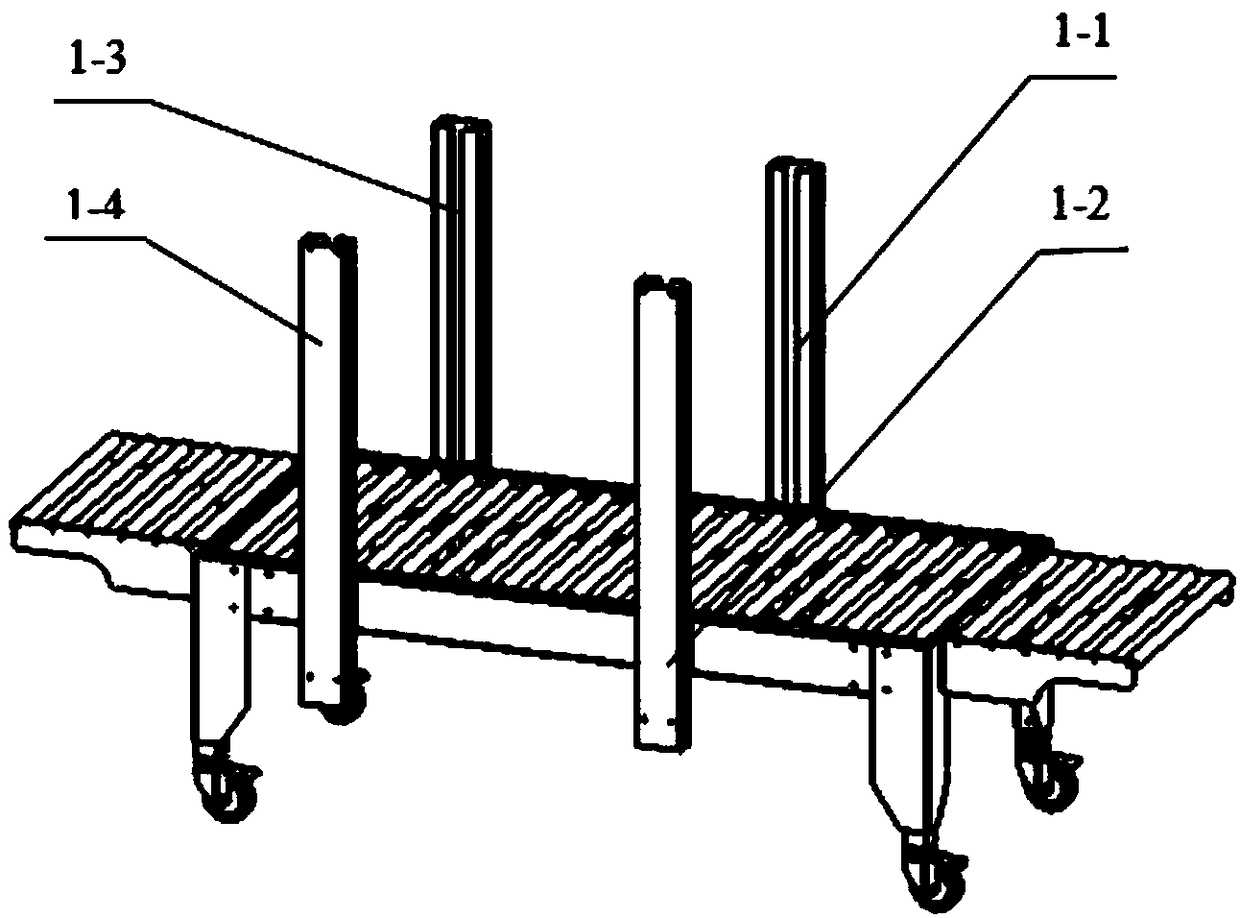

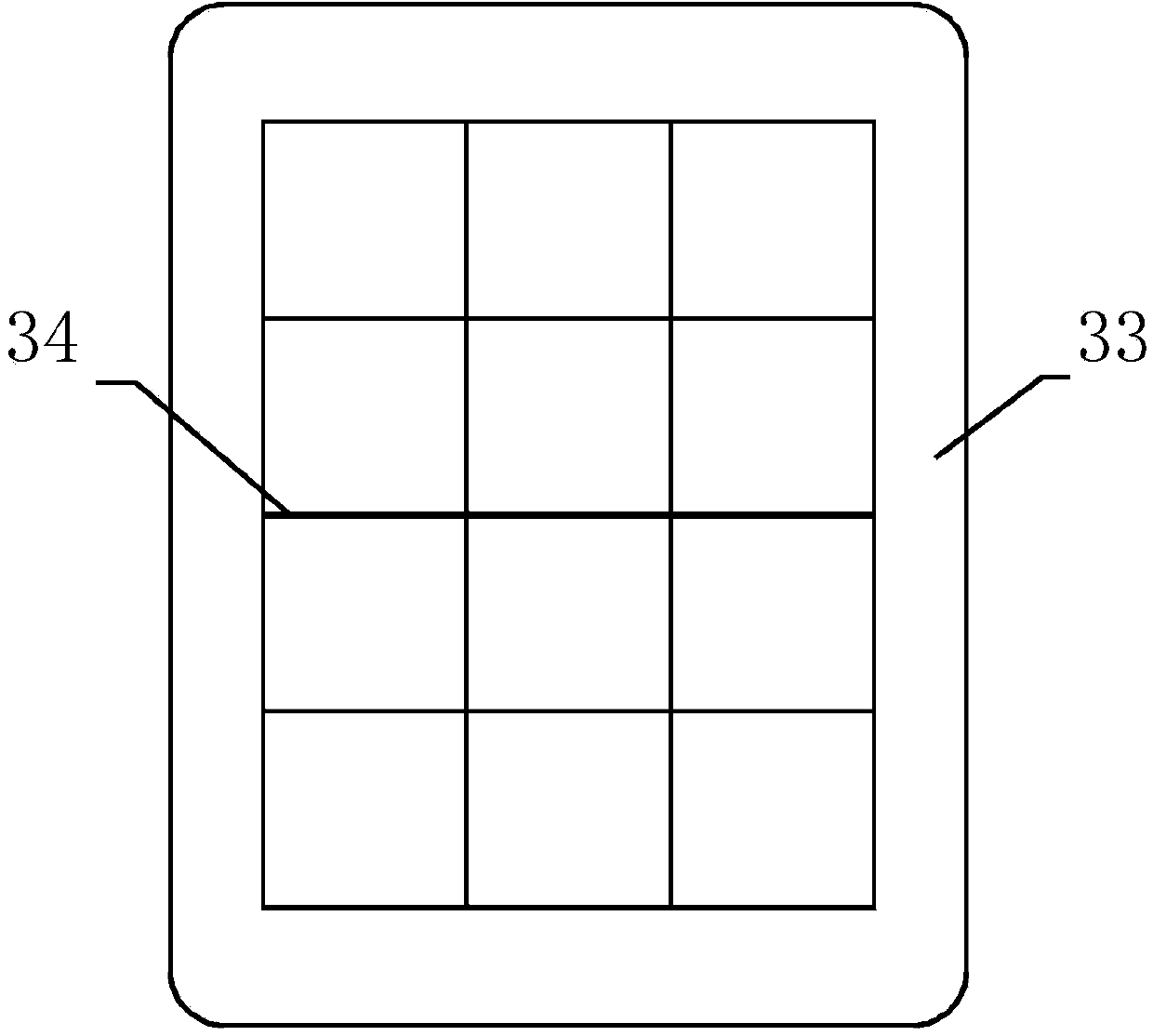

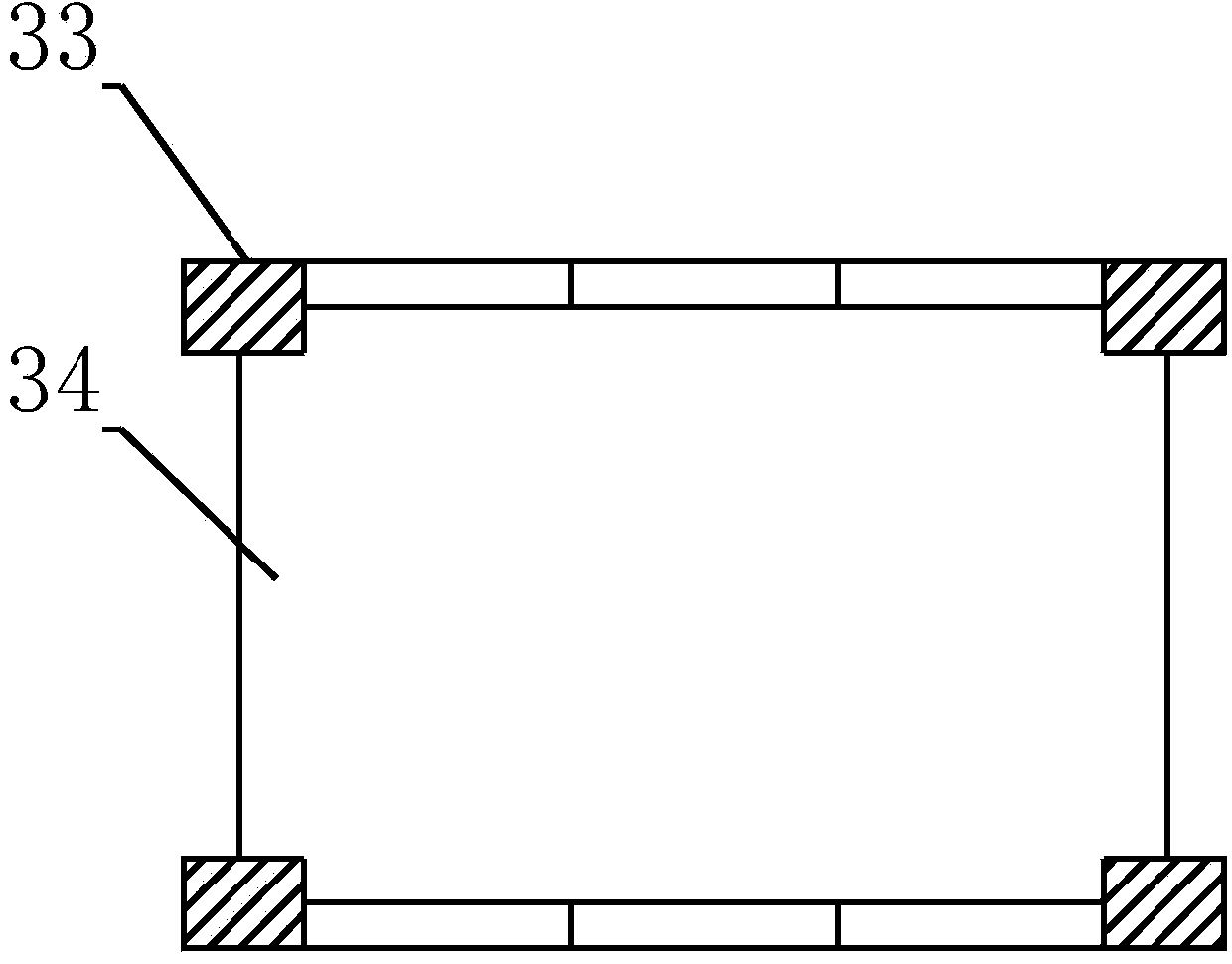

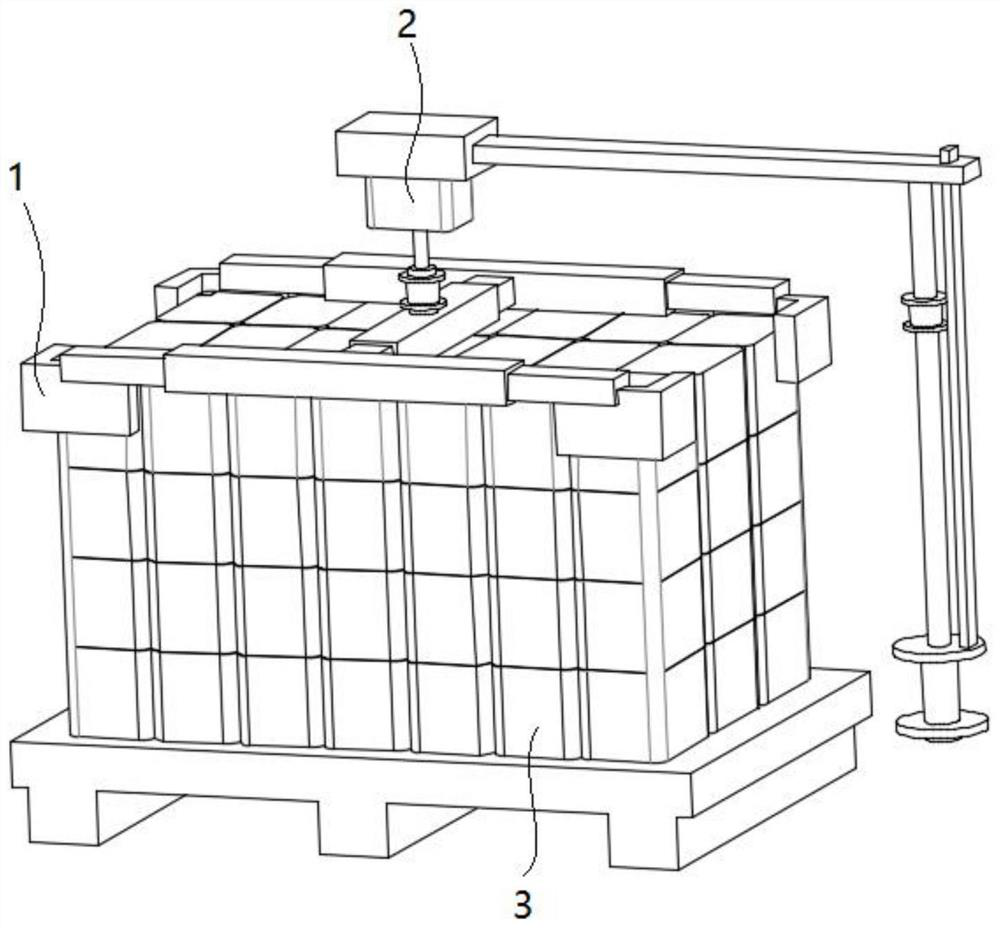

The invention discloses an automatic ice cream packaging system which comprises an ice cream feeding mechanism (1), an integrated conveying mechanism (2), a rack (3) and a box packaging line (5), wherein the integrated conveying mechanism (2) is vertically arranged at the tail end of the ice cream feeding mechanism (1), and the box packaging line (5) is parallel to the integrated conveying mechanism (2). Ice cream is quickly shot into ice cream grooves in integrated conveying belts (223) on the integrated conveying mechanism (2) one by one through an accelerating belt (13) at the rear end of the ice cream feeding mechanism (1); after the ice cream grooves in one integrated conveying belt (223) is full of ice cream, the integrated conveying belt (223) is driven by a corresponding servo motor to quickly run to the position under a robot grabbing mechanism (4) fixed on the rack (3), and the ice cream is simultaneously grabbed through the robot grabbing mechanism (4) to be put in a packaging box on the box packaging line (5). The system has the advantages of being simple and quick in running, high in automatic box packing efficiency and high in precision.

