Dimeric fatty acid diamine, preparation method and method for preparing dimeric fatty acid diisocyanate

A technology of dimer fatty acid diisocyanate and dimer fatty acid diamine, which is applied in the field of chemical synthesis of materials, can solve problems such as difficult industrial production, and achieve the effect of simple and feasible process, easy implementation and pure product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

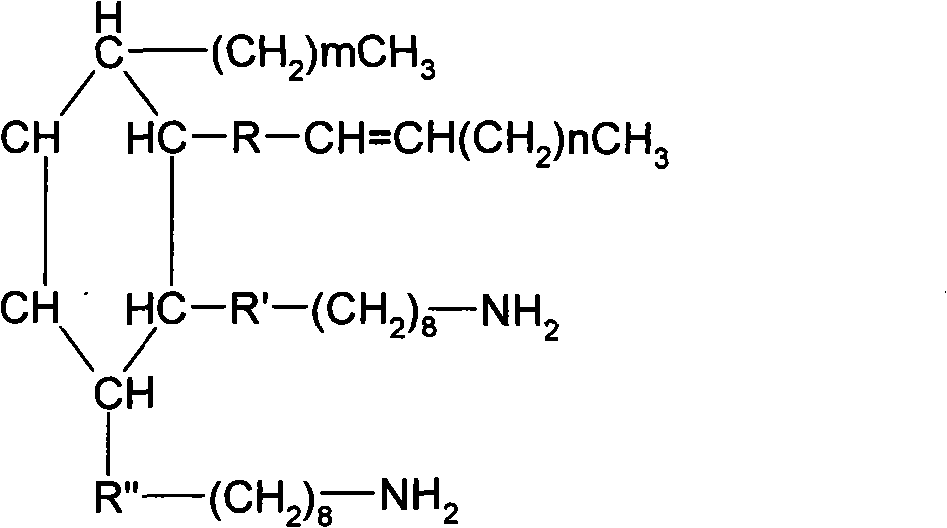

[0028] Preparation of dimer fatty acid diamine:

[0029] Under ice-salt bath cooling conditions, 60 g of ether reaction medium diethyl ether, 3.7 g of metal hydride reducing agent sodium borohydride and 5.6 g of dimer fatty acid diamide were added into the reaction flask. After mixing, the ice-water bath was removed and replaced with a heating water bath, and the reaction mixture was heated to reflux step by step, and reacted for 30 hours. Extracted 4 times with dichloromethane, using 20g of dichloromethane each time, after the extraction was completed, the extracts were combined.

