Patents

Literature

83results about How to "Eliminate assembly gaps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

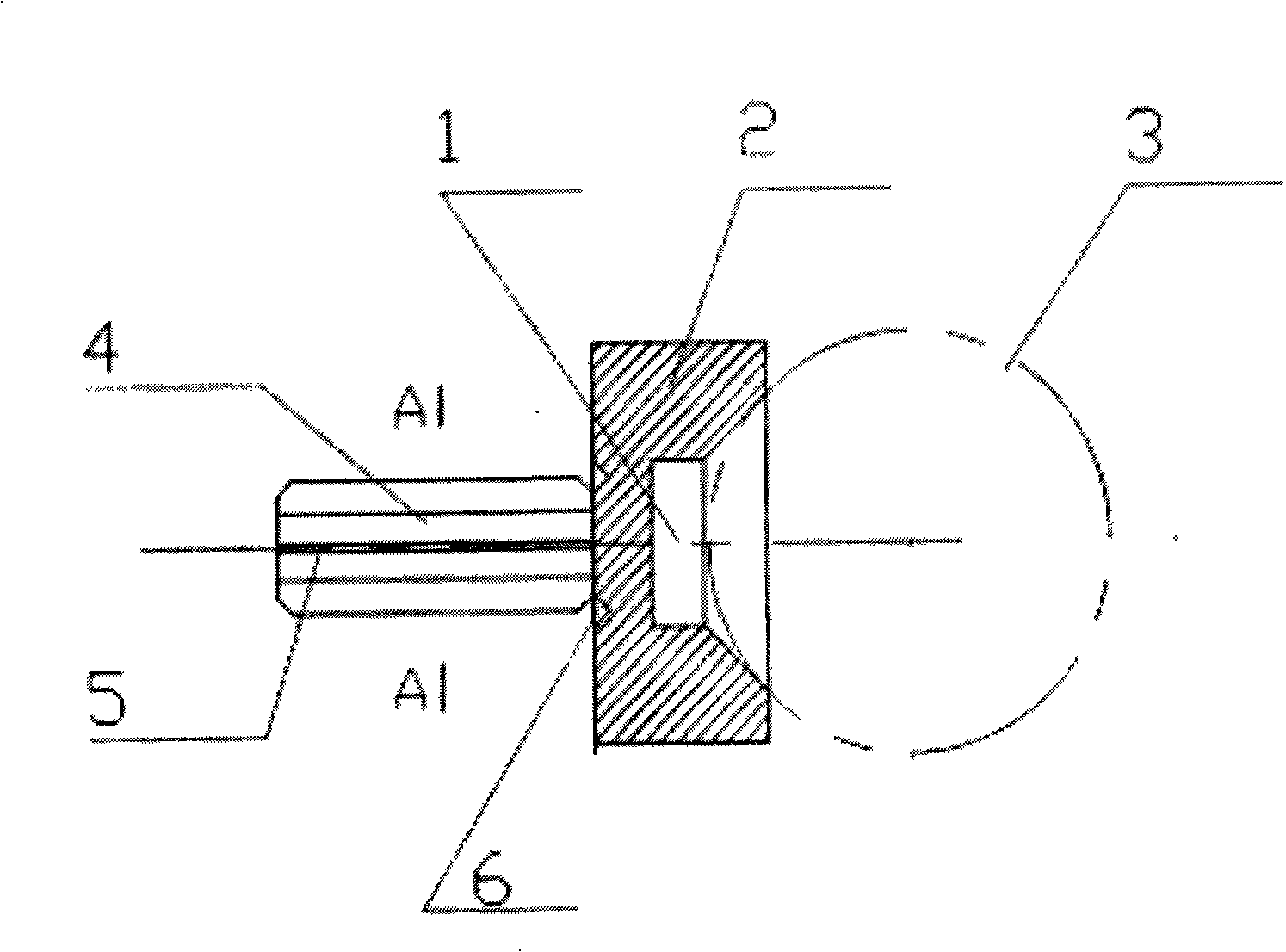

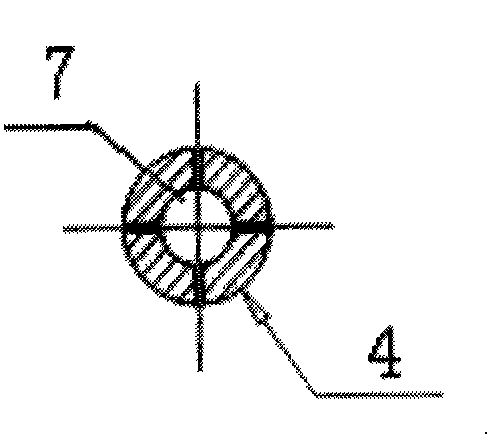

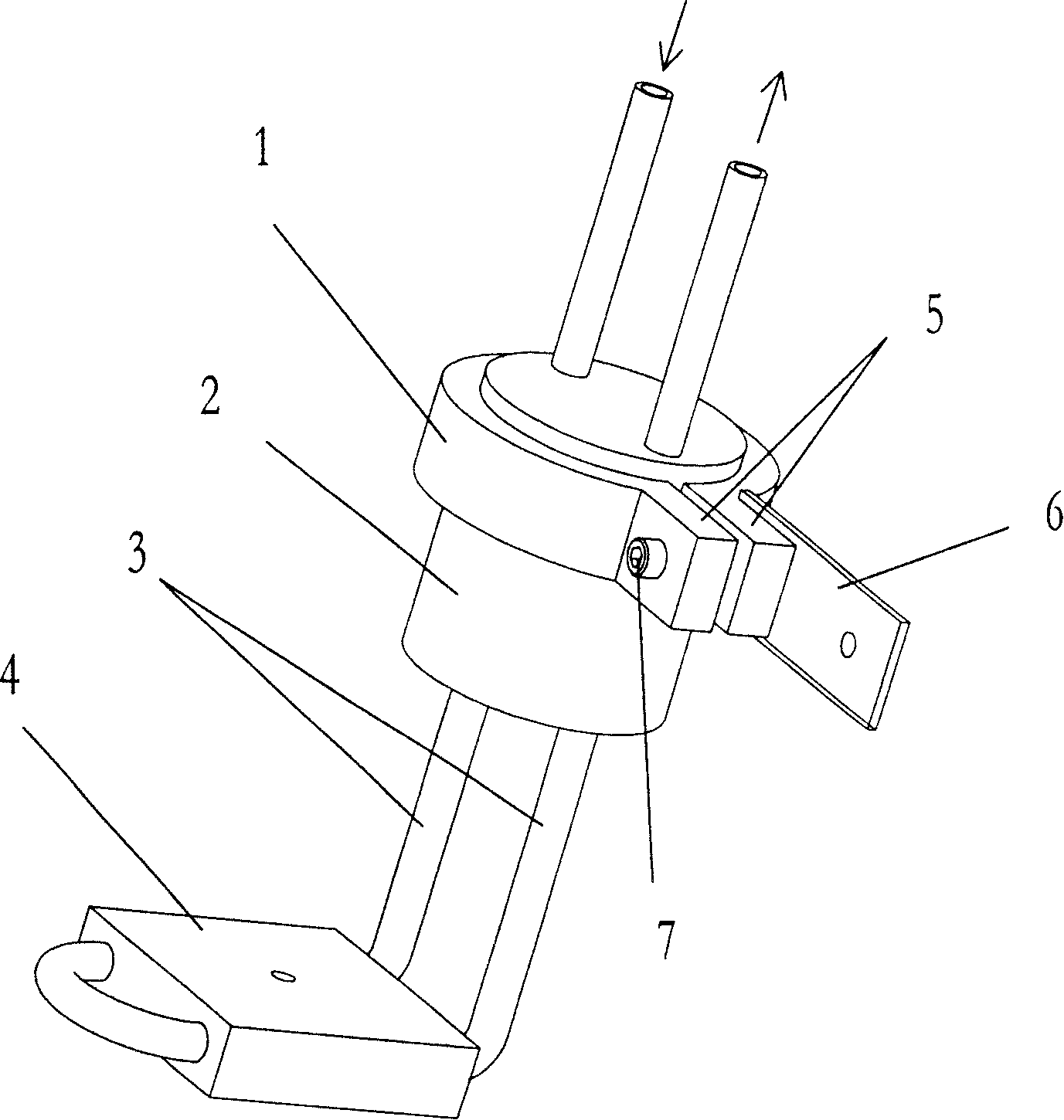

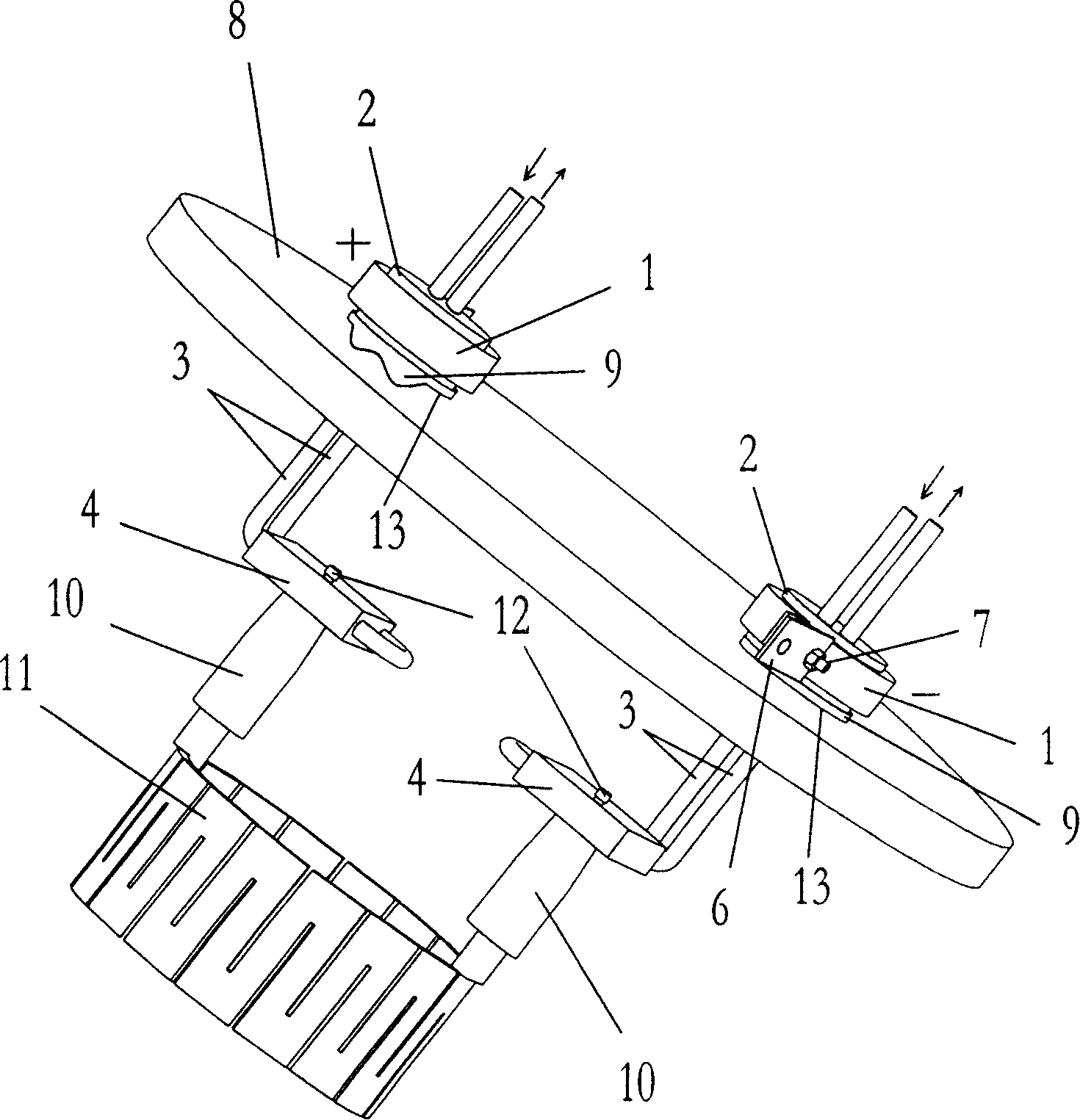

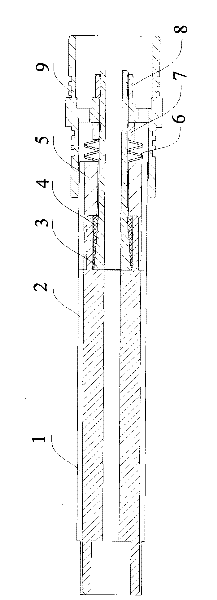

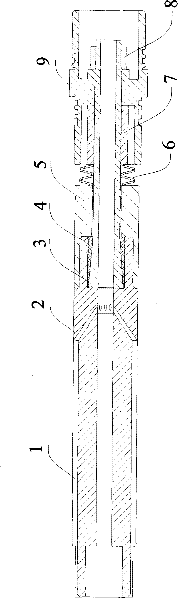

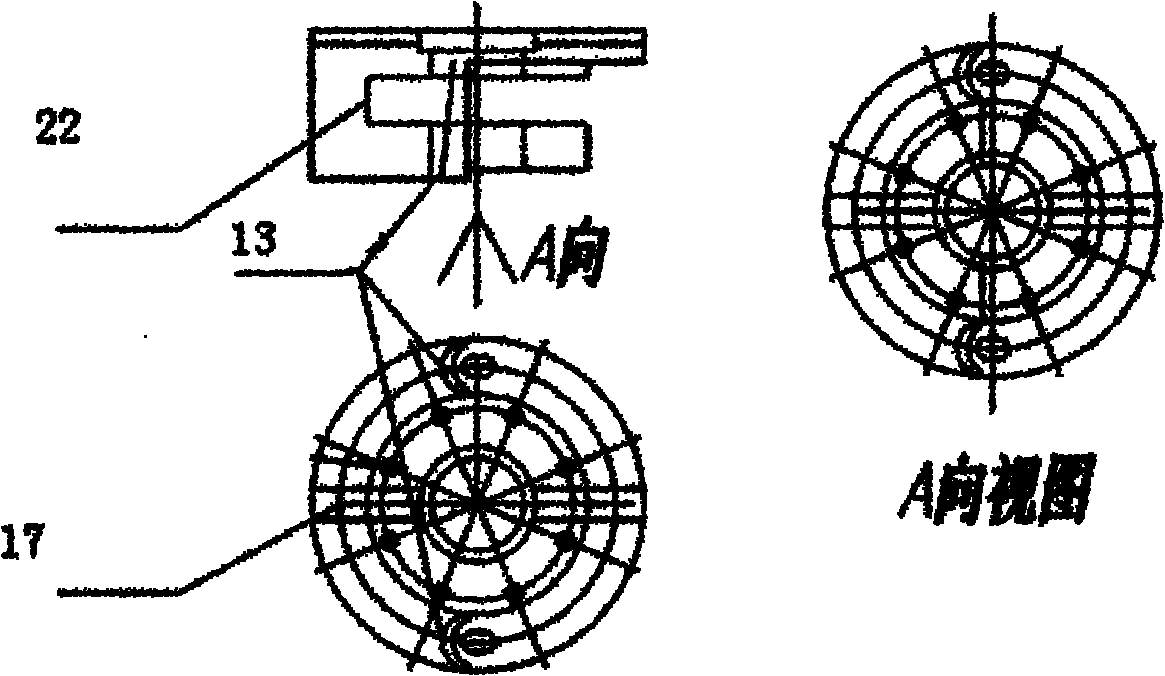

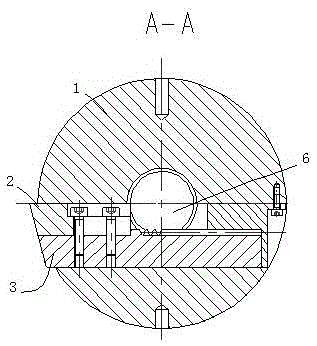

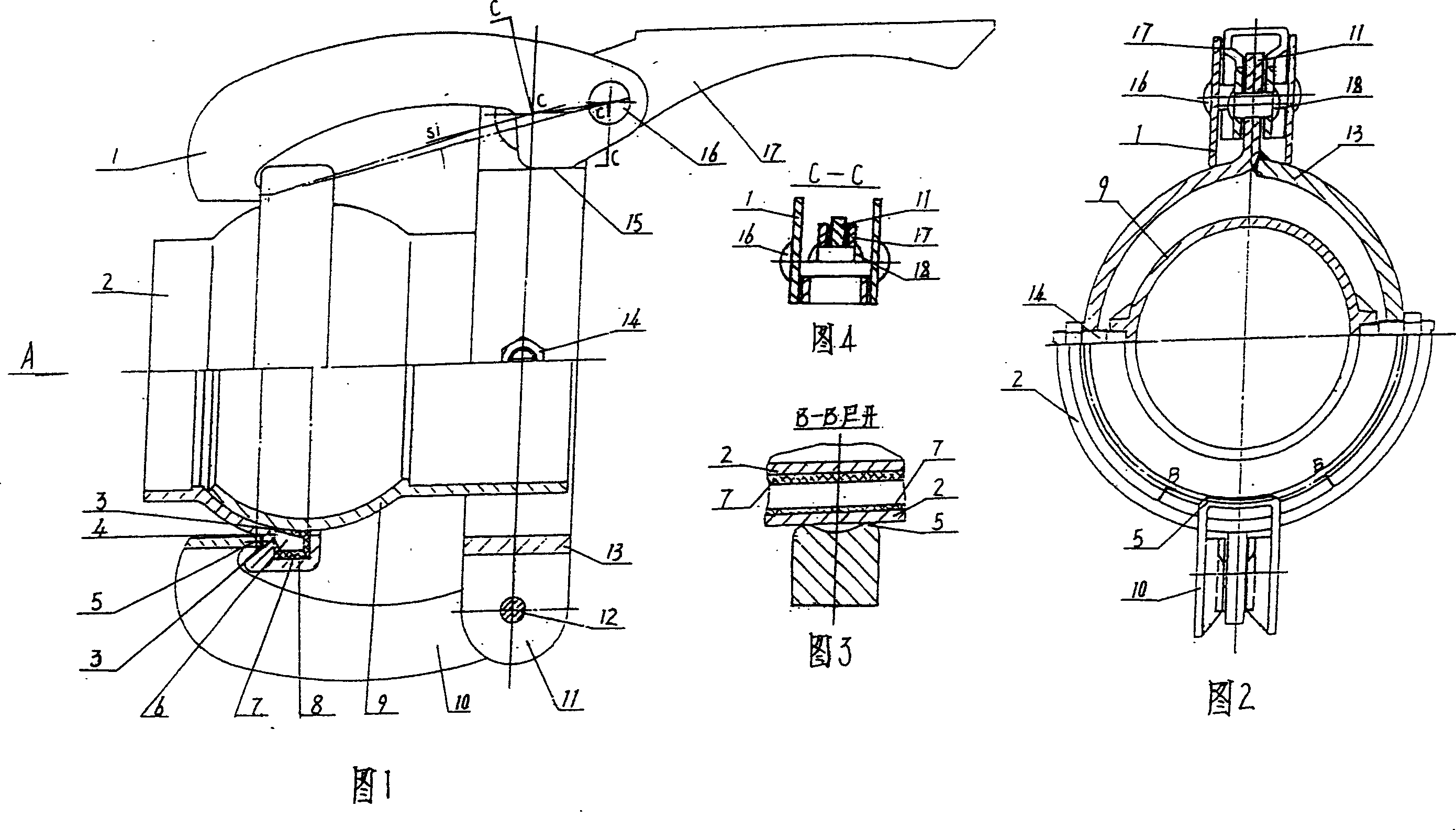

Self-centering target ball mounting stand for small bore diameter

InactiveCN101408406ARealize automatic centering and fixingEliminate assembly gapsUsing optical meansElectromagnetic wave reradiationEngineeringPore diameter

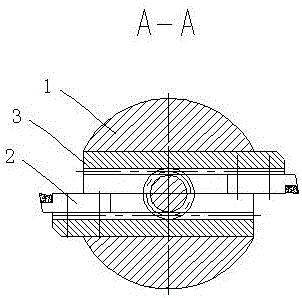

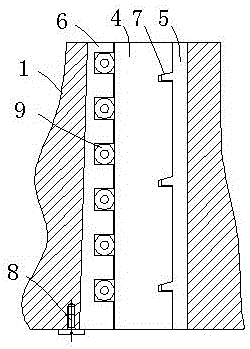

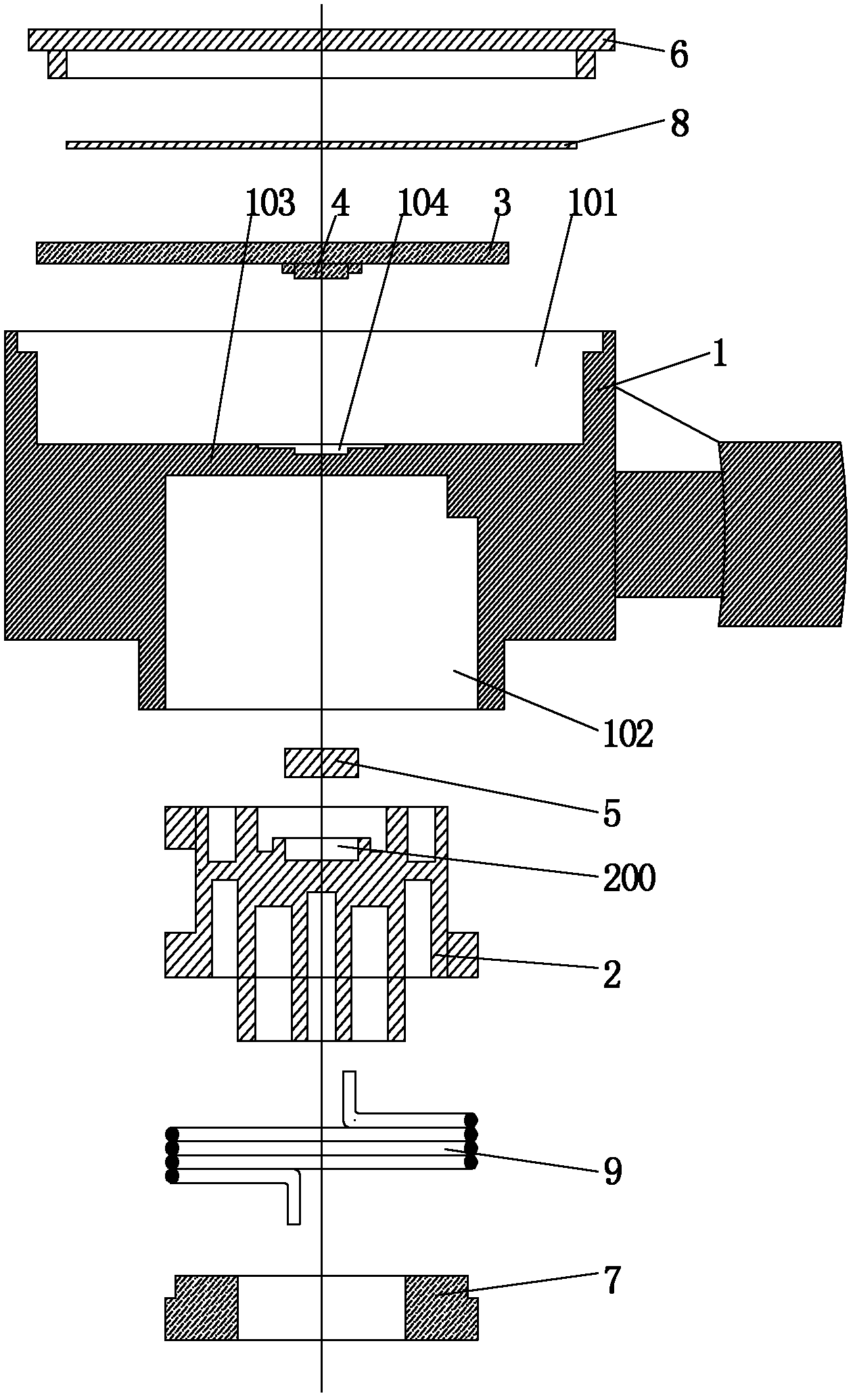

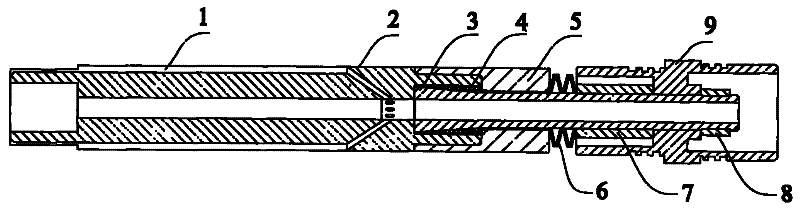

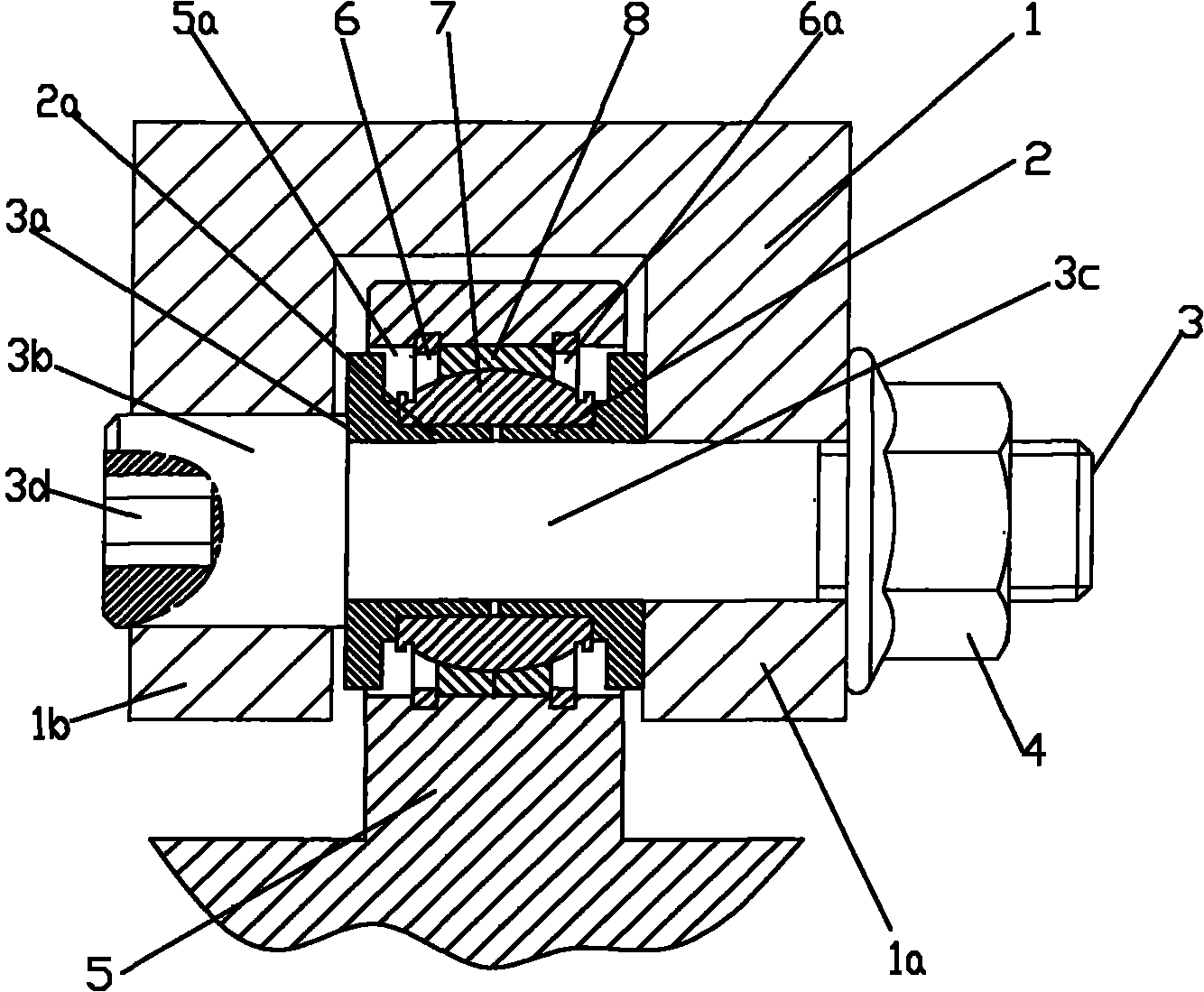

The invention discloses a self-centering target-ball mounting seat used for small caliber. A column-shaped magnet (1) absorbing a target-ball 3 is arranged at the center of an axial outer sphere groove of the big-end step of a target-ball mounting seat head (2); the center of a positioning column (4) is hollow; a groove (5) provided with the cross-shaped section projection is arranged along the whole length of the column face of the hollow positioning column (4). A target-ball column-shaped magnet is arranged at the center of the sphere groove to absorb the target-ball so as to realize the self centering. The hollow positioning column (4) is divided into four pieces of elastic positioning pieces by the cross groove and the elastic positioning pieces generate elastic distortion to lead the positioning column to closely contact with apertures to be measured so as to eliminate the mounting clearance between the two parts, avoid the bigger deviation of the measurement result and reduce the mounting error of the target-ball mounting seat. The self-centering target-ball mounting seat is especially suitable for the laser tracing measurement of apertures of 3 to 8mm and the aperture tolerance under IT12.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

