Cigarette weight control calibration system

A technology of weight control and calibration system, which is applied in the fields of tobacco, cigarette manufacturing, application, etc., can solve quality accidents, rely on weight control systems, affect corporate brand image and other issues, and achieve the effect of avoiding quality accidents and maintaining corporate image

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

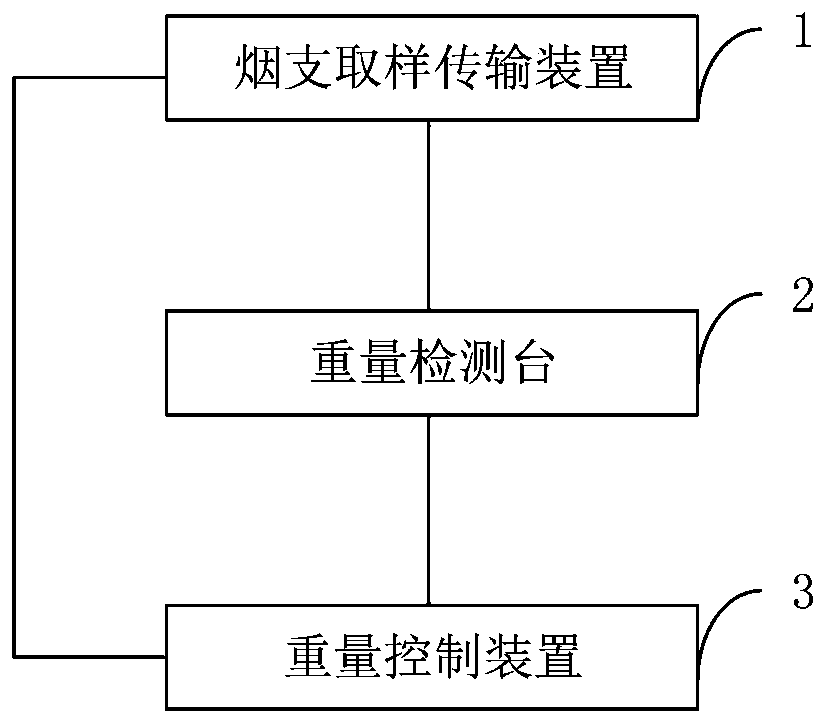

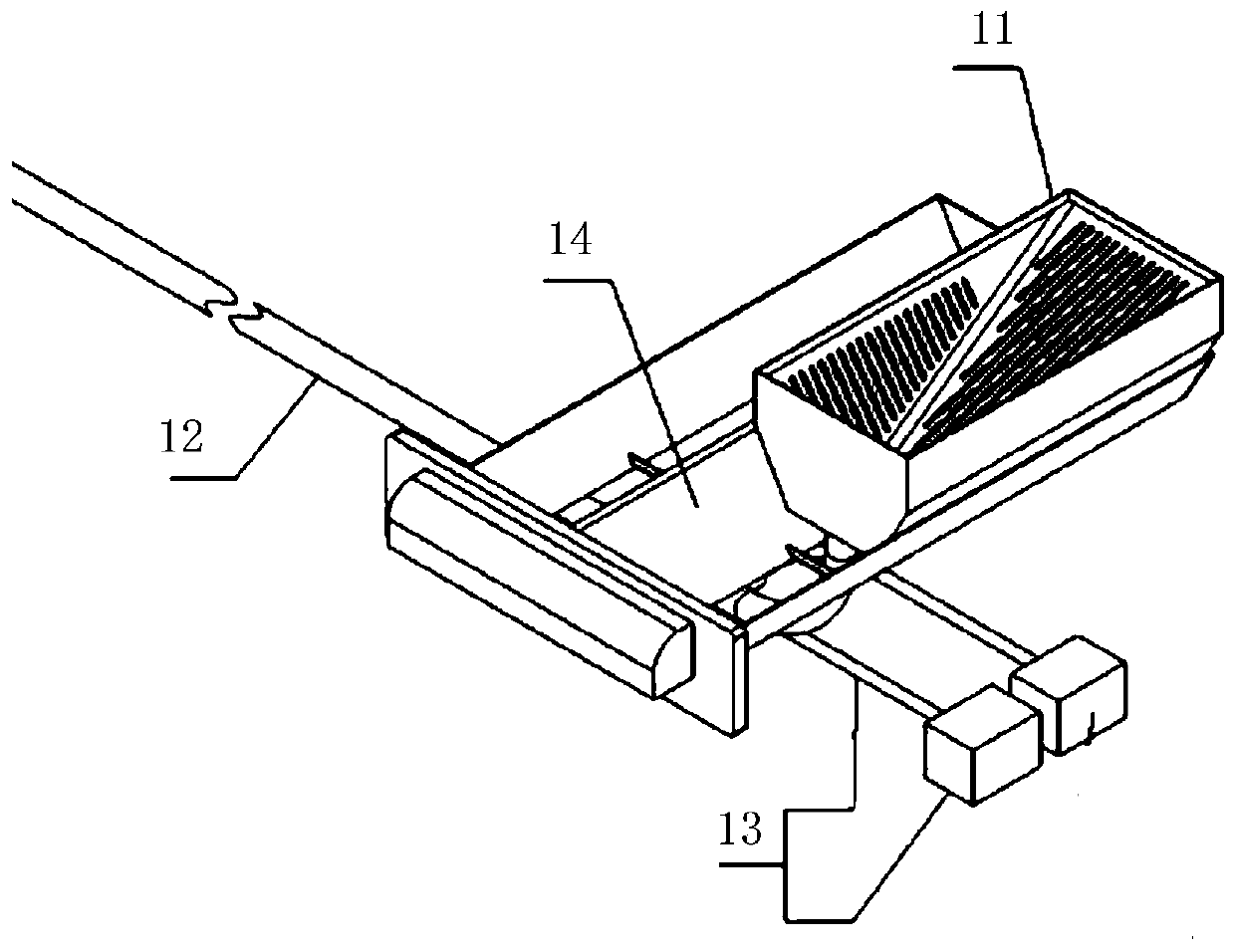

[0043] figure 1 It is a structural schematic diagram of a cigarette weight control calibration system provided by an embodiment of the present invention. like figure 1 As shown, this embodiment provides a cigarette weight control and calibration system, including: a cigarette sampling transmission device, a weight detection platform, and a weight control device;

