Patents

Literature

210results about How to "Avoid Quality Accidents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

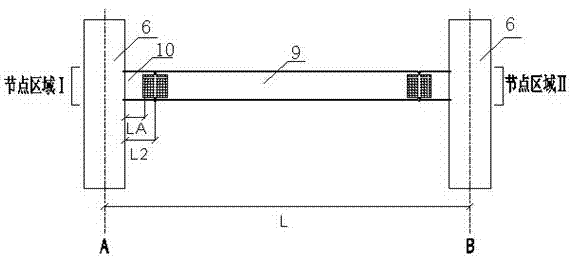

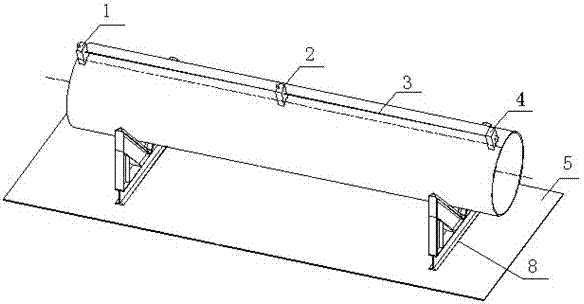

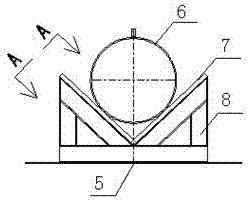

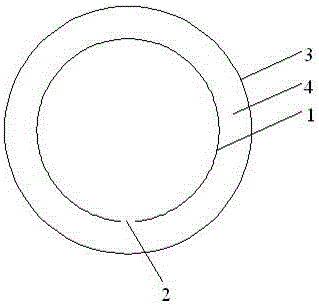

Radial positioning method for joint part of round pipe component

The invention relates to a radial positioning method for a joint part of a round pipe component. The method includes the following steps: determining a reference surface, acquiring out-of-roundness of two ports of a round pipe according to the reference surface, and performing roundness correction on the ports of the round pipe; measuring two ends of the round pipe after being subjected to port roundness correction according to the reference surface to acquire an upper end point of each port, and performing joint punching on the upper end point to acquire a punching point identity; according to the punching point identity, adopting a laser alignment method for measuring to acquire bending error of the round pipe; according to the bending error of the round pipe, adopting a fire correction method and the laser alignment method to align the round pipe, and determining an axial position of a joint according to size specified by a drawing; adopting the laser alignment method to determine out-of-roundness of the axial position of the joint of the round pipe, and acquiring radial error. By the radial positioning method, the problem of radial positioning of the joint part on a finished pipe with deviation in outer diameter and tortuosity is solved, and connecting accuracy of the component and integral safety of structure are guaranteed.

Owner:ANHUI WEIHONG STEEL STRUCTURE GRP

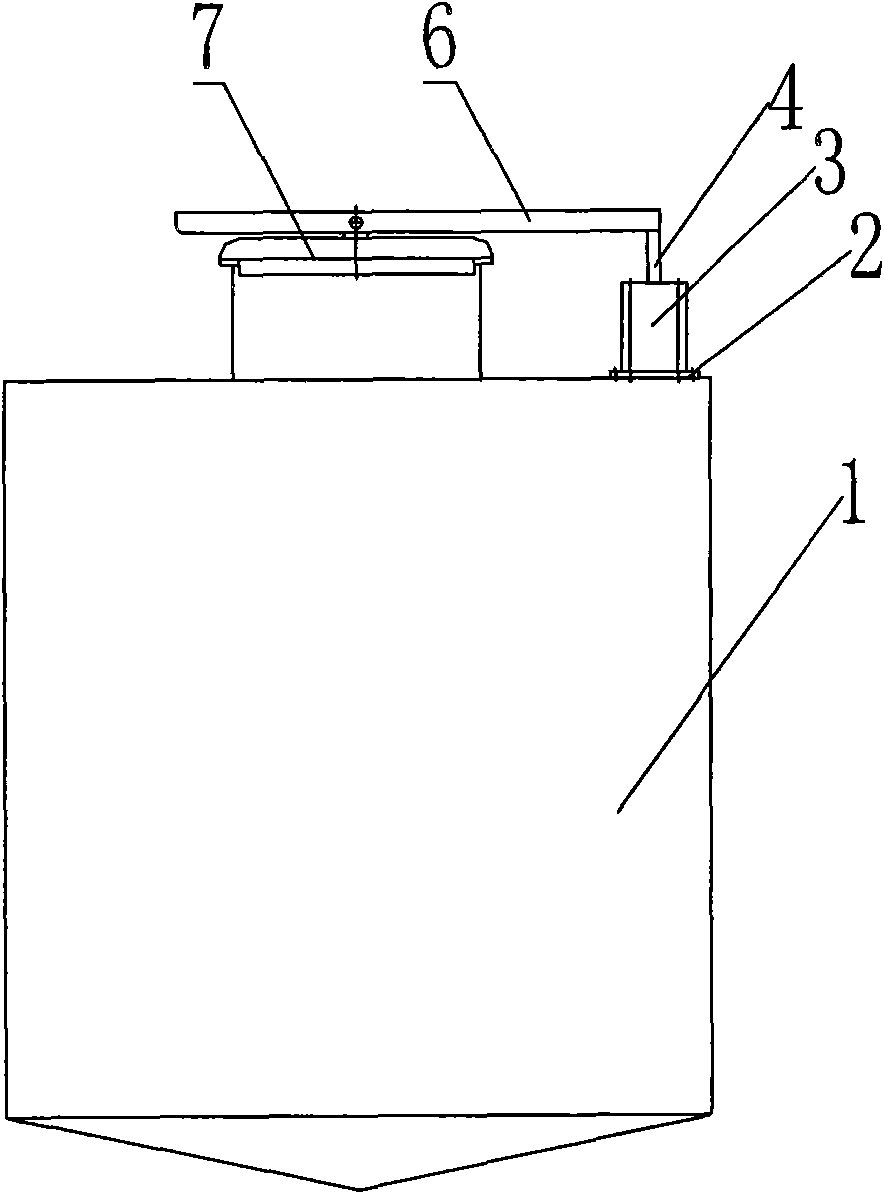

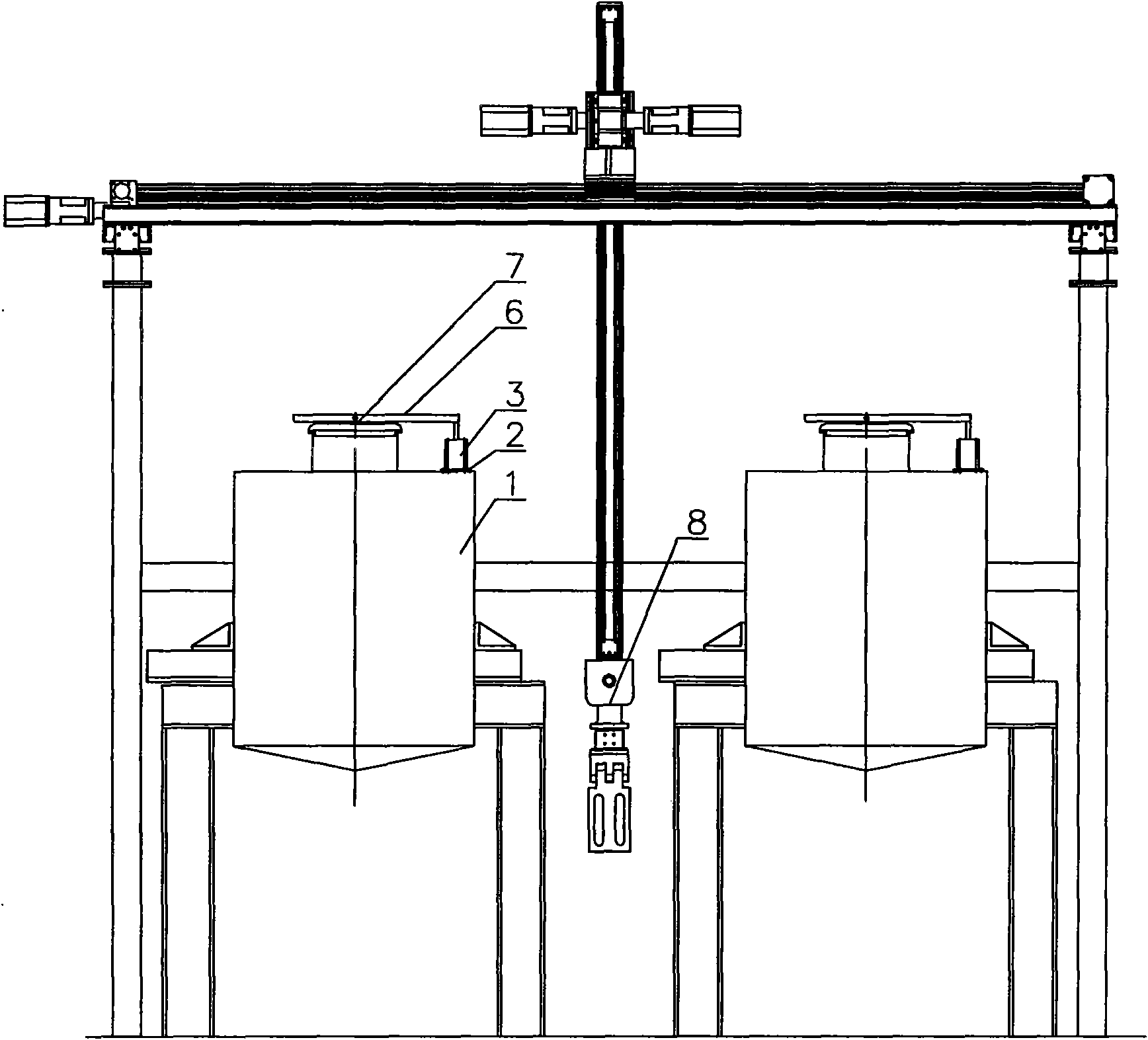

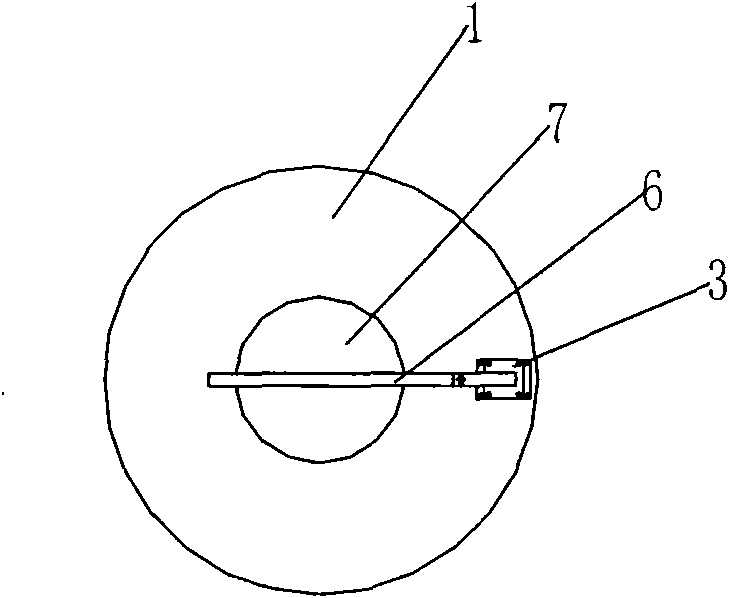

Automatic uncovering device of tobacco dedicated charging bucket

The invention discloses an automatic uncovering device of a tobacco dedicated charging bucket, comprising a charging bucket and a rectilinear swinging combined cylinder, wherein the top of the charging bucket is provided with an opening, and the opening is provided with a bucket cover; the rectilinear swinging combined cylinder is fixed on the charging bucket, and the piston rod of the rectilinearswinging combined cylinder faces upwards; and the piston rod is connected with the bucket cover via a batten connecting bar. In the scheme, the rectilinear swinging combined cylinder is connected with the bucket cover of the charging bucket, thus driving the bucket cover of the charging bucket to carry out lifting and rotating combination movement; thus the invention can open and close the bucketcover of the charging bucket, realizes the automation of opening and closing the bucket cover of the charging bucket and satisfies the production automation requirement of a full-automatic sugar kitchen system.

Owner:SHANGHAI TOBACCO GRP CO LTD +1

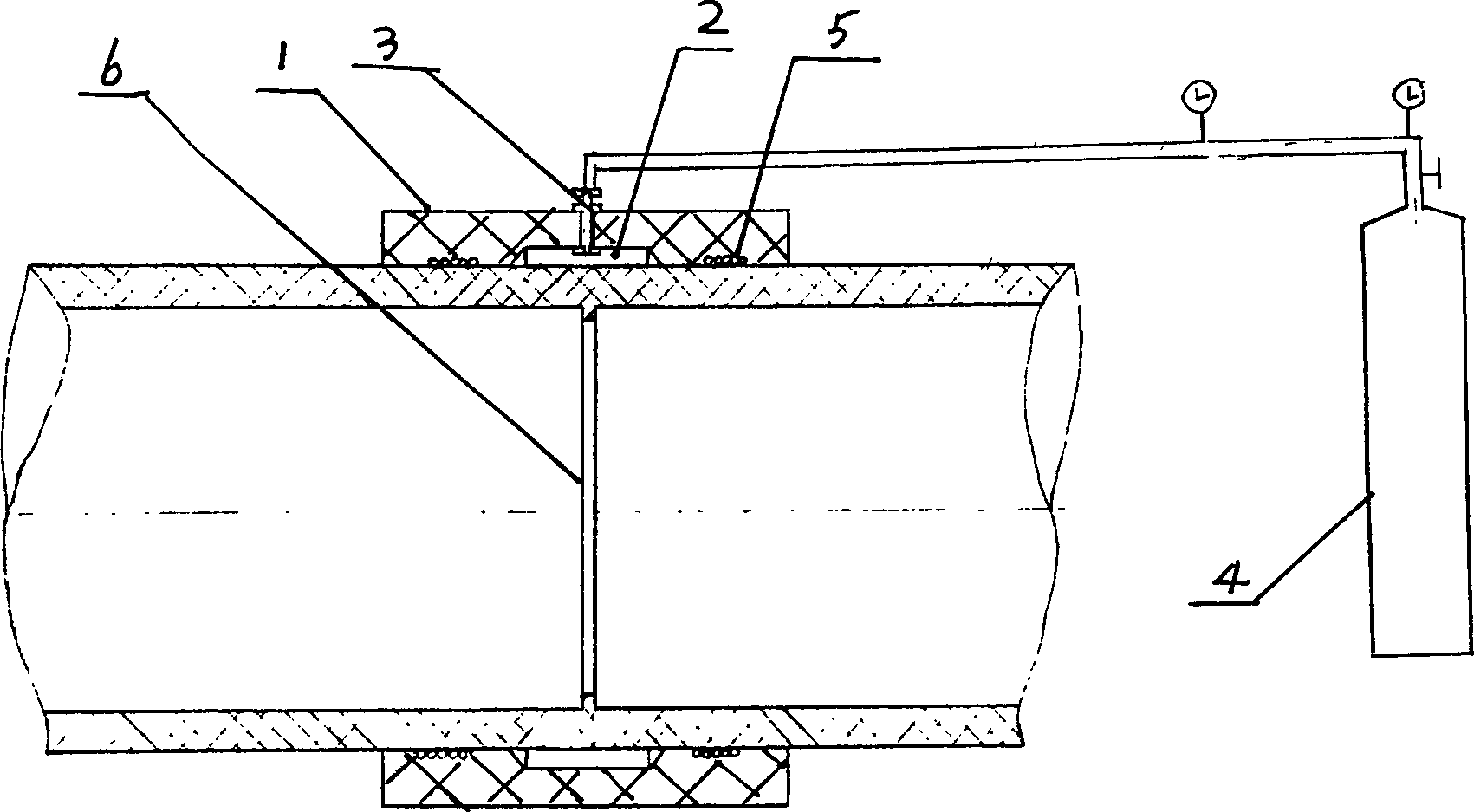

Pipe joint rapid leak hunting method

InactiveCN1595089AImprove securityImprove reliabilityMeasurement of fluid loss/gain rateEngineeringHigh pressure

This invention provides a pipe joint leak hunting method, especially that of pipe joint of water bottom transmission engineering. It mainly locates the pipe joints into the apparatus full of high pressure gas inside and measure the leak through observing the changes of the high-pressure gas. This method is simple and convenient and quick and solves the main technique difficulty in the field.

