Method for testing light/chlorinated water composite color fastness of textiles

A test method and technology of chlorinated water, applied in chemical method analysis, weather resistance/light resistance/corrosion resistance, measuring device, etc., to achieve the effect of improving economic benefits, preventing quality accidents, and improving market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

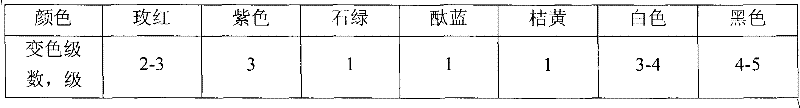

[0009] Press nylon ammonia fabrics of different colors according to (available chlorine concentration: 20mg / L, fabric soaking time: 30min, fabric carrying liquid rate 100%, light irradiation amount 85KJ / m 2 ·nm) Under this process condition, the compound color fastness test of light fastness and chlorinated water is carried out, if see the following table 1:

[0010] Table 1 Composite color fastness to light and chlorinated water of different fabrics

[0011]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com