Method for preparing electroplated diamond grinding wheel with orderly arranged abrasive materials

An electroplating diamond, orderly arrangement technology, applied in electrolytic coatings, liquid chemical plating, metal material coating processes, etc., can solve the problems of short service life, small abrasive blade height, and small abrasive holding force of electroplated diamond grinding wheels. Achieve the effect of increasing service life, improving grinding quality, and avoiding workpiece burns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

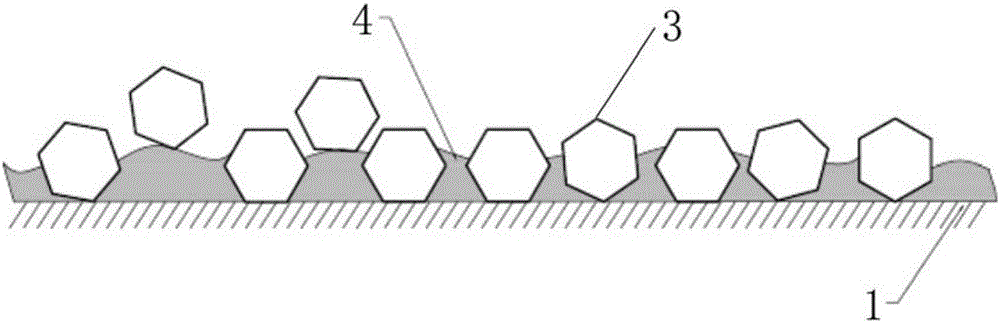

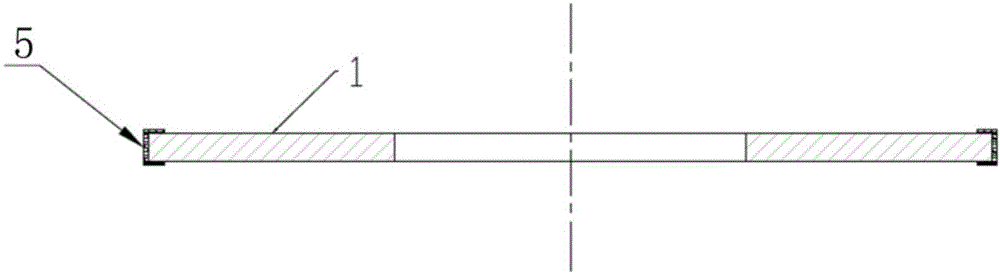

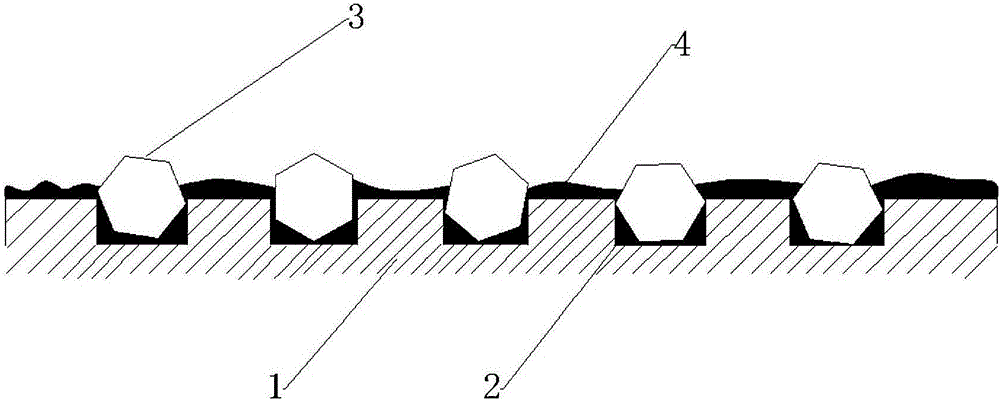

[0039] The electroplated diamond grinding wheel that the abrasive material of the present embodiment arranges orderly, as figure 2 , 3 As shown, it includes a grinding wheel substrate 1 and an abrasive layer 5, and the surface of the grinding wheel substrate 1 is provided with blind holes 4 arranged in an orderly manner; the abrasive layer 2 includes a diamond abrasive 3 and a metal coating 4, and the root of the diamond abrasive 3 is inlaid In the blind hole 4 , a metal plating layer 4 is deposited on the surface of the grinding wheel base 1 and in the blind hole 2 , for consolidating the abrasive 3 in the blind hole 2 .

[0040] Wherein, the particle size number of the diamond abrasive is 30 / 35, and the average particle diameter of the abrasive is 550 μm; the embedding rate of the abrasive is set to be 50% respectively. The diameter of the blind hole is 0.6mm, the depth is 0.15mm, and the hole spacing is 1.0mm; the thickness of the metal (nickel) coating is 23% of the aver...

Embodiment 2

[0060] The electroplated diamond grinding wheel with abrasives arranged in order in this embodiment comprises a grinding wheel substrate and an abrasive layer, and the surface of the grinding wheel substrate is provided with orderly arranged blind holes; the abrasive layer includes diamond abrasives and a metal coating, and the diamond abrasives The root is embedded in the blind hole, and the metal coating 4 is deposited on the surface of the grinding wheel substrate and in the blind hole, for consolidating the abrasive in the blind hole.

[0061] Wherein, the particle size number of the diamond abrasive is 30 / 35, and the average particle diameter of the abrasive is 550 μm; the embedding rate of the abrasive is set to 40%. The diameter of the blind hole is 0.6 mm, the depth is 0.15 mm, and the hole spacing is 1.0 mm; the thickness of the metal (nickel) coating is 12.7% of the average grain size of the abrasive, that is, 70 μm.

[0062] The preparation method of the electroplat...

experiment example

[0075] In this experimental example, the service life of the electroplated diamond grinding wheel obtained in Examples 1 and 2 is detected. The detection method is: the electroplated diamond grinding wheel of embodiment 1, 2 and comparative example 1, 2 is installed on the same deburring machine tool, the processed workpieces are all automobile engine cylinder blocks (gray cast iron material), both adopt the same grinding Technology, after several deburring processing tests, the service life is characterized by the average number of processed workpieces. Among them, comparative examples 1 and 2 are electroplated diamond grinding wheels prepared by traditional technology (burying sand method), and the substrate specification size, abrasive grain size, embedding rate and electroplating process parameters are the same as those of examples 1 and 2 respectively.

[0076] By the formula t=δγ / K·i c η (where γ—metal density; δ—coating thickness; η—cathode current efficiency, value 95...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com