Automatic packing equipment for multi-model express carton boxes

A multi-model, carton technology, applied in the direction of packaging, transportation packaging, transportation and packaging, etc., can solve the problems that affect the development of the express delivery industry, low efficiency, and affect the speed and quality of logistics, and achieve reliable packaging, convenient maintenance, and save manpower and material resources The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

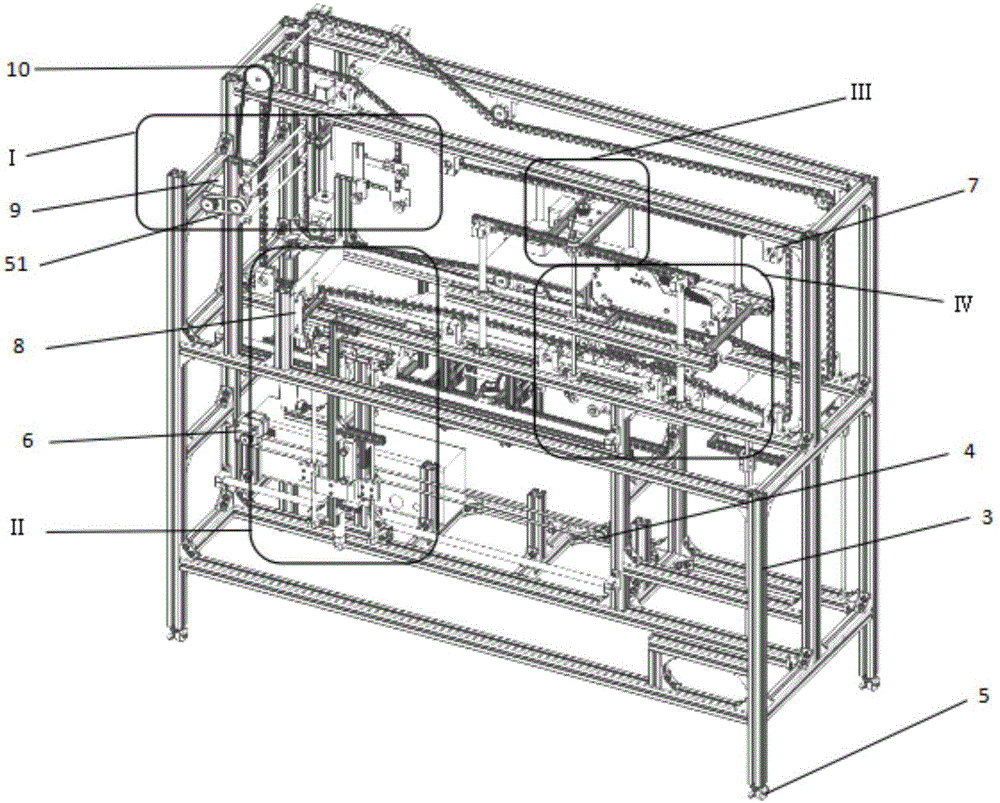

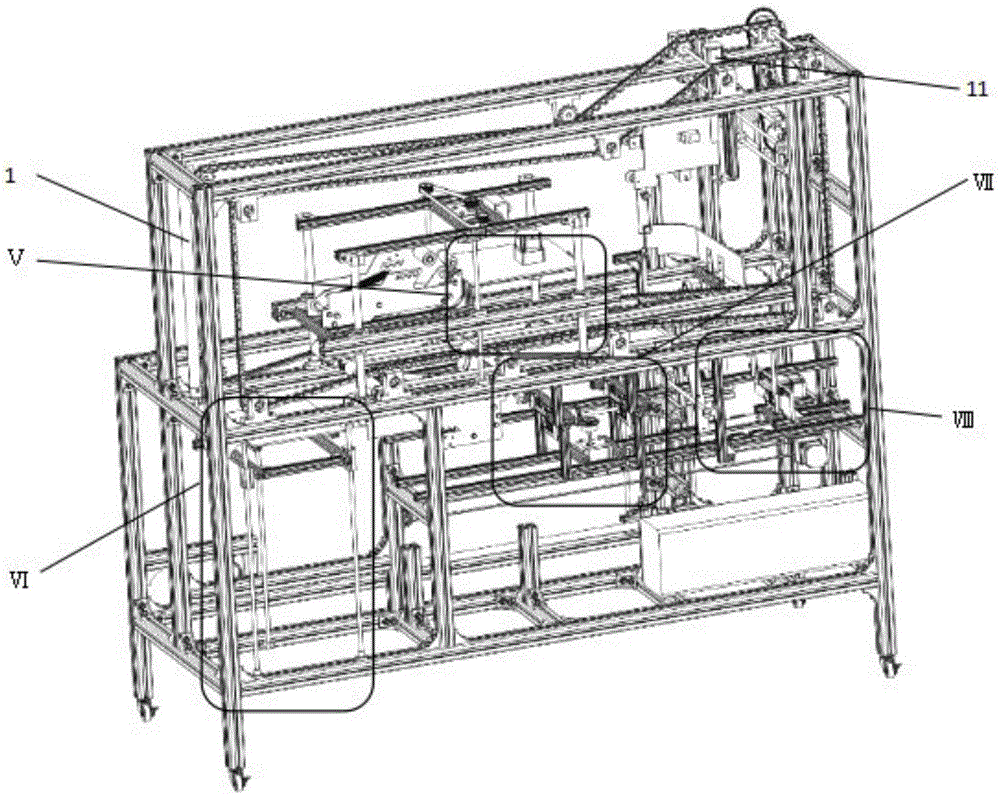

[0030] Such as figure 1 , 2, 3, 4, 5, 6, 7, 8, and 9 show automatic packaging equipment for multi-model express cartons, including box selection module II, box opening module