Patents

Literature

296 results about "First pass yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

First pass yield (FPY), also known as throughput yield (TPY), is defined as the number of units coming out of a process divided by the number of units going into that process over a specified period of time. Only good units with no rework or scrap are counted as coming out of an individual process.

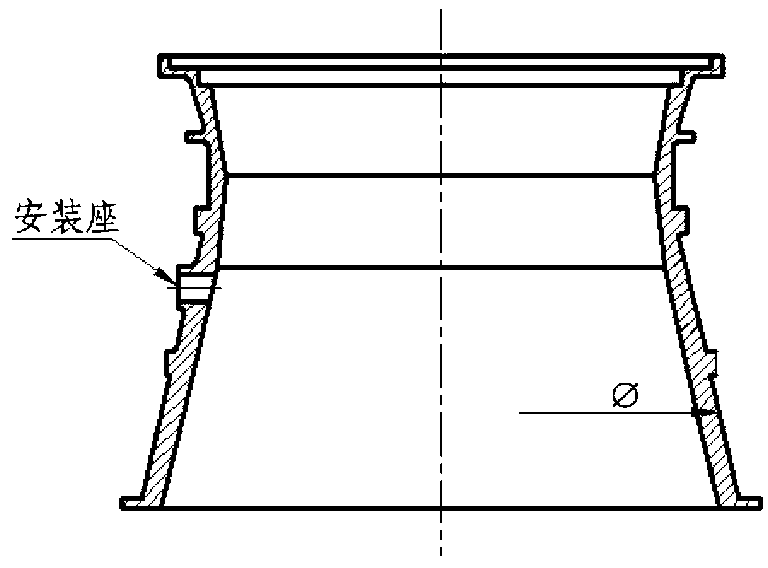

Method for detecting diameter of outer wall of tapered case of aviation engine on line

InactiveCN102927952AGuaranteed accuracyReduce manufacturing costMeasurement devicesNumerical controlAviation

The invention discloses a method for detecting the diameter of an outer wall of a tapered case of an aviation engine on line. According to the method, a five-coordinate numerical control milling center with a Renishaw MP10 trigger-type measuring head is equipped, tapered case parts and a mounting seat on the surface of a tapered case are equipped; a fine adjustment ring gauge of the used measuring head is measured on line; a point contact-type measurement mode is adopted; a machine tool siemens control system Sinumeric 840 D on-line measurement technology is adopted; and an on-line measurement quick tool path amendment and error compensation generation technology is adopted. The method has a broad application prospect; and by the on-line measurement technology, a numerically-controlled machine tool is impelled to form a machining and detecting integrated numerical control machining unit. By the method, the traditional manufacturing mode that a design characteristic is equipped with a set of measurement tool in the current industry is changed, the manufacturing cost of the tool is saved, repair labor-hour is saved, and first-pass yield of product processing is improved, so that the development period and the production cost of new products are reduced.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

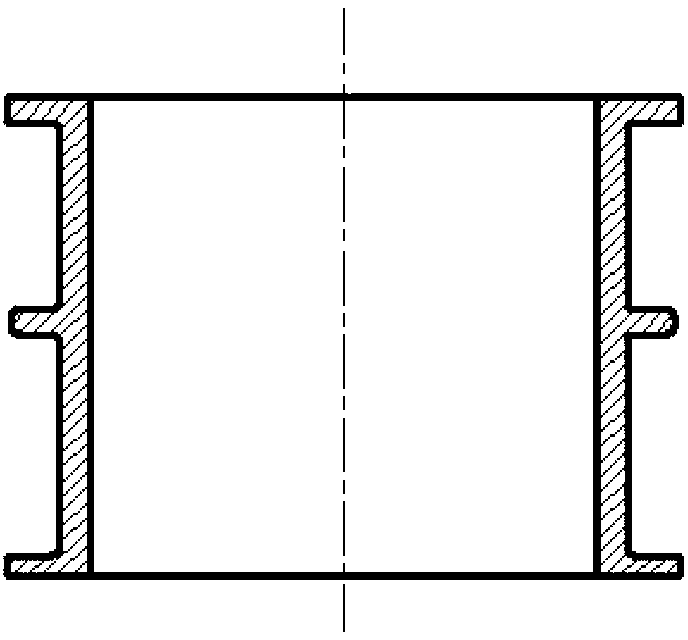

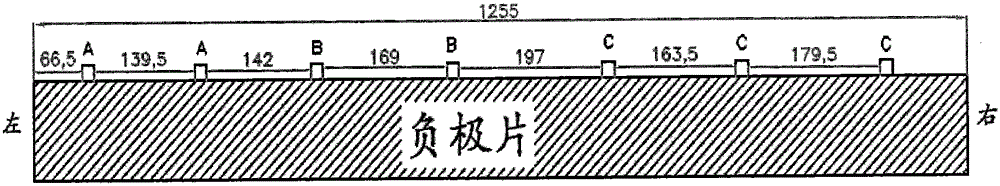

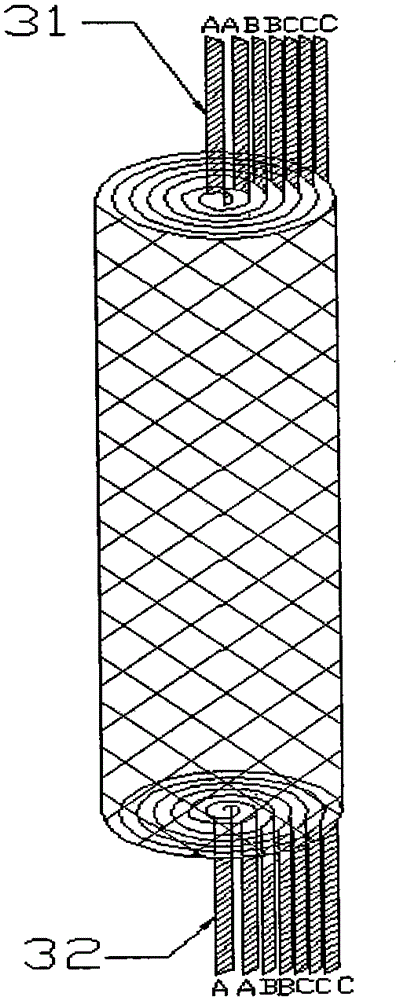

Multi-tab size-variable high magnification lithium ion battery

InactiveCN106257710ALower internal resistanceIncrease the number of tabsSecondary cellsElectrolyte layer coatingFirst pass yieldEngineering

The invention discloses a multi-tab size-variable high magnification lithium ion battery. The multi-tab size-variable high magnification lithium ion battery mainly comprises a positive pole piece, a negative pole piece, a diaphragm, an electrolyte and a housing. The battery is prepared from pole pieces with different sizes of multiple tabs through winding. A preparation method of the multi-tab lithium ion battery pole piece comprises fully stirring to mix active substances, a conductive agent and a binder according to a certain ratio to obtain slurry, uniformly coating a current collector with the slurry through a coating machine, wherein two sides of the current collector form blank zones, and preparing multiple tabs with different intervals and different widths, wherein the height values of the tabs are determined according to cell thickness and diameters. A winding method replaces a laminated soft package battery preparation process or a process of increasing the number of cylindrical form cell tabs so that a structure is simple, production efficiency is high and a first pass yield is high.

Owner:OPTIMUM BATTERY CO LTD

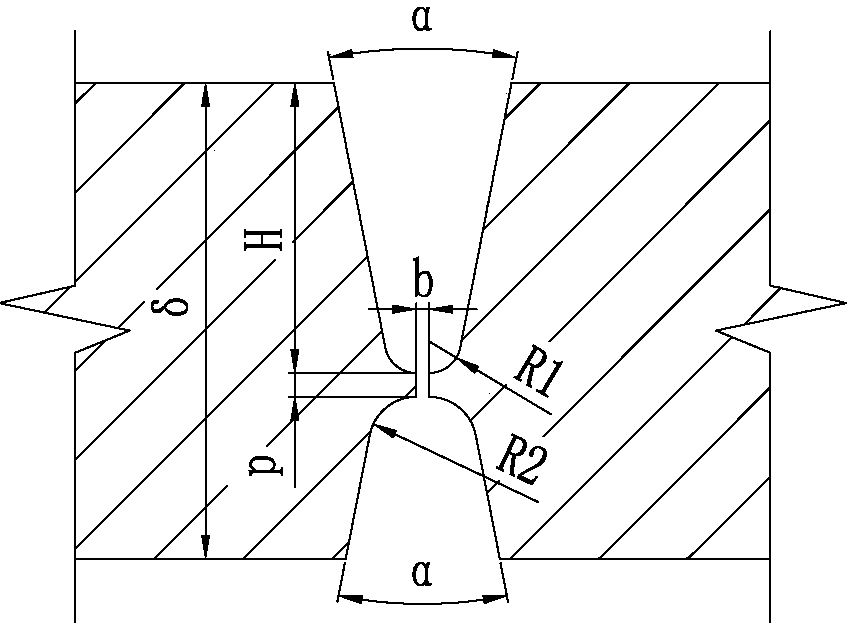

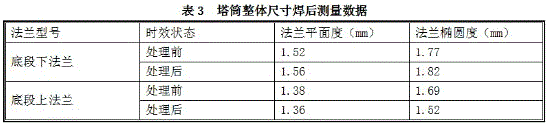

Super-thick steel plate welding method

ActiveCN104384677AImprovement design is reasonableImproved Design ReliabilityWelding/soldering/cutting articlesMetal working apparatusSocial benefitsHydrogen

The invention relates to a super-thick steel plate welding method. According to the method, the fabrication weldability of super-thick steel can be effectively improved, and the construction efficiency and the weld inspection first-pass yield can be improved. The method comprises the following steps of 1, processing a welding groove; 2, preparing before welding; 3, preheating before welding; 4, welding. The method is simple; the improved design of the welding groove is reasonable and reliable, and the method is suitable for common domestic single wire submerged arc welding machines and is high in practicability; a combined welding process of taking super low hydrogen electrode arc welding as backing weld and adopting submerged arc welding for filling and cosmetic welding is adopted, and the welding advantages of the two processes are integrated; the fabrication weldability of the super-thick steel plate is greatly improved, the welding quality of the super-thick steel plate is controlled, the first-pass yield of super-thick steel plate butt weld inspection is improved, and the method can be widely applied to welding construction of low-alloy high-strength structural steel super-thick steel plates which are 60-300mm in thickness and has good technical, economic and social benefits.

Owner:NO 9 METALLURGICAL CONSTR

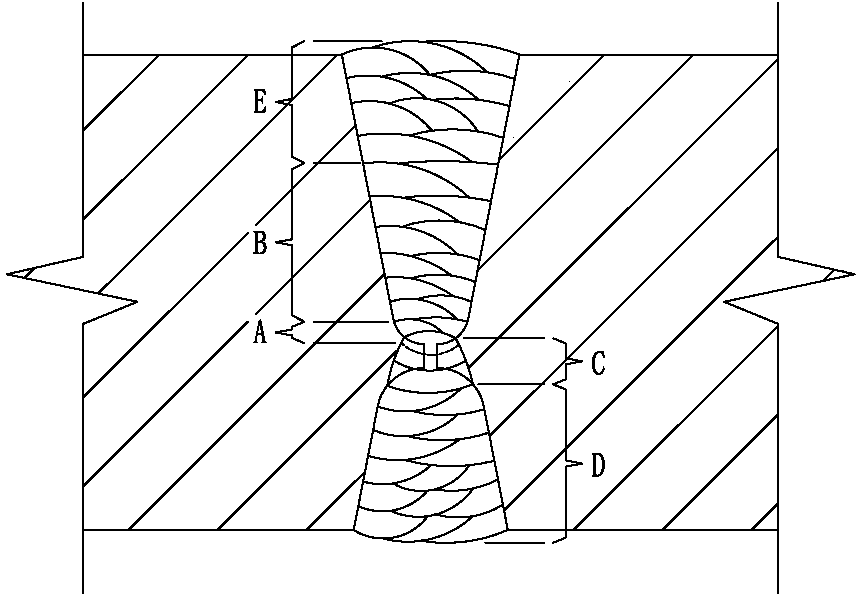

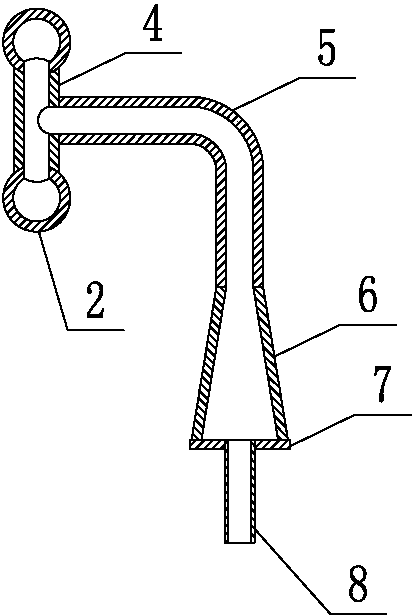

Welding process of ultra-supercritical fossil power unit for welding SA335-P91/P92 steel

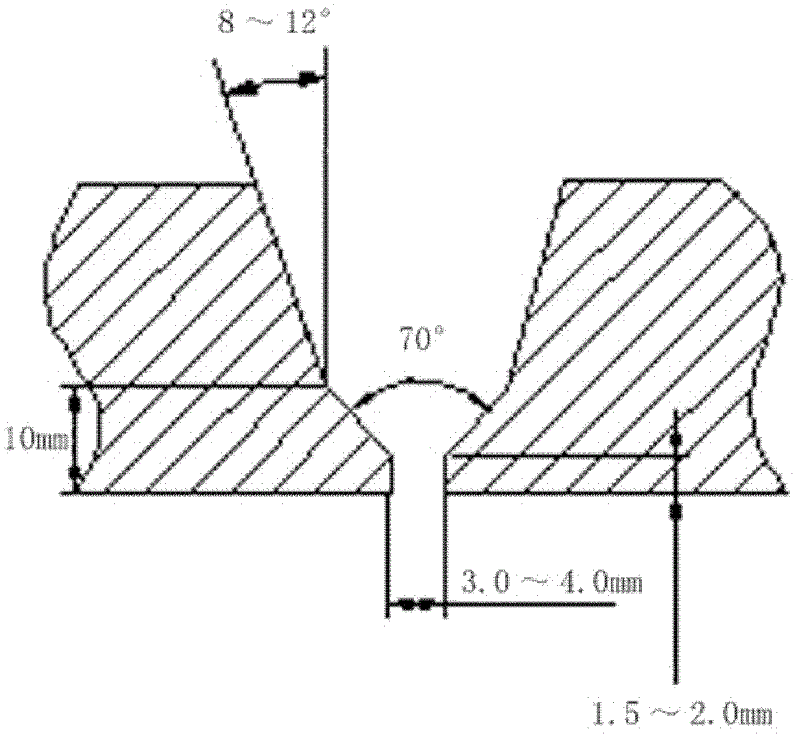

InactiveCN102615380AImprove the first pass rate of weldingImprove accuracyArc welding apparatusWorkpiece edge portionsShielded metal arc weldingPower flow

The invention relates to a welding process of an ultra-supercritical fossil power unit for welding SA335-P91 / P92 steel. The process is characterized by comprising three aspects of preparation before welding, welding parameter optimization and welding process optimization. In workpiece selection, a manual arc welding electrode is used as a welding workpiece; in welding bead arrangement, a welding bead is arranged in a double V-shaped or U-shaped groove shape, and the surface of the groove is cleaned; contra-aperture assembly is carried out, pipelines to be welded are arranged in the welding bead, each section of pipeline is propped firmly after contra-aperture connection, and the requirements on the contra-aperture of each section of pipeline are that: the staggered joint is 0.1-1.0mm, the gap is 3.0-4.0mm, and the truncated edge is 1.5-2.0mm; a large-diameter thick-wall pipe is fixed in the groove by a positioning block; and a welding area is preheated before welding, and then multi-layer welding bead welding is carried out in a GTAW (gas tungsten arc welding) and SMAW (shielded metal arc welding) combined welding method. According to the welding process disclosed by the invention, a multi-layer welding bead welding technology with a small-dimension electrode, a small current parameter and small swing is adopted, the impact toughness of a weld joint is improved, and the first-pass yield of welding can be greatly improved.

