Tobacco shred mark distribution station

A technology for distributing stations and grades, which is applied in the fields of tobacco, paper cigarettes, and conveyors, etc. It can solve the problems of large area occupied by the switching operation platform, no pipe butt joint detection function, and a large workload for pipe clamp removal, so as to reduce the eddy current The possibility of reducing space and preventing quality accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

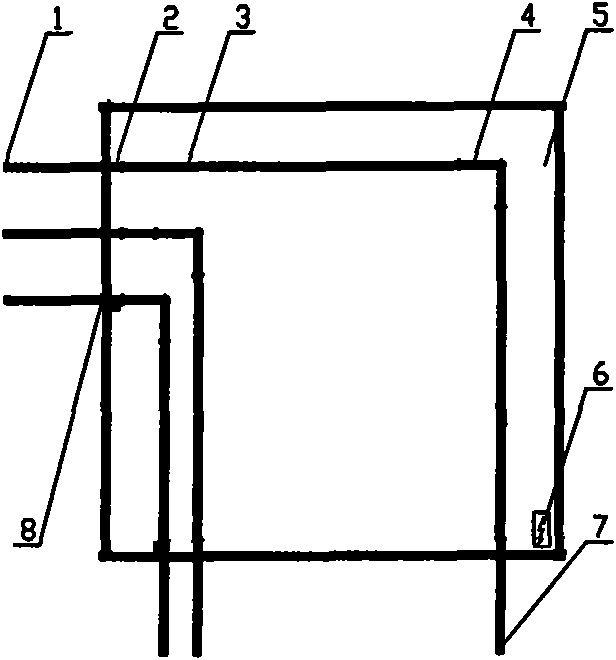

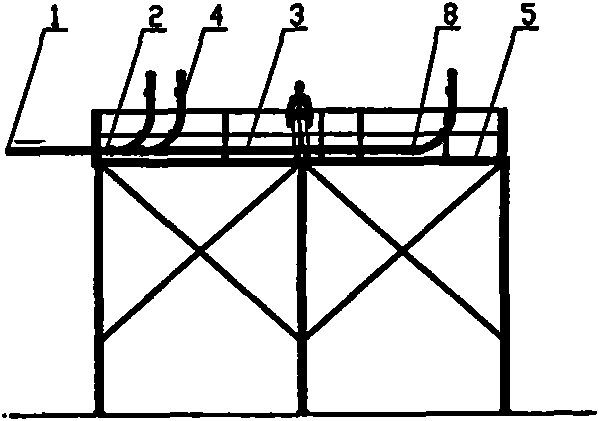

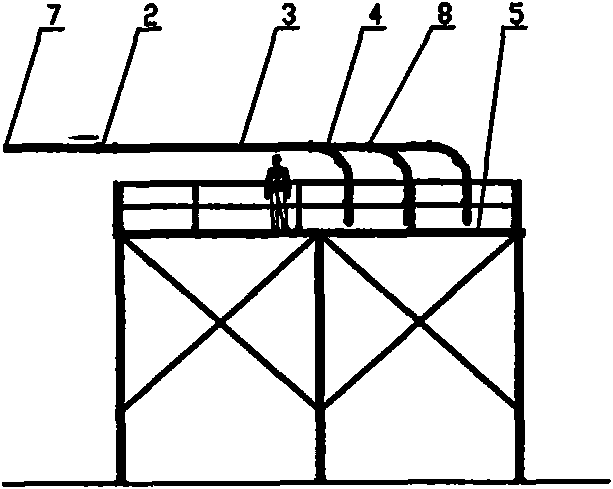

[0019] A shredded tobacco grade distribution station, including a manual grade distribution station, an automatic grade distribution station, and a control station 6. The manual grade distribution station includes a pipe 7 from a cigarette maker and a shredded tobacco conveying pipe from a pneumatic shred distribution machine, respectively. 1 connected connecting pipes. The pipeline 1 from the pneumatic wire distribution machine and the pipeline 7 from the cigarette machine are laid to the switch work platform 5, and fixedly connected with the positioning straight pipe 2 with a stainless steel fast fixing clamp 8. When grade distribution is required, the control The station 6 accepts the command of the corresponding relationship of the pipe switching, and the operator selects two switching straight pipes 3 and switching elbows 4, and connects them with a stainless steel fast fixing clamp 8. The control station 6 collects the position information after the detection pipeline is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com