Owner:杜广才

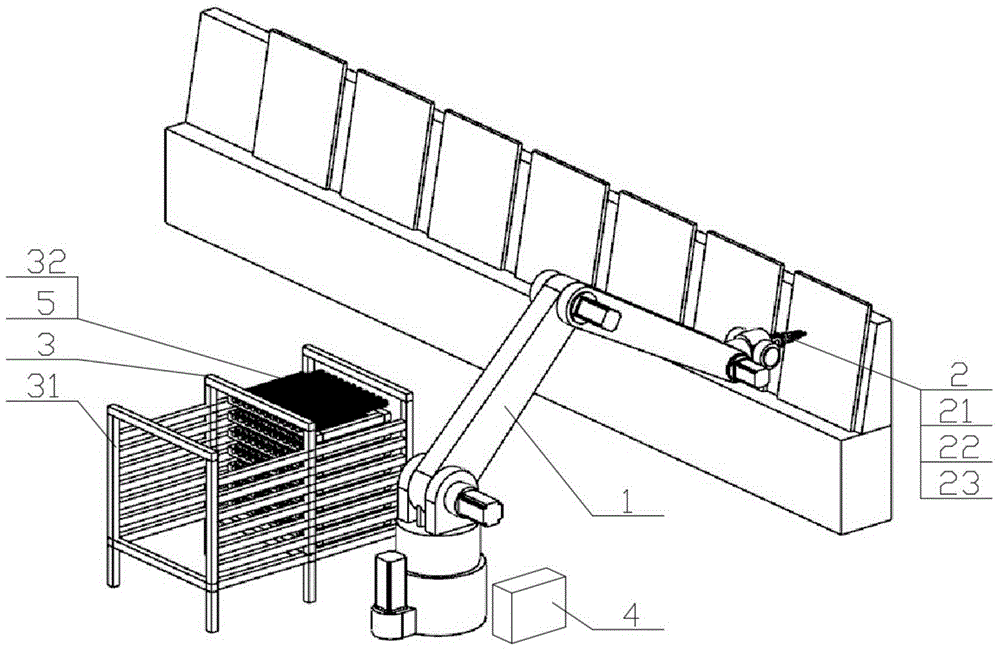

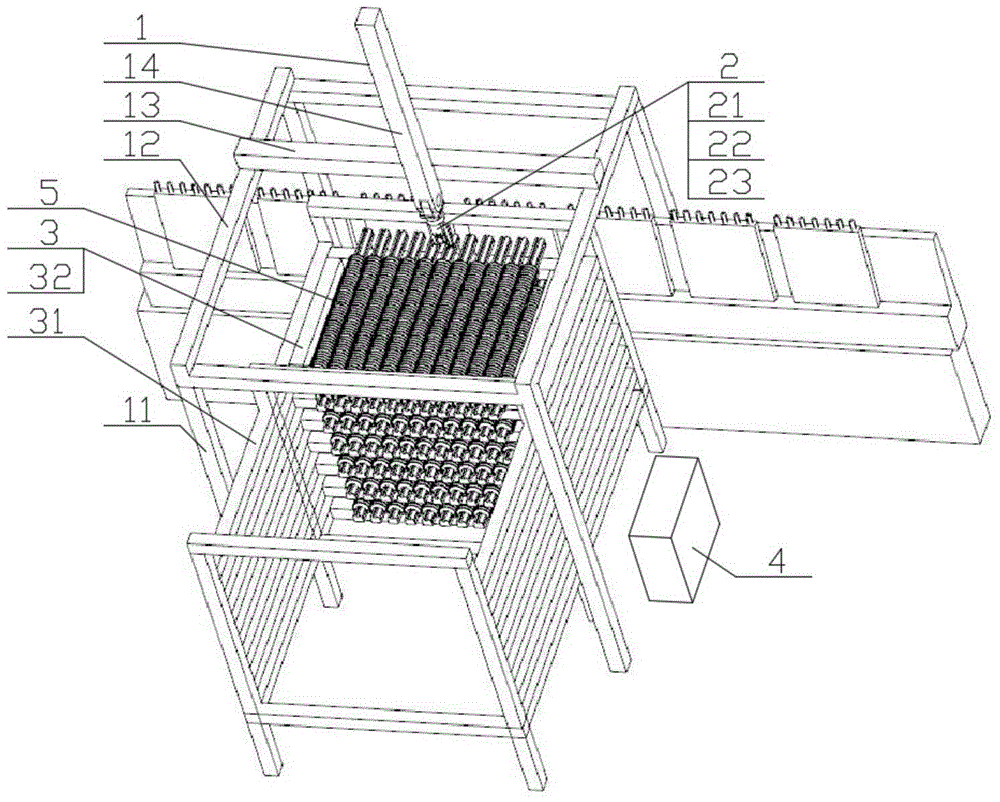

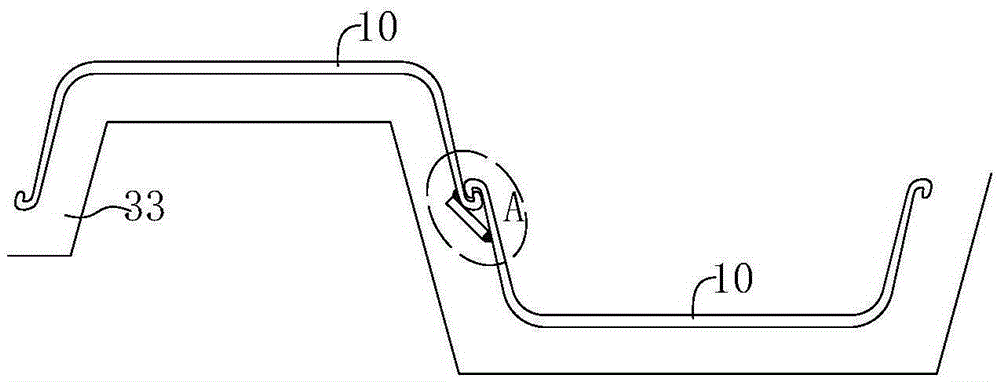

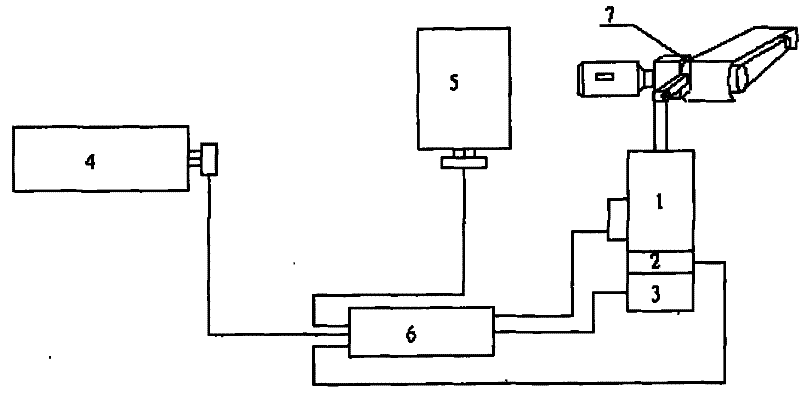

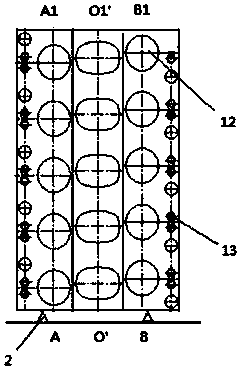

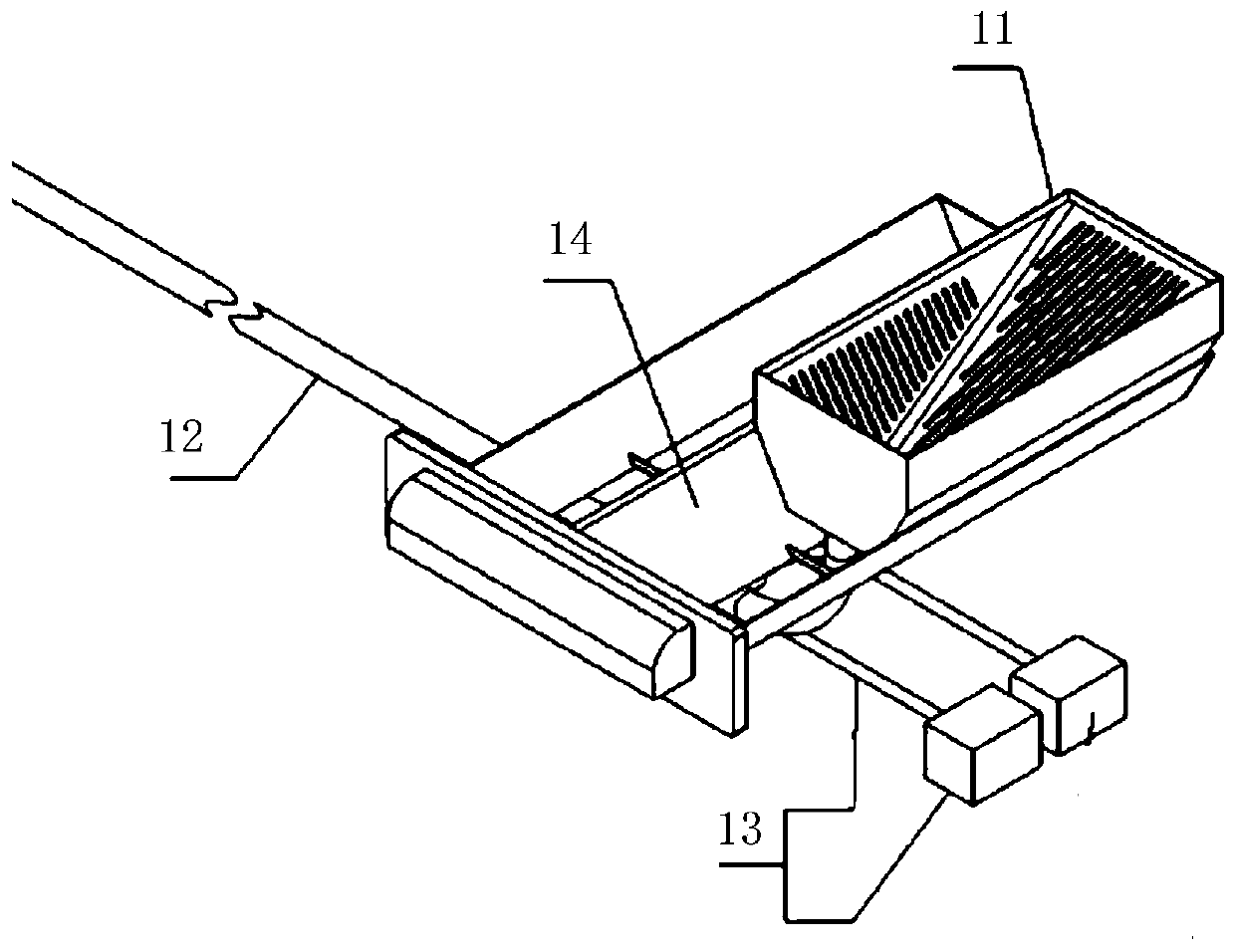

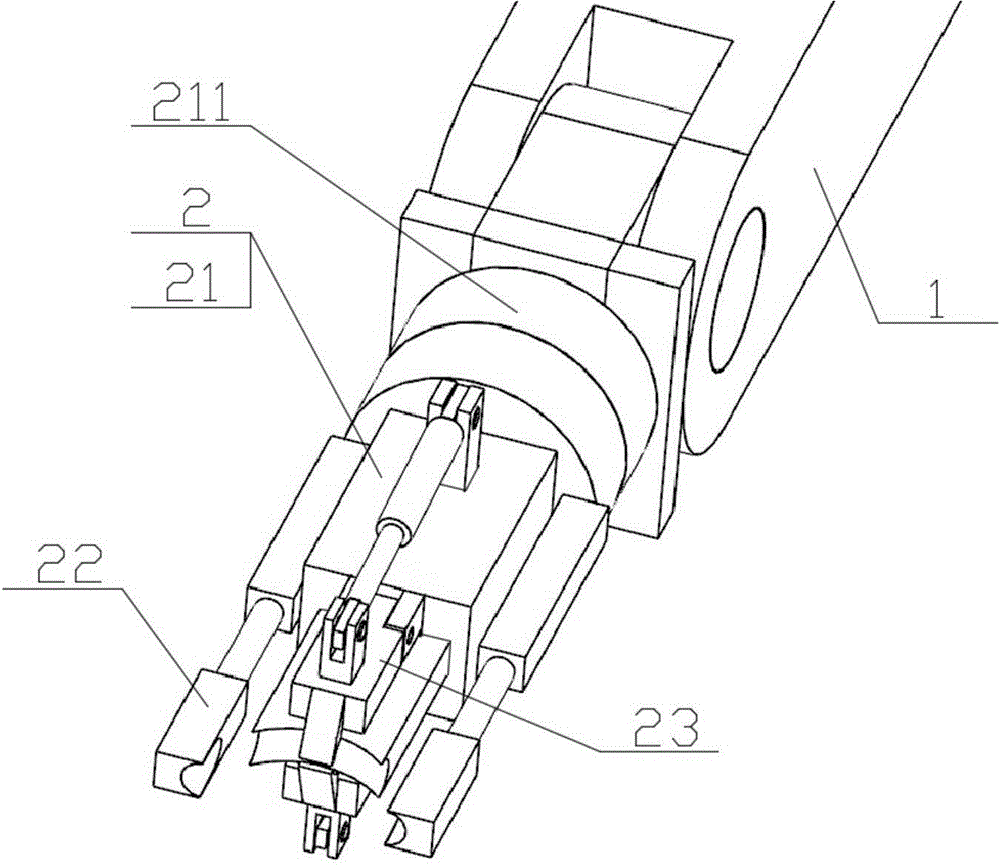

Digital-bus-based automatic small-U-shaped-pipe inserting system of fin assembly

The invention discloses a digital-bus-based automatic small-U-shaped-pipe inserting system of a fin assembly. The digital-bus-based automatic small-U-shaped-pipe inserting system comprises a mechanical arm (1), a mechanical hand (2), a bracket and small U-shaped pipe bearing tray assembly (3) capable of supplying small U-shaped pipes circularly and an electric control device (4). The mechanical arm is fixedly mounted on the ground and comprises an X-coordinate driving mechanism, a Y-coordinate driving mechanism and a Z-coordinate driving mechanism. The mechanical hand comprises a body (21), clamping fingers (22) and a supporting finger (23). The bracket and small U-shaped pipe bearing tray assembly capable of supplying the small U-shaped pipes circularly comprises a multilayer bracket (31), small U-shaped pipe bearing trays (32), a power device (33) and an electric control mechanism (34). The electric control mechanism comprises an industrial control computer, a power supply loop, a mode identification loop, a counting loop, a small U-shaped pipe grabbing loop, a pipe insertion control loop and the like. The digital-bus-based automatic small-U-shaped-pipe inserting system has the advantages that automatic operation can be achieved, influence of human factors on production progress is reduced, and quality of products obtained through pipe insertion processes can be guaranteed.

Owner:XUZHOU DKEC ELECTRICAL TECH

Clamping manipulator for tobacco dedicated charging basket

ActiveCN101670577AAchieve releaseRealize the clamping effectTobacco preparationManipulatorRectangular coordinatesEngineering

The invention discloses a clamping manipulator for a tobacco dedicated charging basket, comprising a paw guide rail, two paw clamping sheets, a rotary servo motor, a swinging servo motor and a three-dimensional rectangular coordinate robot, wherein two paw clamping sheets can slide along with the paw guide rail and are mutually connected via a cylinder; the rotary servo motor is fixed on the supporting seat of a first motor and can drive the paw guide rail to rotate; the swinging servo motor is fixed on the supporting seat of a second motor and can drive the supporting seat of the first motorto rotate; and the three-dimensional rectangular coordinate robot is connected with the supporting seat of the second motor. The scheme controls clamping, dumping, shaking, transporting and releasingof the charging basket by the clamping paw by controlling the components of the cylinder, the servo motor, the rectangular coordinate robot and the like, thus realizing automation control, improving feed liquor preparing efficiency, avoiding quality accident of artificially missending material, lowering raw material consumption and worker labor intensity to the utmost, and improving workshop sanitary environment.

Owner:SHANGHAI TOBACCO GRP CO LTD +1

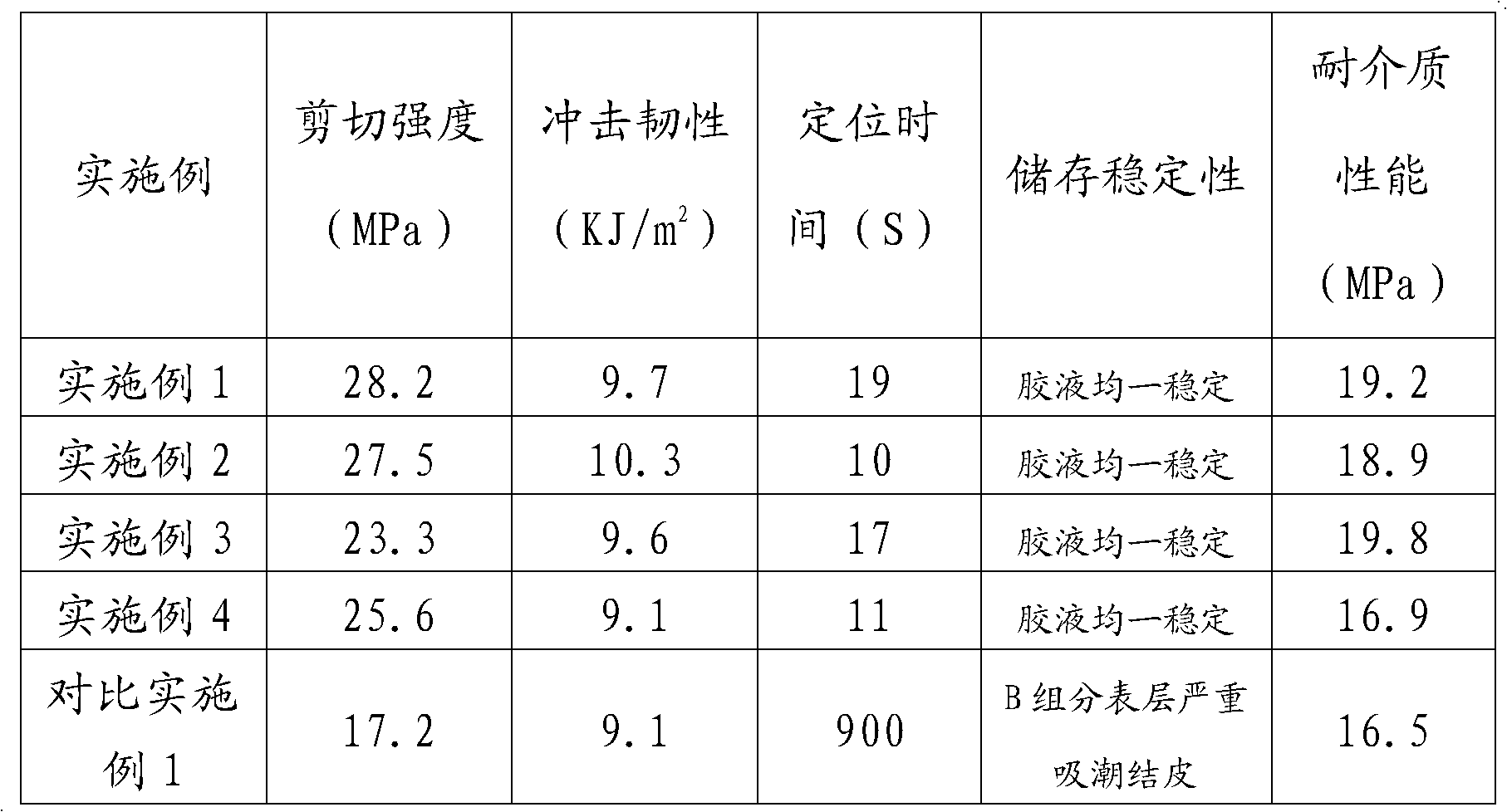

Solar crystalline silicon rod splicing glue and preparation method thereof

ActiveCN103160211AShorten positioning timeReduce moisture sensitivityOrganic non-macromolecular adhesiveAdhesiveOptoelectronics

The invention relates to solar crystalline silicon rod splicing glue and a preparation method thereof. The solar crystalline silicon rod splicing glue is composed of anaerobic liquid cement and accelerant. The preparation method comprises a step of respectively preparing the anaerobic liquid cement and the accelerant. When the solar crystalline silicon rod splicing glue is used, the accelerant is coated on the surface of a crystalline silicon rod to be sticked, then the crystalline silicon rod sticked with the accelerant is aired, the anaerobic liquid cement is coated on the accelerant of the crystalline silicon rod, and adhesion is fast carried out after the process of butt joint. According to the solar crystalline silicon rod splicing glue, under a premise that enough strength and toughness exist in the process of cutting crystal plates, the solar crystalline silicon rod splicing glue has the advantages of being fast in positioning time, convenient to operate and good in chemical-medium-resisting property and storage stability. The solar crystalline silicon rod splicing glue can become a first choice of adhesive for industries.

Owner:YANTAI DARBOND TECH

Non-preheating aluminium carbon zirconium mass immersion type sprue

InactiveCN1429673AImproved thermal shock stabilityStrong impact resistanceMelt-holding vesselsManufacturing technologyMaterials science

Owner:维苏威高级陶瓷(鞍山)有限公司

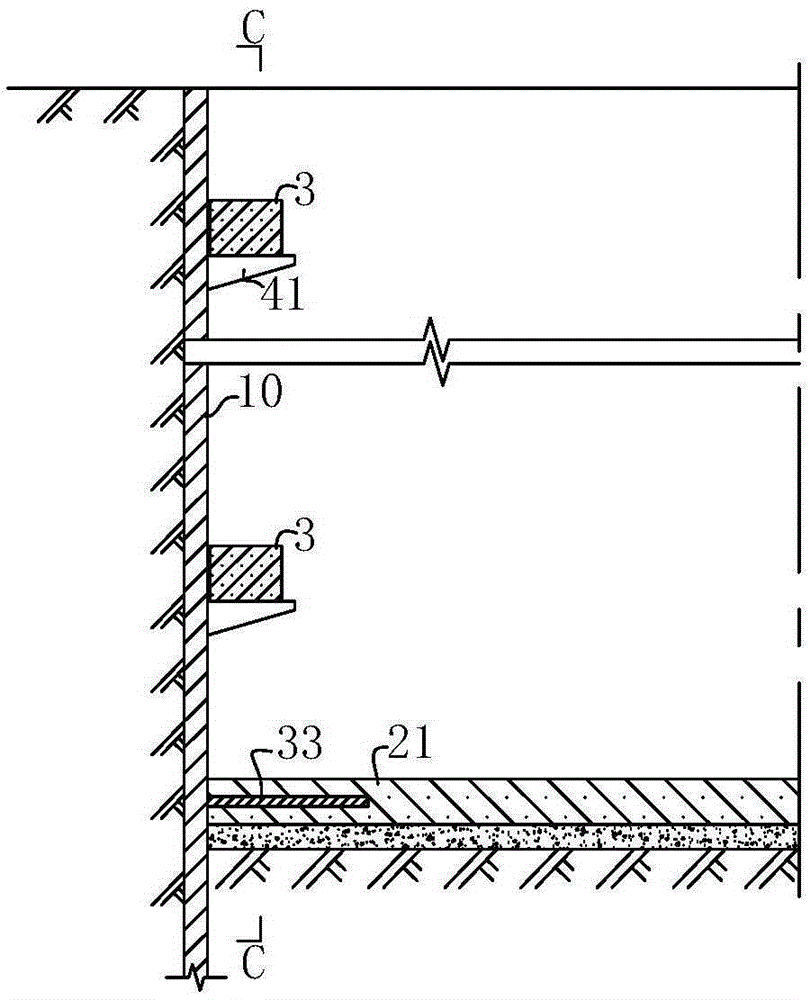

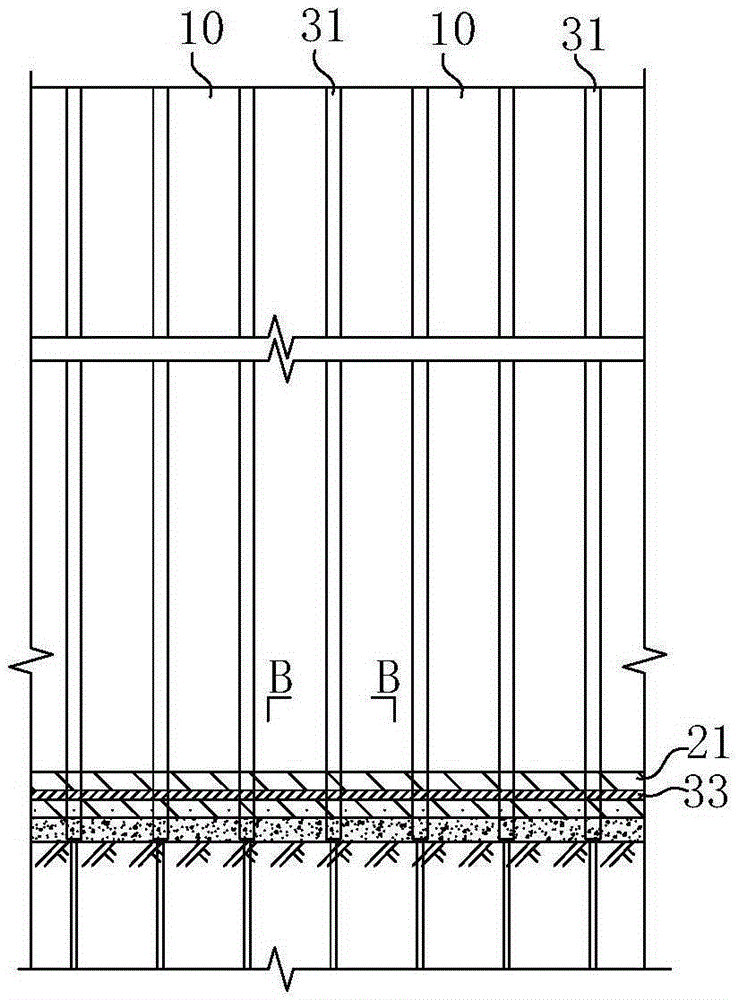

Construction method for round underground continuous wall two-in-one structure

ActiveCN105256810AEasy to assembleGuarantee welding qualityArtificial islandsExcavationsPurlinReinforced concrete

The invention discloses a construction method for a round underground continuous wall two-in-one structure. The construction method includes the following steps that (1) bracket steel sheet piles are prefabricated, and round steel reinforced concrete enclosing purlins are prefabricated in a segmented mode; (2) pile sinking is carried out; (3) a foundation pit is excavated; (4) gaps in locking positions of the steel plate piles are blocked; (5) the round steel reinforced concrete enclosing purlins are assembled; (6) the foundation pit continues to be excavated downwards until the design depth is reached, and the gaps in the locking positions of the steel plate piles are continuously blocked through waterstop steel strips; (7) a bottom plate waterstop steel plate is welded to the inner side faces of the steel plate piles, and the bottom plate waterstop steel plate surrounds the inner side of a support in the circumferential direction in an endless shape; and (8) a cushion layer is laid, then a bottom plate is cast to reach a set thickness, and the bottom plate waterstop steel plate is made to stretch into the bottom plate. Through the construction method, the support cost for the foundation pit of an underground building can be reduced effectively; on the basis, the support is used as an outer wall of the underground building, the novel structure that the support and the outer wall are integrated is formed, and a foundation is laid for reducing the overall construction cost of the underground building.