Owner:GUANGDONG SHAOGUAN YUEJIANG POWER GENERATION

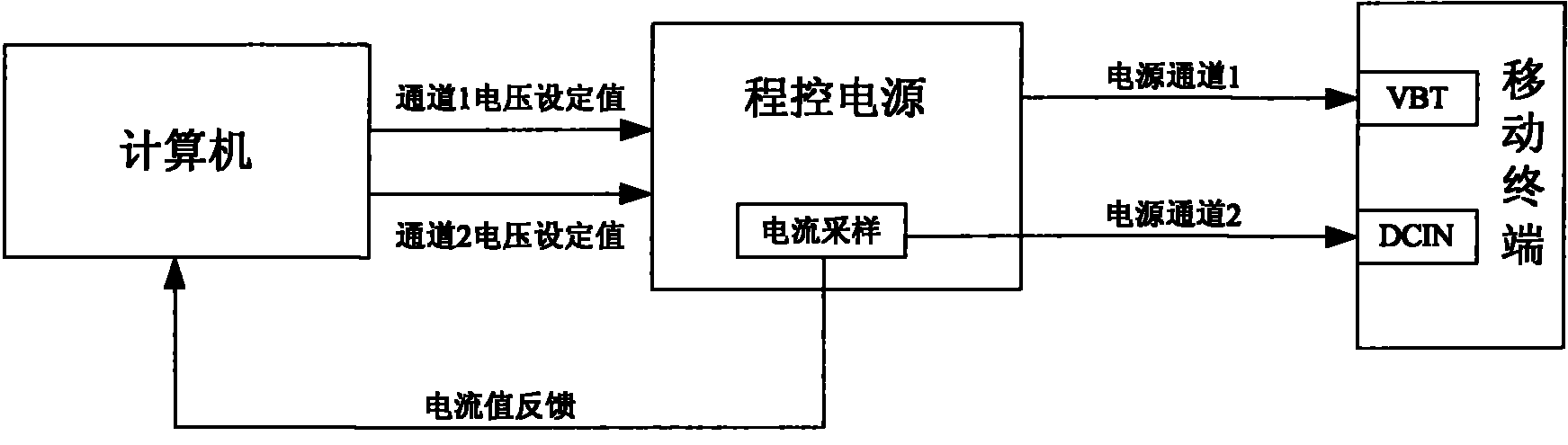

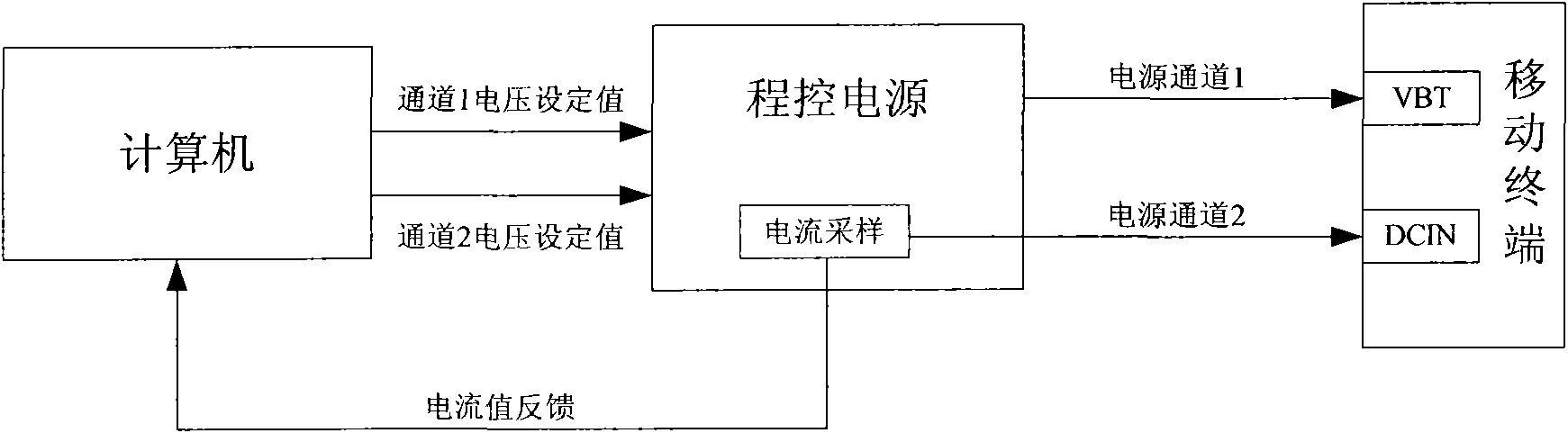

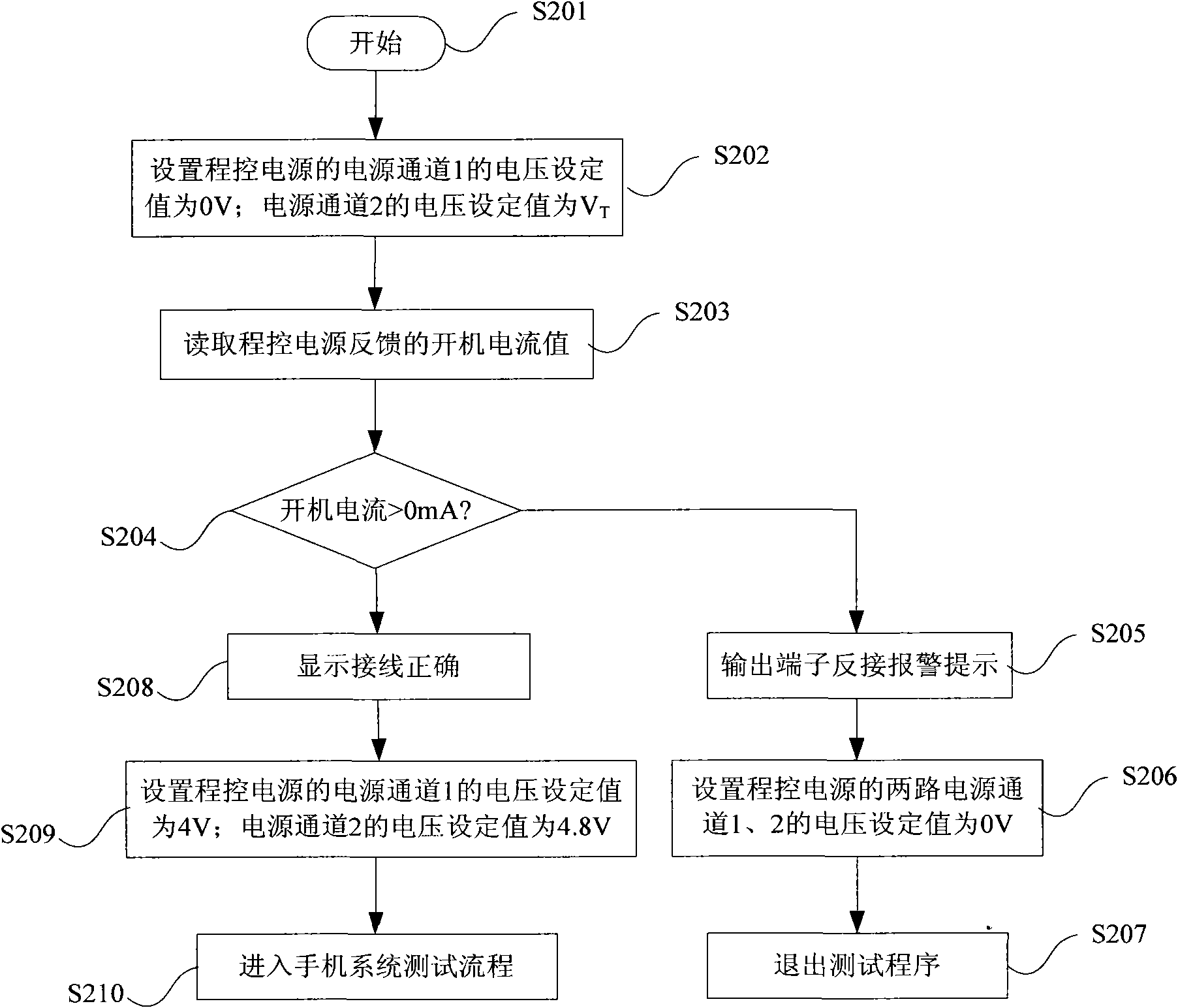

Method and system for supplying power to mobile terminal

ActiveCN101814757ASimple designEnsure power supply securityBatteries circuit arrangementsEmergency protective circuit arrangementsElectricityFirst pass yield

The invention discloses a method and a system for supplying power to a mobile terminal. In the method, two power supply channels 1 and 2 of a programmable power supply are used for supplying power supply voltages needed by a battery terminal and a charging terminal of the mobile terminal when the mobile terminal works normally. The method particularly comprises the following steps that: the character that the charging terminal of the mobile terminal also generates startup current when the loaded power supply voltage is insufficient is utilized, and before electricity is supplied to the mobile terminal formally, whether a power supply terminal of the mobile terminal is correctly connected is judged by outputting a test voltage in advance and detecting the startup current, so the power supply safety of the mobile terminal is ensured, the problem that the mobile terminal is damaged due to reverse connection of the power supply terminal is avoided, furthermore, the generation of fault machines is reduced, the production cost is reduced, and the first pass yield rate of production is improved. The method for power supply has a simple design, can provide conveniences for a line operator to make judgments, and is suitable for popularization and application in related mobile products such as mobile phones, MP4 and the like.

Owner:QINGDAO HISENSE MOBILE COMM TECH CO LTD

Manufacturing method of 6063 aluminum alloy sections

InactiveCN107058821AReduce deformation, size is difficult to control and other adverse factorsIncrease productivityManufacturing technologyWaste product

The invention belongs to the field of 6 series aluminum alloy materials, and particularly relates to a manufacturing method of 6036 aluminum alloy sections. According to the existing 6036 manufacturing technology, waste products are likely to be produced, and therefore the manufacturing cost is improved. In order to solve the problem, the manufacturing method of the 6036 aluminum alloy sections comprises a casting process, an extrusion process and an aging process. In the casting process, ingredients are controlled within a certain range, and impurities are reduced. In the gas hole extrusion process, air cooling adopts the water cooling process, and adverse factors of deformation and difficult size control caused by water cooling to production are reduced, and the production efficiency and the first-pass yield are greatly improved. By means of the manufacturing method, 6036 aluminum alloy sections achieve the mechanical performance of 6063-T6, the strength of extension is larger than or equal to 250 MPa, the yield strength is larger than or equal to 220 MPa, and the percentage elongation after fracture is larger than or equal to 10%.

Owner:江苏江南创佳型材有限公司

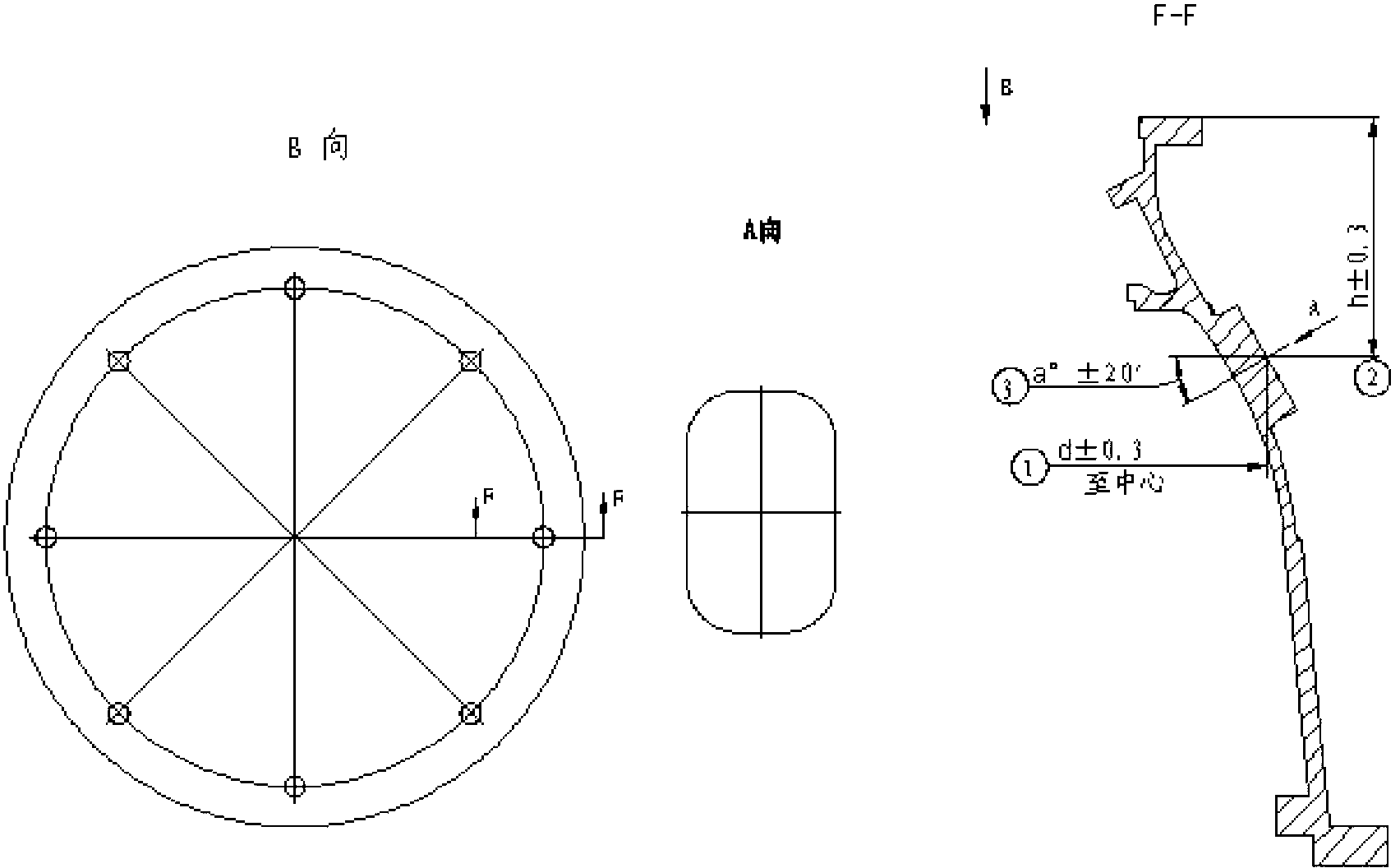

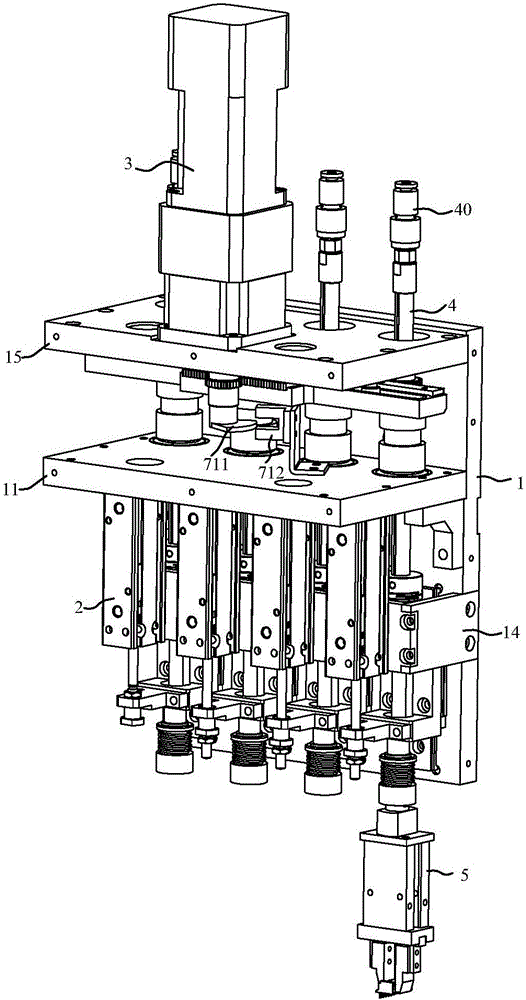

Electronic component insertion machine

ActiveCN106102438AImprove pass rateMeet development needsPrinted circuit assemblingElectrical componentsFirst pass yieldElectronic component

The invention discloses an electronic component insertion machine and belongs to the component insertion machine technical field. The electronic component insertion machine comprises a machine body, a PCB transportation and positioning device, a component supplying device, a manipulator and a component sucking and inserting device; the machine body is provided with a component insertion station; the component suction and insertion device comprises a supporting plate, lifting motors, a rotating motor and air suction guide rods; end portions of the air suction guide rods are provided with suction nozzles; air flow channels are arranged in the air suction guide rods; the supporting plate is provided with a mounting seat; the air suction guide rods are provided with lifting seats; the lifting motors can drive the lifting seats to rise and descend; the rotating motor can drive the air suction guide rods to rotate; the manipulator can drive the component suction and insertion device to be switched between the component supplying device and the component insertion station; and when being switched, the component suction and insertion device can suck electronic components from the component supplying device and insert the electronic components in a PCB. The electronic component insertion machine of the invention has the advantages of high component insertion speed and high accuracy. With the electronic component insertion machine adopted, erroneous insertion and missed insertion caused by manmade factors can be avoided, the first pass yield of individual PCBs is improved, and production speed is increased.

Owner:GUANGDONG XINSHI PHOTOELECTRIC TECH

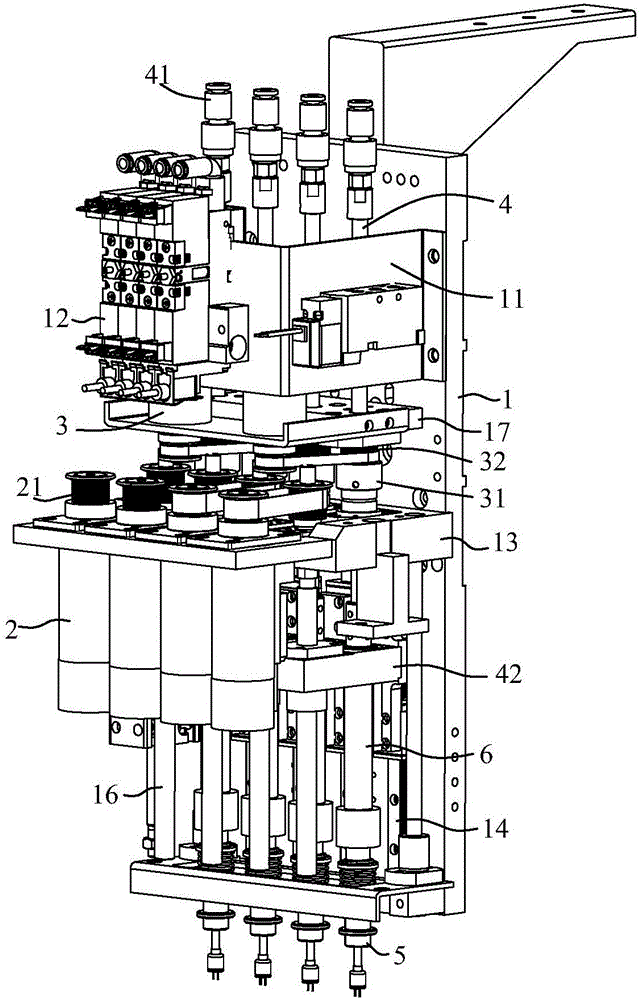

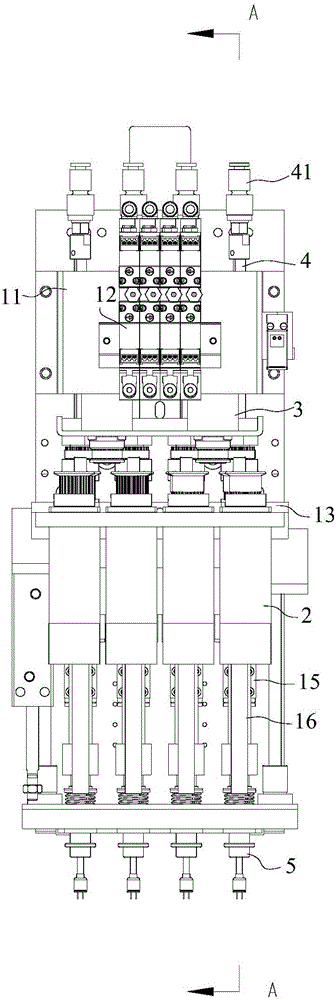

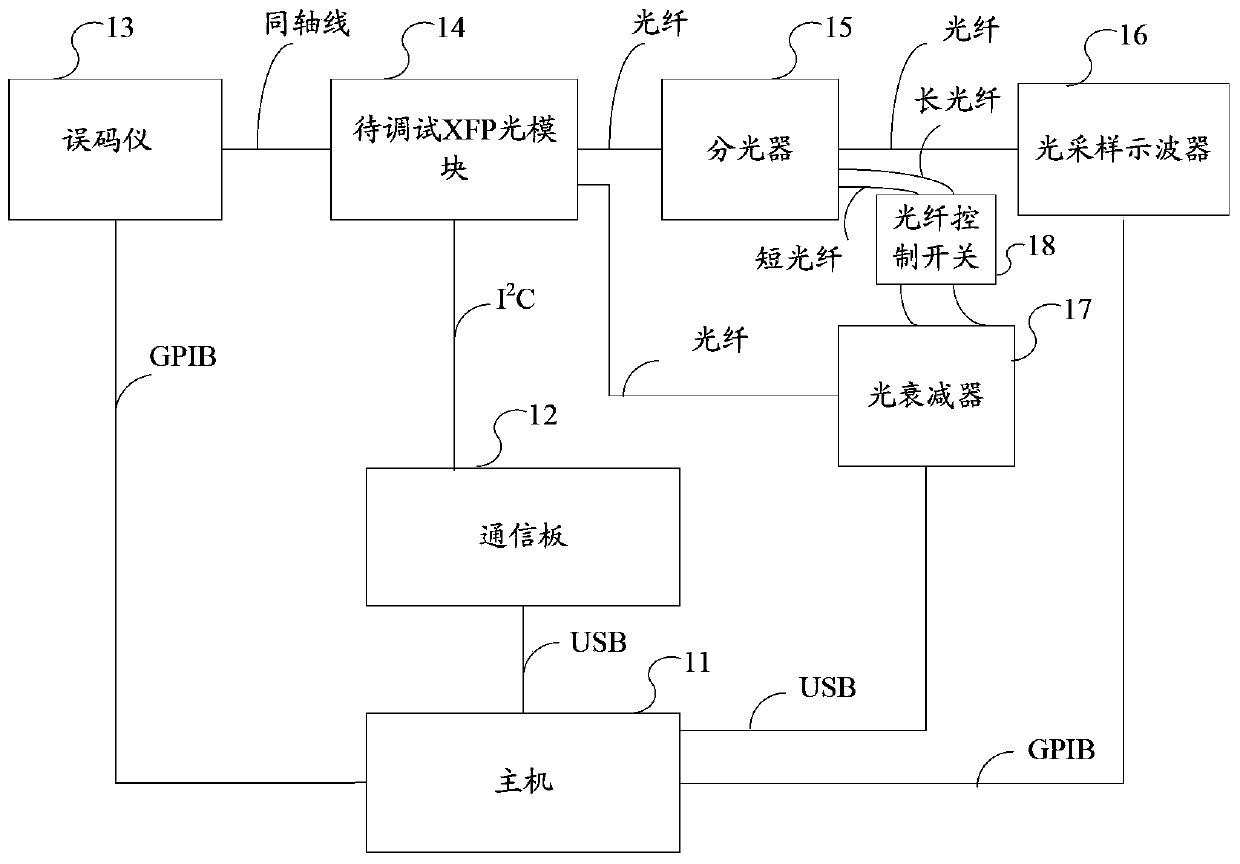

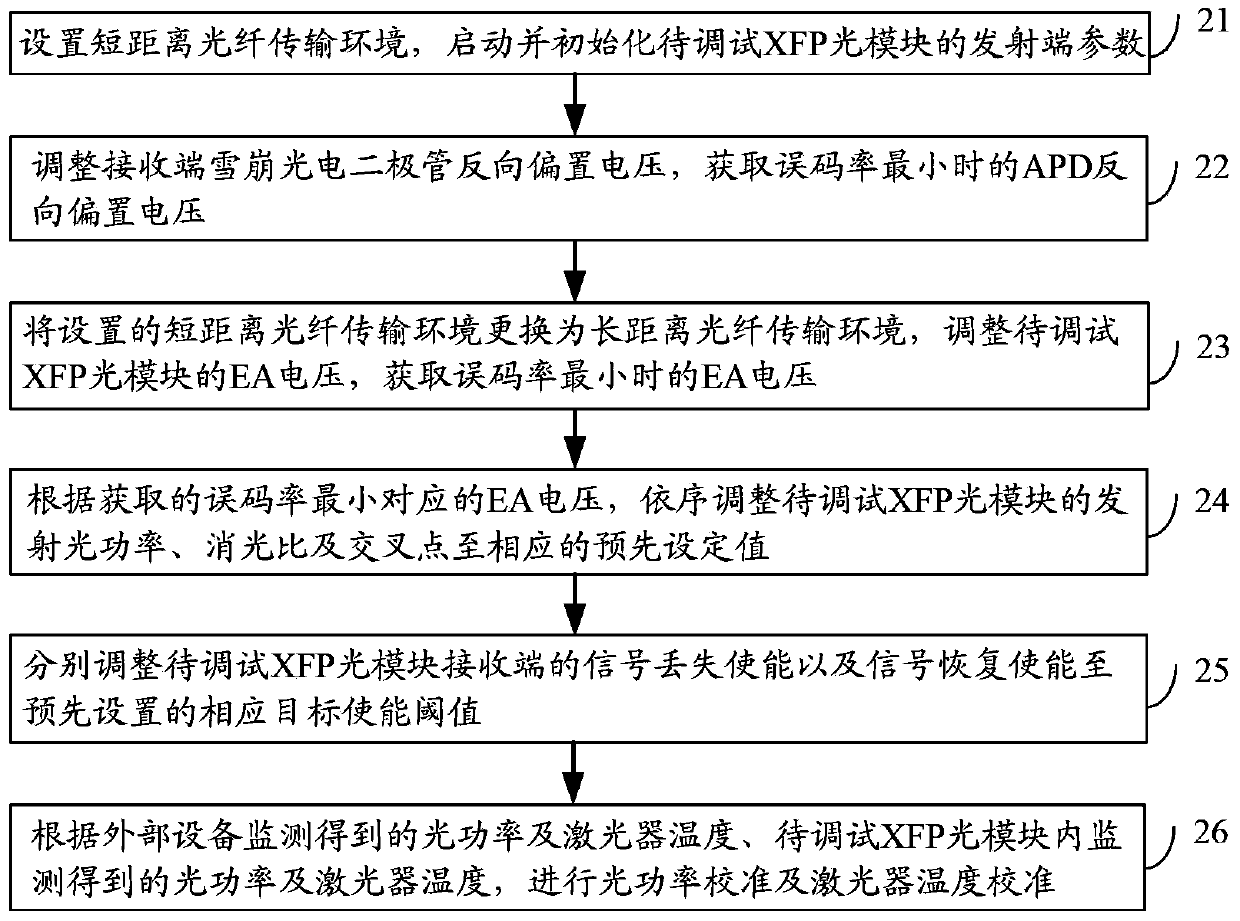

Normal-temperature debugging system based on hot-pluggable optical module and normal-temperature debugging method

ActiveCN103401605ASimplify the debug test processImprove production straight-through rateTransmission monitoring/testing/fault-measurement systemsOptical ModuleShortest distance

The invention discloses a normal temperature debugging system based on a hot-pluggable optical module and a normal temperature debugging method based on the hot-pluggable optical module. The method comprises the following steps: setting a short-distance optical fiber transmission environment, and starting and initiating the parameter of the transmitting end of a to-be-debugged XFP (10 Gigabit Small Form Factor Pluggable) optical module; adjusting the APD (Avalanche Photo Diode) reverse bias voltage of the receiving end of the to-be-debugged XFP optical module to obtain error code rate information, and if the error code rate does not reach the minimum, writing an instruction of increasing the step length of the APD reverse bias voltage into the to-be-debugged XFP optical module; if the error code rate reaches the minimum, acquiring the APD reverse bias voltage when the error code rate is minimum; changing the set short-distance optical fiber transmission environment into a long-distance optical fiber transmission environment, adjusting the EA (Electro-Absorption) voltage of the to-be-debugged XFP optical module to obtain error code rate information, and if the error code rate does not reach the minimum, writing an instruction of reducing the step length of the EA voltage into the to-be-debugged XFP optical module; and if the error code rate reaches the minimum, acquiring the EA voltage when the error code rate is minimum. Through the application of the system and the method, the production first pass yield of the XFP optical module is increased.