Owner:苏州澳昆智能机器人技术有限公司

Automatic corner and edge carton sealing machine device for cover and tray cartons of various specifications

ActiveCN108438357AMeet packaging needsImprove packaging efficiencyWrapper twisting/gatheringEngineeringCarton

The invention discloses an automatic corner and edge carton sealing machine device for cover and tray cartons of various specifications. The automatic corner and edge carton sealing machine device comprises a rack, a carton conveying device, an automatic packaging tape pasting device, a packaging tape bending device, a height adjusting device and a width adjusting device. According to the size andspecification of a cover and tray carton, a carton sealing machine is in the right working state through the height adjusting device and the width adjusting device, the cover and tray carton is driven by the carton conveying device to advance, the carton conveying device stops motion after the cover and tray carton reaches a packaging tape pasting station, the automatic packaging tape pasting device works to paste packaging tape to four edges of the cover and tray carton, then the cover and tray carton is driven by the carton conveying device to continuously advance, the carton conveying device stops motion after the cover and tray carton reaches a packaging tape bending station, the packaging tape bending device works, and the suspended packaging tape is pasted to a side face box of thecover and tray carton until the carton sealing task is completed. By means of the automatic corner and edge carton sealing machine device for cover and tray cartons of various specifications, one carton sealing machine can be used for completing the corner and edge packaging of the cover and tray carton at a time, convenience and quickness are achieved, the packaging requirement is met, and the packaging efficiency is improved.

Owner:BEIJING UNIV OF TECH

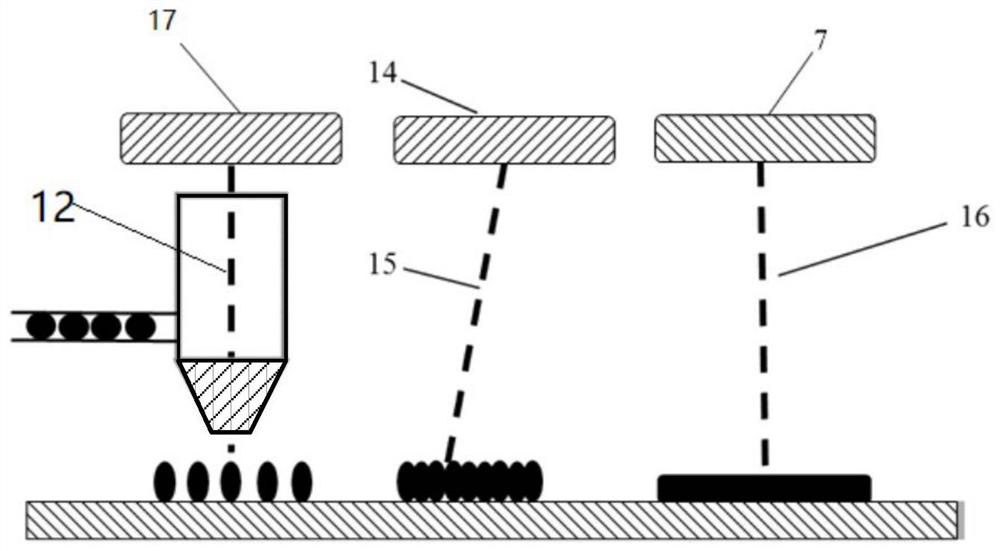

Laser welding-brazing packaging method and device for three-dimensional weld joint

ActiveCN112008178AReduce residual stressWetting and spreadingFinal product manufactureSolder feeding devicesFiller metalConnected device

The invention provides a laser welding-brazing packaging method and device for a three-dimensional weld joint. The method comprises the steps of step S1, carrying out surface treatment on a joint of ato-be-connected device, and selecting low-temperature brazing filler metal with a proper size; step S2, performing in-situ melting on the low-temperature brazing filler metal through laser melting brazing, spraying the molten brazing filler metal to the joint through high-pressure airflow, and completing preliminary connection through an auxiliary wetting and filling method; and step S3, after the brazing filler metal is sprayed, applying a second laser to heat the brazing filler metal again for secondary remelting, conducting heat preservation aftertreatment on the weld joint after a periodof time, and completing metallurgical connection. According to the technical scheme, three heating procedures are adopted to sequentially complete melting, filling, wetting and interface reaction of the brazing filler metal, and rapid low-temperature welding is achieved; and compared with traditional one-time laser welding, the method has the advantages of being more sufficient in wetting and spreading, good in weld joint integrity, high in welding performance and surface quality and low in residual stress.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

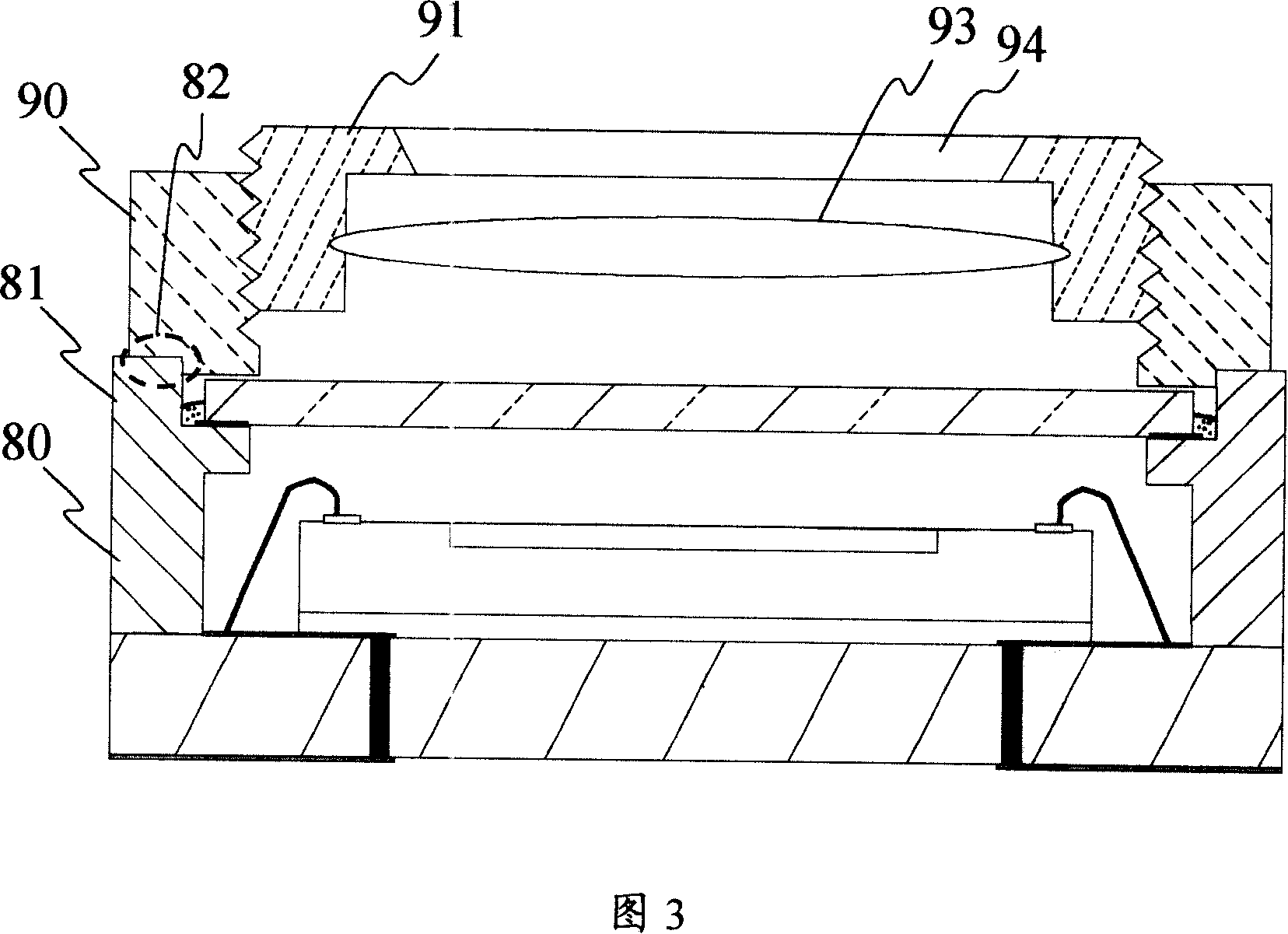

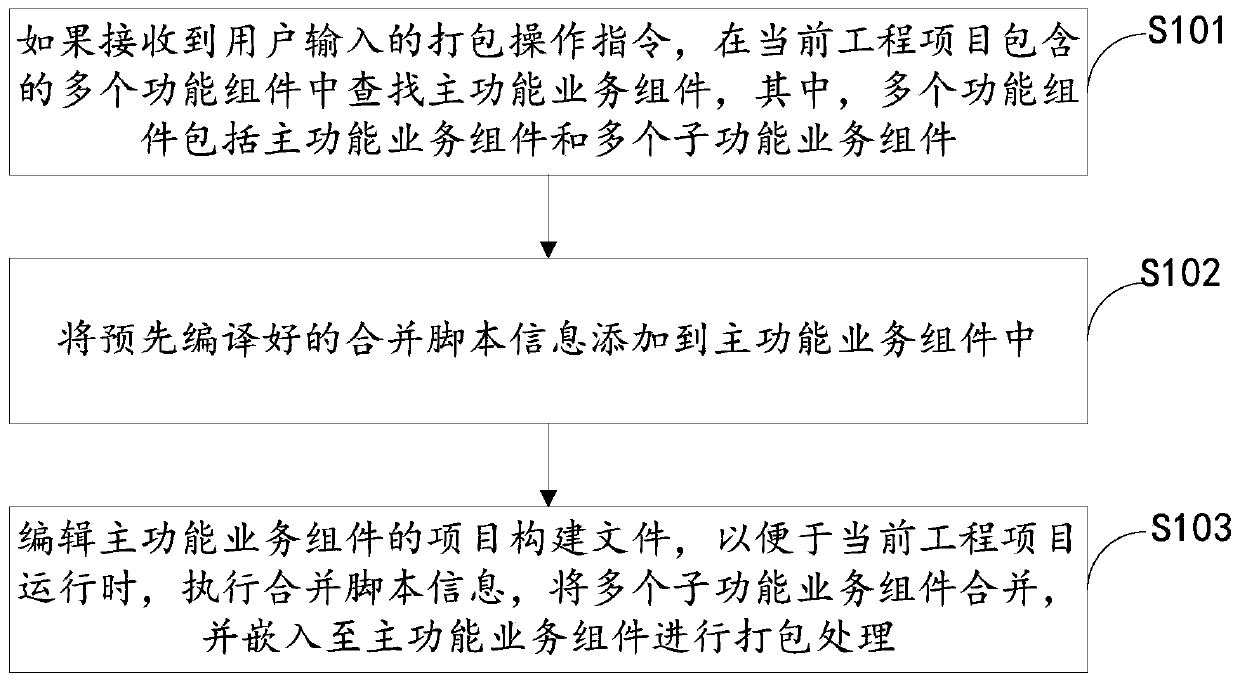

Optical transducer packaging structure and optical sensing module

InactiveCN101132013AReduce areaReduce volumeTelevision system detailsColor television detailsEngineeringColloid

The present invention is an optic-sensor package and an optic-sensing module. The optic-sensing chip is packed by substrate, frames and optic-transparent layer: the frame is set on the substrate and around the optic-sensing chip, and top of the frame extends to the optic-sensing chip and out of a fixing structure of which profile is 'L' type; bending part of the fixing structure forms a container space which can contain and locate the optic-transparent layer. The package has simple structure, is easy to be shaped, and is good for point colloid and sealing. In addition, when the optic-sensor package and lens group are combined into optic-sensing module, smaller size of lens substrate can be used to reduce package area.

