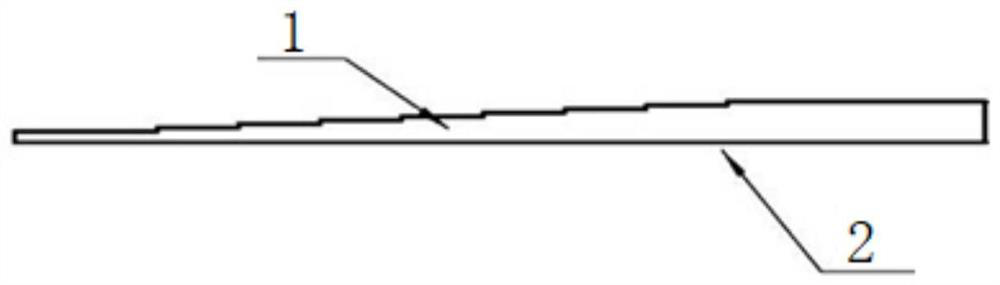

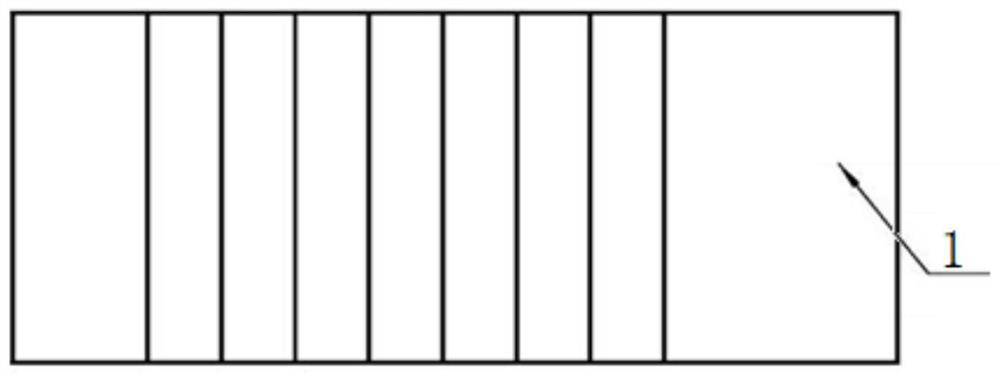

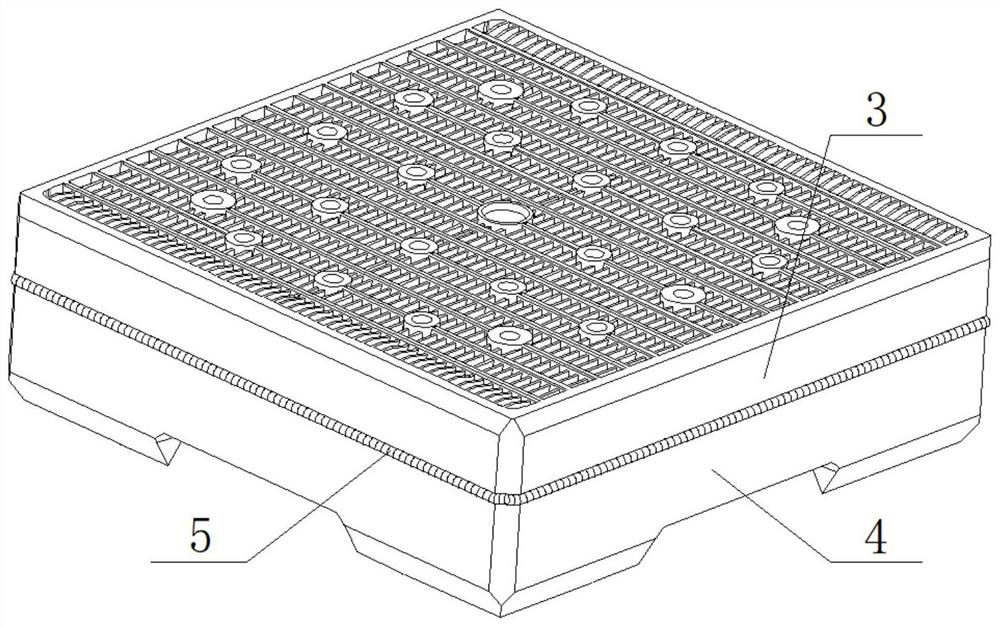

Electron beam welding method for nuclear fuel lower tube base adopting local 3D printing structure

An electron beam welding and 3D printing technology, applied in electron beam welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of time-consuming, labor-intensive, time-wasting and money-wasting, and achieve good economic value and increase the first-time yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Although the electron beam welding method of the nuclear fuel lower nozzle adopting a partial 3D printing structure of the present invention can be implemented in many different ways, this article will describe the exemplary embodiments in detail with reference to the accompanying drawings, without intending to limit the protection of the present invention The scope is limited to the exemplary embodiments. Accordingly, the drawings and description of the detailed description are to be considered as illustrative in nature of the invention and not as limiting.

[0039] The following will be further described in detail through specific embodiments.

[0040] The present invention provides an electron beam welding method of a nuclear fuel lower pipe seat adopting a partial 3D printing structure, comprising the following steps:

[0041] Step S1: Welding process control sample

[0042] Before each production shift welds the product, use the product welding parameter welding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com