Owner:HISENSE BROADBAND MULTIMEDIA TECH

Special-shaped electronic component inserter

ActiveCN106132184AImprove pass rateMeet development needsElectrical componentsProduction rateFirst pass yield

The invention discloses a special-shaped electronic component inserter, which is applied to the technical field of inserters. The special-shaped electronic component inserter comprises a machine body, a PCB transport positioning device, a component supply device, a manipulator and a component absorbing and inserting device, wherein the machine body is provided with a component inserting station; the component absorbing and inserting device comprises a support plate, a lifting air cylinder, a rotary motor and a plurality of suction guide rods; a material clamping air cylinder is arranged at the bottom end of each suction guide rod; an airflow channel is arranged in each suction guide rod; the support plate is provided with an installation base; each suction guide rod is provided with a lifting base; each lifting air cylinder can drive the corresponding lifting base to lift; the rotary motor can drive the suction guide rods to rotate; the manipulator can drive the component absorbing and inserting device to be switched between the component supply device and the component inserting station; and the component absorbing and inserting device can insert an electronic component on a PCB when the component is switched. The special-shaped electronic component inserter is high in insertion speed and high in accuracy rate; the phenomena of man-made misinsertion and insertion leakage are overcome; the first pass yield of the single board is improved; and the production rate is improved.

Owner:GUANGDONG XINSHI PHOTOELECTRIC TECH

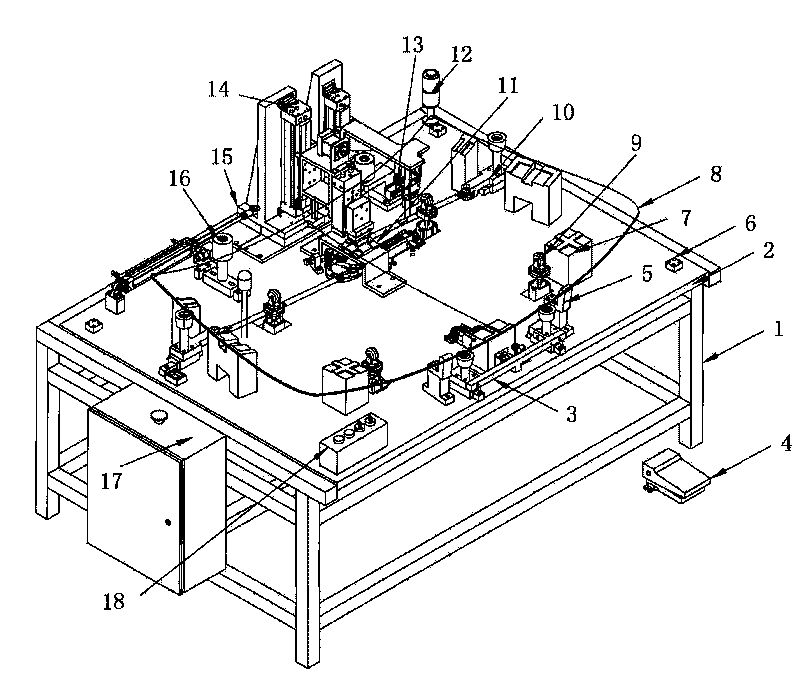

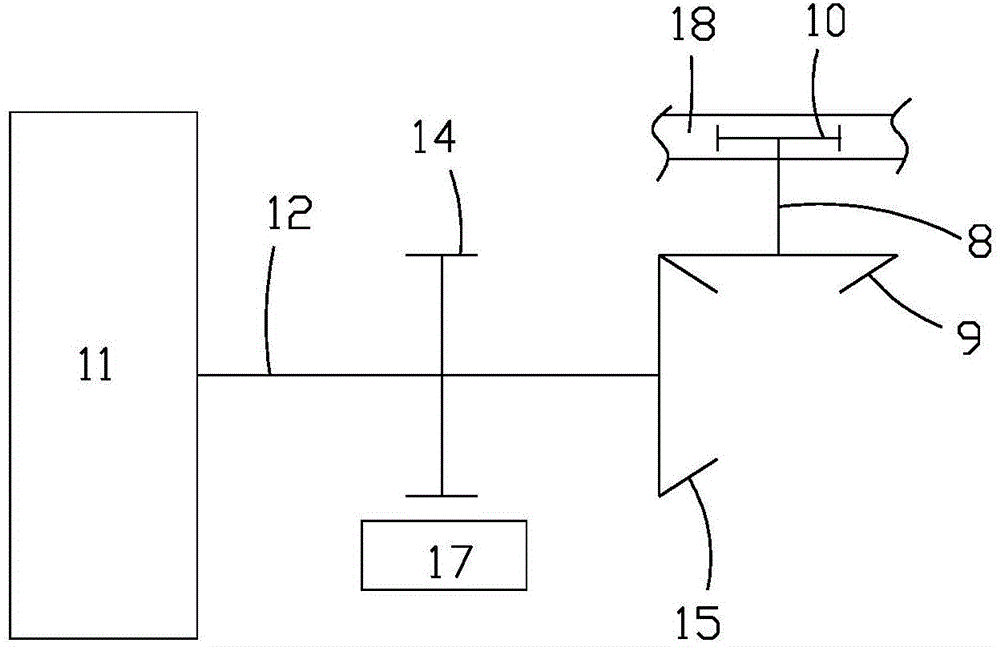

Method for bonding automobile glass rain sensor bracket

InactiveCN101746432AImprove first-time yieldImprove efficiencyWindowsWindscreensFirst pass yieldEngineering

The invention relates to a method for bonding an automobile glass rain sensor bracket, which comprises the following steps: the rain sensor bracket to be installed is put on a rain sensor bracket groove (25) with the adhesive surface up; a guide movable pulley (9) is in a high position; the glass is arranged against a locating device (16) along a guide block (5); when a foot switch is started, the guide movable pulley (9) automatically descends, a clamping unit (10) and a clamping unit (3) successively move to abut against the smaller-end locating device (16) and clamp the glass (8); a rain sensor bracket installation unit (14) works, a compressing block (12) rotates 180 degrees along with a swing driver (21), a cylinder (19) descends and then ascends, the swing driver (21) resets, the clamping units reset, and the guide movable pulley jacks up the glass (8); and the glass is taken out to complete the operation. Compared with the prior art, the invention enhances the first pass yield by 5%, enhances the efficiency by 25% and reduces the defects generated in the intermediate link.

Owner:FUYAO GRP SHANGHAI AUTOMOBILE GLASS CO LTD

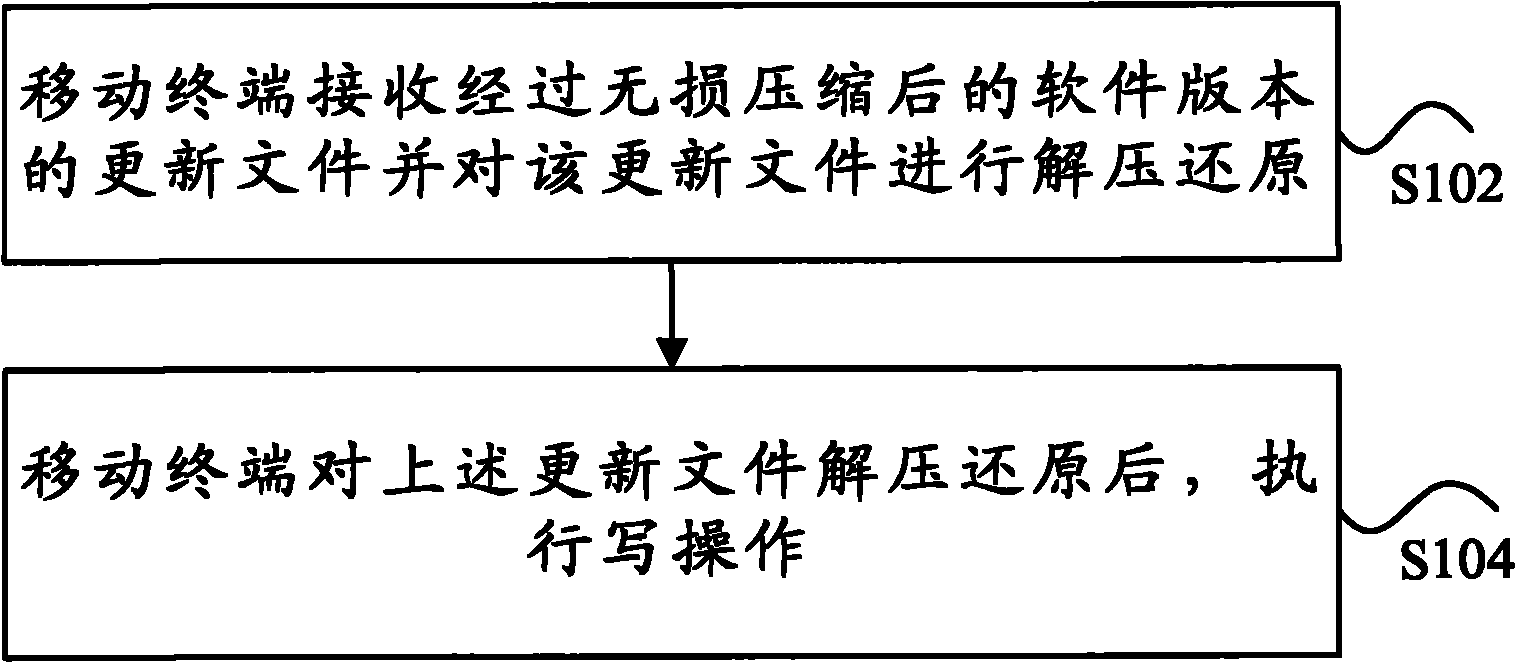

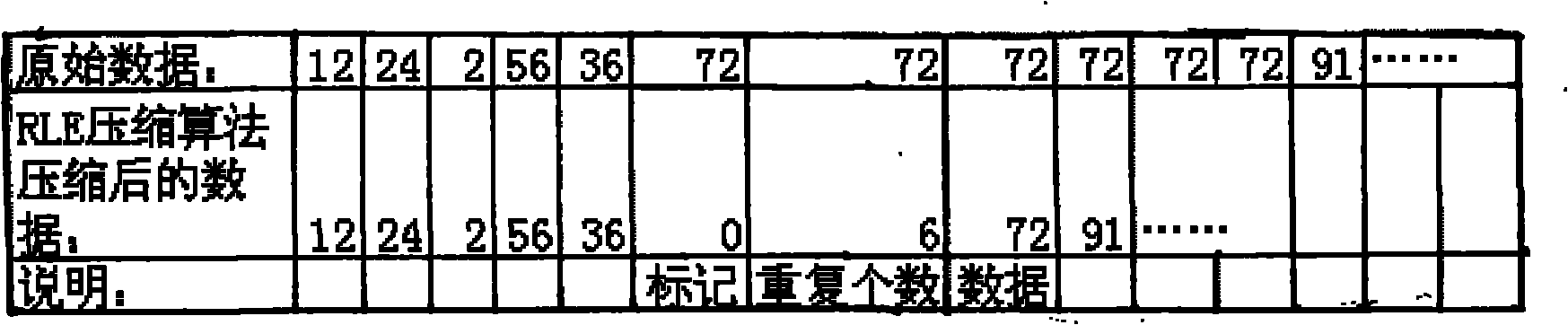

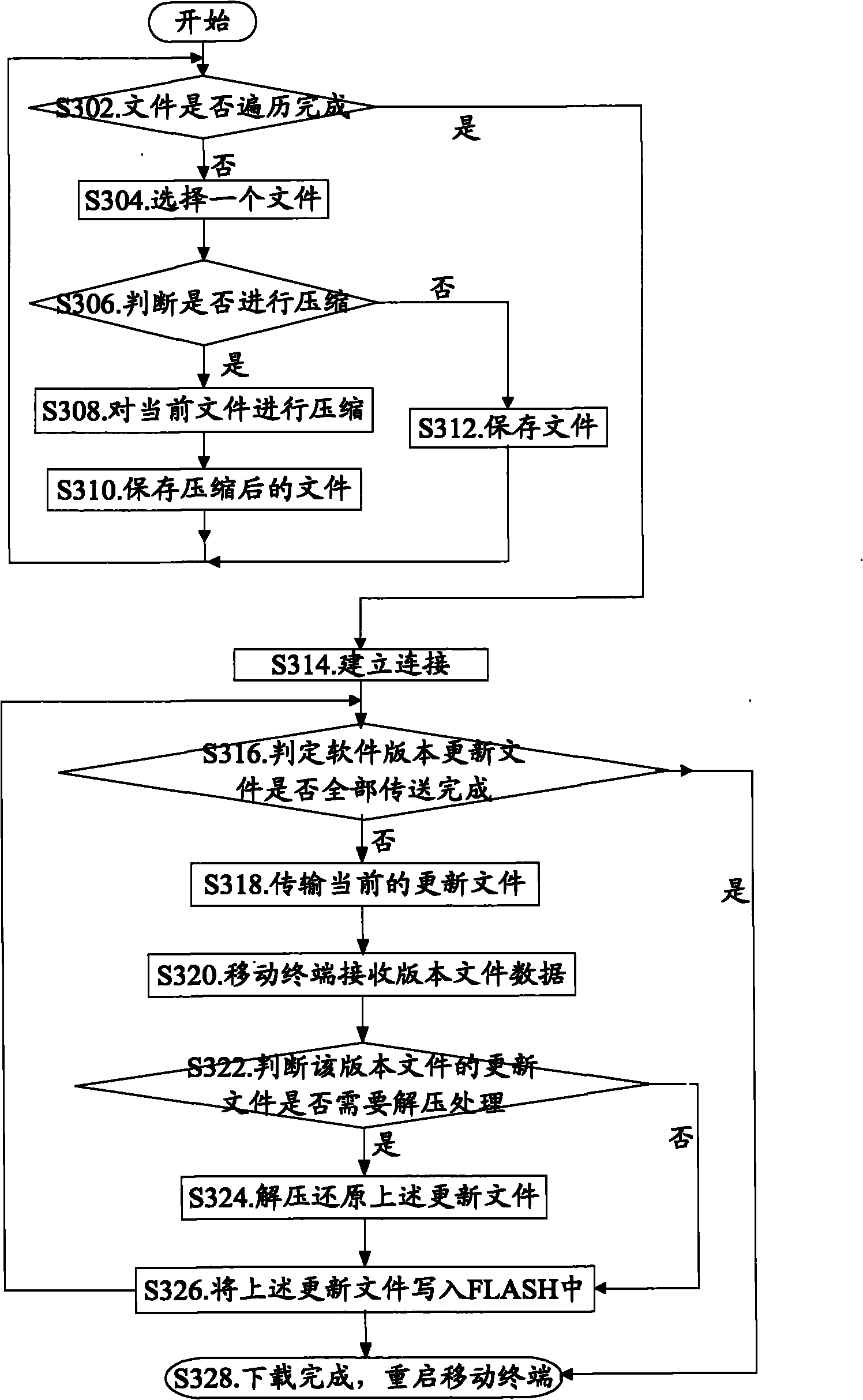

Method of software version upgrade and terminal and system

InactiveCN101984405AReduce upgrade timeFast and secure upgrade processProgram loading/initiatingSoftware deploymentLossless compression algorithmFirst pass yield

Owner:ZTE CORP

Composition of drip irrigation zone material

The invention relates to a composition of a drip irrigation zone material. The composition is prepared from the following materials in parts by mass: 100 parts of polyethylene resin, 5-10 parts of a coloring agent, 0.5-2 parts of a processing modifier and 0.01-1 part of a processing assistant. The preparation method of the composition comprises the following steps: adding the coloring agent, the processing modifier and the processing assistant into the polyethylene resin; and carrying out melt extrusion through a double-screw extruder after mixing, and cooling and dicing to obtain the composition of the drip irrigation zone material. According to the composition disclosed by the invention, an appropriate amount of the processing modifier is added into the polyethylene resin, so that the problems that a drip irrigation zone product is difficult to form in a production process, low in production efficiency, poor in outline quality, and the like, are solved; meanwhile, product processing performance is improved, accumulated materials at a neck mould are reduced, product outline quality is improved, and first-pass yield of the product is increased. The composition of the drip irrigation zone material disclosed by the invention has the advantages of being good in processing performance, attractive in appearance, excellent in ageing resistance and the like, is widely applied to the industries such as agriculture, forestry and city greening, and has a wide scope of application and economic benefits.

Owner:吉林喜丰节水科技股份有限公司

Material transfer mechanical hand and plate stamping production line

InactiveCN106180453AIncrease productivityAvoid manual contactMetal-working feeding devicesStripping-off devicesProduction lineFirst pass yield

The invention relates to the field of vehicle part transmission, and provides a material transfer mechanical hand and a plate stamping production line. The material transfer mechanical hand provided by the invention comprises a first X-direction rail device, a second X-direction rail device and a material grabbing device; the second X-direction rail device is slidably arranged on the first X-direction rail device in the X-direction; and the material grabbing device is slidably arranged on the second X-direction rail device in the X-direction. The second X-direction rail device can slide in the X direction, the material grabbing device and the second X-direction rail device can slide in the same X-direction, and materials can obtain sum of two movement speeds in the same direction, so that material transfer production efficiency is remarkably improved; besides, the mechanical hand is used for grabbing and transferring materials, so that safety accidents can be effectively reduced, and operators are prevented from being in contact with materials by hands, and therefore, the surface quality first-pass yield of materials such as products is ensured.