Owner:JIANGSU DONGHENAN GEOTECHNICAL TECH CO LTD

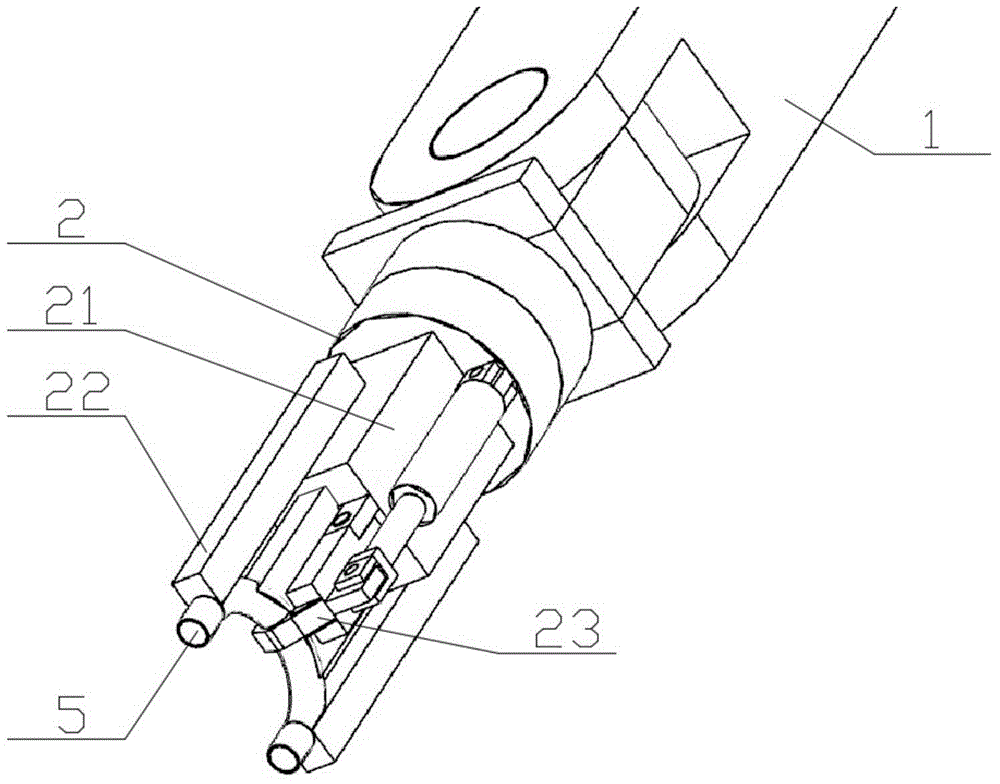

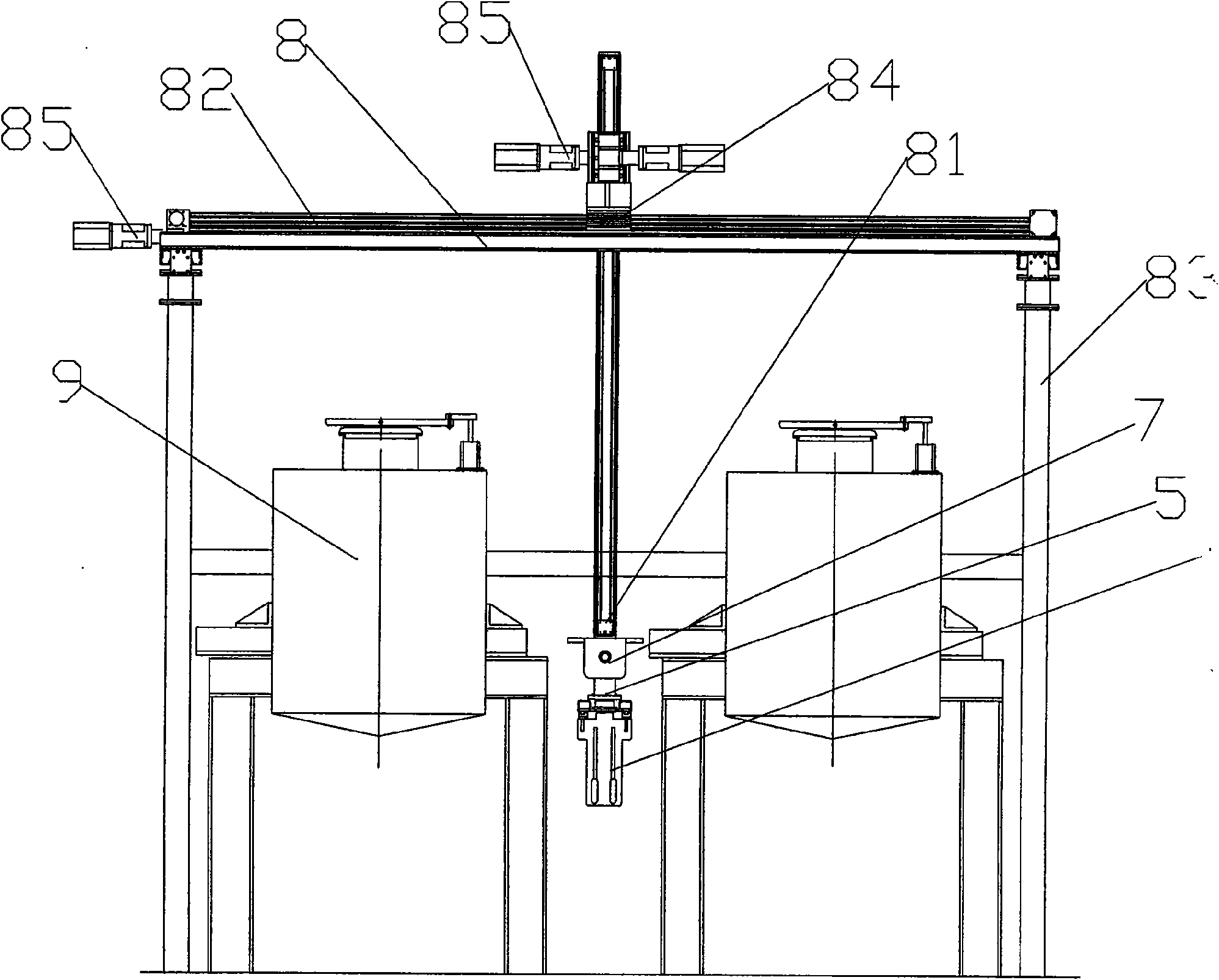

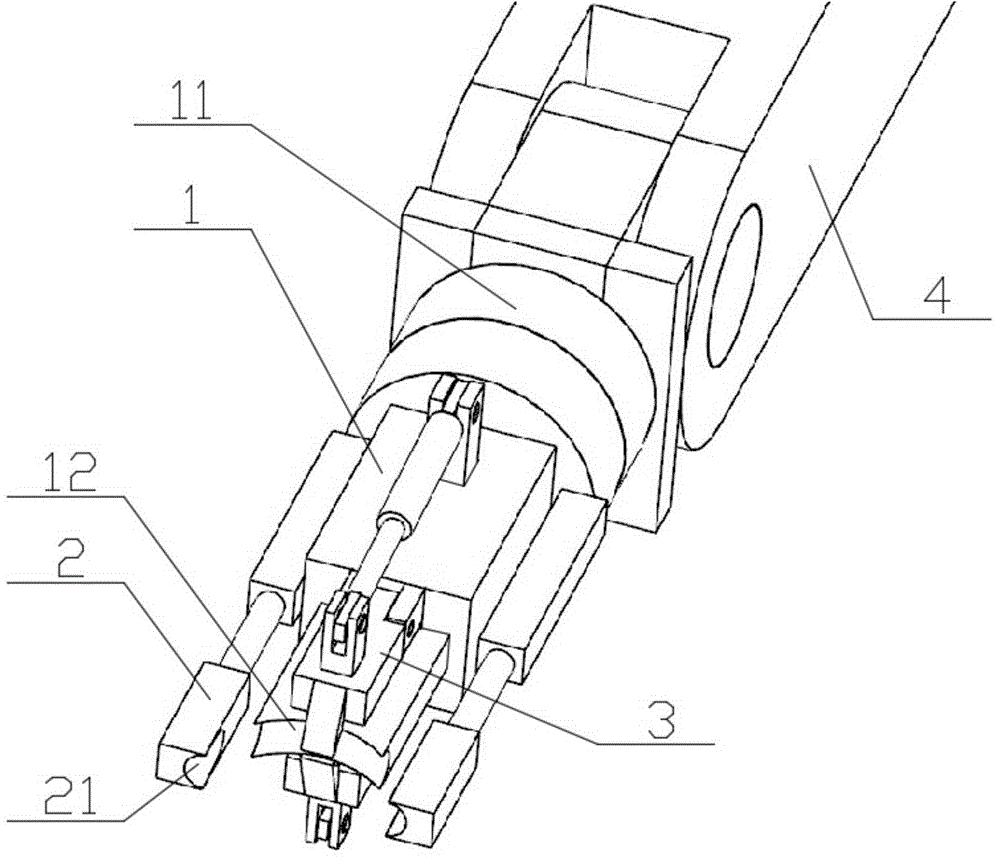

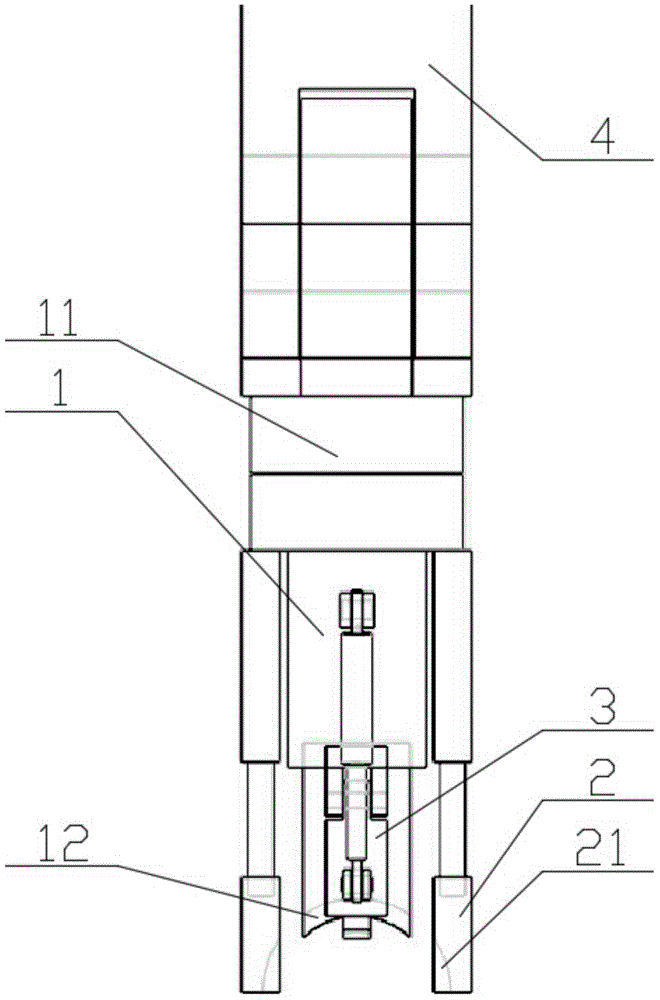

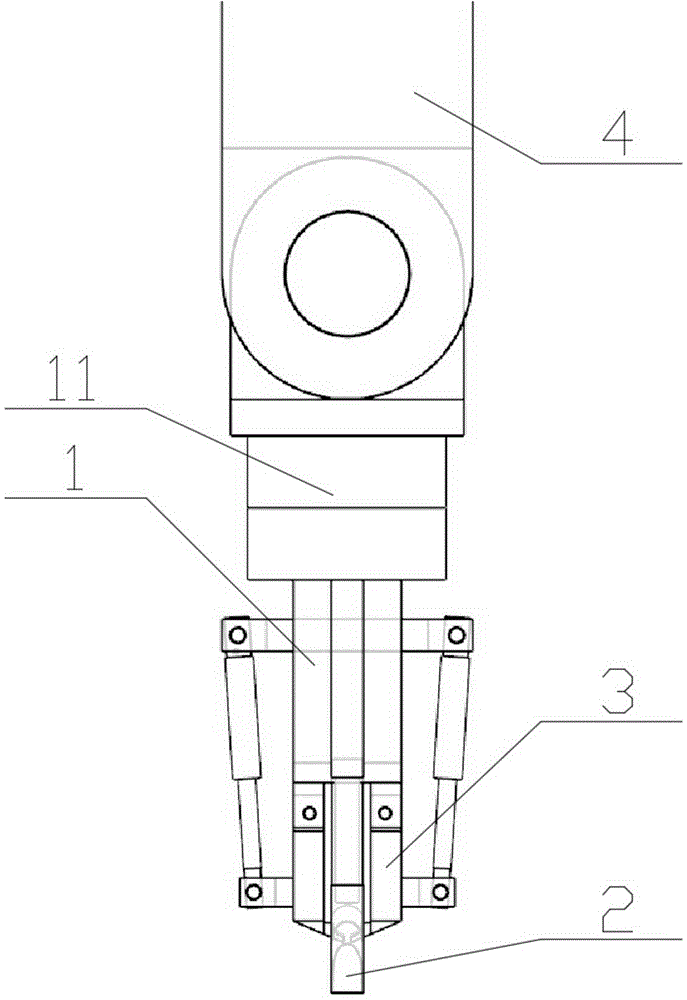

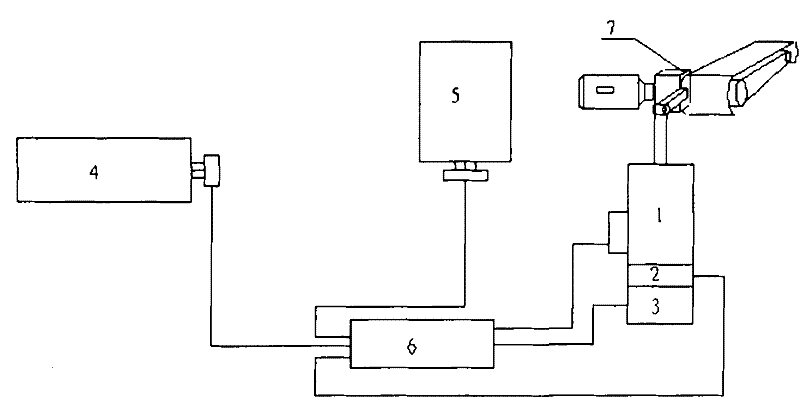

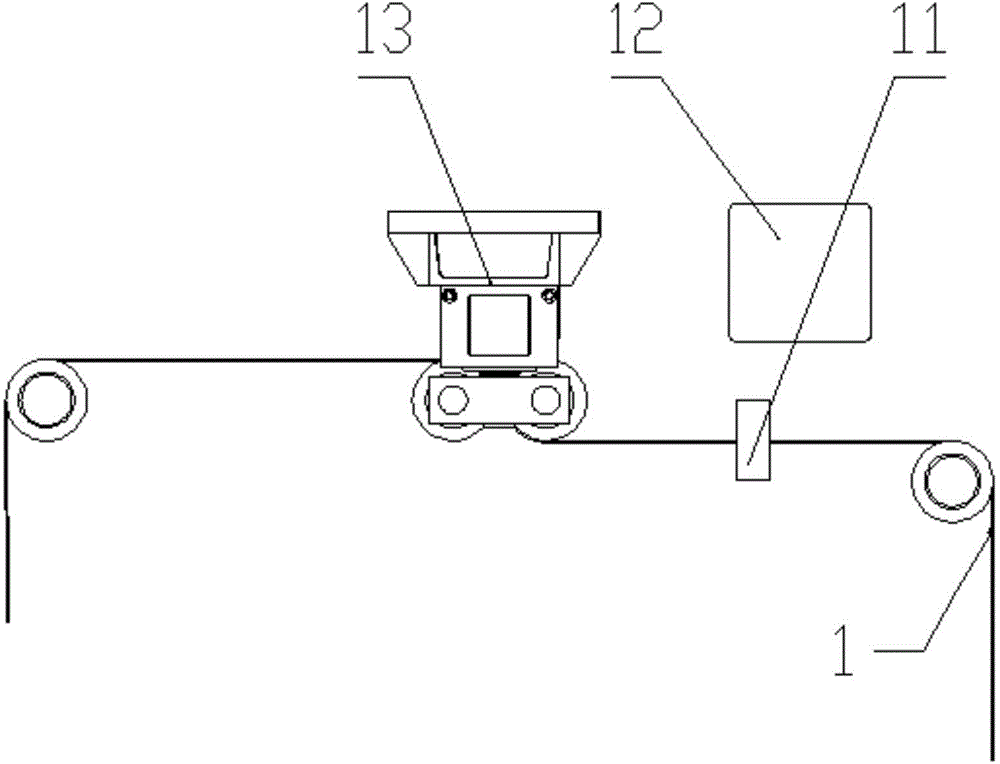

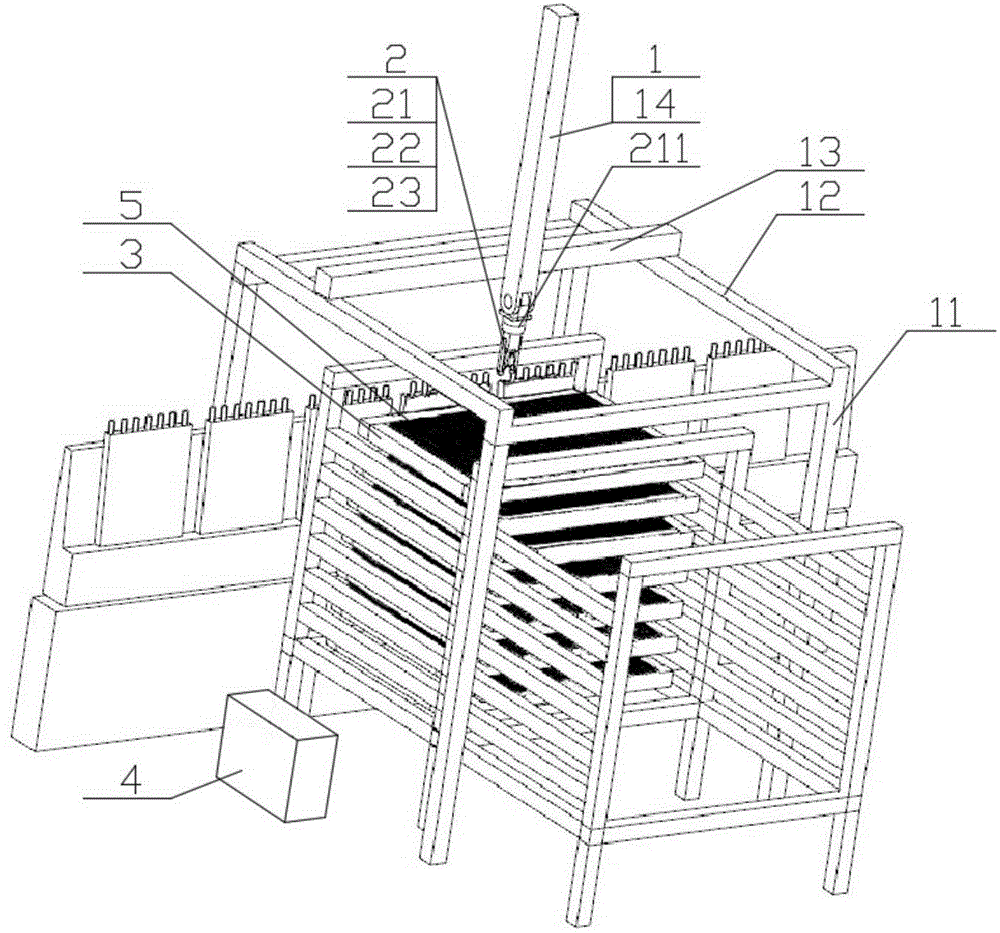

Unordered automatic pipe grabbing and inserting manipulator for small U-shaped pipes of fin assembly

ActiveCN104669288AReduce labor intensityGuarantee product qualityGripping headsMetal working apparatusEngineeringManipulator

The invention discloses an unordered automatic pipe grabbing and inserting manipulator for small U-shaped pipes of a fin assembly. The unordered automatic pipe grabbing and inserting manipulator comprises a body (1), two clamping fingers (2) and two lifting fingers (3), the top end of the body is connected with the tail end of a mechanical arm (4) through a mounting seat (11), a C coordinate rotating mechanism is arranged in the mounting seat, arc-shaped grooves I (11) and arc-shaped grooves II (21) matched with outer diameter and U-shaped radian size of the small U-shaped pipes are formed in the bottom end face of the body and the inner side faces of the clamping fingers respectively, a position sensor and a distance sensor are arranged on the body, the clamping fingers and the lifting fingers are arranged in a mutually perpendicular manner and connected with a transmission connection mechanism respectively, and distance size from the upper surface of the finger end of each lifting finger to the groove bottom of the corresponding arc-shaped groove I is matched with diameter size of each small U-shaped pipe. The unordered automatic pipe grabbing and inserting manipulator can realize automated operation, influence, on production progress, of human factors can be lowered, and product quality in the pipe inserting process can be guaranteed.

Owner:XUZHOU DKEC ELECTRICAL TECH

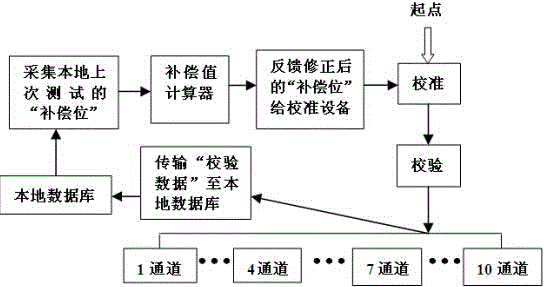

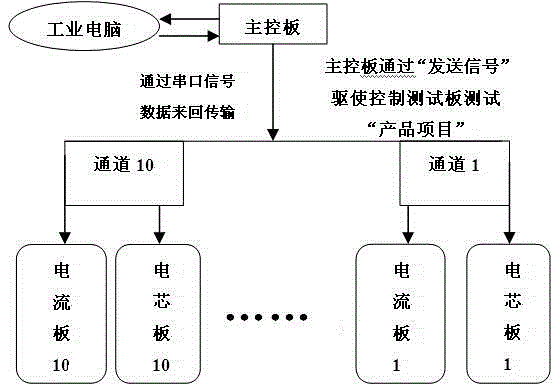

Multichannel calibration and verification device and method for multiple sections of electric-quantity management ICs

ActiveCN104133185AImprove scalabilityExpand the scope of testingElectrical measurementsTest efficiencyComputer module

The invention provides a multichannel calibration and verification device and method for multiple sections of electric-quantity management ICs. The method mainly controls a plurality of channel test boards through a main control board to test the multiple sections of electric-quantity management ICs and in a test process, a localized closed-loop correction method is adopted to calibrate voltage and current precision of the multiple sections of electric-quantity management ICs. Moreover, through adoption of a channel self-detection module, precision calibration is carried out on cell boards and current boards of the channels of the device so that precision calibration of a voltage and current reference source of the device is realized and stability of the reference source of the device is ensured. The method also uses a channel combination module according to practical needs to combine the plurality of channels into large channels so as to meet test demands of the multiple sections of electric-quantity management ICs. The method uses a method of using the plurality of channels to carry out parallel tests simultaneously so that test efficiency of the multiple sections of electric-quantity management ICs is improved, expandability of the multichannel calibration and verification device is strengthened, demands that users configure the channels flexibly according to practical conditions can be met and user use cost is reduced.