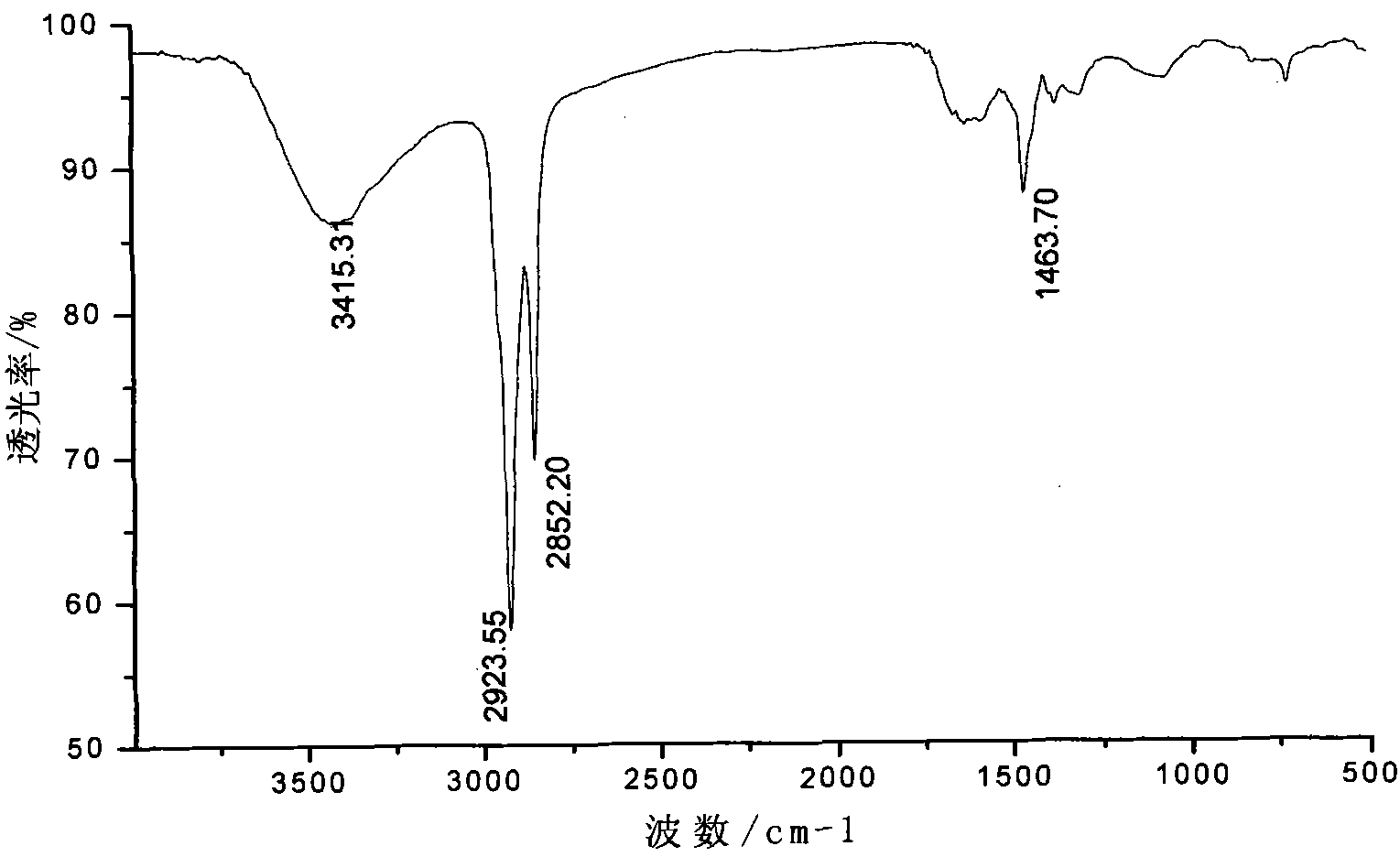

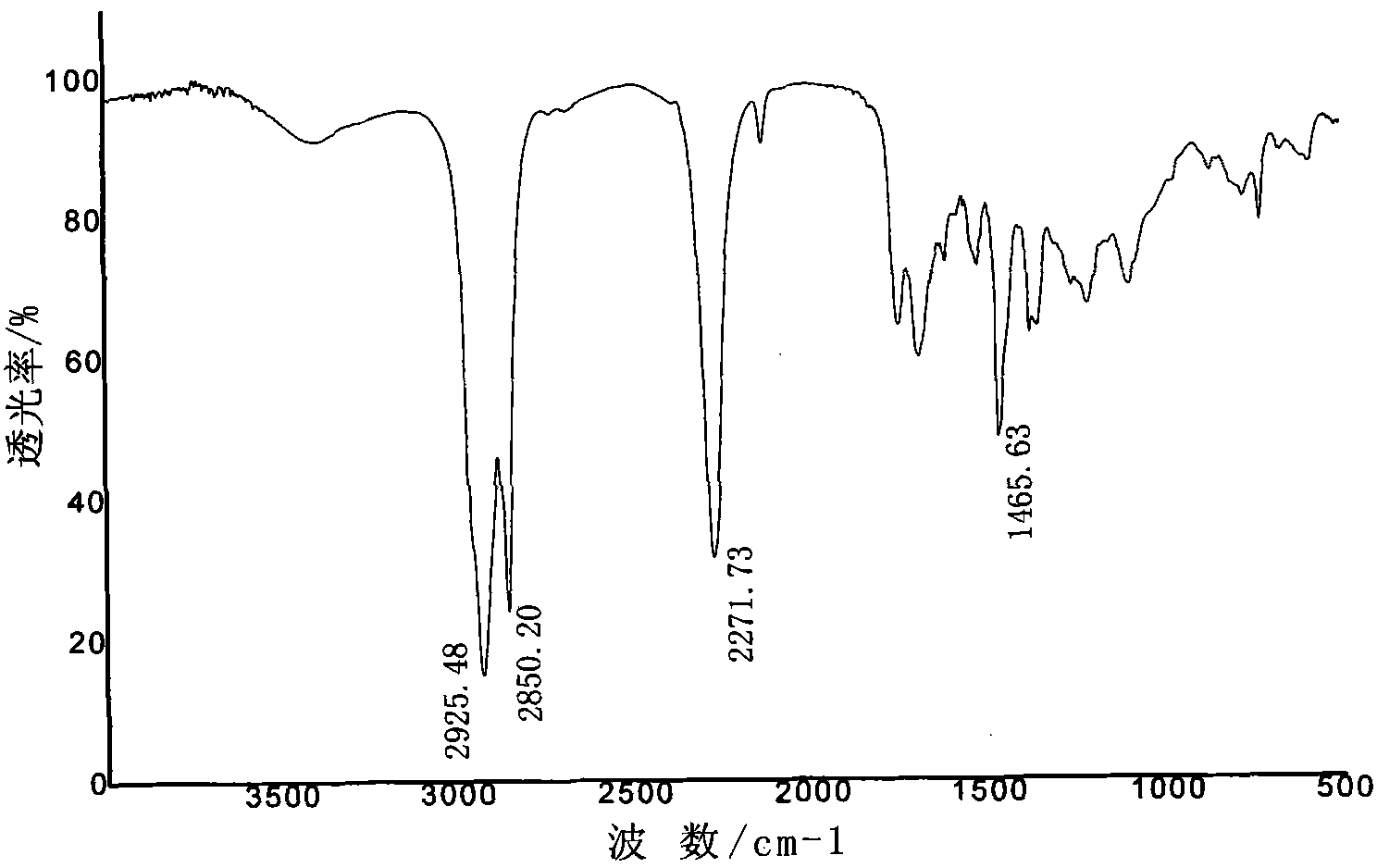

[0030] The combined extracts were washed twice with water, and the amount of water used for each wash was 20 g. Dry with 5 g of anhydrous sodium sulfate for 3 hours. Then add 5g of active carbon and decolorize for 15 minutes. Finally, methylene chloride was removed by vacuum distillation. The temperature of the vacuum distillation was 40° C., and the vacuum degree was 10 mmHg. After 40 minutes o...

Embodiment 2

[0043] Under cooling in an ice-salt bath, 60 g of tetrahydrofuran, 3.8 g of lithium aluminum hydride, and 5.6 g of dimer fatty acid diamide were added to the reaction flask. After the addition, the ice-water bath was removed and replaced with a heating water bath, and the reaction mixture was heated to reflux step by step, and reacted for 48 hours. Extract with ethylene dichloride 4 times, use 20g ethylene dichloride each time, after the extraction is completed, combine the extracts.

[0044] The combined extracts were washed twice with water, and the amount of water used for each wash was 20 g. Dry with 5 g of anhydrous sodium sulfate for 3 hours. Then add 5g of active carbon and decolorize for 15 minutes. Finally, dichloroethane was removed by vacuum distillation to obtain dimer fatty acid diamine. The vacuum distillation temperature was 50° C., and the vacuum degree was 10 mmHg. After 50 minutes of distillation, no solvent was distilled out, and the distillation was stopp...

Embodiment 3

[0049] Under cooling in an ice-salt bath, 60 g of tetrahydrofuran, 5.3 g of potassium borohydride and 5.6 g of dimer fatty acid diamide were added to the reaction flask. After the addition, the ice-water bath was removed and replaced with a heating water bath, and the reaction mixture was heated to reflux step by step, and reacted for 48 hours. Extract with chloroform 4 times, use 20g chloroform each time, combine extract solution after extraction finishes.

[0050] The combined extracts were washed twice with water, and the amount of water used for each wash was 20 g. Dry with 5 g of anhydrous sodium sulfate for 3 hours. Then add 5g of active carbon and decolorize for 15 minutes. Finally, chloroform was removed by vacuum distillation to obtain dimer fatty acid diamine. The vacuum distillation temperature was 50° C., and the vacuum degree was 10 mmHg. After 50 minutes of distillation, no solvent was distilled out, and the distillation was stopped. A light yellow liquid prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com