Owner:SIGURD MICROELECTRONICS CORP

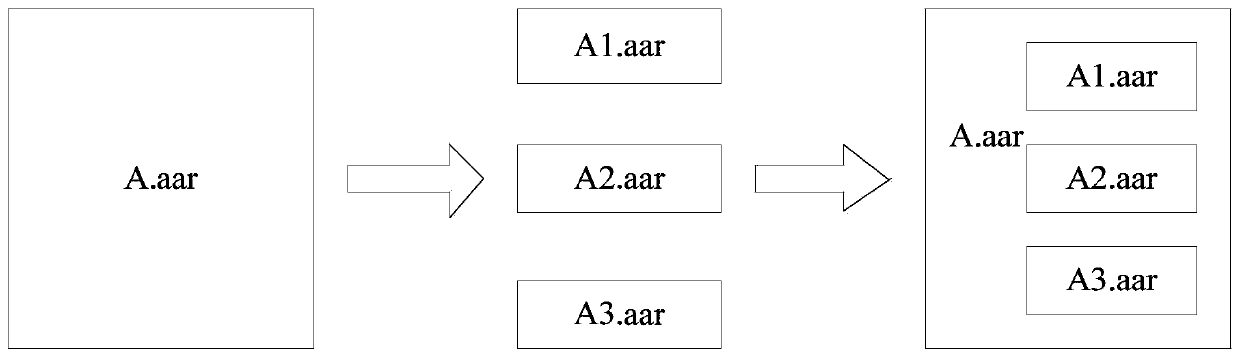

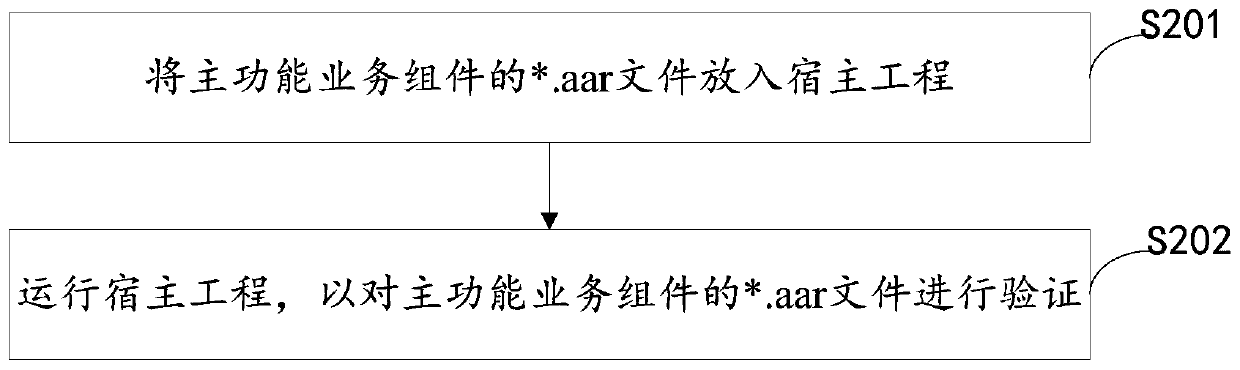

Service component packaging method and system and server

ActiveCN110321131AMeet packaging needsImprove experienceVersion controlCode compilationUser inputService component

The invention provides a service component packaging method and system and a server, and the method mainly comprises the steps: searching a main function service component from a plurality of functioncomponents contained in a current engineering project if a packaging operation instruction inputted by a user is received, and enabling the plurality of function components to comprise the main function service component and a plurality of sub-function service components; then adding pre-compiled combined script information into the main function service component; and finally, editing a projectconstruction file of the main function business component, so as to execute the combined script information when the engineering project runs, combine the plurality of sub-function business components, and embed the combined sub-function business components into the main function business component for packaging processing. The invention can be well compatible with gradle construction scenes of various versions, meets the packaging requirements of users for various service components, and improves the user experience.

Owner:北京百佑科技有限公司

Packaging bag sealing machine and packaging bag sealing method

ActiveCN106275577ASave materialMeet packaging needsPackaging by pressurising/gasifyingEngineeringMechanical engineering

The invention discloses a packaging bag sealing machine. The packaging bag sealing machine comprises a machine body. A cutting device used for cutting packaging bags is arranged on the machine body. The machine body is further provided with a vacuumizing device and a sealing device, wherein the vacuumizing device draws out air in the packaging bags, and the sealing device seals the edges of the packaging bags. According to the packaging bag sealing machine, the cutting device, the sealing device and the vacuumizing device are arranged on the machine body at the same time, and therefore a series of steps comprising cutting, vacuumizing and sealing of the packaging bags can be completed. The packaging bag sealing machine has the advantages of being simple in structure and convenient to use. The invention further discloses a packaging bag sealing method. The packaging bag sealing method comprises the steps that the packaging bags are cut, one edge of each packaging bag is sealed, objects are put in the packaging bags, vacuumizing is conducted, and the other edge of each packaging bag is sealed. By the adoption of the packaging bag sealing method, the packaging bag of an appropriate length can be obtained through cutting according to the length of the packaged objects, and then packaging of the objects is conducted; and in this way, packaging bag materials are saved, and the packaging demands of objects of different lengths is also met.

Owner:ZHONGSHAN TAILI HOUSEHOLD PROD MFG

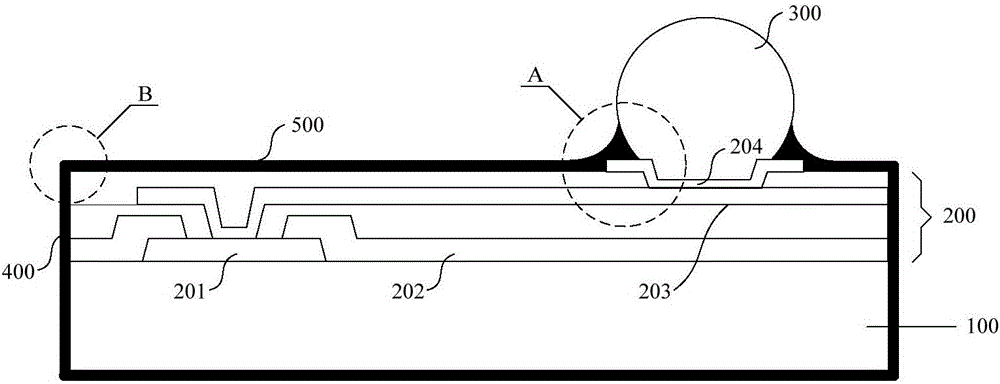

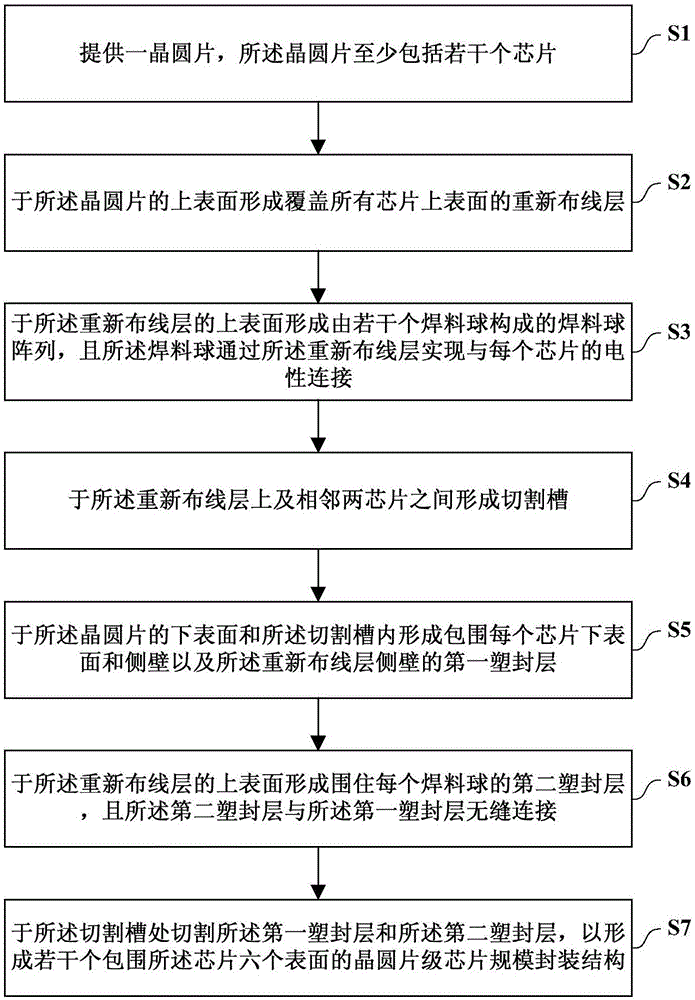

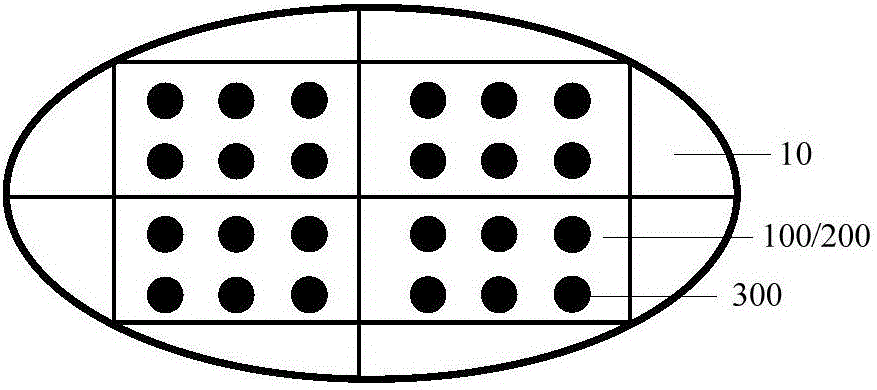

Silicon wafer stage chip scale packaging structure and manufacturing method thereof

InactiveCN106684053AEffectively fixedReduce the risk of delaminationSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingSolder ball

The invention provides a silicon wafer stage chip scale packaging structure and a manufacturing method thereof. The silicon wafer stage chip scale packaging structure comprises a chip, a rewiring layer, a plurality of solder balls, a first plastic packaging layer and a second plastic packaging layer, wherein the rewiring layer covers the upper surface of the chip; the plurality of solder balls are formed on the upper surface of the rewiring layer and are electrically connected to the chip by the rewiring layer; the first plastic packaging layer surrounds the lower surface and side wall of the chip and the side wall of the rewiring layer; and the second plastic packaging layer is formed on the upper surface of the rewiring layer, surrounds each solder ball and is in seamless connection with the first plastic packaging layer, thereby forming the silicon wafer stage chip scale packaging structure surrounding the six surfaces of the chip. The silicon wafer stage chip scale packaging structure has the beneficial effects that the packaging protection surrounding the six surfaces of the chip is formed through seamless connection of the two plastic packaging layers, the buckling deformation of the packaging structure resulting from stress is effectively compensated, the packaging structure with the relatively big size can be prepared, and the packaging requirement of the large-sized chip is met.

Owner:SJ SEMICON JIANGYIN CORP

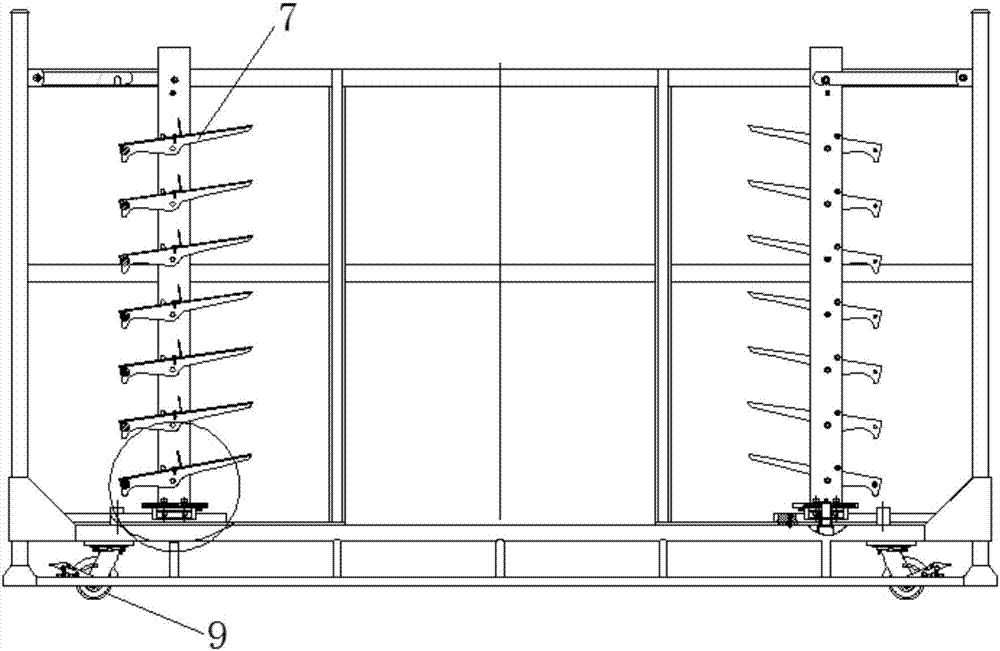

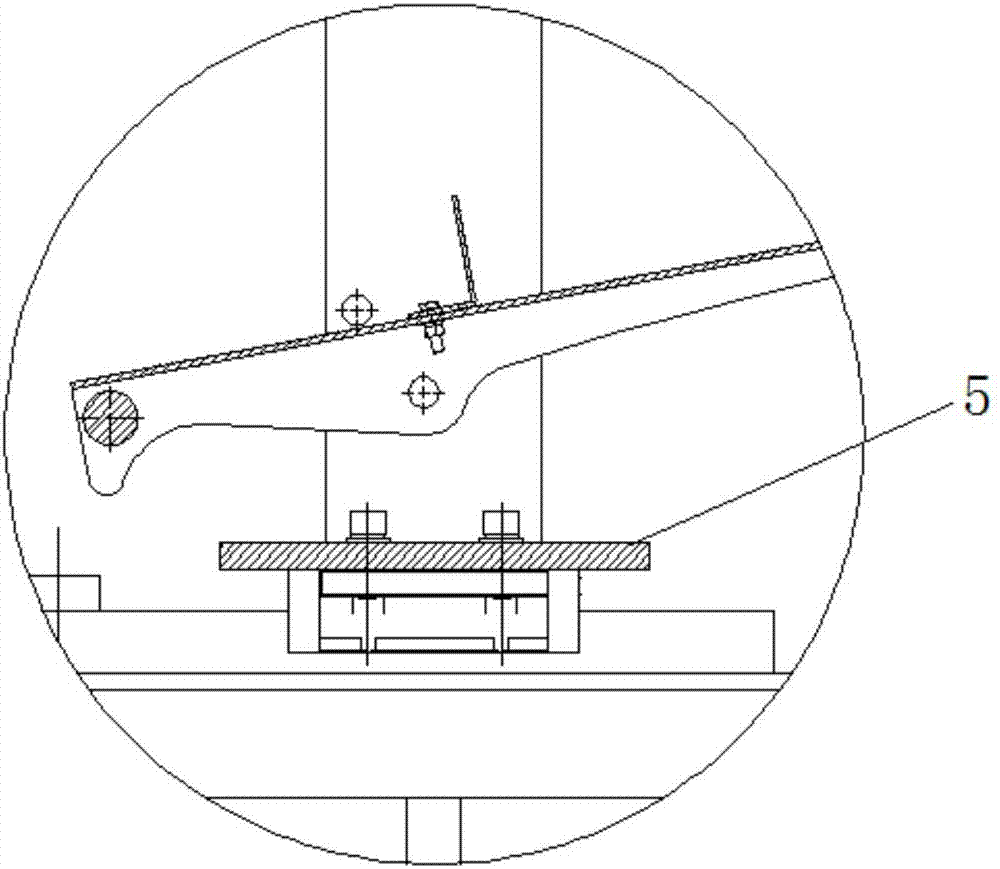

Supporting member for supporting roof, structure and method

PendingCN107225552AMeet placementImprove versatilityWork tools storageOther workshop equipmentEconomic benefitsEngineering

