Short fiber finished product subsequent production line

A production line and staple fiber technology, which is applied in the field of polyester staple fiber production, can solve the problems such as the blade cannot be alarmed, the thickness of the tow is uneven, and there are many weak filaments.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

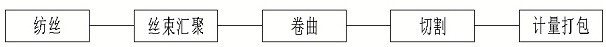

[0050] see Figure 1~17 , the present invention relates to a finished short fiber finished product production line, the short fiber finished finished production line includes a spinning machine 9, an oiling ring 10, a silk storage box 11, a wire guide frame 12, a tail silk alarm device 13, a curling Machine 14, tow amplitude modulation device 15, spinning cutting machine 16 and baler 17; described spinning machine 9, oiling ring 10, silk storage box 11, guide frame 12, crimping machine 14, spinning cutting machine 16 Set up sequentially with packer 17;

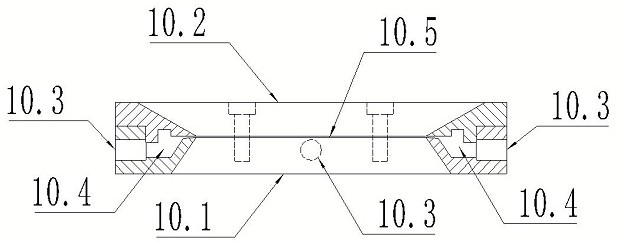

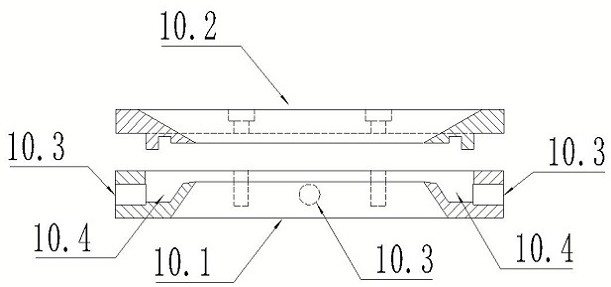

[0051] The oiling ring 10 includes a chassis 10.1 and a top cover 10.2; the top cover 10.2 is fixedly installed on the chassis 10.1 by bolts; the outer ring of the chassis 10.1 is provided with a plurality of evenly distributed oil inlets 10.3; the inner ring of the chassis 10.1 An oil storage chamber 10.4 is provided; the inner edge of the chassis 10.1 and the top cover 10.2 forms an oil overflow seam 10.5; the oil inlet 10....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com