Welding method of stainless steel plate-fin radiator

A stainless steel plate, welding method technology, applied in welding equipment, welding equipment, manufacturing tools and other directions, can solve the problems of radiator core leakage, brazing seam is easy to be cracked, etc., to improve the qualification rate of brazing, solve the problem of brazing Weld cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] This example is a method of applying metal flake solder to the radiator core assembly, adding connecting plates, enlarging side plates, and adopting two times of vacuum brazing and two times of argon arc welding to make a stainless steel plate-fin radiator. Its implementation steps are:

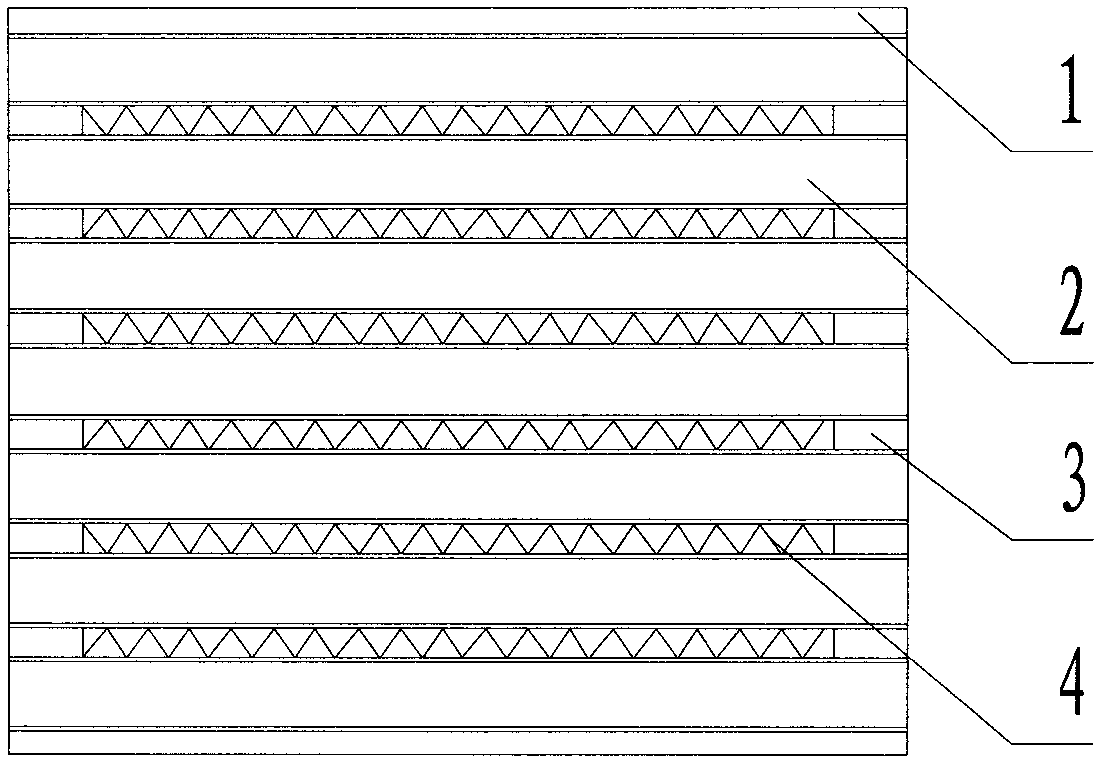

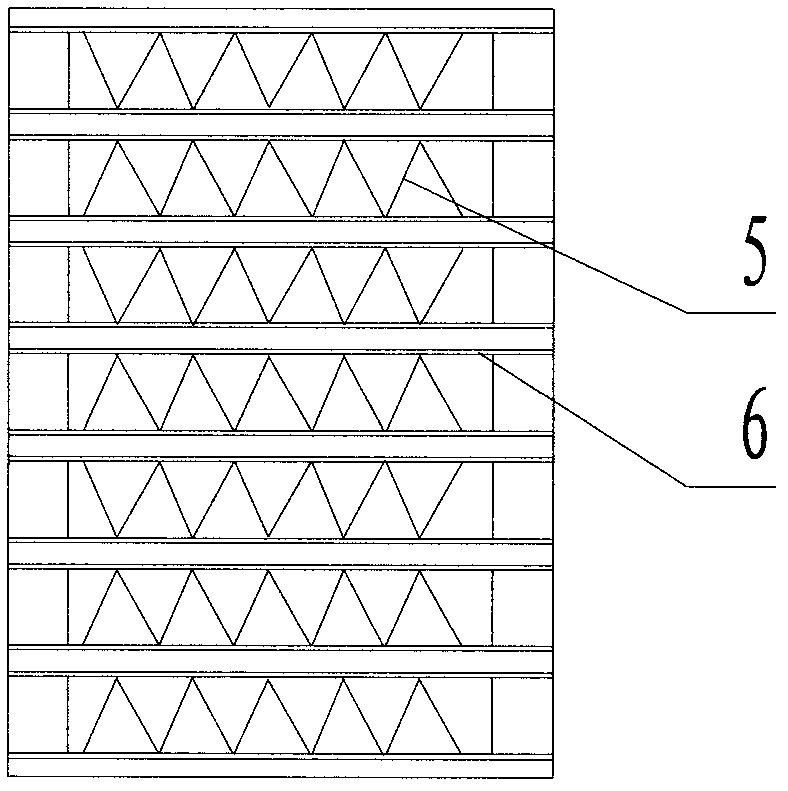