Owner:济南达宝文自动化设备工程有限公司

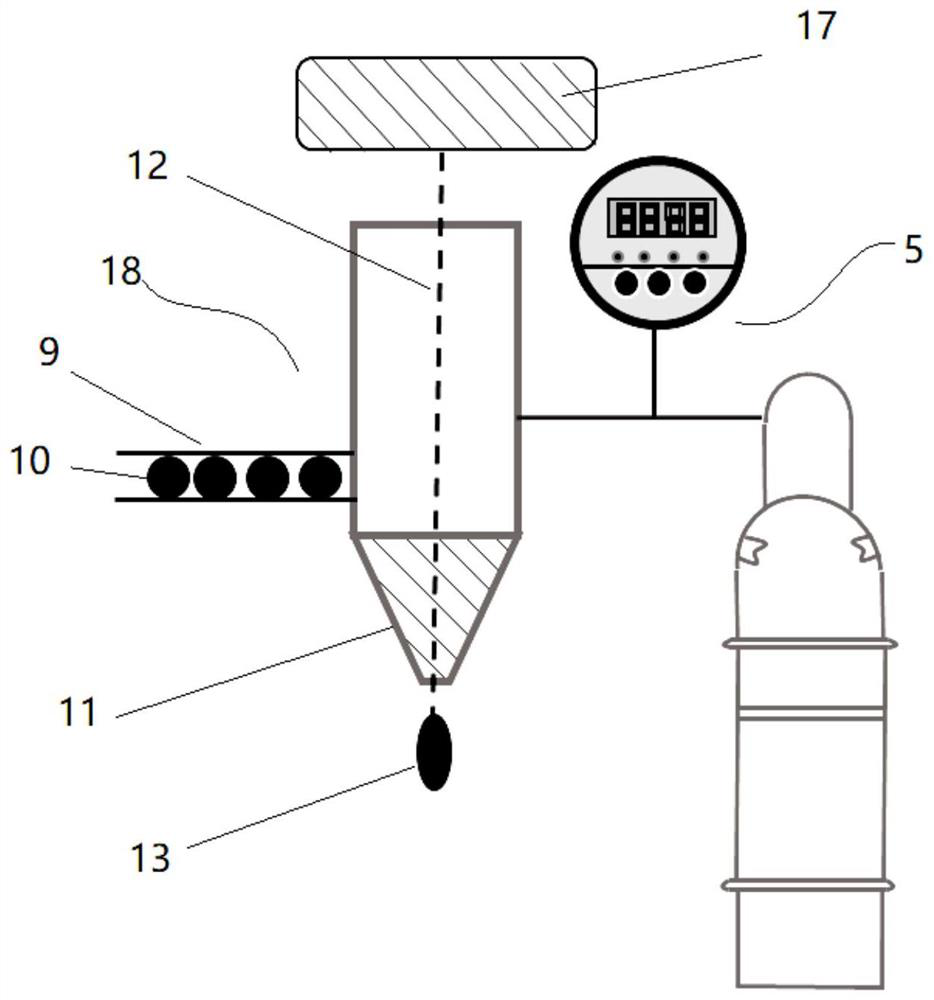

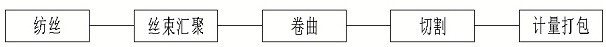

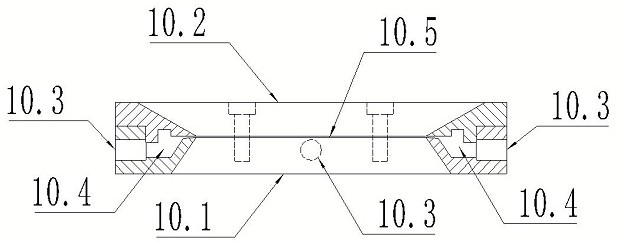

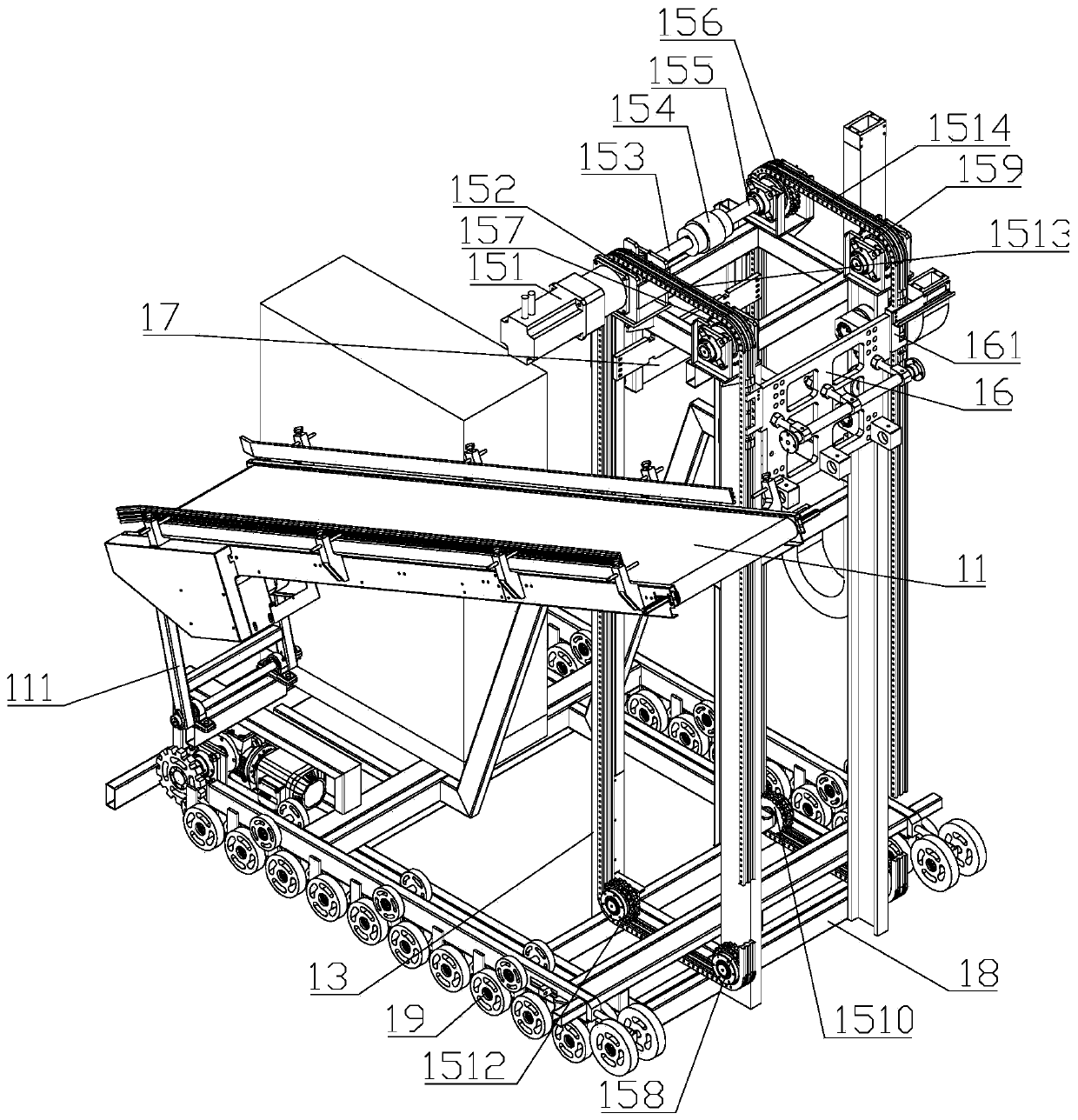

Short fiber finished product subsequent production line

PendingCN111809259AEvenly distributedAvoid mixingNew-spun product collectionArtificial thread manufacturing machinesYarnFiber

The invention relates to a short fiber finished product subsequent production line. The short fiber finished product subsequent production line comprises a spinning machine (9), an oiling ring (10), ayarn storage box (11), a yarn guide frame (12), a tail yarn alarm device (13), a crimping machine (14), a yarn bundle breadth adjusting device (15), a yarn cutting-off machine (16) and a packing machine (17), wherein the spinning machine (9), the oiling ring (10), the yarn storage box (11), the yarn guide frame (12), the crimping machine (14), the yarn cutting-off machine (16) and the packing machine (17) are sequentially arranged. The short fiber finished product subsequent production line is stable in product quality, low in failure rate in the production process, low in production cost andadjustable in packing belt.

Owner:江苏华西村股份有限公司

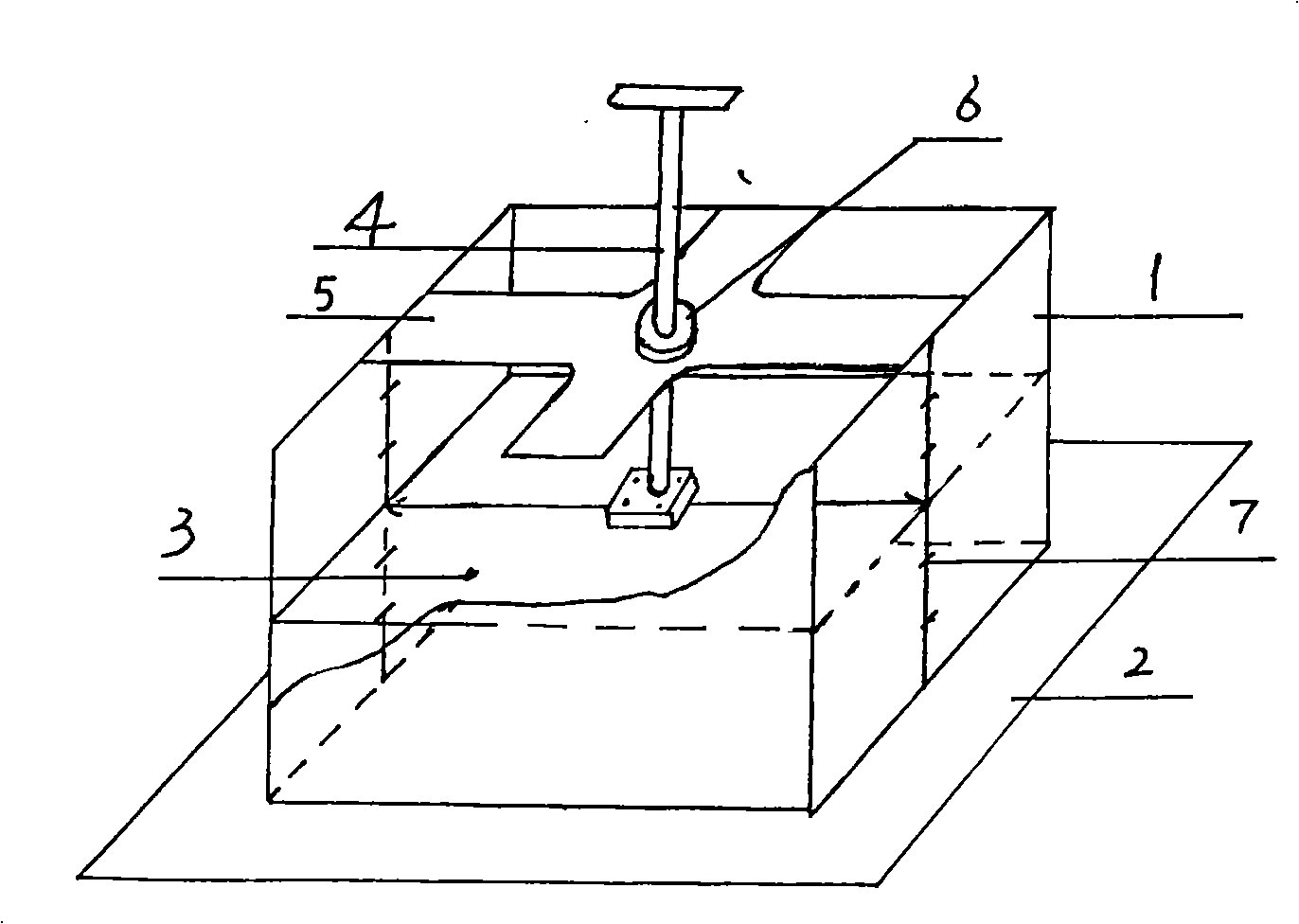

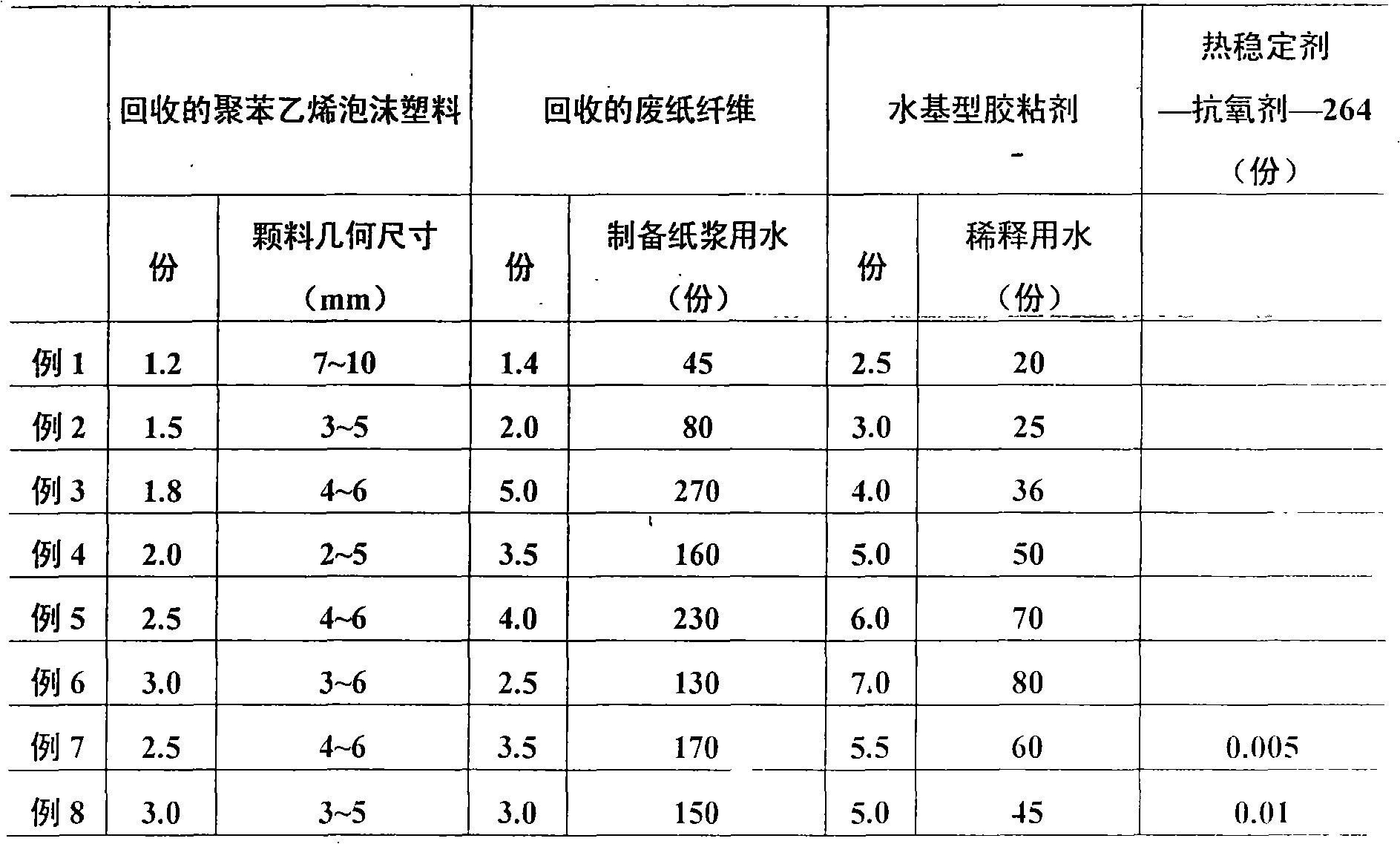

Polystyrene foam recovery regeneration buffer packing gasket and production method thereof