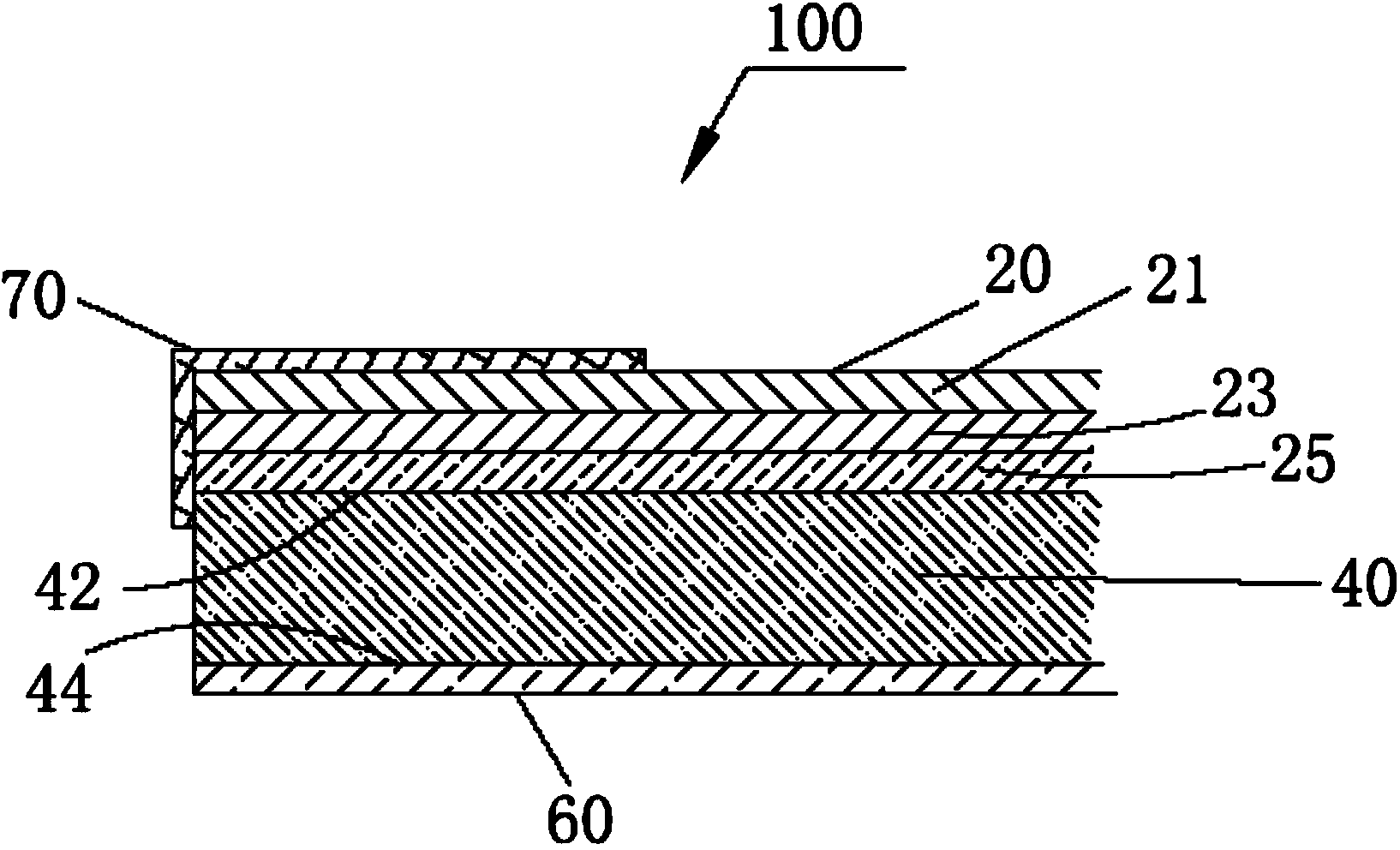

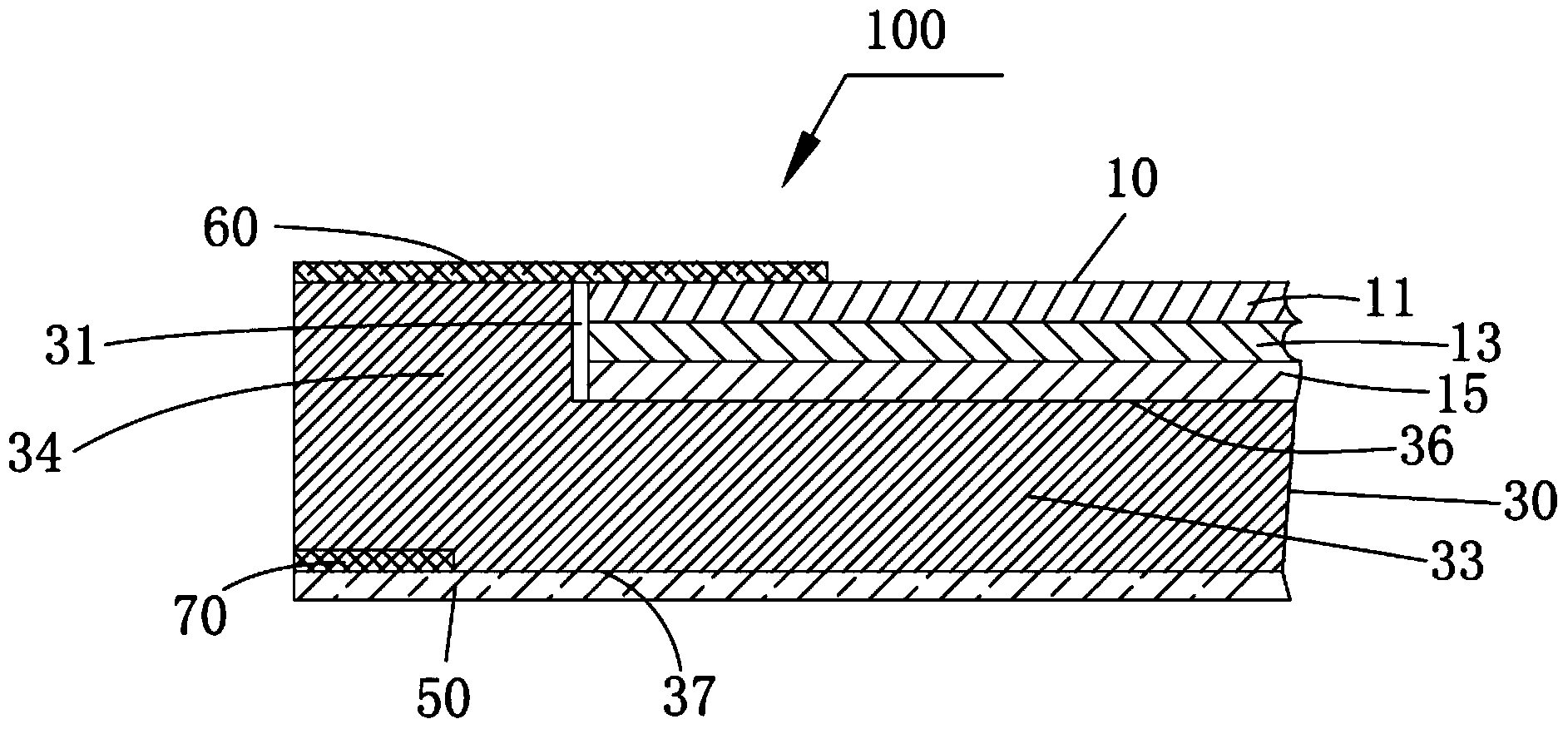

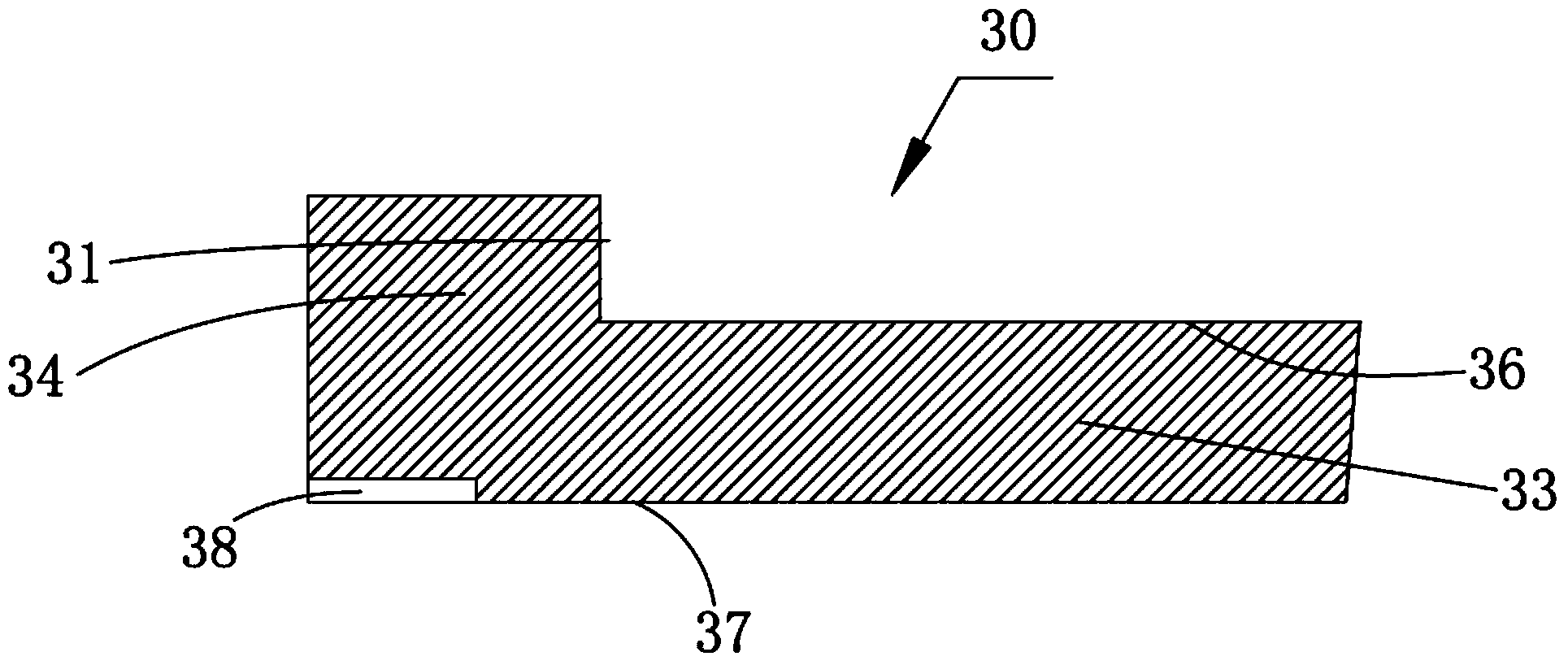

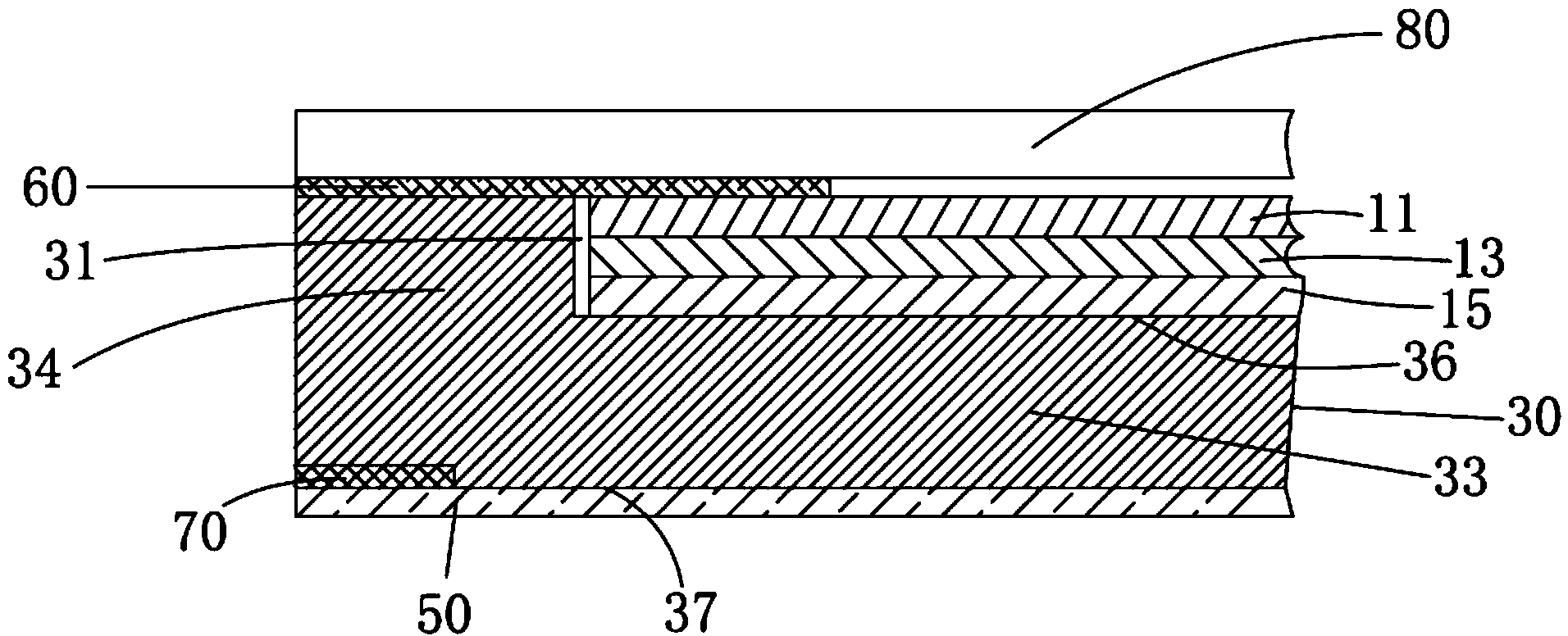

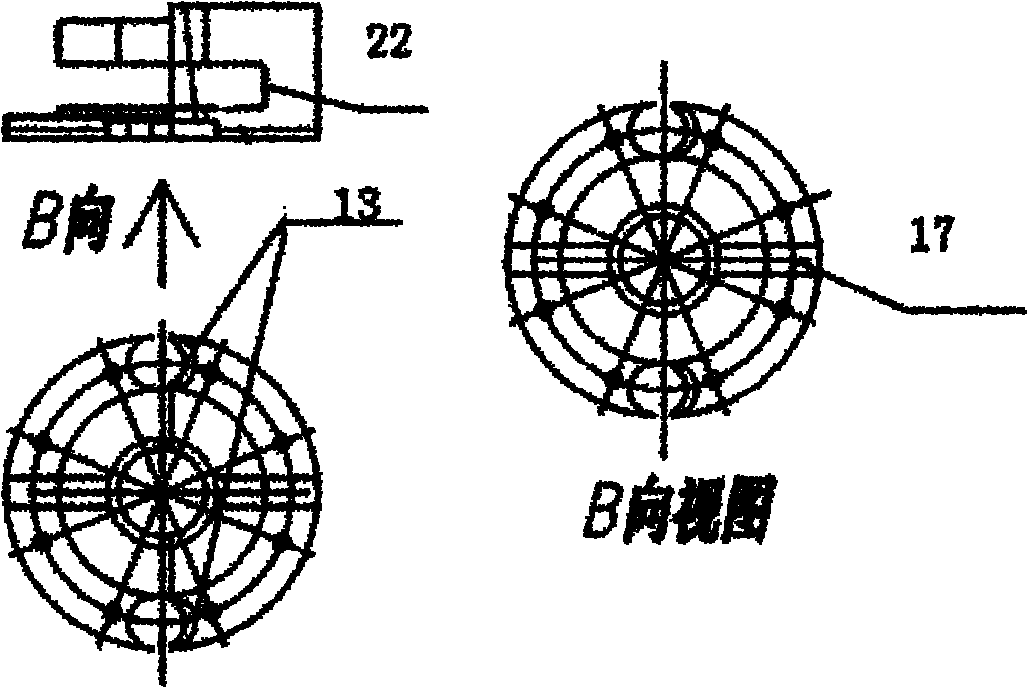

Backlight module and display with the same

InactiveCN104373871AEasy to assembleEliminate assembly gapsLight fasteningsNon-linear opticsLight guideDisplay device

The invention provides a backlight module. The backlight module comprises an optical membrane, adhesive tape and a light guide plate. The optical membrane is arranged on one side of the light guide plate. One part of the adhesive tape adheres to the peripheral side wall of the light guide plate, and the other part of the adhesive tape adheres to the outer side of the optical membrane. The optical membrane is fixed to the light guide plate through the adhesive tape and is directly and stably fixed to the light guide plate through the adhesive tape, and therefore back plates, rubber frames and other parts in existing backlight modules are omitted, assembly gaps existing in the backlight module assembly process are eliminated, and the overall thickness of the backlight module is reduced. In addition, the backlight module is simple in structure, and therefore the manufacturing cost is reduced, the assembly process of the whole backlight module is more convenient and rapid, and the assembly efficiency is greatly improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

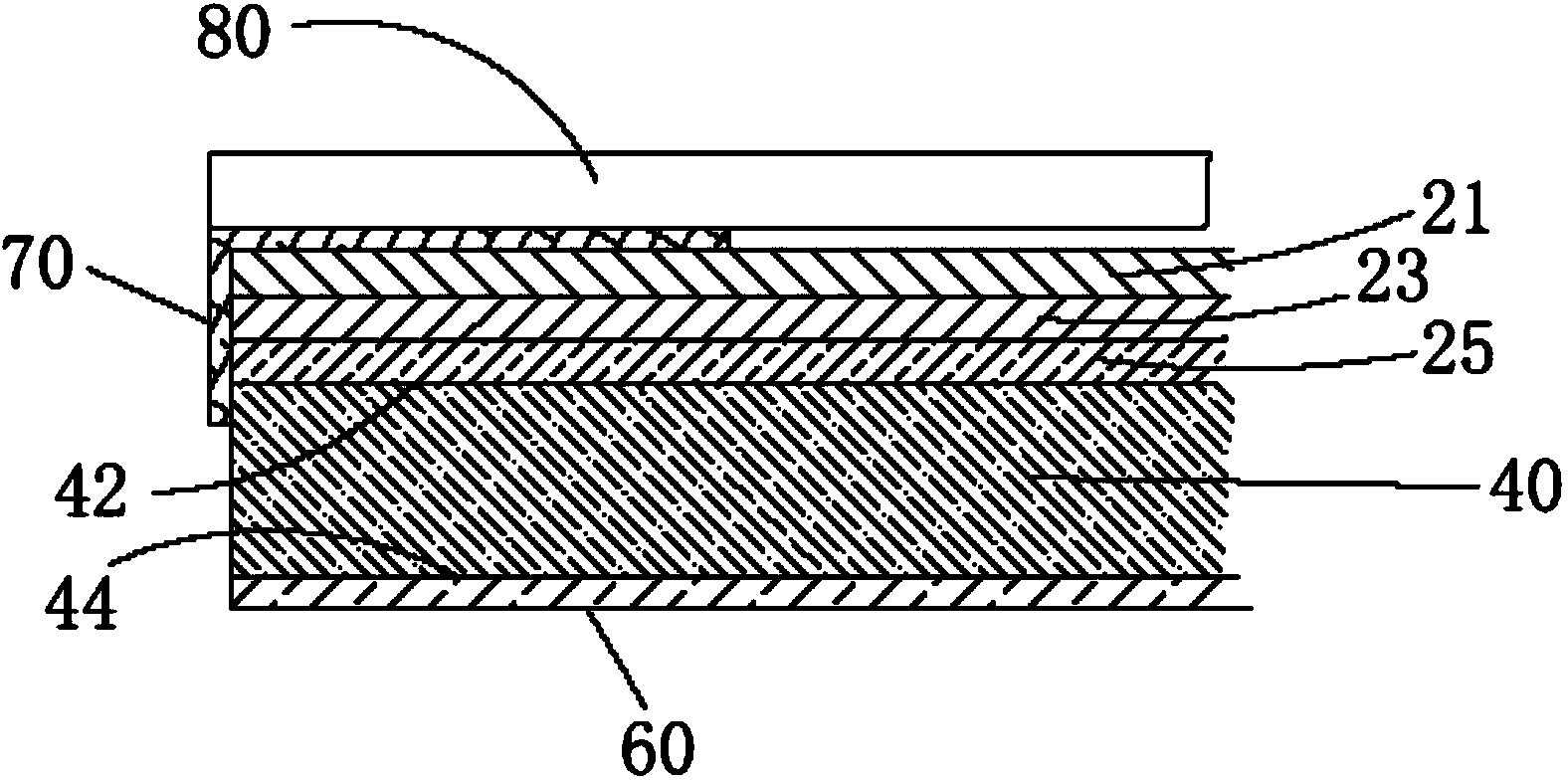

Backlight module and display with the same

InactiveCN104375324AEasy to assembleEliminate assembly gapsOptical light guidesNon-linear opticsLight guideDisplay device

The invention provides a backlight module. The backlight module comprises an optical membrane, a light guide plate, a reflection piece and first adhesive tape. The optical membrane is arranged in the light guide plate. An open groove is formed in the edge of the lower surface of the light guide plate. The open groove is used for containing the first adhesive tape. The peripheral edge of the reflection piece adheres to the side, opposite to the optical membrane, of the light guide plate through the first adhesive tape. The reflection piece is fixed to the light guide plate through the first adhesive tape. The invention further provides a display. By means of the backlight module, the optical membrane and the reflection piece are fixed under the condition that no rubber frame exists, and therefore back plates, rubber frames and other parts in existing backlight modules are omitted, the overall thickness of the backlight module can be reduced, and the narrow-edge frame design is achieved. In addition, the backlight module is simple in structure, and therefore the manufacturing cost is reduced, and the assembly process of the whole backlight module is made more convenient and rapid.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

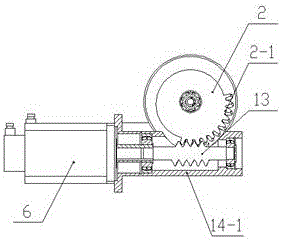

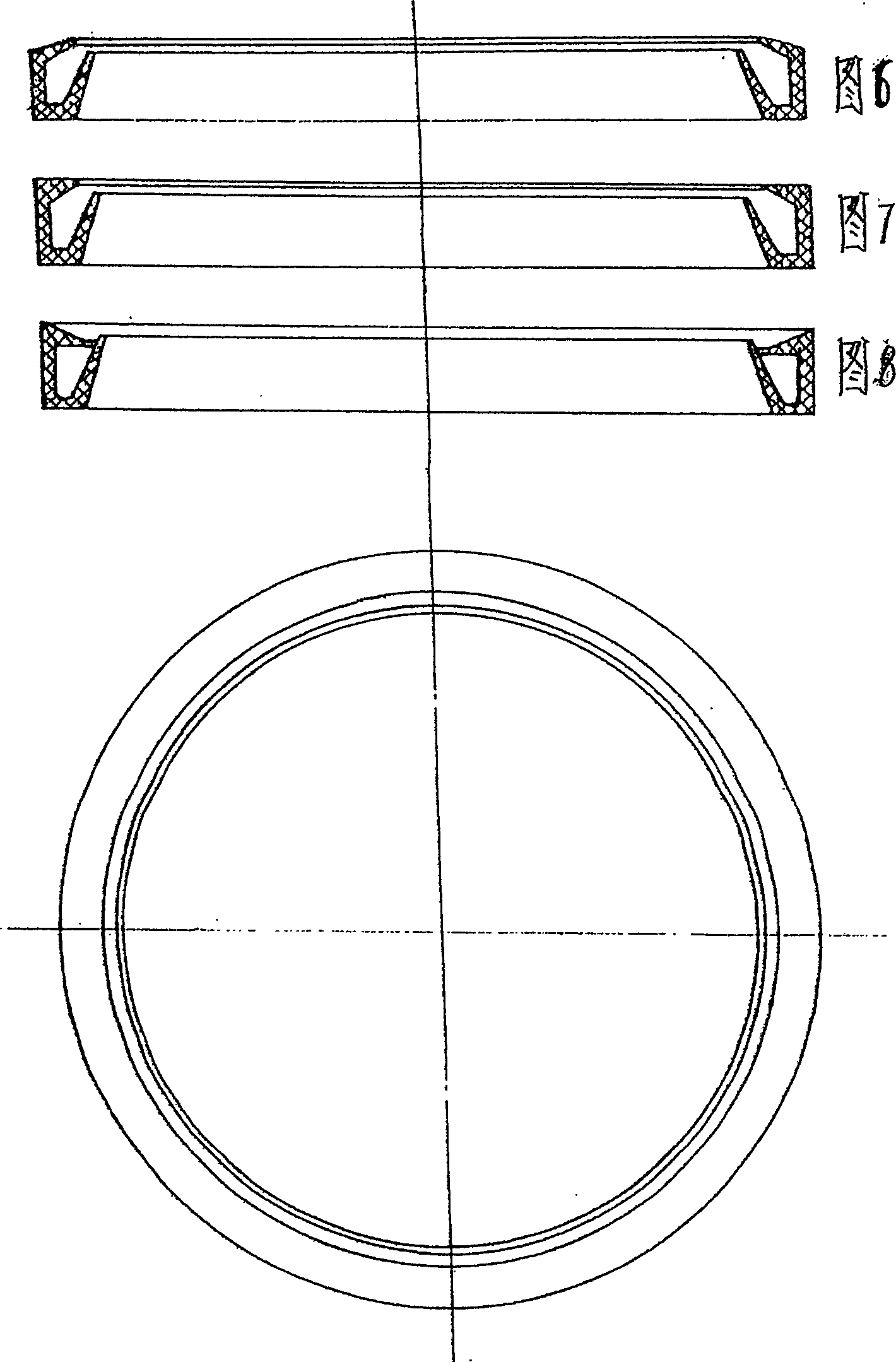

Boring mechanical arm boring tool structure

InactiveCN105642928AImprove shock absorptionSimple structureTurning toolsFeeding apparatusEngineeringMechanical engineering

The invention discloses a boring mechanical arm boring tool structure which comprises a tool installing groove located in the front portion of a tool handle and used for installing a tool. The tool comprises a tool bit part for forming a cutting edge, and an installing handle part for installation and tool radial feed transmission. The cutting edge of the tool bit part is exposed out of the tool installing groove. The structure is characterized in that a transmission rack is arranged on the inner side face of the installing handle part and used for tool radial feed transmission. The structure has the advantages of being simple in structure, capable of conveniently achieving feed transmission, improving assembling efficiency, eliminating assembling clearance and improving machining stability and the like.

