Cantilever beam supporting device and preparation method thereof

A support device and cantilever beam technology, which is applied in the direction of signal devices, power devices, transportation and packaging, etc., can solve problems such as easy breakage and self-heavyness, and achieve the effects of eliminating quality accidents, good fatigue performance, and avoiding quality risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

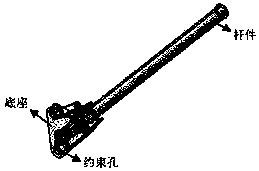

[0044] Such as figure 1 As shown, the cantilever beam supporting device of this embodiment includes a base and a rod connected to the base. The base is provided with several holes for fixing the supporting device on the frame of a car, for example. The thickness of the base can be set between 10-50mm. The number of holes is preferably 3-4. A number of metal gaskets can be added or removed in the hole. The rod is also provided with a number of fixed wings, which can be used to fix the supported parts. The number of wing plates is preferably 3 or more, for example 3-5. The width of the wing plate can be designed to be about 60mm. The rod is preferably tubular, the outer diameter of the tube can be between 40-100mm, and the thickness of the tube wall can be between 2-12mm.

[0045] The following describes the preparation of the overall molding method such as figure 1 The method of the cantilever beam support device is shown.

[0046] Step 1: Plasticize the resin through a...

Embodiment 2

[0054] This embodiment is prepared in an integral molding manner by molding and injection molding. figure 1 Basically the same structure as the method of cantilever beam support device.

[0055] Step 1: Prepare a thermoplastic continuous fiber-reinforced nylon composite material sheet with a continuous fiber weight content of 55%, wherein the fiber is a basalt continuous fiber.

[0056] Step 2: Prepare fiber-reinforced nylon composite pellets with good fluidity with a fiber weight content of 50% by melt dipping and pultrusion, wherein the fiber is glass fiber with a length of about 80mm.

[0057] Step 3: Cut the sheet prepared in step 1, put it into an oven to bake and heat, the baking temperature is 280°C, and the baking time is 1min to soften the material, and then put it into a mold.

[0058] Step 4: Bake the pellets prepared in step 2 at 120°C for 2 hours, control the moisture content below 0.2%, then vacuum-introduce the material into the hopper, and inject the mold into...

Embodiment 3

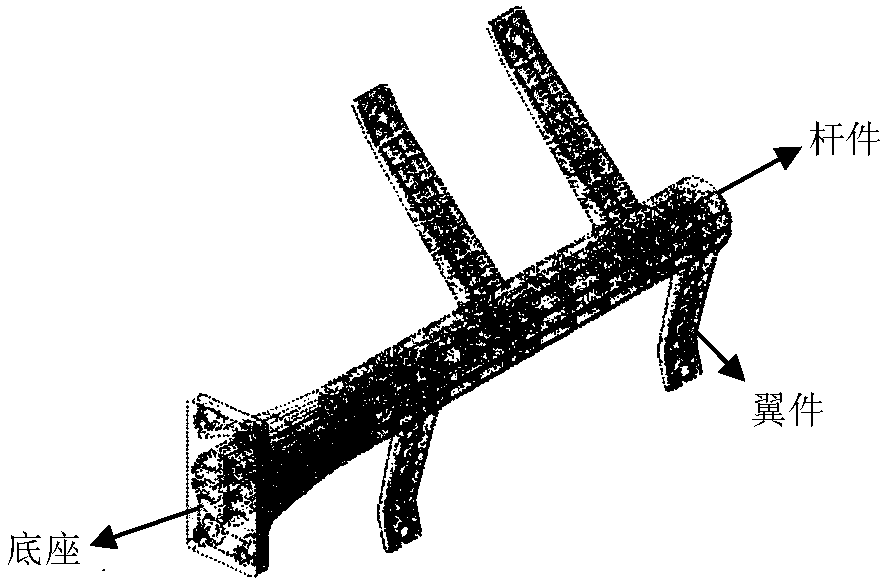

[0063] Such as figure 2 As shown, the cantilever beam supporting device in this embodiment includes a base and a rod, and the rod is inserted into the base to form a connection. Adhesives such as epoxy or polyurethane adhesives can be used to secure the rods to the base. The base is provided with several holes for fixing the supporting device on the frame of a car, for example. A number of metal gaskets can be added or removed in the hole. The thickness of the base can be set between 20-200mm. The number of holes is preferably 3-4. The rod is preferably tubular, the outer diameter of the tube can be between 40-100mm, and the thickness of the tube wall can be between 2-12mm.

[0064] In this embodiment, the base rods are manufactured separately, and then assembled into such figure 2 The cantilever beam support shown. In particular, in this embodiment, the fiber-reinforced epoxy resin is used to mold the base, and the fiber-reinforced epoxy resin is wound or extruded to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com