Owner:GREAT WALL MOTOR CO LTD

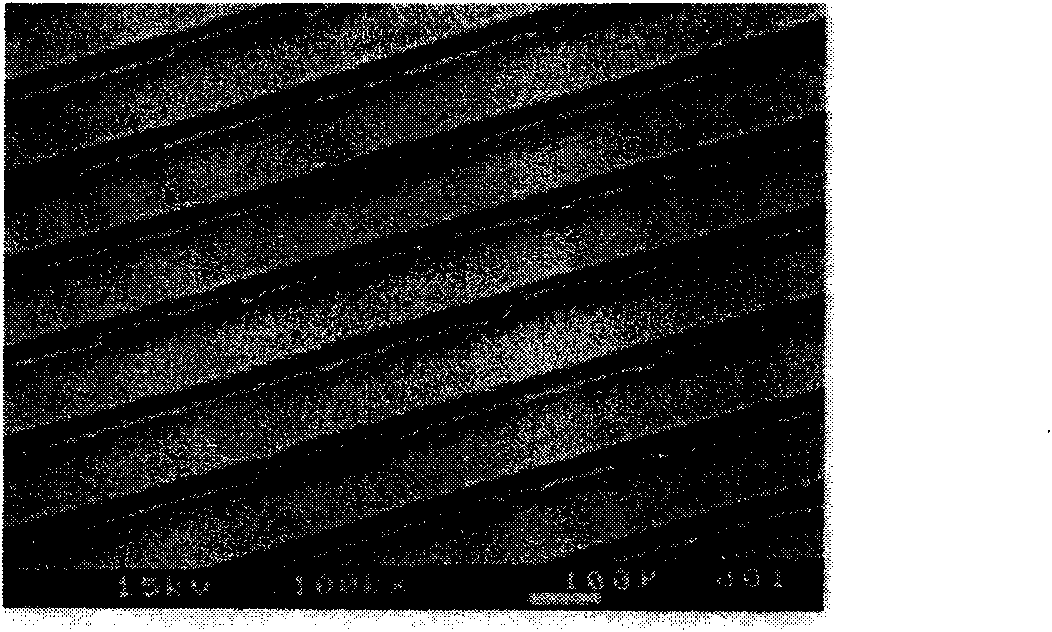

Polishing skin and method for polishing cambered surface of micro ceramic product through same

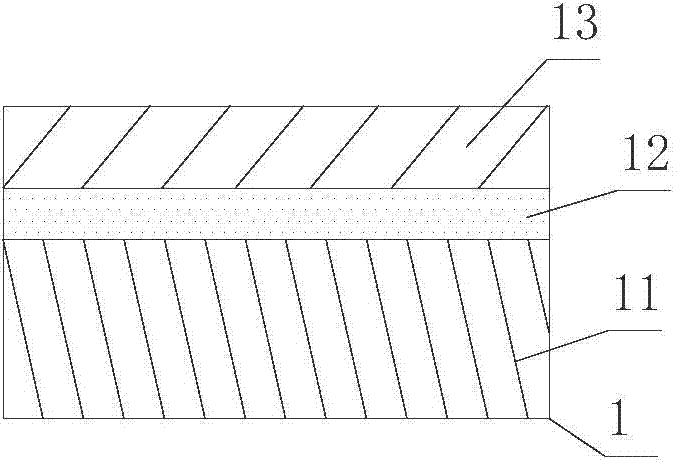

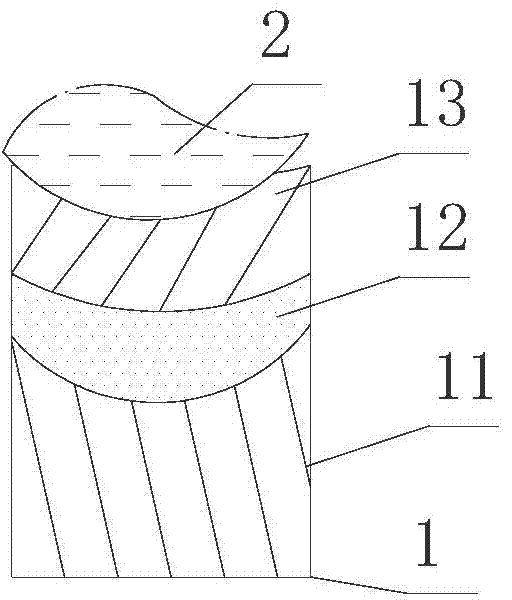

InactiveCN104742034ASimple structureEasy to produceSynthetic resin layered productsAbrasion apparatusMetallurgyFirst pass yield

The invention aims to provide a polishing skin. The polishing skin comprises a first layer, a second layer and a third layer in sequence. The first layer is made of sponge, the second layer is made of bonding rubber, and the third layer is made of resin. The polishing skin is simple in overall structure and convenient to produce; due to the combination of the sponge and the resin, the polishing skin can deform according to the cambered surface of the product to be machined in the polishing process to achieve overall cambering zero-damage polishing, and practicability is high. The invention further aims to provide a method for polishing the cambered surface of the micro ceramic product. The process is simple, and the production cycle is short. Components are easy to obtain, and the cost is low. By combining mechanical grinding with chemical etching and adopting accurate pressure control, overall cambering ultra-smooth nano-scale zero-damage precision polishing is achieved, the removal amount of 15 microns-50 microns of the ceramic product can be achieved, the first pass yield is larger than 90%, and the surface roughness is smaller than 5 nanometers.

Owner:LENS TECH

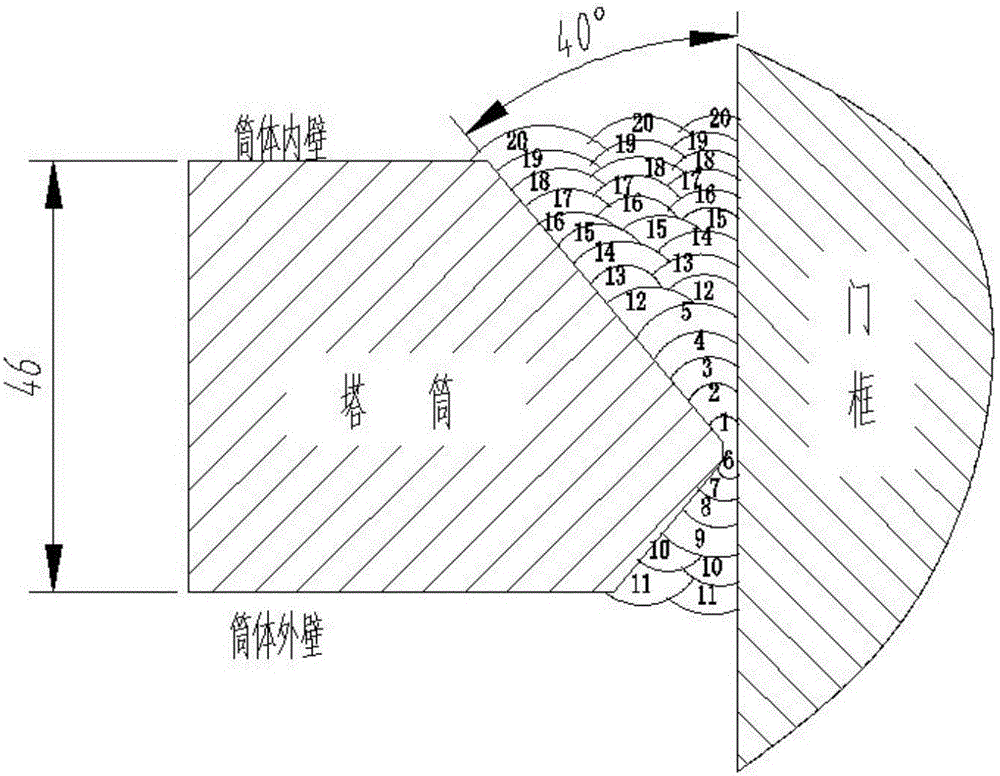

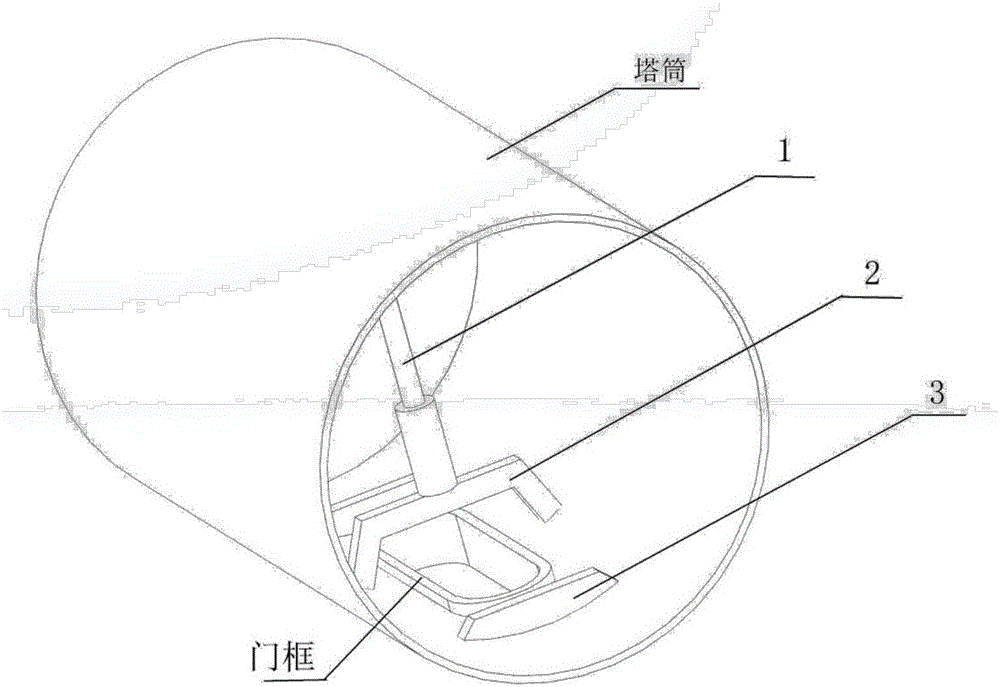

Method for welding door frame of ultra-low-temperature high-power wind turbine tower

ActiveCN106002008AReduce mistakesIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesElectricityStress concentration

The invention discloses a method for welding a door frame of an ultra-low-temperature high-power wind turbine tower. The method comprises the following five main steps: preparing materials of the door frame; cutting a door hole; mounting an anti-deformation tool; welding corner weld of the door frame and the tower; and carrying out stress relief treatment after welding. Stress concentration of a welding region of the door frame and the tower under the working condition of ultra-low temperature and the condition of high-power generation requirements can be eliminated, defects of welding cracks and lamellar tearing are avoided, and requirements of impact energy at the low temperature of minus 40 DEG C are met; influences of stress concentration to yield of flatness and ovality of a flange of the tower is avoided; and first-pass yield of inspection and acceptance of the tower is improved.

Owner:SINOHYDRO BUREAU 4 JIUQUAN NEW ENERGY EQUIPCO

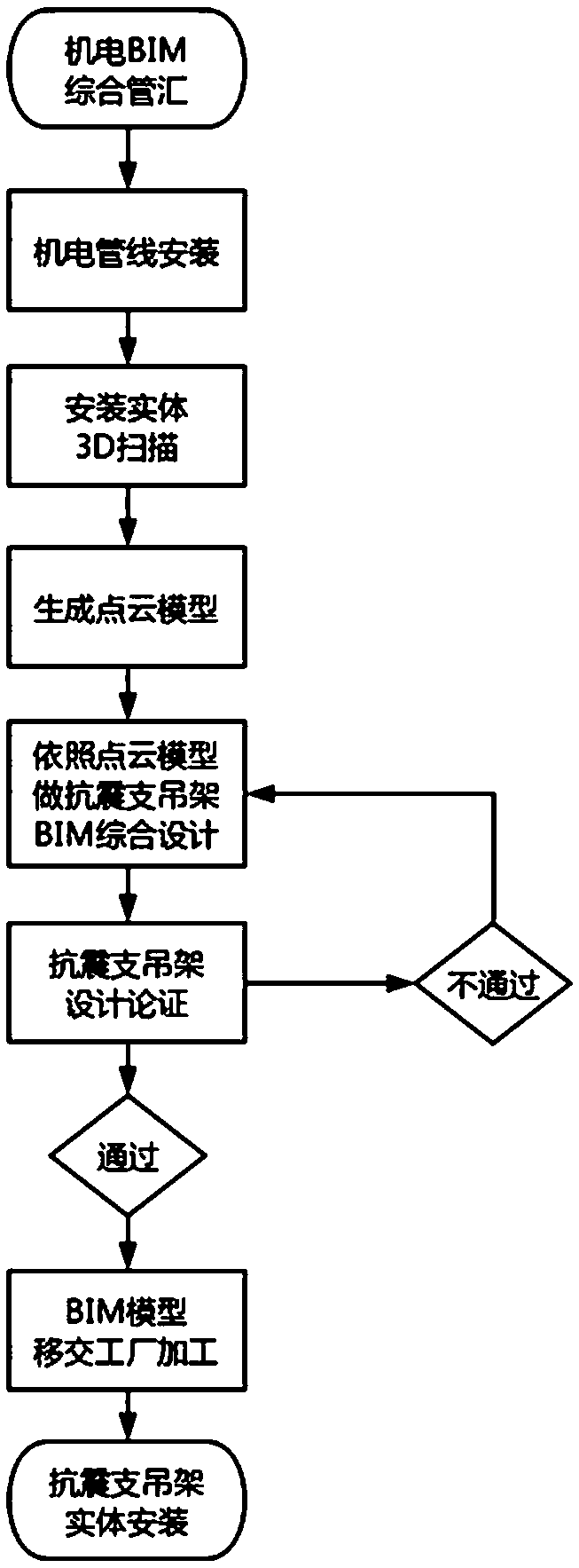

Construction method for anti-seismic support post on the basis of BIM (Building Information Modeling)+3D (Three-Dimensional) scanning technology

ActiveCN107633133AImprove the first-time installation pass rateImprove the correct rate of installationBuilding material handlingSpecial data processing applicationsPoint cloudFirst pass yield

The invention discloses a construction method for an anti-seismic support post on the basis of a BIM (Building Information Modeling)+3D (Three-Dimensional) scanning technology. The construction methodcomprises the following steps that: utilizing an electromechanical full-profession BIM comprehensive manifold model to guide the installation of an electromechanical full-profession pipeline; after installation is finished, using a 3D scanner to carry out 3D scanning on a field entity installation situation; after processing is carried out, generating a point cloud model, importing the point cloud model into Revit software to be checked; comparing with the electromechanical full-profession BIM comprehensive manifold model, carrying out timely rectification, and revising the model according tothe practical situation of a construction field; on the basis of the point cloud model, carrying out the BIM comprehensive design of the anti-seismic support post; demonstrating an anti-seismic support post design model, and transferring the design model to a factory to be processed if demonstration is qualified; and finally, comparing with the model to install the anti-seismic support post entity. By use of the method, the construction environment of the anti-seismic support post can be reduce to a maximum degree, and the first pass yield and the installation efficiency of the installation of the anti-seismic support post can be improved.

Owner:CHINA CONSTR FIRST GRP THE SECOND CONSTR +1

Method for removing ceramic core of hollow blade of turbine of aircraft engine

A method for removing a ceramic core of a hollow blade of a turbine of an aircraft engine comprises the four steps of primary core removing, secondary core removing, third core removing and ultrasonic cleaning. The concentration of KOH alkali liquor used in primary core removing is 40%, the concentration of KOH alkali liquor used in secondary core removing is 30%, and the concentration of KOH alkali liquor used in third core removing is 40%. Every time core removing is conducted, the temperature of the alkali liquor ranges from 160 DEG C to 200 DEG C, the pressure of the alkali liquor fluctuates between 0.4 MPa and 0.5 MPa, water is added every six hours, and soaking time is 48 hours. According to the method, the concentration of the alkali liquor is reduced, the water is added every six hours, and it is guaranteed that salt generated due to reactions is sufficiently dissolved; the alkali liquor is replaced every 48 hours, the concentration of the alkali liquor changes in a stepped mode, and it can be guaranteed that the chemical reactions are conducted effectively; the pressure of the alkali liquor fluctuates in a pulse mode, core cracking can be facilitated, the reaction interface between the alkali liquor and the core is enlarged, and the reacting dose is increased. Through the method, the ceramic core removing period can be shortened to six days from over twenty days, and the first pass yield of core removing can be higher than 90%.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

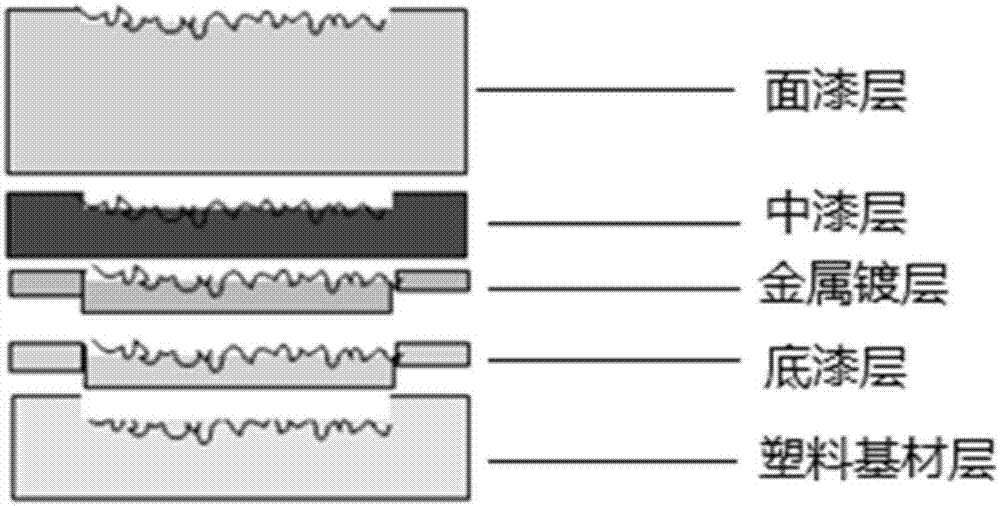

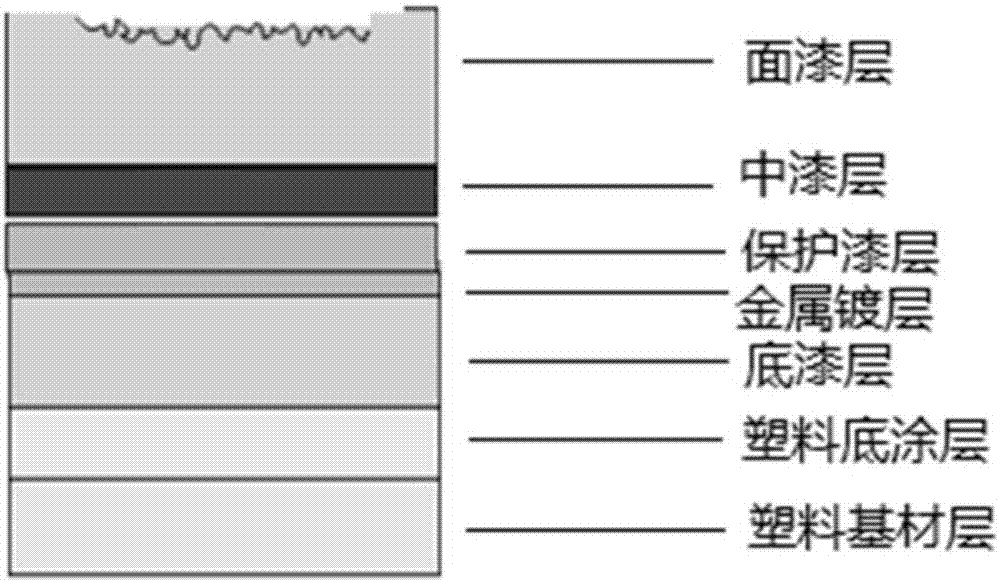

Surface treatment process of plastic base material and plastic part

InactiveCN107216477AHigh industry pass rateReduce processPretreated surfacesPolyurea/polyurethane coatingsLaser etchingLacquer

The invention discloses a surface treatment process of a plastic base material and a plastic part. The treatment process disclosed by the invention comprises the following steps: (1) spraying primer onto the surface of a plastic base material with spark patterns texture, preheating, curing, thus obtaining a primer layer; (2) plating a metal coating on the surface of the primer layer; (3) spraying intermediate paint onto the surface of the metal coating, preheating, curing, thus obtaining an intermediate paint layer; and (4) spraying finishing paint onto the surface of the intermediate paint layer, preheating, curing, thus obtaining a surface coating. By adopting the treatment process, a plastic part with a pseudo-metal and matte effect can be produced only by virtue of three times of spraying and one time of true plating, and fewer procedures are needed; and moreover, a 3D laser etching process is not needed by virtue of the treatment process of the invention, the cost is low, and the production efficiency is greatly increased; and in addition, the industrial first pass yield of the plastic part produced by virtue of the treatment process of the invention can reach up to 80 percent, and the yield is greatly increased.