Owner:CHONGQING TECH & BUSINESS INST

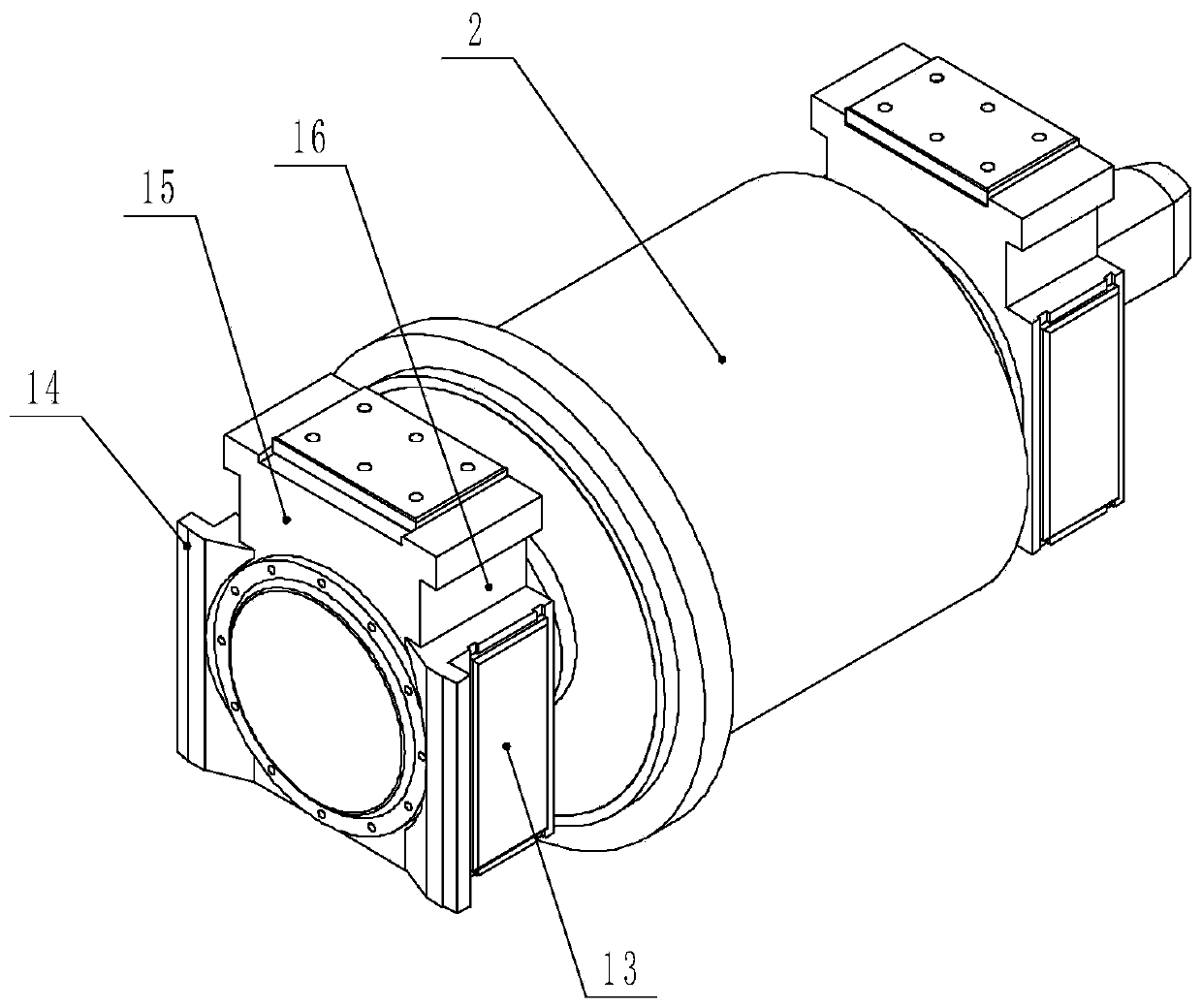

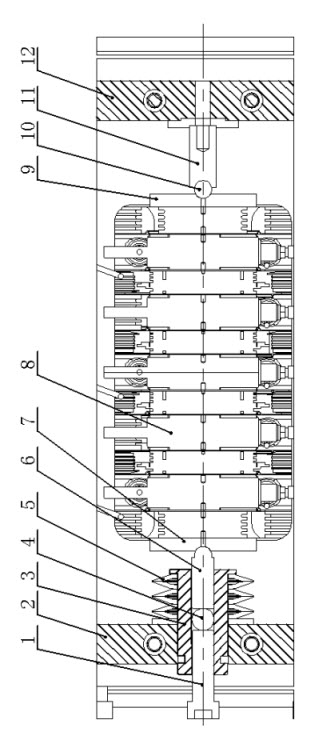

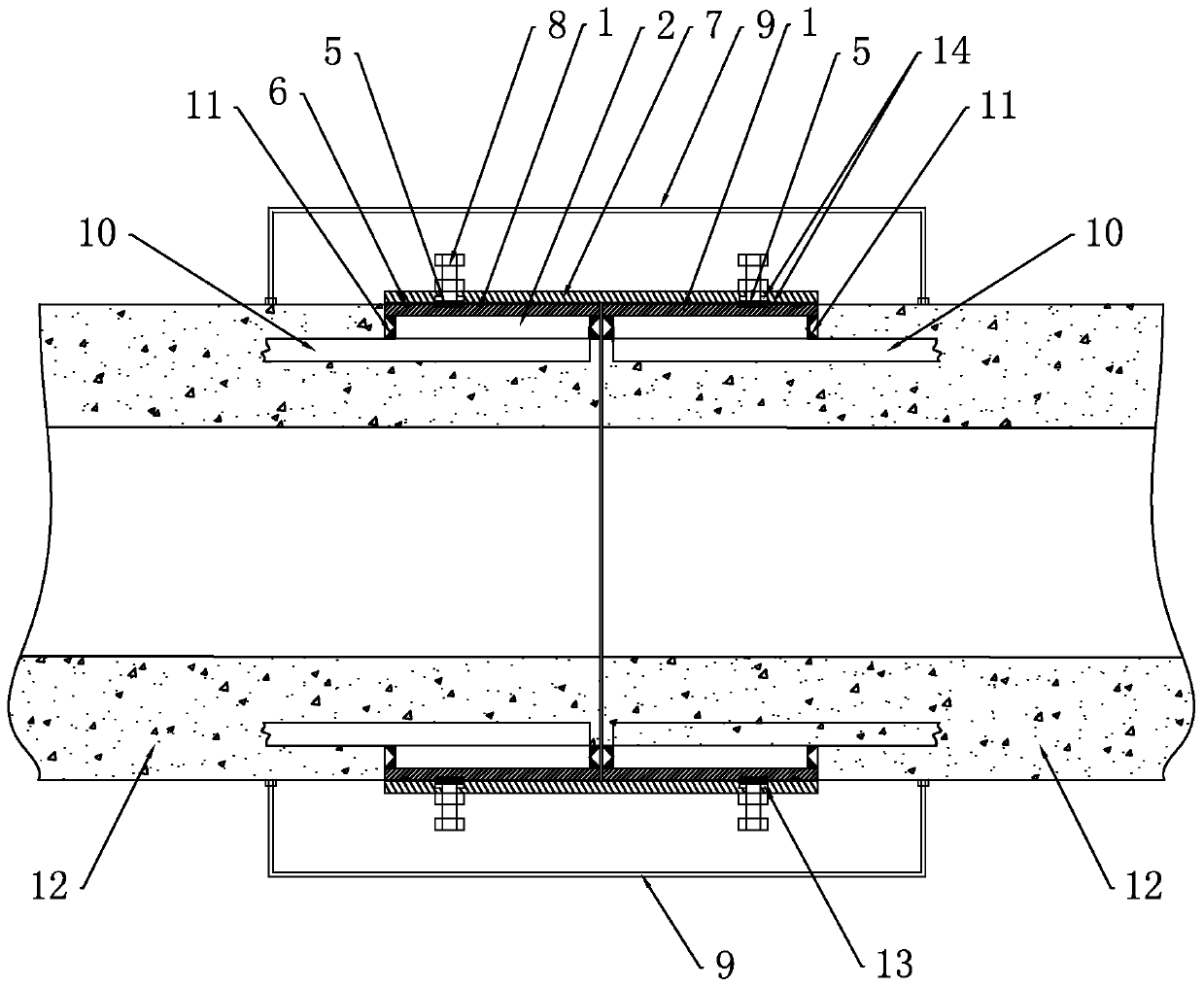

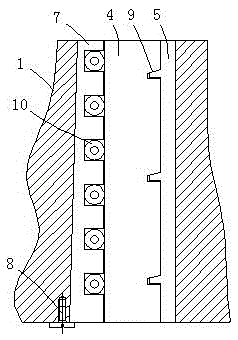

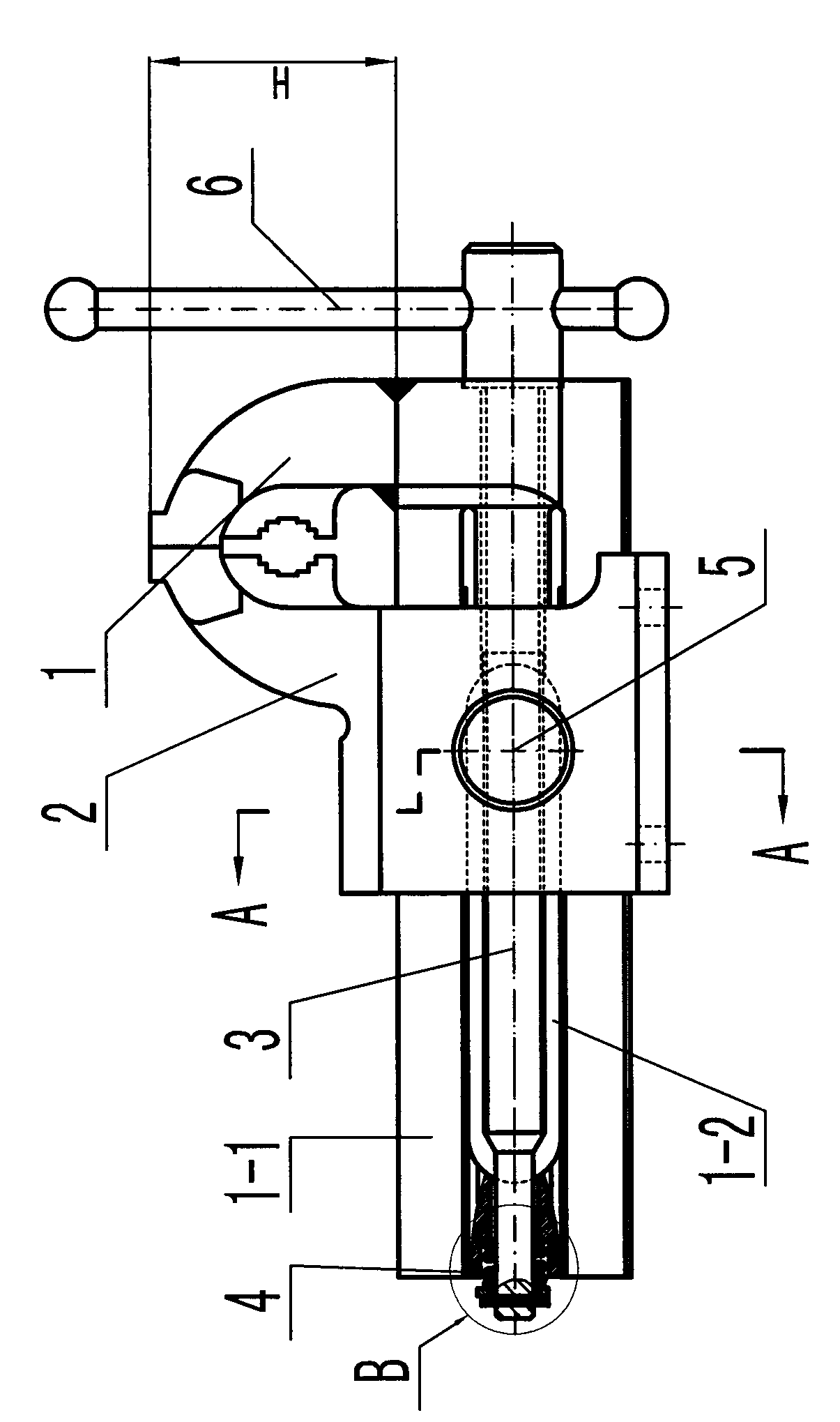

Large shaft cross wedge rolling mill

InactiveCN110449467AImprove stabilityImprove applicabilityMetal rolling stand detailsGuiding/positioning/aligning arrangementsRolling millEngineering

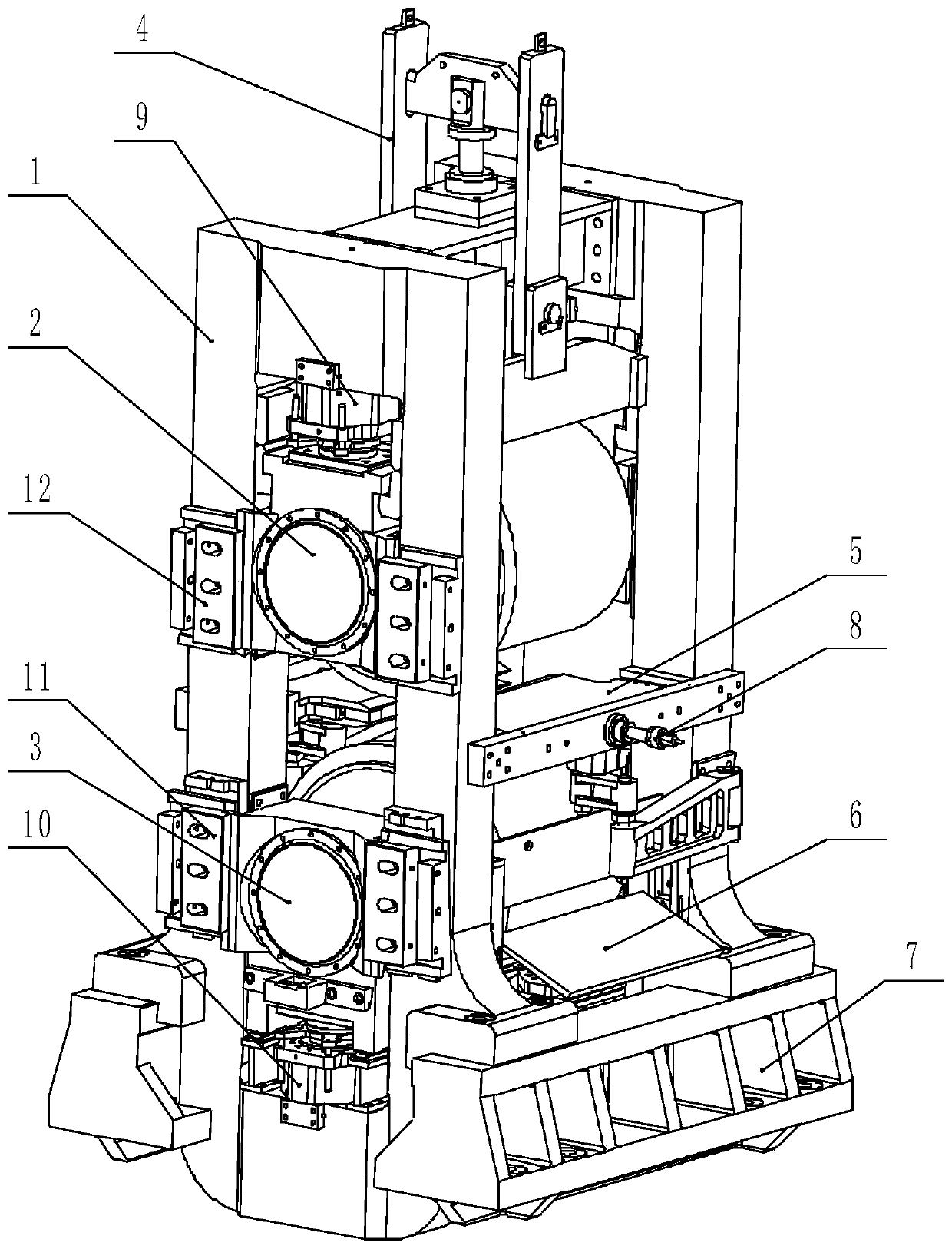

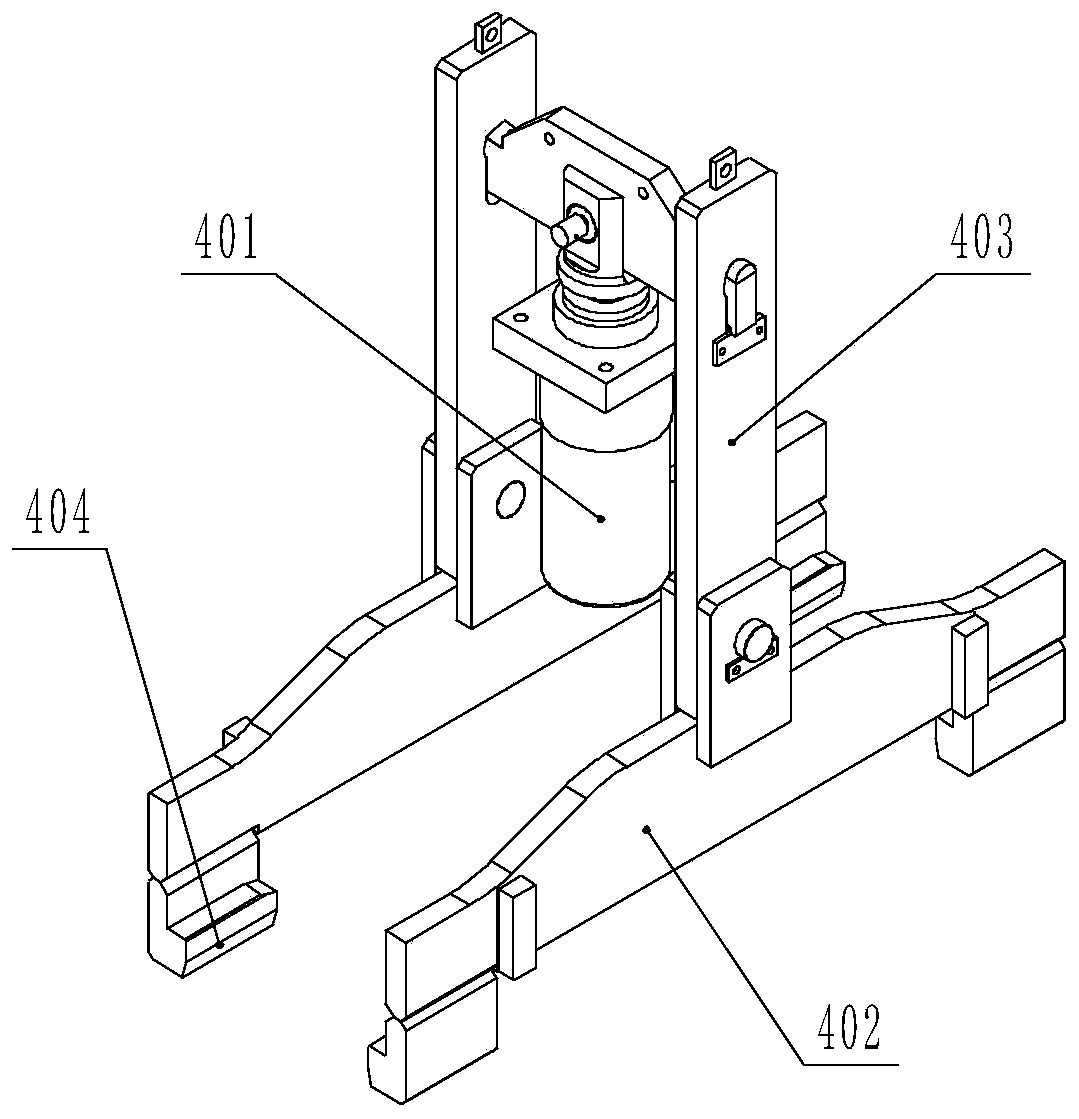

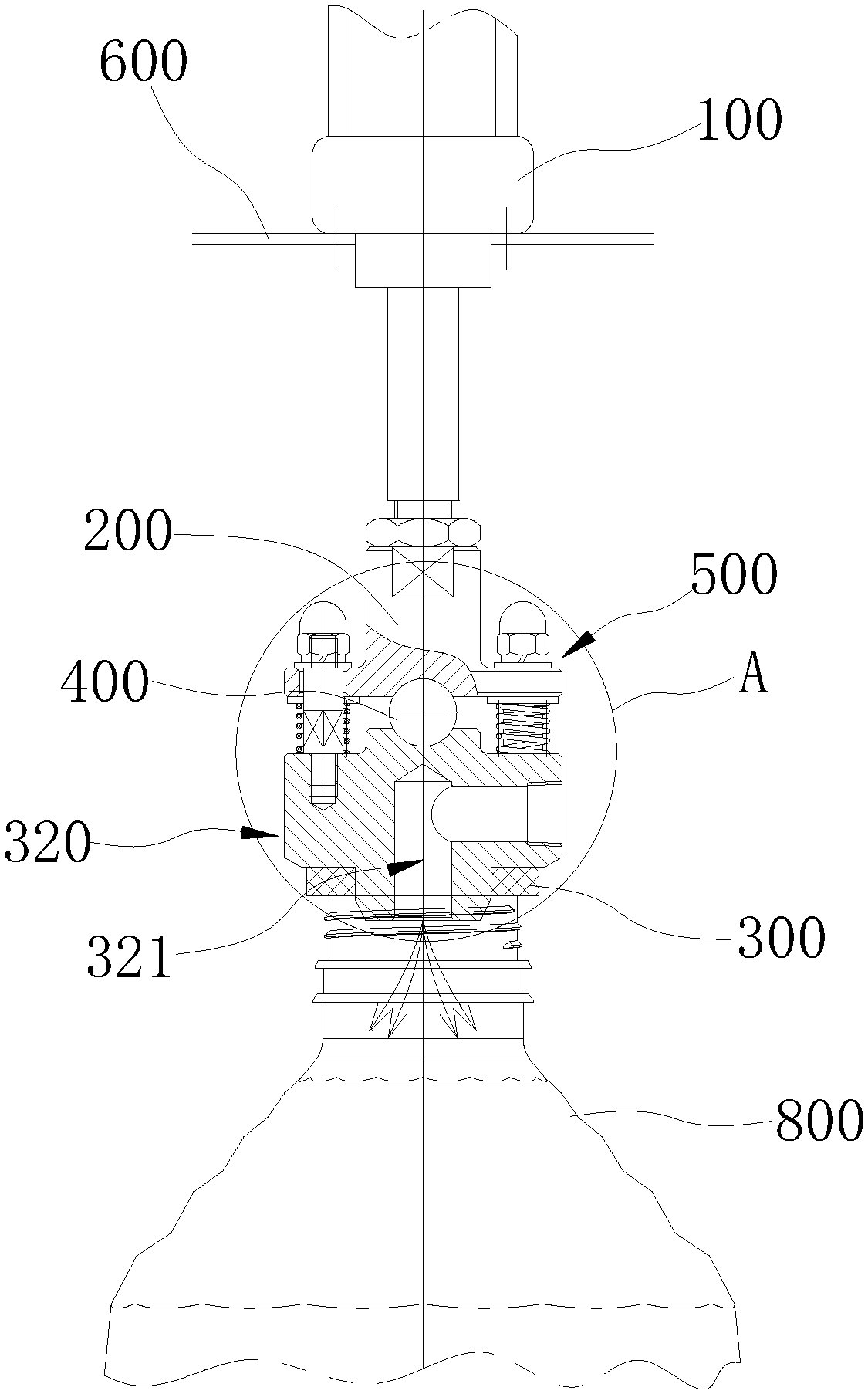

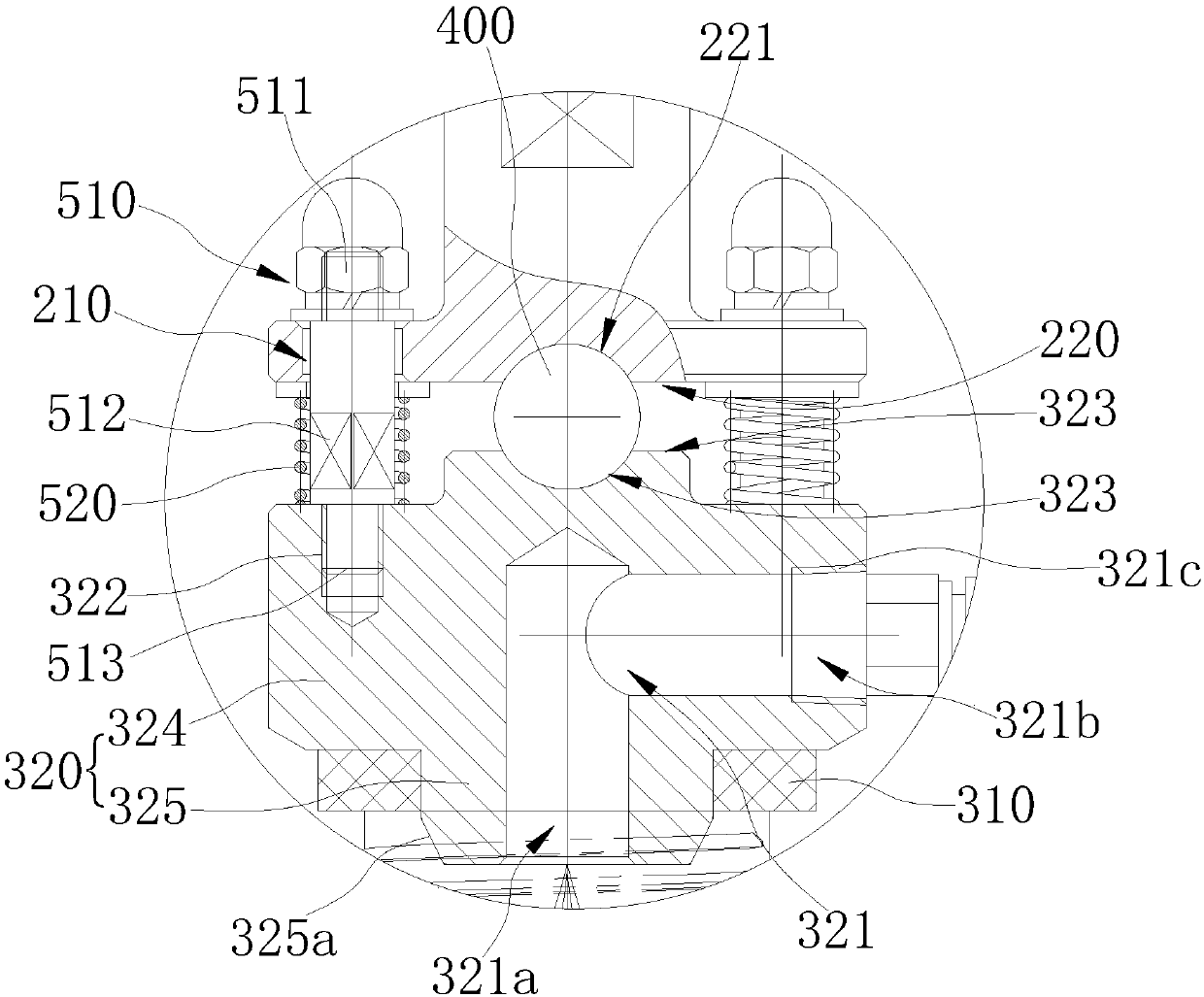

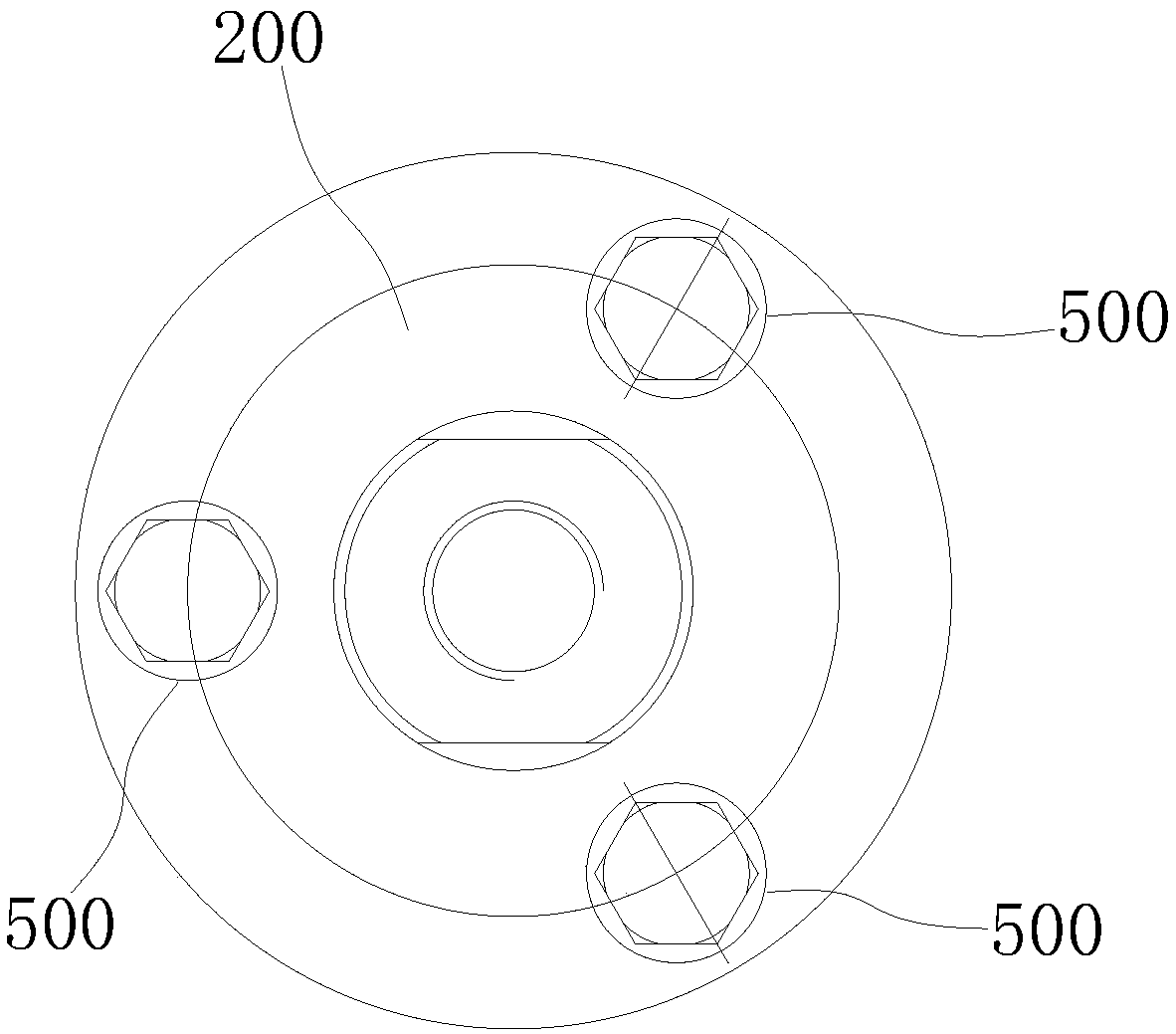

The invention provides a large shaft cross wedge rolling mill which comprises a rack, a balancing device arranged at the top of the rack and a roller device arranged in the middle of the rack. The bottom of the rack is provided with a driving device used for driving the roller device to adjust; the roller device comprises an upper roller and a lower roller which are arranged on the rack, the position, corresponding to the upper roller, of the rack is provided with a limiting mechanism for limiting the movement of the upper roller, and the position, corresponding to the lower roller, of the rack is provided with an adjusting mechanism for adjusting the axial position of the lower roller; and the rack is provided with a guide mechanism corresponding to the position between the upper roller and the lower roller. The large shaft cross wedge rolling mill has the advantages of simple structure, easy adjustment and good universality, can adapt to rolling of products with various specifications through simple operation adjustment, and is beneficial to improving the machining efficiency of the products; and the balancing device arranged on the rack can eliminate assembly gaps of the upper roller or a bearing pedestal together with a pressing servo cylinder, thereby being beneficial to improving the working stability of the upper roller.