The invention relates to a polystyrene foam plastics recycling regeneration cushion packaging pad and a fabrication method thereof, belongs to the field of the packing material, and mainly solves the problems of the polystyrene foam plastics, the waste paper fiber recycling and the energy conservation and the environmental protection. The recycled polystyrene foam plastics are crushed into particles with 2-10 mm, the waste paper fiber is produced into paper pulp, and water is filtered out naturally, after the paper pulp is evenly mixed with the water-based adhesive diluted with the water according to a certain mass ratio; a die is infused, which is dewatered through pressurization and molded; then drying is performed; and finally the finished product can be obtained through surface finishing. The polystyrene foam plastics recycling regeneration cushion packaging pad and the fabrication method thereof have the advantages that both the polystyrene foam plastics and the waste paper fiber are recycled material, easy to obtain and have low cost; the fabricated cushion packaging pad has light weight and good cushioning property, can fully meet the requirements of product packing and also can be reused; since the adhesive adopts the environmental friendly water-based adhesive, not only the white pollution is greatly reduced, the energy resources and the resources are saved, but also the rejected material can be changed into resources, the development of the cyclic economy can be promoted, and meanwhile, the process is simple and convenient, the implementing is easy, and no pollution is generated.

Owner:青岛联大利丰塑料制品有限公司

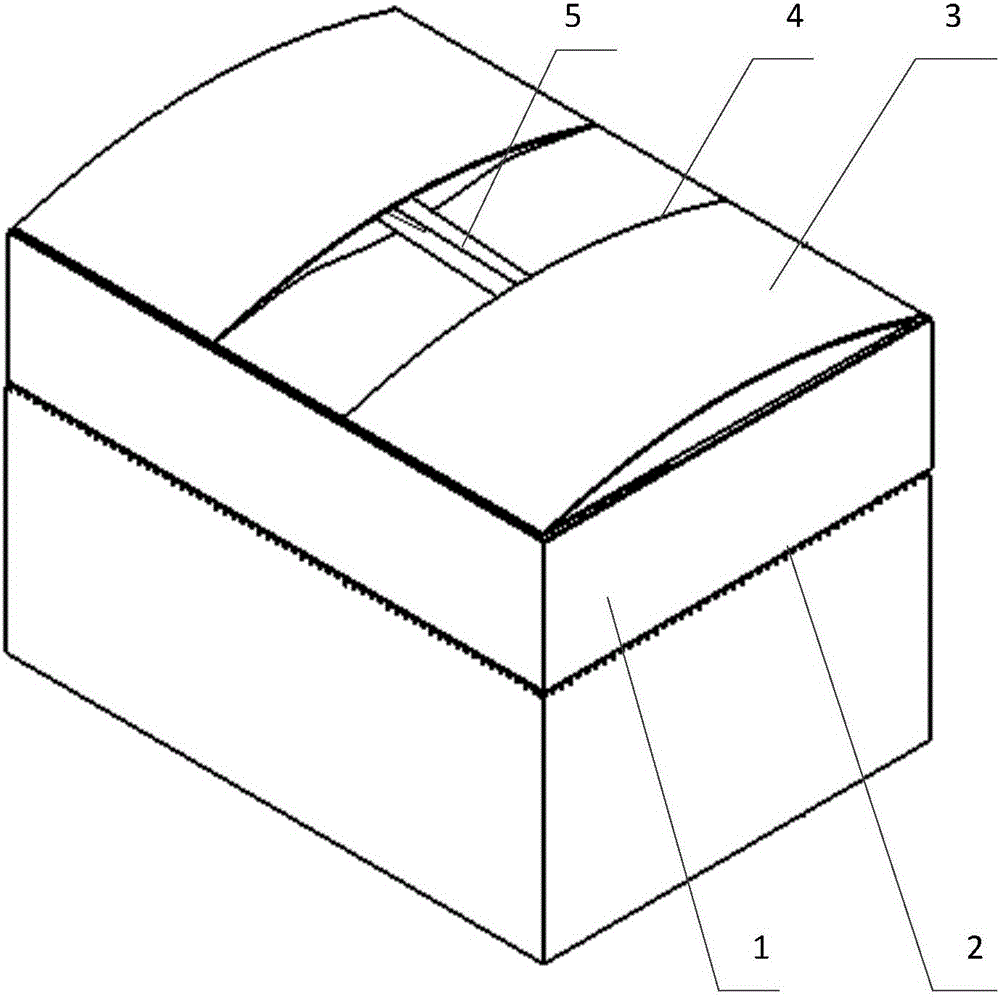

Paperboard buffer structure and packaging box with same

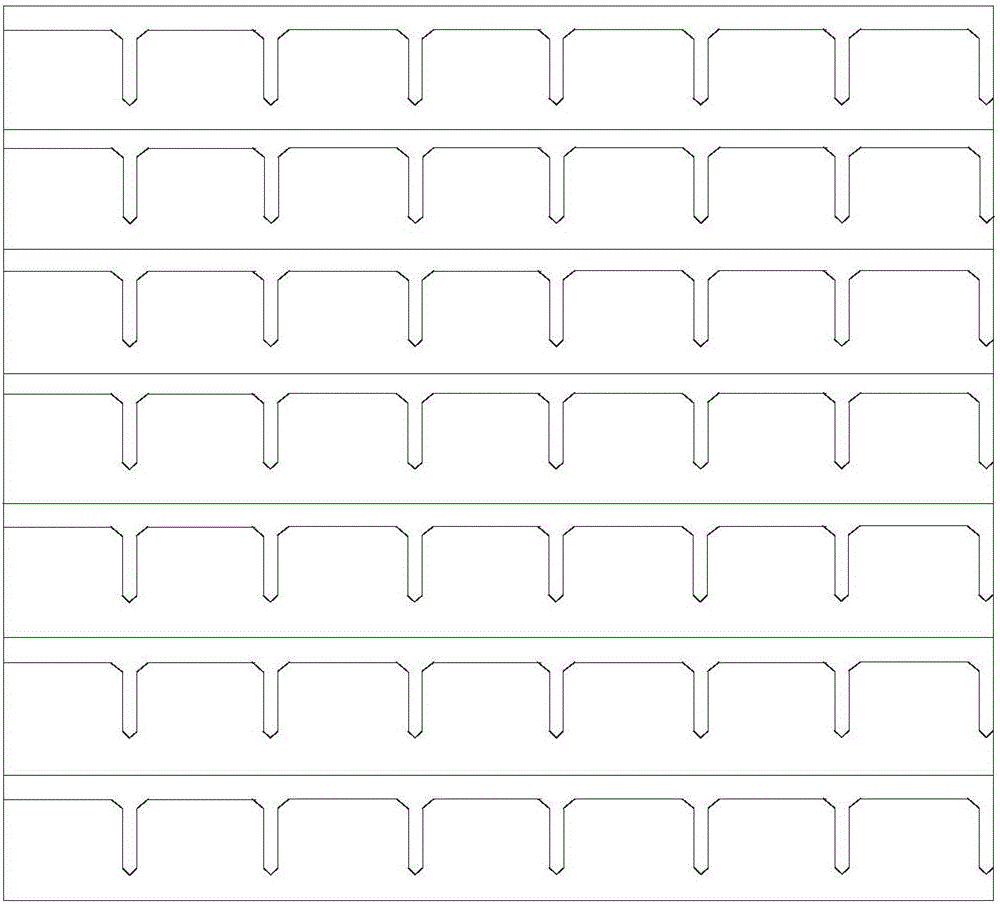

PendingCN106742503AMeet packaging needsIncrease profitRigid containersDamagable goods packagingBiochemical engineeringPaperboard

The invention provides a paperboard buffer structure and a packaging box with the same, and belongs to the field of packaging. The paperboard buffer structure comprises fixing faces arranged at the two ends and a buffer part arranged between the two fixing faces. The buffer part is provided with a plurality of folded marks. The buffer part comprises a supporting piece capable of being folded into a packaging body used for mounting an object to be packaged through the folded marks. The supporting piece comprises a plurality of supporting units. Each supporting unit comprises a first supporting face and a second supporting face. The corresponding middle parts of the first supporting faces and the second supporting faces are provided with through holes matched with the object to be packaged in boundary dimension. The object to be packaged is fixed to the middle part of the supporting piece through the through holes. The paperboard buffer structure and the packaging box with the same have the beneficial effects that buffering and positioning are integrated, low carbon and environmental protection are realized, and cost is greatly reduced; and processing is easy, no complex models are required, assembling is made convenient, and production efficiency is greatly improved.

Owner:苏州美盈森环保科技有限公司

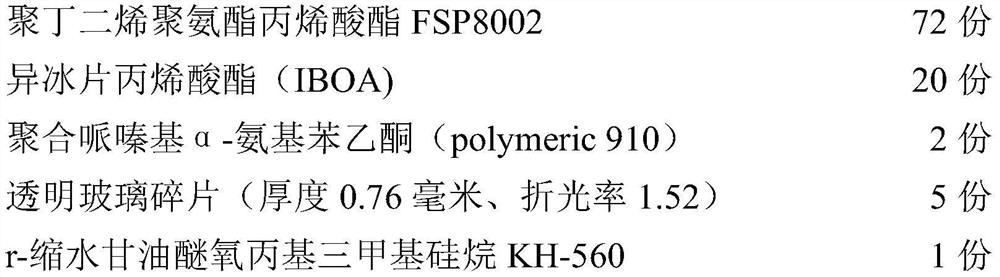

Photocuring liquid adhesive film composition and application thereof

PendingCN114456768AReduce power generation costsShorten the production cycleNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer sciencePhotosens

The invention discloses a light-cured liquid adhesive film composition and application thereof in a cold lamination packaging photovoltaic module. The light-cured liquid adhesive film composition comprises the following raw materials in percentage by mass: 45-90% of a photosensitive polymer; 5-70% of a photoactive monomer; 0-5% of a photosensitizer; 0.1-5% of transparent particles; 1-5% of an adhesion promoter; the photosensitive polymer is a photocuring polybutadiene polymer and / or a polyisoprene oligomer with the refractive index of 1.50 to 1.52; the photosensitizer is a free radical type or cationic macromolecular photosensitizer; the transparent particles are rigid or elastic solid particles, the refractive index of the transparent particles is 1.49-1.52, and the particle size of the transparent particles is 0.05-2.0 mm. The photocuring liquid adhesive film composition can replace a thermoplastic solid adhesive film to be used for lamination packaging of a photovoltaic module, the production period of the photovoltaic module can be greatly shortened, and the photovoltaic power generation cost is reduced.

Owner:HANGZHOU KEWANG SPECIAL INK CO LTD

Automatic assembly machine for door lock knob assembly

PendingCN110871356ANo human intervention requiredIncrease productivityAssembly machinesMachineMechanization

The invention discloses an automatic assembly machine for a door lock knob assembly. The automatic assembly machine for the door lock knob assembly comprises a rotating disc, a first assembly conveying mechanism, a lining cover installation device, a clamping ring installation device, a fourth assembly installation device and a qualified product discharging device. At least six tool positions which are annularly arranged at intervals are arranged on the rotating disc; the first assembly conveying mechanism is installed on a machine table and corresponds to the first station; the lining cover installation device is installed on the machine table and corresponds to the fourth station; the clamping ring installation device is installed on the machine table and corresponds to the sixth station; the fourth assembly installation device is installed on the machine table and corresponds to the eighth station; and the qualified product discharging device is installed on the machine table and corresponds to the eleventh station. The automatic assembly machine can automatically assemble a first assembly into the door lock knob assembly, and the entire process is performed automatically without manual intervention, so that production efficiency is greatly improved, the labor cost is reduced, and in vigorous advancement of mechanization of today, the automatic assembly machine has good market prospects.

Owner:厦门迈通科技有限公司

Full-automatic rail positioning box filling machine

The invention provides a full-automatic rail positioning box filling machine. The box filling machine comprises a box filling mechanism, two positioning mechanisms, a power source, a product conveying mechanism and a box conveying mechanism. The two positioning mechanisms are fixedly arranged on the left side and the right side of the box filling machine respectively, and positioning rails are arranged on the positioning mechanisms; the box filling mechanism is arranged between the two positioning mechanisms, and the positioning mechanisms drive the box filling mechanism to carry out the box filling motion according to determined paths of the positioning mechanisms; the power source provides power for the box filling machine through the positioning mechanisms, the two ends of the box filling mechanism are made to run in the positioning rails, and therefore the box filling motion is done; and the product conveying mechanism is used for conveying products to be contained in a box to the box filling mechanism; and the box conveying mechanism is used for conveying the box. The full-automatic rail positioning box filling machine is simple in structure, easy to maintain, simple and reliable in running, easy to observe after being damaged and convenient to replace, and the damage to the products and the box can be reduced.

