Welding preheating temperature intelligent measurement and control system

A preheating temperature, measurement and control system technology, applied in the field of detection systems, can solve problems such as difficult acquisition of preheating temperature, difficulty in field wiring, incomplete preheating temperature records, etc., achieve great economic value and environmental protection value, improve the first-time yield, Flexible installation and deployment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

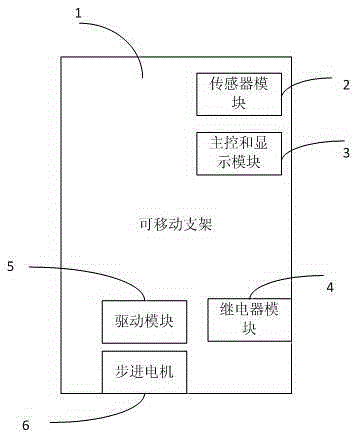

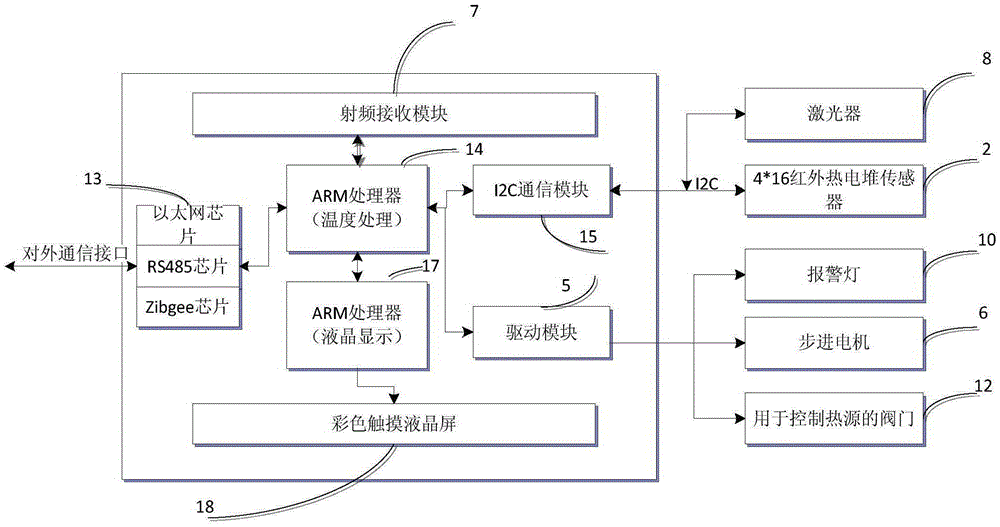

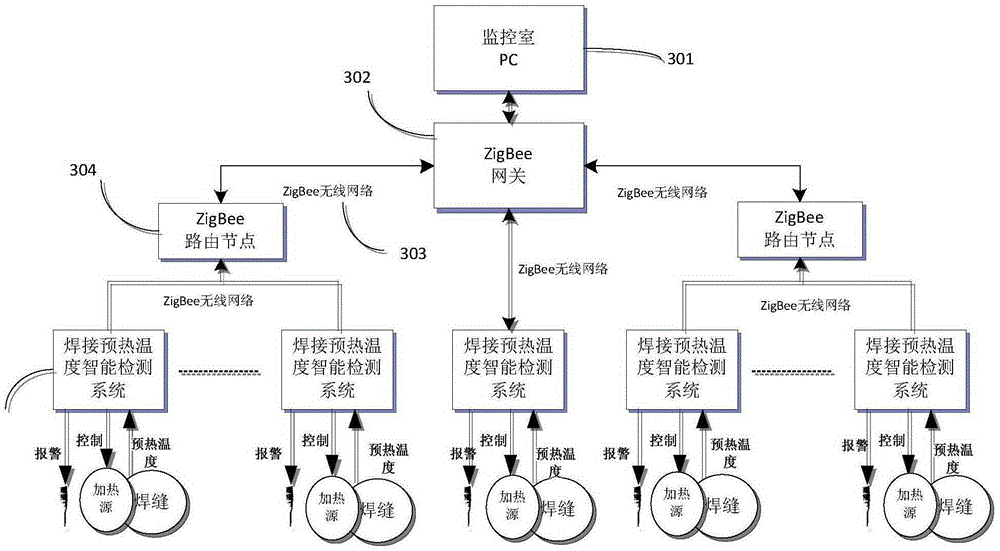

[0013] Such as figure 1 As shown, an intelligent measurement and control system for welding preheating temperature, the whole system consists of a movable support 1, a sensor module 2, a main control and display module 3, a relay module 4, a drive module 5, and a stepping motor 6. The sensor module 2 , the main control and display module 3 , the relay module 4 , the drive module 5 , and the stepper motor 6 are installed on the movable bracket 1 . The stepper motor 6 receives the control of the main control and display module 3, and with the support of the drive module 5, the movable support 1 can be moved accordingly; the relay module 4 can control the The valve of the external heating source stabilizes the preheating temperature within a certain set temperature range; the sensor module 2 can collect temperature data in a certain area near the preheating hot spot under the control of the main control and display module 3; the main control And the display module 3 completes al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com