Owner:中重科技(天津)股份有限公司

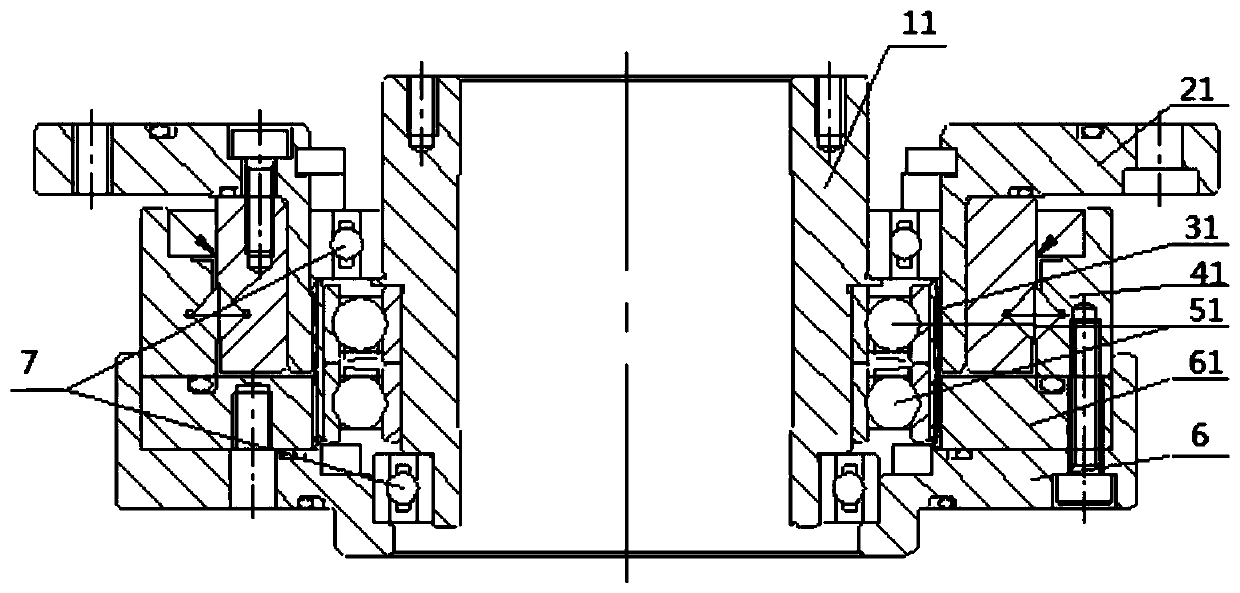

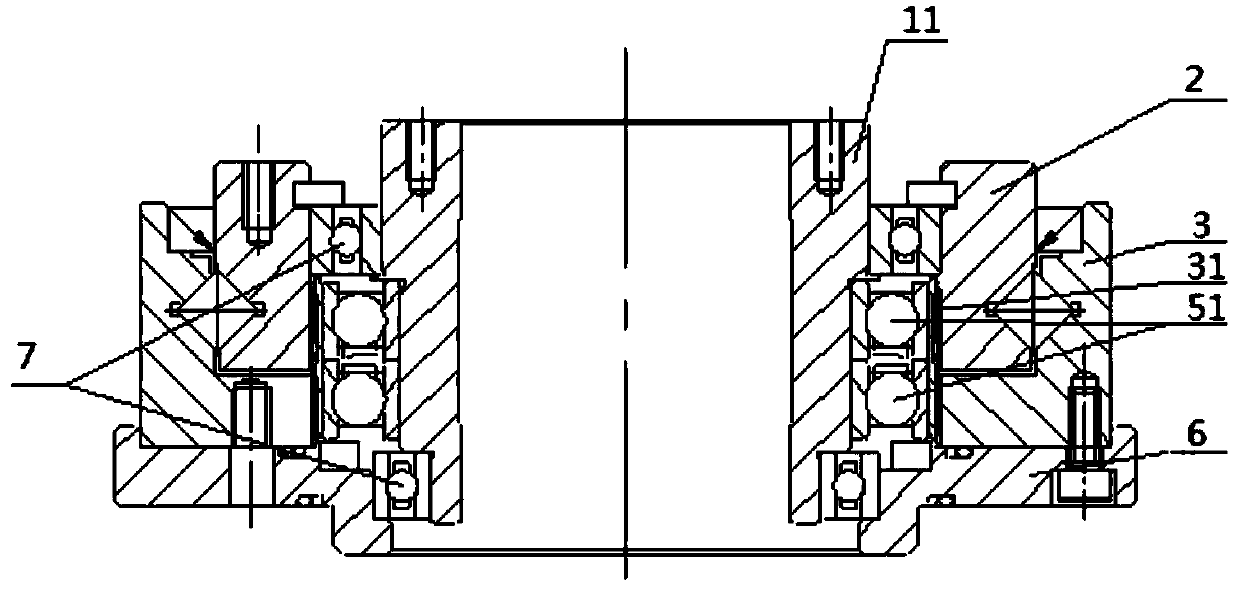

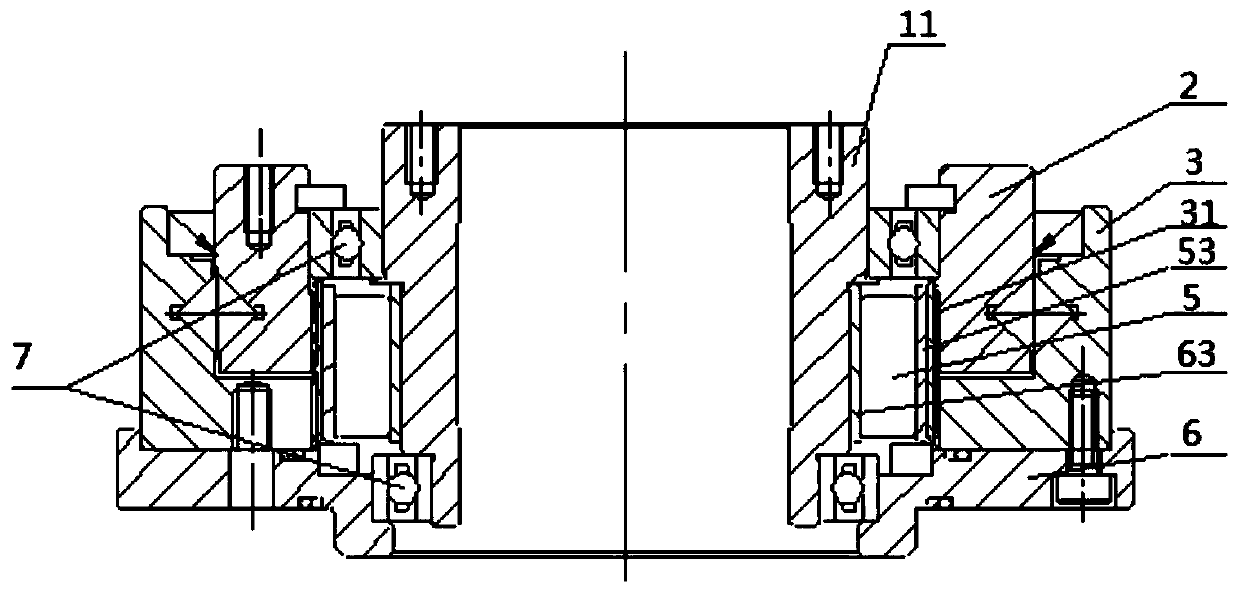

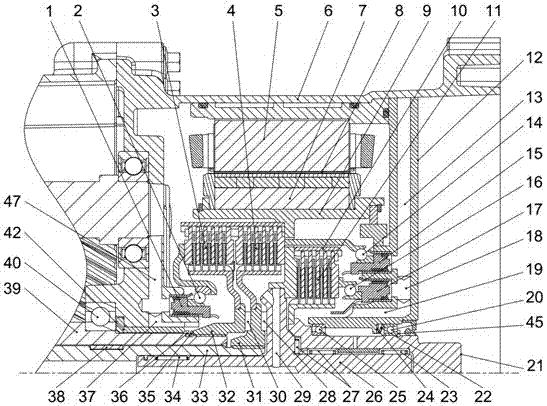

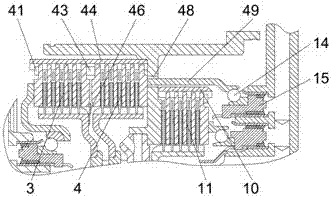

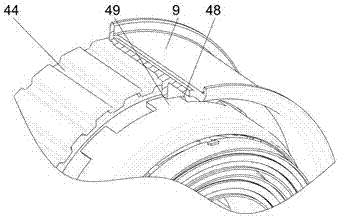

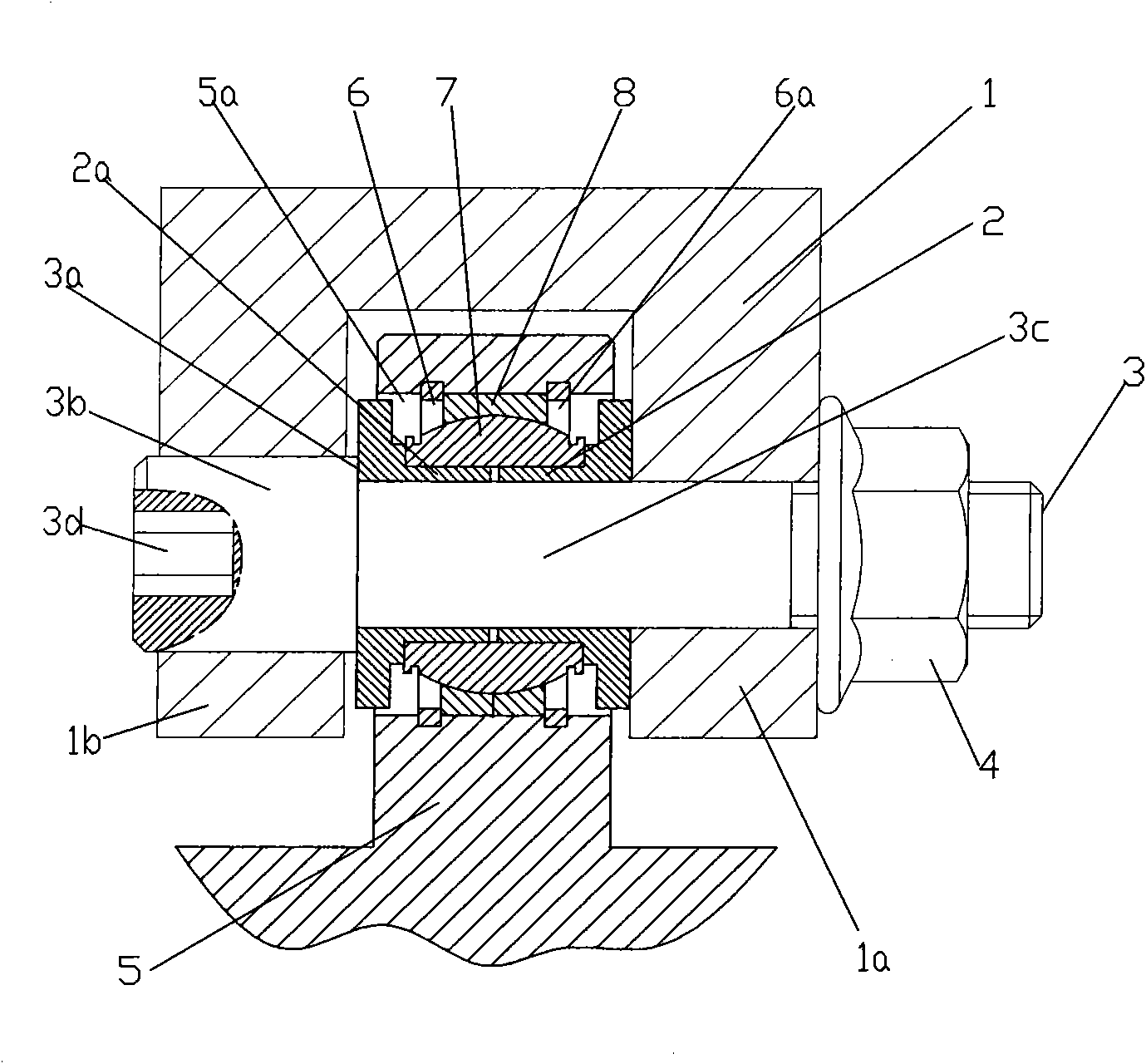

Integrated type double-rigid-wheel harmonic speed reducer without inner and outer ring rolling needle type flexible bearing

The invention provides an integrated type double-rigid-wheel harmonic speed reducer without an inner and outer ring rolling needle type flexible bearing. A new wave generator, a new inner ring, a new outer ring, a new flexible wheel, a rolling needle, rigid wheel end covers and a deep groove ball bearing are included; the new wave generator is composed of a wave generator body and a rolling needle flexible bearing inner ring; the new flexible wheel is composed of a flexible wheel body and a rolling needle flexible bearing outer ring; the new inner ring is composed of a fixed rigid wheel and a crossed roller bearing inner ring; the new outer ring is composed of an output end rigid wheel and a crossed roller bearing outer ring; and the new wave generator, the new inner ring, the new outer ring and the new flexible wheel are all integrated parts. In the technical field of harmonic speed reducers, the problems that a gap is likely to exist in the radial direction of the speed reducer, transmission is not stable, and rigidity is poor exist, and the double-rigid-wheel harmonic speed reducer which is small in body type, small in weight, compact in structure and high in rigidity is provided.

Owner:南通振康机械有限公司 +1

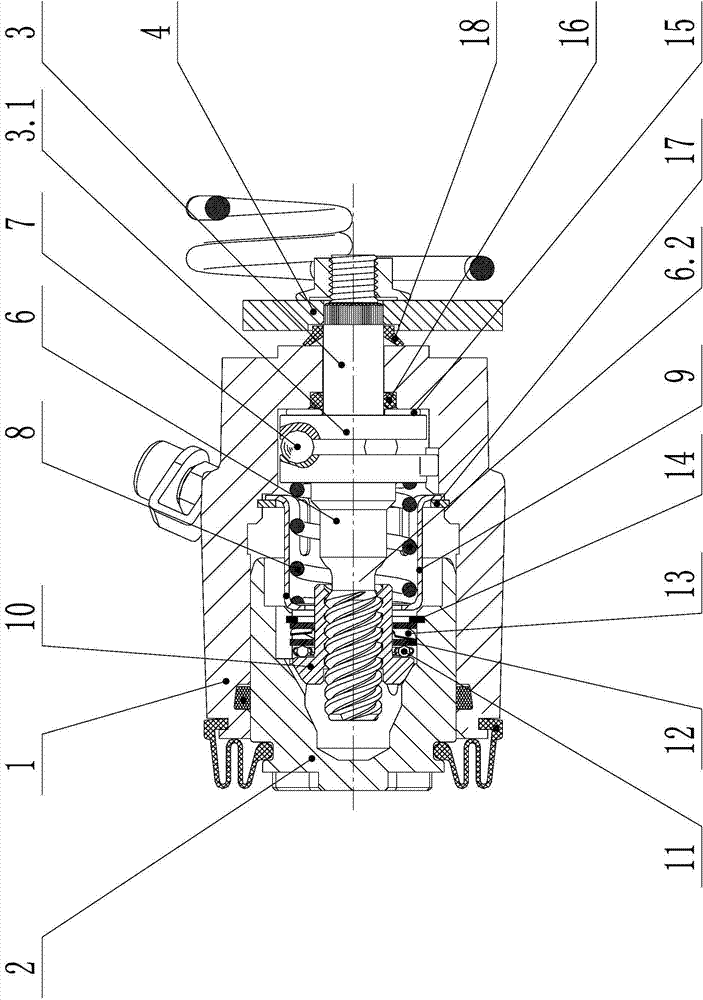

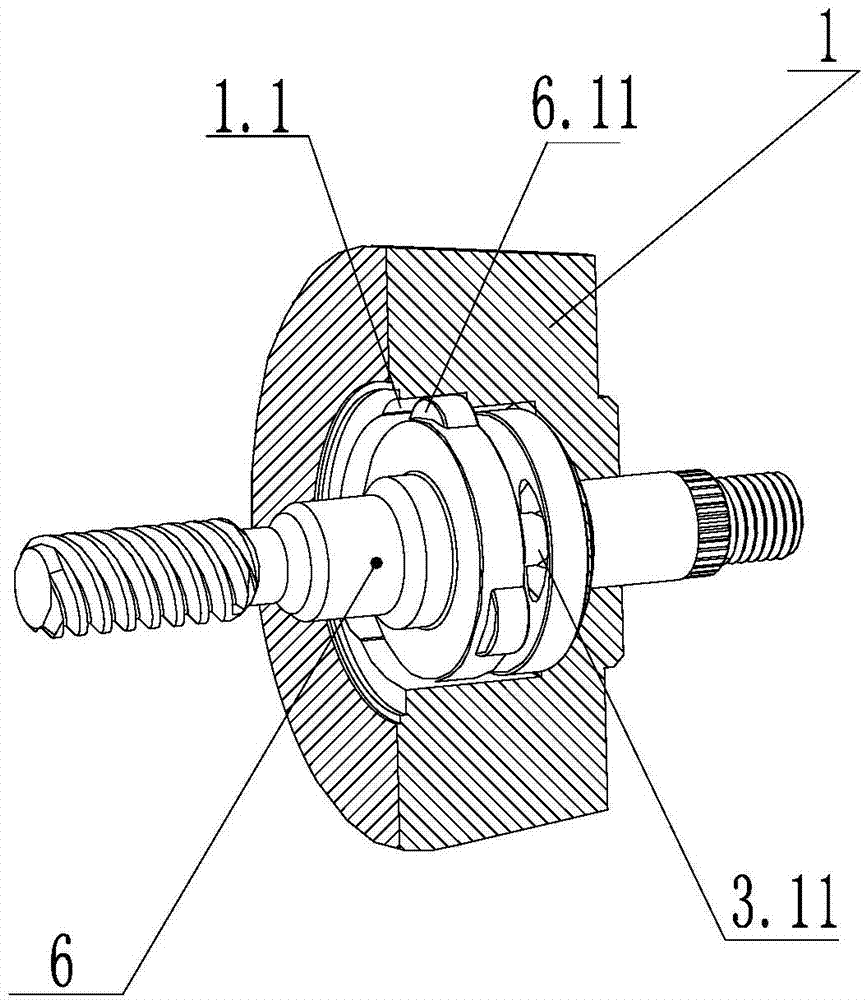

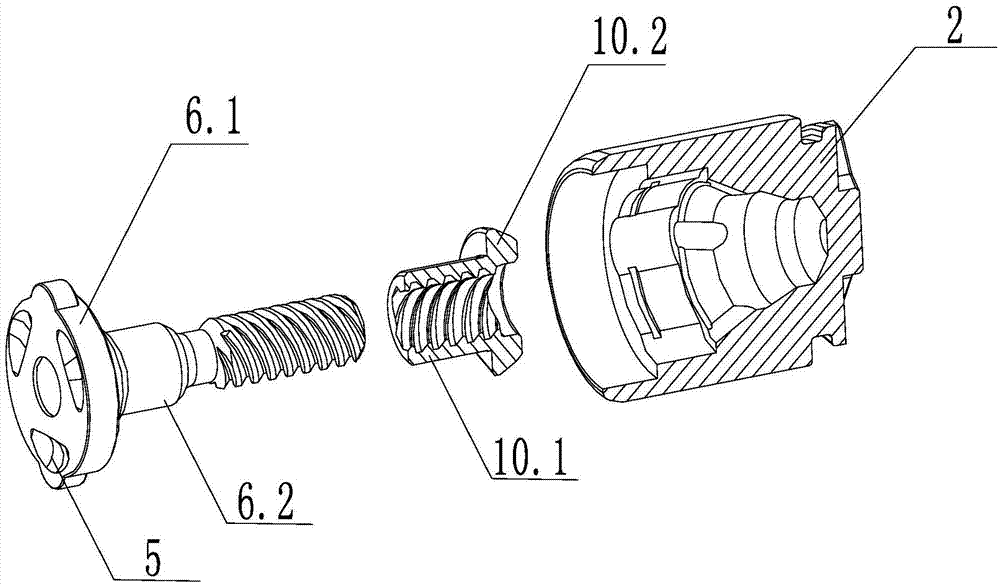

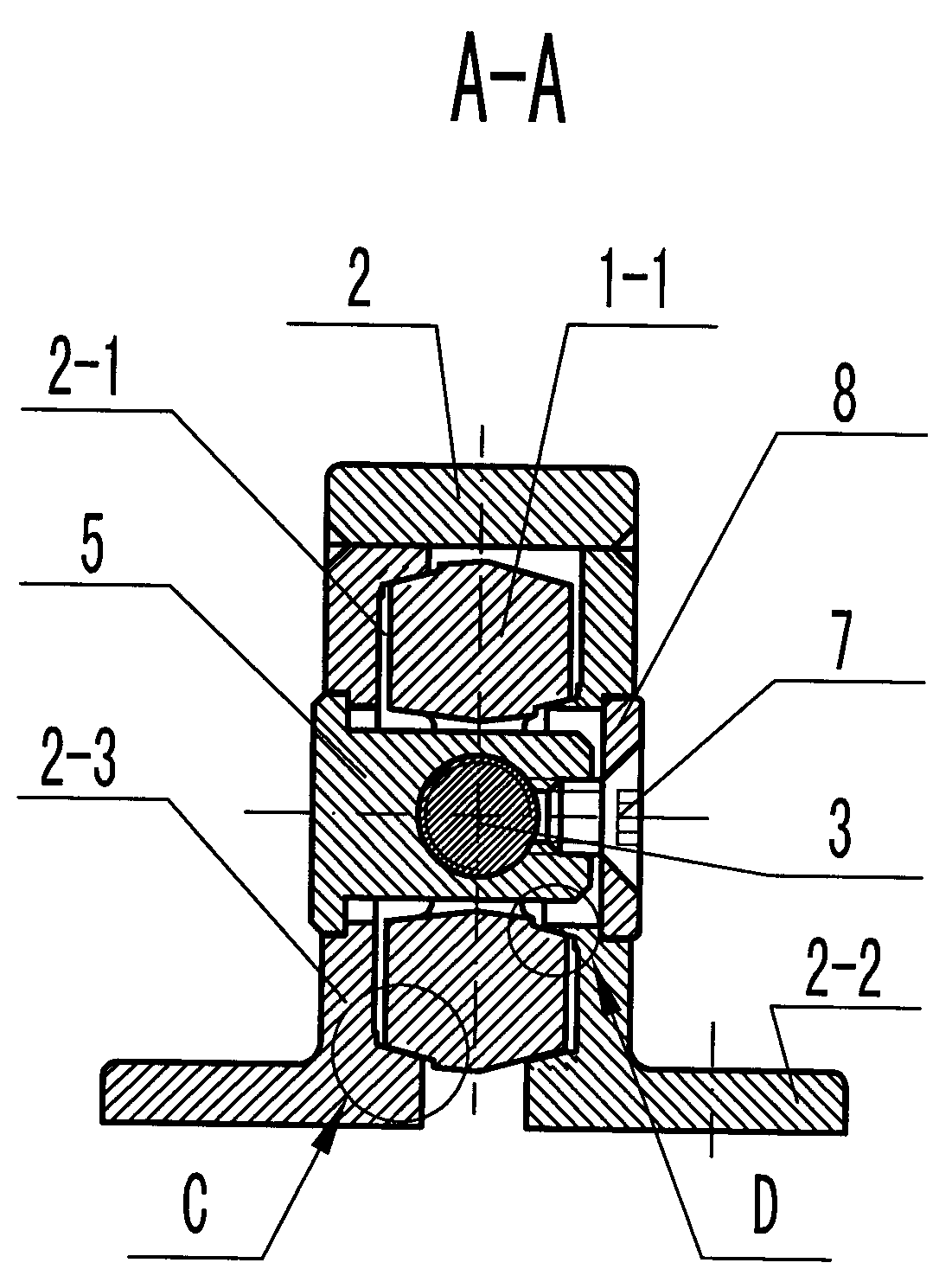

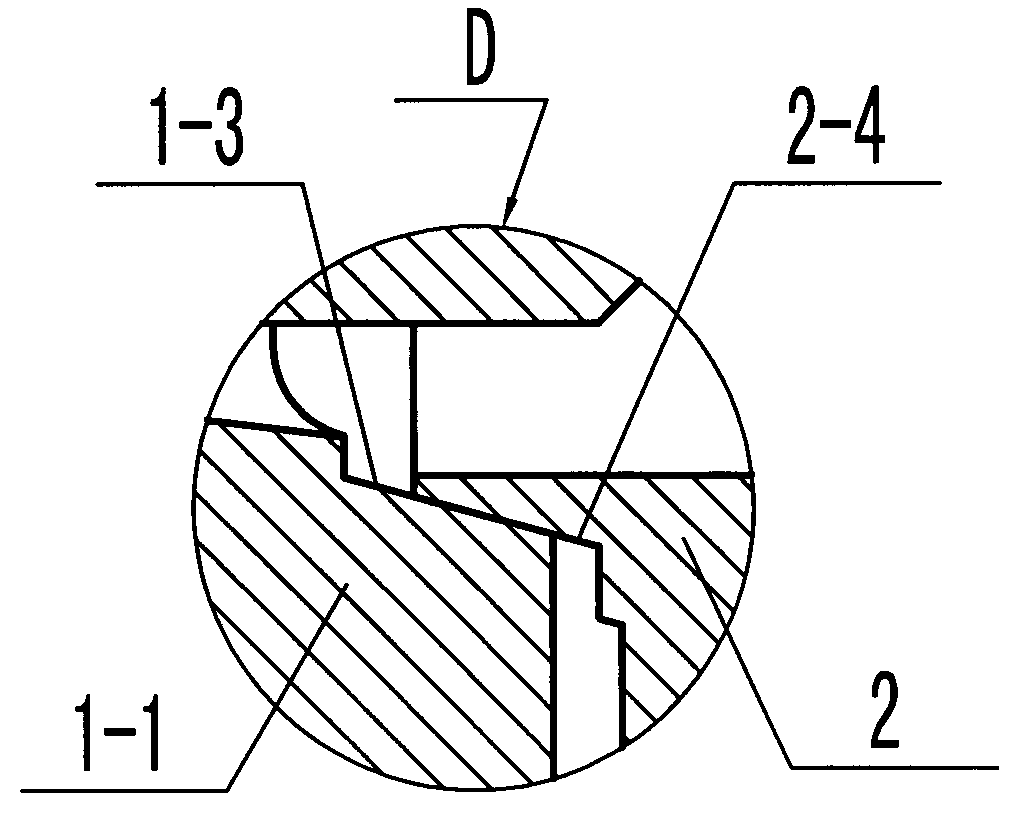

Disk brake cylinder assembly with parking mechanism and brake caliper

InactiveCN104712689AReduce misalignmentEliminate assembly gapsBrake actuating mechanismsActuatorsDrive shaftEngineering

The invention discloses a disk brake cylinder assembly with a parking mechanism and a brake caliper. The disk brake cylinder assembly comprises a cylinder block, a piston, a travel adjusting threaded sleeve, a travel adjusting threaded rod, a steel ball, a drive shaft, a plane sliding bearing, an O-shaped seal ring and a spring resetting device. One end of the travel adjusting threaded rod is provided with a multi-head saw-tooth thread. The other end of the travel adjusting threaded rod is a ball disk with slope rolling ways. Arc-shaped guide bosses are evenly distributed on the outer edge of the ball disk, and the bosses are matched with grooves in a cylinder hole and prevent the travel adjusting threaded rod from rotating. The travel adjusting threaded rod has good centering performance, and therefore an auxiliary piston having the centering function in the piston is omitted. By the adoption of the disk brake cylinder assembly with the parking mechanism, the movement type of parts of the parking mechanism is simplified, and the risk that multiple leaking points exist in existing known structures is avoided. The disk brake cylinder assembly with the parking mechanism is simple in structure and higher in safety performance, the parts can be more easily machined, the transmission efficiency of the parking brake force is improved, and low cost, high performance and higher safety performance are effectively combined.