Owner:SICHUAN KELUN PHARMA CO LTD

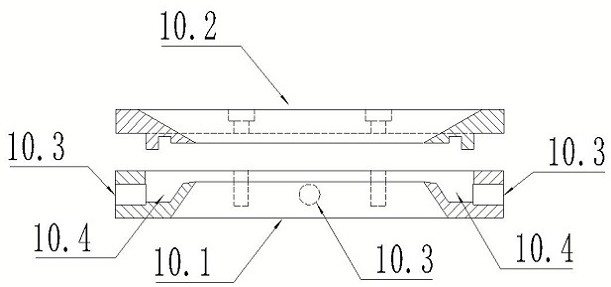

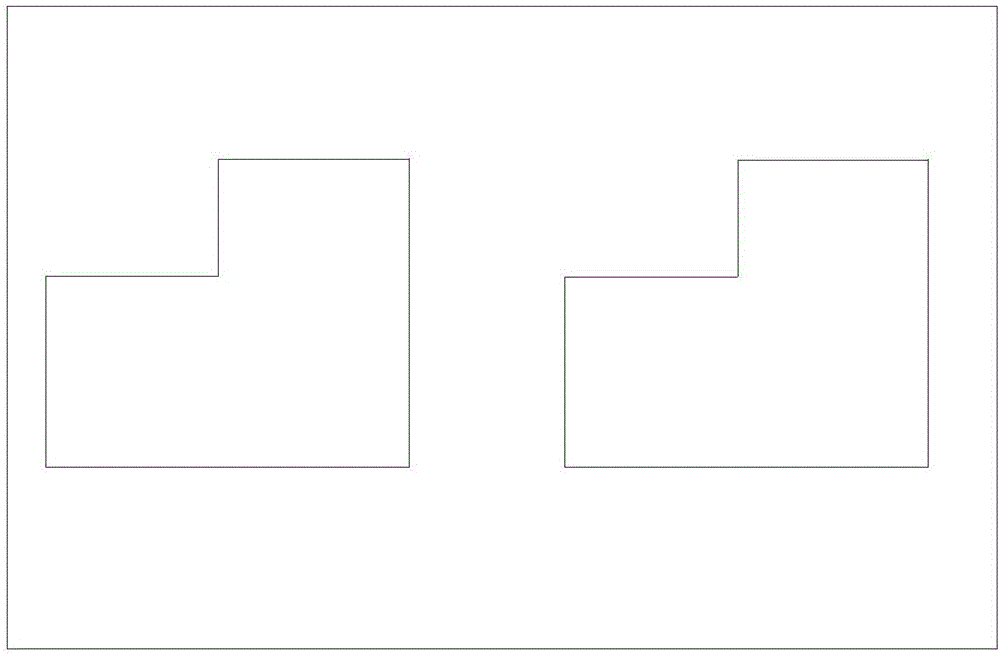

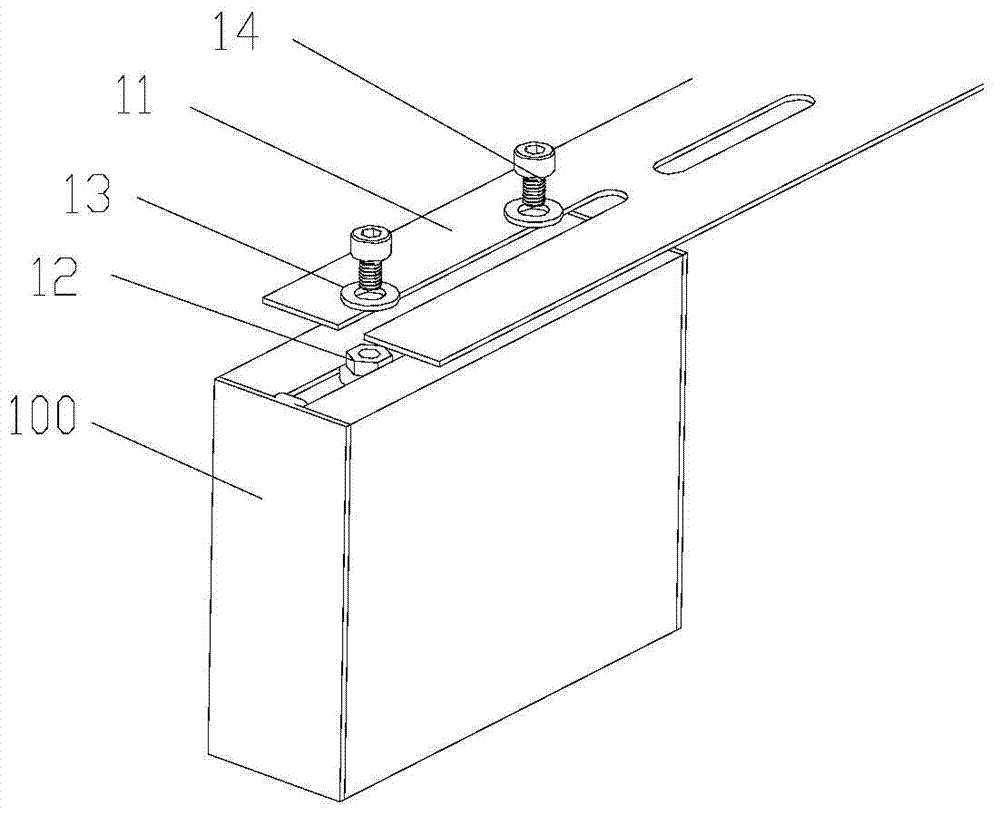

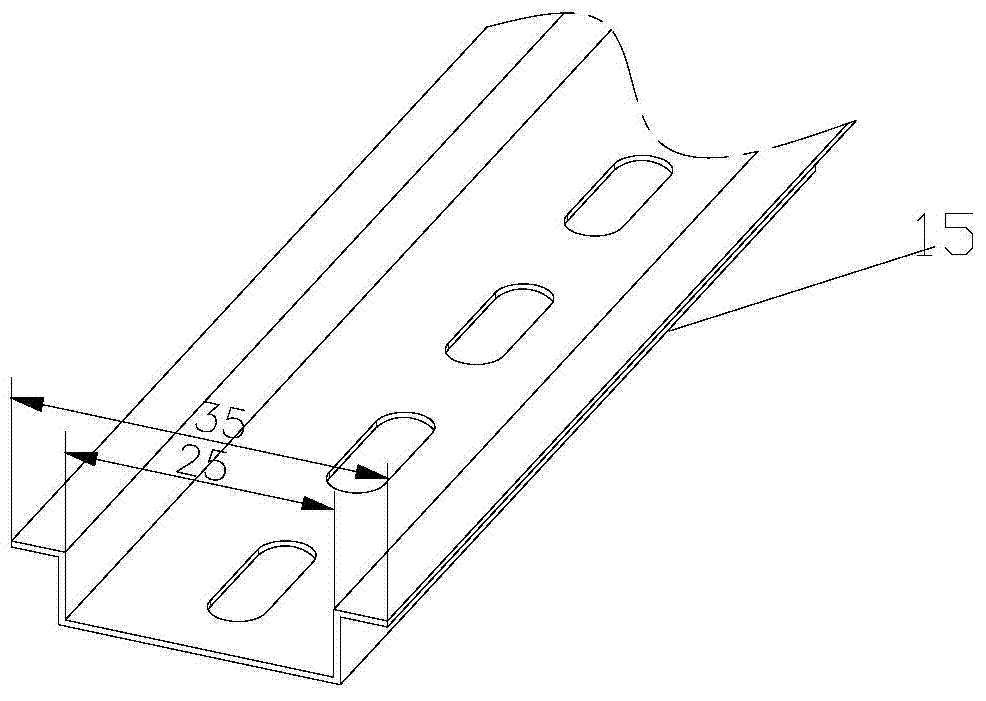

Supporting frame, forming assembly device of supporting frame and boxing method of supporting frame

The invention discloses a supporting frame, a forming assembly device of the supporting frame and a boxing method of the supporting frame. The supporting frame comprises an upper supporting frame body and a lower supporting frame body, the upper supporting frame body and the lower supporting frame body respectively comprise a location part, a wrapping part and a supporting part, and the upper supporting frame body and the lower supporting frame body can both be formed and installed through corresponding forming assembly device bodies. The related forming assembly device comprises the upper supporting frame body forming assembly device body, the lower supporting frame body forming assembly device body and a carrying device. The upper supporting frame body forming assembly device body only serves forming and assembly of the upper supporting frame body, and the lower supporting frame body forming assembly device body only serves forming and assembly of the lower supporting frame body. The carrying device enables product arrays located at different boxing operation stages to be located at the optimum positions. The supporting frame can completely replace a foam plate in the prior art under the effect of the supporting frame forming assembly device to be installed on the exteriors of the product arrays, the original packing requirement is met, and the functions of fixing the product arrays and reserving gaps between the product arrays and a box body are achieved.

Owner:HANGZHOU ZHONGYA MACHINERY CO LTD

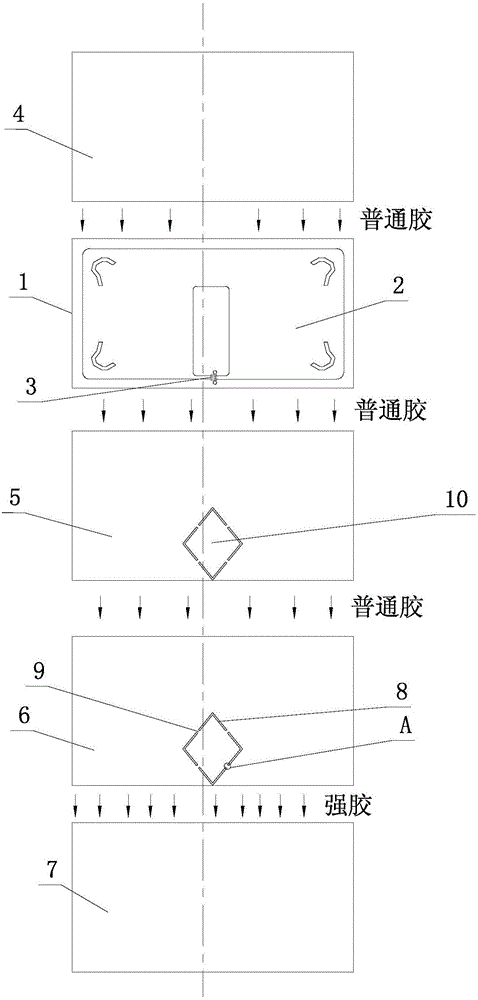

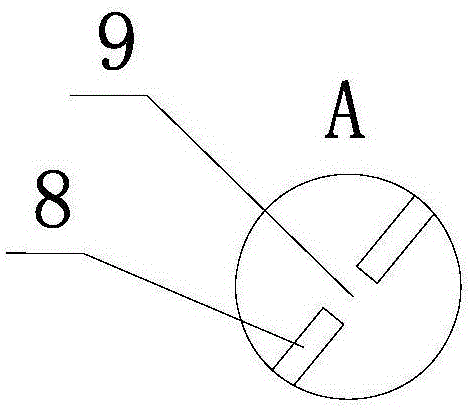

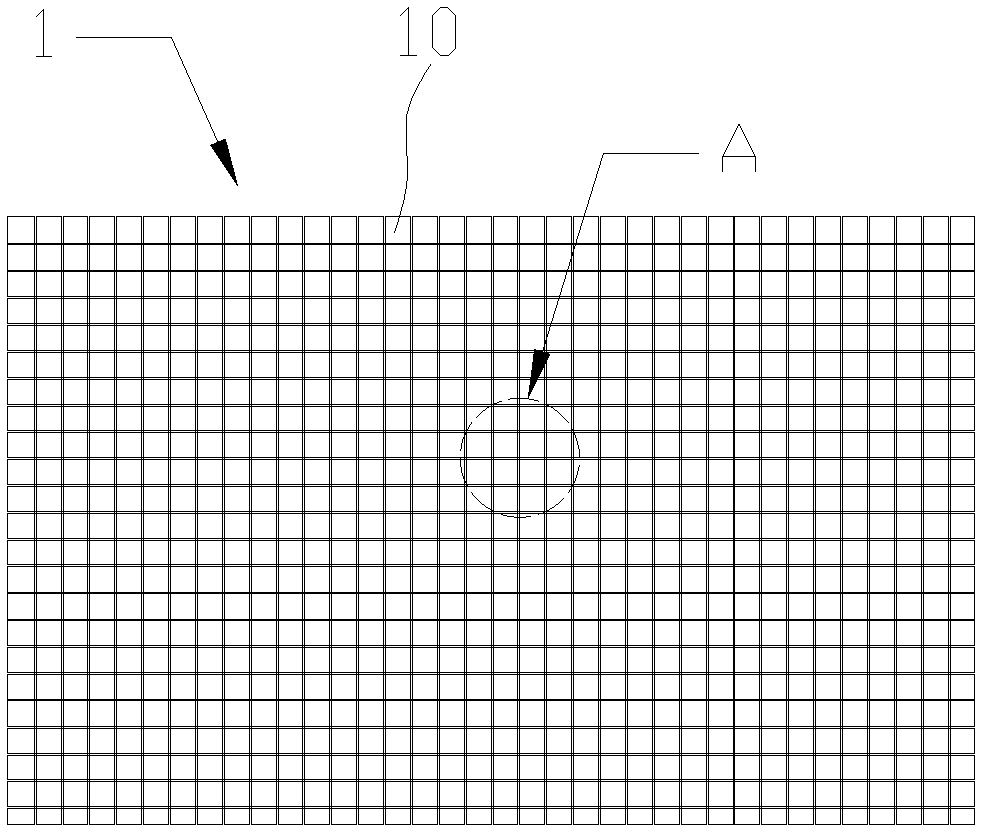

Frangible electronic label resistant to metal

The invention discloses a frangible electronic label resistant to a metal. The frangible electronic label comprises a surface paper layer (4), a base plate (1), an ethylene Vinyl acetate copolymer (EVA) isolation layer (5), an aluminum layer (6) and a bottom paper layer (7) which are sequentially bonded from top to bottom, wherein the base plate (1) is made of a frangible film; a signal circuit (2) and a chip (3) are arranged on the lower surface of the base plate (1); multiple groups of tool marks are arranged on the EVA isolation layer (5) and the aluminum layer (6) and penetrate through the EVA isolation layer (5) and the aluminum layer (6); each group of tool marks comprises two tool marks (8) arranged on the same straight line; a region encircled by connecting the EVA isolation layer (5) and the aluminum layer (6) into a circle in a head-to-tail manner by the multiple groups of tool marks forms a region easy to separate (10); and the chip (3) and a small part of signal circuit (2) are bonded with the region easy to separate (10). The label is isolated from metal interference, and can be effectively prevented from being reused by a lawless person.

