Porous NiAl/Al2TiO5 composite material and preparation method thereof

A composite material and porous material technology, which is applied in the field of material synthesis and processing, can solve the problem of limited application fields, small adjustment ranges of porosity and thermal expansion coefficient of porous materials, and it is difficult to meet the high temperature resistance, thermal conductivity and thermal conductivity of automobile exhaust purifier carriers. Thermal shock resistance comprehensive performance requirements and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The first step: powder raw material preparation

[0055] Prepare industrially pure Ni, Al, TiO 2 、Al 2 o 3 , C powder raw materials, including Ni, TiO 2 、Al 2 o 3 , C powder particle size is 200 mesh, Al powder particle size is 100 mesh.

[0056] Step Two: Al 2 TiO 5 powder synthesis

[0057] TiO 2 、Al 2 o 3 Powder according to molar ratio TiO 2 : Al 2 o 3 = 1: 1 (mol) weighing, mixed on a planetary ball mill for 4 hours, packed into a mould, adopted a compression molding method, and applied a pressure of 50MPa to make a cylindrical compact of Φ20mm and a height of 20mm. Put the green compact in a resistance furnace for sintering, the sintering process is 1450℃×2h, and the product Al is first obtained through the sintering reaction 2 TiO 5 , and then the sintered Al 2 TiO 5 The green body is crushed and ball milled into a powder with a particle size of 200 mesh for later use;

[0058] The third step: Ni+Al powder preparation

[0059] Weigh the Ni and...

Embodiment 2

[0070] The difference with Example 1 is that in the ratio of raw materials Al 2 TiO 5 The content is 20%, namely (Ni+Al):Al 2 TiO 5 (wt%)=80:20; the carbon powder content is 10% of the total mass of the reaction system, and the reaction in the whole compact is completed within 5 to 7 seconds. The relevant properties of the product are shown in Table 2.

[0071] Table 2

[0072] Raw material ratio (Ni+Al): Al 2 TiO 5 (wt%)

Embodiment 3

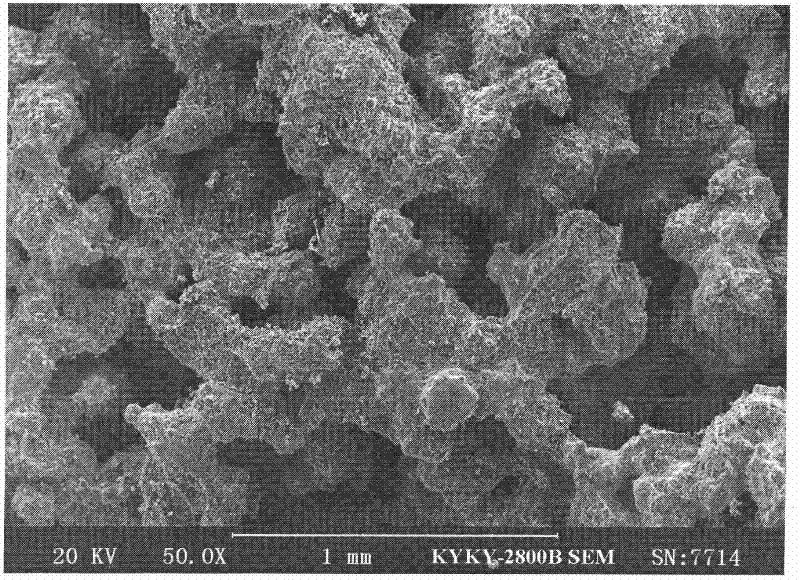

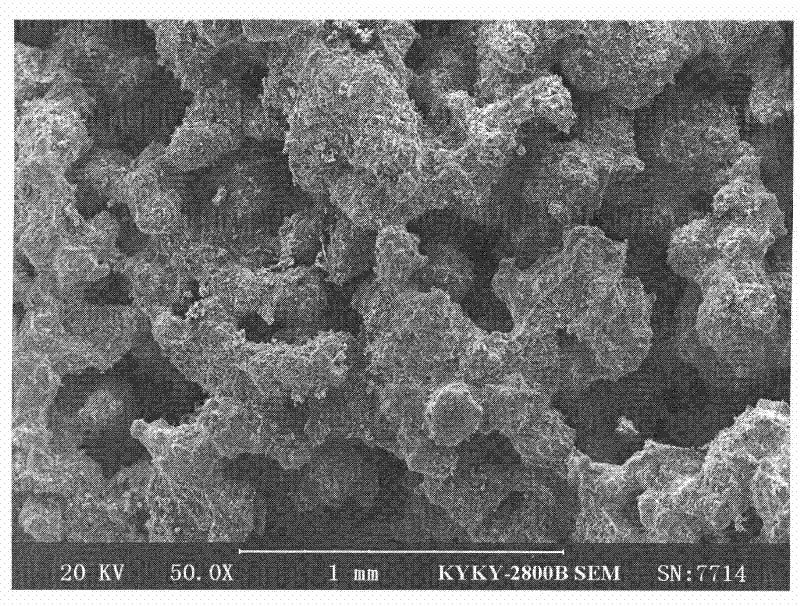

[0074] The difference with Example 2 is that in the ratio of raw materials Al 2 TiO 5 The content is 30%, namely (Ni+Al):Al 2 TiO 5 (wt%)=70:30, the relevant properties of the product are shown in Table 3, and the microscopic appearance of the product is shown in figure 2 .

[0075] table 3

[0076] Raw material ratio (Ni+Al): Al 2 TiO 5 (wt%)

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com