Owner:武汉万向汽车制动器有限公司

Non-contact type angular sensor for automobile electronic accelerator

InactiveCN102494605AEliminate assembly gapsAccurate angle detectionUsing electrical meansContact typeEngineering

The invention discloses a non-contact type angular sensor for an automobile electronic accelerator, which comprises a casing, a rotor, a circuit board, a chip, a magnet, a cover plate and a rotor cover casing. The casing is provided with a circuit board assembly cavity and a rotor containing chamber, the chip is welded to the circuit board, a partition board is arranged between the circuit board assembly chamber and the rotor containing chamber of the casing, and the partition board is provided with a chip positioning frame. After the circuit board is assembled into the circuit board assembly chamber, the chip is matched into the chip positioning frame, and the cover plate is assembled on a chamber opening of the circuit board assembly chamber. The rotor is provided with a magnet containing chamber. After the rotor is assembled in the rotor containing chamber of the casing, the center of magnet containing chamber and the center of the chip positioning frame are located on the same axis, the magnet is assembled in the magnet containing chamber, and the rotor cover casing is fixed in the rotor containing chamber and located below the rotor. The non-contact type angular sensor for the automobile electronic accelerator can detect that the chip is coaxial with the magnet, thereby being favorable for improving detecting accuracy and saving programming.

Owner:CHANGZHOU WANXIANG AUTOMOBILE PARTS

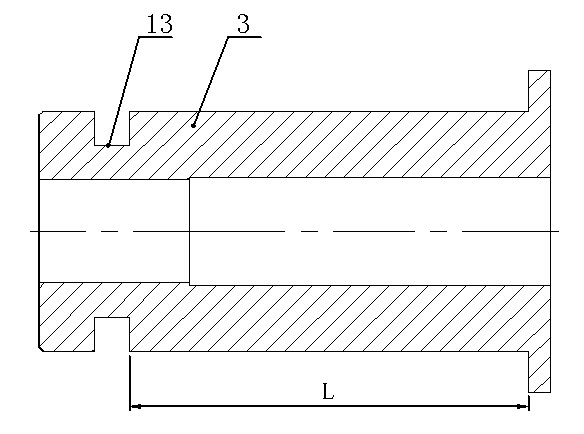

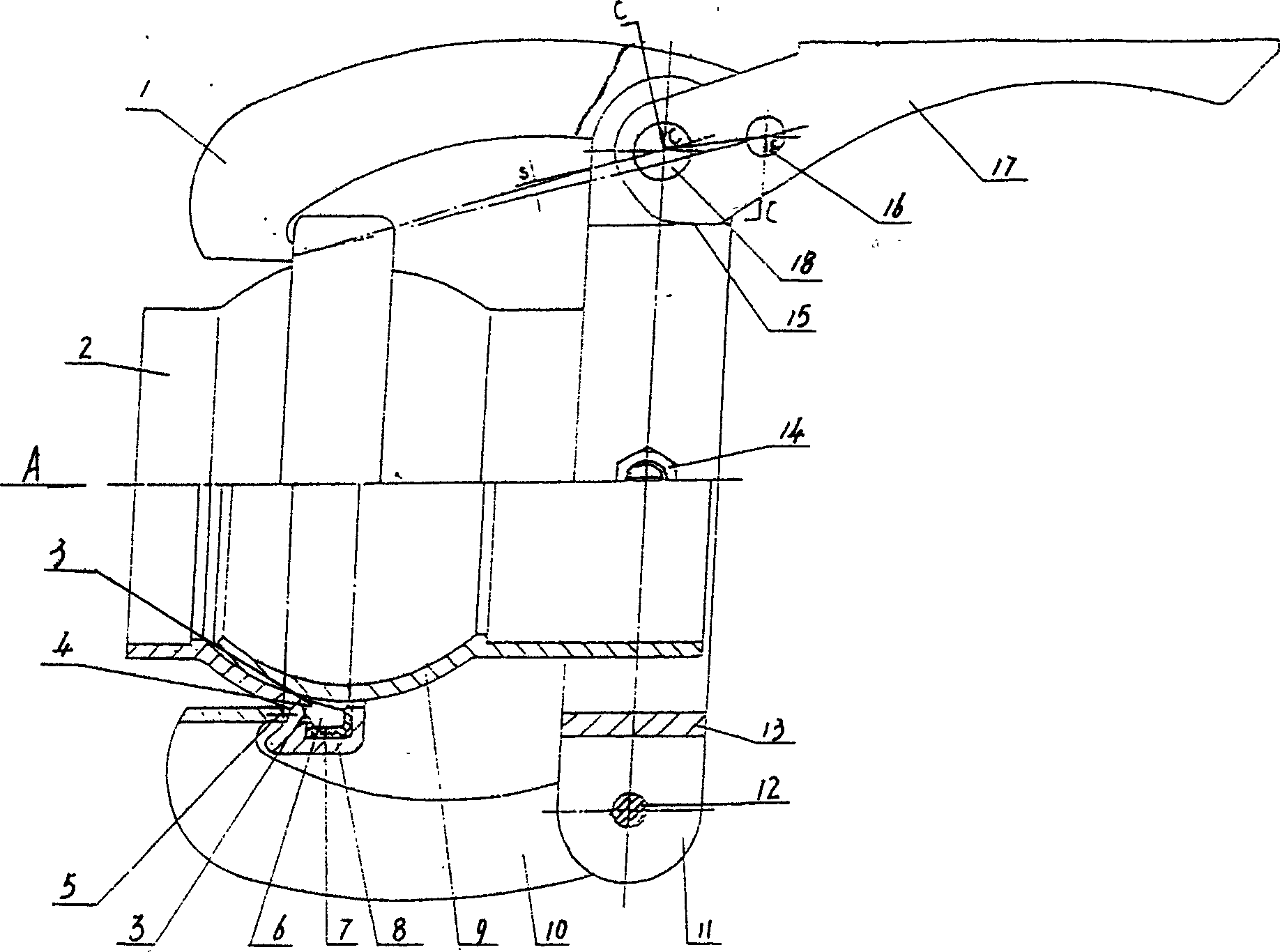

Combination type hollow bearing roller

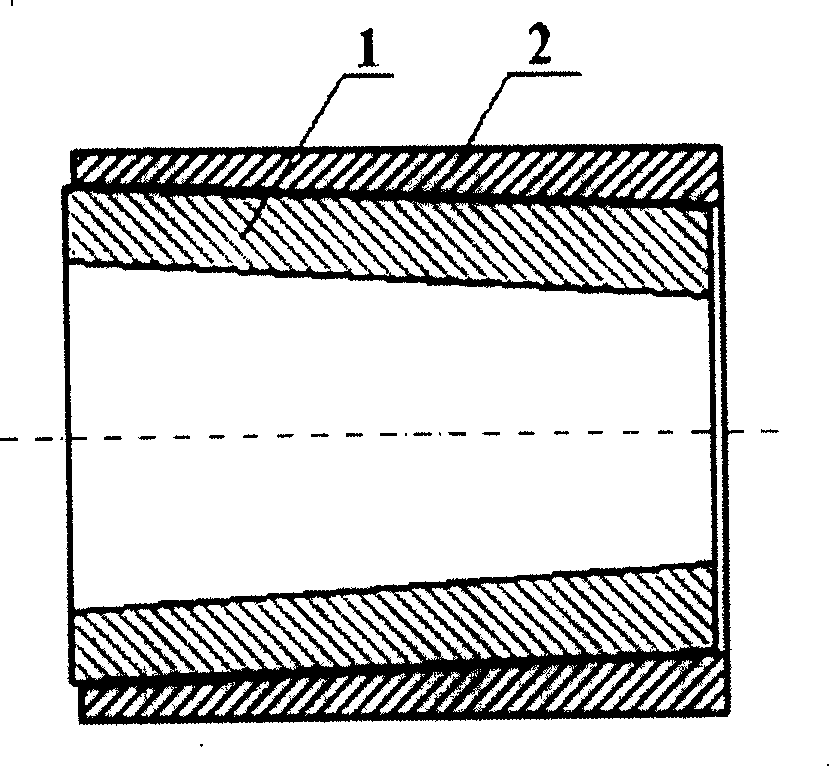

The invention relates to a combined hollow bearing roller, wherein an expanding sleeve 1 is arranged in a sleeve 2, the sleeve 2 is of a cylindrical shape or a circular cone shape, an inner cavity is of an inner frustum shape, the expanding sleeve 1 is of a frustum shape, and the inner cavity is of an inner frustum shape. When the expanding sleeve 1 is forced to axially move from a large diameter end to a small diameter end through applying an axial force to the expanding sleeve 1 and the sleeve 2, because the incremental launching effect of a conical surface, the outer ring diameter of the sleeve 2 is evenly increased, thereby achieving the purpose of eliminating the assembly gap of a bearing and increasing the precision grade. The combined hollow bearing roller has four advantages of saving materials, high limiting rotational speed, high assembly accuracy and vibration reduction anti-noise and the like.

Owner:潘存云

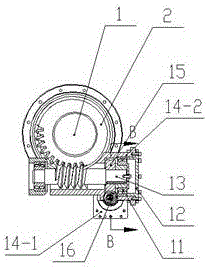

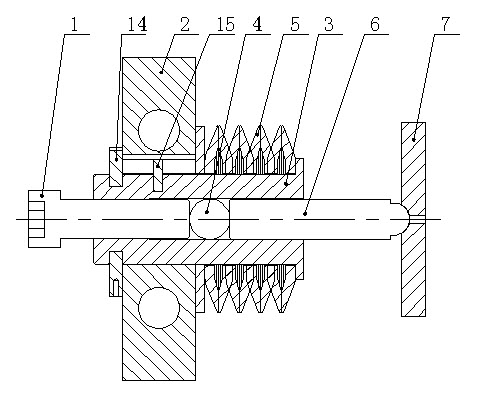

Radial adjusting mechanism of Y-shaped rolling mill

ActiveCN105728471ARealize online adjustmentAccurate transmission adjustment positionMetal rolling stand detailsMetal rolling arrangementsRadial positionEngineering

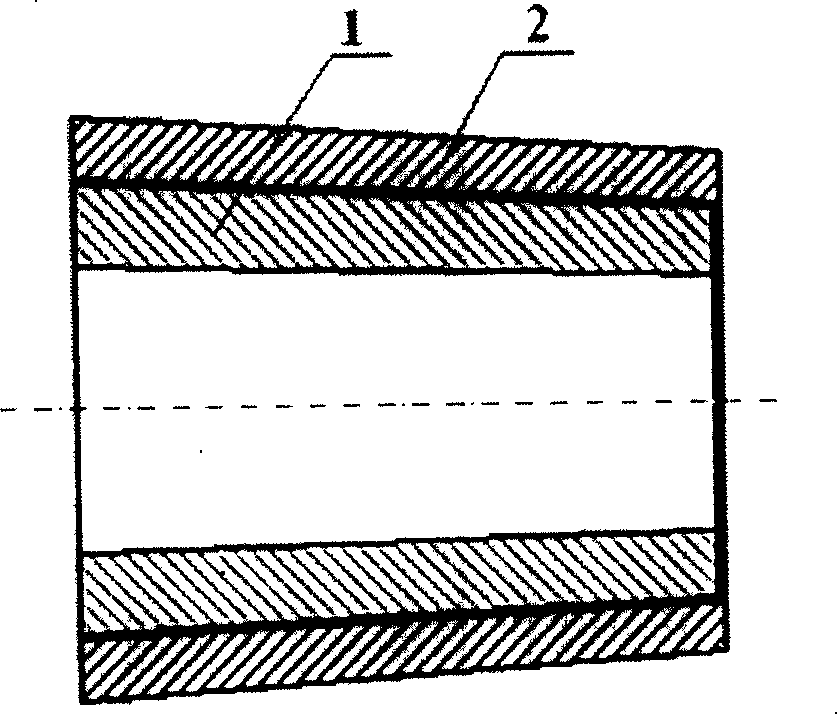

The invention discloses a radial adjusting mechanism of a Y-shaped rolling mill and aims to overcome the problems that some of the Y-shaped rolling mills have no radial adjusting devices, the rolling reduction is non-adjustable, or the radial adjustment is achieved under unreasonable transmission structures, the adjustment amount is extremely small and difficultly meets the basic requirement of steady transmission, the service life of the rolling mill is seriously influenced, or the structure is complex, the processing and manufacturing difficulty is high, the cost is high, and the rolling mill is unsuitable for rolling special-shaped products. The radial adjusting mechanism of the Y-shaped rolling mill is characterized in that a main eccentric sleeve and a secondary eccentric sleeve are mounted on each main shaft; a worm mechanism sleeves each main eccentric sleeve; the worm mechanism drives the eccentric sleeves to rotate and accurately adjust the radial position of the roller. The radial adjusting mechanism of the Y-shaped rolling mill has the beneficial effects that on-line adjustment can be implemented; the requirements of the manufacturing accuracy and the assembly accuracy are relatively low; the adjusted radial position accuracy is high; the worms are located on front and back surfaces or the sides of the rolling mill; the servo control motor is conveniently mounted; the radial position can be rapidly and accurately adjusted on line.

Owner:沈阳重机重矿机械设备制造有限公司 +1

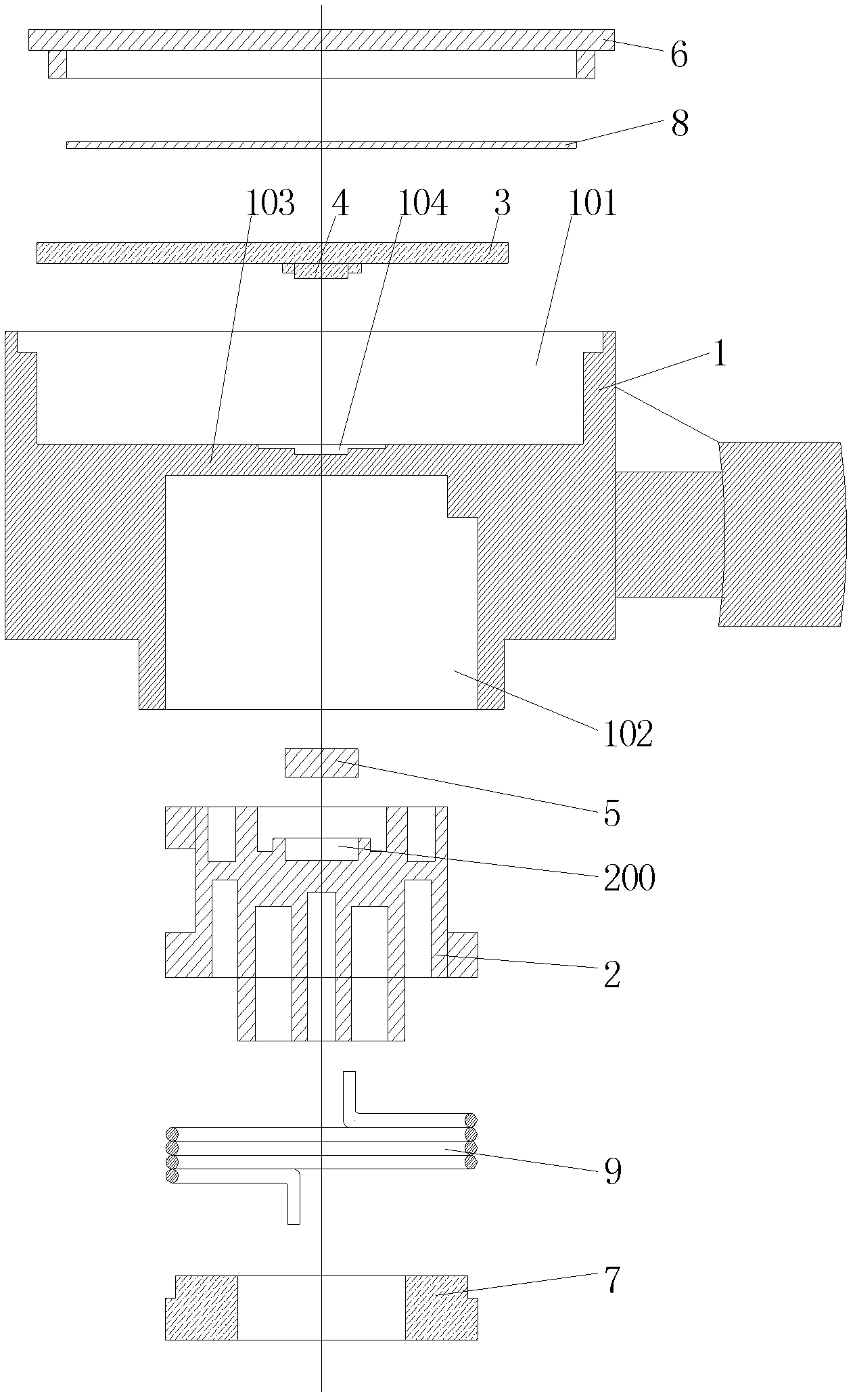

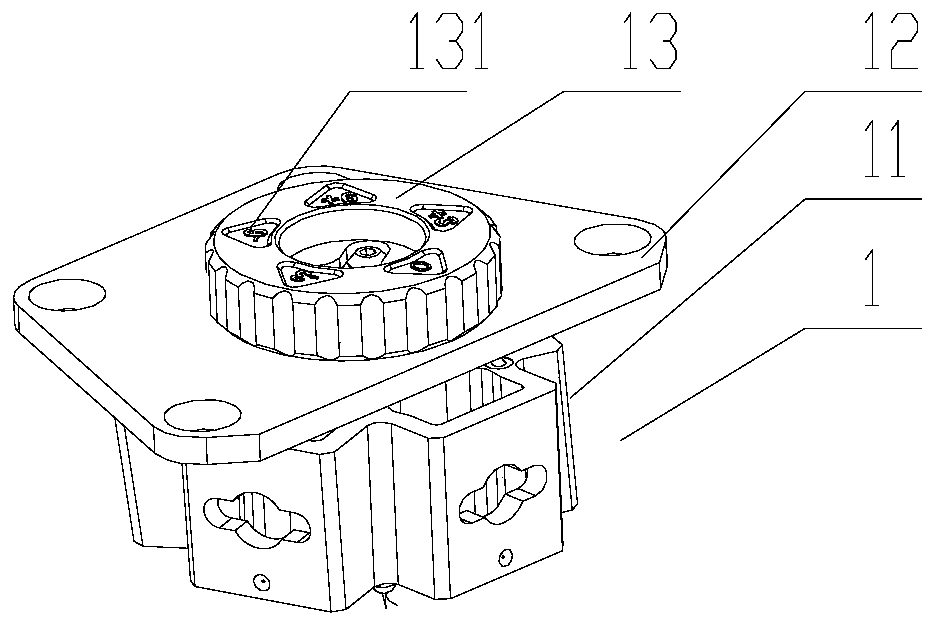

Flange type angle lock device and display screen module

PendingCN110767113AImprove assembly qualityEliminate assembly gapsIdentification meansStructural engineeringMechanical engineering

The invention provides a flange type angle lock device. The flange type angle lock device comprises a lock cylinder assembly and a quick lock assembly which is matched and locked with the lock cylinder assembly; the lock cylinder assembly comprises an angle turning core, a turning core cover plate fixedly connected with the angle turning core, an angle adjusting knob fixedly connected with the turning core cover plate, and a compression locking device installed in the angle adjusting knob, wherein the turning core cover plate is located between the angle turning core and the angle adjusting knob; the angle adjusting knob is located between the turning core cover plate and the compression locking device; and the lock cylinder assembly further comprises a positioning and mounting assembly connected with the angle turning core. By using the technical scheme provided by the invention, not only the rapid splicing and locking of a display screen module is realized, but no tools are needed inthe entire splicing process, so that the splicing process is simplified while the splicing precision is improved, and the cost of the product is also saved.