Owner:立芯科技股份有限公司

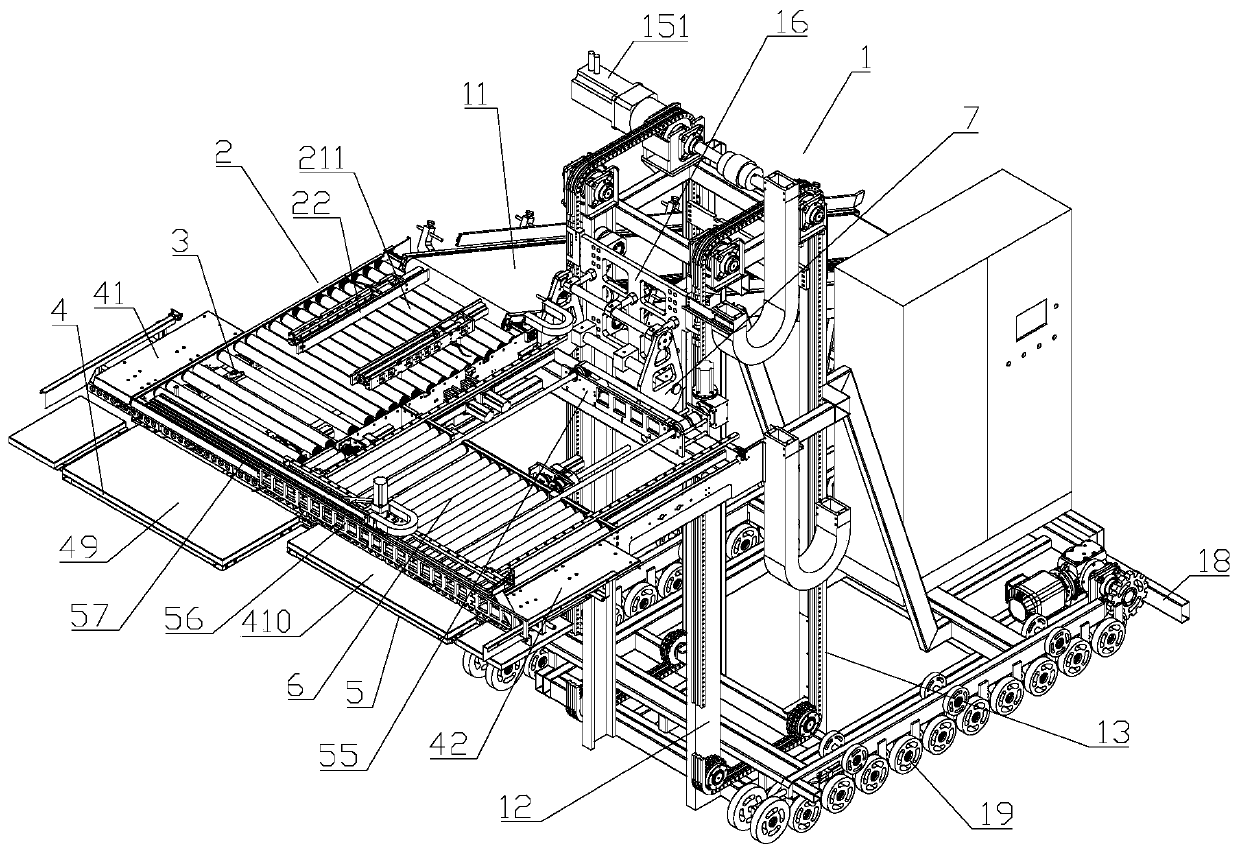

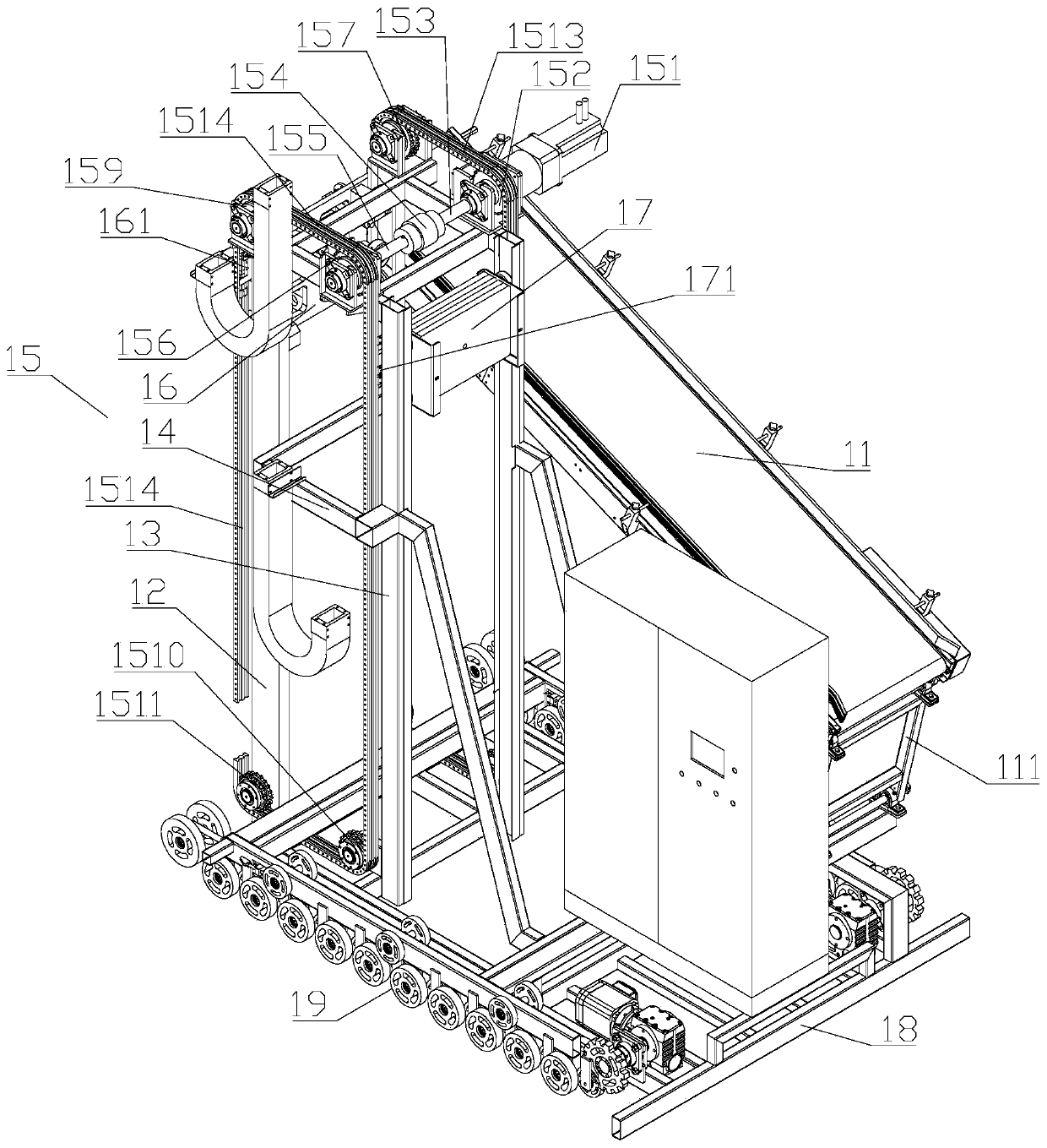

Automatic truck loading equipment

PendingCN111017588AEasy to integrateReduce labor costsStacking articlesSupporting framesSprocketTruck

The invention provides automatic truck loading equipment. The equipment comprises a folding lifting type truck frame, a feeding device, a discharging assembly, a tray assembly and a pushing assembly.The folding lifting type truck frame comprises a conveying belt mechanism, a fixing frame, a lifting assembly, a bottom frame and a walking chain wheel set. The rear end of the feeding device is hinged to the conveying belt mechanism. The feeding device, the discharging assembly, the tray assembly and the pushing assembly are matched to form an integrated structure, and the integrated structure isdriven by the folding lifting type truck frame to ascend and descend. According to the automatic truck loading equipment, goods collection, carrying, loading and unloading are integrated, so that theautomation degree is high.

Owner:TIANJIN XUTENGDA AUTOMATION EQUIP CO LTD

Adhesive tape twining packaging device

The invention discloses an adhesive tape twining packaging device. The adhesive tape twining packaging device comprises a rotary tape conveying mechanism and an auxiliary rolling operating platform arranged at the adhesive tape outlet end of the rotary tape conveying mechanism. The rotary tape conveying mechanism comprises a servo motor and an adhesive tape conveying roller connected to the servomotor. The servo motor can drive the adhesive tape conveying roller to conduct cyclic forward and reverse rotation not exceeding 180 degrees in the vertical direction. A plurality of driving rollers are arranged on the auxiliary rolling operating platform and are arranged in parallel in the horizontal direction. When the device operates, articles to be packaged are placed on the conveying rollers;the conveying rollers drive the articles to be packaged to rotate; at the moment, adhesive tape sent from the adhesive tape conveying roller is pasted onto the articles to be packaged, the packagingadhesive tape can automatically package the articles along with rotation of the articles; meanwhile, the servo motor can drive the adhesive tape conveying roller to conduct cyclic forward and reverserotation in the vertical direction so that the adhesive tape can be uniformly twined to the two ends of each article to be packaged to wrap the article completely.

