Monitoring system and method for sand blasting machine

A monitoring system and sandblasting machine technology, applied in the field of sandblasting machines, can solve the problems that sandblasting parameter data cannot be stored in large quantities, sandblasting machine failures are not easy to be found, and sandblasting machine failure rates are high, so as to improve the first pass rate, Good guiding significance and the effect of improving production tempo

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

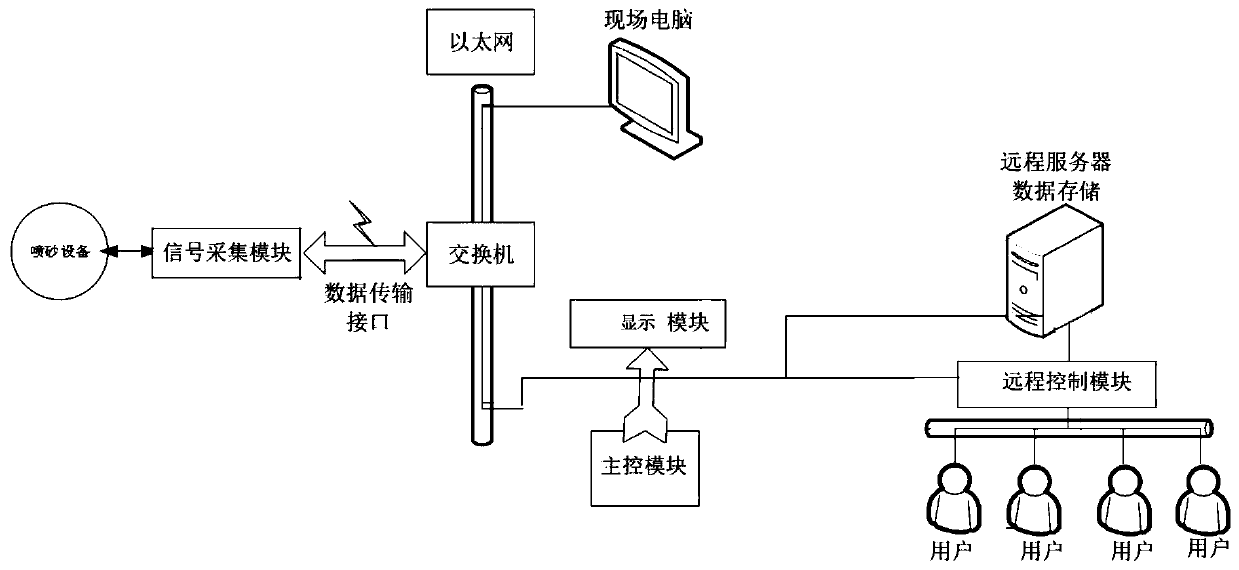

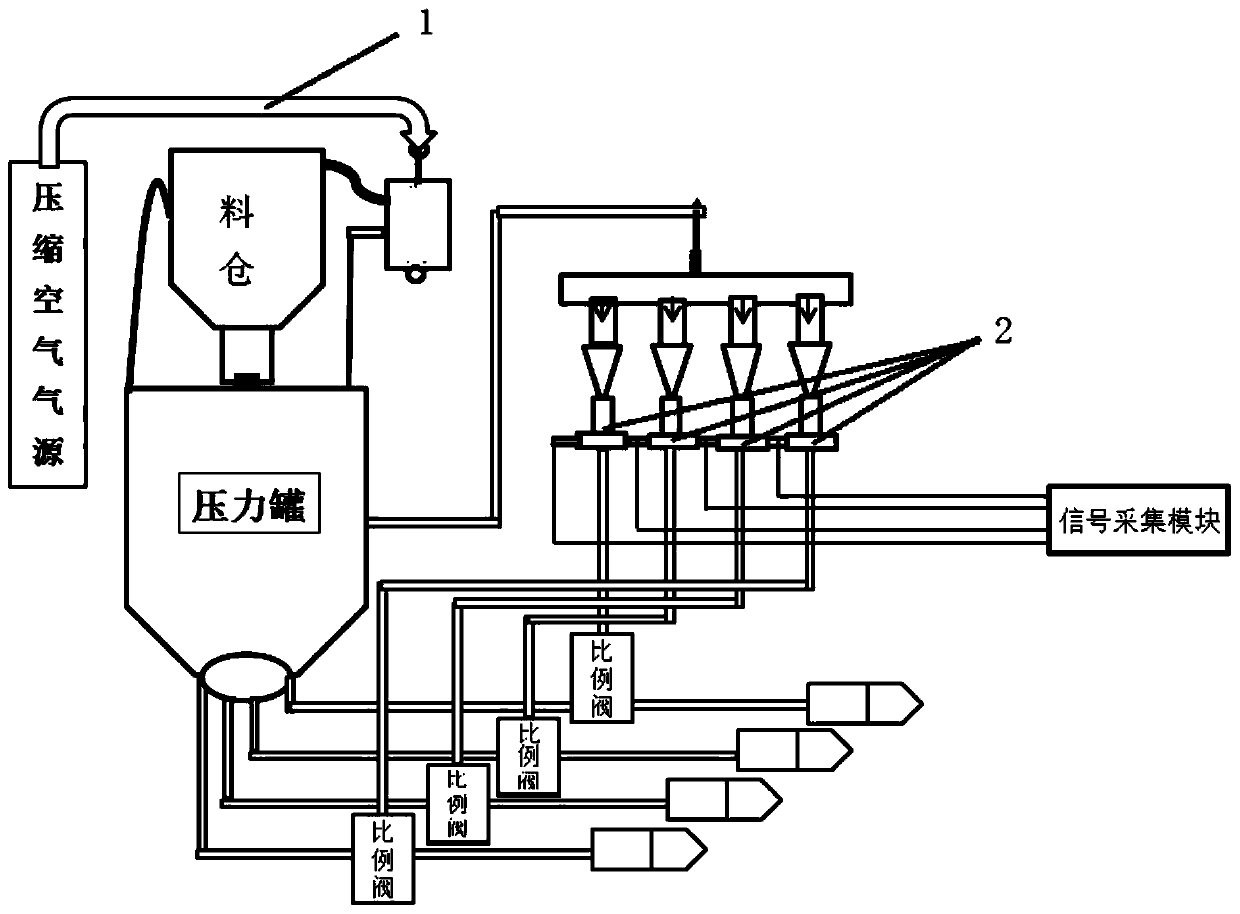

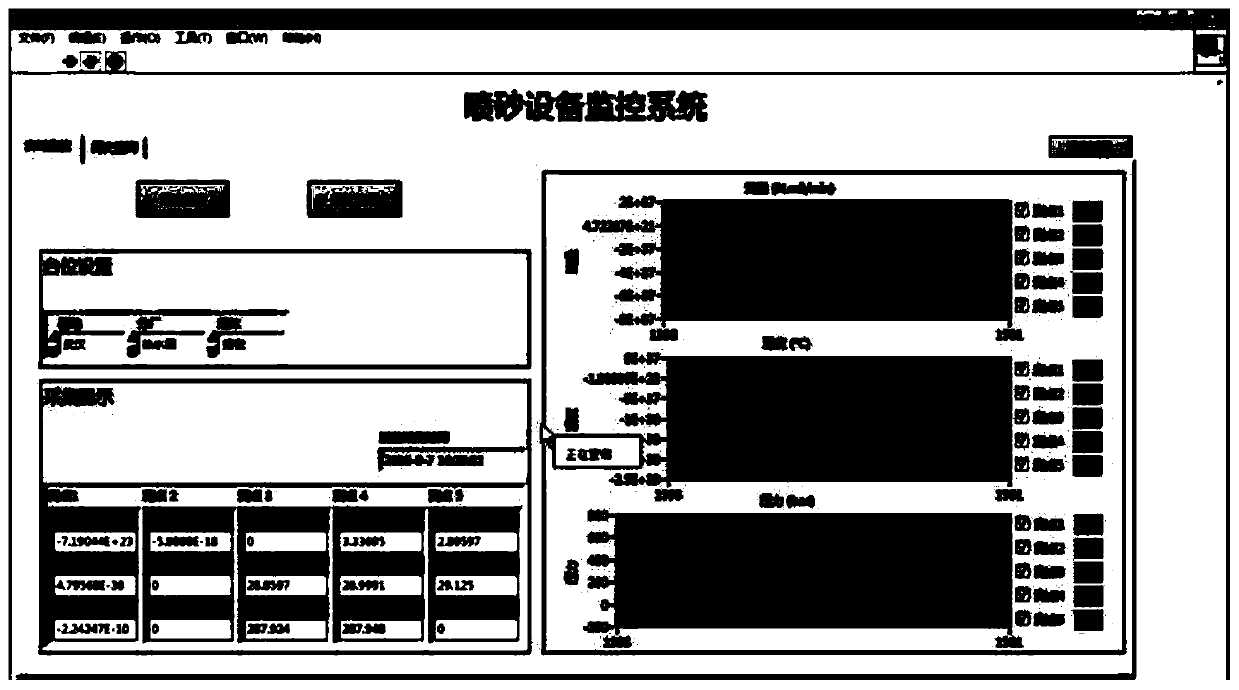

[0032] The system block diagram of the monitoring system of the present embodiment is as attached figure 1 As shown, including the flow meter and signal acquisition module, the flow meter can measure the sandblasting machine (ie figure 1 Sandblasting equipment) pressure, flow, temperature and other related process parameters, the flow meters are respectively set on each measuring point on the main air intake pipeline and air branch pipeline of the sandblasting machine, and the signal acquisition module collects the data of each measuring point , the digital signal is transmitted to the main control module through the data transmission interface for processing, and the main control module configures different addresses for the flowmeters of different measurement points, and completes the data of different measurement points in a cyclic reading manner; for example image 3 As shown, the specific display is the pressure, flow, and temperature of different measuring points. In ord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com