Owner:SHENZHEN UNIVIEW LED

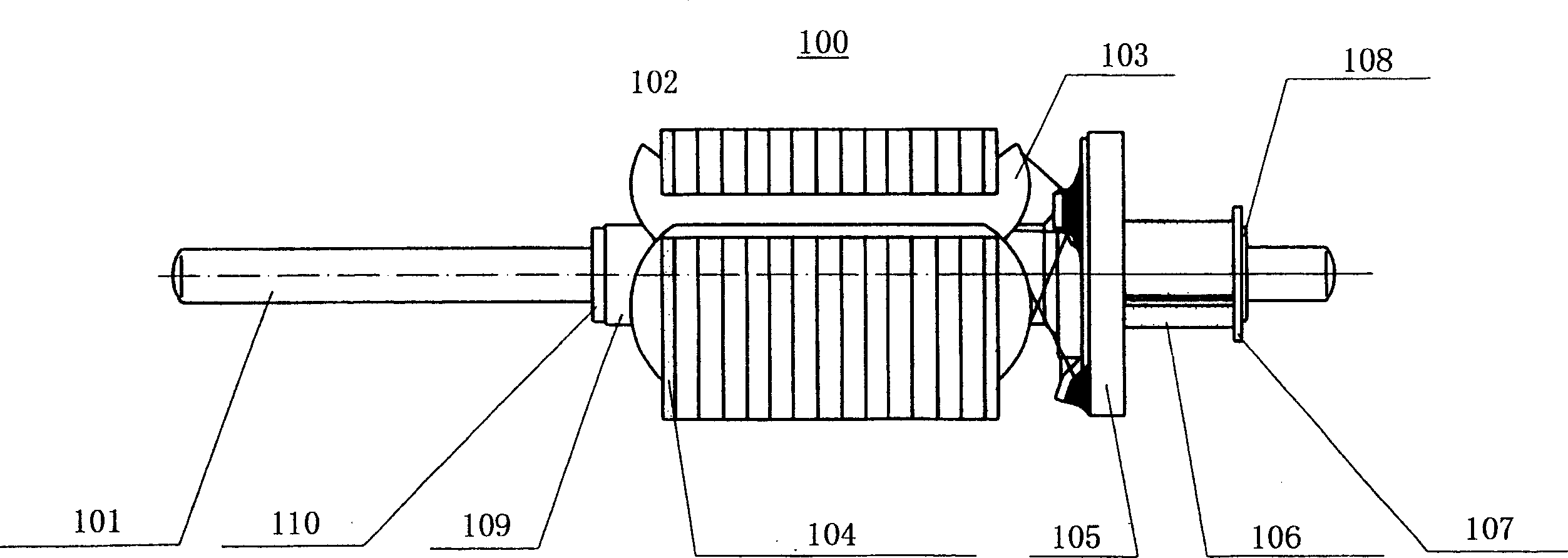

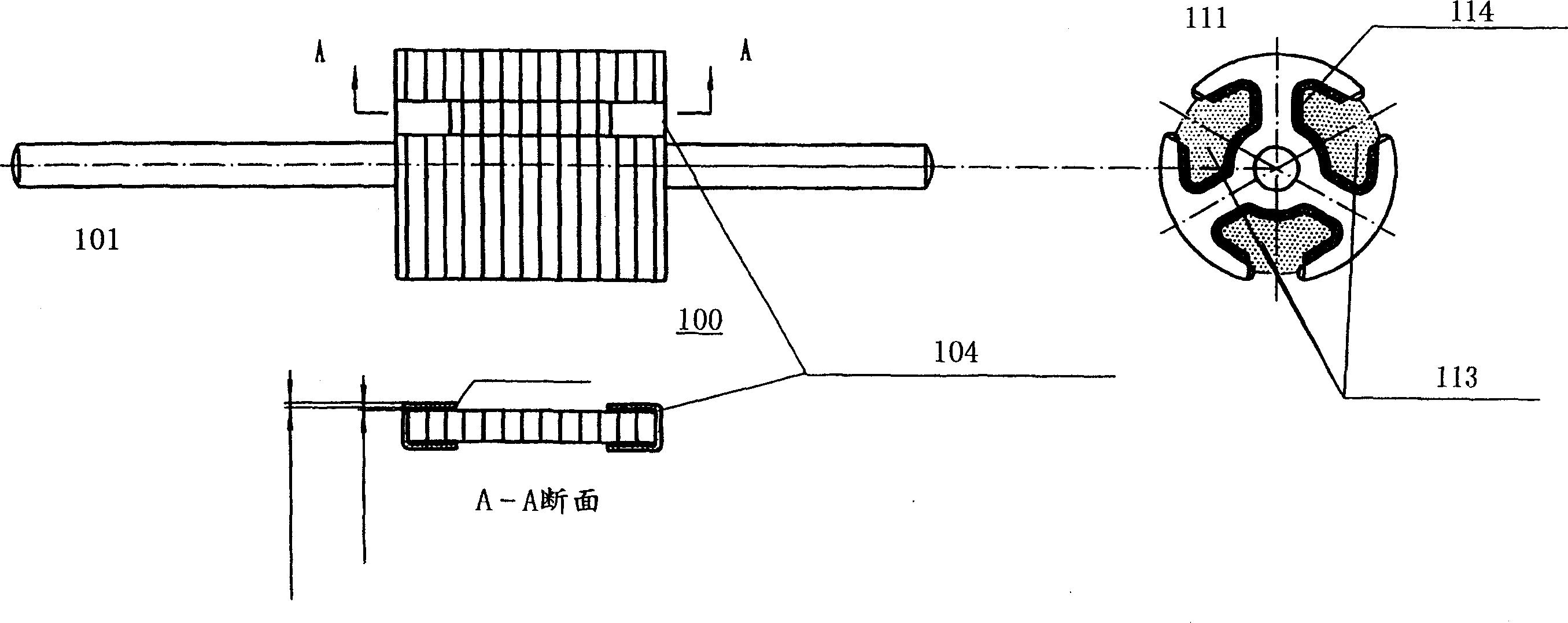

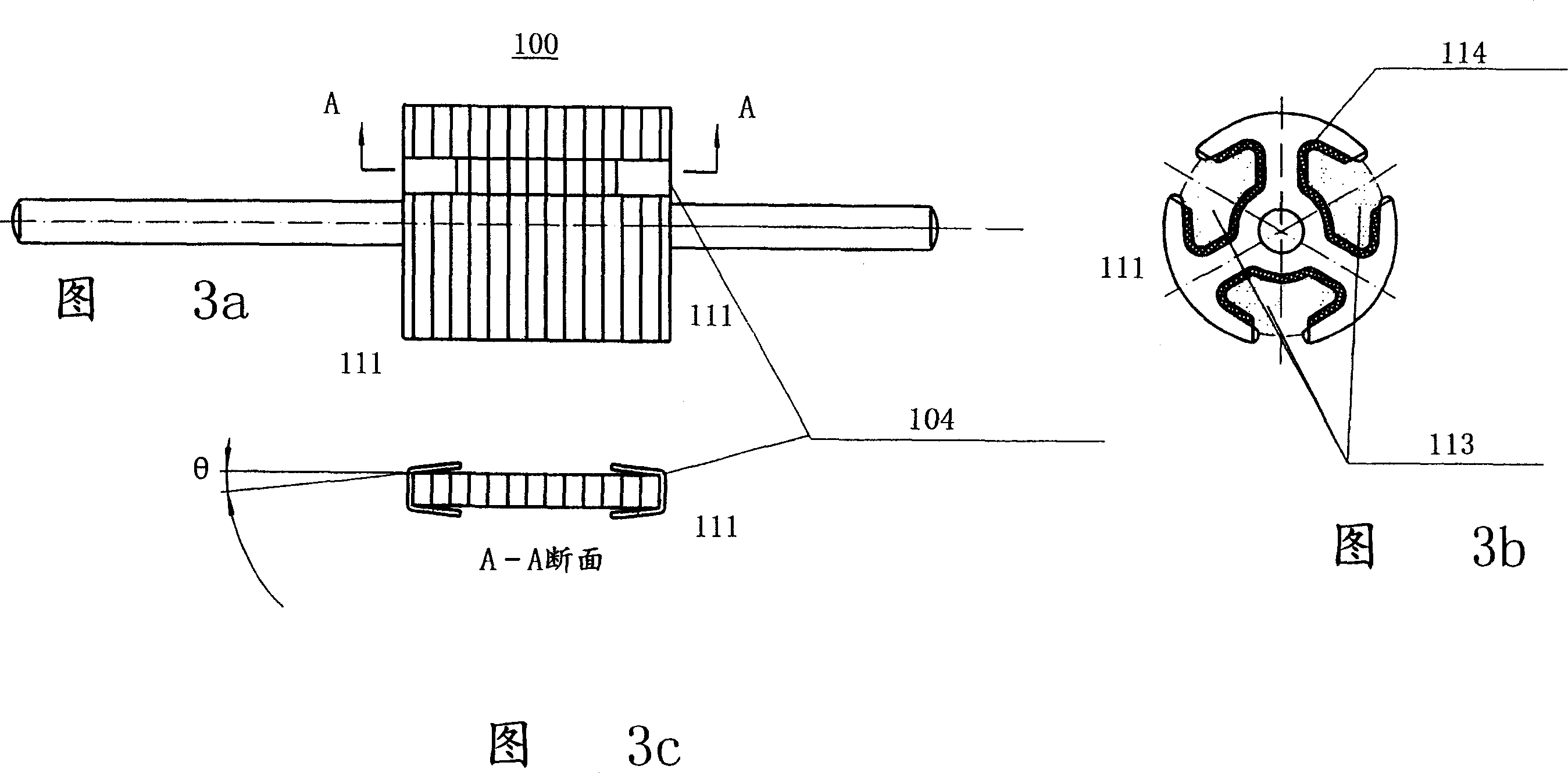

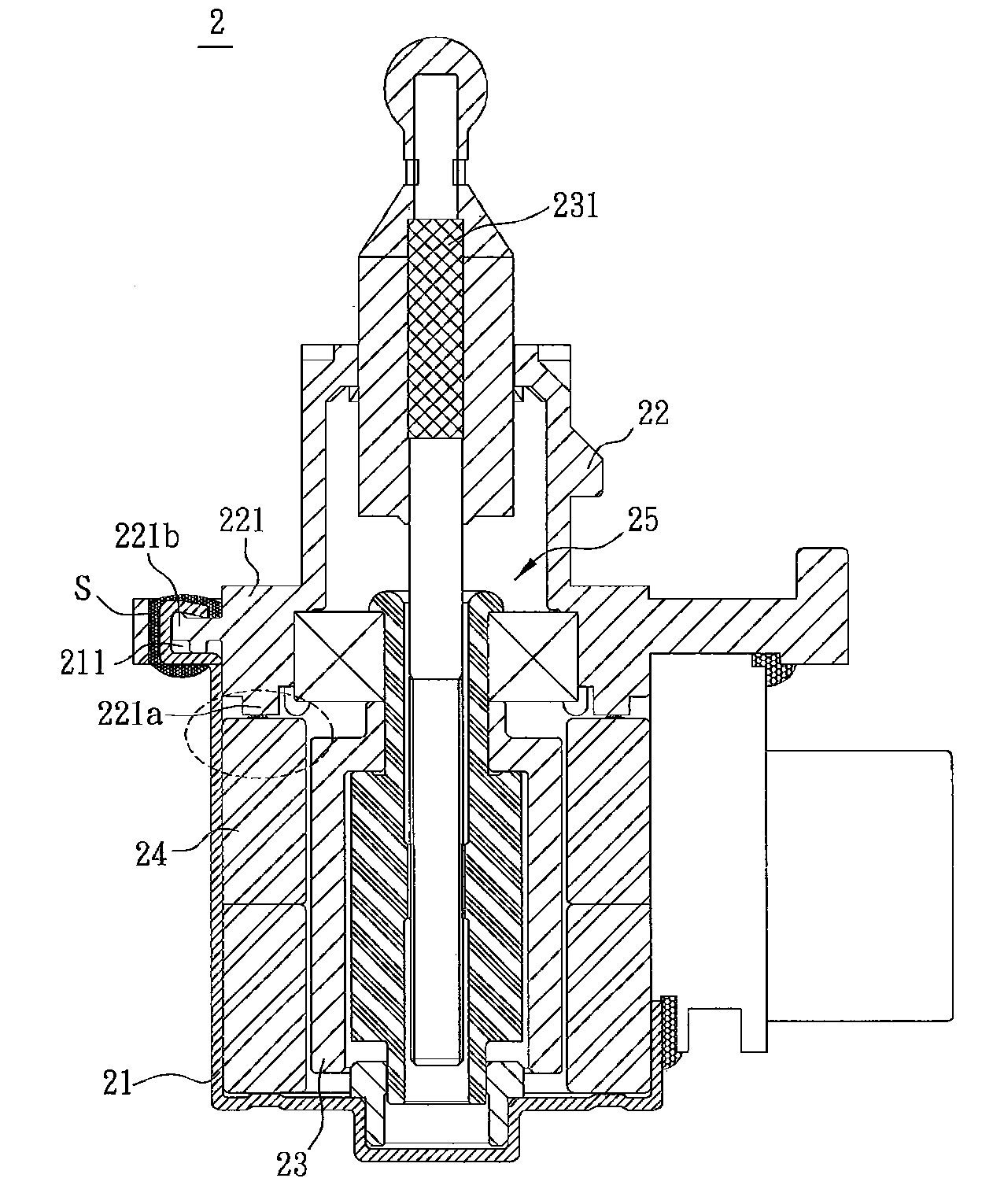

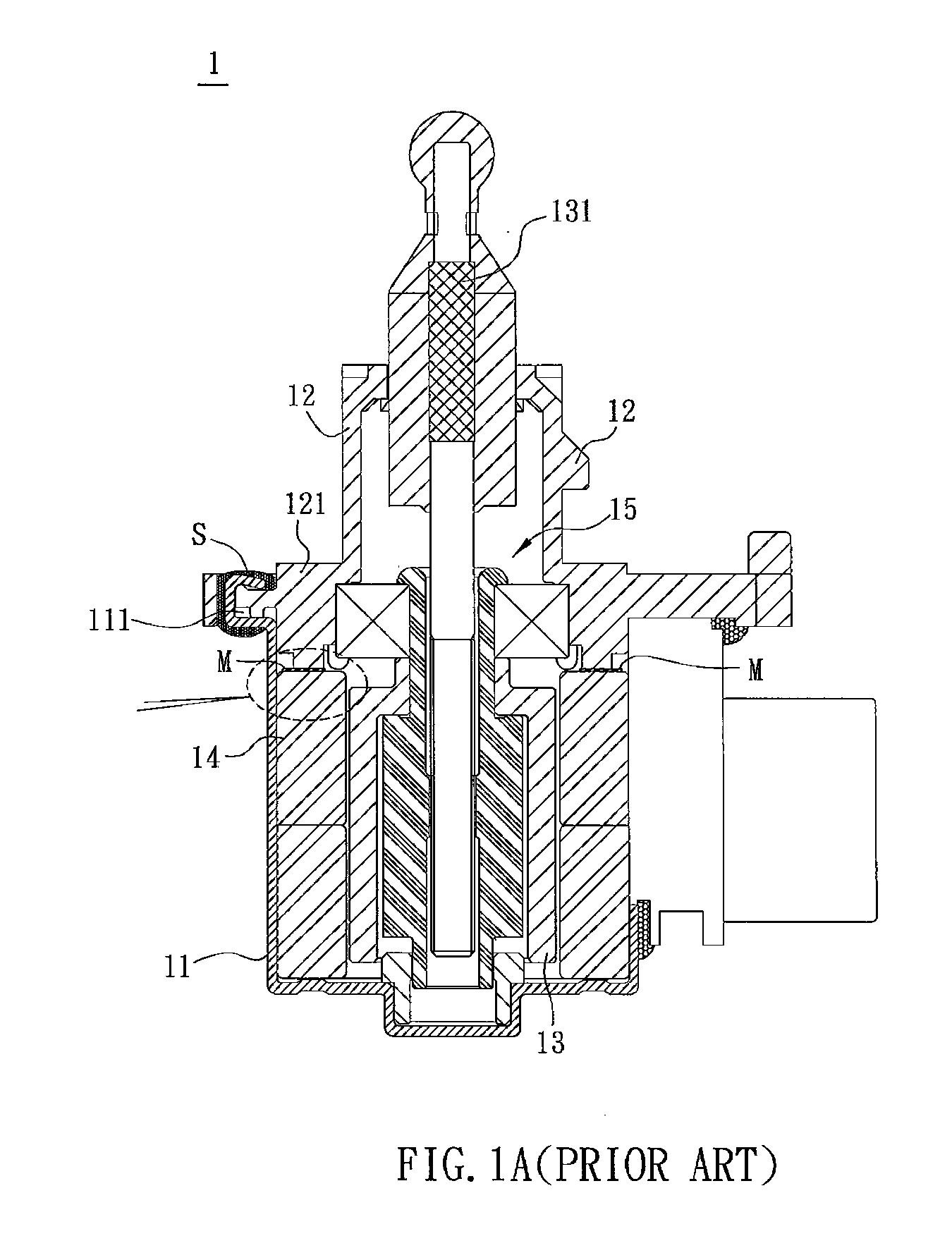

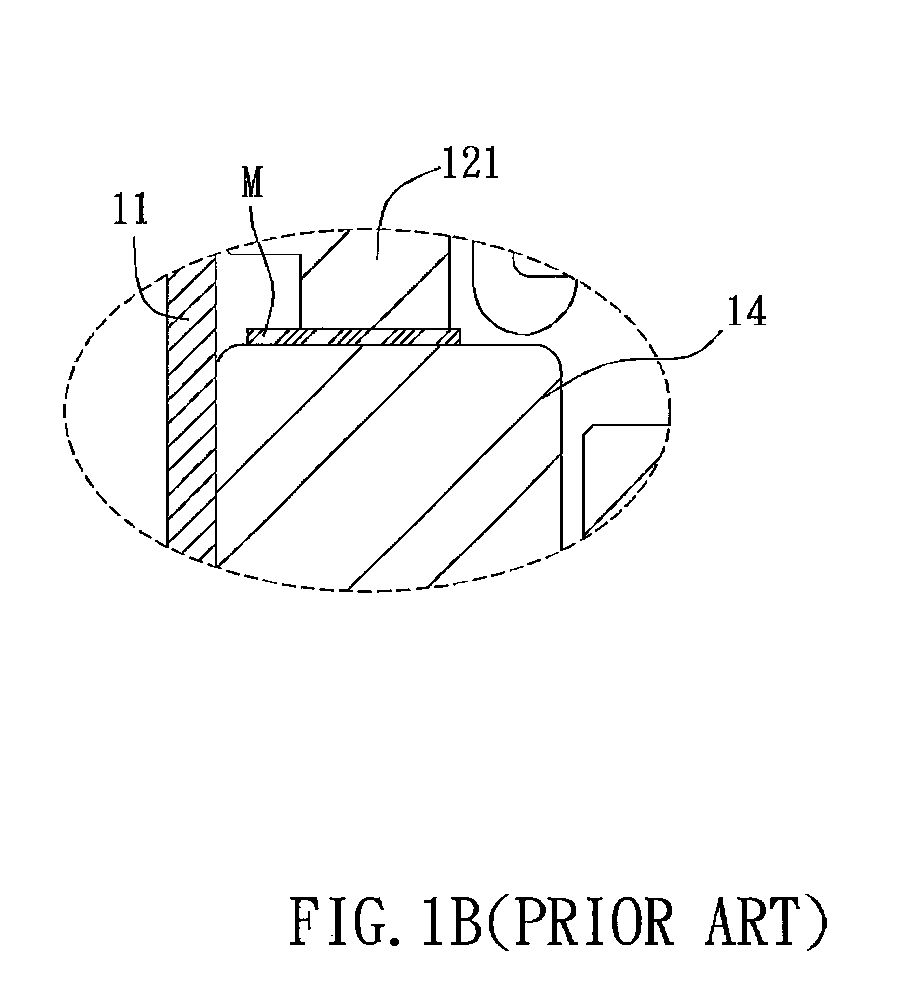

Mini DC motor

InactiveCN1567679AIncrease track lengthReduce manufacturing costWindings insulation shape/form/constructionMechanical engineeringDC motor

The invention provides a microtype DC machine rotor and its making method, including a rotor iron core and a rotating shaft through the center of the iron core, where there are wire slots for winding coil, axially made on the iron core, two ends of the rotor iron core are both installed with an insulating piece concentric with the iron core, and the extended edge round the wire slot of each insulating piece is bent at a right angle to the inside of the wire slot.

Owner:萃进有限公司

Three-clutch electromechanical coupling driving device for motor vehicle

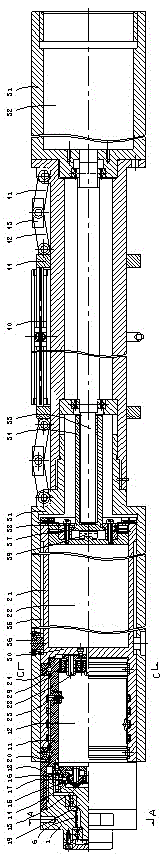

PendingCN106891714AReduce axial sizeReduce the moment of inertiaGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingBall bearingElectric machinery

The invention discloses a three-clutch electromechanical coupling driving device for a motor vehicle. The three-clutch electromechanical coupling driving device comprises a shell body, a front end cover, a motor, an input shaft, a rotor support, a supporting shaft, a cut-off clutch and a double clutch. The motor is provided with a rotor and a stator. The cut-off clutch and the double clutch are integratedly arranged inside the motor. The rotor is connected with the rotor support connected with the supporting shaft. The left end of the supporting shaft is supported on an even-number gear output shaft of the double clutch through a bearing. The even-number gear output shaft of the double clutch is supported on an odd-number gear output shaft of the double clutch through a bearing. The odd-number gear output shaft of the double clutch is supported on the shell body through a bearing. The right end of the supporting shaft is supported on the input shaft through a bearing set. The input shaft is supported on the front end cover through a ball bearing. The three-clutch electromechanical coupling driving device has the beneficial effects of being small in axial size, small in part number, low in cost and high in precision.

Owner:CHINA FIRST AUTOMOBILE

Flexible water-cooling metal electrode for monocrystalline furnace

InactiveCN101205630AGood thermal fieldReduce assembly clearances and errorsAfter-treatment apparatusOhmic-resistance electrodesGraphite electrodeStainless steel electrode

The invention relates to a flexible water-cooling metal electrode used for a mono-crystal furnace, comprising a water-cooling copper pipe electrode, a stainless steel terminal clamp and a copper gland cover, wherein, the lower part of the water-cooling copper pipe electrode is welded with the stainless steel terminal clamp, and a water-cooling cycle is formed; the upper part of the water-cooling copper pipe electrode passes through the copper gland cover and is hermetically welded with the copper gland cover; the water-cooling copper pipe electrode is a complete water-cooling copper pipe which passes through the stainless steel terminal clamp and then returns back to the stainless steel terminal clamp to form a water-cooling cycle. Because the water-cooling copper pipe has an ability of plastic deformation and can be properly deformed under an exogenic action, thereby a position of the stainless steel terminal clamp can be conveniently moved within a certain range, and then a position of a connecting point between a stainless steel electrode and a graphite electrode and a heater. The invention is favorable for removing errors caused by factors like processing, assembly, time-dependent deformation and so on, and for accurately fixing the heater, thereby a good thermal field is obtained.

Owner:GRINM ELECTRO OPTIC MATERIALS

Motor

A motor includes a first housing, a second housing, a rotor and a stator. The second housing is assembled with the first housing to form an accommodating space. The second housing has a flange adjacent to the connection between the first and second housings. The rotor has a shaft extended outwardly from the second housing and disposed in the accommodating space. The stator is disposed corresponding to the rotor and in the accommodating space. The flange has at least one protruding portion. When the second housing is assembled with the first housing, the protruding portion presses against the stator and is deformed so that the first and second housings are sealed.

Owner:DELTA ELECTRONICS INC

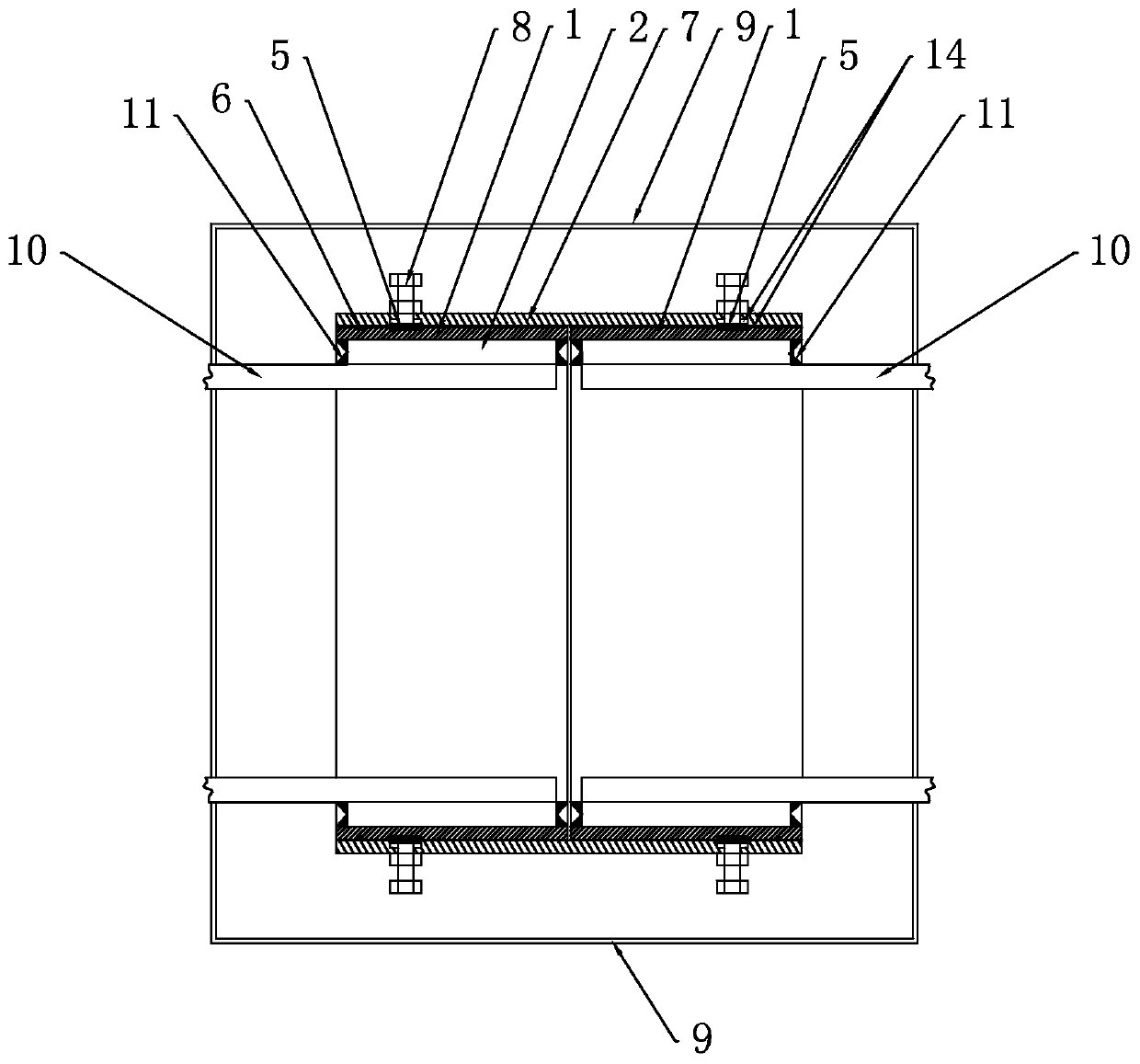

Mechanical press mounting structure of group large-power flat-plate power electronic device

ActiveCN101794767AEasy to controlImprove toleranceSemiconductor/solid-state device detailsSolid-state devicesMachine partsEngineering

The invention relates to a mechanical press mounting structure of a group large-power flat-plate power electronic device, which is technically characterized in that firstly, a left ejector pin is coaxially installed in a spring mandrel in a sliding mode, the spring mandrel is installed on a left support plate through a key pin which is mounted along the radial direction of the spring mandrel, a set of disk springs is mounted on the spring mandrel at the right end of the support plate, an annular groove is radially manufactured on the spring mandrel at the right end of the support plate, and a limiting chuck is mounted in the annular groove; secondly, a press mounting screw is coaxially engaged in the spring mandrel at the left side of the left ejector pin; and thirdly, the right end of the left ejector pin and a left pressure plate are in spherical pair installation, and the left end of the a right ejector pin and a right pressure plate are in spherical pair installation. In the mechanical press mounting structure, the disk springs are adopted as driving elements, the compression stroke of the disk springs are accurately controlled through machining parts and has nothing to do with the assembly precision; the mechanical pressing force is accurately controlled with constant pressure; and the structure has large latitude for the assembly length of power device series, eliminates the assembling clearance, has self-adaption for the length of the power device series in a certain range, and has high press mounting precision.

Owner:TIANJIN RES INST OF ELECTRIC SCI +1

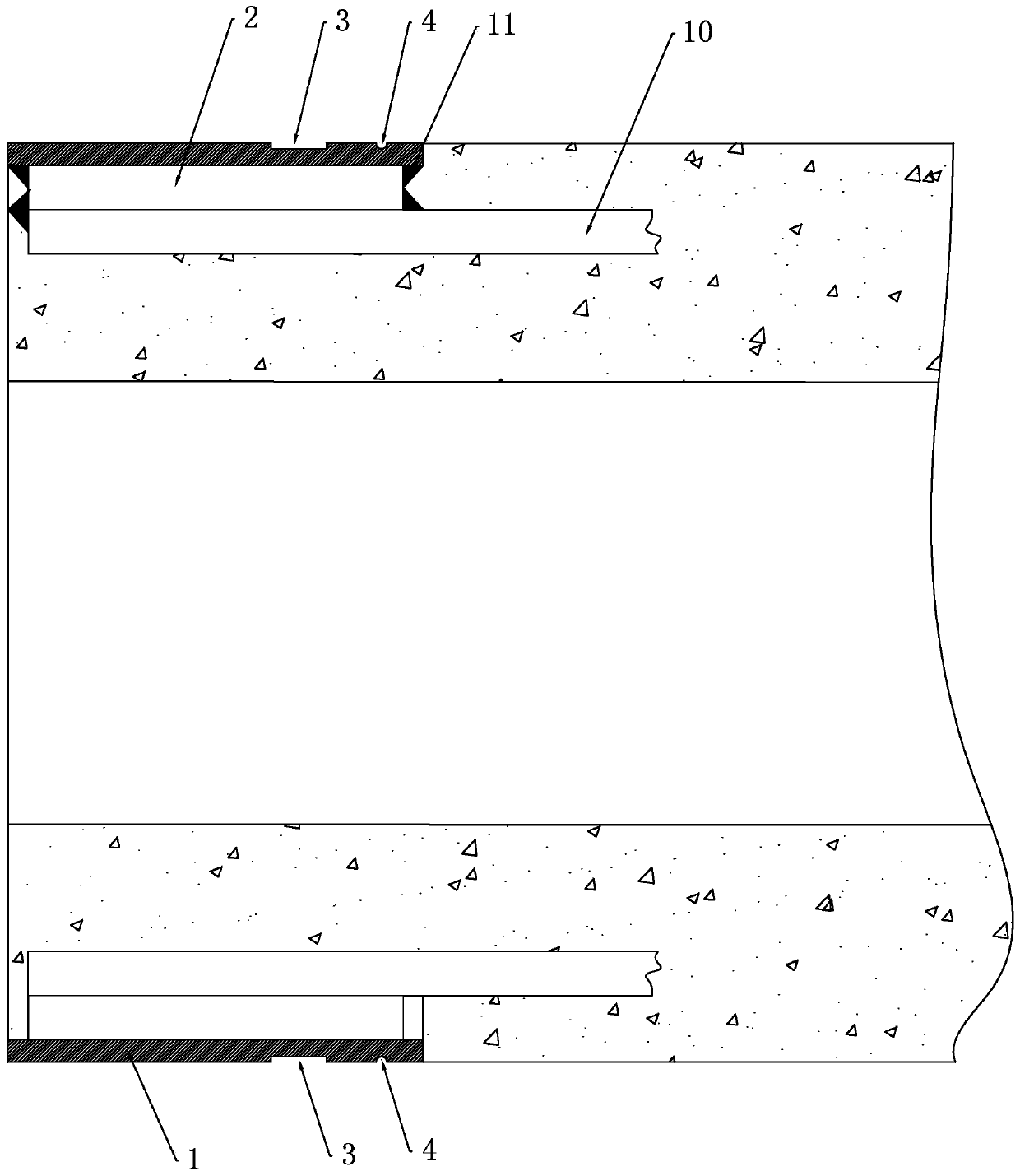

High-bending-resistance hold hoop joint mechanically connected with precast concrete beam-column pile rods

PendingCN109989487AImprove connection quality and performanceEliminate machining deviation and assembly clearanceBuilding constructionsBulkheads/pilesThreaded fastenerPrecast concrete

The invention relates to a high-bending-resistance hold hoop joint mechanically connected with a precast concrete beam-column pile rod. The hold hoop joint comprises two reinforcing hoops which are oppositely arranged, and a plurality of reinforcing ribs are fixedly connected to the inner side of each reinforcing hoop; a positioning groove and a sealing groove are horizontally formed in the outercircle face of each reinforcing hoop at intervals, a stress ring is arranged in each positioning groove, and a sealing ring is arranged in each sealing groove. An outer hoop sleeves the outer side ofthe two reinforcing hoops, a groove corresponding to each positioning groove is formed in the inner side wall of the outer hoop, a threaded fastener penetrating through the grooves is arranged on theouter hoop, and the threaded fastener is used for fixing the outer hoop and the stress rings to the reinforcing hoops in an abutting mode together. According to the hold hoop joint, manual welding process operation is avoided, the quality is controllable, mechanical connection is reliable, the labor intensity is reduced, the anti-corrosion performance is good, the steel consumption is extremely low, and the product cost and the construction cost are greatly reduced.

Owner:NANJING JULI INTELLIGENT MFG TECH INST CO LTD +1

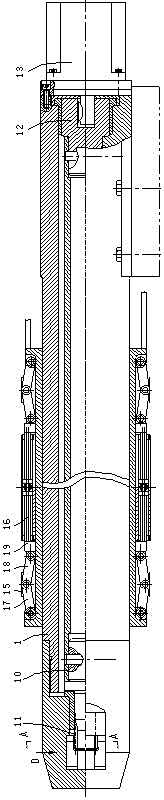

Electromagnetic wave logging tool coil supporting and pulling device

InactiveCN101054898BSimplify tensile structure designSimple structureElectric/magnetic detection for well-loggingBorehole/well accessoriesFailure rateCoil array

An bearing and pulling device for electromagnetic wave logging instrument coil array comprises a coil rack, an inner cone sleeve is housed on the inner circumference side of the end of the coil rack and is housed for bearing and pulling the coil rack; a protective sleeve is housed on the outer circumference side of the end of the coil rack and is housed for cramping the coil rack. The bearing andpulling device for electromagnetic wave logging instrument coil array of the invention simplifies design of the bearing and pulling structure for electromagnetic wave logging instrument, meanwhile improves the bearing and pulling performance and reliability of the instrument, reduces manufacturing cost and is convenient for carrying and dismantling and mounting, with low failure rate and convenient maintenance.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Self error correction leakage test mechanism and leakage test device

PendingCN107631845AReduce the "scrap rate"Firmly connectedMeasurement of fluid loss/gain rateEngineeringLeakage test

The invention discloses a self error correction leakage test mechanism and a leakage test device. The mechanism comprises a driving source, a gland in driving connection with the driving source, a leakage test assembly comprising a sealing member, a leakage test probe arranged at an interval from the gland, a rotation supporting body pressing against between the gland and the leakage test probe, and at least two elastic telescoping assemblies, wherein the leakage test probe is provided with a leakage test air channel, the sealing member is arranged on the leakage test probe and is used for incrimping sealing with a container port of a to-be-tested container, and the at least two elastic telescoping assemblies are connected between the gland and the leakage test probe and are arranged at intervals in a mode of surrounding the supporting body. The mechanism is advantaged in that for mounting errors of a cylinder and the to-be-tested container, assembling slits at contact portions of thesealing member and an end surface of the container port can be automatically adapted and eliminated, the automatic error correction function is realized, a problem that qualified containers are determined to be disqualified containers can be prevented, not only accuracy and reliability of the test result be improved, but also the rejection rate of containers is reduced, and avoidable loss of enterprises can be avoided.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

Linear adjustment device for aligning transverse ribs of high-torque screw-thread steel

InactiveCN102179409AOvercoming dotsOvercoming the lack of linear contactMetal rolling stand detailsScrew-threads articlesUniversal jointHigh torque

The invention relates to a linear adjustment device for aligning transverse ribs of high-torque screw-thread steel, belonging to the technical field of steel rolling machinery. In the invention, a left adjustment disc and a right adjustment disc are adjusted to relatively rotate by adjusting a wedge to move up and down; the position of the wedge is fixed by an adjusting bolt when the left adjustment disc and the right adjustment disc are adjusted to needed angles so that the variation of an angle (phase) is generated between a left roll shaft sleeve and a left universal joint shaft which are respectively connected with the left adjustment disc and the right adjustment disc, and thus, the ultimate purpose of adjusting the relative angle (phase) between two rolls is ultimately achieved.

