Monitoring method for liquid holdup in process of preparing high-purity elemene

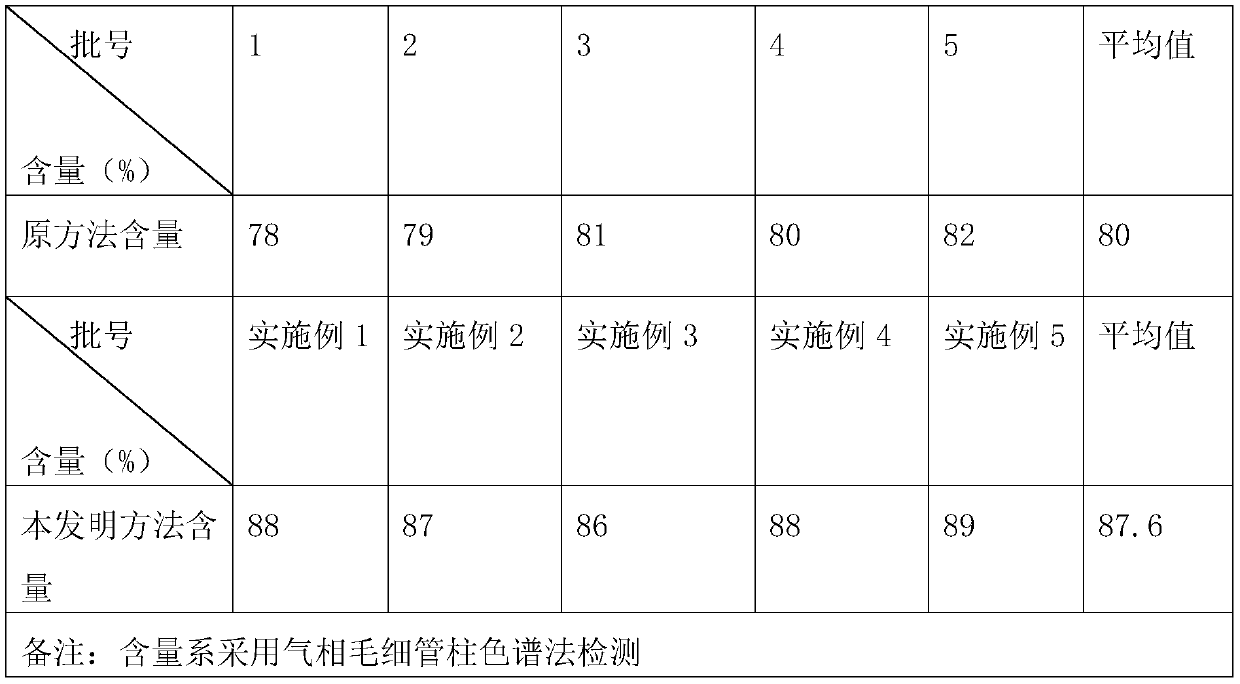

A technology of elemene and liquid holding capacity, which is applied in the field of separation and rectification of natural medicines to achieve the effects of stabilizing product quality, stabilizing column efficiency and improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