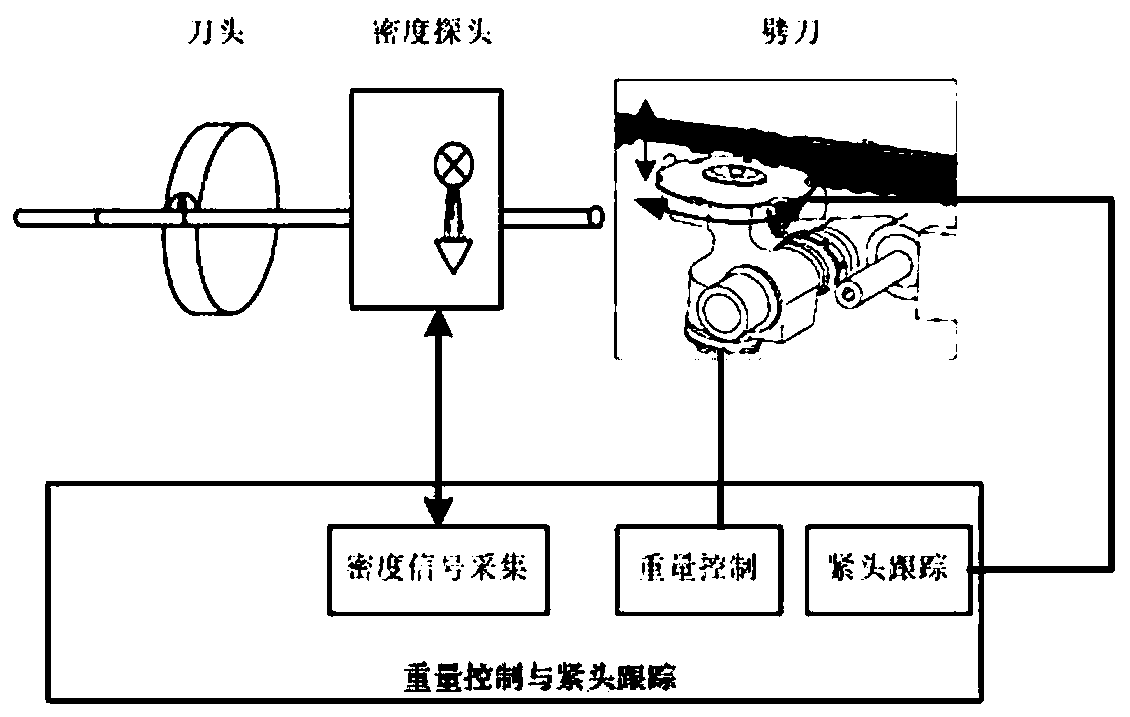

[0044] The weight control device is used to detect the weight of the cigarette, obtain the first weight value, and send a sampling signal to the cigarette sampling transmission device;

[0045] The cigarette sampling transmission device is used to receive the sampling signal sent by the weight control device, extract the cigarette and transmit it to the weight detection station;

[0046] The weight detection station is used to detect the weight of the cigarette, obtain a second weight value, and send the second weight value to the weight control device;

[0047] The weight control device is further configured to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com