Beading cave pretreatment construction method

A construction method and pretreatment technology, which is applied in the direction of foundation structure engineering, soil protection, sheet pile walls, etc., can solve the problems of high cost, inconvenient construction, limitations, etc., to ensure filling degree, simple and efficient process, and avoid quality The effect of the accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

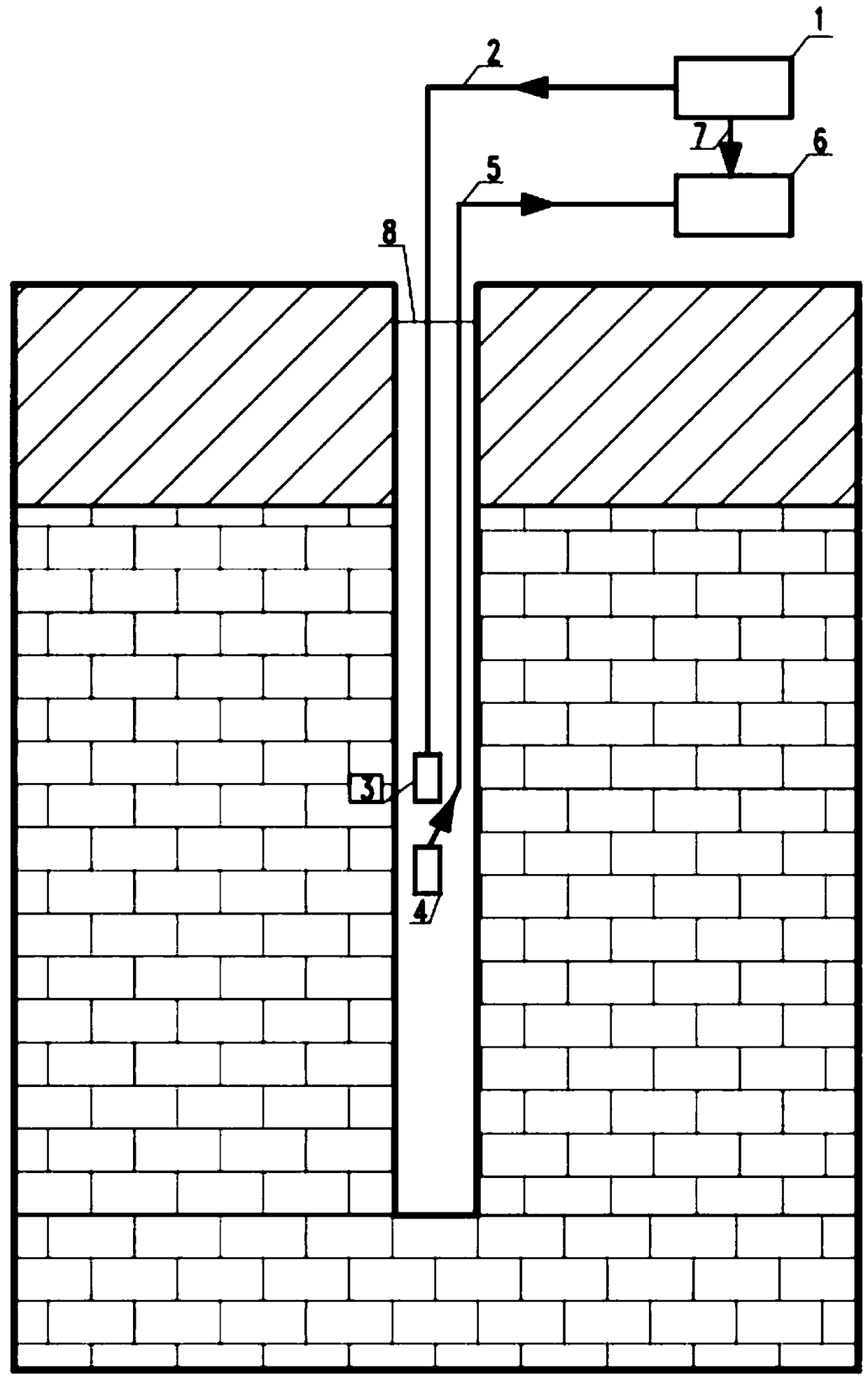

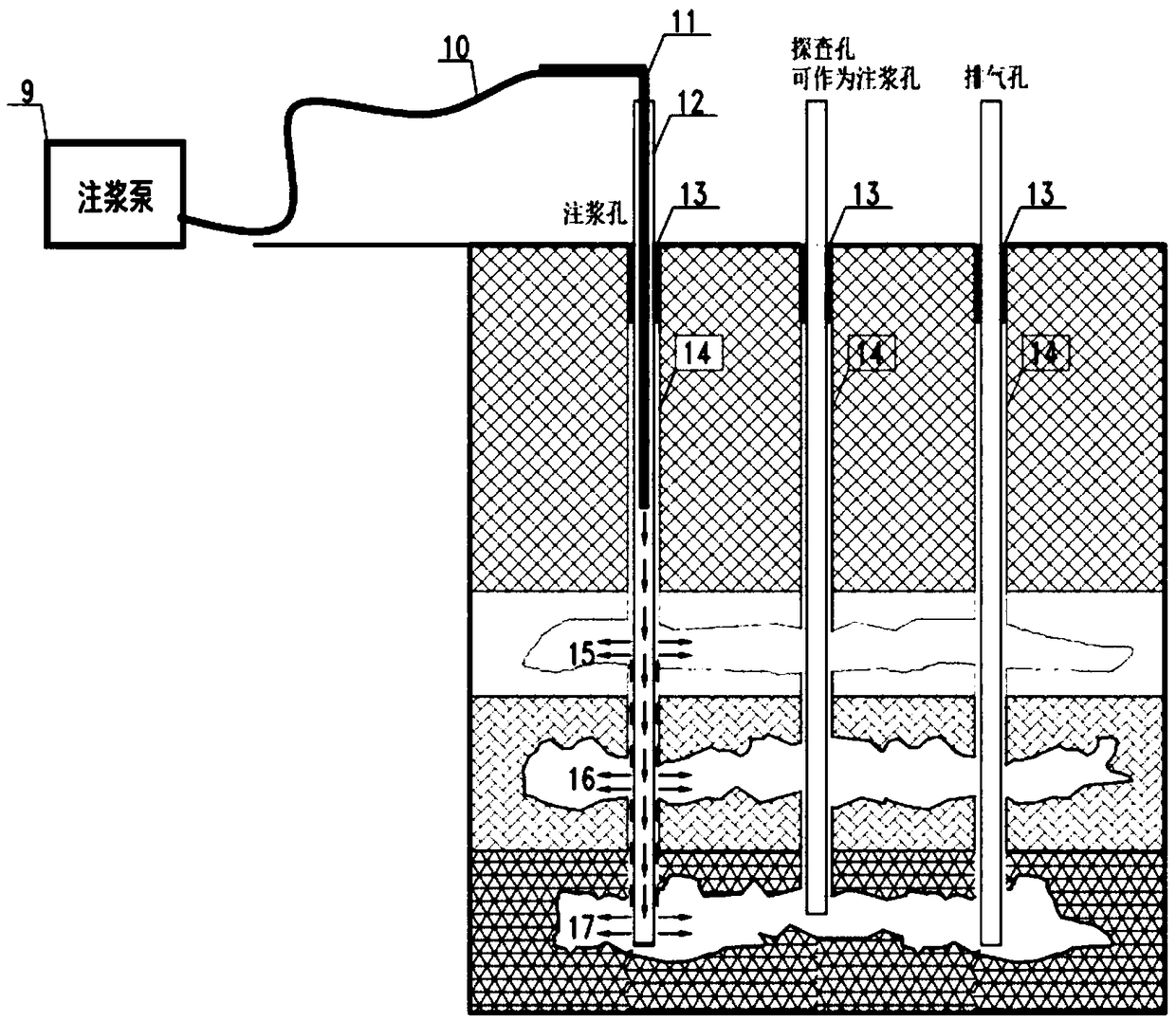

[0021] refer to figure 1 with figure 2 , the present embodiment provides a construction method for pretreatment of beaded karst caves, the specific method is as follows:

[0022] The advanced drilling method and tube wave detection method are used to detect the beaded karst caves, and the advanced drilling rig is used to drill the pile positions in the areas where the karst caves have been proven to form advanced drilling holes 14. Three drilling holes are tentatively designated for exploration and injection. Slurry and exhaust; pre-embed 48*3 thick sleeve valve pipe 12, the sleeve valve pipe 12 is made of PVC, and a group of 4Φ8mm grouting holes are opened every 330mm on the sleeve valve pipe 12 in the grouting section of the cave. The longitudinal length is 60mm, and each group of grouting holes is wrapped with a layer of rubber sleeve, which is 80mm long, and is wrapped when the sleeve valve tube 12 is lowered to ensure that the grouting hole is just at the corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com