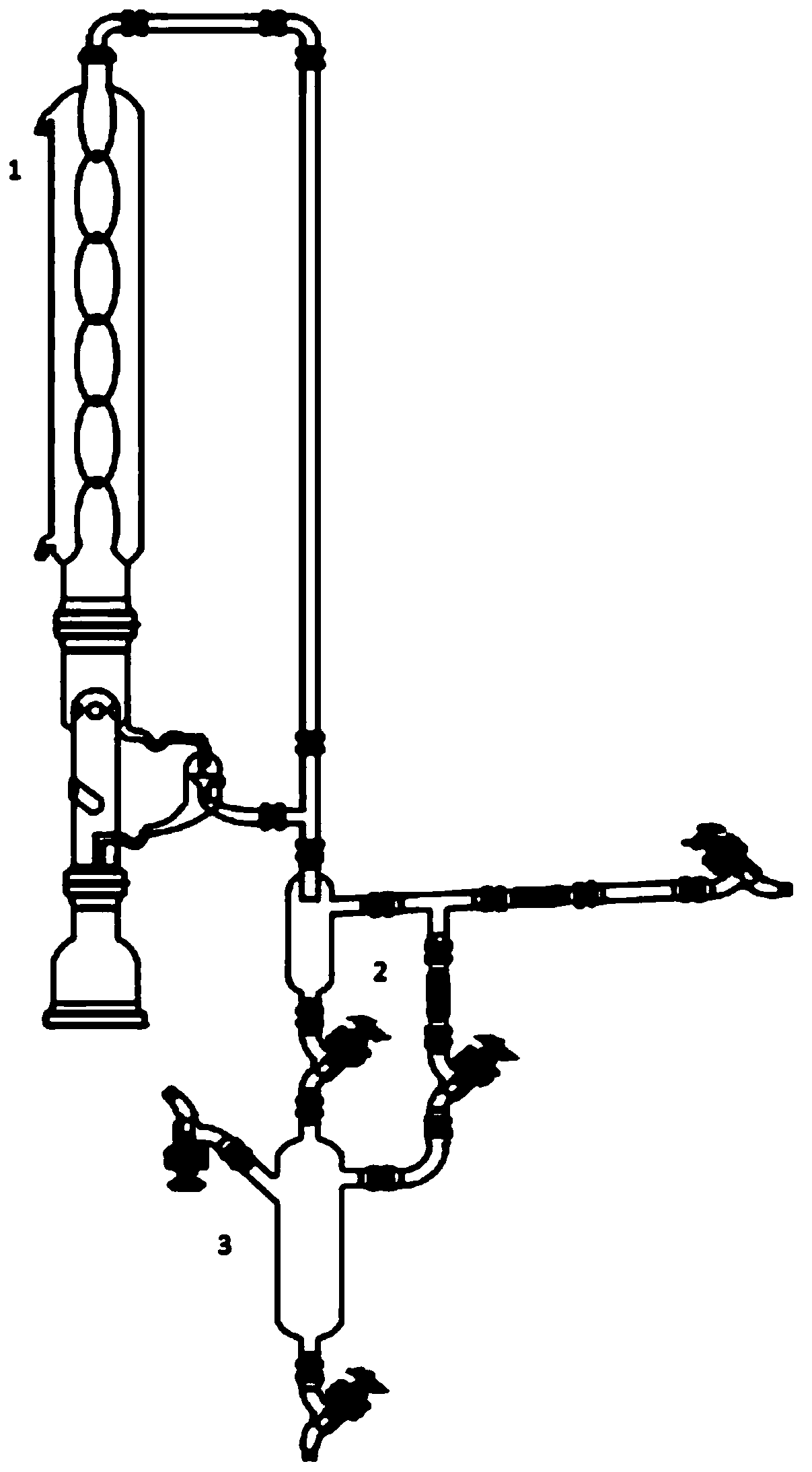

Method used

Image

Examples

Embodiment 1

[0028] A method for monitoring liquid holdup in the process of preparing high-purity elemene:

[0029] A. Put 3000 grams of turmeric oil into the tower kettle of the vacuum precision fractionation equipment. The tower kettle starts to set the heating temperature to 300°C, adjust the valve on the vacuum pipeline to control the vacuum degree below 500Pa, until there is reflux, adjust the tower kettle Set the temperature at 260°C for 30 minutes of full reflux and begin to receive Fraction 1. The liquid holdup of Fraction 1 is controlled at 4mL / min, and the reflux ratio is controlled at 4:1;

[0030] B. Until crystallization occurs, begin to receive fraction 2 until the crystallization disappears;

[0031] C. Full reflux for 60 minutes;

[0032] D. Start to receive fraction three after step C, the liquid hold-up is controlled at 2mL / min, and the reflux ratio is controlled at 5:1 until the fractions received are clearly stratified;

[0033] E. Start receiving fraction 4 after ste...

Embodiment 2

[0035] A method for monitoring liquid holdup in the process of preparing high-purity elemene:

[0036] A. Put 3000 grams of turmeric oil into the tower kettle of the vacuum precision fractionation equipment. The tower kettle starts to set the heating temperature to 300°C, adjust the valve on the vacuum pipeline to control the vacuum degree below 500Pa, until there is reflux, adjust the tower kettle Set the temperature at 260°C for 30 minutes of total reflux and begin to receive Fraction 1. The liquid holdup of Fraction 1 is controlled at 7mL / min, and the reflux ratio is controlled at 4:1;

[0037] B. Until crystallization occurs, begin to receive fraction 2 until the crystallization disappears;

[0038] C. Full reflux for 60 minutes;

[0039] D. Start to receive fraction three after step C, the liquid hold-up is controlled at 5mL / min, and the reflux ratio is controlled at 5:1 until the fractions received are clearly stratified;

[0040] E. Start to receive fraction 4 after s...

Embodiment 3

[0042] A method for monitoring liquid holdup in the process of preparing high-purity elemene:

[0043] A. Put 3000 grams of turmeric oil into the tower kettle of the vacuum precision fractionation equipment. The tower kettle starts to set the heating temperature to 300°C, adjust the valve on the vacuum pipeline to control the vacuum degree below 500Pa, until there is reflux, adjust the tower kettle Set the temperature at 260°C for 30 minutes of full reflux and begin to receive Fraction 1. The liquid holdup of Fraction 1 is controlled at 11mL / min, and the reflux ratio is controlled at 4:1;

[0044] B. Until crystallization occurs, begin to receive fraction 2 until the crystallization disappears;

[0045] C. Full reflux for 60 minutes;

[0046] D. Start to receive fraction three after step C, the liquid hold-up is controlled at 7mL / min, and the reflux ratio is controlled at 5:1 until the fractions received are clearly stratified;

[0047]E. Start to receive fraction 4 after st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com