Patents

Literature

57results about How to "Reduce additional bending moment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

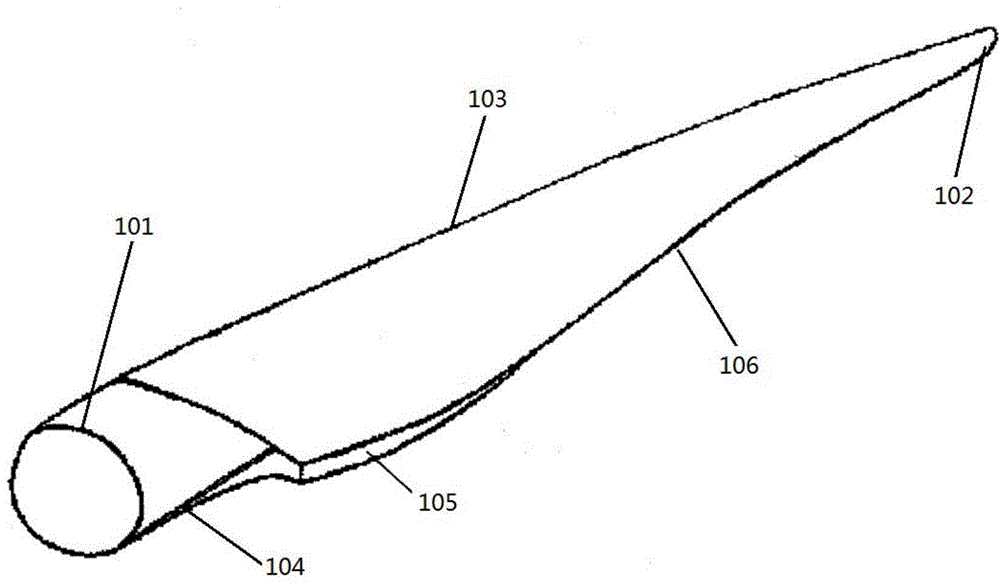

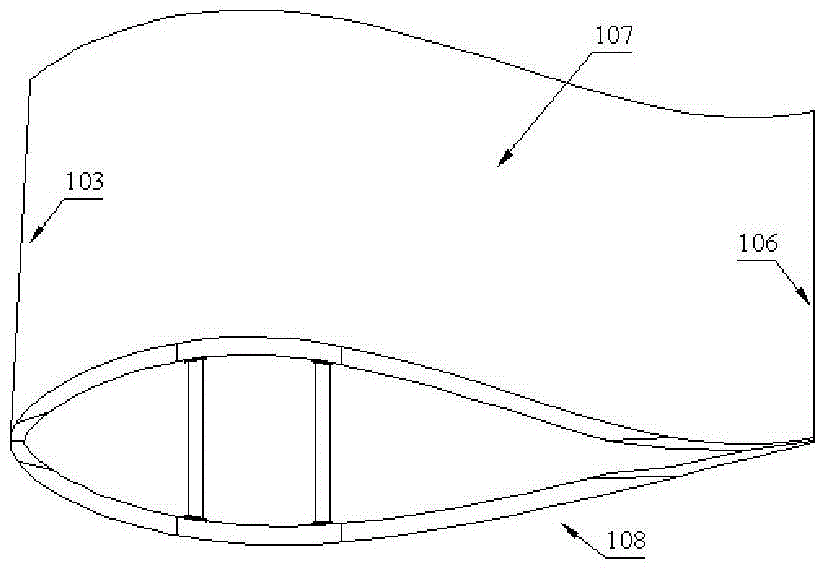

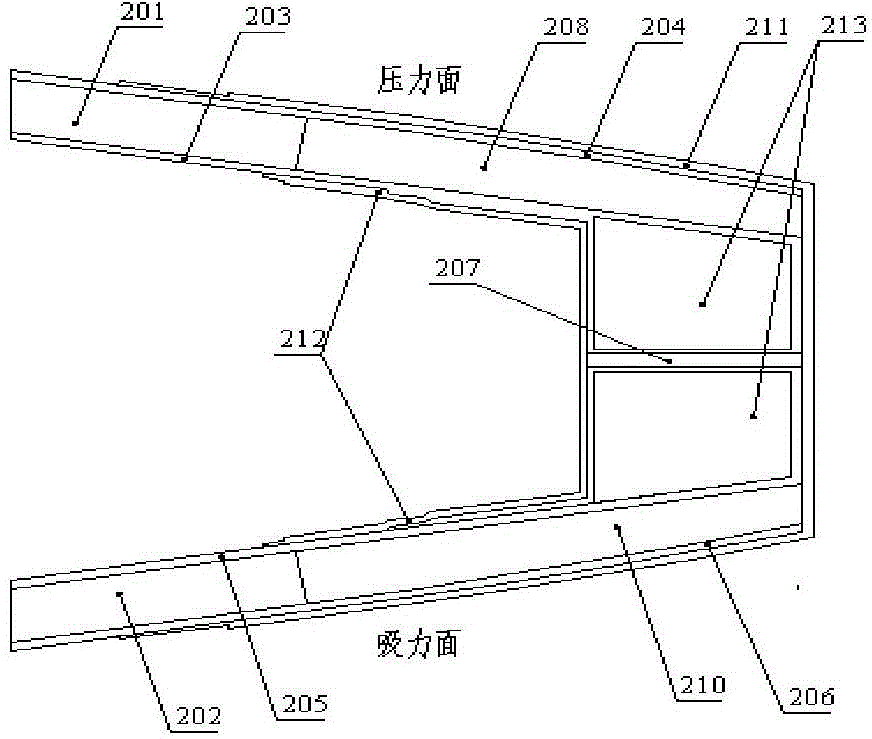

Blunt trailing edge type wind turbine blade as well as implementing device and method thereof

ActiveCN104696167ACompact structureIncrease profitMachines/enginesWind energy generationFiberTurbine blade

The invention discloses a blunt trailing edge type wind turbine blade and a processing method thereof. The blade is made of a fiber laminating composite; trailing edge reinforced fiber single layers at the blunt trailing edge part are alternately laid along a pressure surface trailing edge line and a blunt trailing edge vertical part; reinforced fiber single layers at the sharp tailing edge part close to a blade tip are retracted towards the inner side of a die in a tangential direction and then laid to