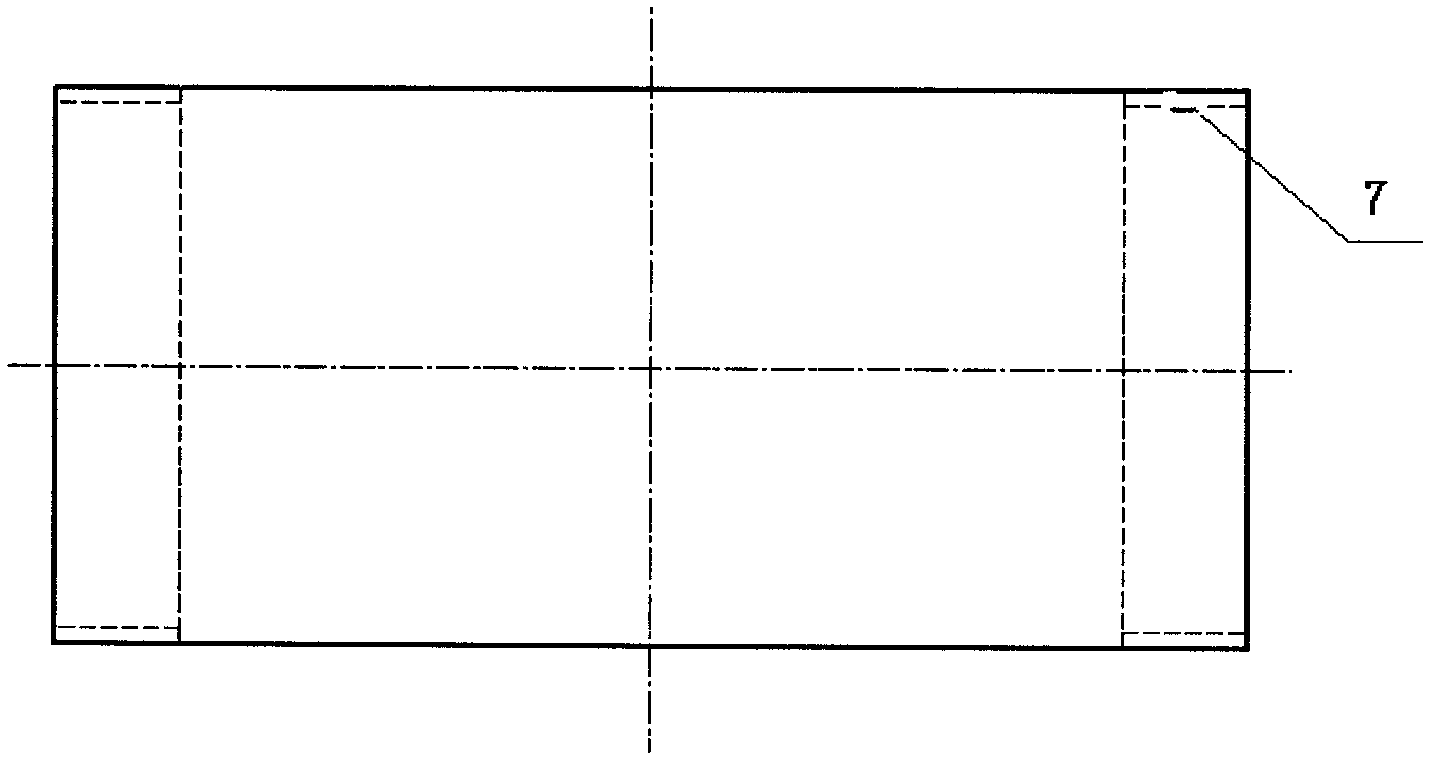

[0028] 1. Parts preparation: radiator core assembly 9 is composed of side plate 1, long seal 2, short seal 3, cold side fin 4, hot side fin 5, and partition 6. The original shape of the side plate is Figure 4 The rectangle shown has a size of 300×170×1.5mm. After improvement, add 10mm to each of the four sides of the side plate to become Figure 5 As shown in the shape, increase the connection plate 7, the shape of the connection plate 7 is as image 3 As shown, the size is: 300×10×1.5mm, and the parts are processed in place according to the drawings;

[0029] 2. Carry out the first vacuum brazing of the radiator core assembly 9: select a stainless steel metal brazing sheet instead ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com