Owner:HUIZHOU BLUEWAY ELECTRONICS

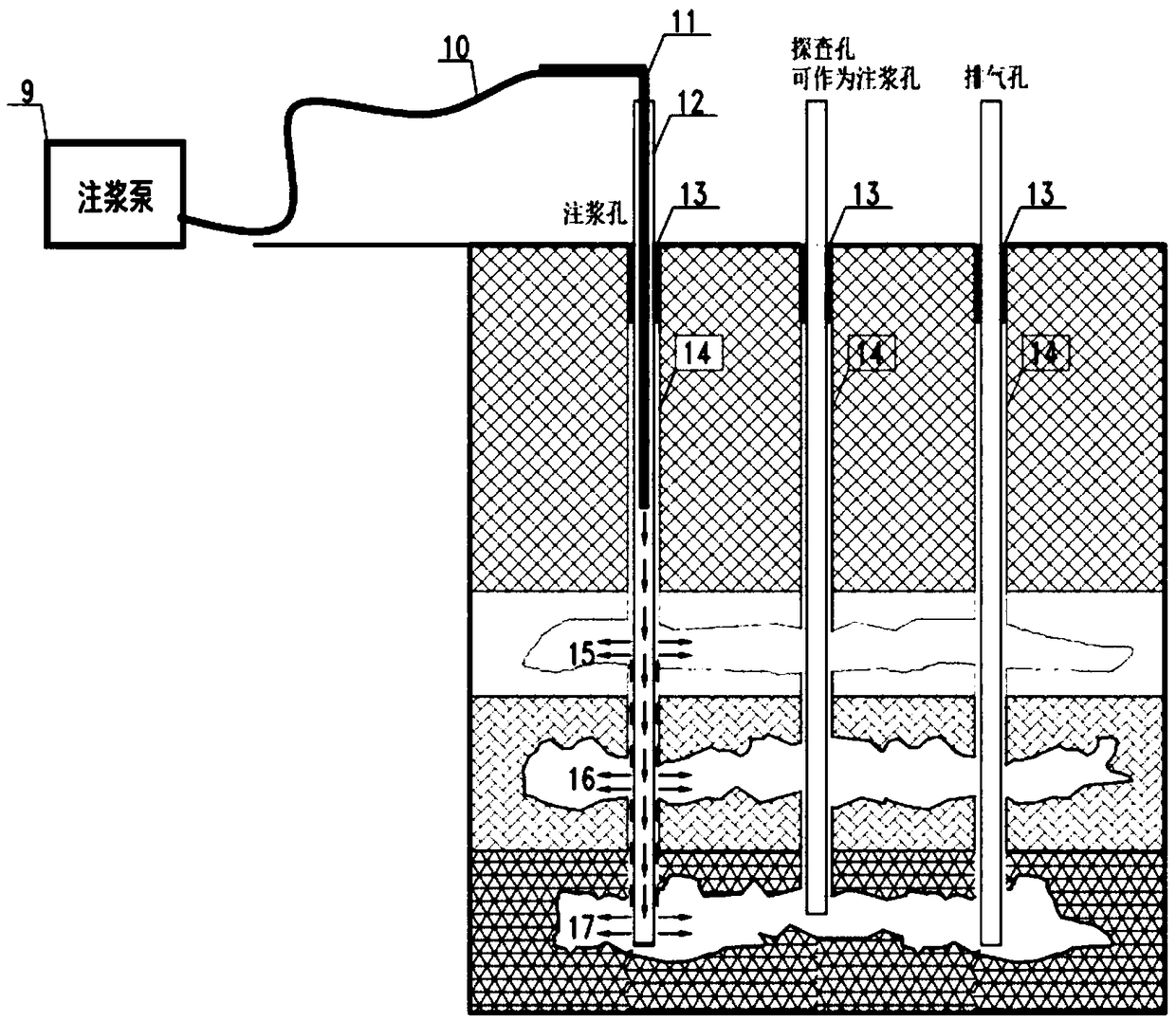

Beading cave pretreatment construction method

InactiveCN109024569AGuaranteed fullnessSolve the difficult problem of handling when the distribution is unevenBulkheads/pilesSoil preservationTreatment resultsWave detection

The invention provides a beading cave pretreatment construction method. A method with an advance boring method and a pipe wave detection method combined is adopted for detecting the size and positionof beading caves. Slurry with different matching ratios is configured according to the size of the beading caves, and the filling degree of the beading caves is ensured. Materials are simple and highin efficiency compared with an original technology, the problem of treatment when the beading caves are distributed not evenly is effectively solved, when the cave treatment slurry reaches the strength of the design requirement, the pipe wave detection method is adopted for checking and accepting the treatment result of the beading caves, a treated foundation meets the requirement for bearing force of a pile foundation, quality accidents caused by the beading caves is extremely avoided, and subsequent construction and later input use can be effectively safely ensured. The beading cave pretreatment construction method belongs to the technical field of foundation and foundation construction.

Owner:CHINA CONSTR FOURTH ENG DIV

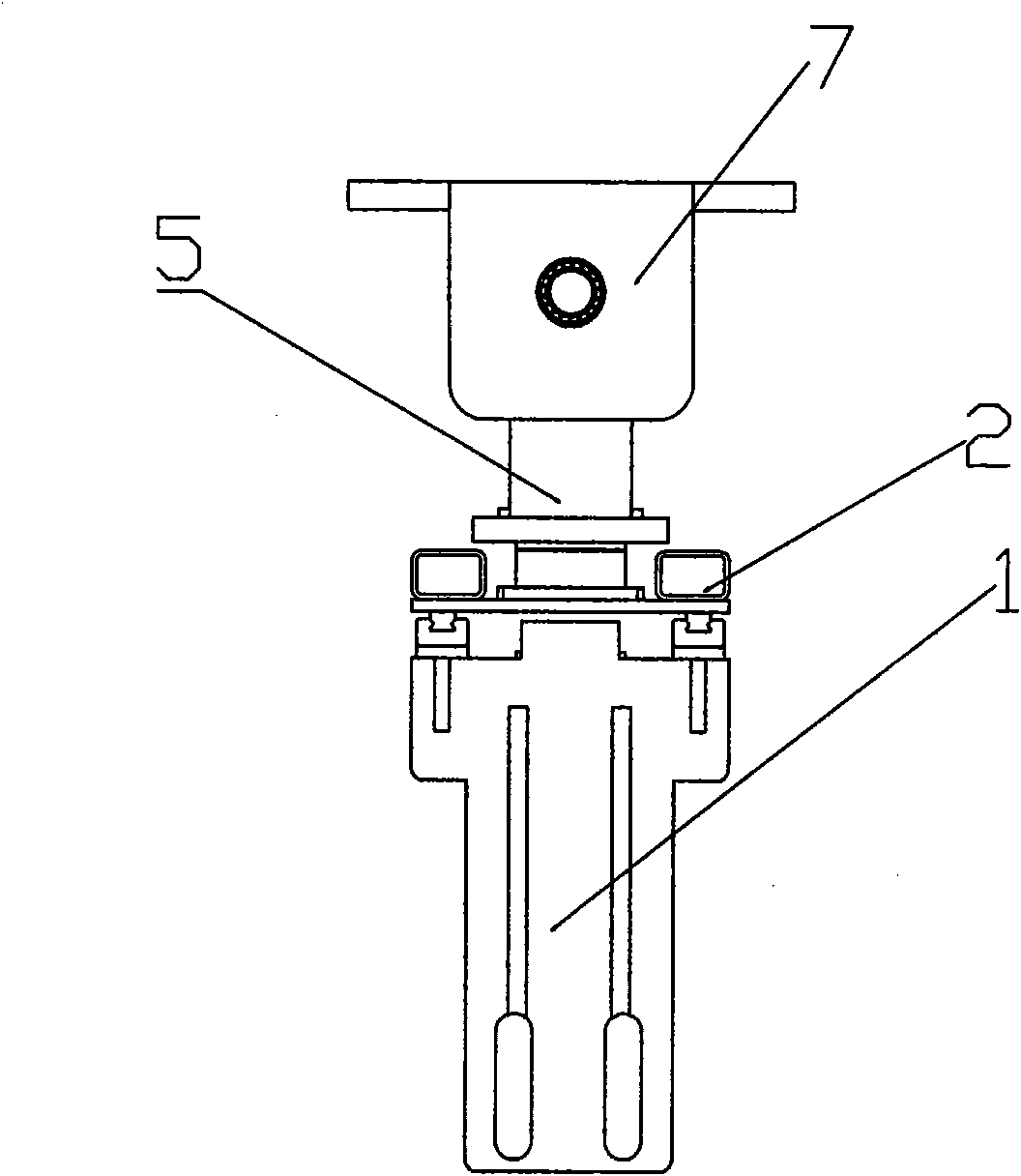

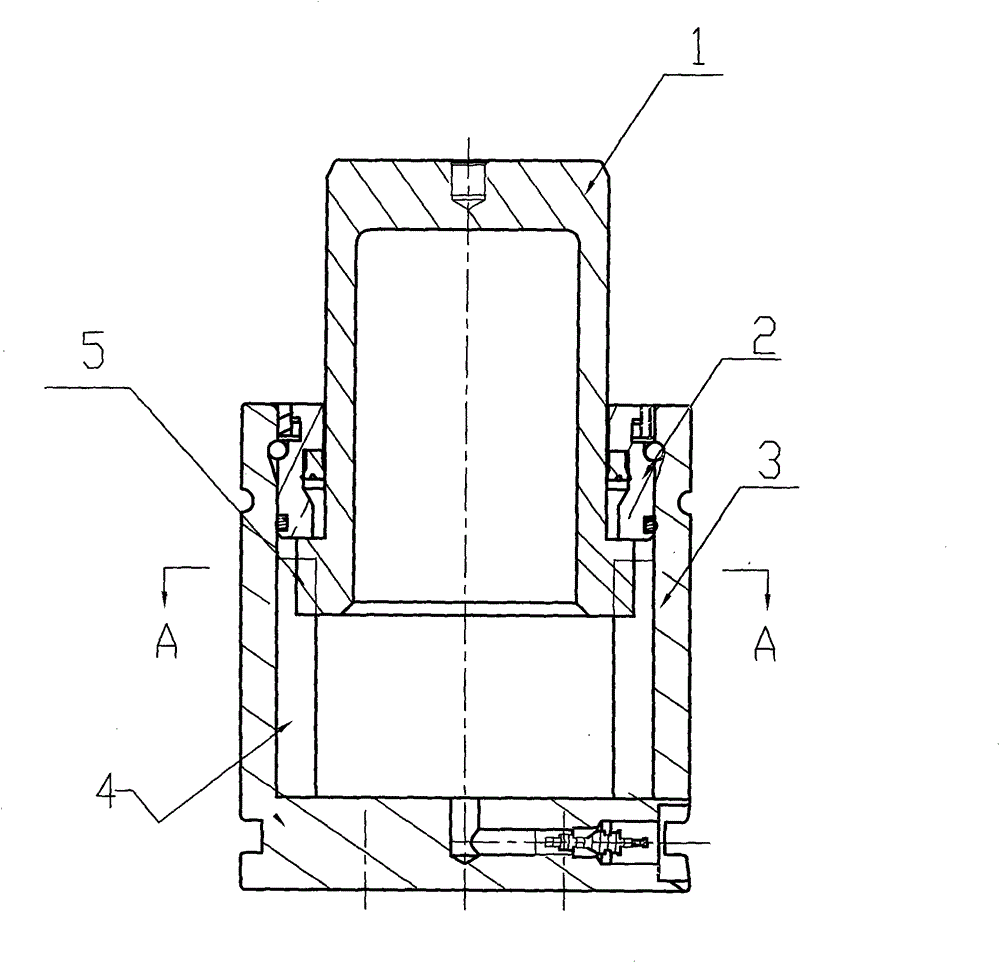

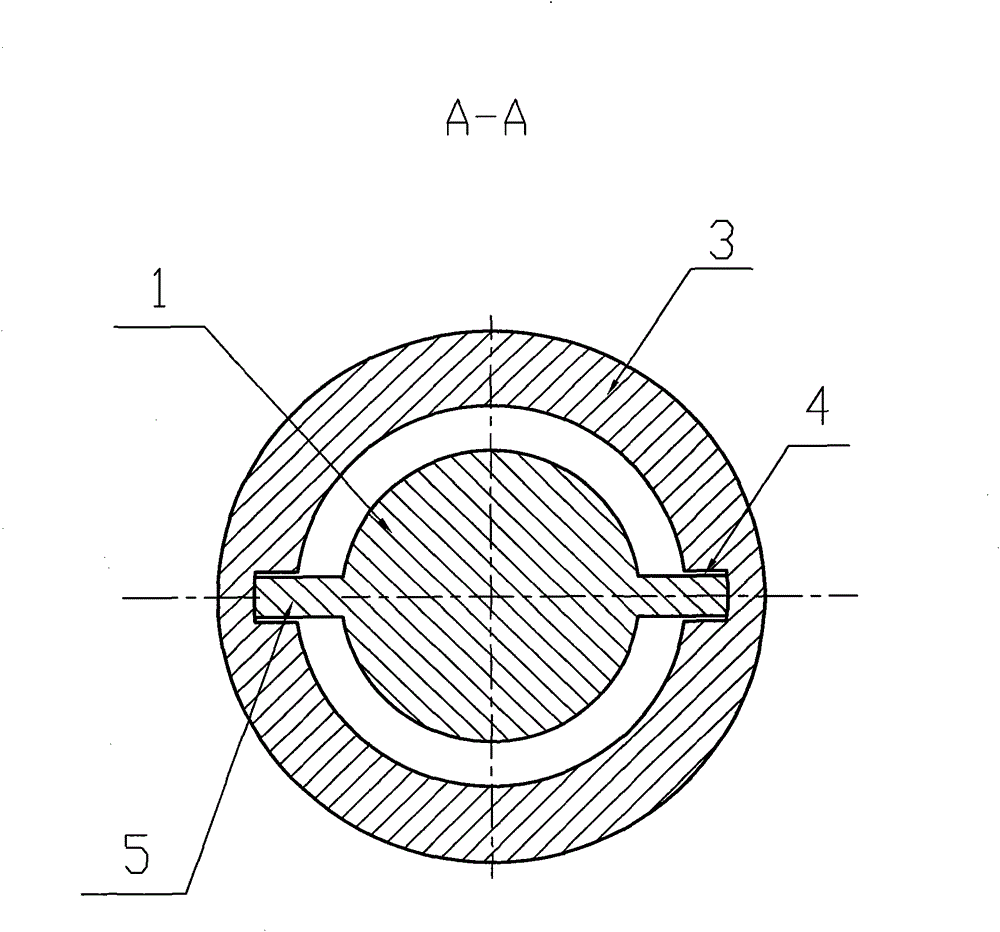

Directional anti-rotating nitrogen spring

InactiveCN104421368AGuaranteed stabilityAvoid Quality AccidentsSpringsGas based dampersNitrogen gasEngineering

The invention relates to a nitrogen spring, in particular to a directional anti-rotating nitrogen spring. The directional anti-rotating nitrogen spring consists of a cylinder barrel, a guide seat, a piston rod and a sealing piece, wherein a guide groove is formed in the inner wall of the cylinder barrel, and a boss matched with the guide groove in the inner wall of the cylinder barrel is arranged at one end of the piston rod. By adopting the technical scheme provided by the invention, when the nitrogen spring works, the piston rod and the cylinder barrel can be prevented from relatively rotating, the piston rod can be guaranteed to linearly move in the cylinder barrel, the orientation of the nitrogen spring can be effectively guaranteed, the piston rod and the cylinder barrel are prevented from relatively rotating, thus the use stability of a die is guaranteed, quality accidents are prevented from occurring, the safety of the die is improved and the service life of the die is prolonged.

Owner:邵阳兴达精密机械制造有限公司

An abrasive belt grinder capable of improving the grinding quality of the abrasive belt grinder and its use method

InactiveCN102294638AImprove grinding qualityAvoid Quality AccidentsBelt grinding machinesAgricultural engineeringBelt grinding

The invention discloses an abrasive belt grinder capable of improving the grinding quality of the abrasive belt grinder, comprising a PLC control system, a grinding head, an executive cylinder, an electric push rod, and a pull pressure sensor controller, the executive cylinder and the electric push rod The tension and pressure sensor controller are connected as a whole and connected with the grinding head. The execution cylinder, electric push rod and tension pressure sensor controller are respectively connected with the PLC control system. The PLC control system is connected with the feed speed sensor and the rotary speed sensor. The invention can realize precise control of the pressure of the abrasive belt on the workpiece during normal operation, and can quickly separate the abrasive belt from the workpiece when the system fails, thereby protecting the workpiece and reducing quality accidents.