Owner:HUAQIN TECH CO LTD

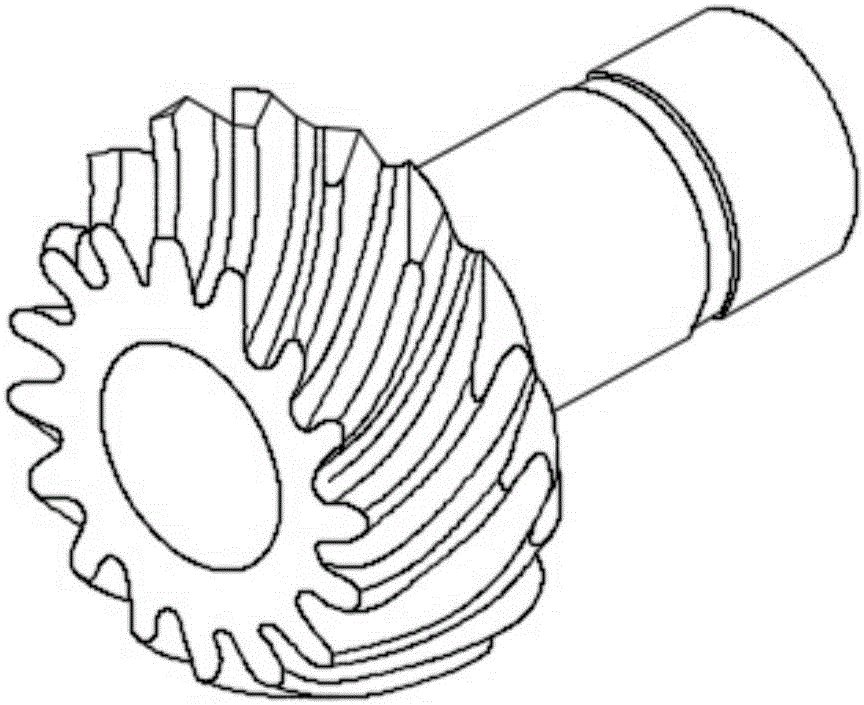

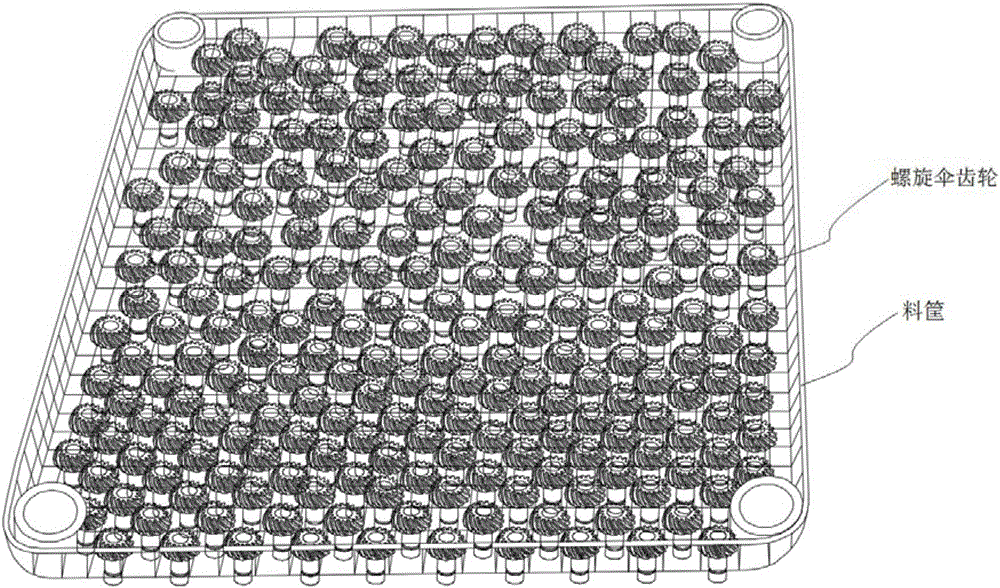

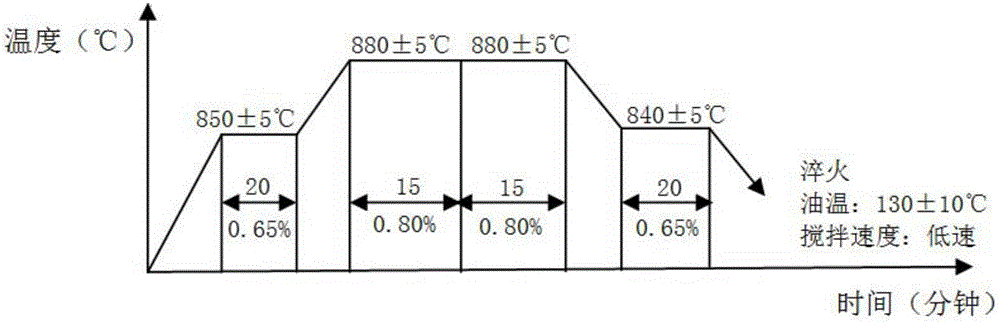

Heat treatment technology for reducing deformation of spiral bevel gear for hay mower

ActiveCN106048192AReduce distortionSmall temperature differenceFurnace typesHeat treatment furnacesCarbon potentialThermal insulation

The invention discloses a heat treatment technology for reducing deformation of a spiral bevel gear for a hay mower and belongs to the field of heat treatment technology. The technology comprises the following steps: 1) preparation of the spiral bevel gear by the adoption of a SCM415 blank; 2) crating; 3) front cleaning; 4) carburizing and quenching: temperature equilibrium at 850 + / - 5 DEG C for 20 + / - 1 min, and carbon potential is 0.65 + / - 0.025%; intensive carburizing and thermal insulation at 880 + / - 5 DEG C for 15 + / - 1 min, and carbon potential is 0.8 + / - 0.025%; diffusion and thermal insulation at 880 + / - 50 DEG C for 15 + / - 1 min, and carbon potential is 0.8 + / - 0.025%; quenching and temperature equilibrium at 840 + / - 5 DEG C for 20 + / - 1 min, and carbon potential is 0.65 + / - 0.025%; and cooling in 130 + / - 10 DEG C of quenching oil; 5) post cleaning; and 6) tempering at the temperature of 175 + / - 5 DEG C for 150 + / - 10 min. According to the invention, deformation of the spiral bevel gear after heat treatment is reduced, and first pass yield for heat treatment can reach 100%.

Owner:常州新区河海热处理工程有限公司

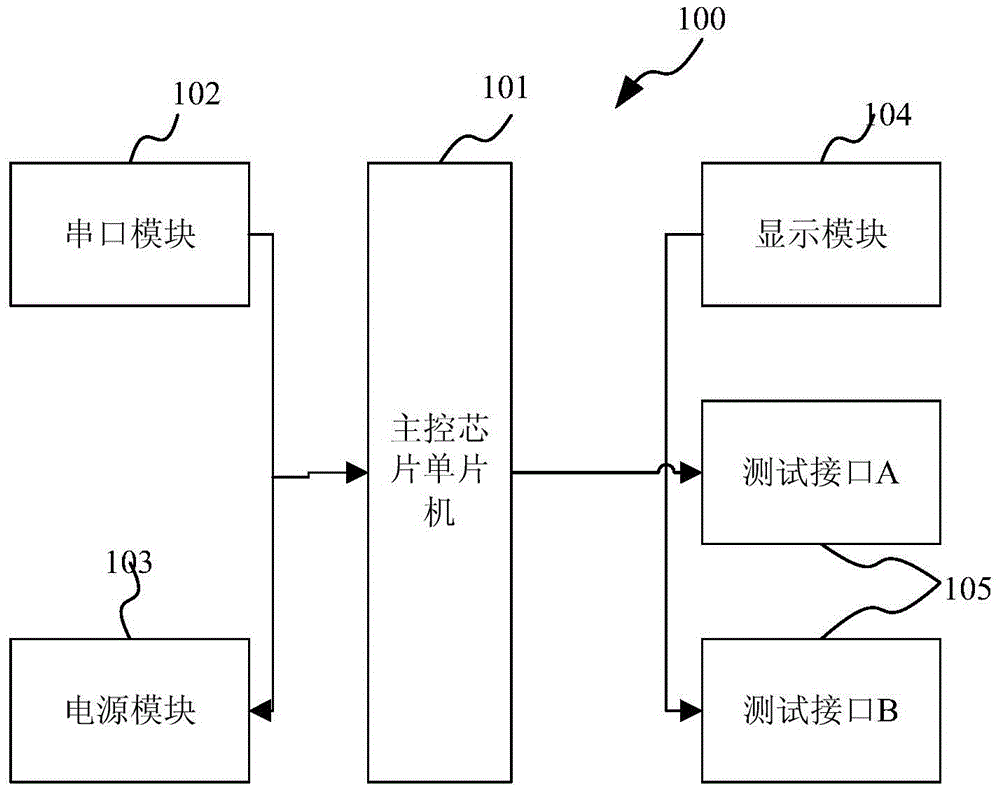

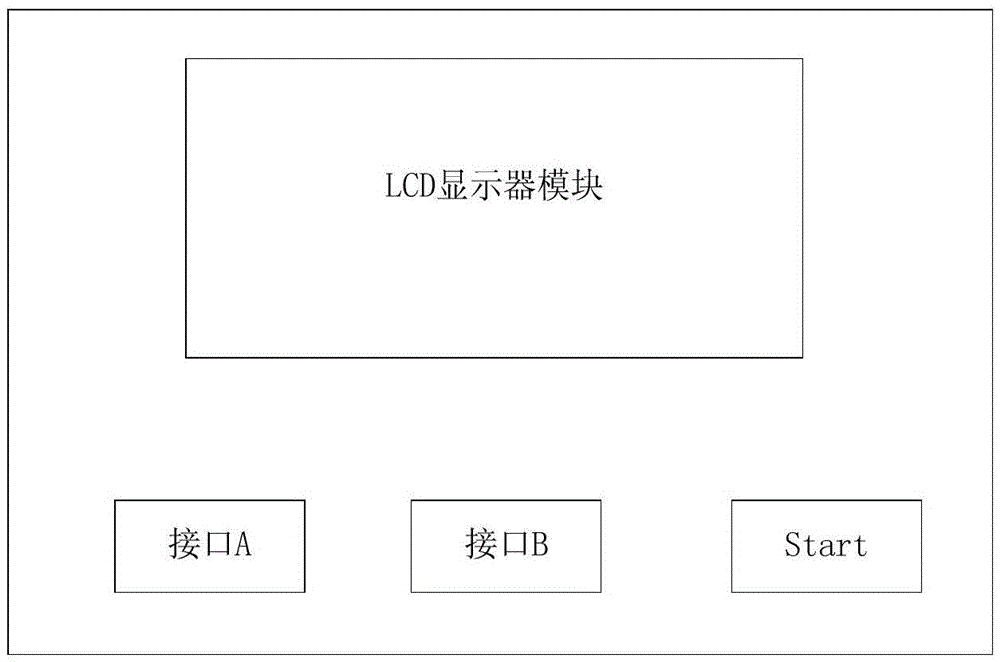

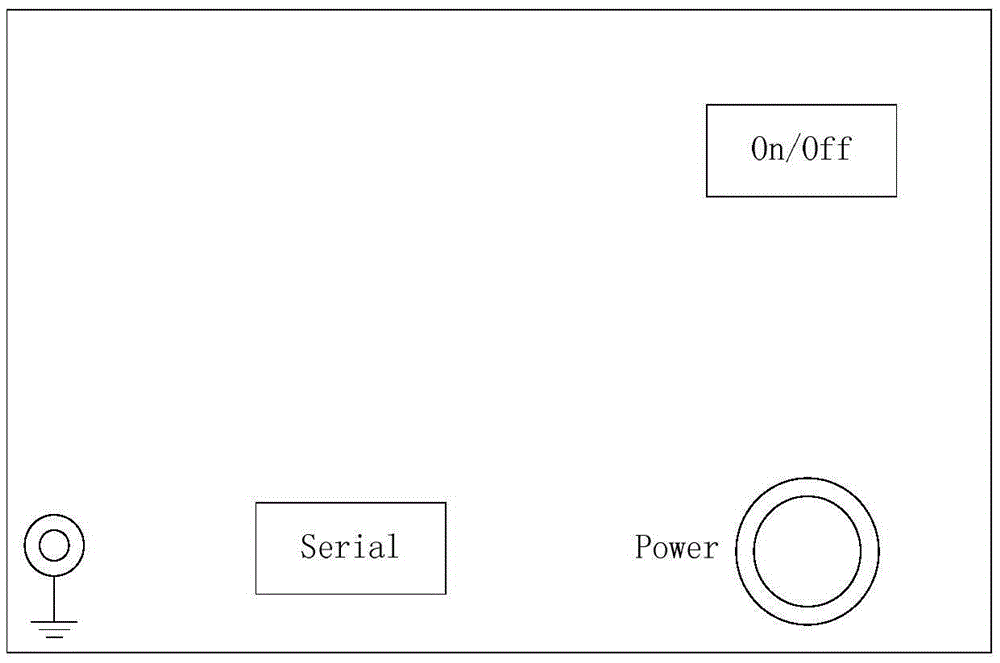

USB3.1 Type-C cable automatic testing method and system

The invention provides a USB3.1 Type-C cable automatic testing method and system, and the system at least comprises a main control part which comprises a main control CPU, carries out the testing of a USB3.1 Type-C cable through the operation of a program, enables a testing result to be displayed on a display screen, and determines whether the testing result is transmitted to a PC or not according to the needs; a serial port module which comprises a serial port on the main control CPU and an external drive chip, and is used for communicating with a computer; and an interface module which is an independent pluggable module and comprises two USB3.1 Type-C testing interface male seat modules. The system can effectively test a signal of the USB3.1 Type-C cable and test whether short circuit or circuit break happens to a power line or not. Meanwhile, the system cannot damage testing equipment, reduces the error of manual operation, improves the testing efficiency and first pass yield, improves the testing efficiency, and reduces the damages to USB Type-C cable rate testing equipment.

Owner:深圳市易通电子科技有限公司

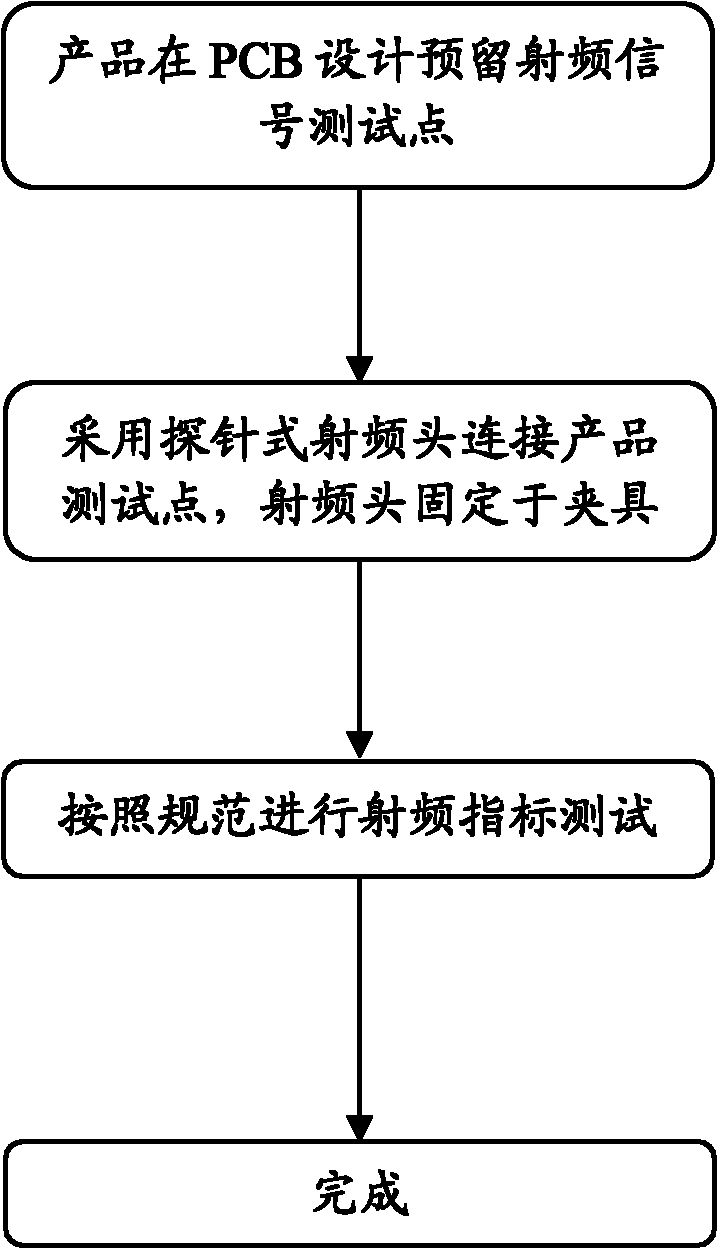

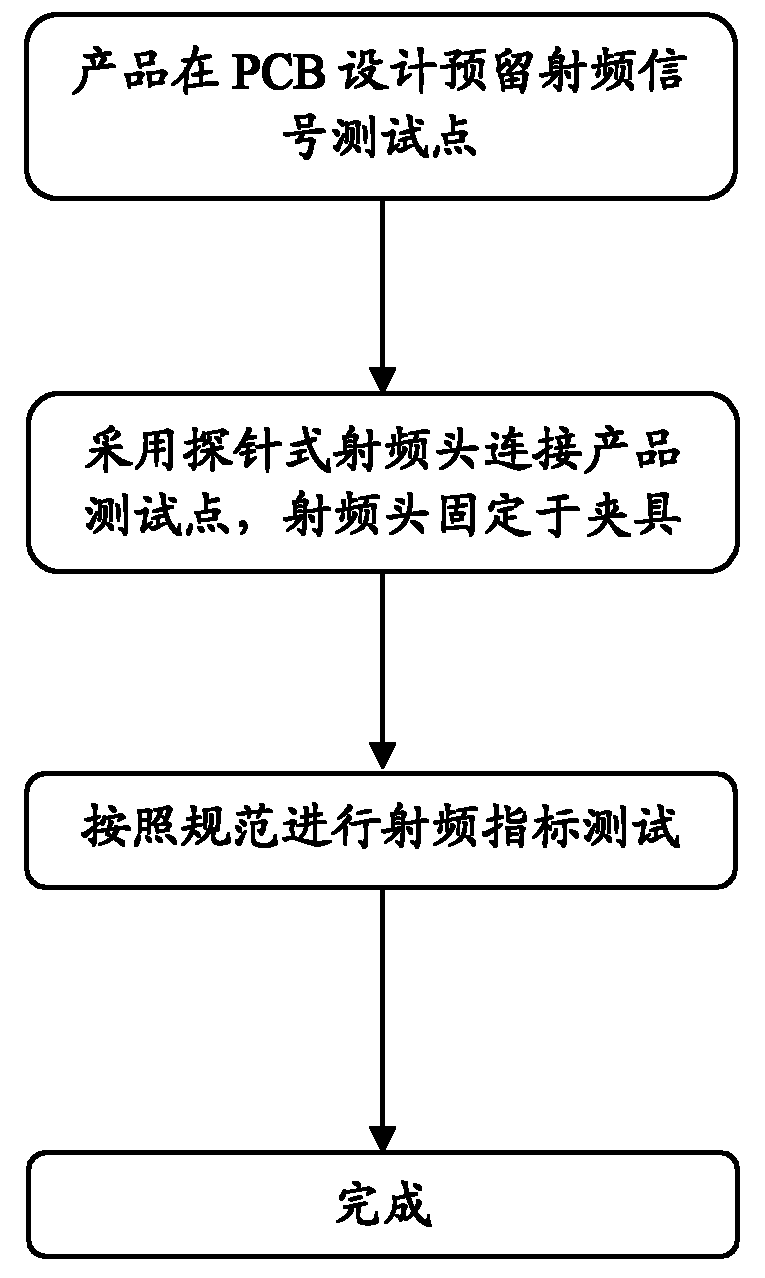

Radio-frequency (RF) signal test connection structure and radio-frequency signal test optimization method

InactiveCN102013930ASolve the costSolve efficiency problemsElectrical testingTransmission monitoringTest efficiencyProbe type

The invention relates to a radio-frequency (RF) signal test connection structure, which comprises a radio-frequency tester, a tested product is provided with a radio-frequency signal test point, the radio-frequency tester is connected with a probe-type radio-frequency head by a radio-frequency cable, and a probe at the end part of the probe-type radio-frequency head is contacted and connected with the radio-frequency signal test point. The invention also relates to a method for realizing radio-frequency signal test optimization based on the radio-frequency signal test connection structure. The radio-frequency signal test connection structure and the radio-frequency signal test optimization method of the invention have the advantages that: the size of the test point is matched with the used probe-type radio-frequency head; the hardware test connection mode is as follows: an RF output port of the tester, the radio-frequency cable, the probe type radio-frequency head, and the radio-frequency signal test point of the tested product are sequentially connected, therefore, the cost for an antenna connector in a BOM of the tested product is saved; the probe-type radio-frequency head is not easy to be damaged, thereby reducing the test cost; the probe-type radio-frequency head is fixed on a clamp for testing, thereby improving the first pass yield of the tested product; meanwhile, the radio-frequency signal test connection structure and the radio-frequency signal test optimization method of the invention are high in test efficiency, simple in structure, fast and convenient to operate, stable and reliable in operating performance, and wide in application scope.

