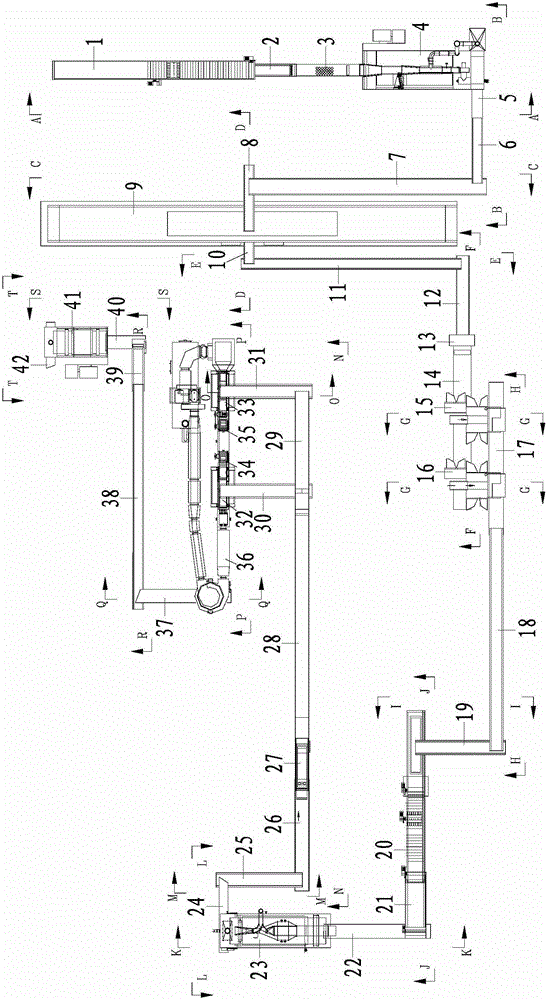

Expanded shredded tobacco processing line

A technology for expanding shredded tobacco and a production line, which is applied in the directions of tobacco, tobacco preparation, tobacco processing, etc., can solve the problems of increasing shredded tobacco, low shredded tobacco expansion rate, and poor effect of maintaining the aroma of shredded tobacco, so as to ensure processing quality and prevent burning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The expanded shredded tobacco processing production line provided by this specific embodiment can continuously process expanded shredded tobacco, does not need manual handling during the entire production process, effectively reduces the amount of crushing, and the shredded tobacco processed by this production line has a high expansion rate and the shredded tobacco aroma is maintained. The effect is better.

[0056] A kind of expanded shredded tobacco processing production line provided in this specific embodiment includes:

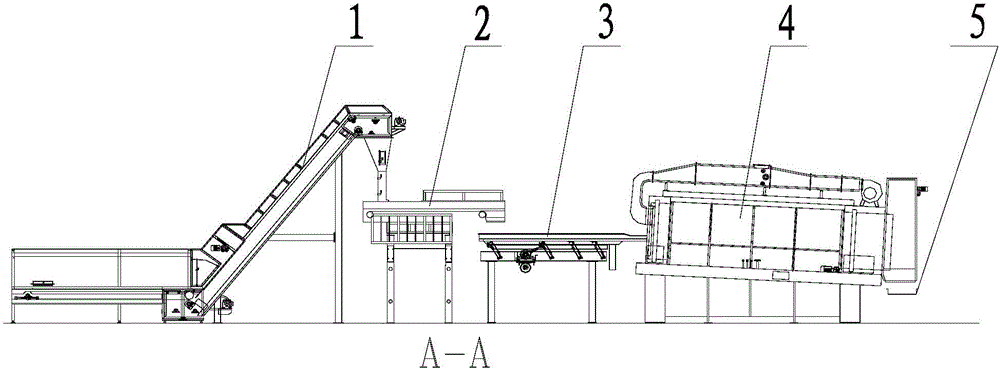

[0057] A first feeder and a first electronic belt scale, the first feeder includes a first bin and an output device for quantitatively outputting tobacco leaves, the first electronic belt scale is connected to the output end of the output device connect;

[0058] The first vibrating conveying device, the tobacco leaves are conveyed to the first vibrating conveying device through the first electronic belt scale;

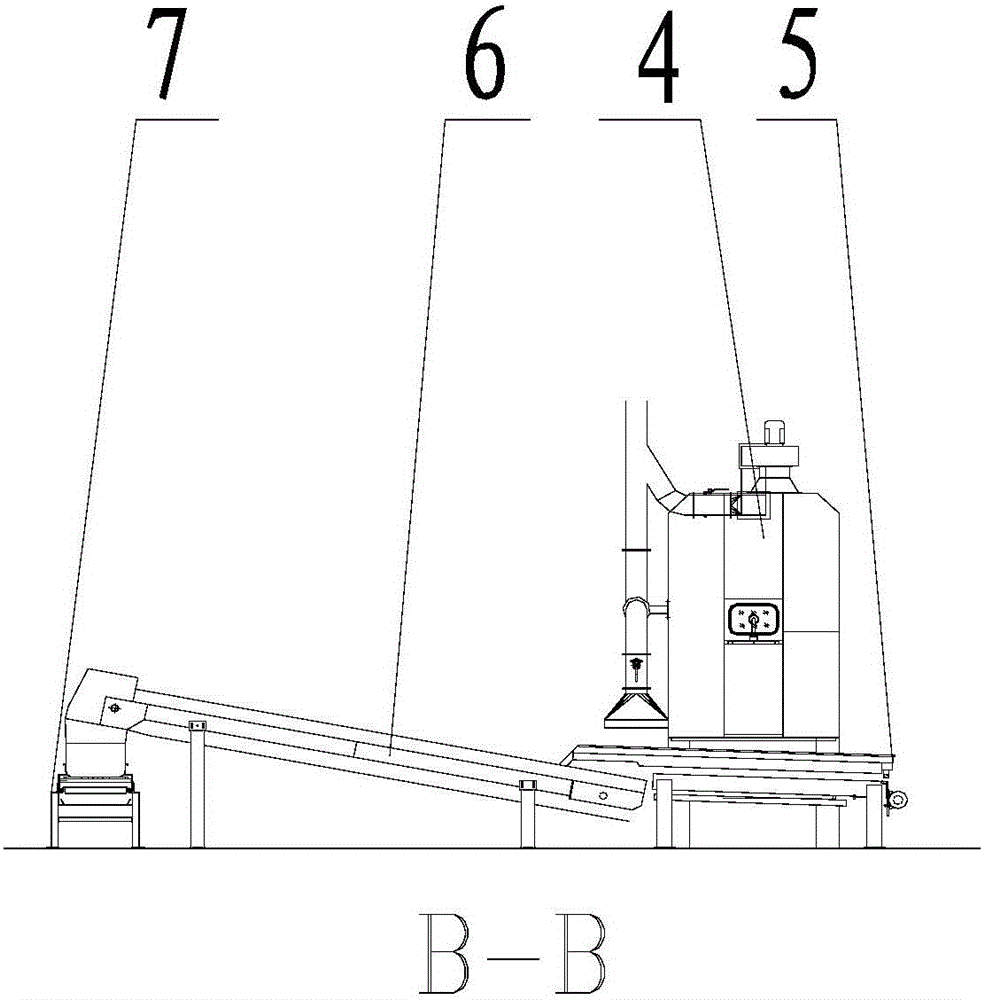

[0059] Drum type dampening feedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com