Solar crystalline silicon rod splicing glue and preparation method thereof

A splicing glue and solar energy technology, applied in adhesives, non-polymer organic compound adhesives, etc., can solve the problems of environmental moisture sensitivity, poor storage stability, and poor impact toughness, so as to avoid quality accidents and improve bonding strength and impact toughness, improving the positioning time of the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

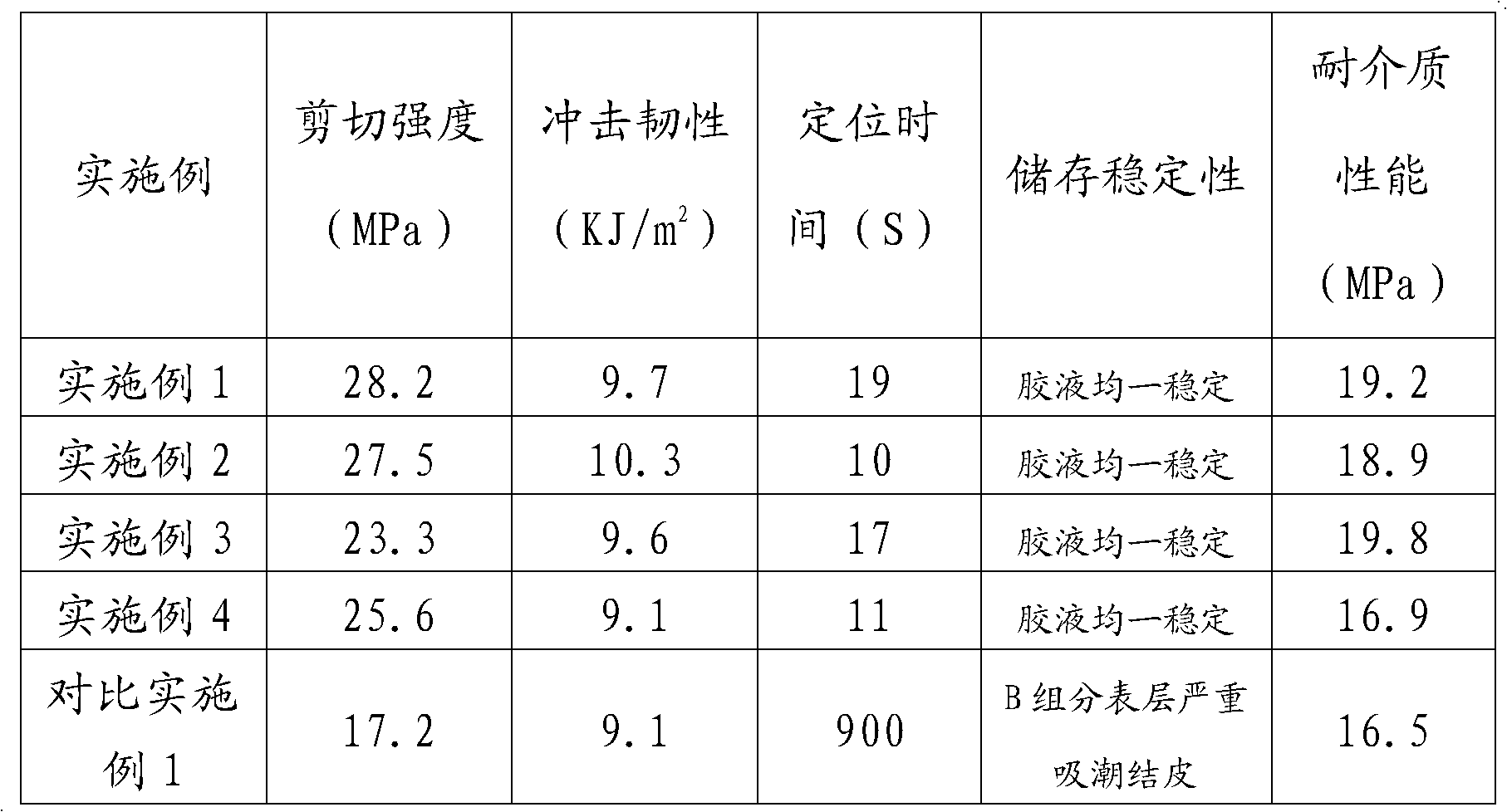

Examples

Embodiment 1

[0029] Accurately weigh the following raw materials: 67 parts of ethoxylated bisphenol A dimethacrylate, 15 parts of tetraethylene glycol polyacrylate, and 0.02 parts of 1,4-naphthoquinone, add them into a double planetary power mixing mixer and mix evenly , then add 0.5 parts of N,N-dimethylaniline and 0.3 parts of saccharin, and heat up to 40°C. Under the condition that the rotation speed of the double planetary power mixer is 500 rpm and the revolution speed is 8 rpm, Mechanically stir for 0.5 hours to completely dissolve, then quickly cool down to room temperature, add 3 parts of benzoyl peroxide, and then add 2 parts of A-187 coupling agent, stir for 1 hour, then vacuum for 10 minutes, and the vacuum degree reaches - 0.1MPa. After discharging, the anaerobic glue solution for splicing solar crystal silicon rods of the present invention is obtained, which is packaged and placed for use.

[0030] Accurately weigh the components of the surface accelerator as follows: add 0.2...

Embodiment 2

[0032] Accurately weigh the following raw materials: 60 parts of bisphenol A epoxy acrylate, 20 parts of ethoxylated bisphenol A dimethacrylate, 10 parts of hydroxyethyl methacrylate, 0.02 parts of hydroquinone and add double planetary power Mix evenly in the mixing mixer, then add 0.2 parts of triethylamine and 0.1 parts of saccharin, heat up to 60°C, under the condition that the rotation speed of the double planetary power mixing mixer is 500 rpm and the revolution speed is 8 rpm, Mechanically stir for 0.5 hours to completely dissolve, then quickly cool down to room temperature, add 2 parts of cumene hydroperoxide, and then add 1 part of A-187 coupling agent, stir for 1 hour, then vacuumize for 10 minutes, and the vacuum degree reaches -0.08MPa. After discharging, the anaerobic glue solution for splicing solar crystal silicon rods of the present invention is obtained, which is packaged and placed for use.

[0033] Accurately weigh the components of the surface accelerator a...

Embodiment 3

[0035] Accurately weigh the following raw materials: 10 parts of ethoxylated bisphenol A dimethacrylate, 20 parts of polyurethane modified diester acrylate, 30 parts of 2-phenoxyethyl acrylate, 0.01 part of p-benzoquinone Mix evenly in the power mixing mixer, then add 0.8 parts of triethanolamine and 0.5 parts of saccharin, and heat up to 50°C. Under the condition that the rotation speed of the double planetary power mixing mixer is 500 rpm and the revolution speed is 8 rpm, Mechanically stir for 0.5 hours to completely dissolve, then quickly cool down to room temperature, add 1 part of tert-butyl peroxybenzoate, and then add 4 parts of A-187 coupling agent, stir for 1 hour, then vacuum for 10 minutes, the vacuum degree to -0.06MPa. After discharging, the anaerobic glue solution for splicing solar crystal silicon rods of the present invention is obtained, which is packaged and placed for use.

[0036] Accurately weigh the components of the surface accelerator as follows: 1 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com