Owner:SHANGHAI GONGJIN COMM TECH

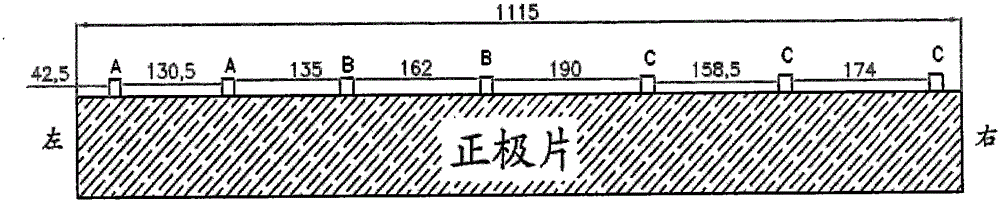

Lithium ion battery and preparation method thereof

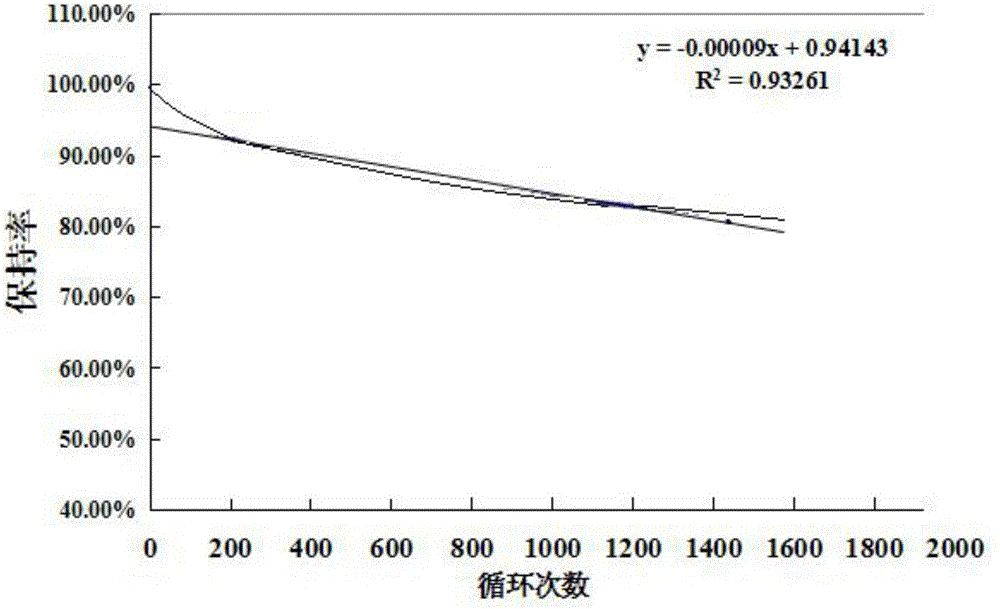

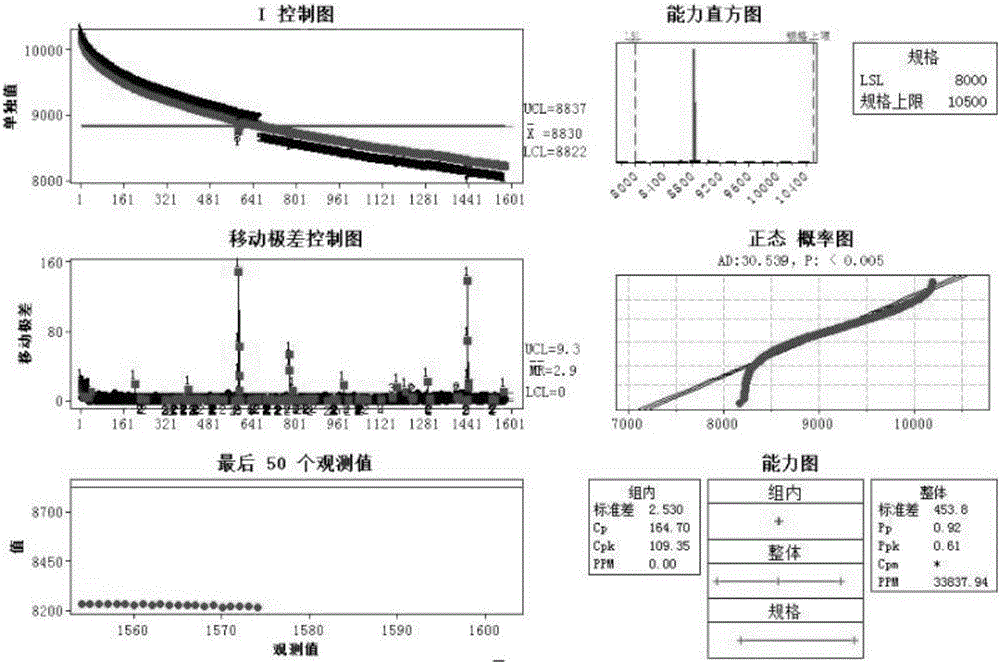

InactiveCN105932282AThe preparation process is highly controllableImprove consistencyFinal product manufactureCell electrodesHigh rateHigh energy

The invention discloses a lithium ion battery and a preparation method thereof. The lithium ion battery comprises cathode slurry and anode slurry, wherein the solid content of the cathode slurry is 50.0%-60.0% and the viscosity number is 6000-8000 cp; the solid content of the anode slurry is 40.0%-50.0% and the viscosity number is 3000-5000 cp. The invention further comprises the preparation method. After circulation for 1500 times, the capacity retention ratio of a lithium iron phosphate system lithium ion battery with high magnification, high energy density and long service life is higher than 80.0% and the energy density is greater than 175 Wh / Kg under the high-rate charge-discharge system of 10-20 C; the preparation method has the advantages of simple selected material system, strong controllability of the preparation process, good product consistency and high section first pass yield; the processing first pass yield of a lithium ion battery with the rated capacity of 10 AH reaches up to 87.5%, and the product percent of pass is high and reaches up to 95.3%.

Owner:湖南锂顺能源科技有限公司

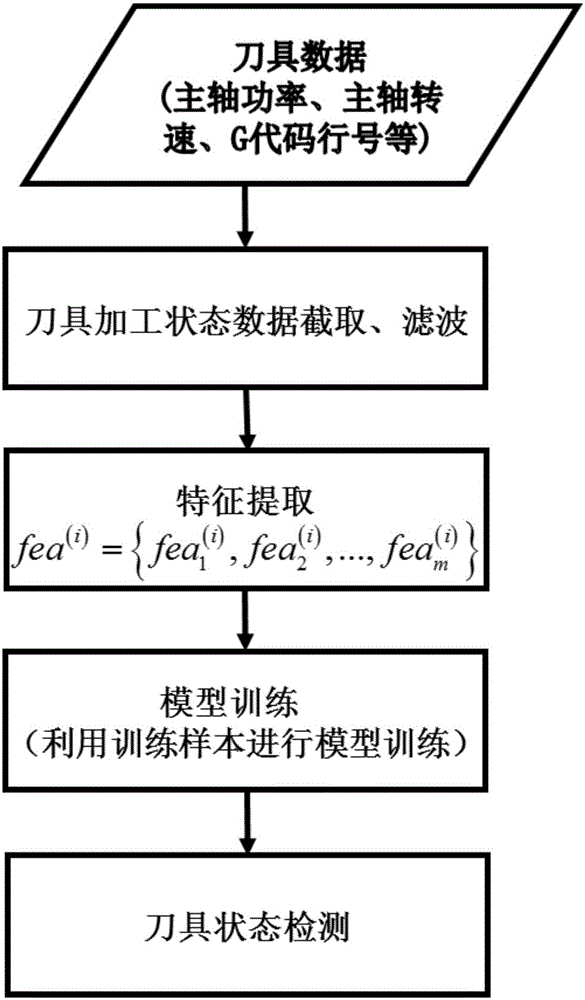

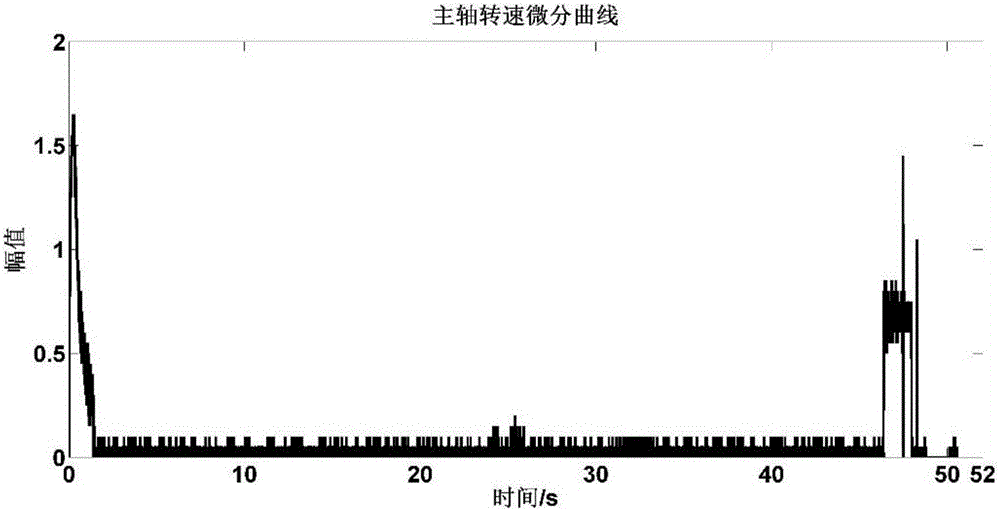

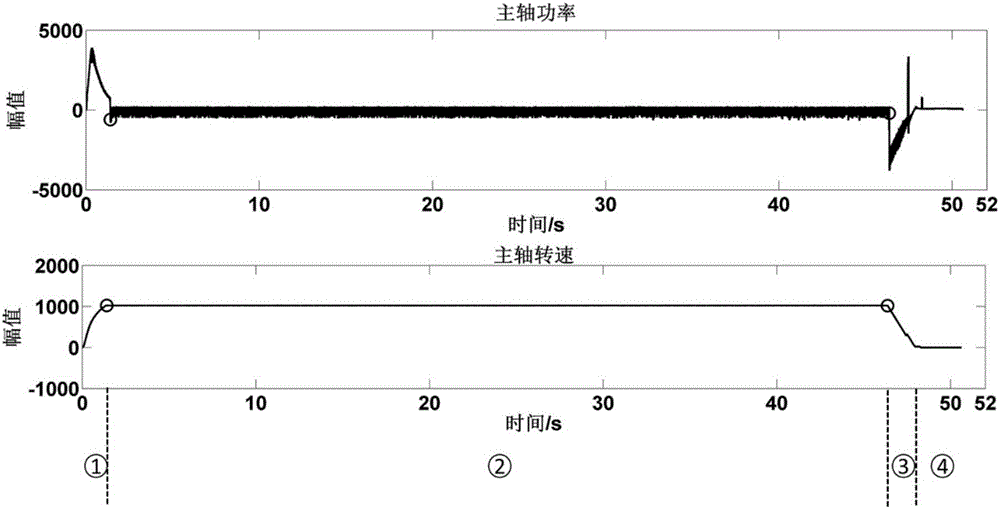

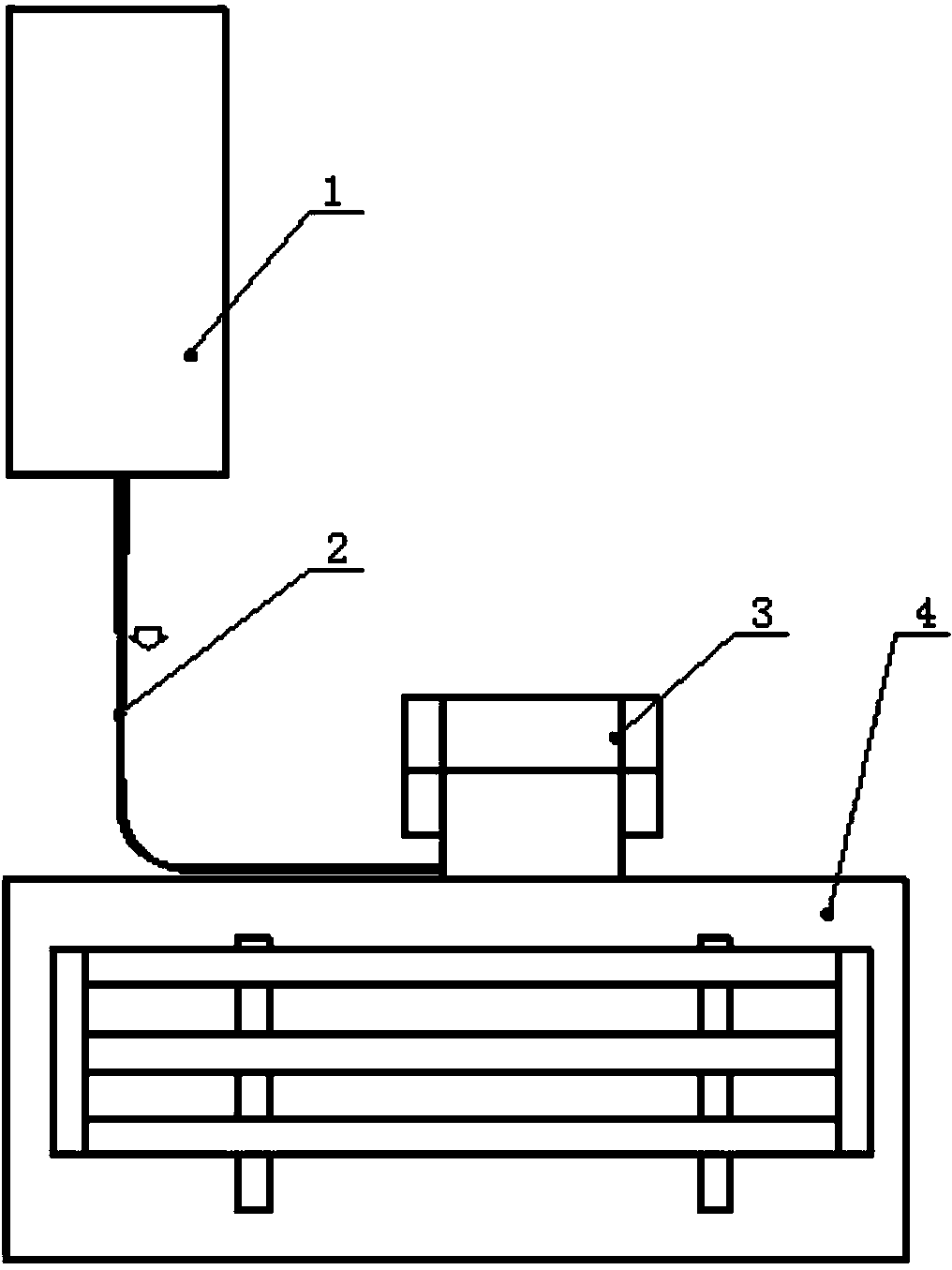

Cutter breakage detection method based on internal data of numerical control system

InactiveCN106647629AGuaranteed to be authenticLow costProgramme controlComputer controlFeature vectorProduction line

The invention discloses a cutter breakage detection method based on internal data of a numerical control system, comprising the following steps: (1) collecting the internal data of a numerical control system as cutter data, recording manufacturing resource data, and intercepting machining state data from the cutter data and pre-filtering the cutter data to get low-frequency data of cutter machining state; (2) extracting signal features characterizing cutter state according to the low-frequency data of cutter machining state to form a feature vector fea={fea<1>, fea<2>,...,fea<m>}, wherein i is the sample number of cutter data, and m is the number of feature dimensions; and (3) carrying out model training according to the feature vector and a corresponding category thereof to get a training model, judging the state of a cutter according to the training model, and completing cutter breakage detection in this way. A real-time accurate cutter breakage detection function is achieved. Subsequent scraping of cutters and parts is avoided. The first pass yield of products of an automatic production line is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

