Three-clutch electromechanical coupling driving device for motor vehicle

An electromechanical coupling and driving device technology, which is applied to the layout of multiple prime movers of power devices, pneumatic power devices, and general power devices, and can solve the problem of large axial size of the transmission, poor assembly process, and difficulty in vehicle layout etc. to achieve the effects of reducing the moment of inertia, improving precision and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] specific implementation plan

[0031] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

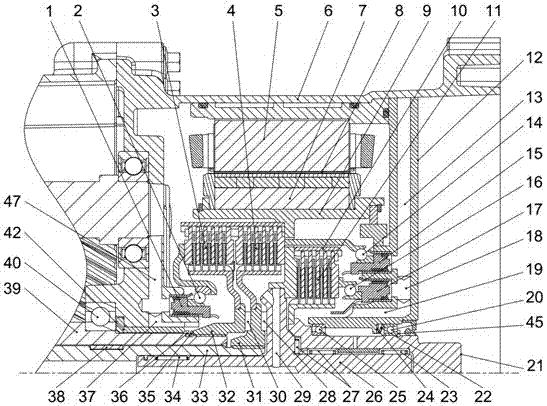

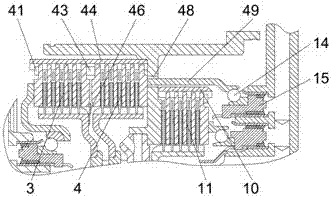

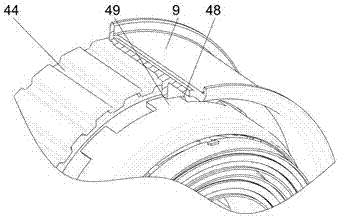

[0032] Such as figure 1 As shown, the control oil passage 18 of the separation clutch 11 is arranged on the front end cover 12, and the high-pressure oil acts on the piston 17 through the control oil passage 18, and the piston 17 transmits the pressure to the separation clutch 11 through the thrust bearing 16 to complete the separation clutch 11. join. The control oil circuit 13 of the even-numbered clutch 4 is arranged on the front end cover 12, and the high-pressure oil acts on the piston 15 through the control oil circuit 13, and the piston 15 transmits the pressure to the even-numbered clutch 4 through the thrust bearing 14 to complete the even-numbered clutch 4. join. The control oil circuit 47 of the odd-numbered clutch 3 is arranged on the housing 6, and the hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com