Owner:ANTON OILFIELD SERVICES (GRP) LTD

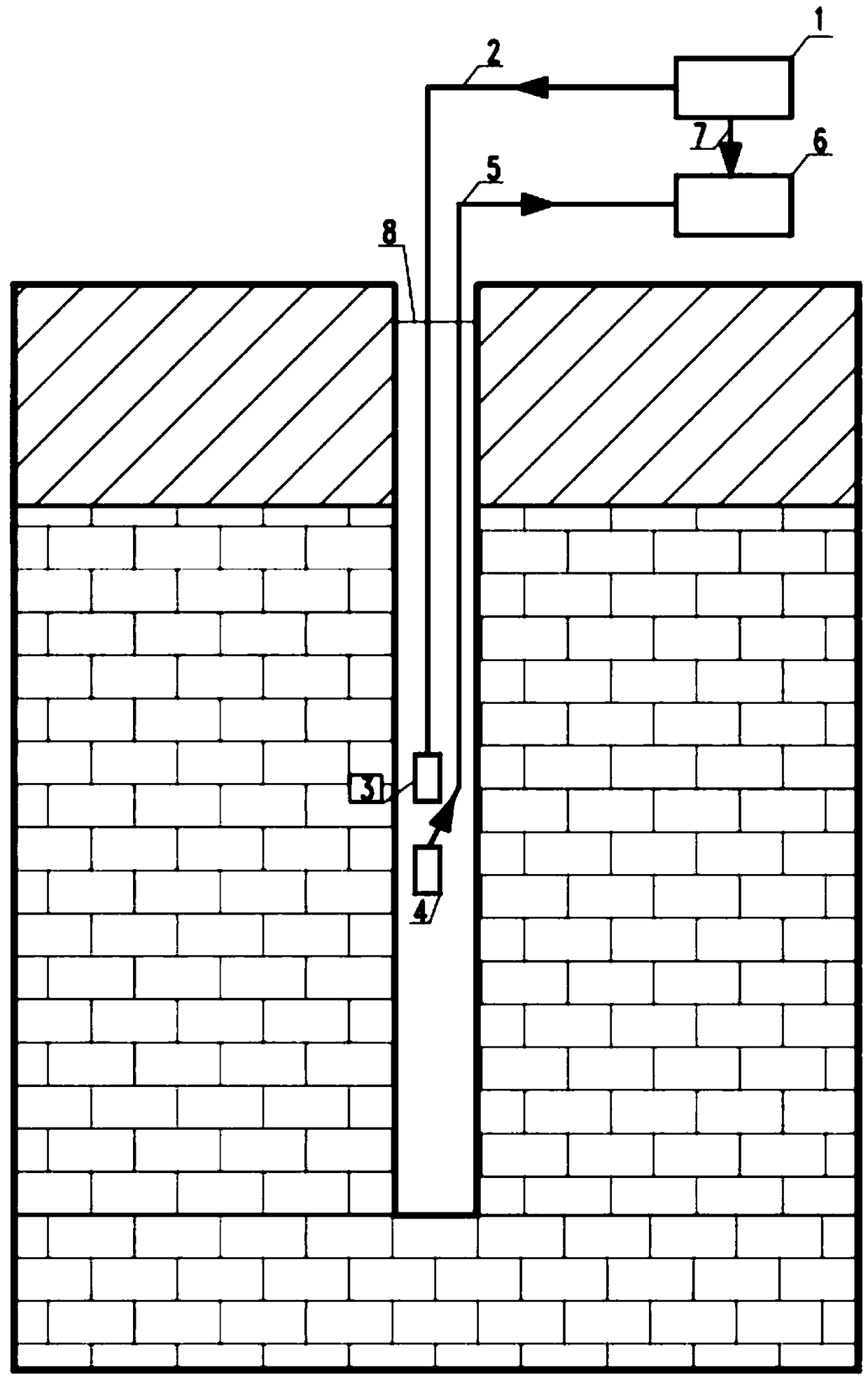

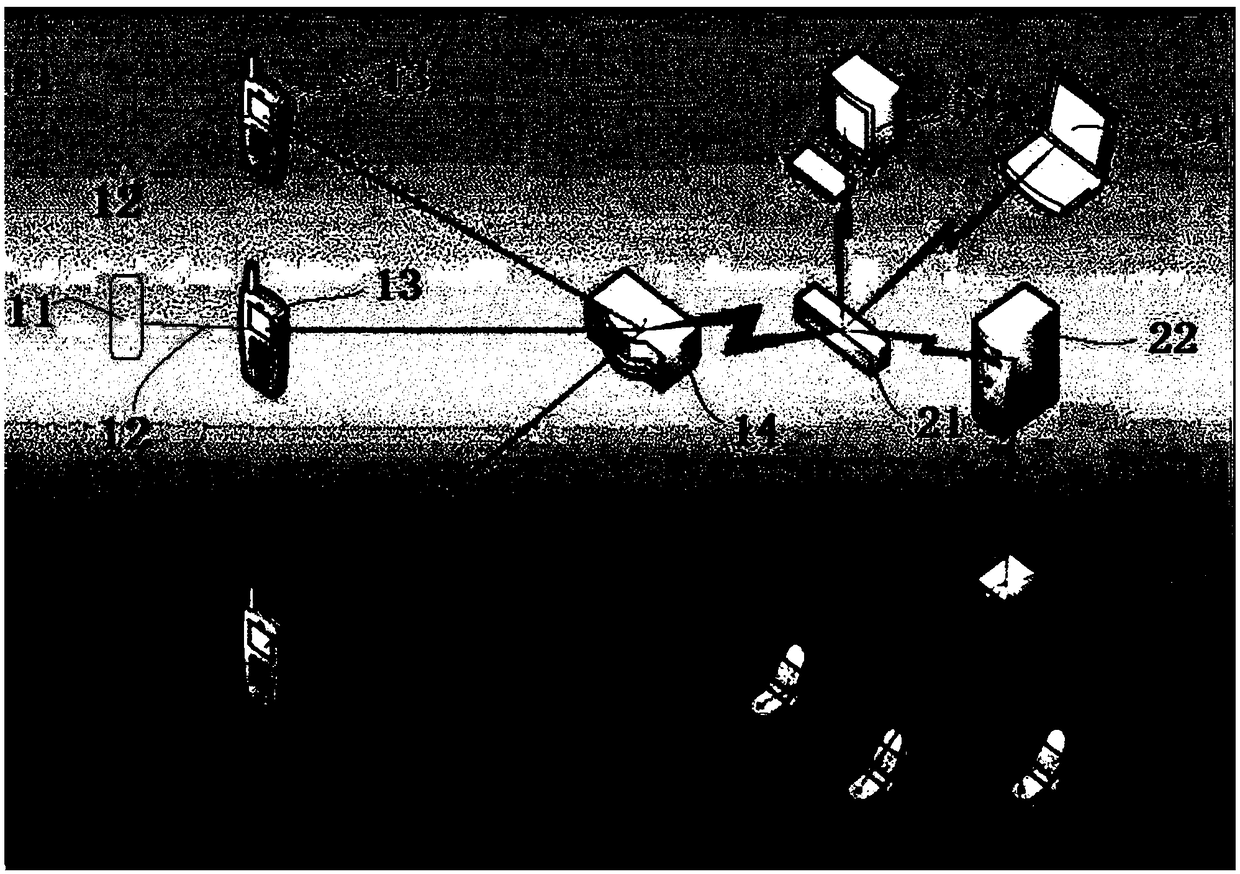

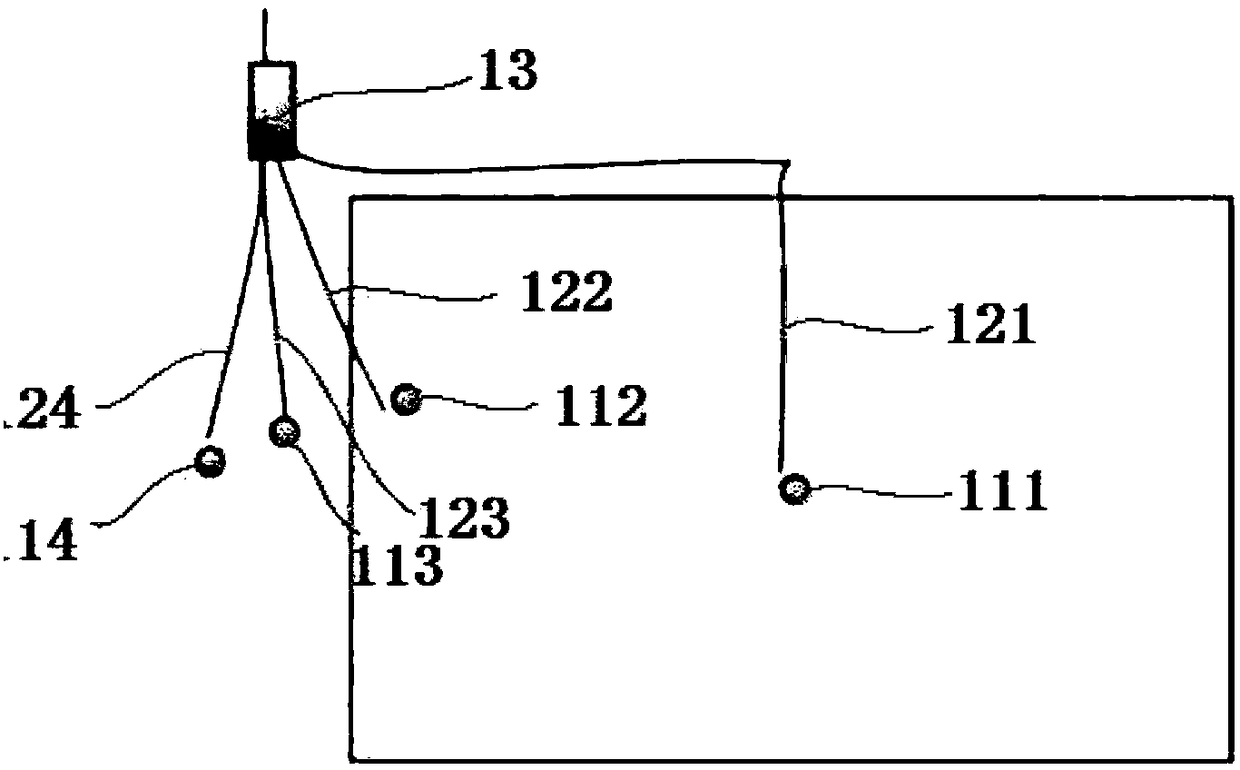

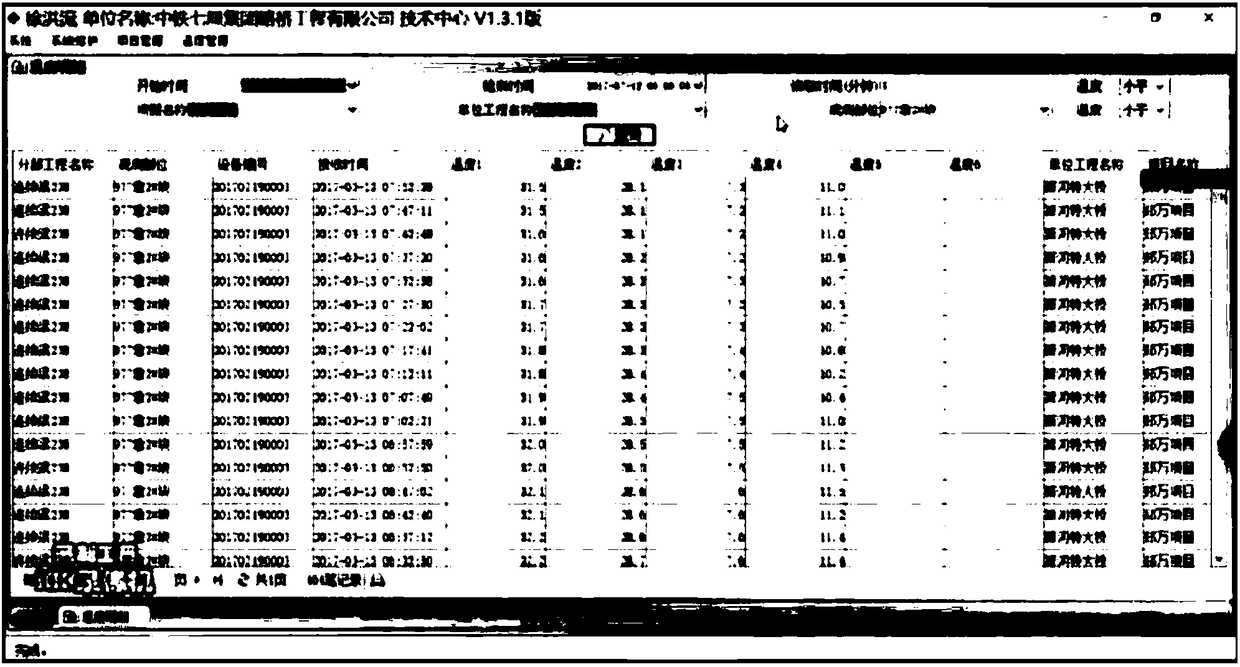

Concrete temperature control early warning system

InactiveCN109470372AMonitor temperature changesEasy accessThermometer detailsTemperature controlEarly warning system

The invention relates to the field of concrete temperature monitoring in the construction process of railways and highways, in particular to a concrete temperature control early warning system. The system includes an on-site temperature acquisition system, a remote processing system and a use terminal, and the on-site temperature acquisition system is used for being placed in a concrete site and measuring the temperature of each placement point, and transmitting the measurement data to the remote processing system; the remote processing system is used for receiving the measurement data, performing arithmetic processing, and transmitting the operation result to the use terminal; the use terminal is used for receiving and displaying the operation result. The system automatically monitors andrecords the temperature data by setting a thermometer in the relevant part of the concrete, then wirelessly transmits the data to a remote server, automatically calculates and processes through software, generates a temperature time coordinate curve or a data record table, feeds back to the use terminal, and provides convenience for the use terminal to conveniently acquire and monitor temperaturechanges and quickly take effective countermeasures to avoid quality accidents.

Owner:ROAD & BRIDGE ENG CO LTD OF CHINA RAILWAY SEVENTH GRP

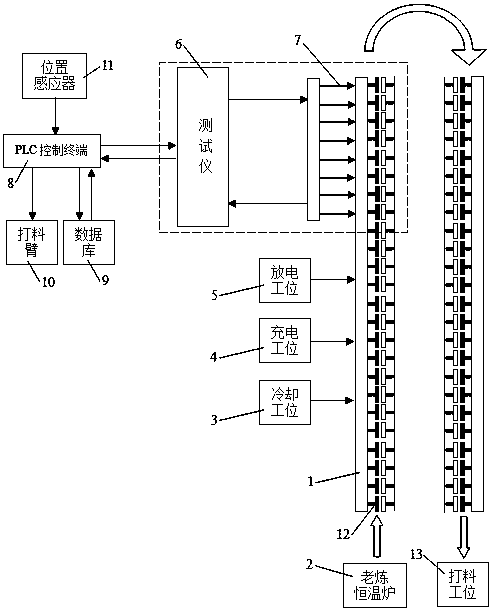

Multi-segment graded testing technology for full-automatic aging machine

InactiveCN108490287AImprove test efficiencyAvoid Quality AccidentsTesting dielectric strengthSortingTest efficiencyElectricity

The invention discloses a multi-segment graded testing technology for a full-automatic aging machine, and the technology employs a multi-segment measurement mode for multiple measurement of the electrical performance parameters of each capacitor, can achieve the flexible setting of quality grading standards according to the mean value of the measurement data of a database while judging whether each capacitor is qualified and avoiding quality accidents, and effectively improves the testing efficiency of the capacitors.

Owner:南通天禾机械科技有限公司

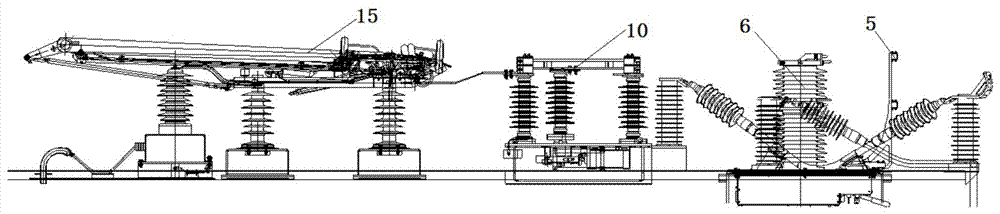

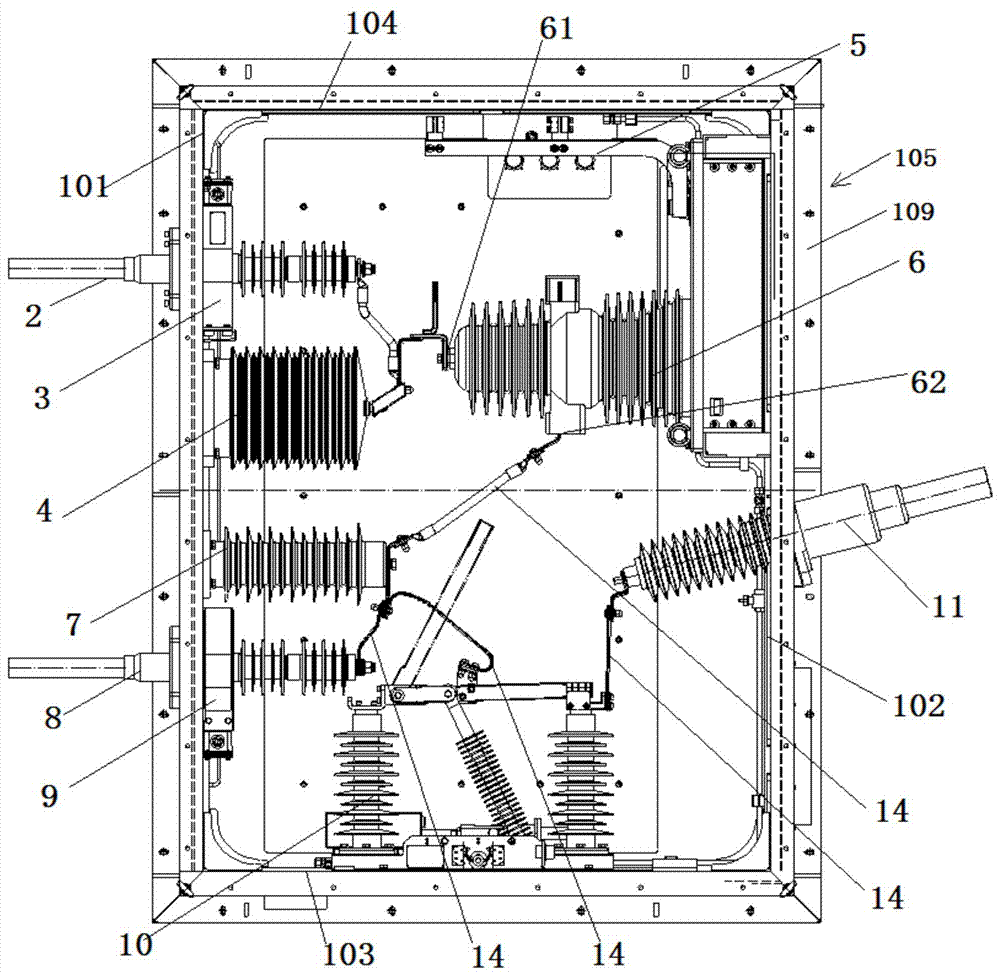

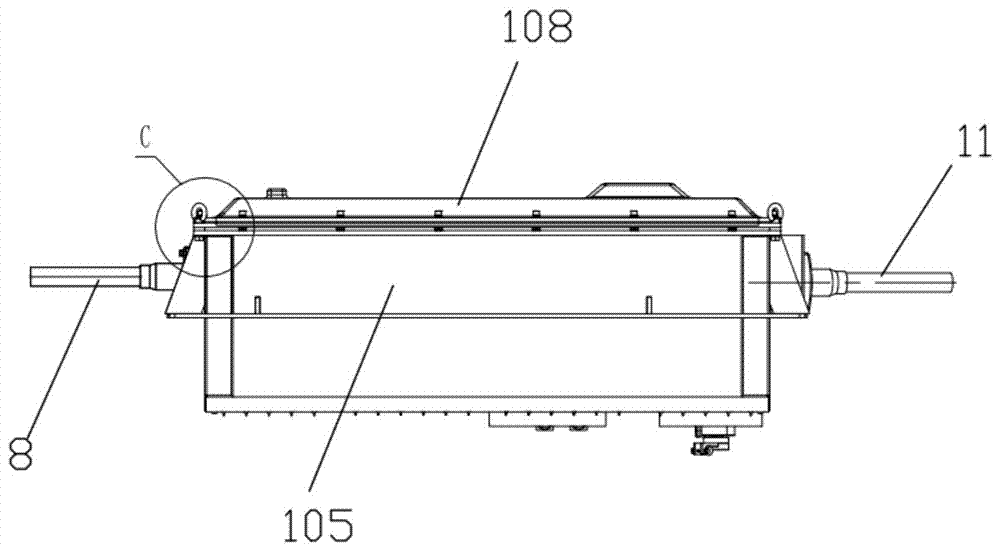

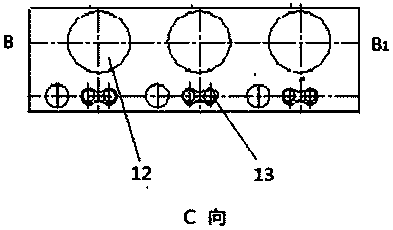

High-voltage equipment box of D-series high-speed train

PendingCN107425439AAnti-pollution flashoverEliminate the effects of usingBus-bar/wiring layoutsBoards/switchyards circuit arrangementsTransformerElectric cables

The invention discloses a high-voltage equipment box of a D-series high-speed train and the high-speed train provided with the high-voltage equipment box. The high-voltage equipment box comprises a box body and a incoming cable terminal, a lighting arrester, a to-transformer cable terminal, a high-voltage isolation switch, a to-other-compartment cable terminal, a vacuum circuit breaker and a high-voltage ground switch which are arranged in the box body, wherein the box body comprises a first side wall, a second side wall, a third side wall and a fourth side wall, the first side wall and the second side wall are opposite to each other, and the third side wall and the fourth side wall are opposite to each other. In the high-voltage equipment box disclosed by the scheme, a high-voltage part is arranged in the sealed box body, the influence of an external environment on product application is eliminated, the insulation capability is greatly improved, the serious problems that pollution flashover occurs in the high-voltage part on a roof caused by environmental factors such as wind, dust, rain, snow and haze when the high-voltage equipment box is originally arranged externally and even some parts are exploded are prevented, and a quality accident caused by environmental influence can be further effectively prevented.

Owner:株洲庆云电力机车配件工厂有限公司

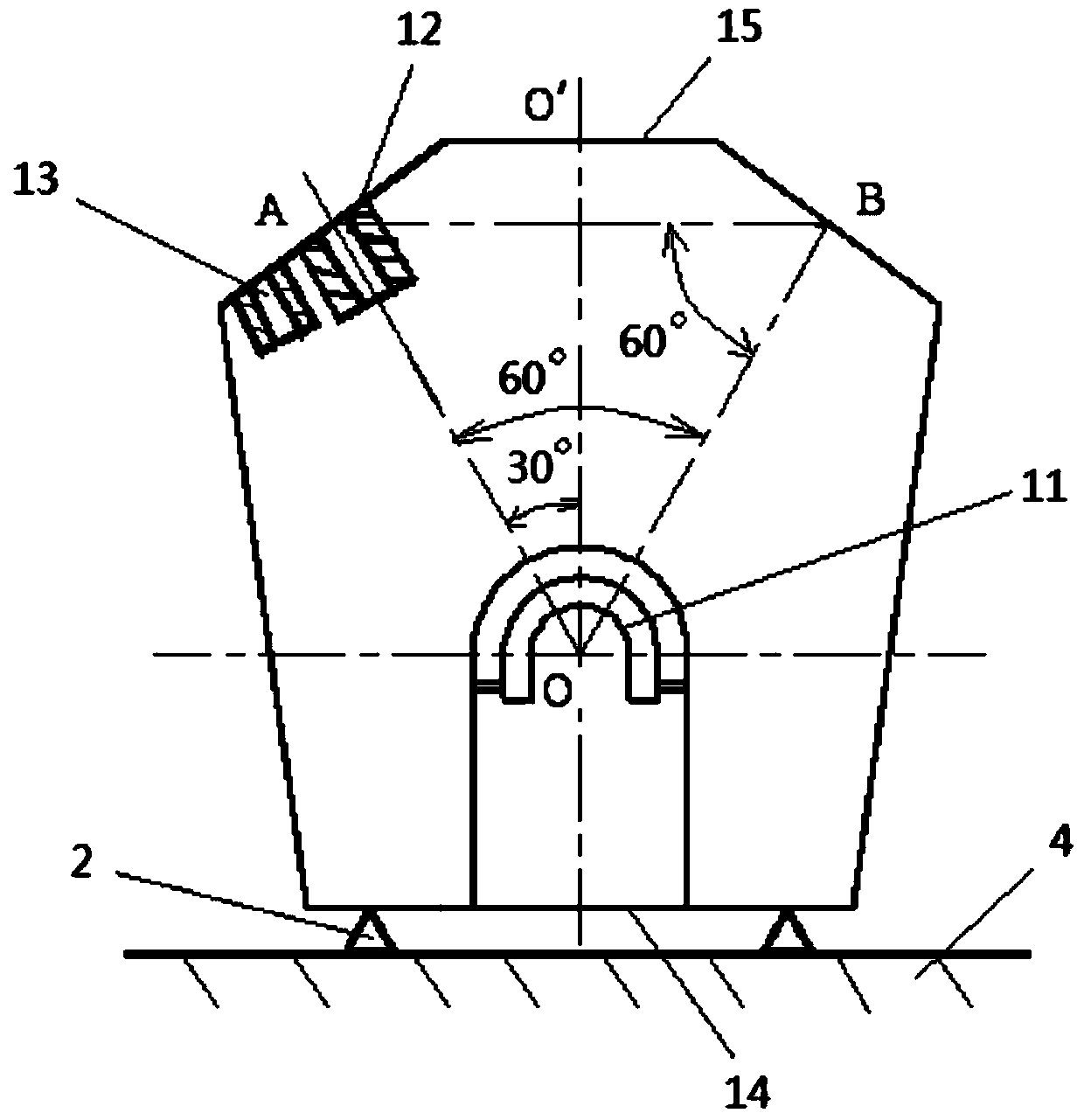

Marking method for V-shaped diesel engine rack blank

ActiveCN104589298AReduce manufacturing costAvoid Quality AccidentsOther workshop equipmentIsoetes triquetraThree-dimensional space

The invention relates to a marking method for a V-shaped diesel engine rack blank. The rack blank is provided with a plurality of coaxial main bearing holes longitudinally distributed in the center of the lower portion, two rows of parallel cylinder sleeve holes and two rows of guide cylinder holes, wherein the two rows of cylinder sleeve holes are symmetrically formed in the two sides of the top, and a 30-degree included angle is formed between the axes of the two rows of cylinder sleeve holes and the central line of a rack. The marking method is characterized in that under the premise that the machining allowance is ensured, the central lines of all the cylinder sleeve holes, the guide cylinder holes, camshaft holes and the main bearing holes, hole round machining lines, rack outline contour machining lines and the machining lines of the two end faces of the rack are marked through five marking positions on a horizontal worktable based on equilateral triangle three-dimensional space operation, wherein all the machining lines meet the design dimension requirements. According to the marking method, conventional marking tools and special single-foot clamping tools are used, the equilateral triangle three-dimensional space operation of the V-shaped rack is achieved at the five marking positions, and the advantages of lowing the production cost and avoiding quality accidents are achieved; the marking method has the advantages that operation is easy and convenient, and the marking precision is high; the marking method is suitable for marking operation of any V-shaped integrated rack and similar parts.

