An abrasive belt grinder capable of improving the grinding quality of the abrasive belt grinder and its use method

A belt grinder, grinding technology, applied in the direction of belt grinder, grinding machine, grinding/polishing equipment, etc., can solve the problem of not directly detecting the rotation speed of the workpiece, the feed speed, the rapid separation function cannot be accurately adjusted, and there is no rapid separation and other issues, to achieve obvious economic and social benefits, simple structure, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

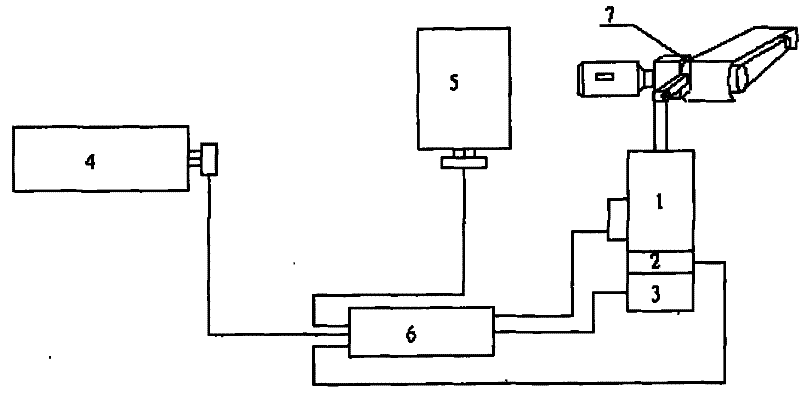

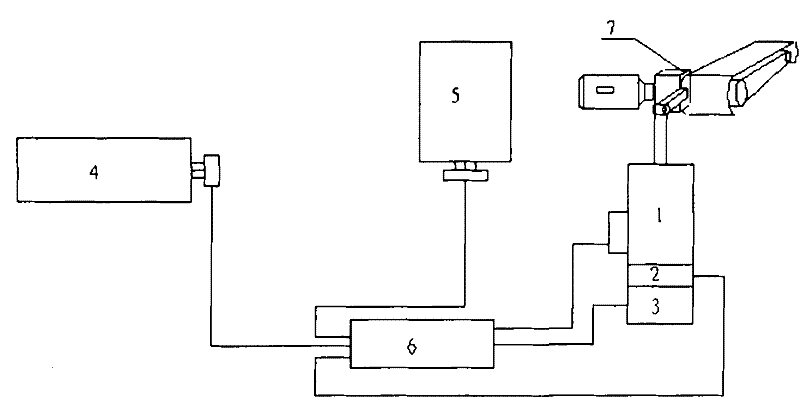

[0014] like figure 1 As shown, a kind of abrasive belt grinder of the present invention can improve abrasive belt grinder grinding quality, comprises PLC control system 6 and grinding head 7, executive cylinder 1, electric push rod 3, and tension pressure sensor controller 2, described The execution cylinder, electric push rod and tension pressure sensor controller are connected as a whole and connected with the grinding head. The execution cylinder, electric push rod and tension pressure sensor controller are respectively connected with the PLC control system, and the PLC control system is connected with Feed speed sensor 5 and rotation speed sensor 4.

[0015] In the present invention, the execution cylinder, tension pressure sensing controller, and electric push rod are connected as a whole, and connected with the grinding head, and the execution cylinder and electric push rod jointly control the abrasive belt: the fast clutch between the abrasive belt and the workpiece is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com