guarantee appropriate die closing clearance; as many reinforced fiber single layers as possible at the round tailing edge part close to a blade root get close to the tailing edge line in the tangential direction to guarantee an enough bonding width for die closing; the laying positions of the reinforced fiber laying layers in the blunt trailing edge vertical part can be flexibly designed according to demand of structural performance, and additional laying layers and laying layer angles can be increased. The trailing edge structure of the blade has higher connection strength and engineering operability, and trailing edge cracking and trailing edge instability can be effectively inhibited.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

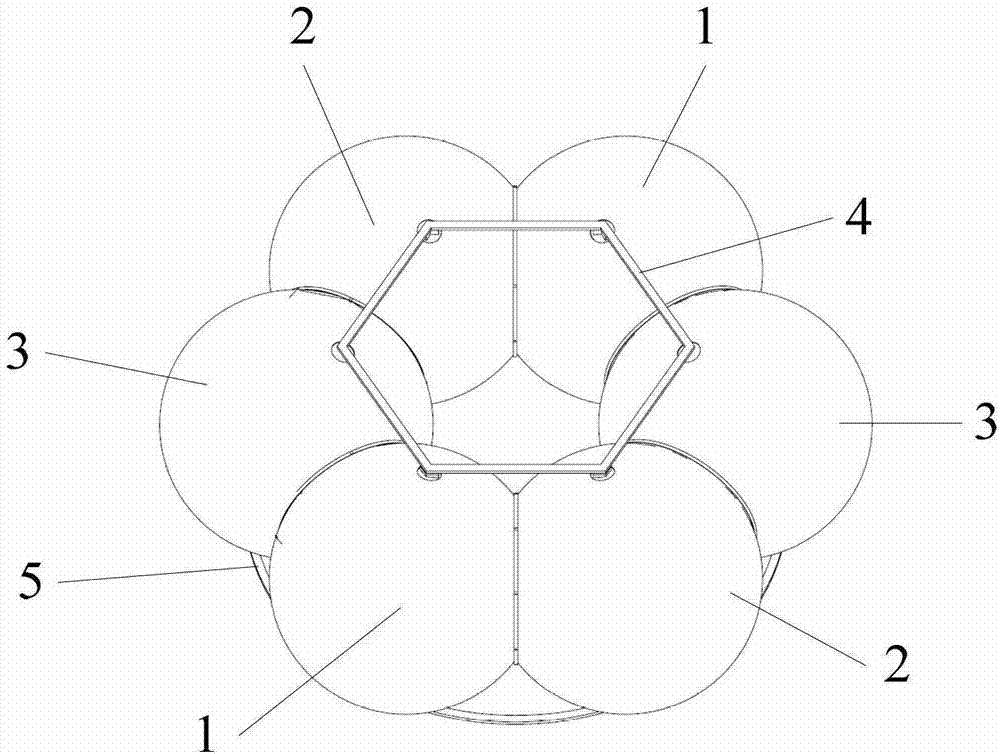

Force-bearing integrated structure with honeycomb-sandwich storage boxes

ActiveCN103482085ACompact form factorCompact layoutCosmonautic power supply systemsHoneycombEngineering