Owner:HUDONG HEAVY MACHINERY

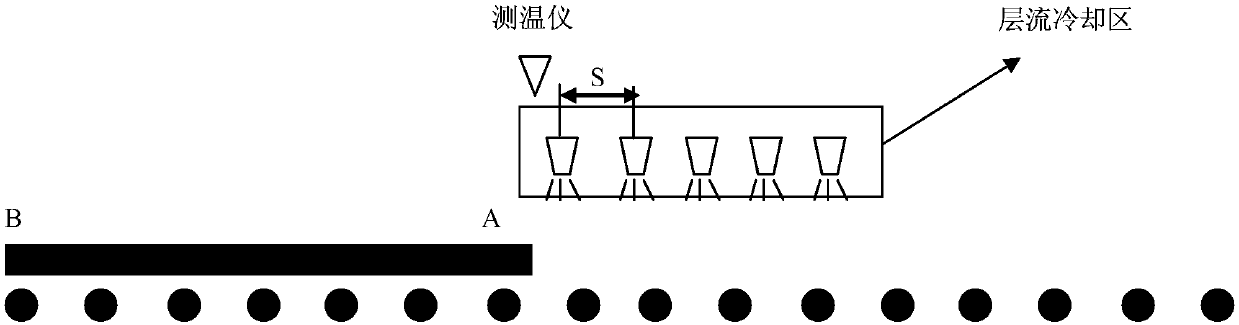

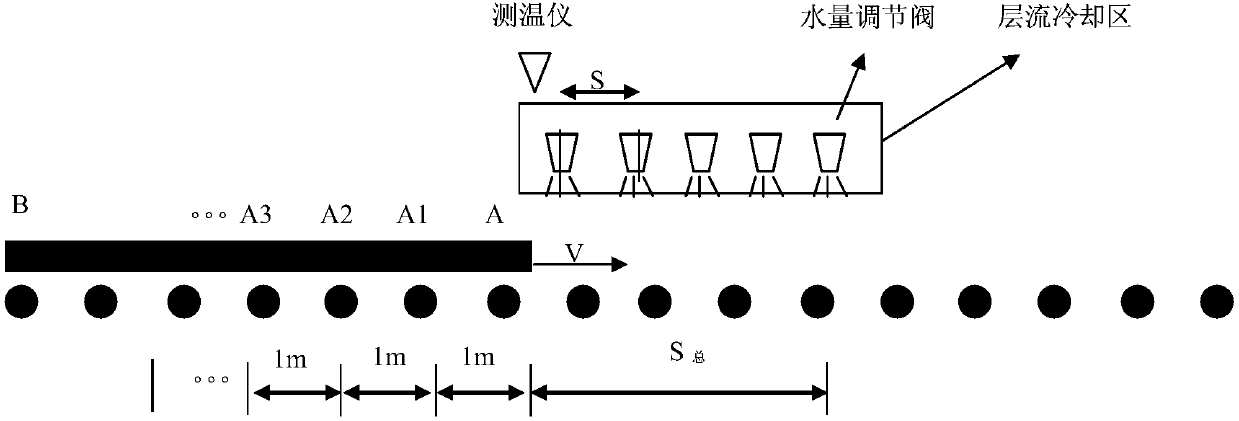

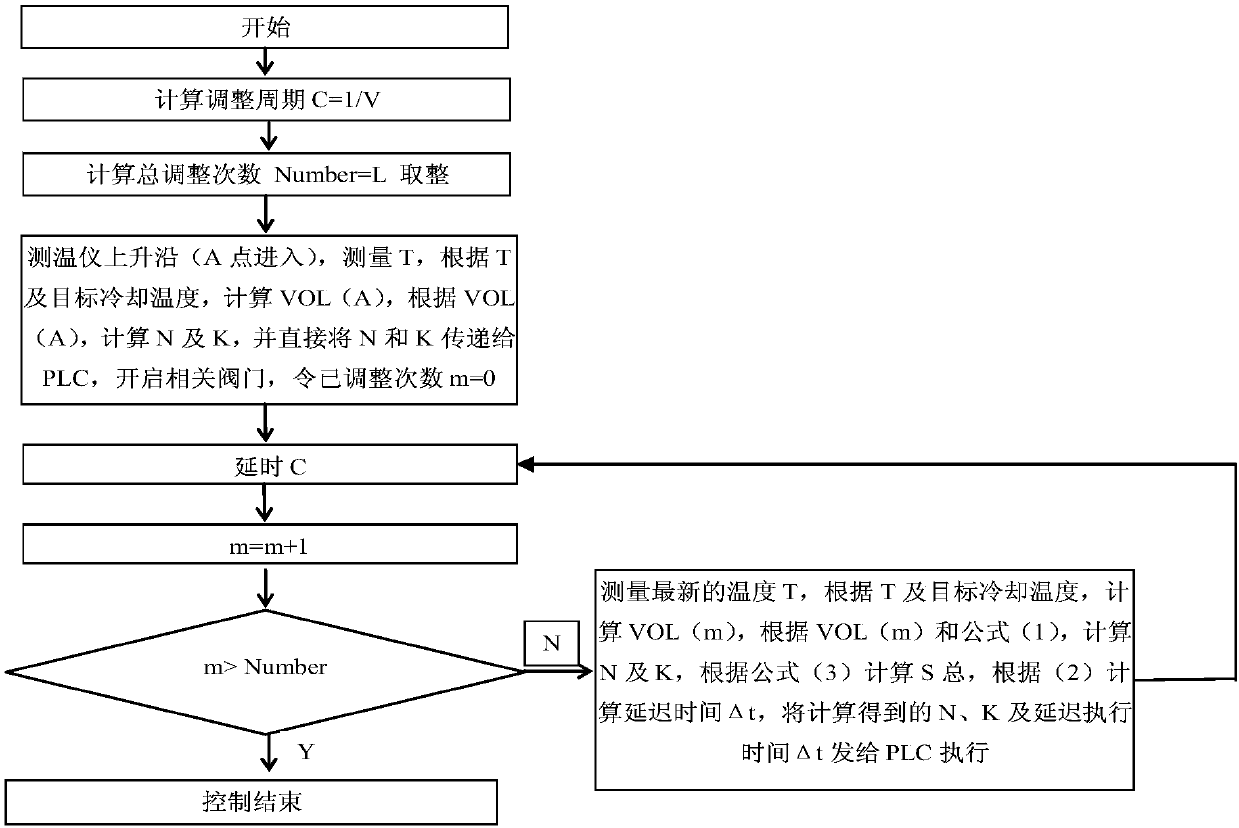

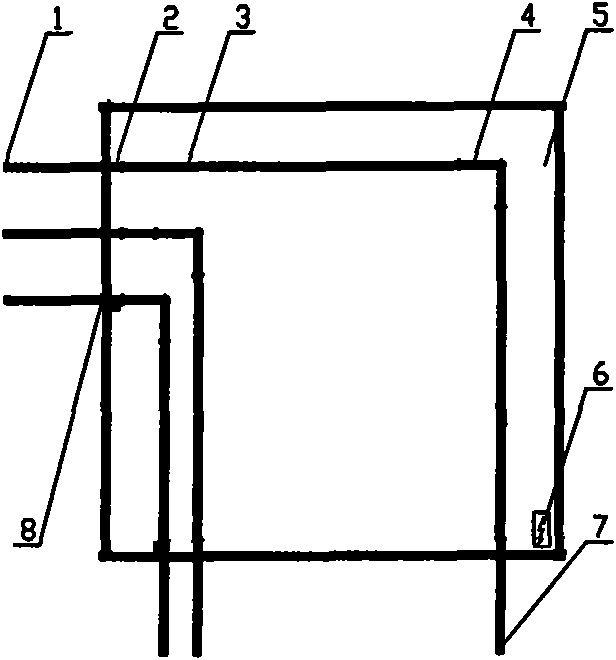

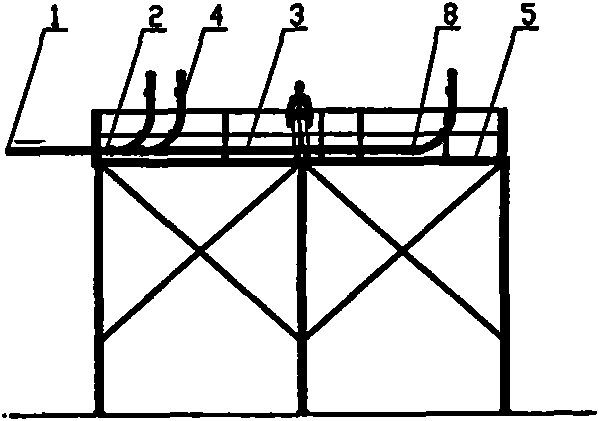

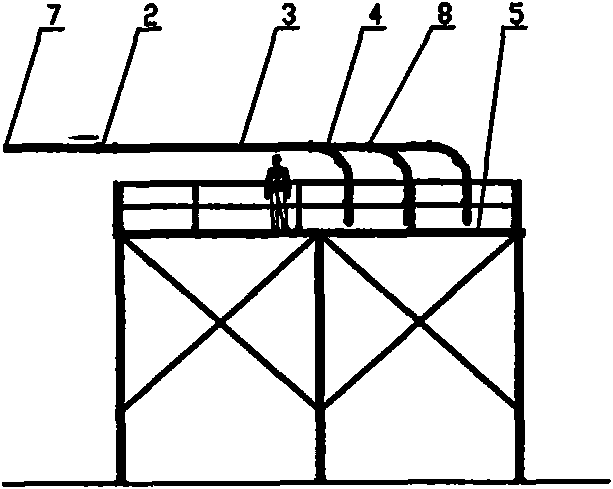

Dynamic water amount adjustment method for laminar flow cooling of medium-thickness plate and wide and thick plate considering head-tail temperature deviation

InactiveCN107052061AGuaranteed uniformityAvoid Quality AccidentsTemperature control deviceTraffic volumeValve opening

The invention provides a dynamic water amount adjustment method for laminar flow cooling of a medium-thickness plate and a wide and thick plate considering head-tail temperature deviation. The steel sheet temperature is detected dynamically according to a certain cycle period by considering the advancing speed of a steel sheet in laminar flow cooling, and the flow of the required cooling water is dynamically calculated according to the newly detected temperature; then, the group number N of valves with the opening degree being 100% and the valve opening degree K of the last group of flow adjustment valves are determined according to the flow, wherein the K is larger than or equal to zero and smaller than or equal to one; and the delay time delta t of flow adjustment is determined according to the valve group number. By means of the dynamic water amount adjustment method, it can be guaranteed that the head and the tail of the steel sheet can be the same in temperature after being cooled, uniformity of product performance is guaranteed, the situation that the head performance is qualified while the tail performance is unqualified, or the tail performance is qualified while the head performance is unqualified is avoided, and controversy about quality is avoided as much as possible.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Tobacco shred mark distribution station

InactiveCN101862032AReduce the amount of crushingFlexible conversionCigarette manufactureBulk conveyorsElectricityBarcode

The invention relates to a tobacco shred mark distribution station, which comprises a manual mark distribution station, an automatic mark distribution station and a control station, wherein the manual mark distribution station comprises a connecting pipeline connected with tobacco shred delivery pipelines from a cigarette making machine and a pneumatic shred matching machine respectively; the connecting pipeline comprises a plurality of switching elbows, straight switching pipes and straight positioning pipes; the automatic mark distribution station comprises an S-shaped elbow; the S-shaped elbow can be driven by a speed reducer or an electric (pneumatic) executer to rotate 360 degrees in a way of taking one end as the centre of a circle; barcodes are pasted on the straight switching pipes and the S-shaped elbow; the control station acquires and detects the position information of the pipelines by utilizing various methods, such as a photoelectric switch, an approach switch, a barcode scanner and the like, after the pipelines are switched and jointed; and the mark distribution station has error correction and alarming functions. The tobacco shred mark distribution station reduces crushing in a tobacco shred delivery process and improves production efficiency and product quality.

Owner:扬州市天宝自动化工程有限公司

Maintenance-free system of belt of conveyor

ActiveCN104891132AReduced commissioning timeSimple structureConveyorsControl devices for conveyorsEngineeringPosition sensor

The invention provides a maintenance-free system of a belt of a conveyor. The maintenance-free system comprises an automatic deviation rectifying system and an automatic tensioning system. The automatic deviation rectifying system comprises a belt edge position sensor, a deviation rectifying controller and a belt deviation rectifying execution mechanism. The deviation rectifying controller controls the belt deviation rectifying execution mechanism to move by combining real-time position information of belt edges. The automatic tensioning system comprises a belt tensile force detection system, a belt tensile force controller and a belt tensile force adjusting execution mechanism. The belt tensile force controller is used for controlling the belt tensile force adjusting execution mechanism to carrying out front and back movement. The maintenance-free system is simple in structure, debugging time of a belt conveyor is greatly reduced, stability of devices is improved, and potential safety hazards are reduced.

Owner:NANTONG YIGAO MACHINERY CO LTD

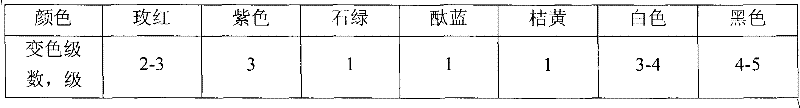

Method for testing light/chlorinated water composite color fastness of textiles

InactiveCN102539304AAvoid Quality AccidentsWeather/light/corrosion resistanceChemical methods analysisColour fastnessColor changes

The invention discloses a method for testing color fastness (light / chlorinated water composite color fastness) of textiles. The method comprises the following technical processes: immersing fabric into available-chlorine chlorinated water with a concentration of 20 mg / L for 30 min, enabling the fabric to absorb the liquid completely, controlling a mangle expression of the fabric, and enabling a liquid rate of the fabric to be 100%; and performing a light fastness test under an illumination condition with an irradiation amount of 85 KJ / m <2>.nm, and determining the performance of light / chlorinated water composite color fastness of the fabric according to sample color-change situations. According to the method disclosed by the invention, the influences on the color fastness of the textiles from the chlorinated water and illumination are comprehensively considered, and a stage test method comprising the steps of immersing by the chlorinated water and performing the light fastness test is adopted, so that the limited situation that the color fastness standard at home and aboard is only determined by light color fastness or chlorinated water color fastness is broken through.

Owner:福建省纤维检验局

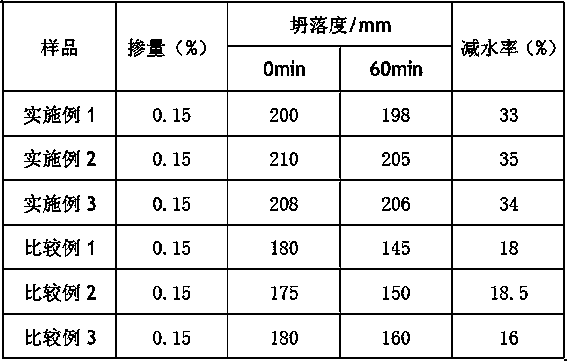

Preparation method of polycarboxylate superplasticizer

The invention discloses a preparation method of a polycarboxylate superplasticizer. The method relates to the technical field of concrete admixture preparation, and comprises the following two stages:a first stage: under a stirring condition, adding acrylic acid, vitamin C, mercaptopropionic acid, a methylallyl polyoxyethylene ether monomer and ammonium persulfate into a reactor, heating to 60 DEG C+ / -5 DEG C, and carrying out heat preservation to react for 1 hour to 5 hours; then, adding a defoaming agent, an air entraining agent, a thickening agent and a corrosion remover into the reactor,and uniformly stirring; a second stage: adding a retarder and water into a substance obtained in the first stage, and uniformly stirring. According to the preparation method of the polycarboxylate superplasticizer provided by the invention, the vitamin C used as one of reaction raw materials is added, so that the product polycarboxylate superplasticizer is modified, and a water reducing effect andan anti-collapse effect are improved.

Owner:广西鸿志新材料有限公司

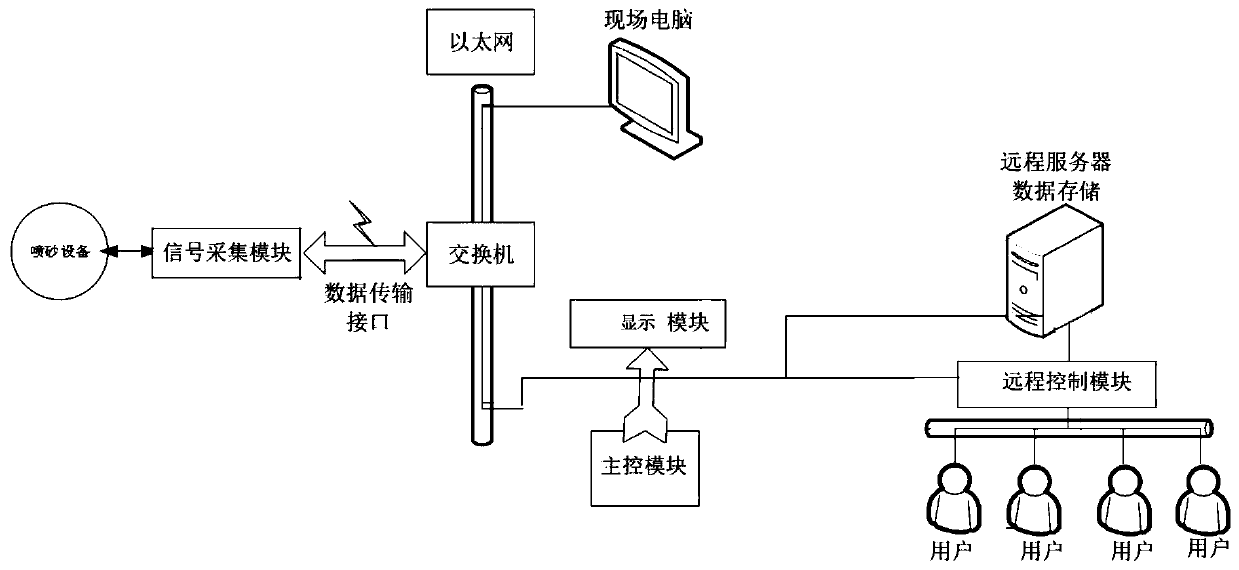

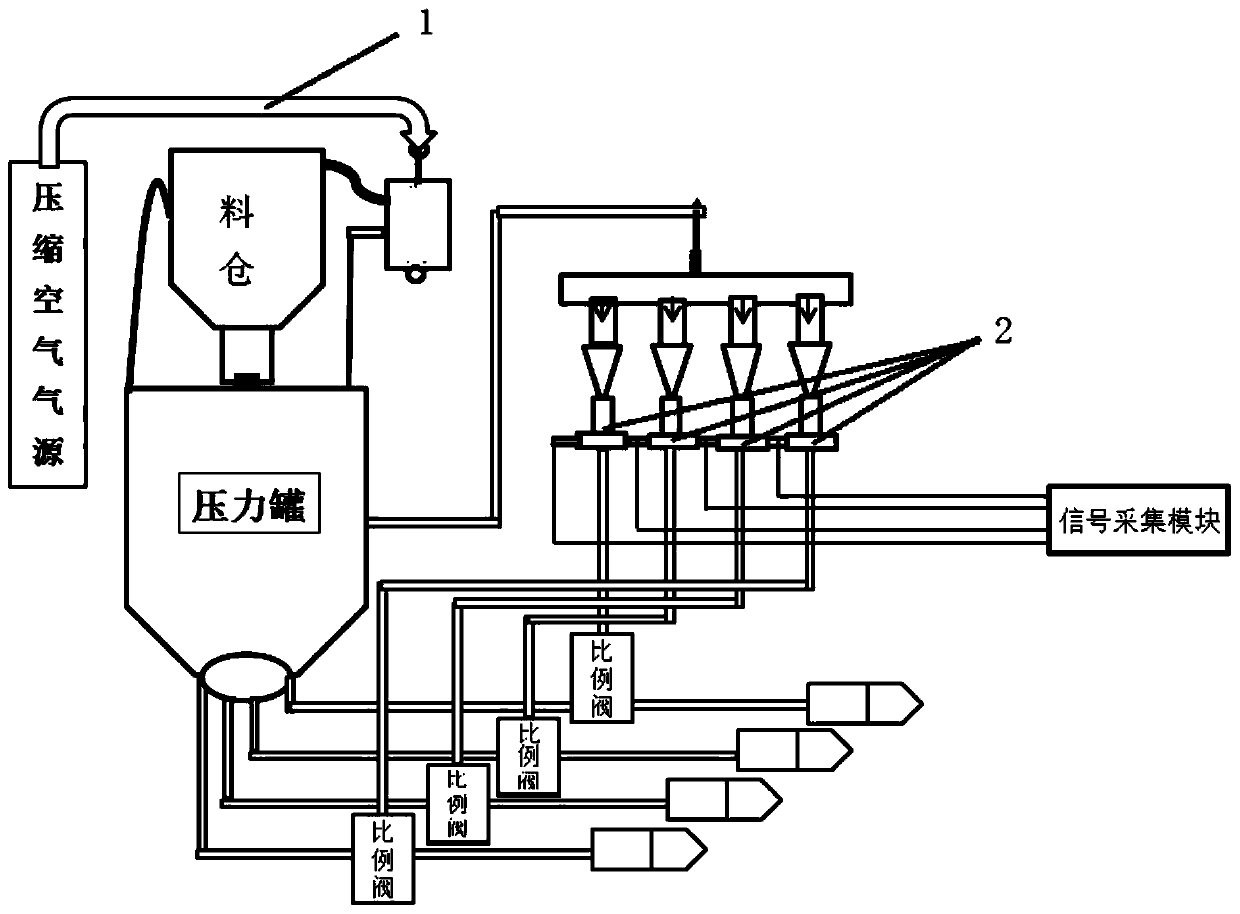

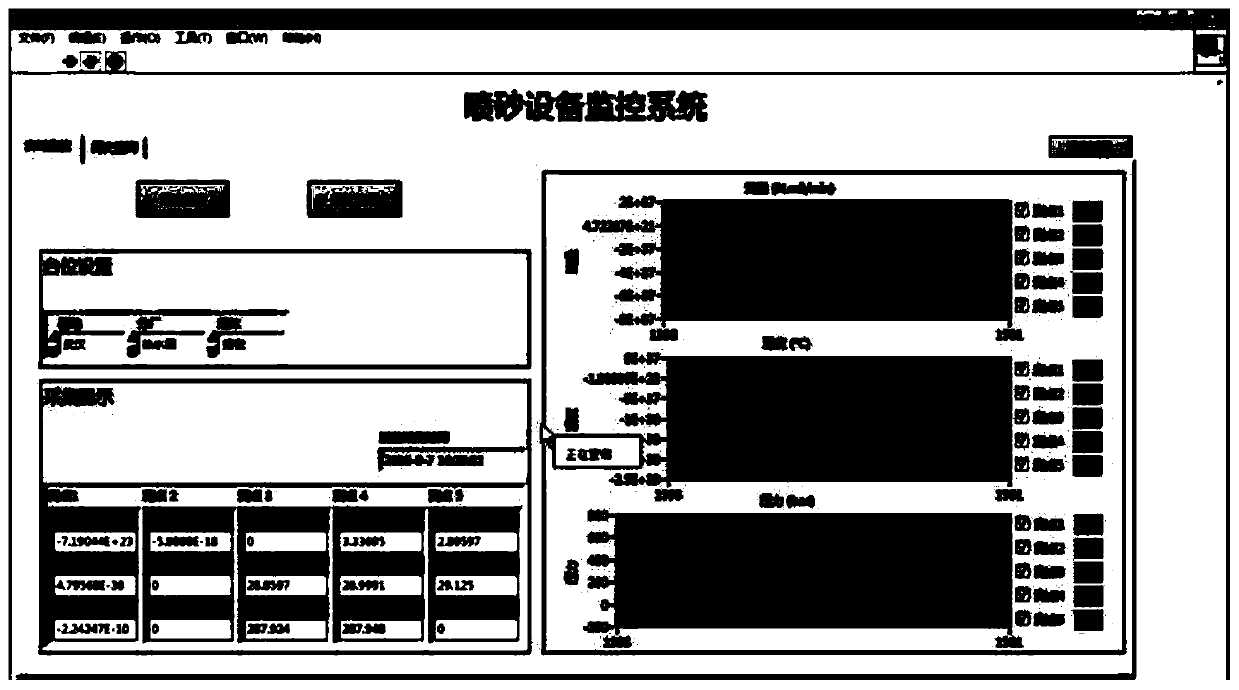

Monitoring system and method for sand blasting machine

InactiveCN110281163AEasy to modifyImprove pass rateAbrasive machine appurtenancesAbrasive blasting machinesSand blastingRemote control