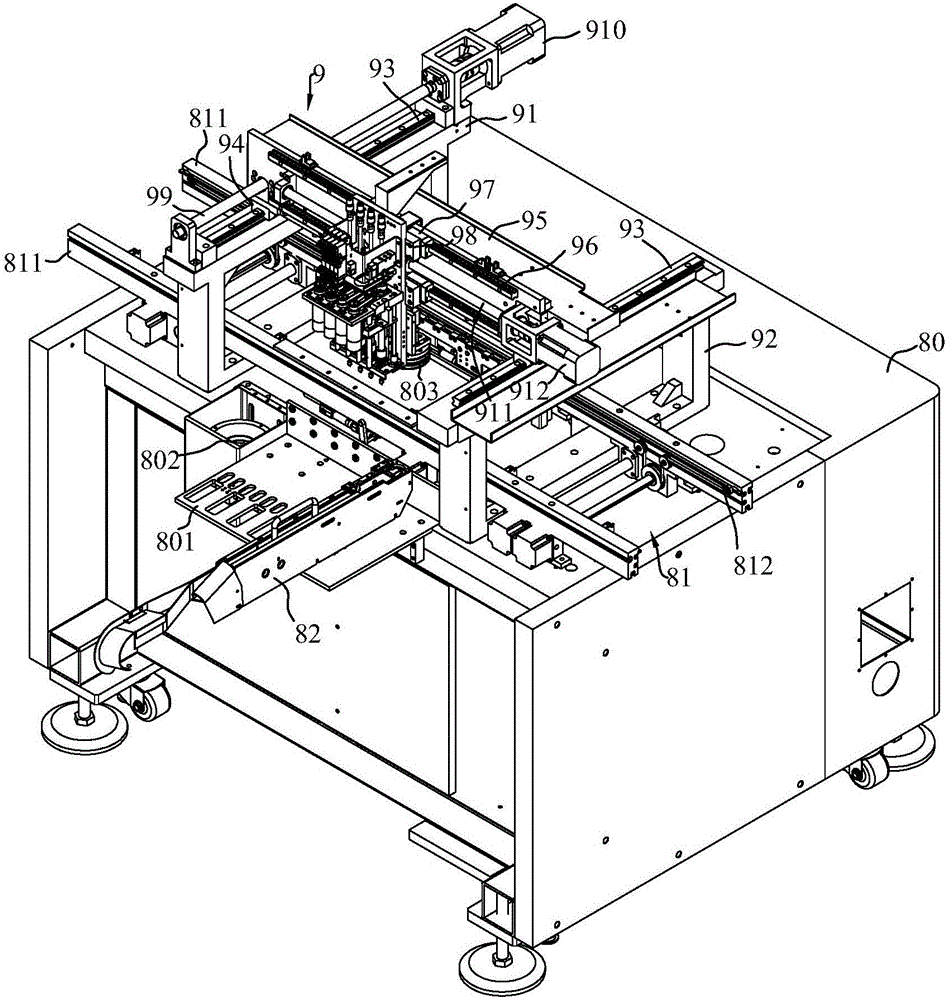

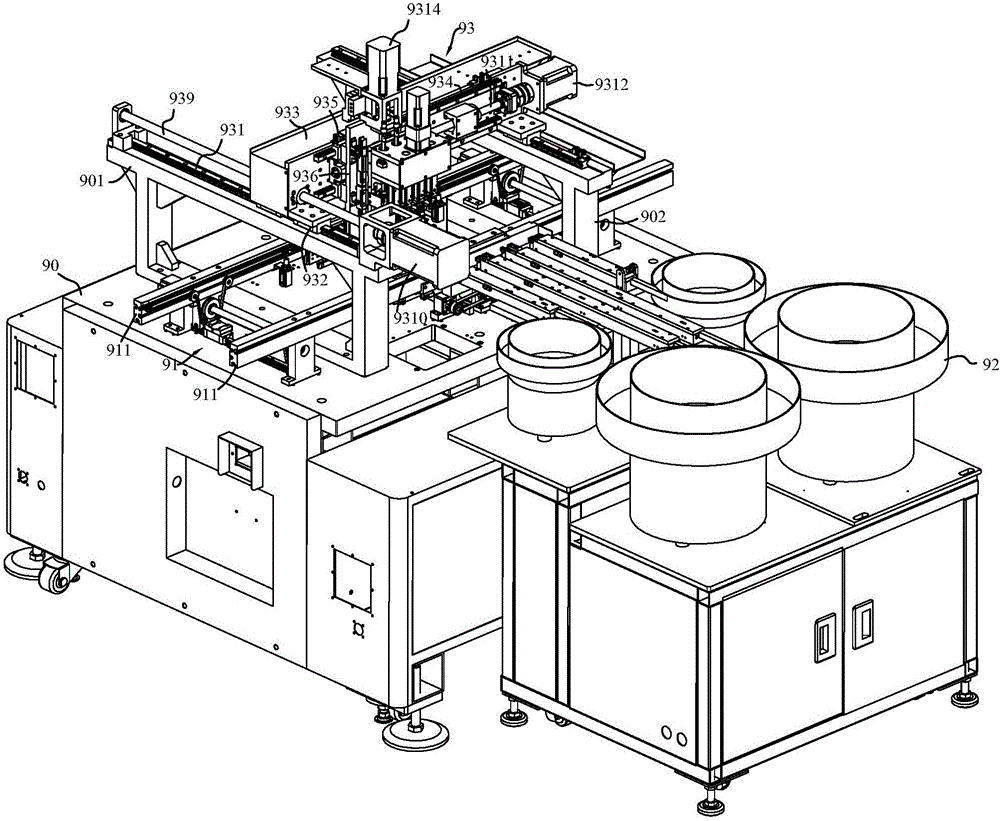

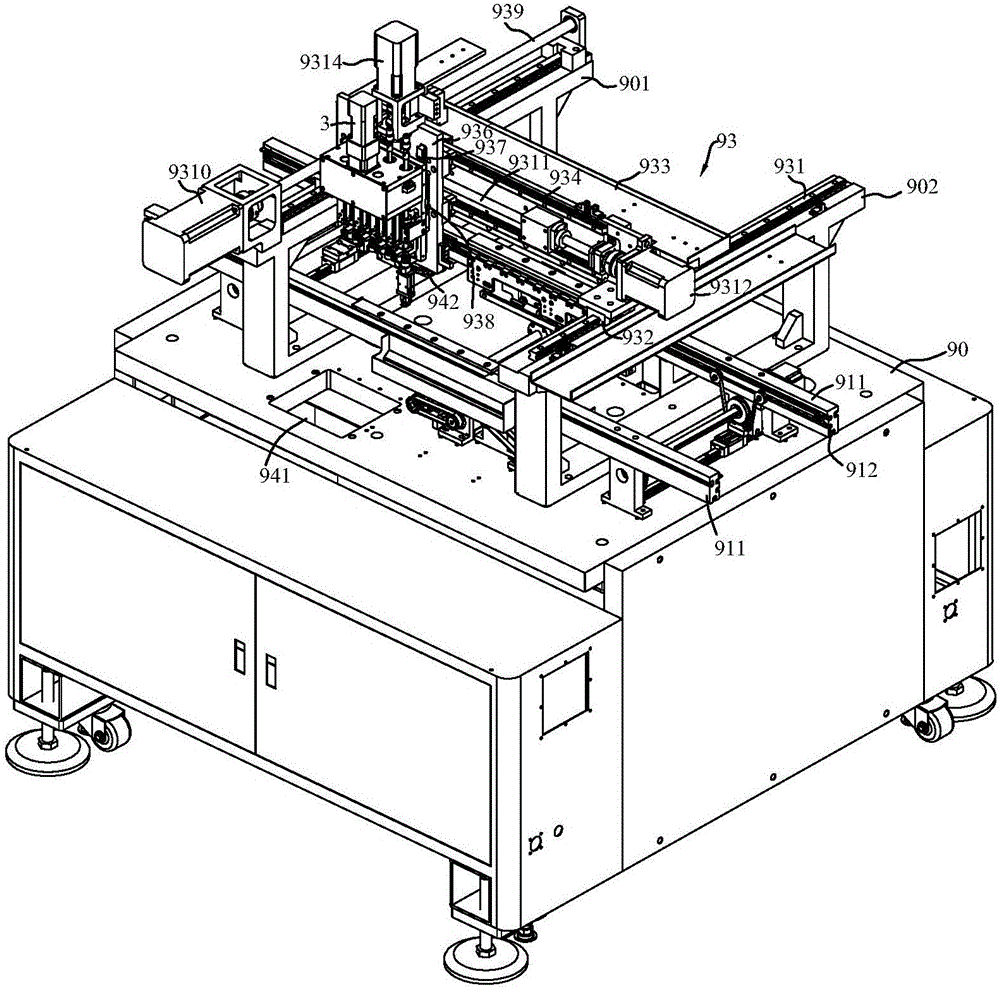

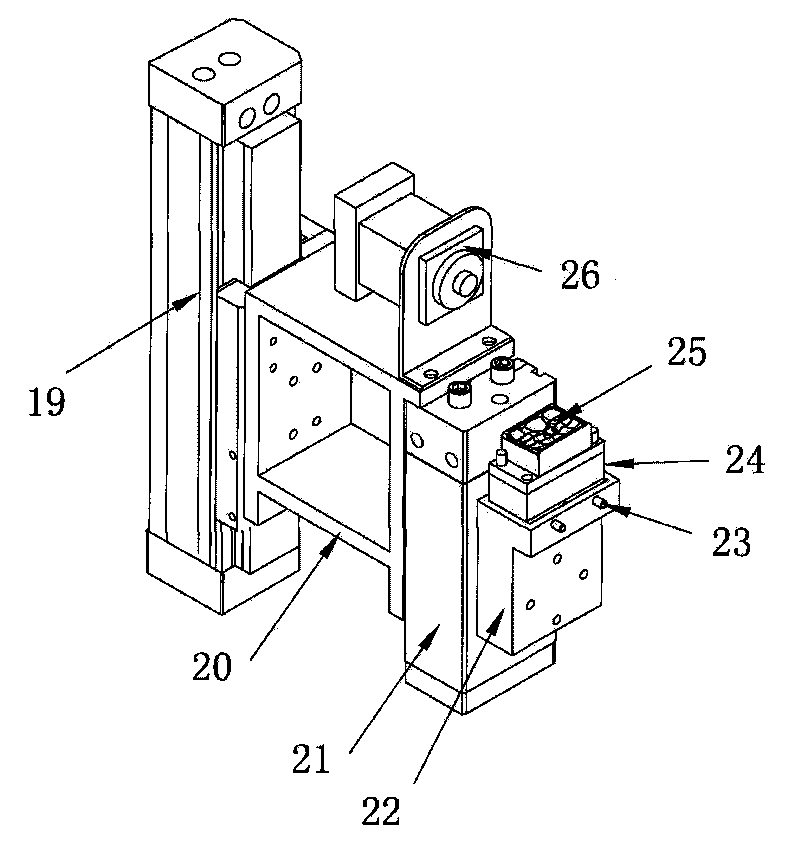

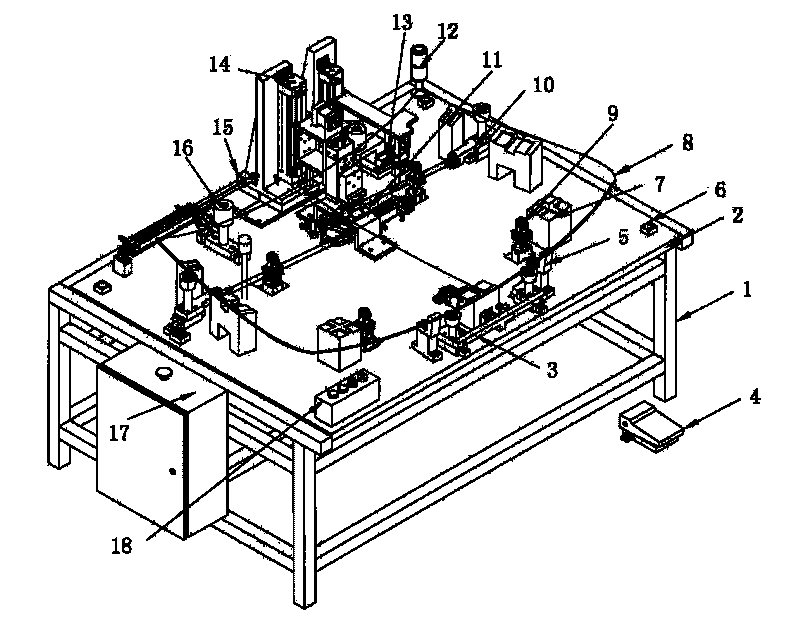

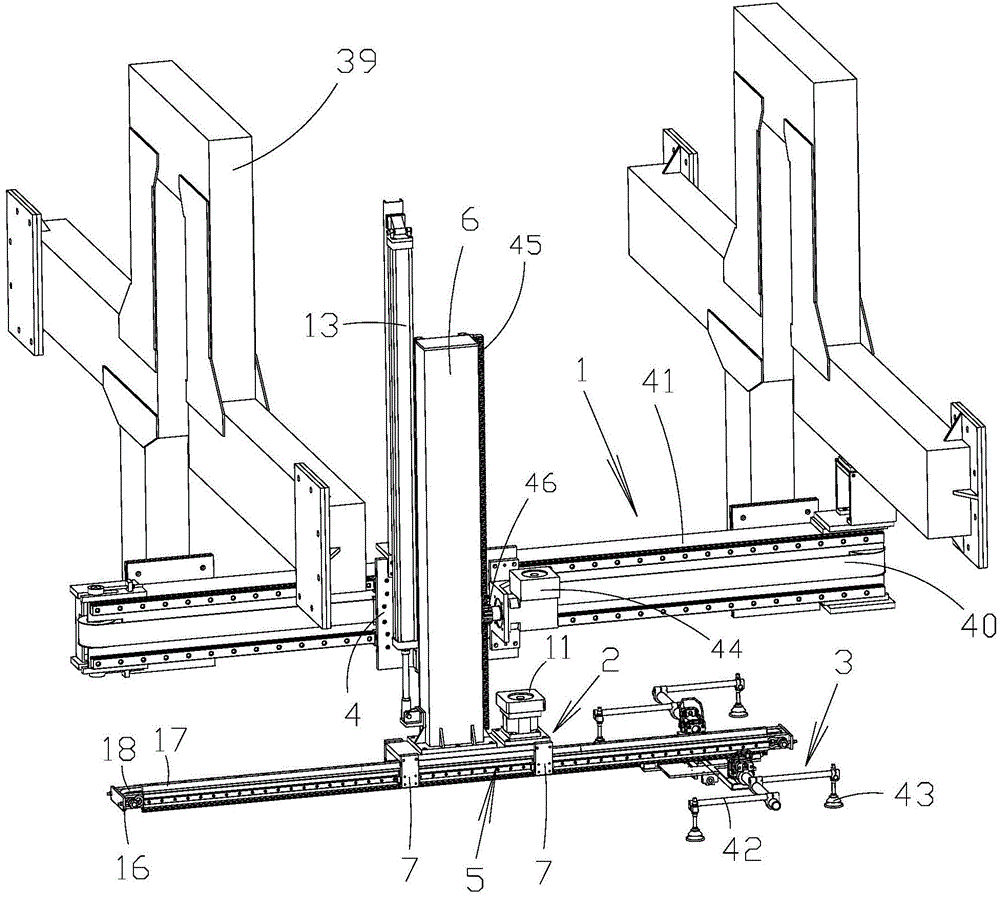

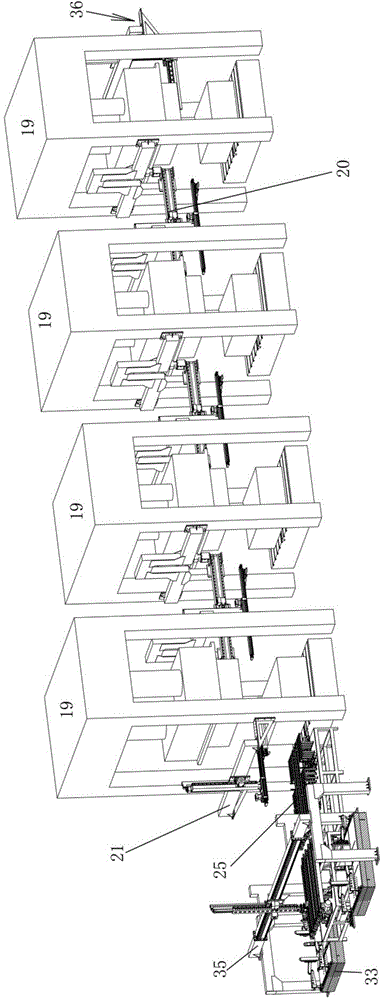

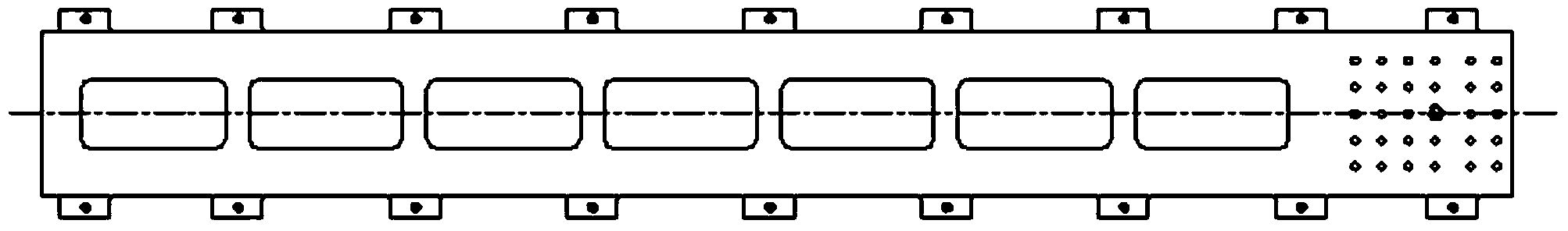

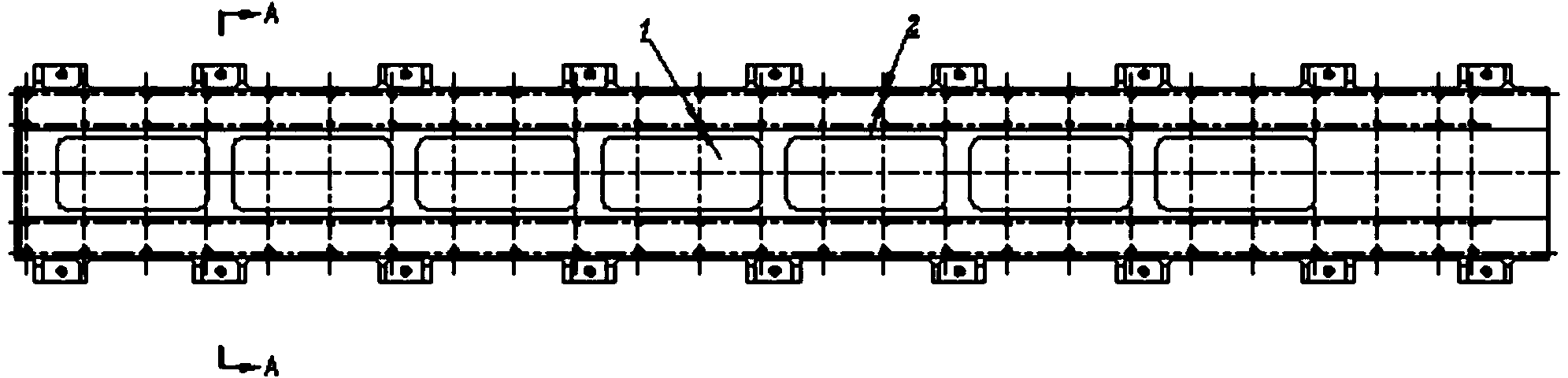

Automatic core assembling machine for core body of warm wind radiator and working method thereof

ActiveCN103419022ARealize the purpose of automatic feedingRealize the purpose of automatic handlingAssembly machinesFirst pass yieldManipulator

The invention relates to an automatic core assembling machine for a core body of a warm wind radiator, which comprises a fin machine, a flat pipe feeding device and an assembly machine. The fin machine is connected with a feed inlet of the assembly machine by a transfer rail; a discharge port of the flat pipe feeding device is also connected with the feed inlet of the assembly machine. The automatic core assembling machine fulfills the aim of automatically feeding fins and flat pipes by the transfer rail and the flat pipe feeding device; assembled flat pipe and fin assemblies are transferred to a designated core body assembling table by two manipulators so as to fulfill the aim of automatic carrying; moreover, the two manipulators alternately work, so that working efficiency is effectively improved. The automatic core assembling machine has a simple structure and is scientifically and reasonably designed; automatic operation in the installing process of the core body is sufficiently implemented; labor is saved, processing cost of a product is reduced, damage and collision to a workpiece, which are caused by manual carrying, are avoided, working efficiency is effectively improved, and the first-pass yield of product quality is improved to the current first-pass yield of PPM500 from the original first-pass yield of PPM10000.

Owner:TIANJIN YAXING RADIATOR

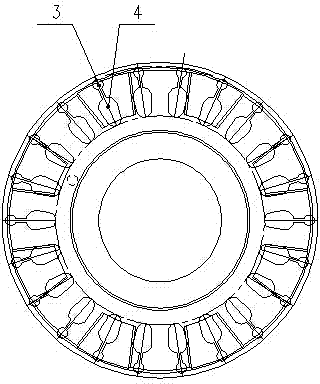

Double-mouse-cage composite cage bar efficient motor rotor and manufacturing method thereof

InactiveCN104767334ASimple structureEasy to produceAsynchronous induction motorsManufacturing stator/rotor bodiesFirst pass yieldCopper

The invention relates to a double-mouse-cage composite cage bar efficient motor rotor and a manufacturing method thereof, and belongs to the technical field of motors. The double-mouse-cage composite cage bar efficient motor rotor comprises a rotor body, an iron core of the rotor body includes an inner mouse cage and an outer mouse cage with mouse cage bars being close to each other or tangent to each other, and end rings at the two ends of each mouse cage bar of the inner mouse cage and the outer mouse cage are connected into a whole; the outer mouse cage is made of a high electrical resistivity aluminum casting material, and the inner mouse cage is made of a low electrical resistivity pure copper (red copper) bar material. The manufacturing method of the composite cage bar efficient motor rotor includes the following steps that 1, the rotor iron cores are overlaid; 2, inner mouse cage pure copper (red copper) bars are arranged alternately; 3, aluminum casting is conducted on the outer mouse cage of the rotor. The device is reasonable and simple in structure, the manufacturing method is scientific and advanced, the first-pass yield of products is high, and the production cycle of the products is shortened.

Owner:江苏利得尔电机有限公司

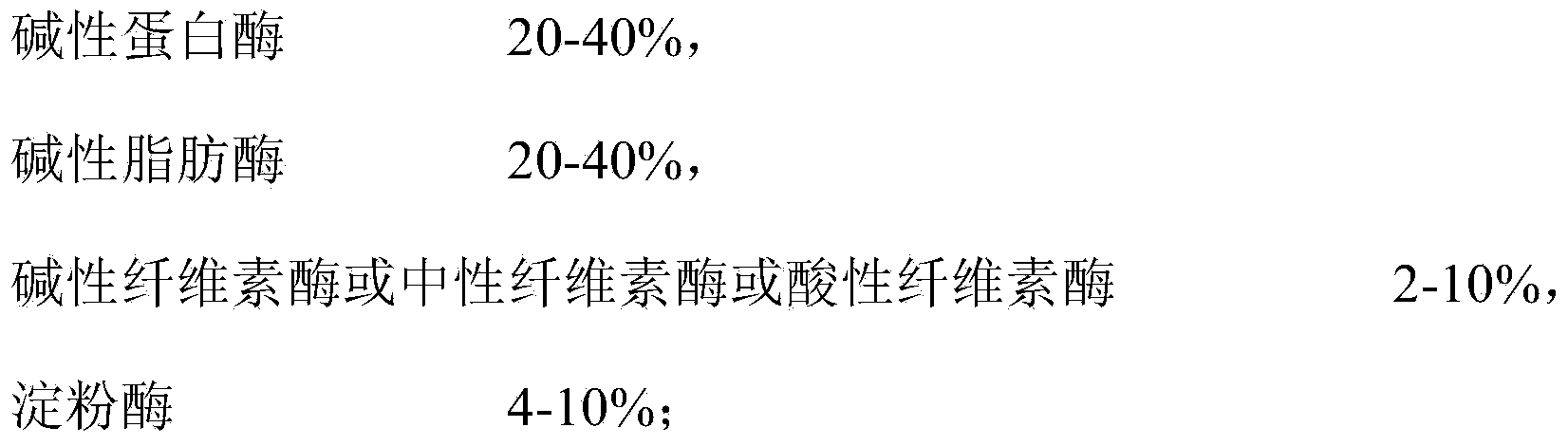

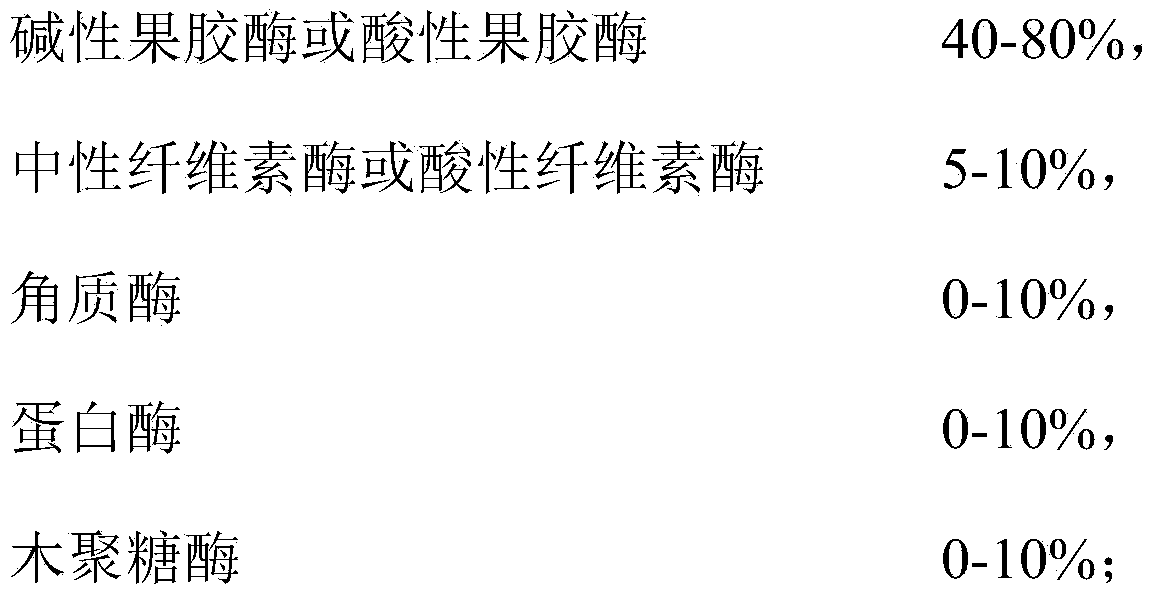

Biological enzyme cold-pad-batch short-process open-width continuous-scouring bleaching and dyeing production technology of cotton knitted fabric

ActiveCN103952918AImprove wearing comfortEnergy consumption hasBiochemical fibre treatmentDry-cleaning apparatus for textilesFiberFirst pass yield

The invention belongs to the technical field of cotton knitted fabric printing and dyeing and particularly relates to a biological enzyme cold-pad-batch short-process open-width continuous-scouring bleaching and dyeing production technology of a cotton knitted fabric. According to the technology with a biological enzyme technique as core, the whole processes of scouring, bleaching and dyeing of the cotton knitted fabric are performed by virtue of an open-width continuous cold-pad-batch approach, and the traditional high-temperature strong-alkali technology and the intermittent production technologies such as an overflow vat process can be replaced by the continuous-scouring bleaching and dyeing production technology. Compared with the traditional technology, the continuous-scouring bleaching and dyeing production technology has the effects of saving water by 30%-50%, gas by 15%-20% and dyes by 5%-10%, reducing emission by about 20%, enhancing the application performance and the wearability of the fibers, improving the handfeel of the fabric, increasing the dye-uptake rate and the first-pass yield, and lowering the repair rate; besides, the consumption of raw materials and the comprehensive cost are lowered and the production efficiency is increased remarkably.

