Method for bonding automobile glass rain sensor bracket

A technology for automotive glass and rain sensors, applied to windshields, motor vehicles, vehicle parts, etc., can solve problems such as low efficiency, large errors, and bubbles, and achieve the effect of improving efficiency and reducing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

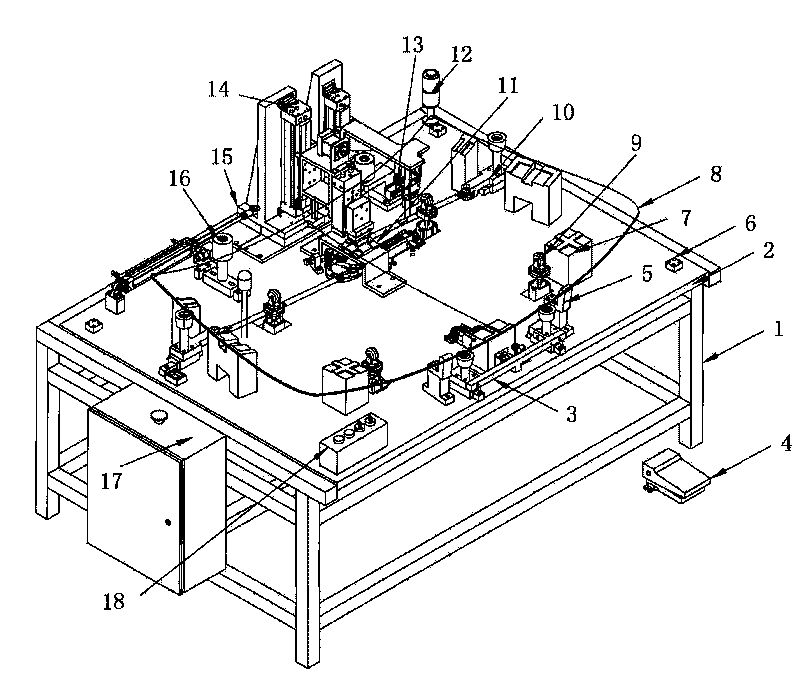

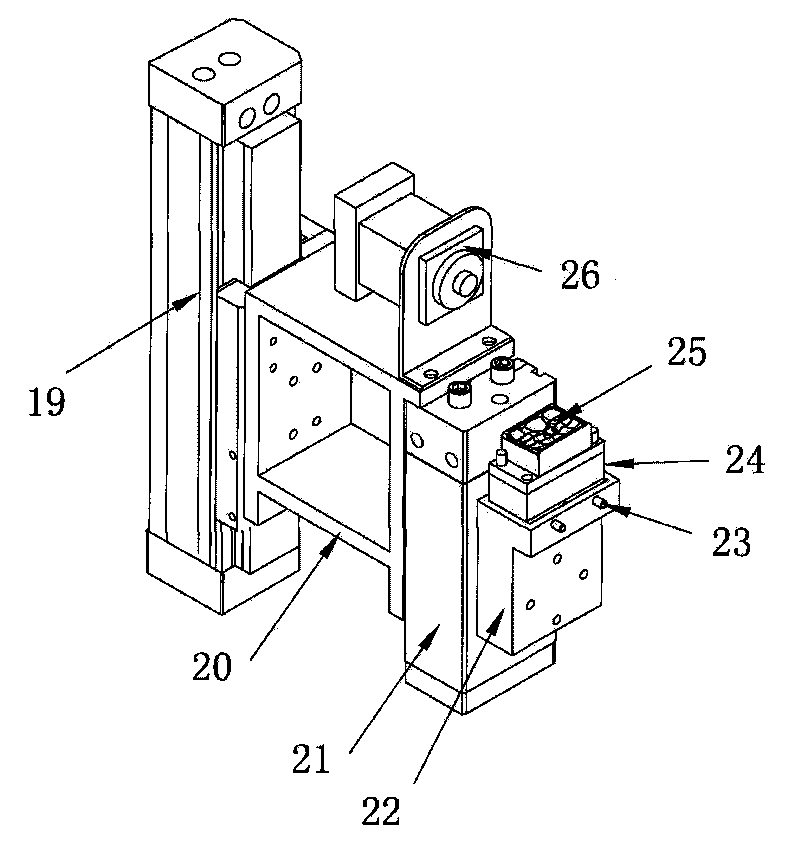

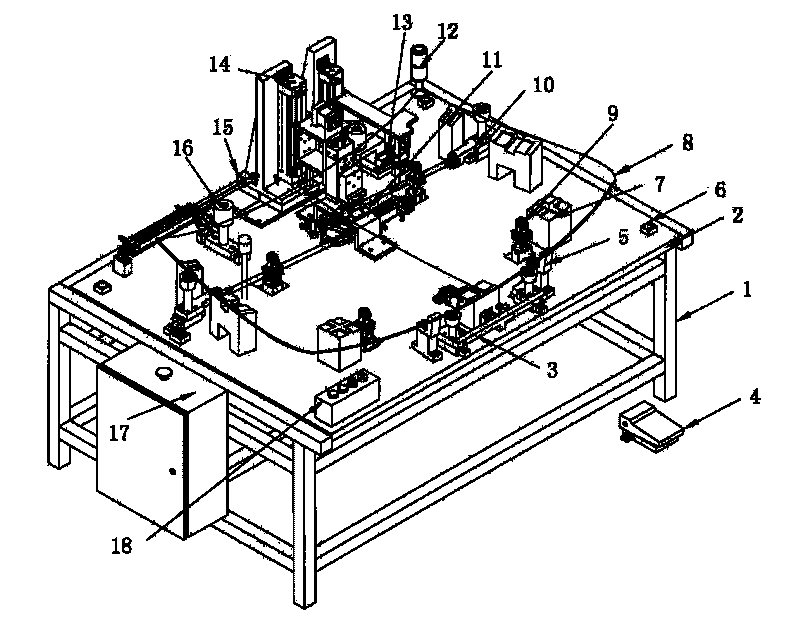

[0019] Such as Figure 1~2 Shown: a new method of bonding automobile glass rain sensor bracket The equipment used includes chassis 1, base 2, guide block 5, guide sliding wheel 9, detection unit 13, rain sensor bracket installation unit 14, positioning device 16. The base 2 is installed on the underframe 1, and each edge of the base 2 is equipped with a plurality of reference blocks 6, and is provided with a plurality of nylon blocks 7, and a corner of the base 2 is provided with a debugging control device 18; One side of the underframe 1 is provided with an electrical box 17, and the electrical box 17 is provided with an emergency stop device; the guide block 5 is provided with a guide sliding wheel 9; the detection unit 13 and the rain sensor bracket installation unit 14 is fixed on two cross rollers; the positioning device 16 is arranged on the base 2, and a clamping unit is arranged beside the positioning device 16; the rain sensor bracket installation unit 14 includes a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com