The invention discloses a force-bearing integrated structure with honeycomb-sandwich storage boxes. The force-bearing integrated structure comprises a plurality of storage boxes connected mutually, wherein the storage boxes are uniformly paved along the circumference; adjacent storage boxes are mutually embedded, flanges are connected by the storage boxes, and clamping blocks and wrapping belts are mutually connected; the load acting positions of the top part and the bottom part of each storage box are respectively provided with a claw-shaped force-transferring structure in an embedded manner; and the claw-shaped force-transferring structures are respectively connected with upper flanges and lower flanges. Different from the traditional satellite design that the actions of structure subsystems and propelling subsystems are completely separated and independent, main force-bearing structures of the structure subsystems and the storage boxes of the propelling subsystems are shared by the force-bearing integrated structure with the storage boxes, so that a spacecraft has compacter appearance and distribution, and further the mass of the structure subsystems and the mass of the propelling subsystems are reduced.

Owner:SHANGHAI SATELLITE ENG INST

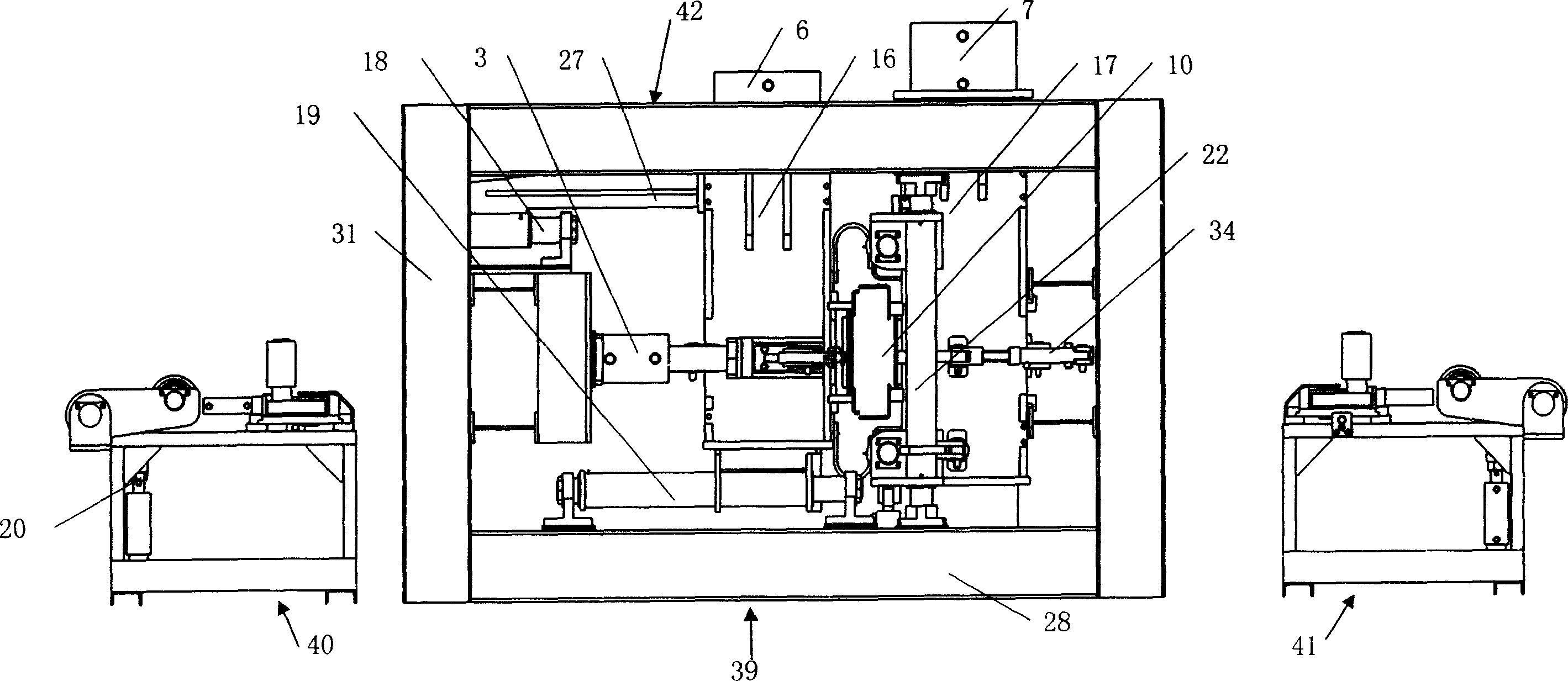

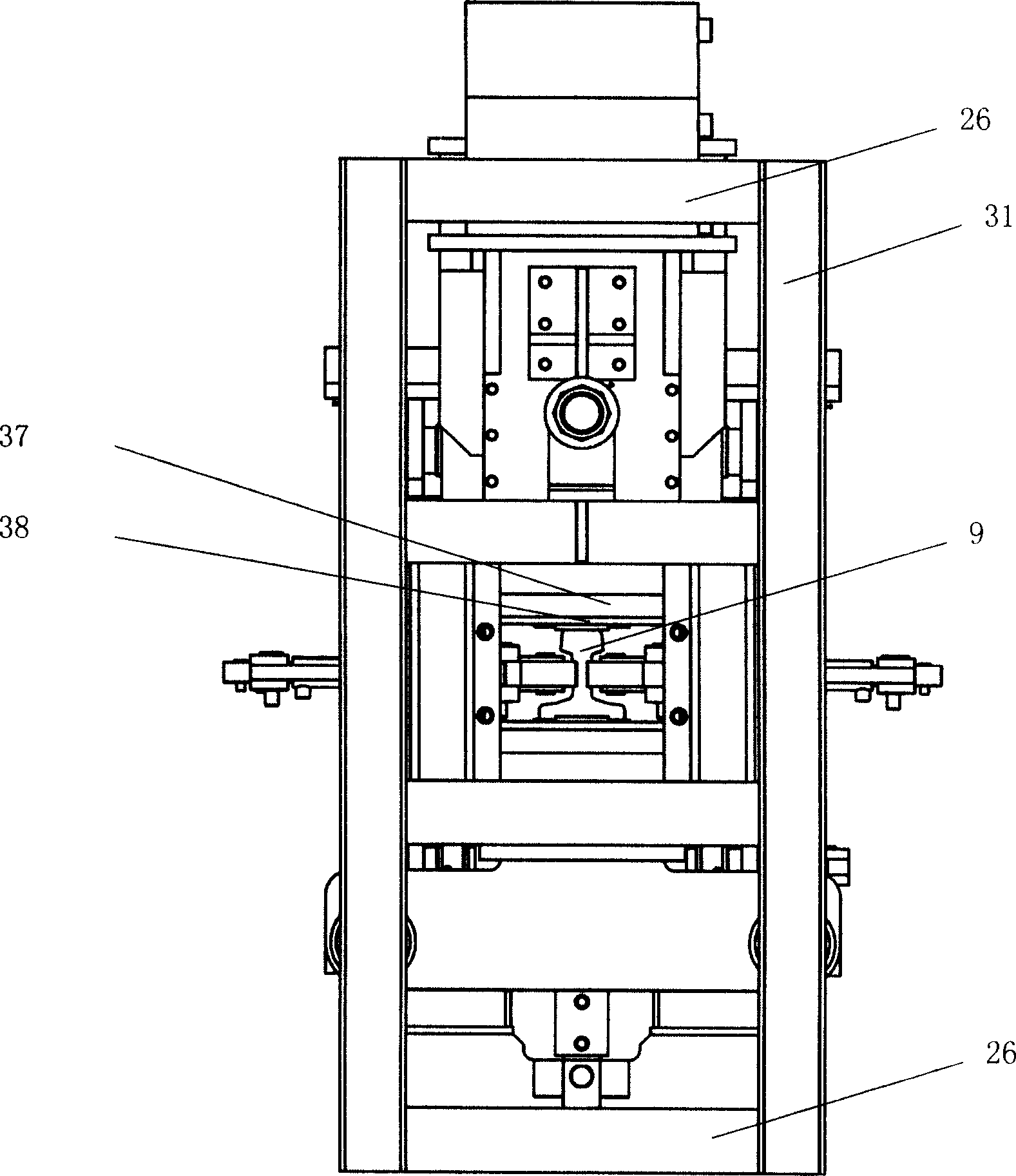

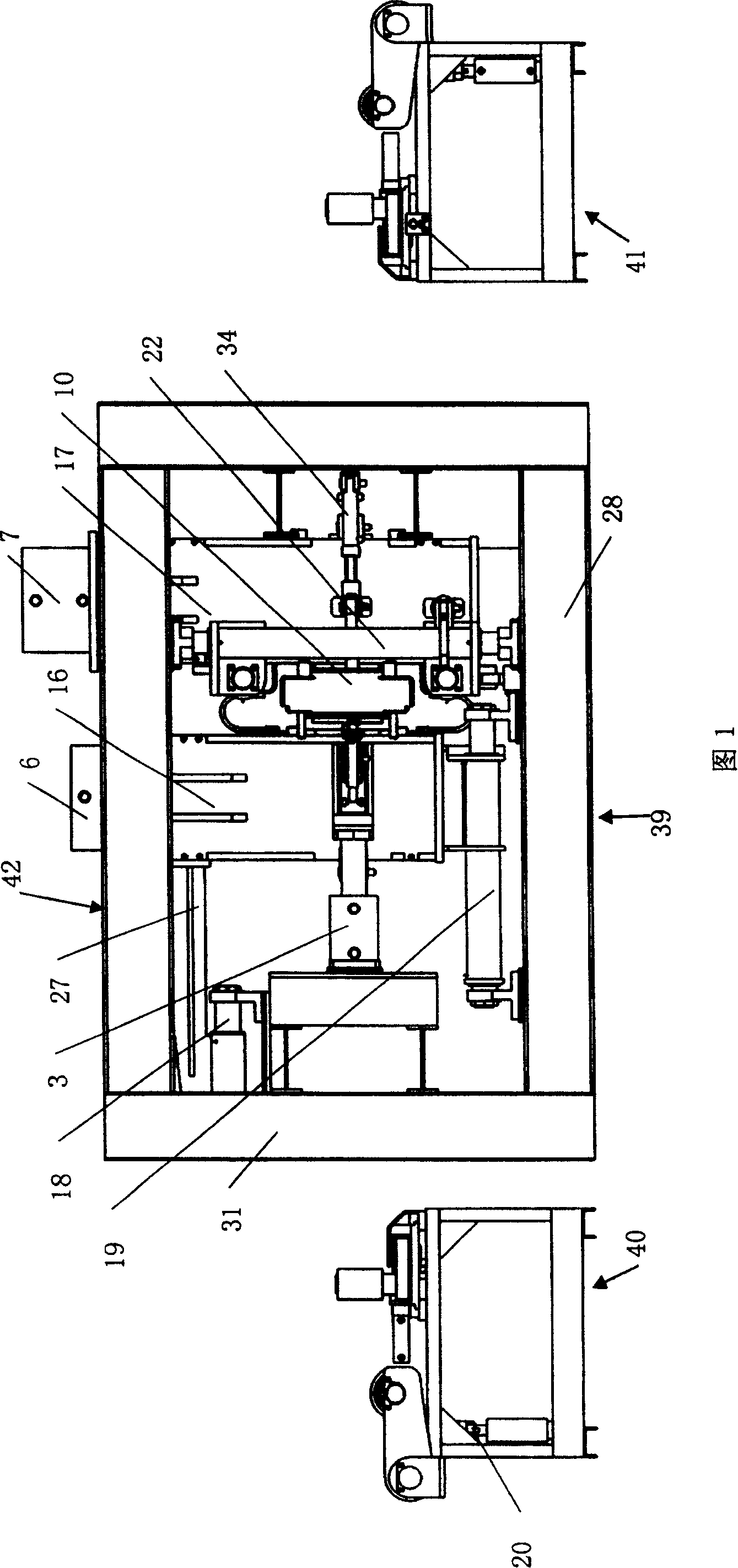

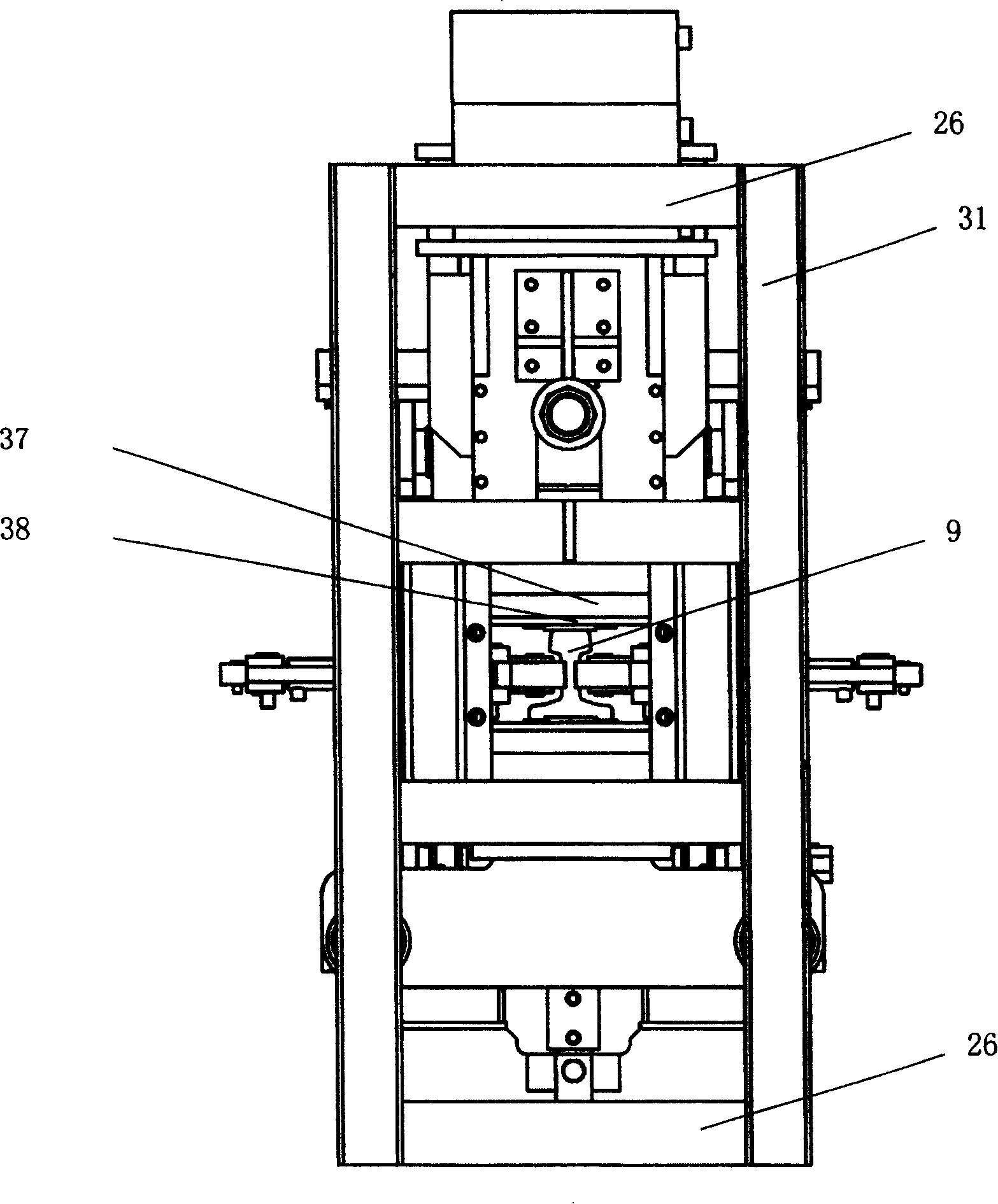

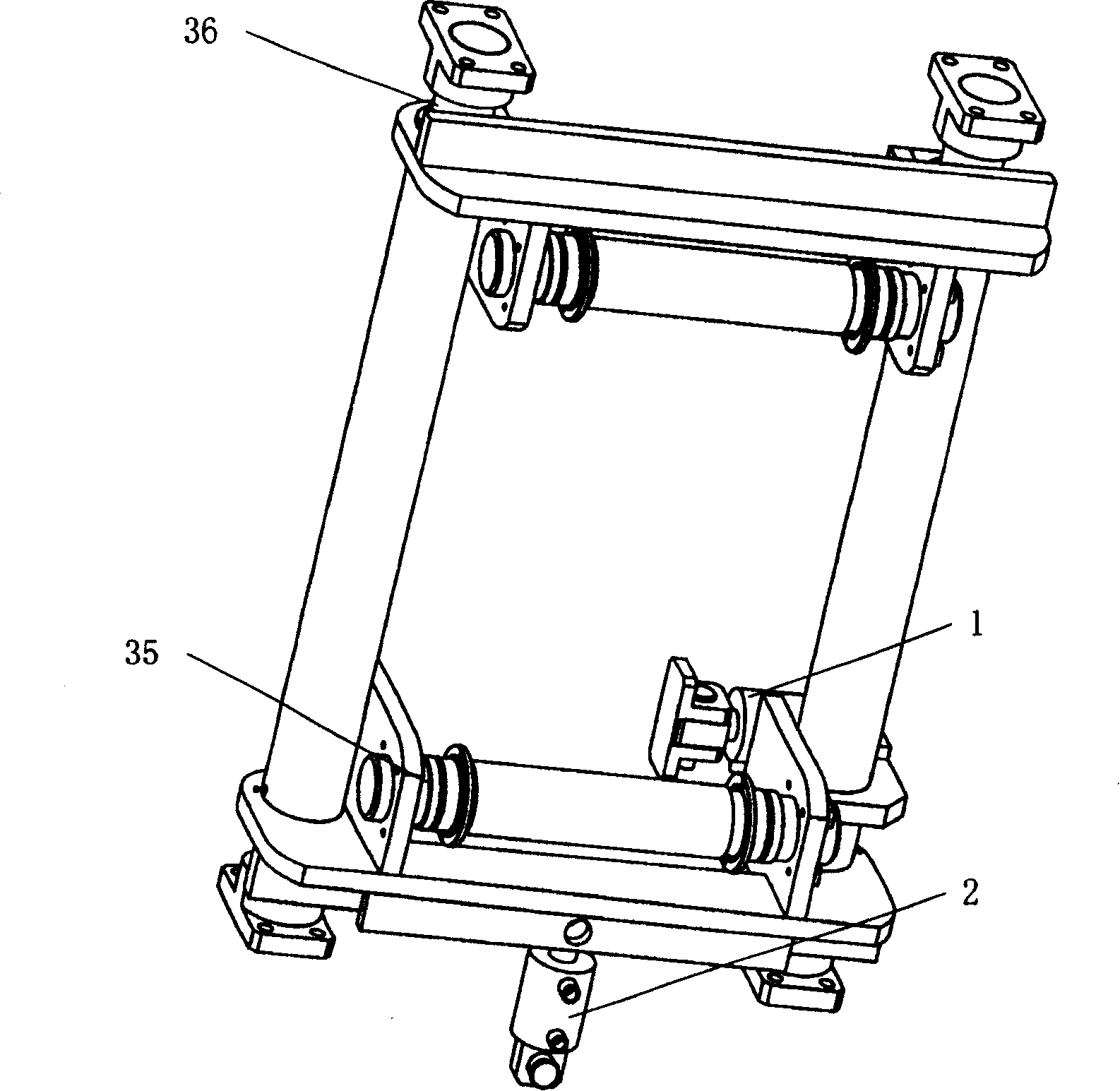

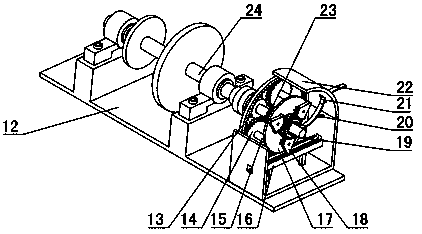

Flash welding machine for fixed steel rail

ActiveCN1876306AImprove working conditionImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesTransformerEngineering

The invention relates to a stationary rail flash welder, comprising main frame and two primary rail racks 40 and 41. The main frame rack 42 is equipped with moving rack 16, static rack 17 and centering rack 22. The moving and static rack are connected with moving rack rail clamping cylinder 6 and static rack rail clamping cylinder 7 on the upper side respectively, static rack rail clamping cylinder 7 is connected with potential transformer cover 37, and the lower part of potential transformer is connected to rail electrode 38. The moving rack 16 is connected with cradle 42vthrough supporting axis 18 and lower supporting axis 19, and the insulated heading cylinder 3 is connected with cradle 42 and moving rack 16. The horizontal centering cylinder I on right of centering rack 22 is connected with static rack 17, and vertical centering cylinder 2 is connected with cradle 42. The moving and static rack is equipped with a unit of horizontal adjusting and locating device respectively. The horizontal clamping device of primary rail racks 40 and 41 on rail bottom is drove by cylinder 21 through rack bar 30, and rack bar 30 drives two gears to rotate and locate rail in horizontal direction. The vertical location for rail is finished by lifting gearing. The invention can obviously improve welder working condition and increases welding quality.

