Construction method for round underground continuous wall two-in-one structure

A construction method and circular technology, which can be applied to underwater structures, infrastructure engineering, construction, etc., can solve the problems that restrict the development and promotion of circular deep underground garages, increase construction period and cost, and high cost of foundation pit support. To achieve the effect of reducing the amount of earth excavation, reducing support costs and improving excavation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Here, the inner surface of the steel sheet pile refers to the side surface of the steel sheet pile in the direction toward the support center.

[0051] A method for constructing a circular underground continuous two-wall integrated structure, comprising the following steps:

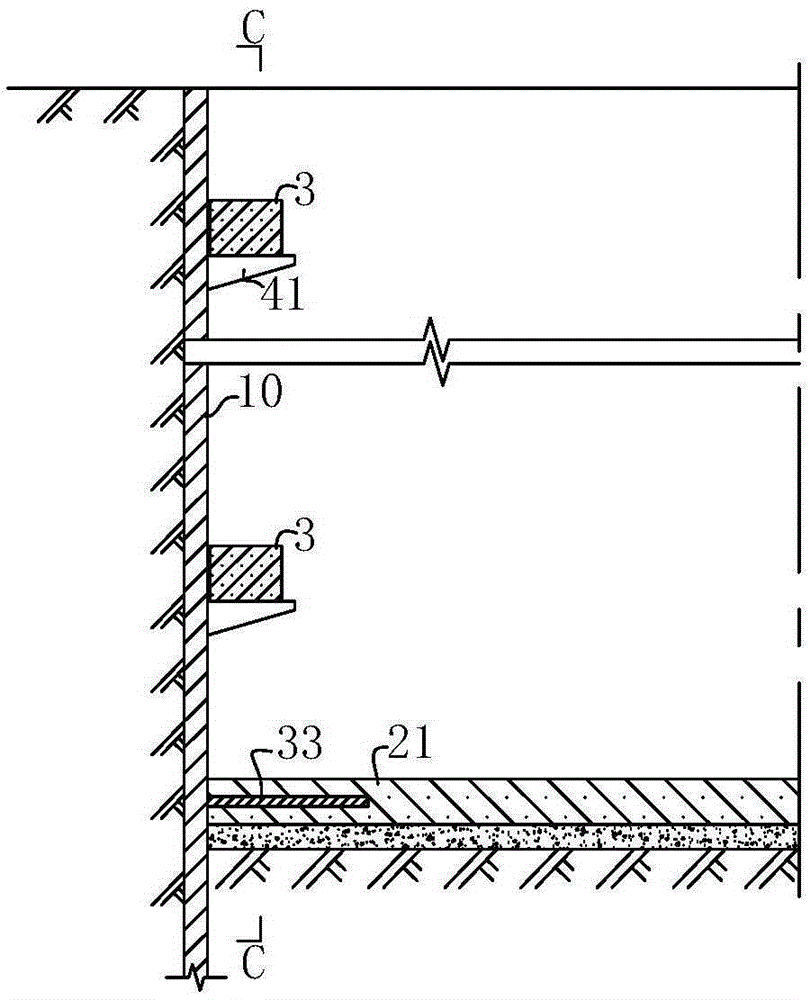

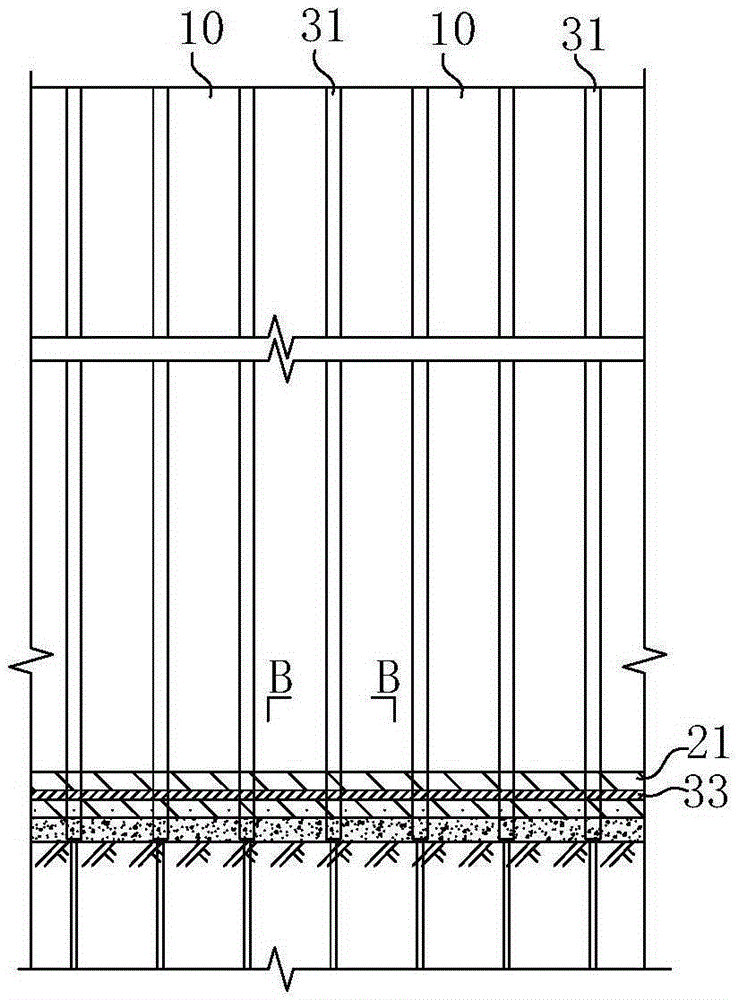

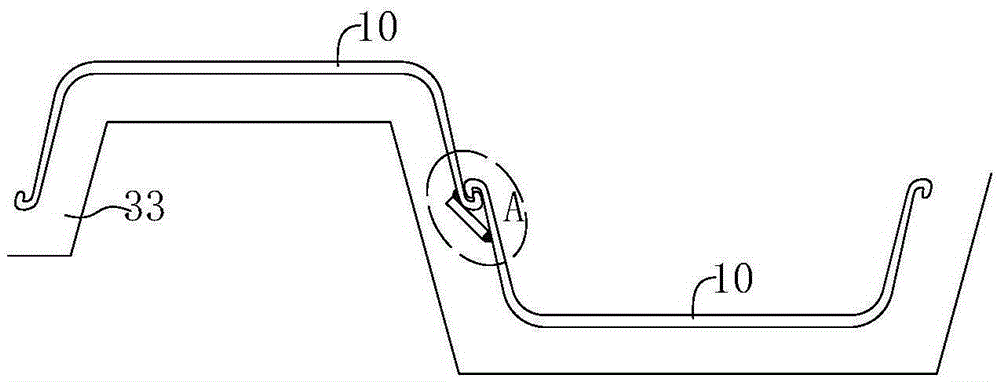

[0052] (1) see Figure 5 with Image 6 , prefabricated corbel steel sheet pile 4: three steel corbels 41 are welded on the outer surface 45 of the web 44 of each U-shaped steel plate 42 to make the corbel steel sheet pile 4, and the supporting surface 46 of the steel corbel 41 It is perpendicular to the length direction of the U-shaped steel sheet pile 42; at the same time, the circular reinforced concrete purlin 3 is prefabricated in sections; the surface of the supporting steel sheet pile 2 and the corbel steel sheet pile 4 is treated with anticorrosion; The web forms the opposite side of the surface of the groove 43 of the U-shaped sheet pile 42;

[0053] (2) Pile sinking: Sink the selected s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com