The invention discloses a monitoring system for a sand blasting machine. The monitoring system comprises a flowmeter, a signal collection module, a master control module, a remote control module and a display module. The signal collection module collects data, measured by the flowmeter, of the work process of the sand blasting machine, the data are transmitted to the master control module through a data transmission interface to be processed, the master control module processes and analyzes the data in real time to obtain an analysis result, and the analysis result is displayed through the display module. The master control module stores the analysis result to a database server. The remote control module is connected with the master control module and used for inquiring real-time and historical data. The sand blasting key technological process is monitored in real time through informationalized means, equipment failures are found in time, the first pass yield of sand blasting is improved, and large-batch quality accidents are eradicated; and relevant process parameters are recorded in real time, and good guiding significance is achieved to subsequent debugging of the sand blasting machine and optimization to new product technological parameters.

Owner:GREE ELECTRIC APPLIANCES WUHAN +1

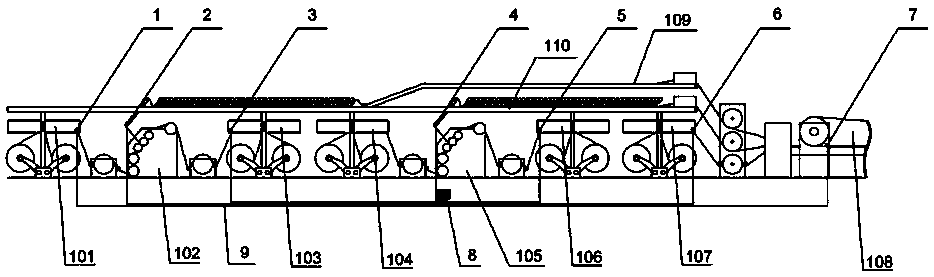

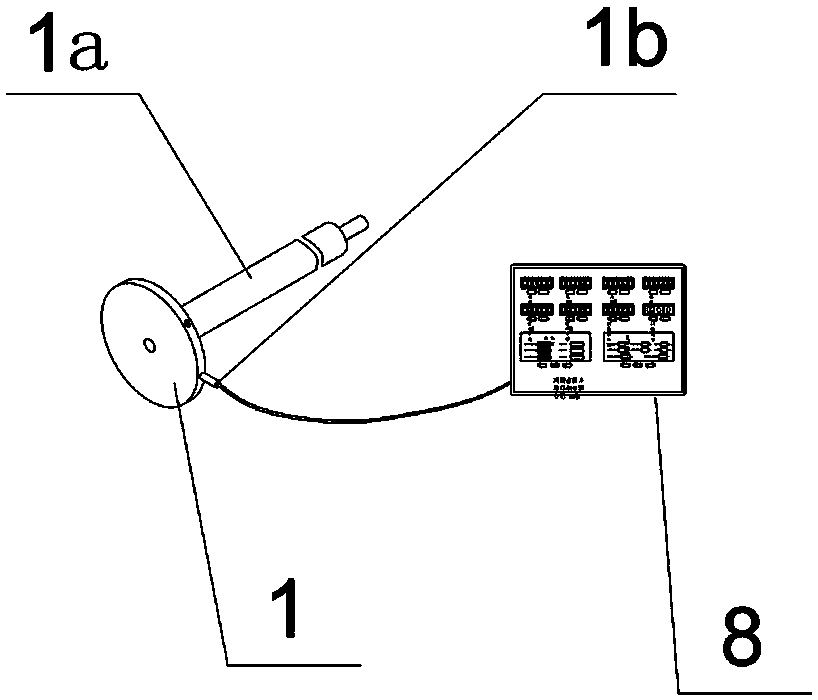

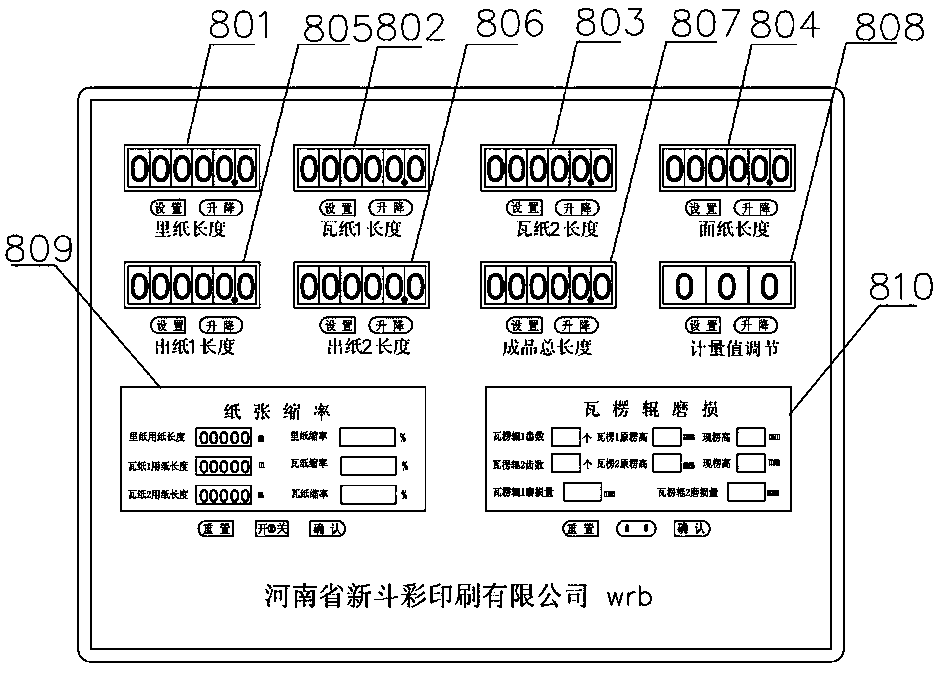

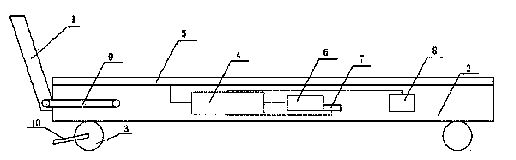

Corrugated board production line real-time monitoring method

InactiveCN107631684AAvoid Quality AccidentsProgramme controlMechanical working/deformationProduction lineMicrocomputer

The invention discloses a corrugated board production line real-time monitoring method, which comprises the following steps: to begin with, mounting a length meter at the end portion of a paper guideroll at a paper exit of each original paper frame on a production line and at the entrance of each overbridge elevator above a corresponding corrugated host; mounting a finished product meter at an entrance of a drying tunnel; and connecting an electromagnetic induction head on each meter to a displayer arranged on a production line master control station correspondingly, so that paper feed lengthof lining paper, tile paper and face paper and paper output length of semi-finished product and finished product paperboards and the like can be displayed on a counter of the displayer; meanwhile, shrinkage ratio of the lining paper and shrinkage ratio of the tile paper are displayed on a paper shrinkage window in real time synchronously; and current corrugation height data of a corrugated rolleris displayed on the displayer in real time synchronously after calculation of a single-chip microcomputer. Through fine collection and calculation of such parameters, real-time states of lining paperand tile paper on the production line can be reflected in real time correctly and reasonably, thereby providing possible quality problems analyzed based on the collected data for managers in real time.

Owner:HENAN XINDOUCAI PRINTING

Efficient logistics trolley

InactiveCN104228901ASimple structureImprove work efficiencyHand carts with multiple axesWeight valueEngineering

The invention discloses an efficient logistics trolley. The efficient logistics trolley comprises a trolley main body, wherein the trolley main body is provided with a handle, a base plate, rollers and a control main plate; the handle is fixedly connected with side walls of the base plate; the rollers are detachably connected with the lower surface of the base plate; the control main plate is arranged in the base plate; and the trolley body is provided with a weight displaying and alarming device. According to the technical scheme, the trolley body is provided with the weight displaying and alarming device, the weight displaying and alarming device comprises a weighing displaying device and a quantifying alarming device; the weighing displaying device can automatically weigh trolley-mounted materials and display the weight value on a display; the work efficiency is improved; the labor intensity of an operator is reduced; and the quantifying alarming device gives an alarm when the weight of the trolley-mounted materials reaches a designated value. The weight of the trolley-mounted materials is effectively prevented from exceeding maximum trolley-mounted load; quality accidents due to the fact that the logistics trolley is collapsed is avoided; the safety performance is improved; the operator can set everyday conveyed materials; frequent counting processes are omitted; and the time and the labor are saved.

Owner:SHANGHAI HEHUA ELECTRONICS TECH

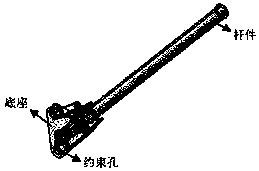

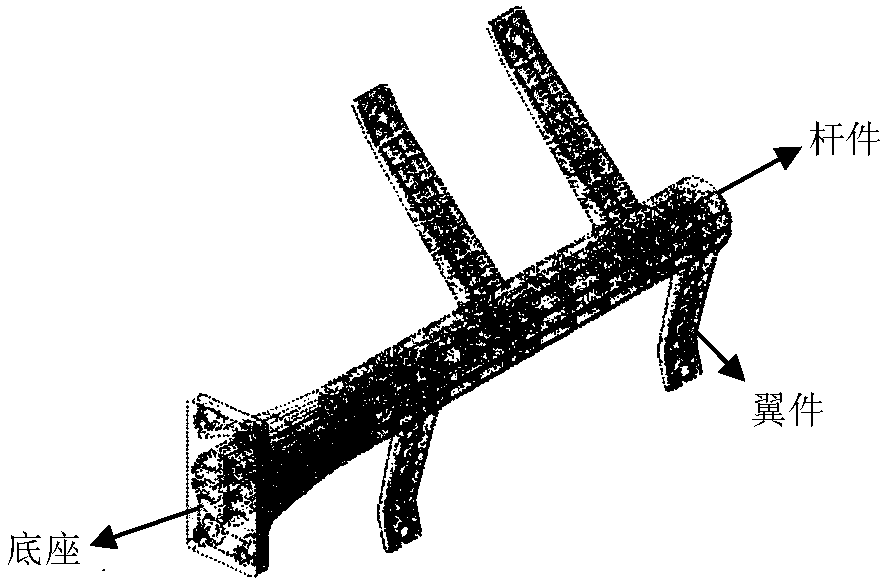

Cantilever beam supporting device and preparation method thereof

InactiveCN107867336ATake full advantage of performanceLightweight effect is goodSuperstructure subunitsSteps arrangementVehicle frameCar manufacturing

The invention belongs to the field of automobile manufacturing, and particularly provides a cantilever beam supporting device and a preparation method thereof. The cantilever beam supporting device comprises a base and a rod piece connected with the base, wherein the base and the rod piece are made of fiber-reinforced resin-based composite materials. The cantilever beam supporting device has the characteristic of lightweight so that the weight of a vehicle can be reduced, and the energy-saving and emission-reducing effects can be achieved. Meanwhile, the cantilever beam supporting device can effectively reduce the resonance effect of the cantilever beam supporting device and a vehicle frame, breaking can be prevented, quality risks are avoided, and the preparation method is simple and feasible.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Construction method for laying refractory bricks of rotary kiln through bricklaying supporting device

The invention belongs to the technical field of laying methods for refractory bricks of rotary kilns, and particularly discloses a construction method for laying refractory bricks of a rotary kiln through a bricklaying supporting device. The construction method comprises the following construction steps that S1, the construction portion of the inner wall of a kiln shell of the rotary kiln is cleaned; S2, a plurality of longitudinal straight lines and circumferential lines are drawn on the inner wall of the kiln shell of the rotary kiln; S3, the bottoms of the refractory bricks are laid, namely the lower semicircles are laid; S4, the bricklaying supporting device is mounted; S5, the tops, namely the upper semicircles, of the refractory bricks are laid; S6, opening sealing and seam sealing work is prepared; S7, after sealing is completed, a lead screw is tightened, and the bricklaying supporting device is contracted, so that brickwork of the circle is made to automatically draw close to the center of the circular ring in a centralized mode; S8, seams in the brickwork and the inner wall of a cylinder are checked; S9, after the refractory bricks of the first circle are laid, the lead screw is tightened, and the bricklaying supporting device is contracted for withdrawing from the first circle; and S10, the steps from the step S3 to the step S9 are repeated for laying of the next circle. By the adoption of the construction method, quality accidents, such as falling and breaking of the refractory bricks, frequently occur during operation of the rotary kiln are avoided to a great extent.