Owner:苏州弘景煦电子科技有限公司

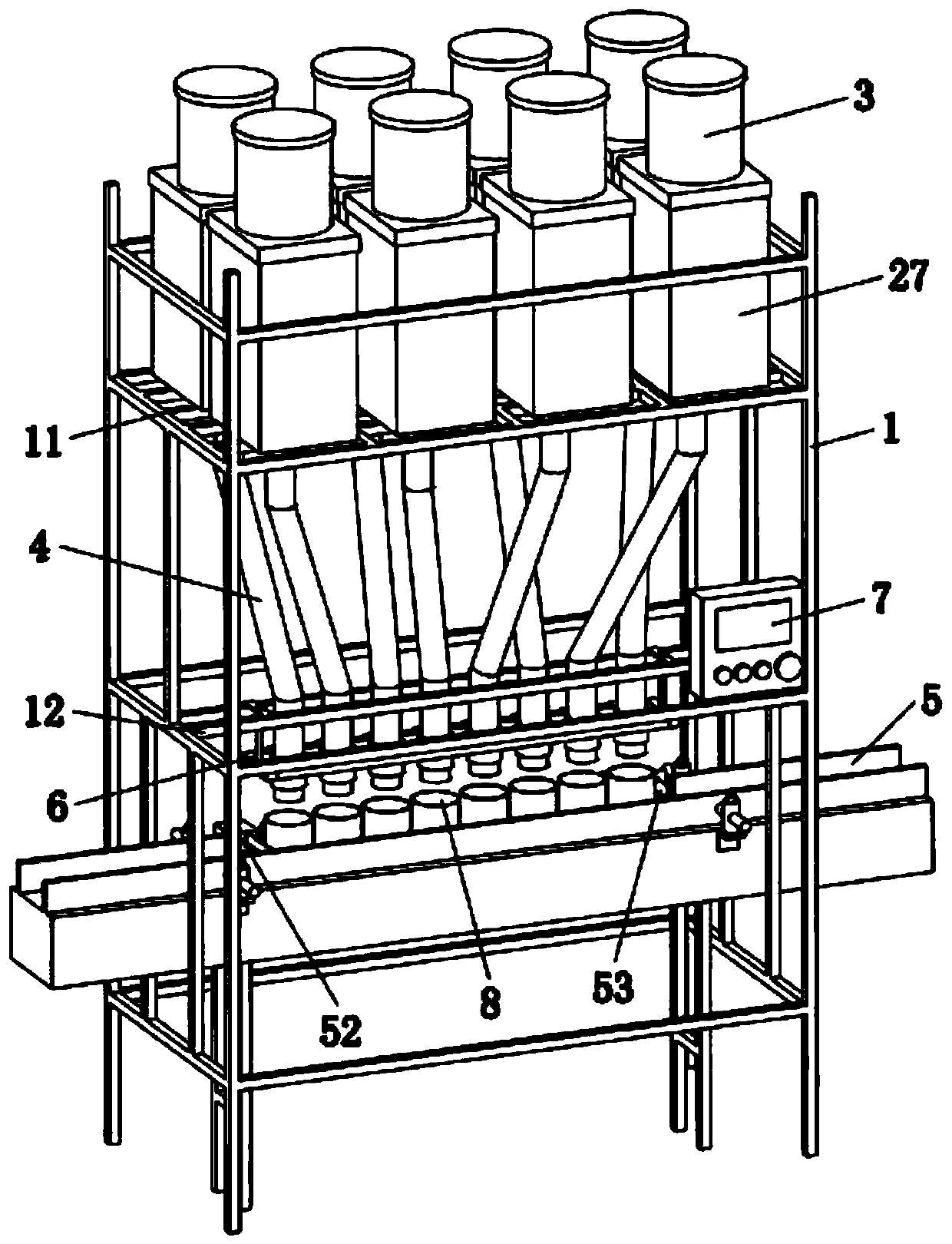

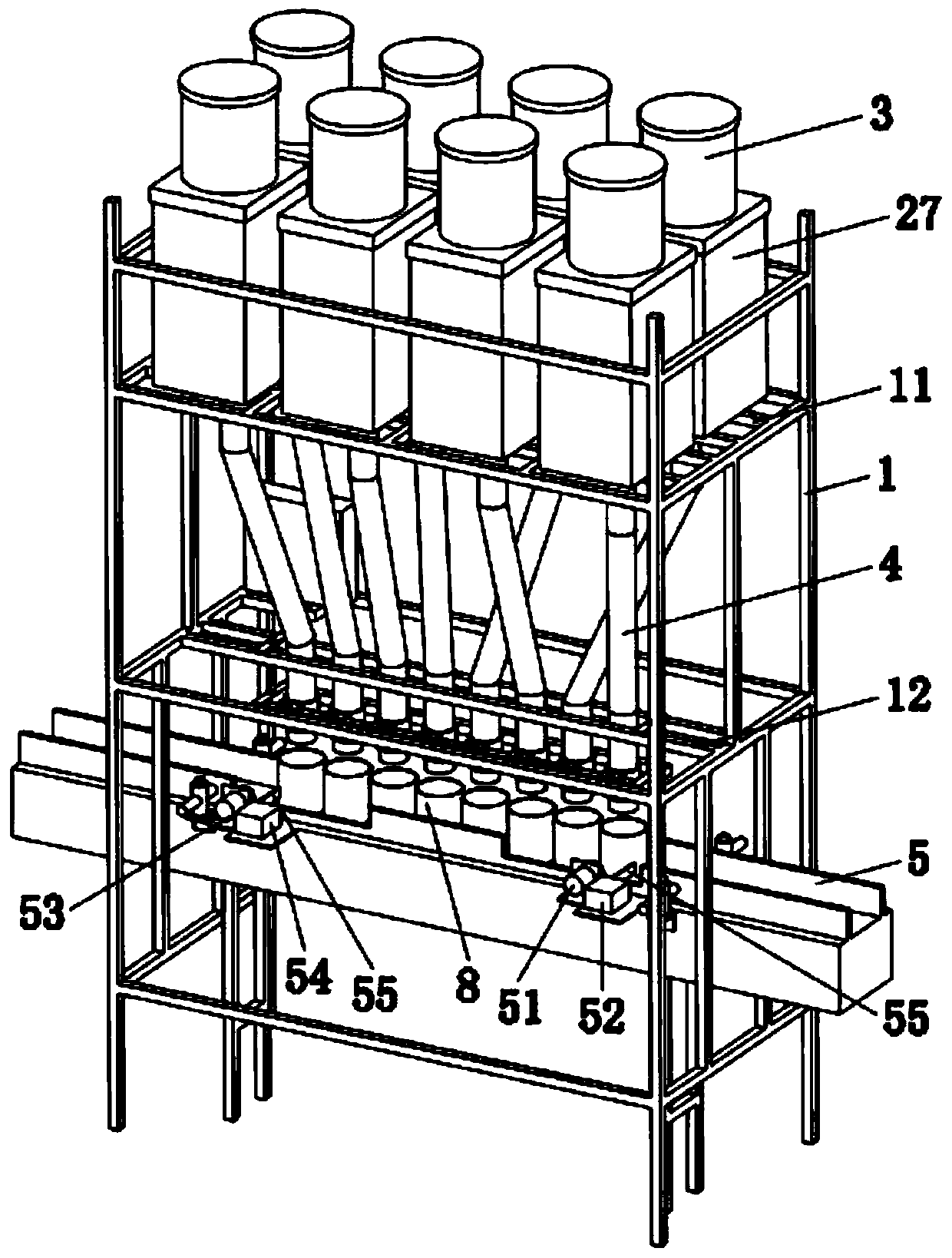

Intelligent split charging machine

PendingCN110294152AImprove packaging efficiencySmall weight deviationPackaging automatic controlSolid materialGramEngineering

The invention discloses an intelligent split charging machine. The intelligent split charging machine comprises a machine frame, a feeding device, a storage cylinder, a material conveying pipe, a conveying line and a control device. The storage cylinder is arranged at the top of the feeding device. The feeding device comprises a first support, a uniforming assembly, a quantitative assembly, a plurality of second supports, weighing sensors and discharging hoppers. The weighing sensors are arranged on the tops of the second supports correspondingly. Each weighing sensor is provided with a discharging hopper. Materials in the storage cylinder are uniformly dispersed by the uniforming assembly and are then conveyed into each discharging hopper by the quantitative assembly to be weighed. A plurality of material conveying pipes are arranged on an upper support. A quantity fixing assembly is arranged in the conveying direction of a conveying line and is used for enabling one empty material bottle to be arranged below each material conveying pipe and completing material conveying of the material bottles. By means of the intelligent split charging machine, split charging of a plurality of materials by part can be completed at one time, so that the material split charging efficiency is greatly improved; and moreover, it can be ensured that the gram-level weight deviation of materials falling into the discharging hoppers is small, and the precision of material split charging is improved.

Owner:大洲新燕(厦门)生物科技有限公司

Portable winding film packaging device

PendingCN113184252AMeet packaging needsEasy to fixWrapping material feeding apparatusWeb rotation wrappingStructural engineeringMechanical engineering

The invention discloses a portable winding film packaging device, and relates to the technical field of winding film packaging. The portable winding film packaging device comprises a positioning fixing mechanism and a rotating winding mechanism; the positioning fixing mechanism comprises a pair of transverse adjusting connecting rods; positioning blocks are arranged at the two ends of the two transverse adjusting connecting rods; the two transverse adjusting connecting rods are connected through a longitudinal adjusting connecting rod; the rotating winding mechanism is rotationally arranged on the longitudinal adjusting connecting rod; the positioning fixing mechanism is used for fixedly clamping the device on goods, and the rotating winding mechanism is located over the goods; an extending mounting rod is arranged on the rotating winding mechanism; a lifting lead screw is arranged on the extending mounting rod; a winding film mounting part is arranged on the lifting lead screw; the winding film mounting part is used for mounting a winding film for packaging; and the rotating winding device is used for rotationally packaging the peripheral sides of the goods. According to the portable winding film packaging device, the lifting lead screw and the positioning fixing mechanism which is rotationally connected with the lifting lead screw are arranged, so that the winding film mounting part synchronously rises when rotating along the positioning fixing mechanism, the winding films with different heights are packaged, and the packaging requirement when the goods are stacked at a high position is met.

Owner:ZHEJIANG TIANNENG BATTERY JIANGSU NEW ENERGY

Centrifugal grain packaging equipment based on screening assembly

ActiveCN113649287AImprove packaging efficiencyImprove efficiencySievingGas current separationMechanical engineeringEngineering

The invention discloses centrifugal grain packaging equipment based on a screening assembly, and relates to the technical field of grain packaging. The centrifugal grain packaging equipment comprises a fixed bracket, the lower surface of an annular fixing plate is fixedly connected with a first feeding mechanism in the annular direction; the upper end of a supporting rod is fixedly connected with a second feeding mechanism; the curved surface, close to the center of the annular fixing plate, of a discharging channel of the first feeding mechanism is fixedly connected with a first centrifugal mechanism; a second centrifugal mechanism is clamped to the top of the first centrifugal mechanism; a centrifugal screen assembly is slidably connected to the upper surface of a screen plate mounting assembly; an arc-shaped discharge hole of a first guide ring is formed in the tangential direction of the outer wall of the first guide ring; and a rotary driving assembly is clamped in a first through hole. Through the design of the first centrifugal mechanism, the second centrifugal mechanism, the rotary driving assembly, a movable driving mechanism and a packaging supporting mechanism, integration of grain screening and centrifugal packaging can be achieved, the grain packaging efficiency is greatly improved, and the labor intensity of workers is greatly reduced.

Owner:宜宾综合保税区供应链管理有限公司

Lunch box

The invention discloses a lunch box. The lunch box comprises a plurality of box bodies, wherein a box cover is arranged at the top part of each box body and can be turned along one side of each box body; rocking wings are respectively arranged at both sides of each box body and are used for packaging; an inserting bolt is arranged on each box cover and is used for fixing; the multiple box bodies are fixedly connected by detachable connecting parts; the lunch box is made of paper. The lunch box has the advantages that by arranging the multiple box bodies, the requirement of splitting package of rice, vegetable and soup is met; before forming, the box bodies can be folded and stacked, so that the space is saved; the lunch box is made of the paper, so that the pollution to the environment is avoided, and the lunch box can be recycled.

Owner:GUANGDONG UNIV OF TECH

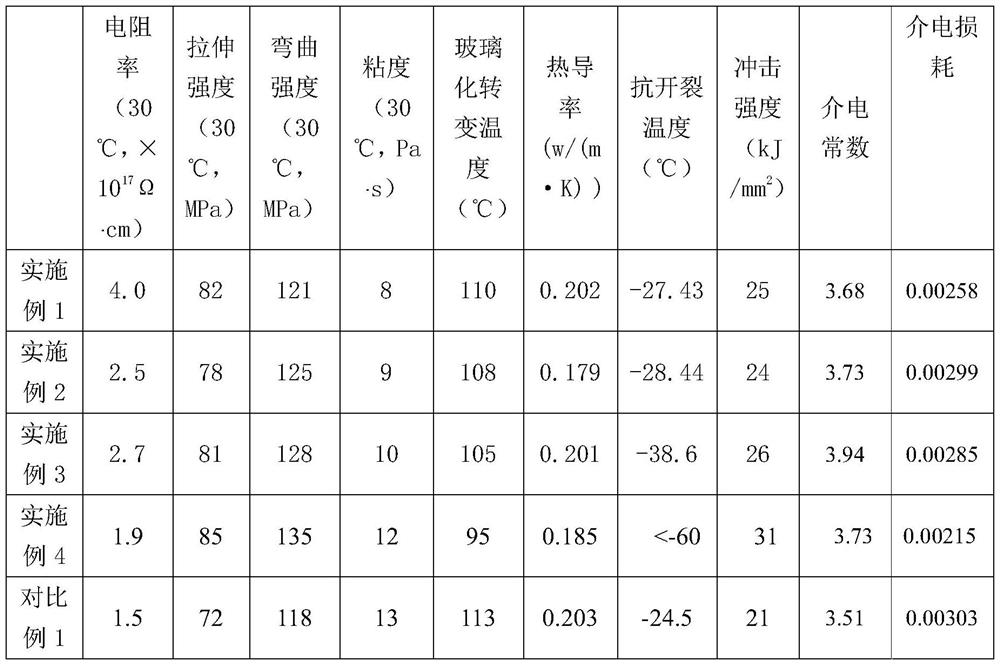

Epoxy resin composite material and preparation method thereof

The invention provides an epoxy resin composite material and a preparation method thereof. The epoxy resin composite material is prepared from, by mass, 2.5-10 parts of monohydroxy polyether alcohol grafted epoxy resin, 100 parts of epoxy resin, 60-100 parts of curing agent and 1 part of accelerant. According to the invention, the tensile strength of the epoxy resin composite material prepared through the method reaches up to 85 MPa, the bending strength reaches 135 MPa, and cracking is still avoided when the temperature is reduced to -60 DEG C, so that the packaging requirement of electricalequipment such as a high-frequency transformer and the like is greatly met, and the preparation method provided by the invention is simple, reliable and suitable for large-scale production.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +1

Cushion pad for packing, packing box and lamp packing method

InactiveCN103359392AEasy to tear intoMeet packaging needsDamagable goods packagingBiomedical engineeringPacking method

The invention relates to a cushion pad for packing, a packing box and a lamp packing method. The cushion pad for packing comprises a plurality of cushion block units which are identically shaped in prisms, and edges of every two adjacent cushion block units are connected. The lamp packing method includes the step of tearing apart connections of the cushion block units of the cushion pad for packing according to a shape of a lamp so as to form an appropriate shape to be cushioned in the packing box, and the cushion pad for packing is filled between the lamp and the packing box. The cushion pad for packing comprises a plurality of cushion block units which are identical in shape, edges of the adjacent cushion block units are connected, the cushion pad can be torn into the appropriate shape conveniently according to needs so as to meet packing requirements on the lamps in different shapes, and the cushion pad for packing has good university and can reduce packing cost. According to the lamp packing method, a same kind of packing boxes is adopted to be used with the cushion pad for packing, and the packing requirements on the lamps different in shape and configuration can be met.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Method for selectively preparing gold-tin eutectic solder on surface of ceramic substrate

The invention discloses a method for selectively preparing gold-tin eutectic solder on the surface of a ceramic substrate. The method comprises the following steps: (1) plating a metal layer on the ceramic substrate via a physical method or an electrochemistry method; (2) treating the metal layer via a photoetching technique to obtain a pattern layer; (3) etching the metal layer by using a metal etching solution to obtain a patterned metal layer; and (4) carrying out electroplating of a gold-tin alloy on the patterned metal layer to form solder, wherein a gold-tin electroplating solution used by electroplating is an electroplating solution of a cyanide-free system and comprises gold salt, tin salt, brighteners, complexing agents and antioxidants. The gold-tin eutectic solder is capable of carrying out electroplating in the specific position to obtain the gold-tin alloy plating layer with bright and dense surface; the gold-tin eutectic bumps are controllable in thickness and can meet different packaging requirements; the melting point of the formed eutectic alloy is 280+ / -0.2 DEG C; the eutectic alloy has high welding performance and oxidation resistance and is used as optimal solder in the field of optoelectronic packaging.

Owner:SYSU CMU SHUNDE INT JOINT RES INST +1

Distributed measuring and controlling node circuit package box

The invention provides a distributed measuring and controlling node circuit package box. The distributed measuring and controlling node circuit package box comprises a main box body, a first end plate and a second end plate, wherein symmetric first slotted structures are formed in the upper inner surface and the lower inner surface of the front end of the main box body; symmetric second slotted structures are formed in the upper inner surface and the lower inner surface of the rear end of the main box body, wherein a distributed measuring and measuring node circuit is packaged in the main box body; the inner surface of the first end plate is provided with first buckle structures which are matched with the first slotted structures and is detachably connected with the main box body; the inner surface of the second end plate is provided with second buckle structures which are matched with the second slotted structures and is detachably connected with the main box body. The distributed measuring and controlling node circuit package box provides possibility for high-density distributed measuring and controlling node circuit package, not only can meet the circuit packaging demands of most of distributed measuring and controlling nodes, but also is especially suitable for the installation demand of the distributed measuring and controlling node circuit in an industrial control field with a narrow space.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com