I, bottom cover closing module VIII, clamping module VII, top Lid closing module V, linkage module III, sealing module IV, conveying module VI, limit switch 25 and frame 3, the box selection module II, unpacking module I, bottom cover closing module VIII, clamping module VII, top cover closing module V, linkage module III, sealing module IV, conveying module VI, and limit switch (25) are connected by industrial aluminum profiles and fixed on the frame.

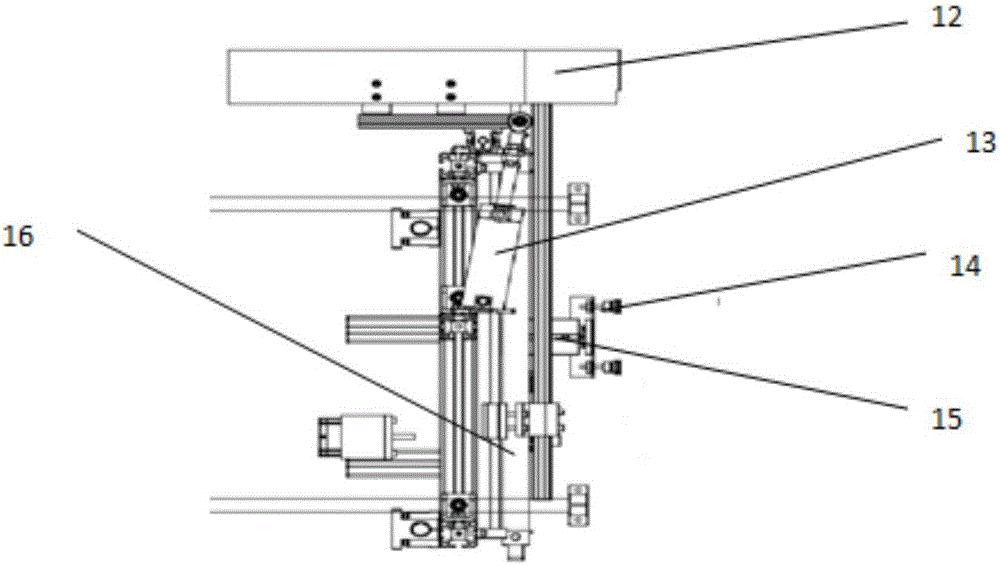

[0031] Further, the box selection module II includes a motor 1 (6), a synchronous belt 1 (4), a lifting cylinder (16), a box selection cylinder (15), a box selection suction cup (14), and the box selection cylinder (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com