Owner:XINMI WANLI IND DEV

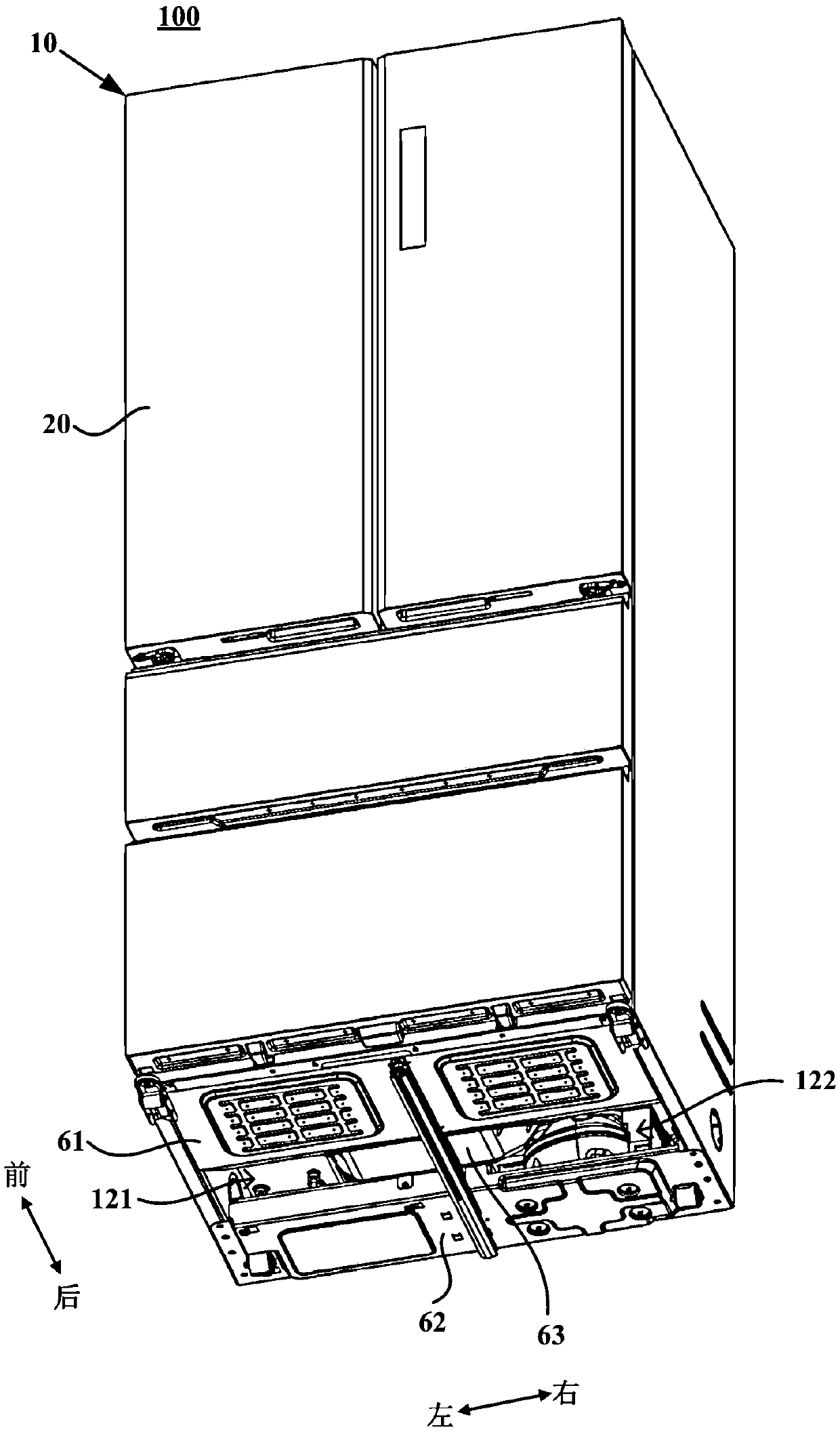

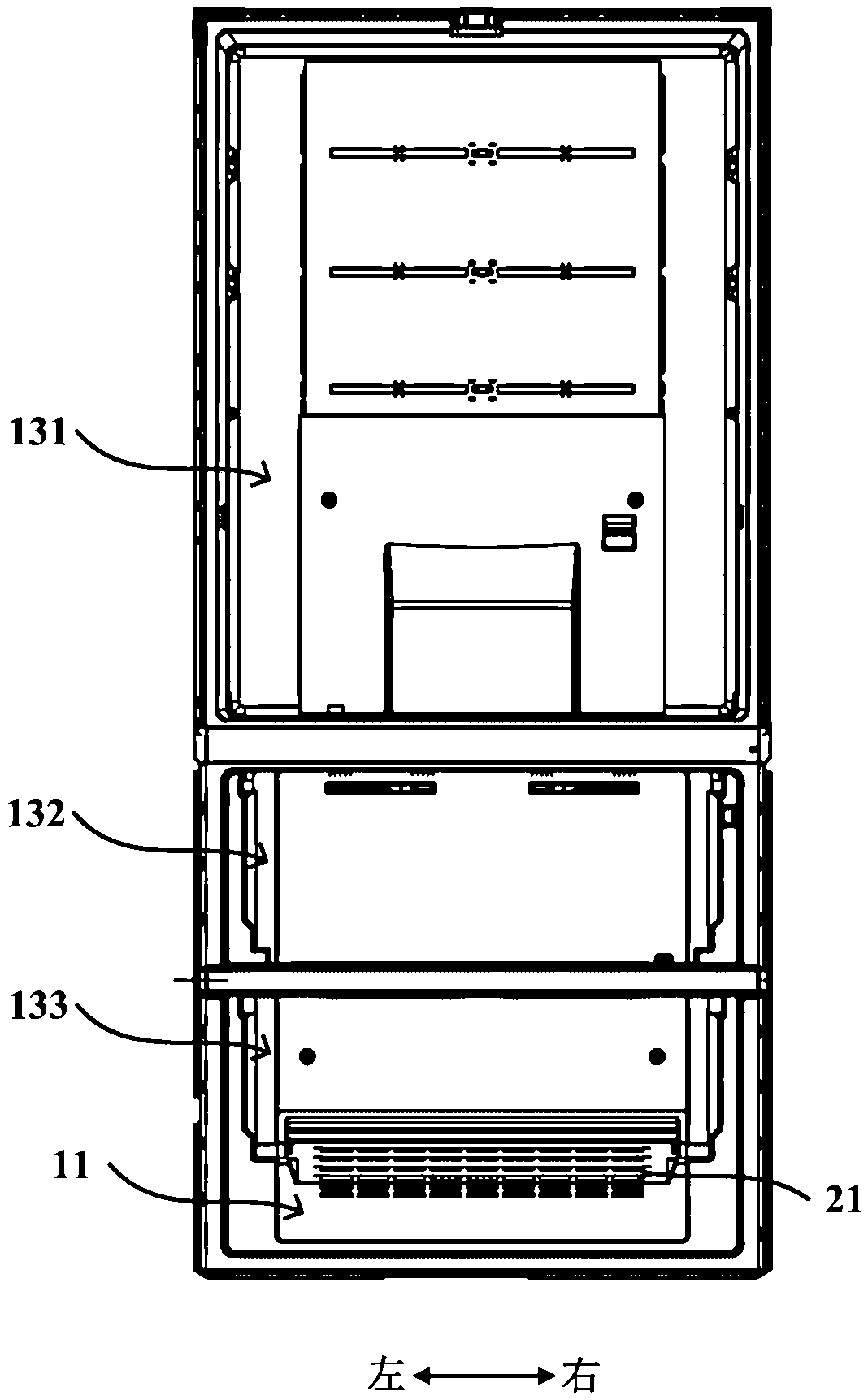

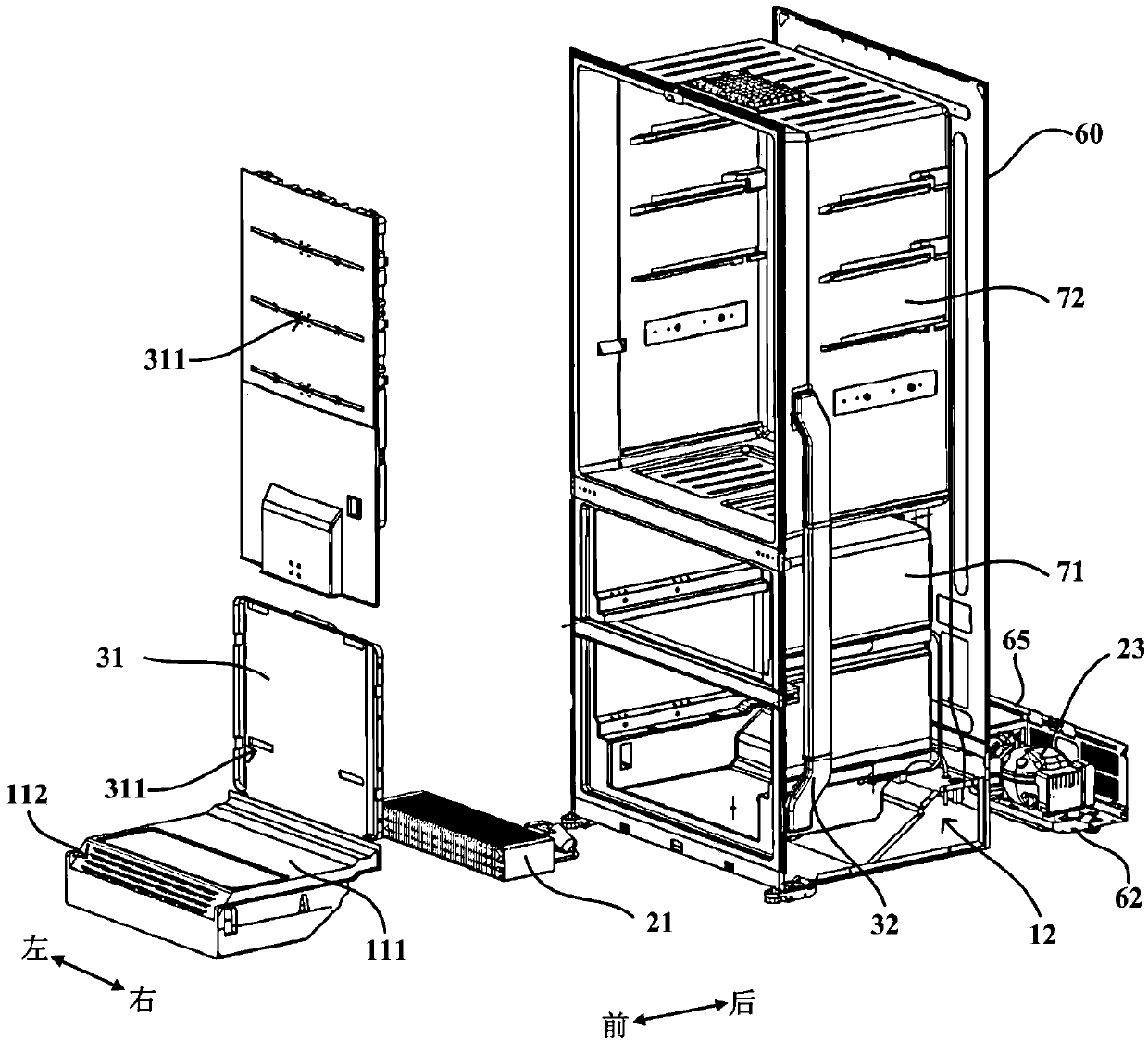

Refrigerator with drainage mechanism

PendingCN110375504AImprove user experienceAvoid Quality AccidentsLighting and heating apparatusDefrostingCooling chamberCooling capacity

The invention provides a refrigerator with a drainage mechanism. The refrigerator comprises a tank, a door body, an evaporator and the drainage mechanism. A cooling chamber and at least one storage space are defined in the tank; the cooling chamber is arranged on the bottom part of the tank and is located right under the storage space; the door body is arranged on the front surface of the tank soas to operationally open and close the storage space; the evaporator is in a flat cube shape as a whole, is horizontally arranged in the cooling chamber and is configured to be used for providing cooling capacity for the storage space; and the drainage mechanism is arranged on the cooling chamber and located under the evaporator, and comprises a main flow-guiding surface, a front flow-guiding surface and a side flow-guiding surface. According to the refrigerator provided by the invention, the cooling chamber is arranged on the bottom part of the tank, so that the height of the storage space onthe lowermost part of the refrigerator from the ground is increased, and a user is prevented from bending down or squatting to pick and place objects; and through the drainage mechanism, condensate water produced by the evaporator can be smoothly discharged to the outer part of the refrigerator, so that the working reliability of the evaporator is effectively ensured.

Owner:HAIER SMART HOME CO LTD

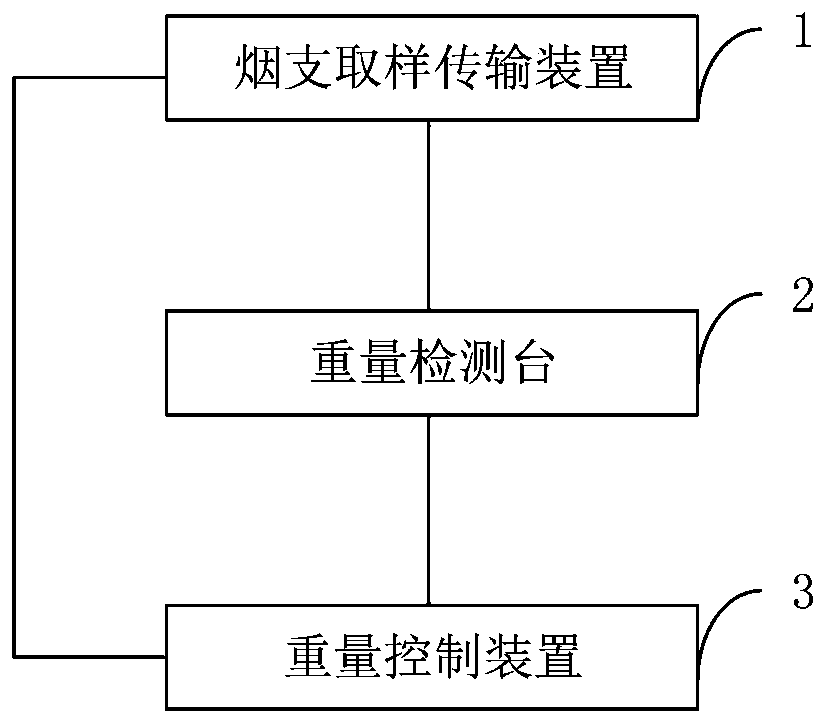

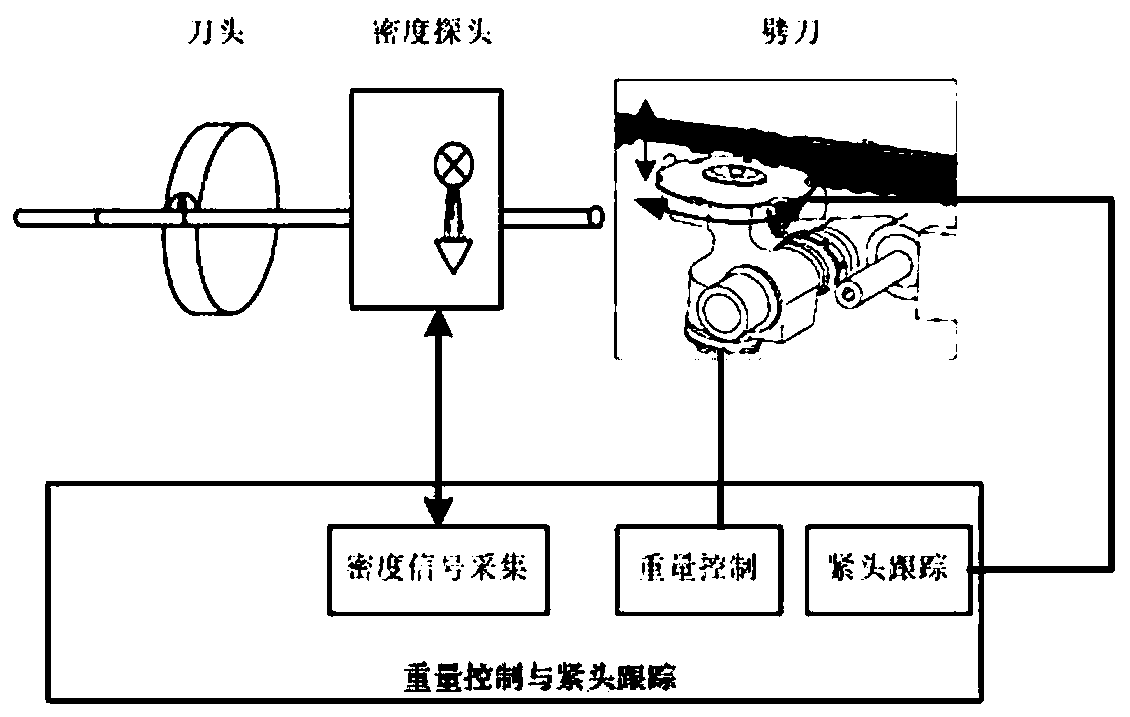

Cigarette weight control calibration system

PendingCN111000285AAvoid Quality AccidentsMaintain corporate imageCigarette manufactureControl engineeringControl theory

The invention relates to a cigarette weight control calibration system which is applied to the technical field of cigarette mechanical equipment and comprises a cigarette sampling and conveying device, a weight detection table and a weight control device. The cigarette sampling and conveying device is used for receiving a sampling signal sent by the weight control device, extracting a cigarette and transmitting the cigarette to the weight detection table; the weight detection table is used for detecting the weight of the cigarette to obtain a second weight value and sending the second weight value to the weight control device; and the weight control device is used for receiving the second weight value, detecting the weight of the cigarette to obtain a first weight value, and calibrating the weight control device according to the second weight value and the first weight value.

Owner:成都忠信机电技术有限公司

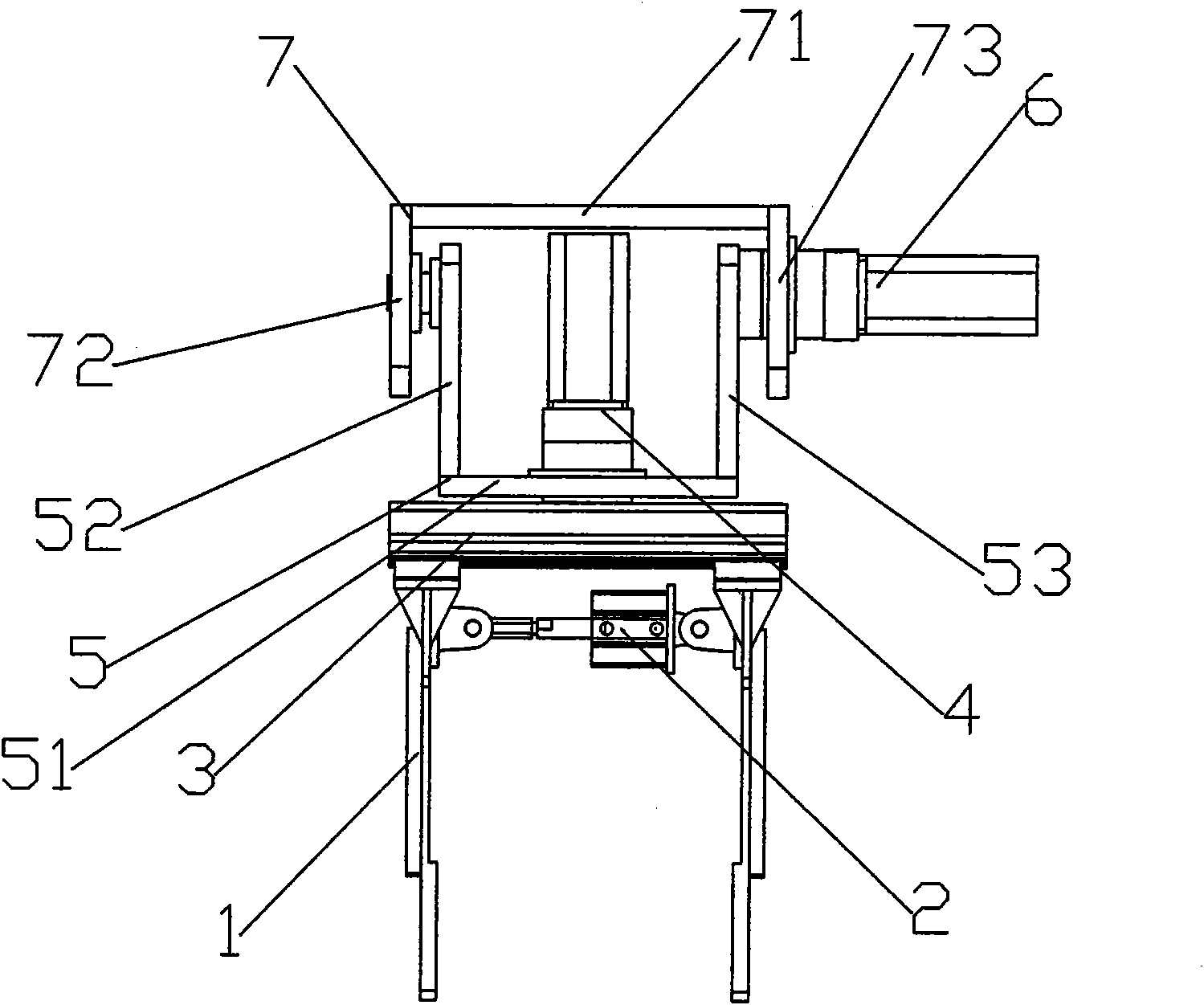

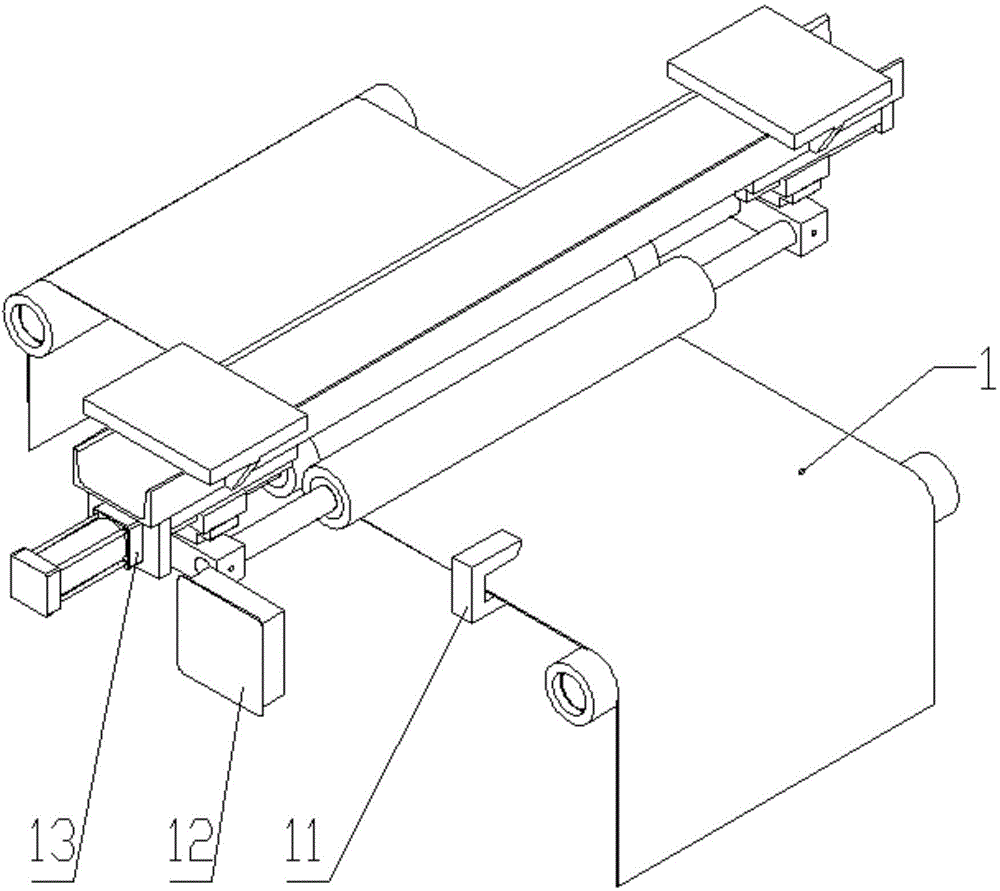

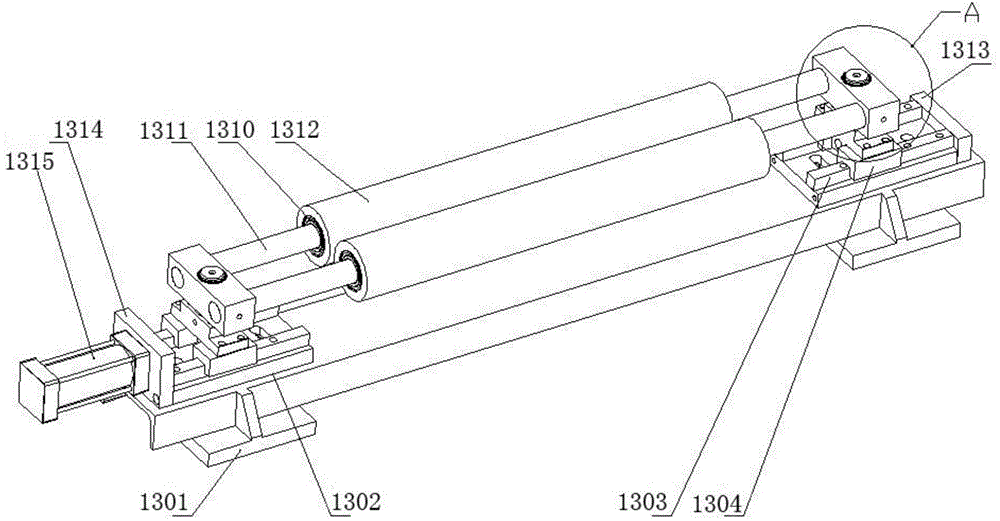

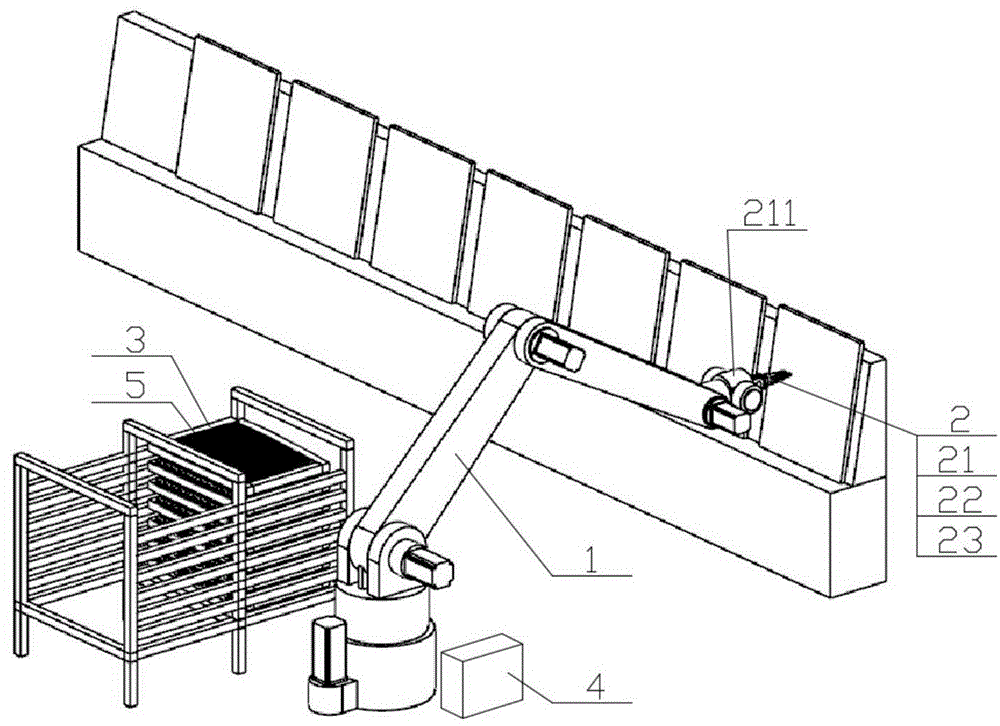

Disordered automatic tube grabbing and inserting unit for small U-shaped tubes of fin assembly

ActiveCN104690528AReduce labor intensityImprove efficiencyMetal working apparatusEngineeringElectric control

The invention discloses a disordered automatic tube grabbing and inserting unit for small U-shaped tubes of a fin assembly. The disordered automatic tube grabbing and inserting unit comprises a mechanical arm (1), a mechanical hand (2), small U-shaped tube bearing trays (3) and an electric control device (4), wherein the mechanical arm is fixedly mounted on the ground and comprises an X-coordinate drive mechanism, a Y-coordinate drive mechanism and a Z-coordinate drive mechanism; the mechanical hand comprises a main body (21), two clamping fingers (22) and two supporting fingers (23); a top end of the main body is connected with a tail end of the mechanical arm through a mounting seat (211); a C-coordinate drive mechanism is arranged in the mounting seat; arc-shaped grooves matched with outer diameters of the small U-shaped tubes (5) and radians of U shapes are formed in a bottom end surface of the main body and inner side surfaces of the clamping fingers; the distance between an upper surface of each supporting finger and the bottom of each arc-shaped groove is matched with the size of each small U-shaped tube. The tube inserting unit can realize automated operation, reduce influence of human factors on a production progress and guarantee the product quality in a tube insertion process.

Owner:XUZHOU DKEC ELECTRICAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com