Owner:SHANDONG IRON & STEEL CO LTD

Bumper installation structure assembly of motorbike back suspension

InactiveCN101913403APrevent axial movementEliminate assembly gapsAxle suspensionsVehicle frameOperations security

The invention discloses a bumper installation structure assembly of a motorbike back suspension, comprising a bumper upper connector, a hinging pin shaft and a U-shaped structure connecting frame fixedly connected with a motorbike frame. The dumper upper connector is embedded between two support lugs of the U-shaped structure connecting frame and is articulated with the U-shaped structure connecting frame via the hinging pin shaft, the hinging pin shaft passes through a hinging hole of the dumper upper connector via a shock-absorbing bushing of a coating, the hinging pin shaft is provided with a shaft shoulder abutted against one axial end face of the shock-absorbing bushing, and the hinging pin shaft extends out the other axial end face of the shock-absorbing bushing and the support lugs of corresponding sides of the U-shaped structure connecting frame and is axially fastened. After the bumper installation structure assembly is installed, the shock-absorbing bushing is compressed by the shaft shoulder end face, thus the assembly gap of the shock-absorbing bushing along the hinging pin shaft is efficiently eliminated, the assembly gap is made to become an adjustable factor and the axial movement of the bumper along the hinging pin shaft when in use is avoided so as to eliminate the abnormal sound in running process of the motorbike and the leftward and rightward deflection of a back wheel and to ensure the security of the whole motorbike operation.

Owner:CHONGQING LONCIN MOTOR

Launch canister rear cover structure and mounting and using method

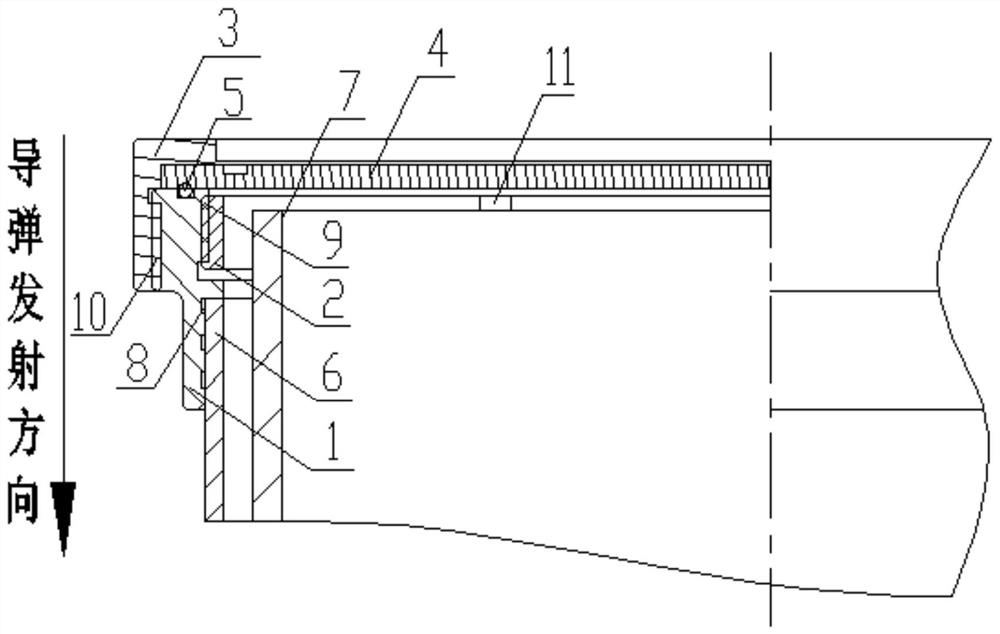

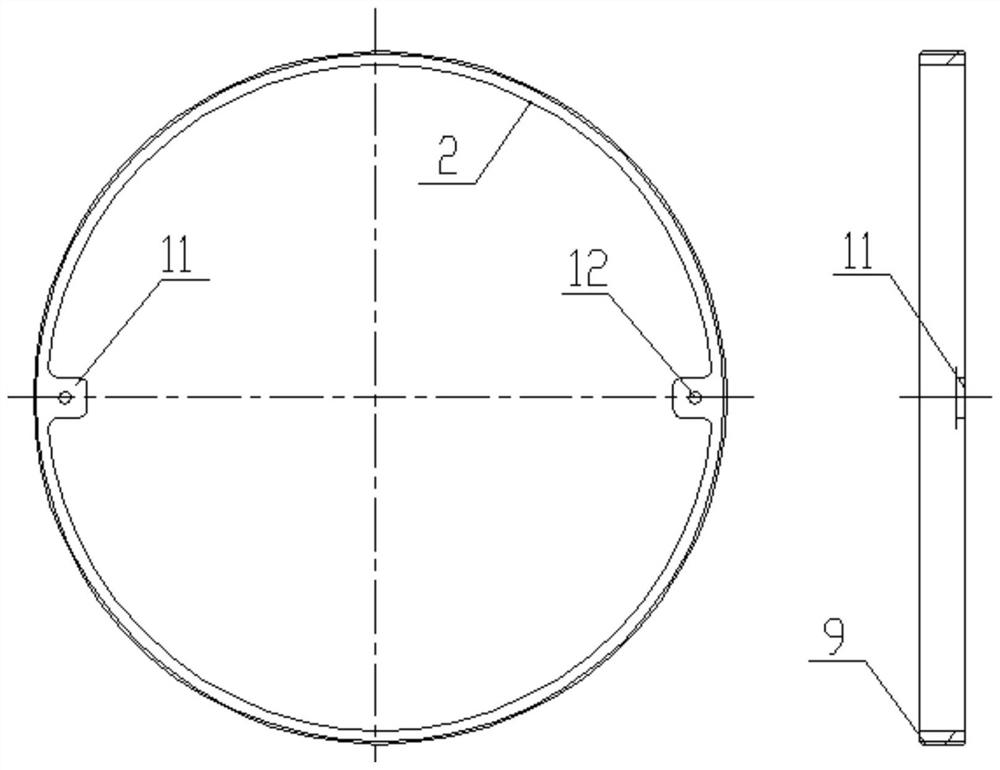

PendingCN112161520AEliminate assembly gapsRealize the limit functionLaunching weaponsEngineeringScrew thread

The invention relates to a launch canister rear cover structure. The launch canister rear cover structure comprises a rear end ring, an inner pressing ring, an outer pressing ring, a fragile cover plate, an O-shaped sealing ring and the like. The rear end ring is of an internal and external double-thread structure, the internal thread is matched with the inner pressing ring, the external thread ismatched with the outer pressing ring, and the rear end ring is provided with the sealing ring. An axially adjustable limiting boss is arranged on the inner pressing ring, and the anti-loosening effect is achieved in cooperation with thread locking glue. The outer pressing ring is arranged on the outer ring of the rear end ring, and the outer pressing ring, the fragile cover plate and the O-shapedsealing ring form a sealing link. A weak link is engraved in the fragile cover plate and is broken through under the action of engine gas flow. The launch canister rear cover structure has the beneficial effects that a limiting mechanism is in threaded connection, has an axial adjustable function, can eliminate an assembly gap between a missile and a launch canister caused by machining errors andrealizes a reliable limiting function on the tail part of the missile; the engine gas flow is used as a fragile cover crushing power source, extra power is not needed, and the advantages of simple structure, low cost, high reliability and the like are achieved; the problem that the missile launching recoil force is too large, and portable launching by an individual soldier group is not facilitated is solved, and the stability of the missile launching posture is improved.

Owner:湖北航天飞行器研究所

Cutting section structure of deep hole boring mechanical arm

The invention discloses a cutting section structure of a deep hole boring mechanical arm. The cutting section is characterized by comprising a cutting section cylinder; a cutter mounting groove is formed in the front position of the cutting section cylinder for mounting a cutter; the cutter includes a tool bit part for forming a cutting edge, and a mounting handle part for realizing installation and radial cutter feeding transmission; the cutting edge position of the tool bit part is exposed out of the cutter mounting groove; and the tool bit part and the mounting handle part are separately designed, and are fixedly connected as a whole by a bolt. The cutting section has such advantages as simple structure, low cost, facilitation of transmission control and capability of further eliminating the assembly gap to improve the transmission control stability.

Owner:CHONGQING TECH & BUSINESS INST

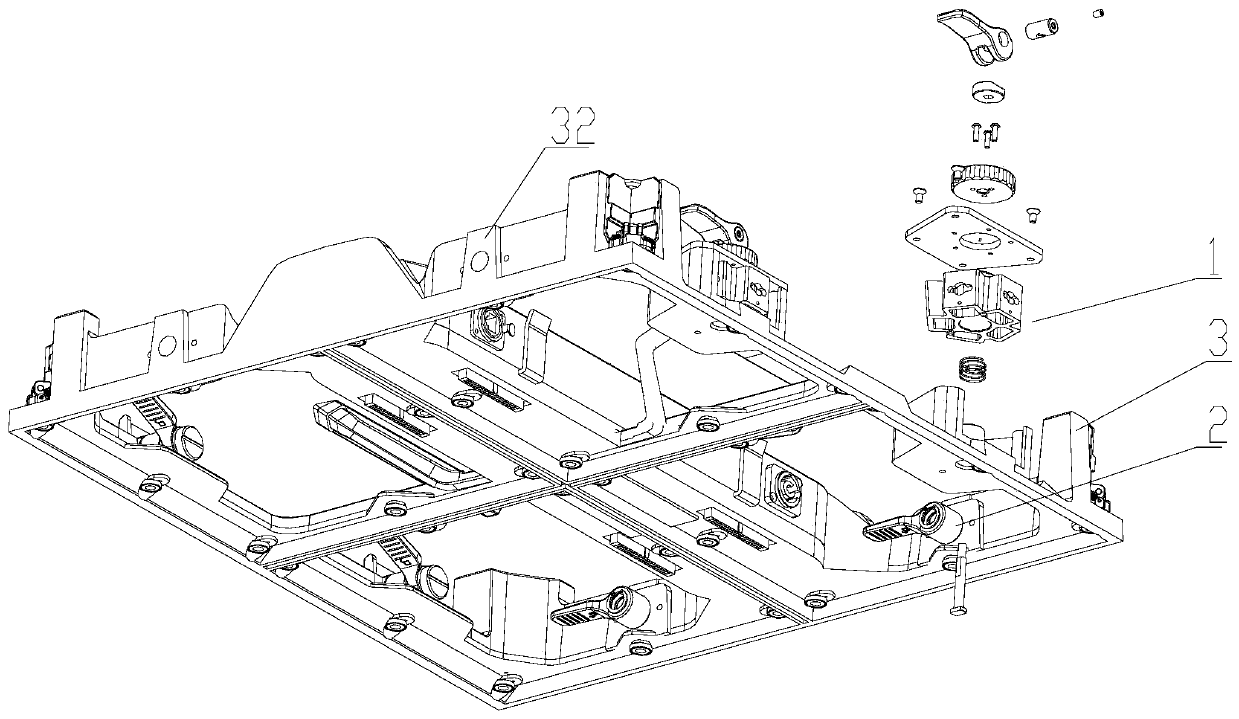

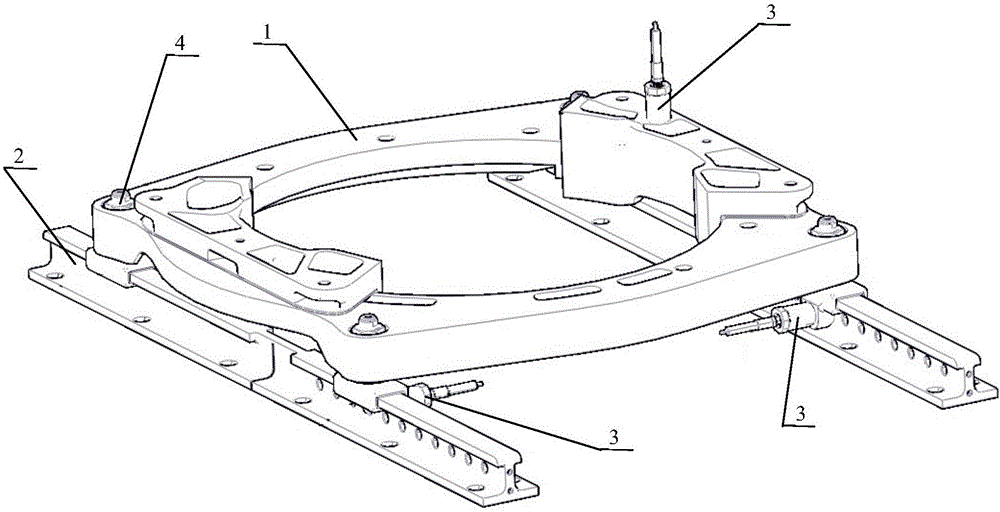

Universally and flexibly installed multi-position adjusting mechanism

PendingCN107176177AProtect the productEliminate assembly gapsVehicle seatsSeating arrangementsAdverse effectEngineering

The invention belongs to the technical field of machines and relates to a universally and flexibly installed multi-position adjusting mechanism. The universally and flexibly installed multi-position adjusting mechanism comprises a rotary seat and a guide rail. The rotary seat is square, and the four corners of the rotary seat are each provided with a through hole which is internally provided with a flexible sliding device; and the rotary seat can be slidably fixed to the guiding rail through the flexible sliding devices, and a seat is installed on the rotary seat. The universally and flexibly installed multi-position adjusting mechanism has the beneficial effects that the rotary seat can deflect towards any directions through a flexible connecting device, the adverse effect brought by installation face deformation after guide rail installation on a product is avoided, and font-and-back moving smoothness can be kept all the time, so that the purpose that the product can be universally and flexibly installed and protected is achieved; two rotary blocks are tightly attached to the rotary seat for friction to eliminate an assembly gap and avoid product waggling during rotating, and therefore stability and smoothness of product rotating in the front-back direction and the horizontal direction of the guide rail are achieved; and front-back and rotary multi-position reliable fixing is achieved.

Owner:北京安达维尔航空设备有限公司

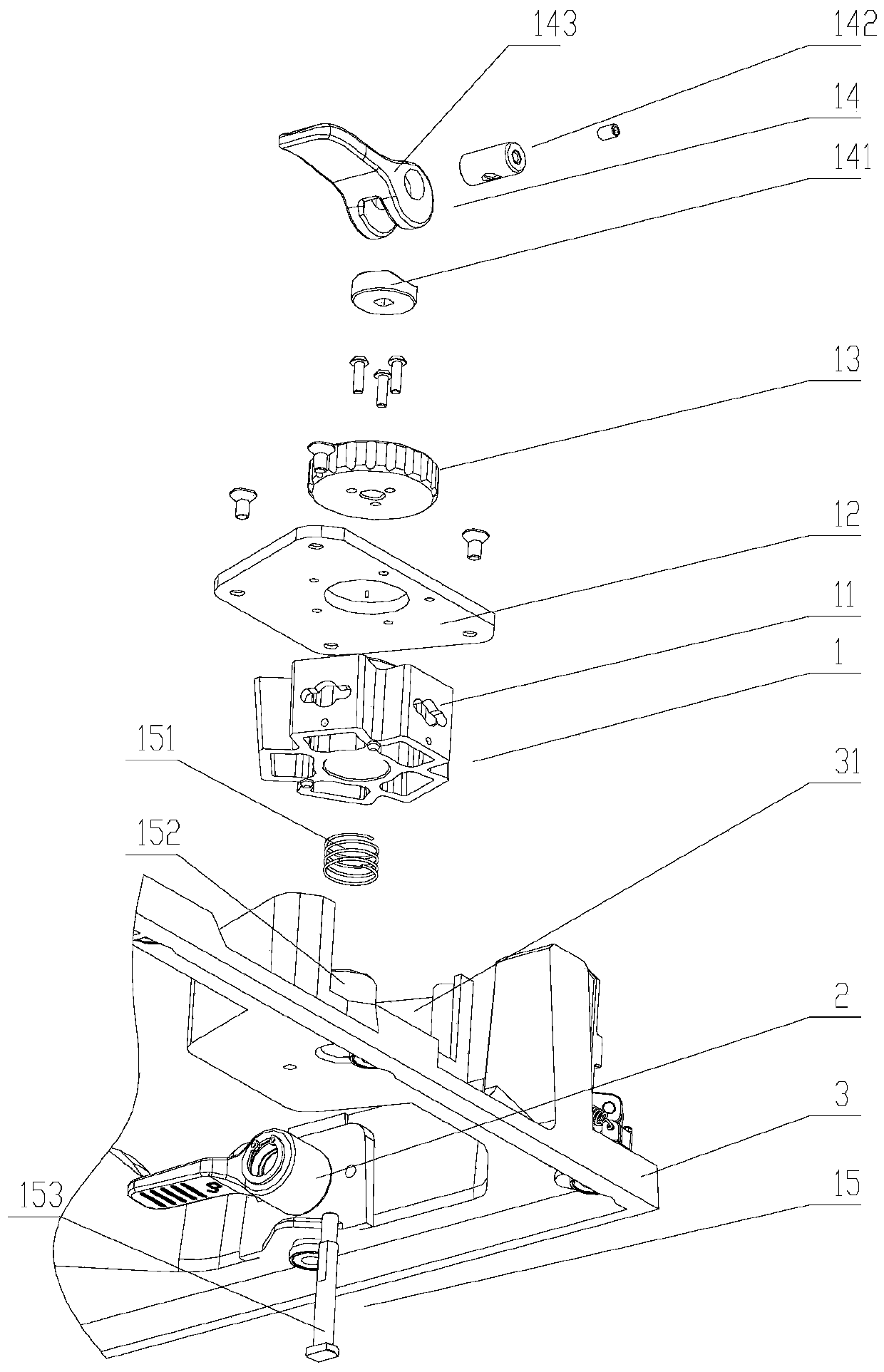

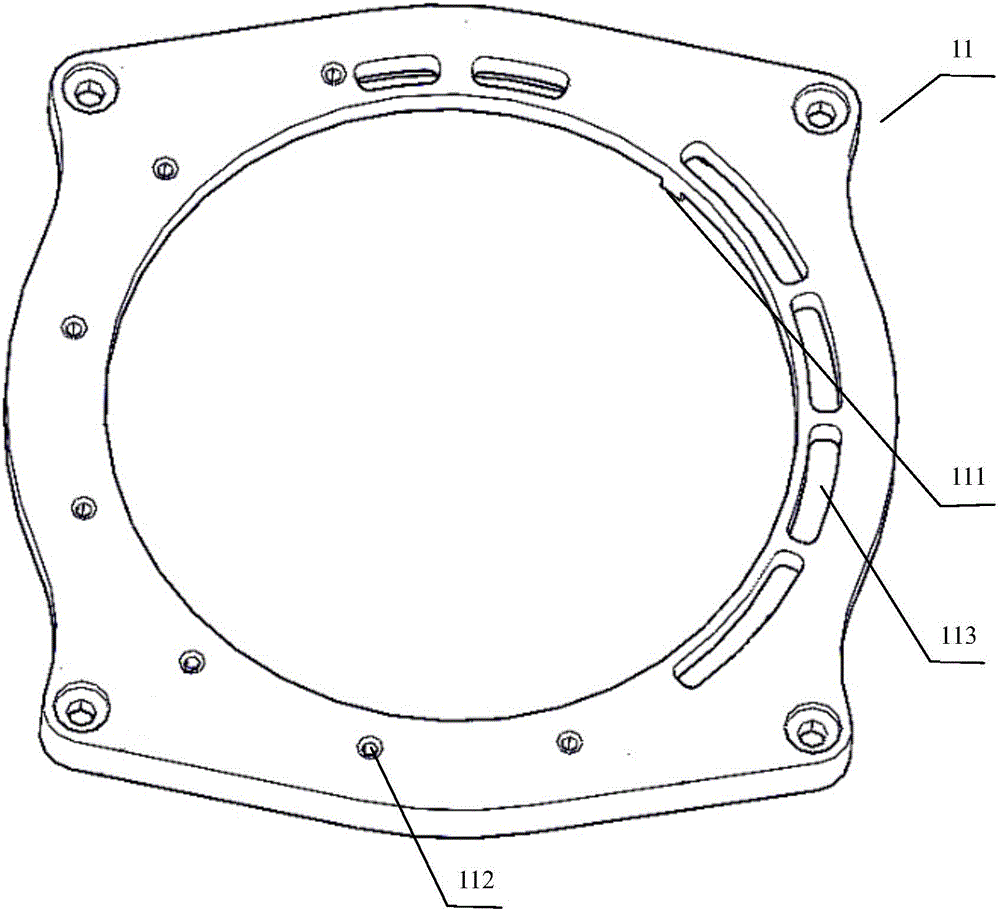

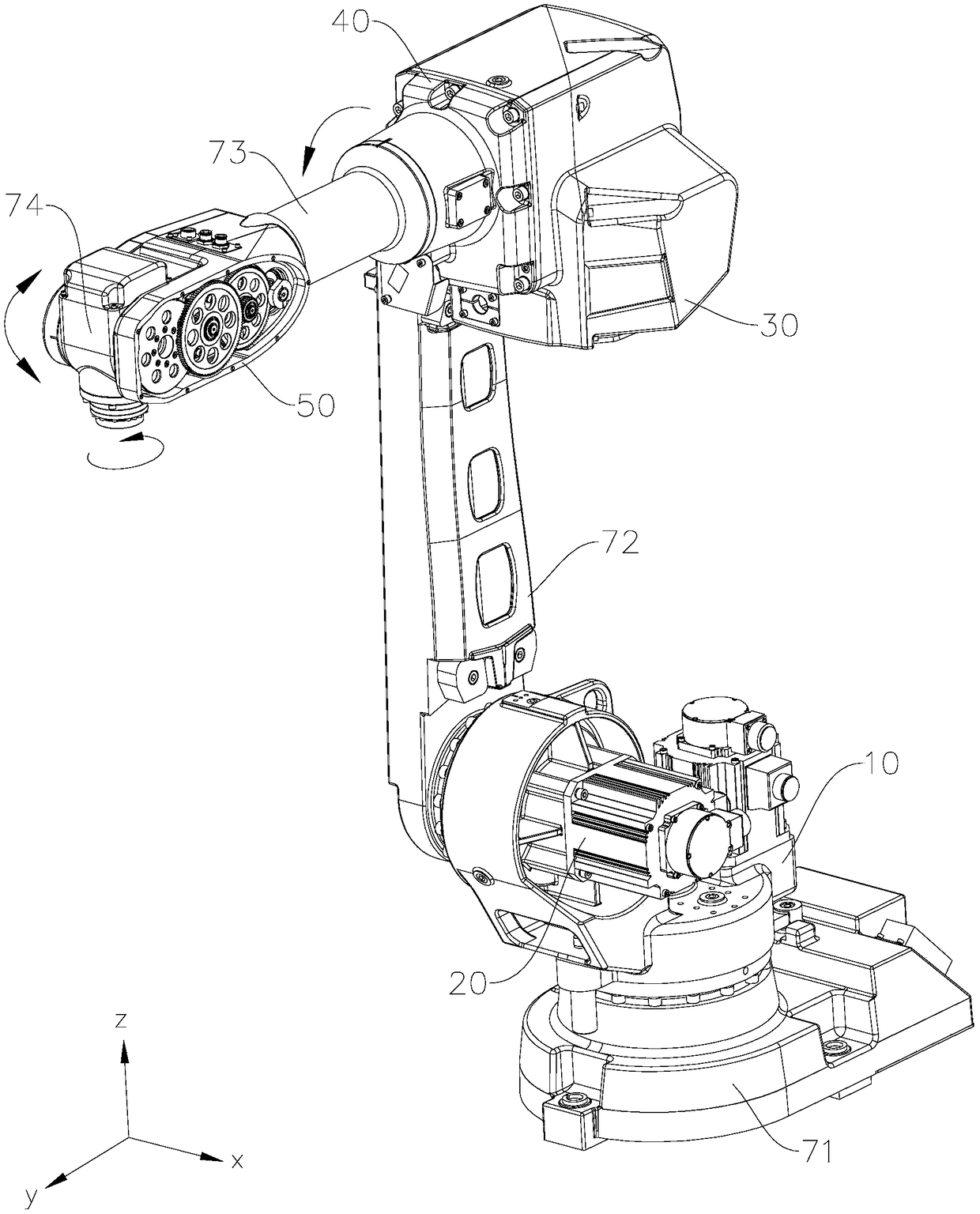

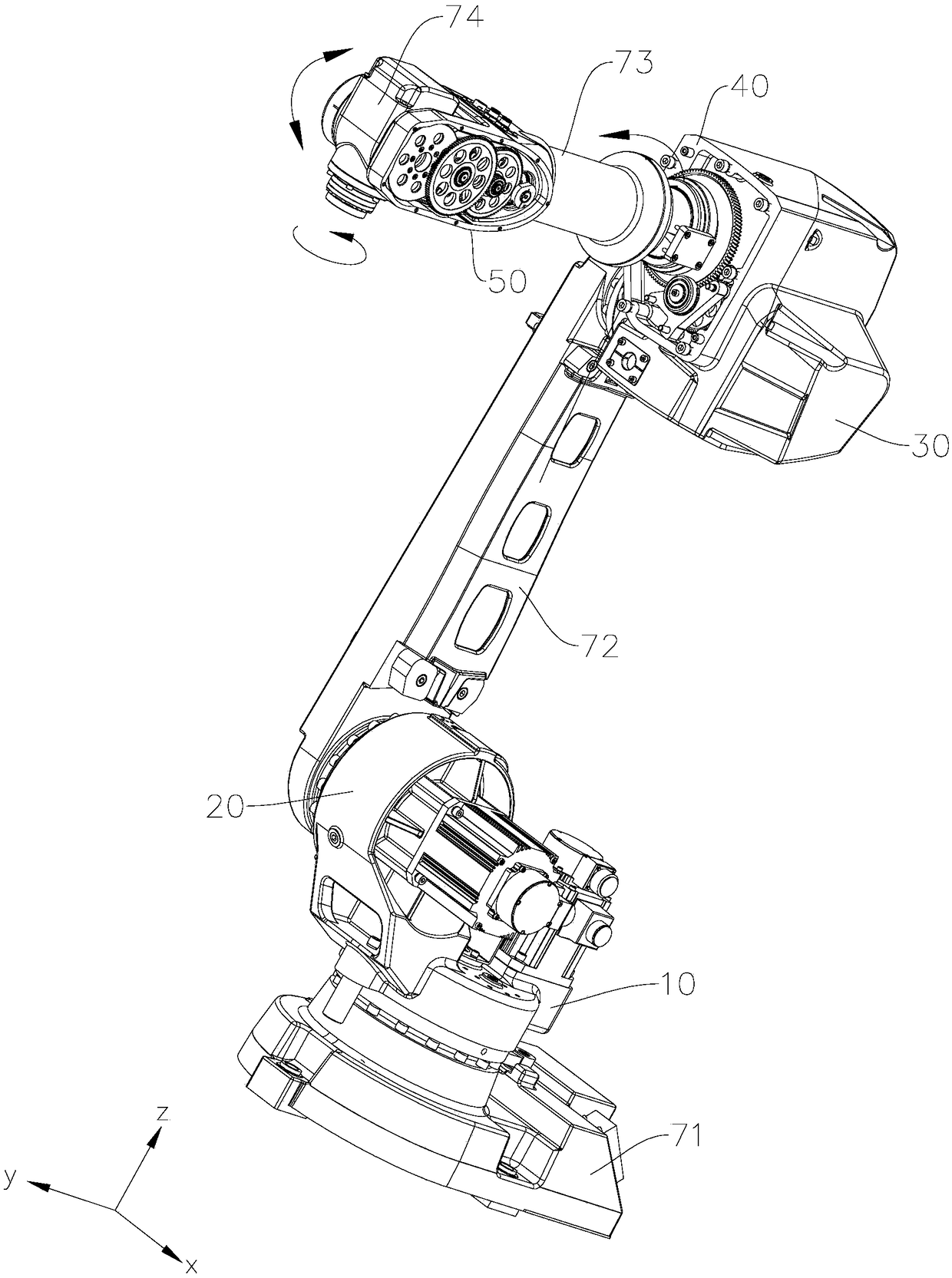

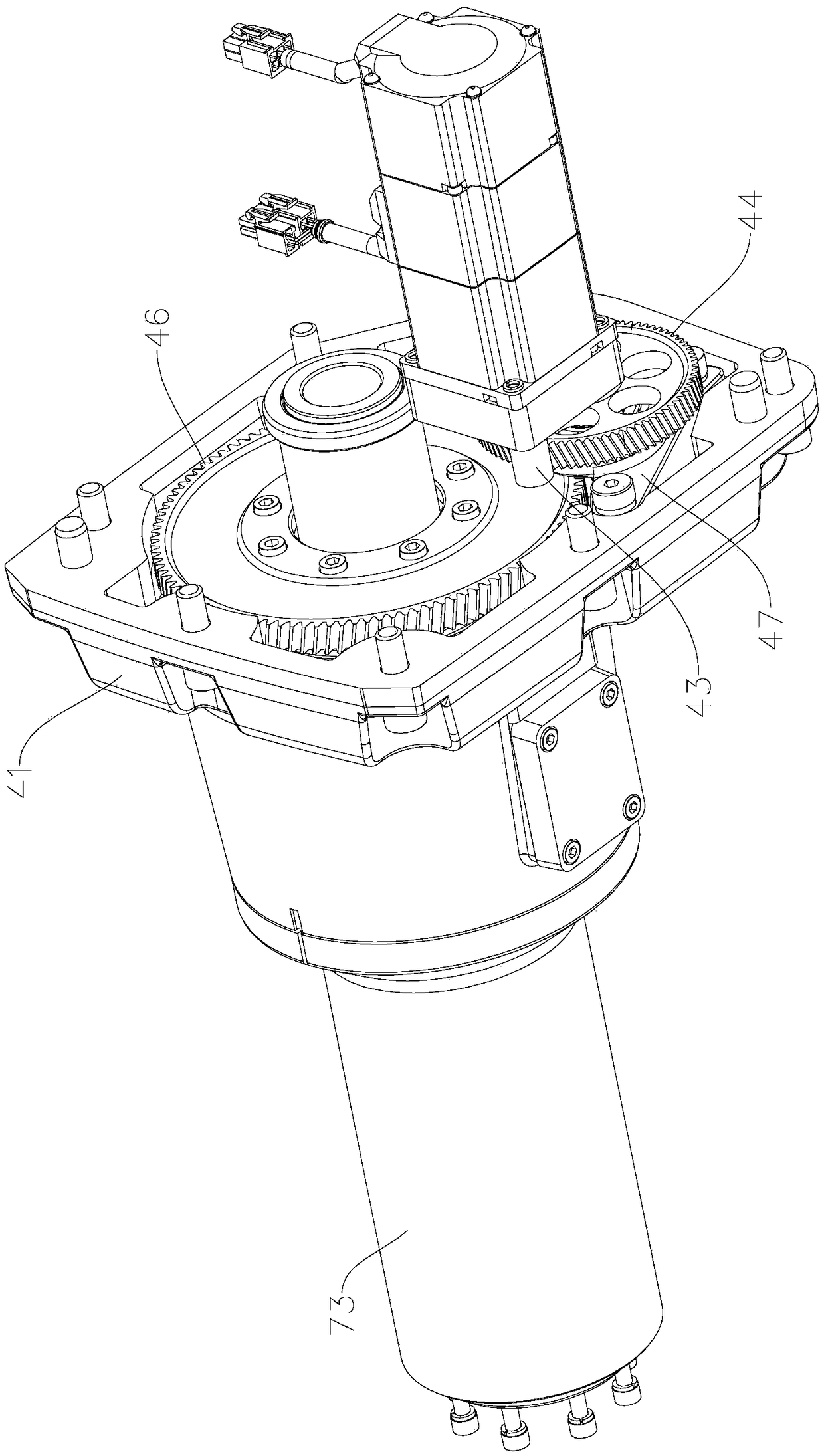

Manipulator with precision transmission device

ActiveCN108638047AIncrease stiffnessImprove transmission stabilityProgramme-controlled manipulatorEngineeringActuator

The invention discloses a manipulator with a precision transmission device, and relates to the technical field of robots. The manipulator with the precision transmission device comprises a wrist, anda wrist moving part for driving the wrist, wherein the wrist is an end effector; the wrist moving part comprises a four-axis driving part for driving the wrist to rotate, and a five-axis moving part for driving the wrist to swing up and down. According to the manipulator with the precision transmission device, the wrist is driven to swing up and down through the five-axis driving part, namely, theaxis position can be radially adjusted through a five-axis speed reduction wheel set, and assembling clearances of a first-stage gearwheel and an input gear are removed, and meanwhile, the assemblingclearances of a second-stage pinion and a second-stage gearwheel is removed. With the adoption of the manipulator with the precision transmission device, the engaging states of the two-stage gear transmission can be synchronously adjusted, so that the adjusted five-axis driving part is high in transmission rigidity and transmission stability; in addition, the four-axis driving part can be optimized, so that the stability of the wrist in rotating can be improved; and the wrist can be accurately positioned.

