Automatic uncovering device of tobacco dedicated charging bucket

An automatic lid opening and material tank technology, which is applied in the fields of tobacco, tobacco preparation, packaging, etc., can solve the problems of slow speed of the material tank cover and cannot meet the production automation of the automatic sugar kitchen system, so as to prevent quality accidents and improve the preparation Efficiency, the effect of improving the sanitation environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be described in detail below in conjunction with the drawings.

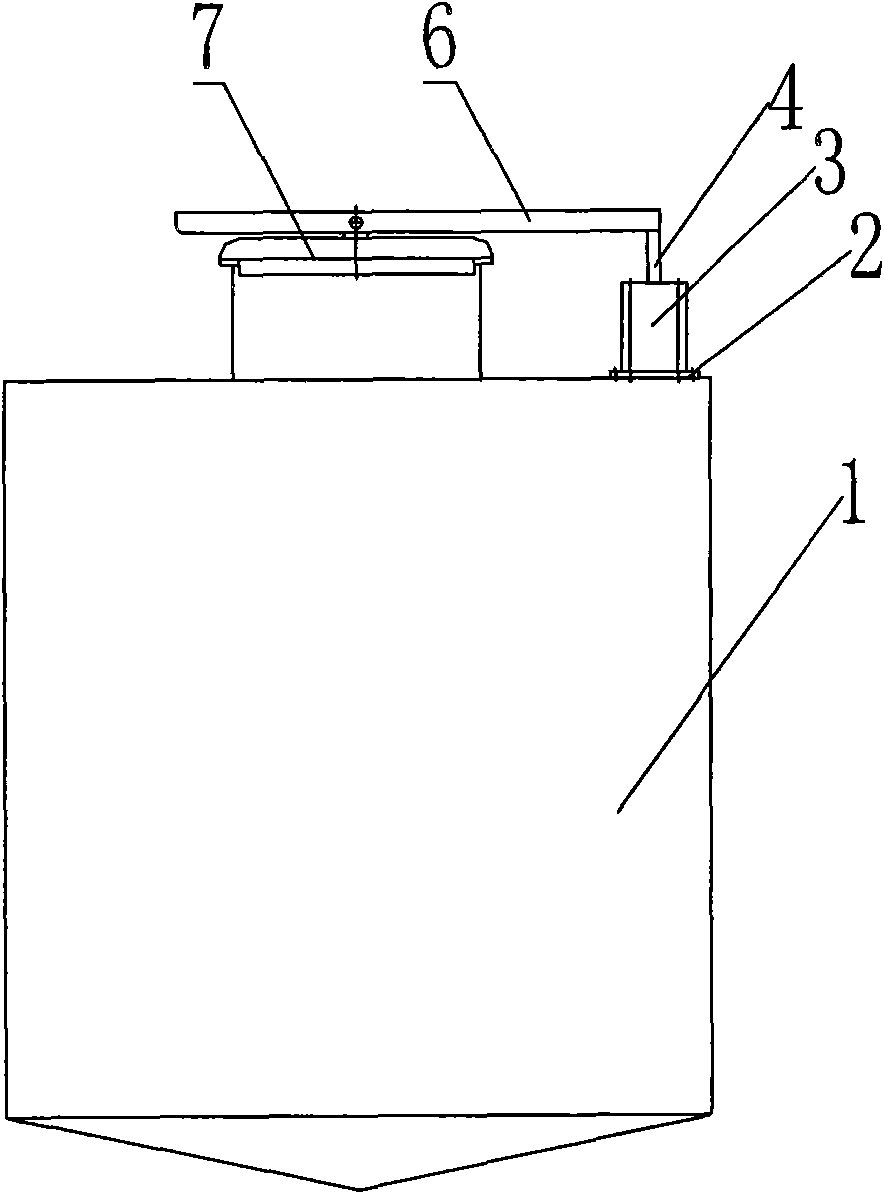

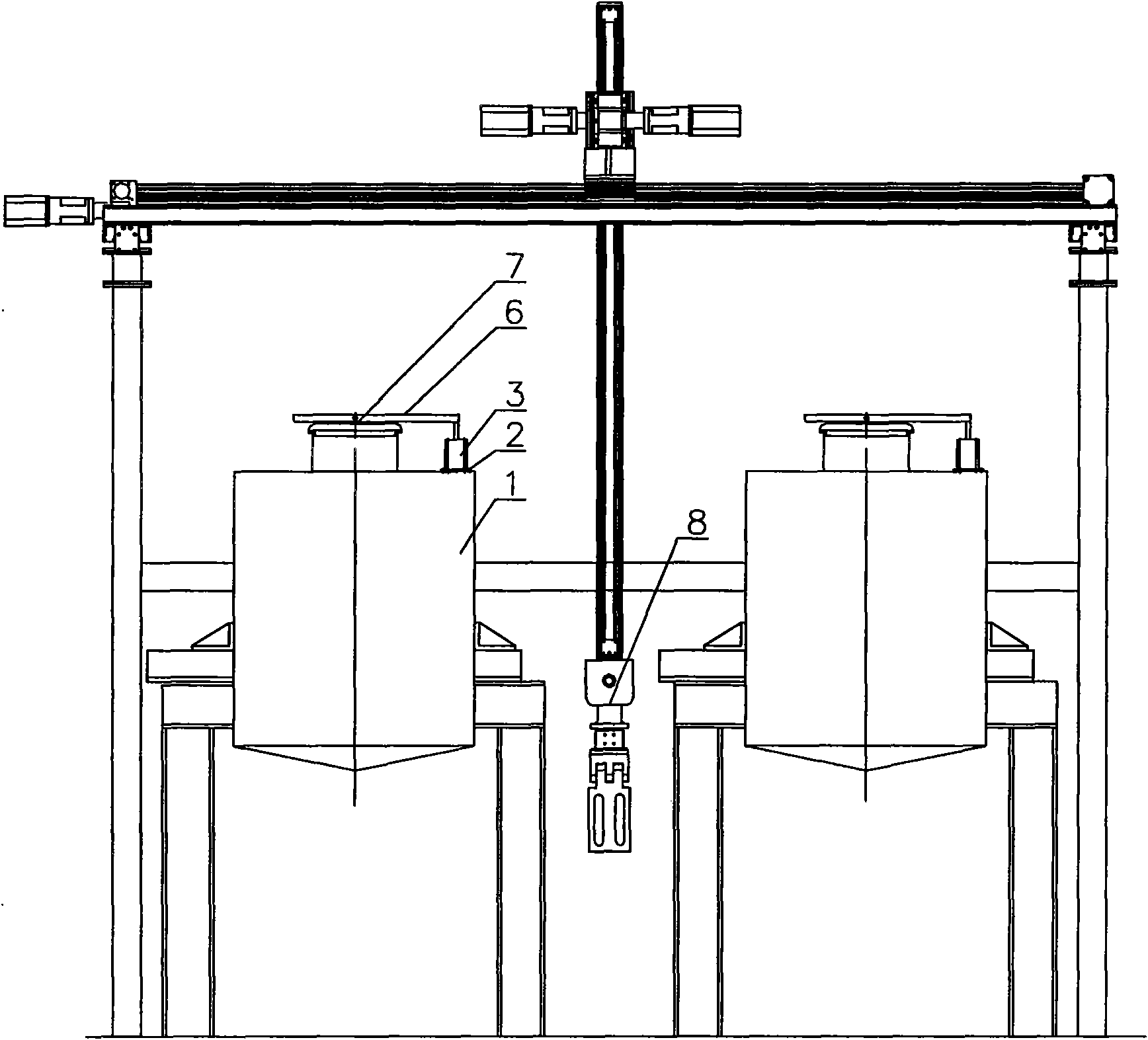

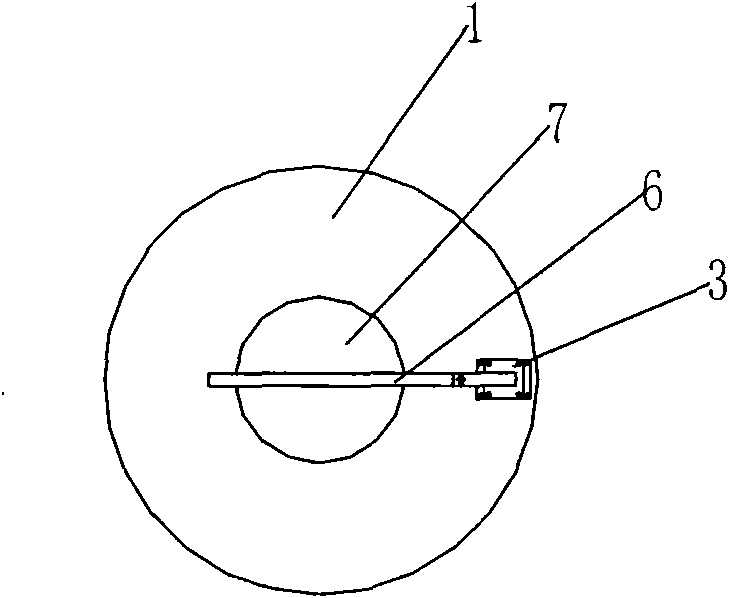

[0016] Such as figure 1 As shown, the automatic lid opening device for the tobacco special material tank includes a material tank 1 and a linear oscillating combination cylinder 3, the top of the material tank 1 is provided with an opening, and a tank cover 7 is provided on the opening. The linear swing combination cylinder 3 is fixed on the top of the tank 1 through the mounting flange 2, and the piston rod 4 of the linear swing combination cylinder 3 is upward. One end of the bead connecting rod 6 of the piston rod 4 is fixedly connected, and the other end of the bead connecting rod 6 is fixed on the lid 7 of the material tank 1. The piston rod 4 of the linear swing combination cylinder 3 can move up and down along a straight line and can rotate around its axis. The stroke and rotation angle of the piston rod 4 up and down can be adjusted and set. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com