Owner:TSINGHUA UNIV

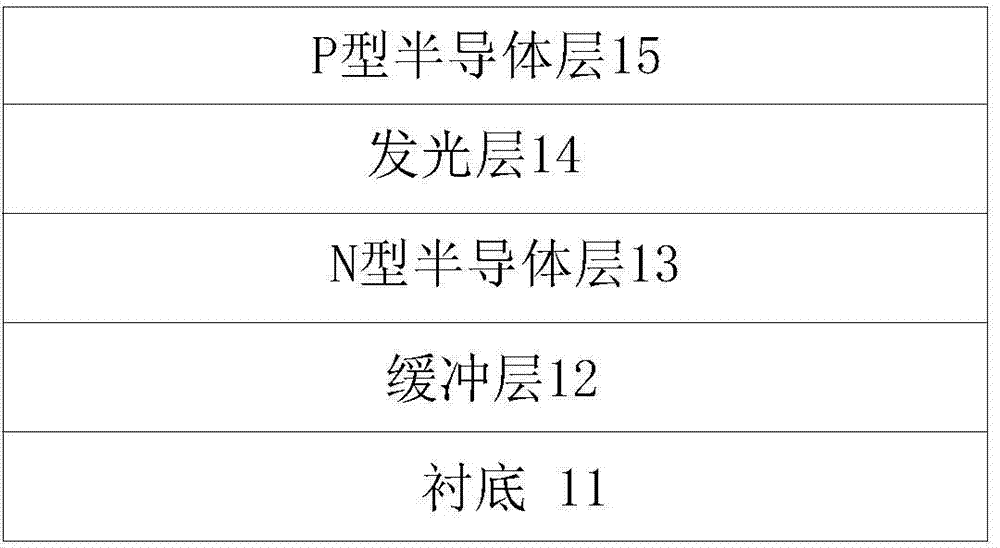

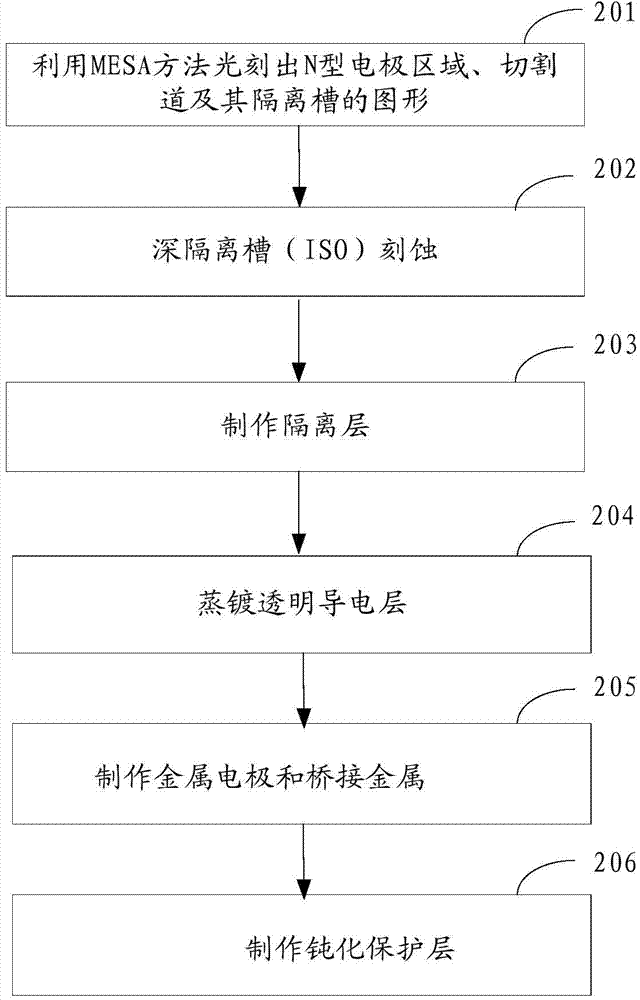

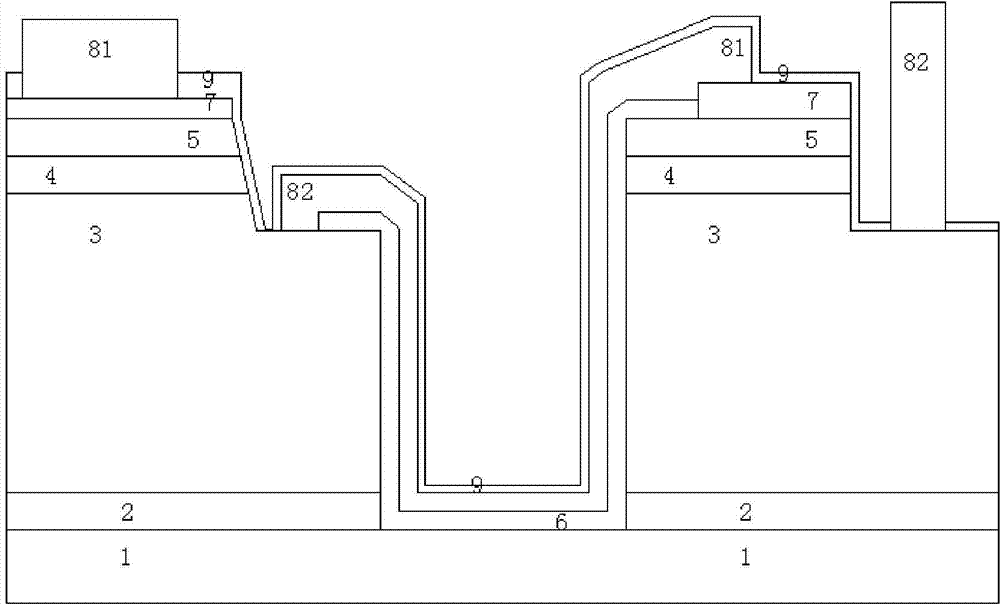

High-voltage light-emitting diode and manufacturing method thereof

ActiveCN104733573AImprove yieldImprove production line straight-through rateSemiconductor devicesEvaporationFirst pass yield

Owner:XIANGNENG HUALEI OPTOELECTRONICS

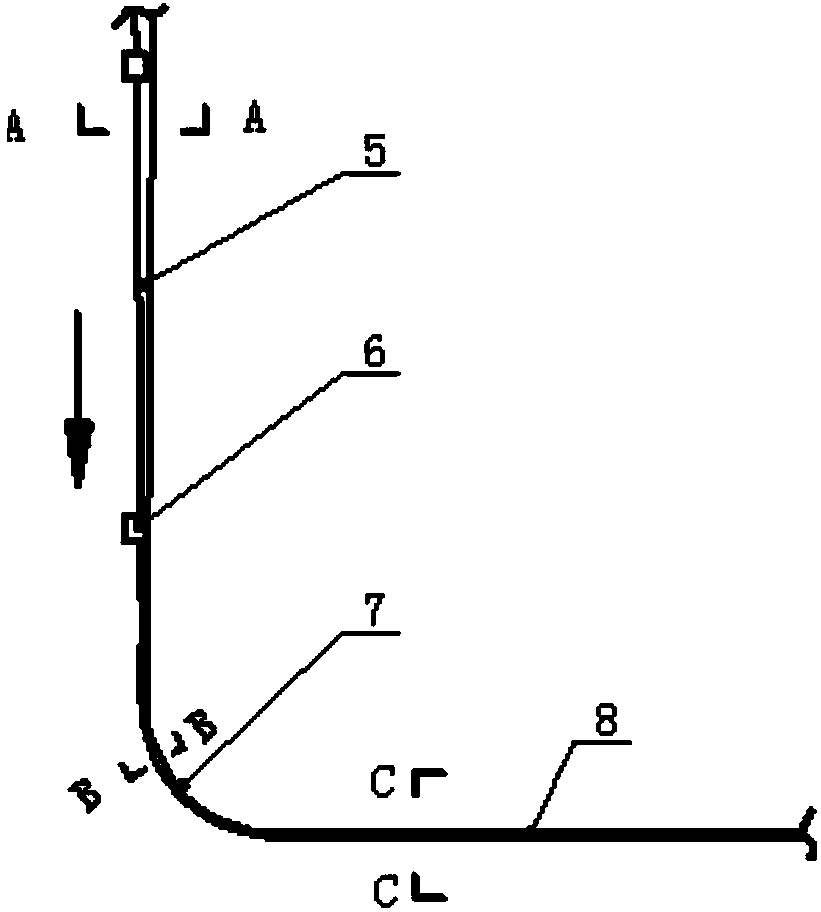

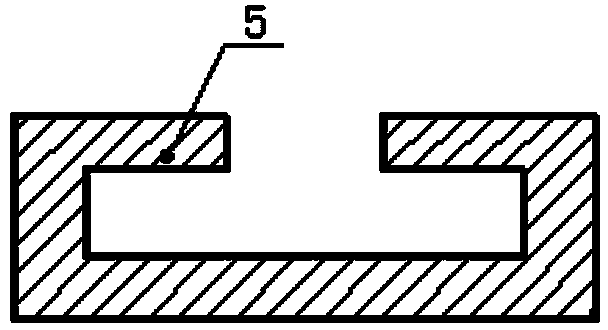

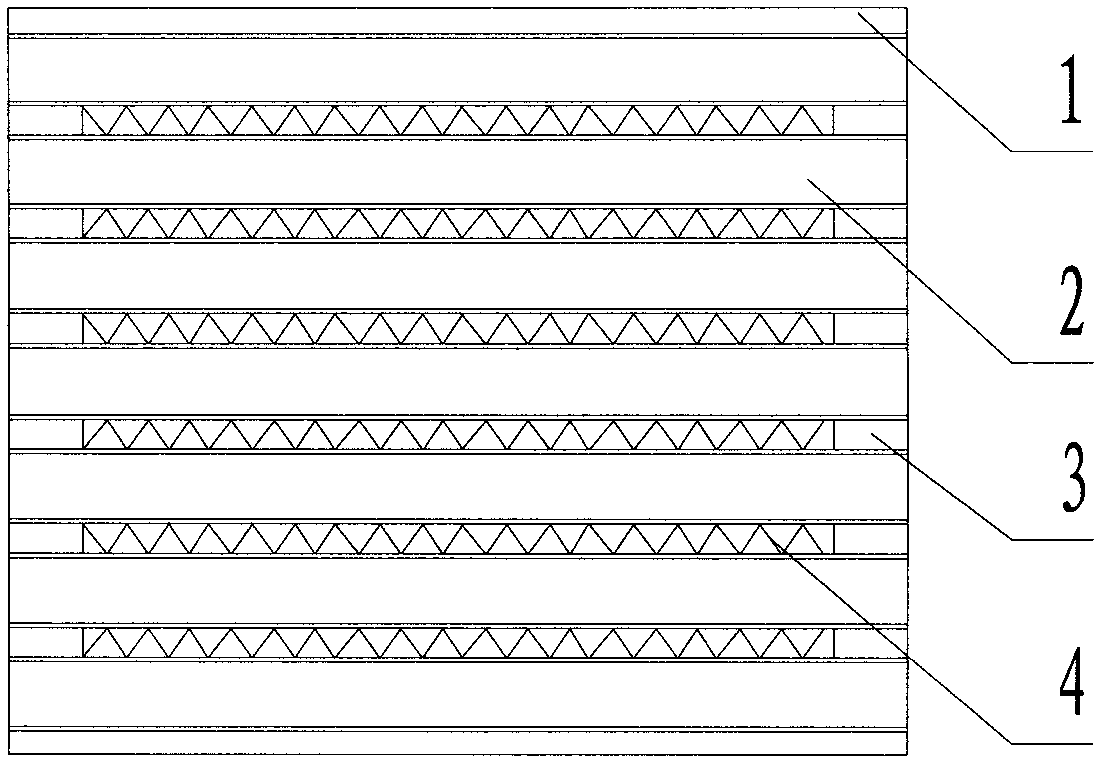

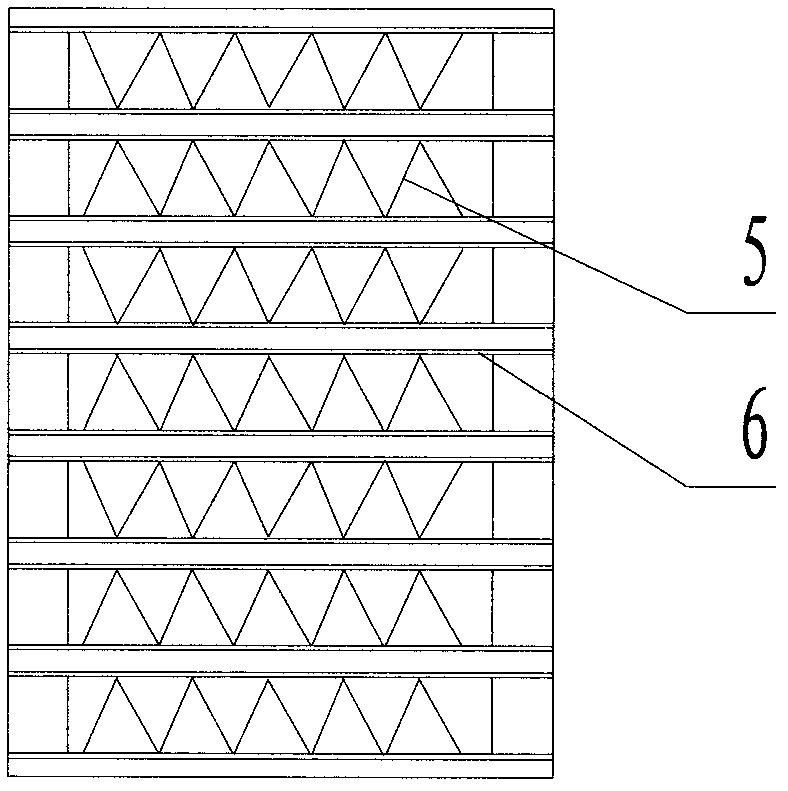

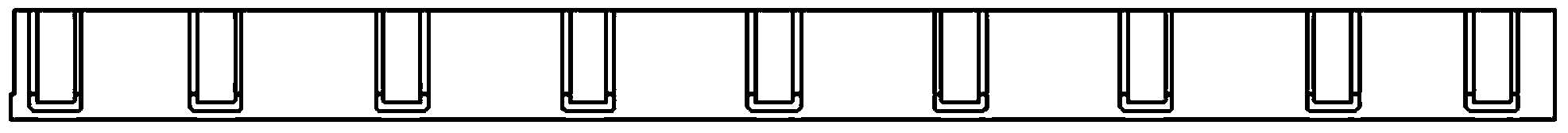

Welding method of stainless steel plate-fin radiator

InactiveCN103157911AImprove brazing pass rateImprove pass rateSoldering apparatusWelding apparatusMetallurgyFirst pass yield

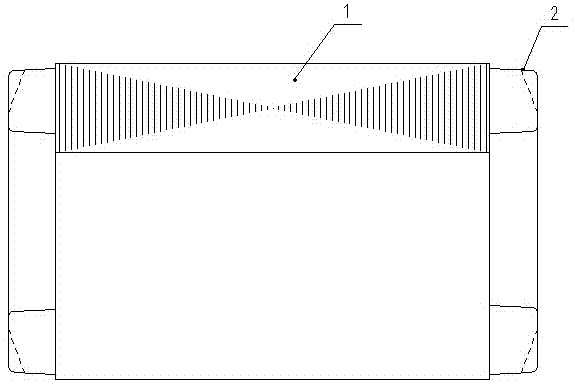

A radiator cell component 9 is formed by a side plate 1, a long strip seal 2, a short strip seal 3, cold edge fins 4, hot edge fins 5 and partition plates 6. When the radiator cell component 9 is assembled and brazed, metal-sheet-shaped stainless steel brazing filler metal is selected, a connection plate 7 is added between the radiator cell component 9 and a gas-collecting hood 8, meanwhile the side plate 1 is enlarged, and a stainless steel plate-fin radiator is made and formed through the method of twice brazing and twice fusion welding. Due to the fact that the metal-sheet-shaped stainless steel brazing filler metal is selected, the first-pass yield of the brazing of the radiator cell component is improved. The connection plate 7 is added to the radiator cell component, the side plate 1 is enlarged, the solder joint of the radiator cell component is far from the welding joint of the arc welding of the gas-collecting hood 8 and the connection plate7 and the side plate 1, and therefore the phenomenon of fissures cannot occur.

Owner:GUIZHOU YONGHONG AVIATION MACHINERY

Automatic wet process lamination method of rigid printed circuit boards

ActiveCN101605432APrevent oxidationImprove liquidityNon-metallic protective coating applicationAlcoholImage transfer

The invention discloses an automatic wet process lamination method of rigid printed circuit boards, comprising the following steps: adding 0.01-1.5% of surface active agent to water; then coating the mixture evenly on the surface of copper to form liquid membrane. The added surface active agent is butanone MEK, carboxyl benzotriazole, citric acid or alcohol antioxidant; with the method of the invention adopted to laminate the rigid printed circuit boards, surface oxidization of copper foil can be effectively prevented and copper surface can be protected; compared with the traditional wet process lamination method, the method of the invention strengthens liquidity of dry film and can better fill scratches and sink marks on the copper surface, thus strengthening binding force of the dry film and the copper surface and improving first pass yield of imaging transfer.

Owner:PANYU NANSHA YAN TIN CHEM

Processing and assembling method for linear combined guide rail of box body

ActiveCN104227360AGood dimensional stabilityHigh dimensional accuracyMetal working apparatusFirst pass yieldEngineering

The invention provides a processing and assembling method for a linear combined guide rail of a box body. The processing and assembling method comprises the following steps of processing a back guide rail body by marking a milling line, roughly milling an appearance, performing artificial aging, finish-milling the appearance, drilling holes, milling two end faces, marking hole lines and boring; processing left and right slide rails by drilling hanging holes, quenching and tempering, straightening, planing all sides, marking planing lines, planing steps, milling appearances, drilling center holes and drilling holes; processing left and right depression bars by straightening, milling appearances, milling lengths, milling arcs, drilling center holes and drilling holes; sleeving parts together, mounting the left and right slide rails, milling sliding surfaces and depression bar mounting faces, and mounting the left and right depression bars for assembly. According to the processing and assembling method, the work efficiency and the product quality are improved, and the first-pass yield of product assembly is improved.

Owner:中国航天科工集团第六研究院二一〇所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com