Owner:GUANGZHOU START TO SAIL IND ROBOT CO

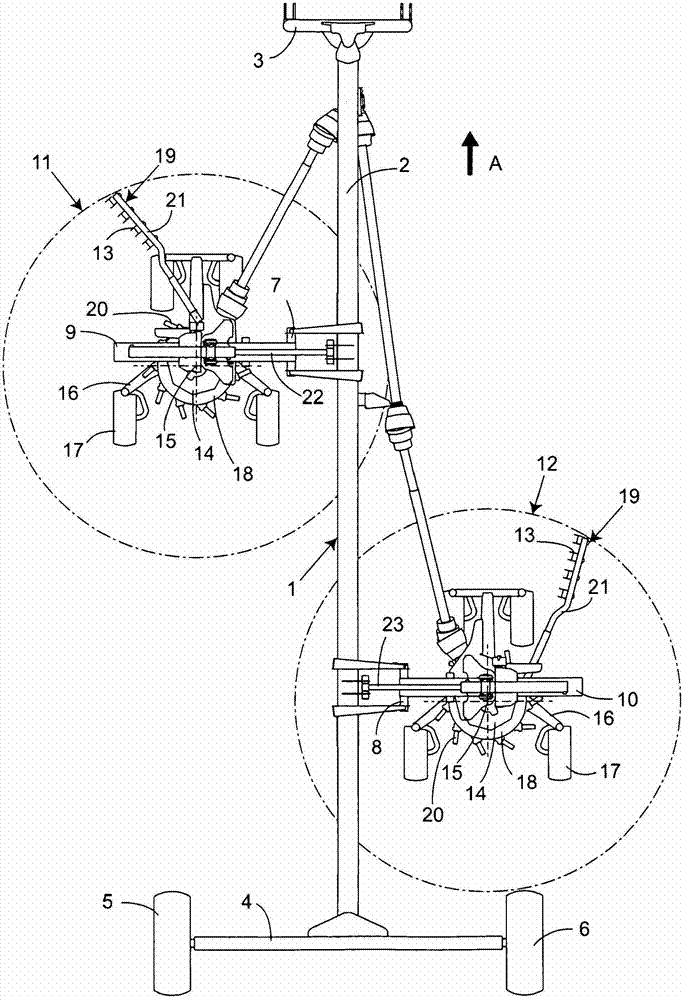

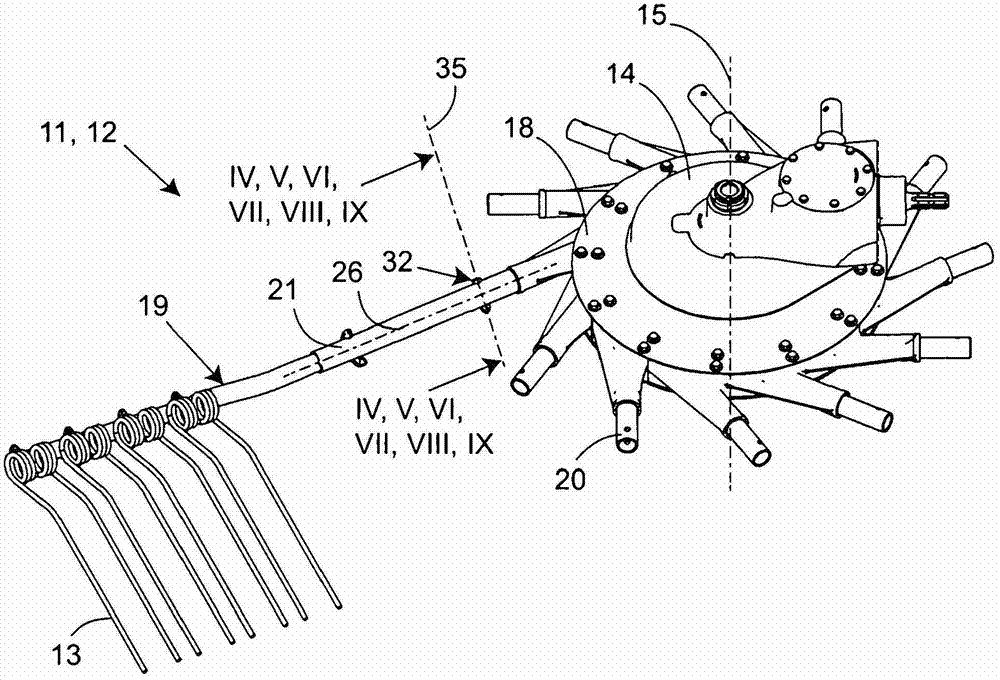

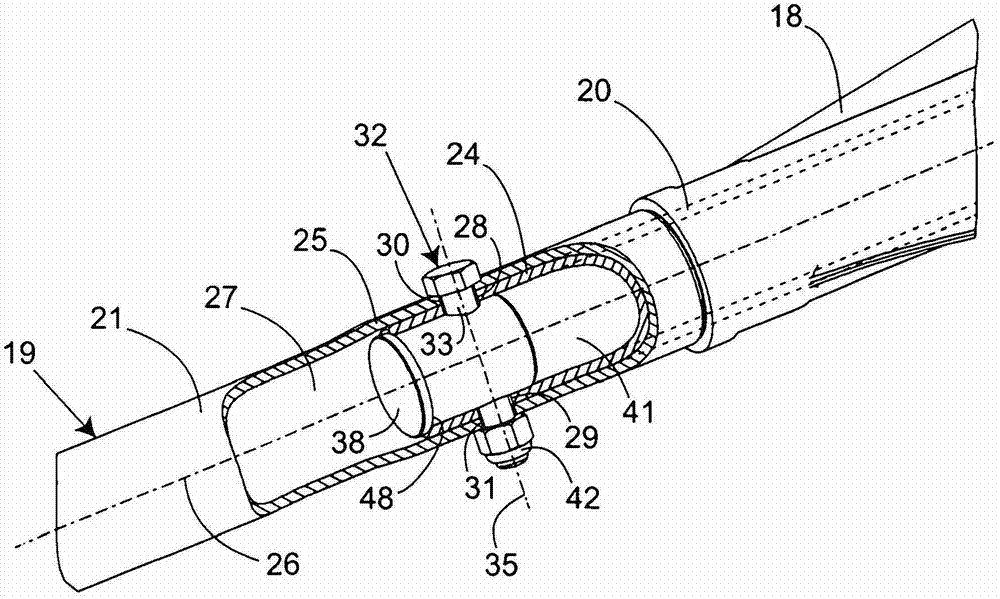

Rotor of haymaking machine provided with arms in two parts connected by an improved connecting device

The present invention relates to a rotor of haymaking machine provided with arms in two parts connected by an improved connecting device. The rotor 11,12 comprises a rotary housing 18 and at least one oscillating arm 19, said oscillating arm comprising at least an internal part 20 connected to the housing 18 and an external part 21 carrying tools 13, one of the parts comprising an engaging portion 24 able to engage partially in an engaged portion 25 of the other part, the said portions each comprising at least one hole 28,29,30,31 and being able to be assembled by means of a connecting device 32 comprising at least one threaded element 33,34 with a shoulder 36,37 , said threaded element 33,34 passing through each hole of the said portions. According to the invention, the connecting device comprises an insert 38 with at least one tapping 39,40 able to be inserted inside the engaging portion 24, the threaded element is screwed in the tapping and the shoulder rests on the engaged portion to tighten the engaged portion against the engaging portion.

Owner:KUHN SA

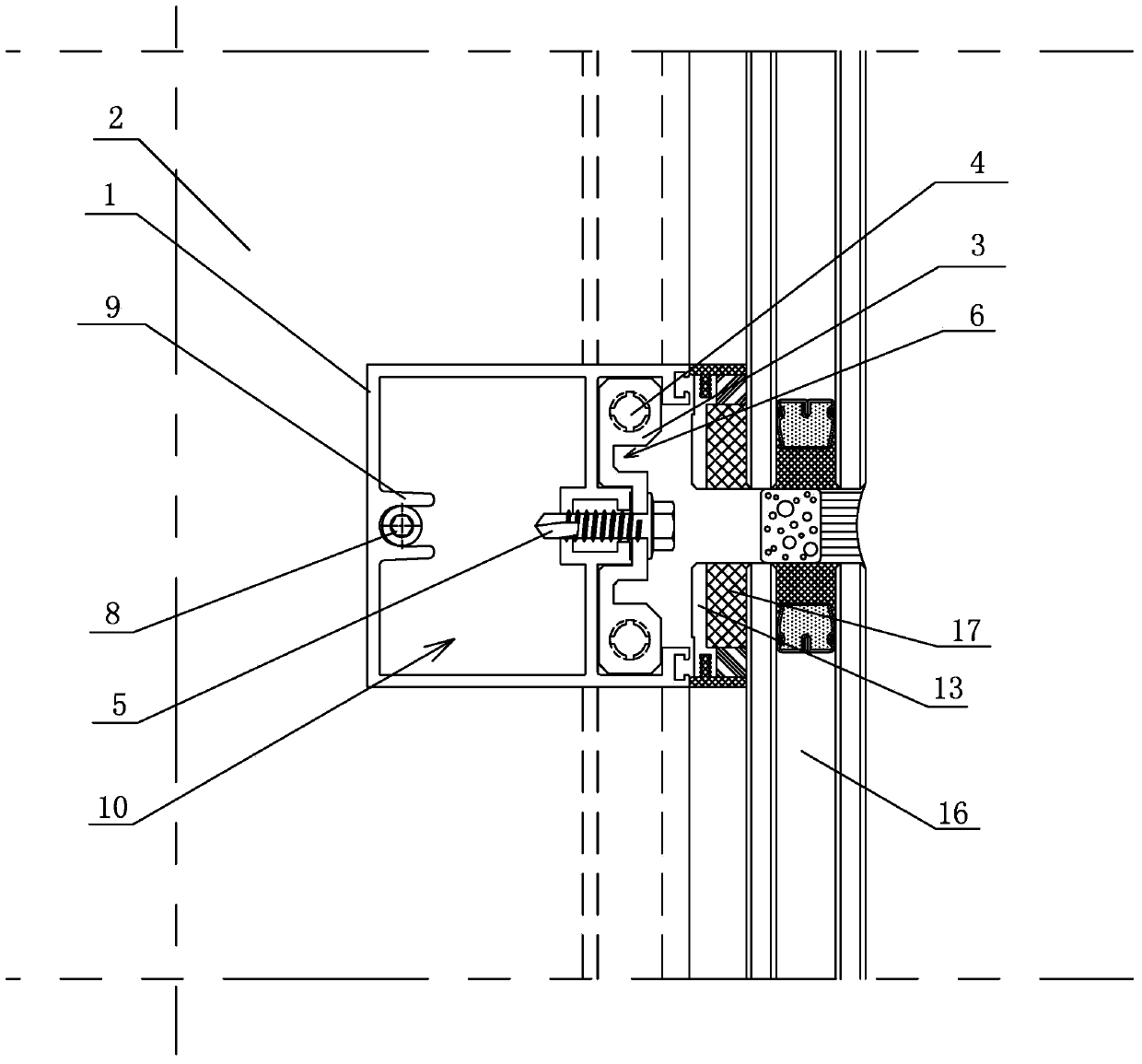

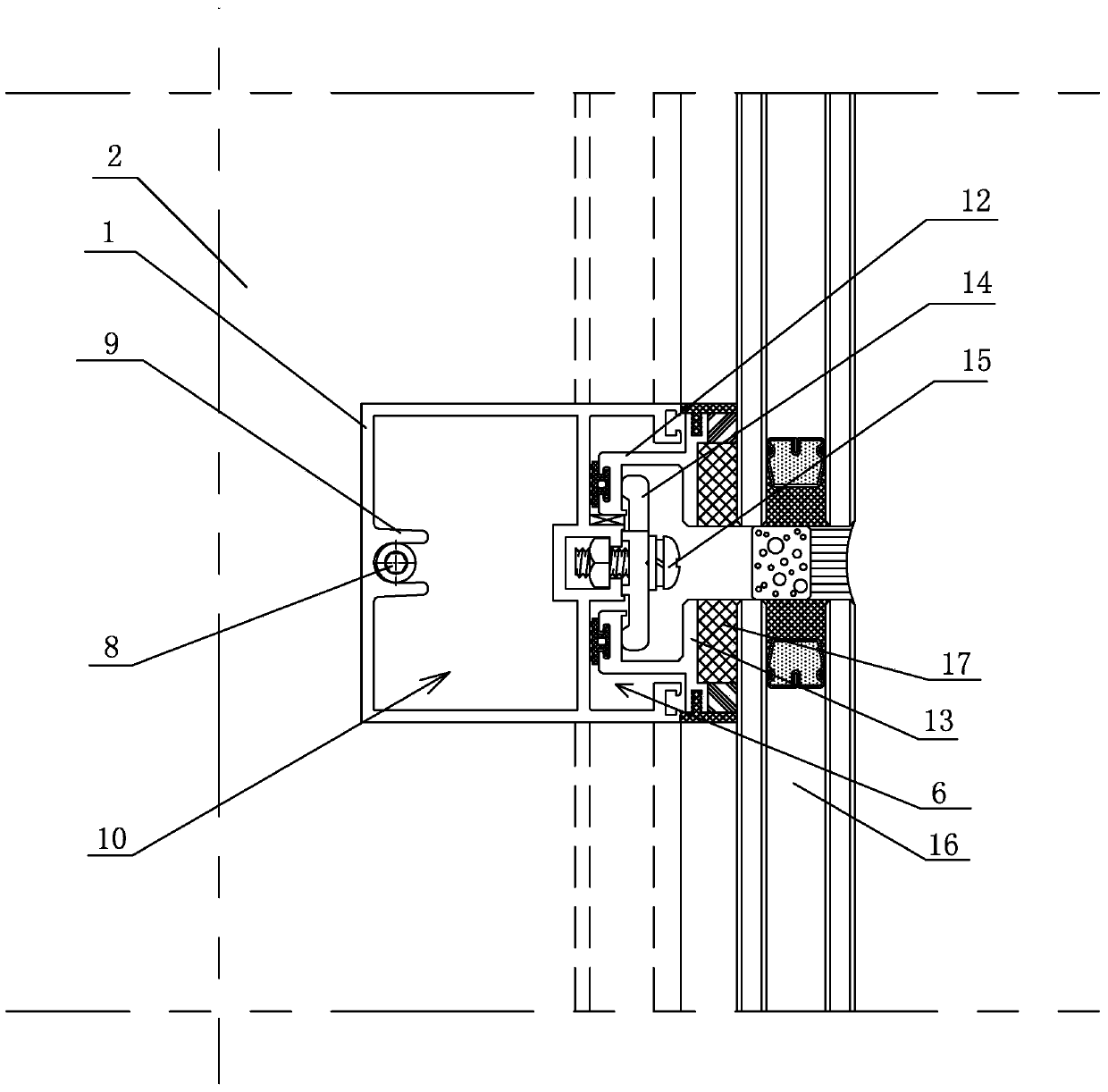

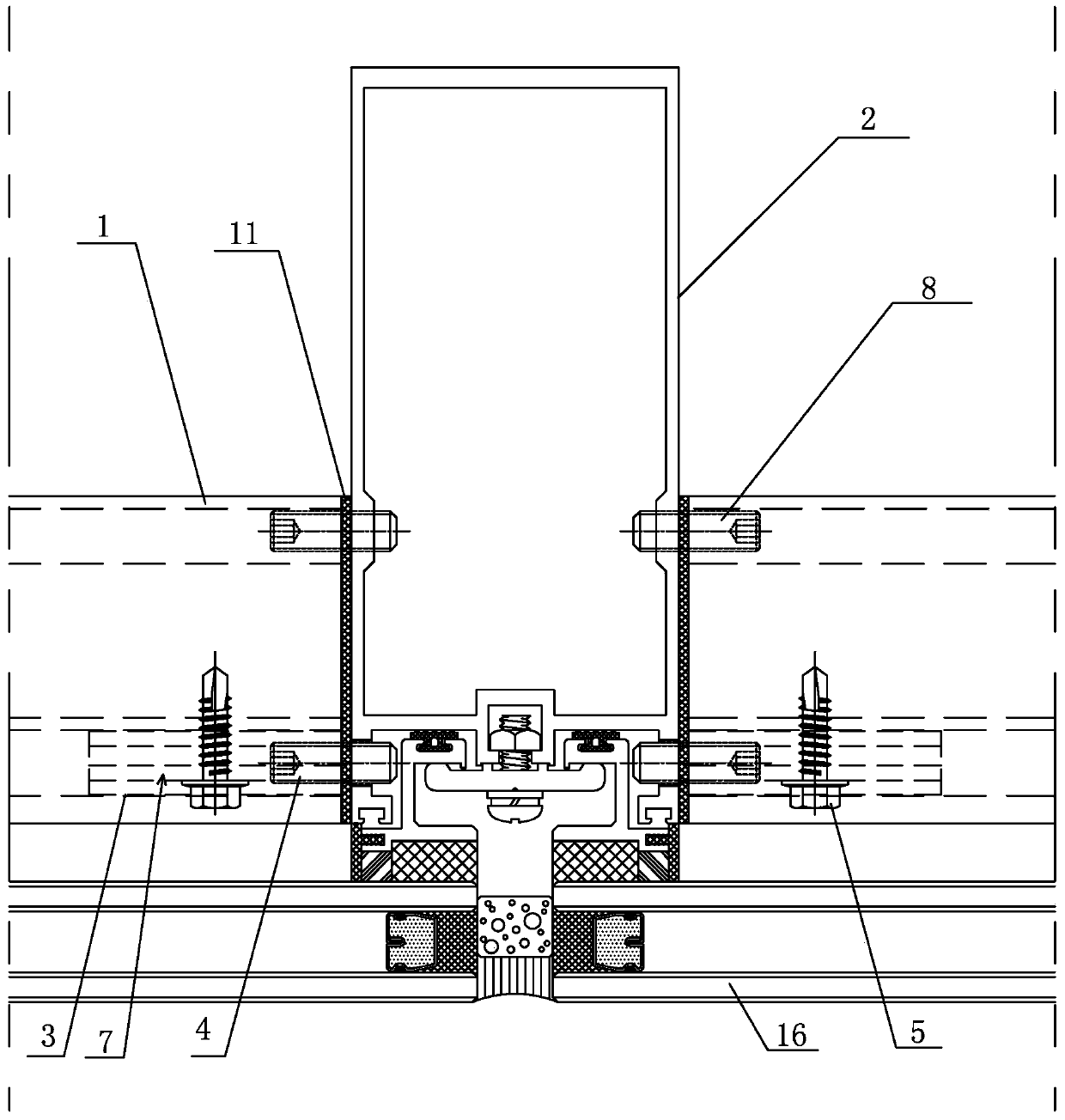

Construction method of beam and column connection structure in glass curtain wall

ActiveCN104695599BReduce additional bending momentQuick installationWallsCross connectionEngineering

Owner:苏州苏明装饰股份有限公司

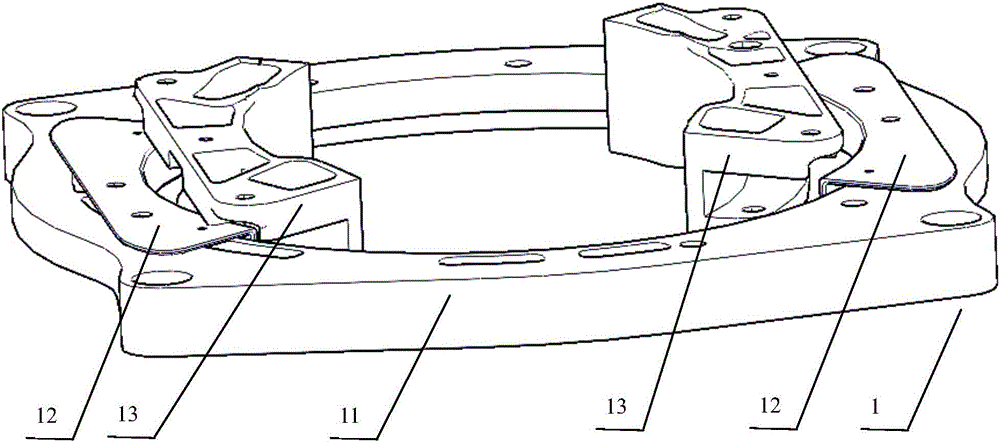

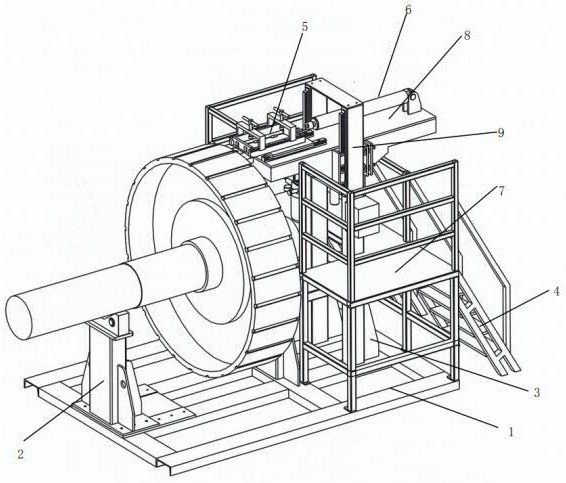

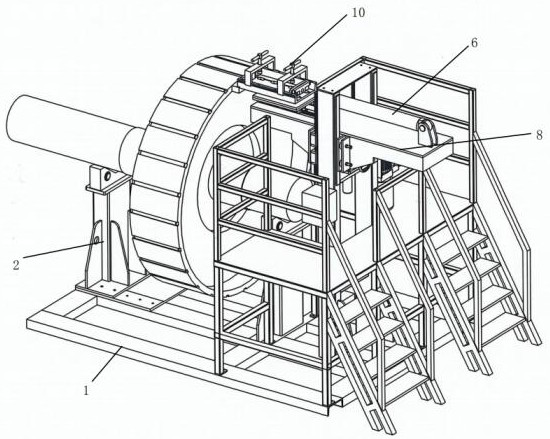

Integral assembly method for rotor magnetic poles of wind driven generator

ActiveCN113824275AEliminate assembly gapsEliminates the risk of misalignmentManufacturing stator/rotor bodiesWind energy generationElectric generatorClassical mechanics

The invention discloses an integral assembly method for rotor magnetic poles of a wind driven generator. The assembly method comprises the following steps: 1, hoisting a rotor support to a rotor supporting table; 2, adjusting the height of a mounting platform; 3, placing a magnetic pole box on a track, controlling a propelling air cylinder to operate and push the magnetic pole box forwards along the track until the magnetic pole boxes abut against a baffle, then placing a next magnetic pole box on the track, controlling the propelling air cylinder to push the magnetic pole box forward along the track until the magnetic pole box abut against the previous magnetic pole box, and pushing other magnetic pole boxes of the magnetic pole one by one according to the method; 4, fastening all the magnetic pole boxes on the magnetic pole assembly tool are together through bolts to form a magnetic pole; and 5, detaching the baffle, and controlling a propelling air cylinder to push the magnetic pole into the rotor support along the track. According to the invention, the product reliability is improved, the labor intensity is reduced, the potential safety hazard is eliminated, and the product quality and the production efficiency are improved.

Owner:JIANGSU CRRC ELECTRIC CO LTD

Spherical double suspension wide hook rapid pipe joint

The sphere double hangs the width ditch pipeline connection part, locks between the handle or the long hook and the gallows spacing after the introduction vice- (15), the suspension hook in own plane of symmetry two sides establishments hook (5), the seal packing collar radial direction lateral section for has the relative smaller aperture (4), assumes cavity body and spring-loaded seal tongue which incompletely seals up (3) isostructuralism, improved the fast attachment operation, increased the joint stability; To is sealed the pressure and the seal packing collar own elastic combination, establishes the seal to distort with is sealed the medium pressure the relation; Retains the shut-down condition by become estranged the coordination to release flows the channel; Sealed the tongue to enhance the establishment seal condition movement sensitivity and the reliable degree. Causes the seal with to divulge a pair of mutually contradictory function, harmoniously melts into the identical seal packing collar in the structure, thus easily realized had the pressure seal, not pressed from releases, to sealed the part the special seal request. Plan idea ingenious reasonable, structure precise simple compact, the manufacture and the use very is all convenient.

Owner:山西征宇喷灌有限公司

Adjustable precision steel forging vise

ActiveCN102873651BReduce manufacturing costReduce welding costsVicesUltimate tensile strengthForging

The invention discloses an adjustable precision steel forging vise which comprises a fixed vise body, a movable vise body, a screw, a nut, a pressing plate and a hexagon socket countersunk screw. The fixed vise body and the movable vise body are both in a component welding structure and are both made by forging steel. The movable vise body is provided with a guide rod which is provided with an elongated groove provided with the screw. The nut matched with the screw is mounted on the fixed vise body, and the pressing plate is tightened by the hexagon socket countersunk screw to be mounted at the end of the nut. A pair of outer guide rails and a pair of inner guide rails are arranged on the left sides and the right sides of the guide rod and the fixed vise body respectively, and the two pairs of guide rails are in a left-right asymmetric guide structure. The adjustable precision steel forging vise has the advantages that gaps among the guide rails are adjustable, the vise bodies are large in laryngeal size, clamping range of jaws is large, guide precision is high, and the vise bodies are high in strength and light in weight; the quick-wear part nut is more convenient to replace and maintain; and even stress on two sides of a workpiece can be achieved when the vise clamps the workpiece, and accordingly self-strength of the guide rod is given to full play, clamping force of the vise is increased, and the like.

Owner:LAIZHOU HONGYUAN BENCH VICE MFR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com