Owner:BEIJING RAILWELD NEW MATERIAL TECH CO LTD +2

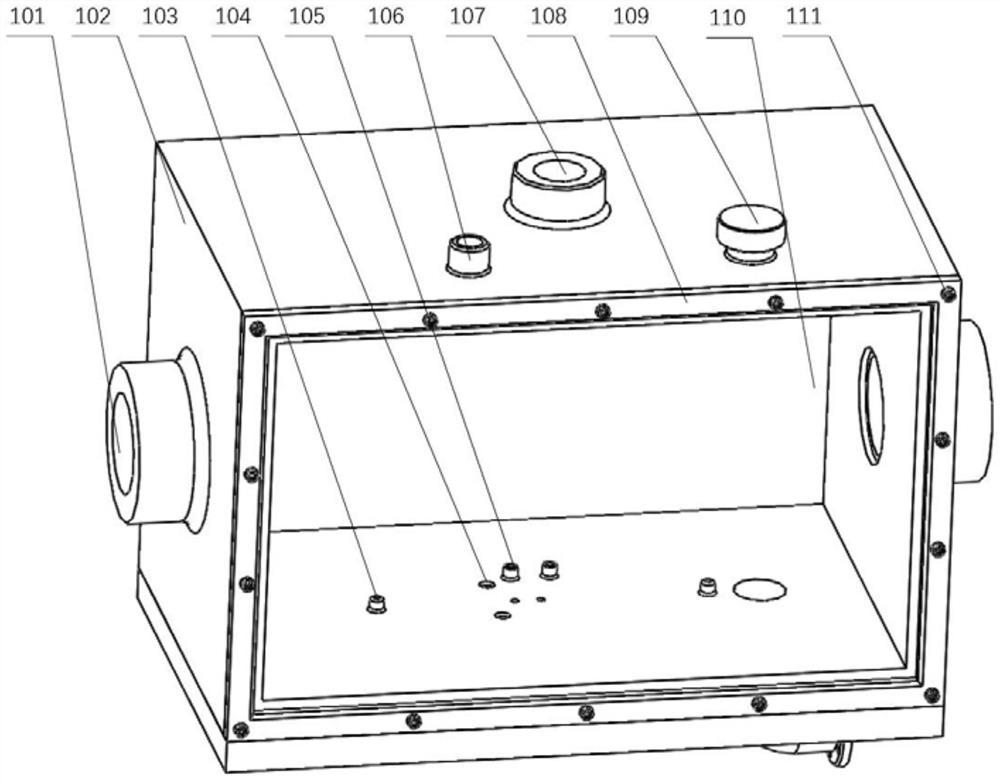

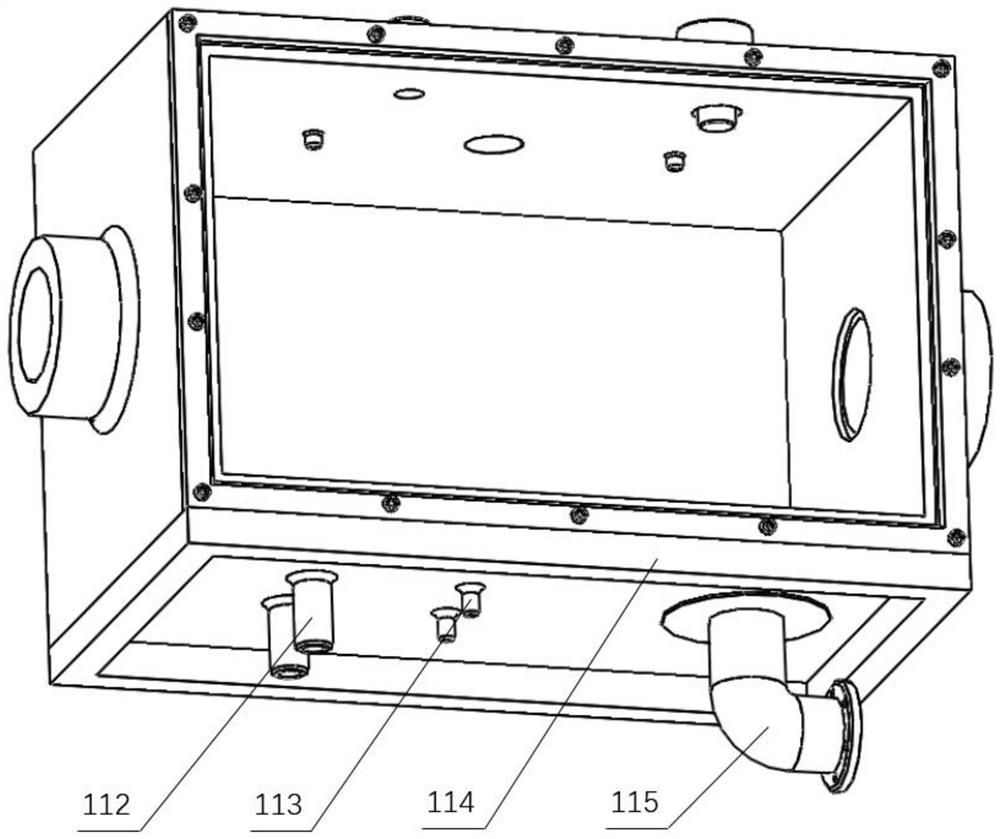

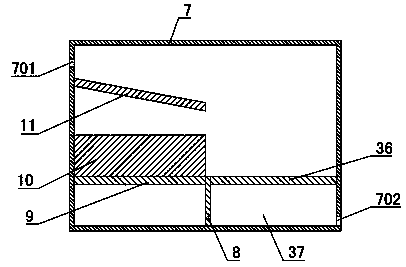

Icing adhesion strength testing device

InactiveCN108645791ADoes not affect test accuracyGood repeatabilityUsing mechanical meansMaterial analysisPull forceEngineering

The invention relates to the field of icing adhesion strength testing,and discloses an icing adhesion strength testing device. The icing adhesion strength testing device comprises a cooling table,a cooling circulator,a sleeve,a part to be tested and a force testing element. The cooling circulator is connected with the cooling table through a refrigerant circulating pipeline,the part to be tested is fixed to the cooling table,and the upper end and the lower end of the sleeve are open. A pull groove is formed in the circumferential direction of at least one end of the sleeve,the end,provided with the pull groove,of the sleeve is arranged on the part to be tested,and liquid is injected into the sleeve and cooled into an icicle through the cooling table; one end of an element with force to betested is connected with a connecting rope sleeve,the connecting rope sleeve is sleeved with the pull groove of the sleeve,the element with the force to be tested exerts pull force to the sleeve through the connecting rope sleeve until the icicle is separated from the surface of the part to be tested,and the icing adhesion strength between the icicle and the part to be tested is calculated. The icing adhesion strength testing device is easy,convenient and fast to operate,and good in result repeatability.

Owner:CRRC QINGDAO SIFANG CO LTD

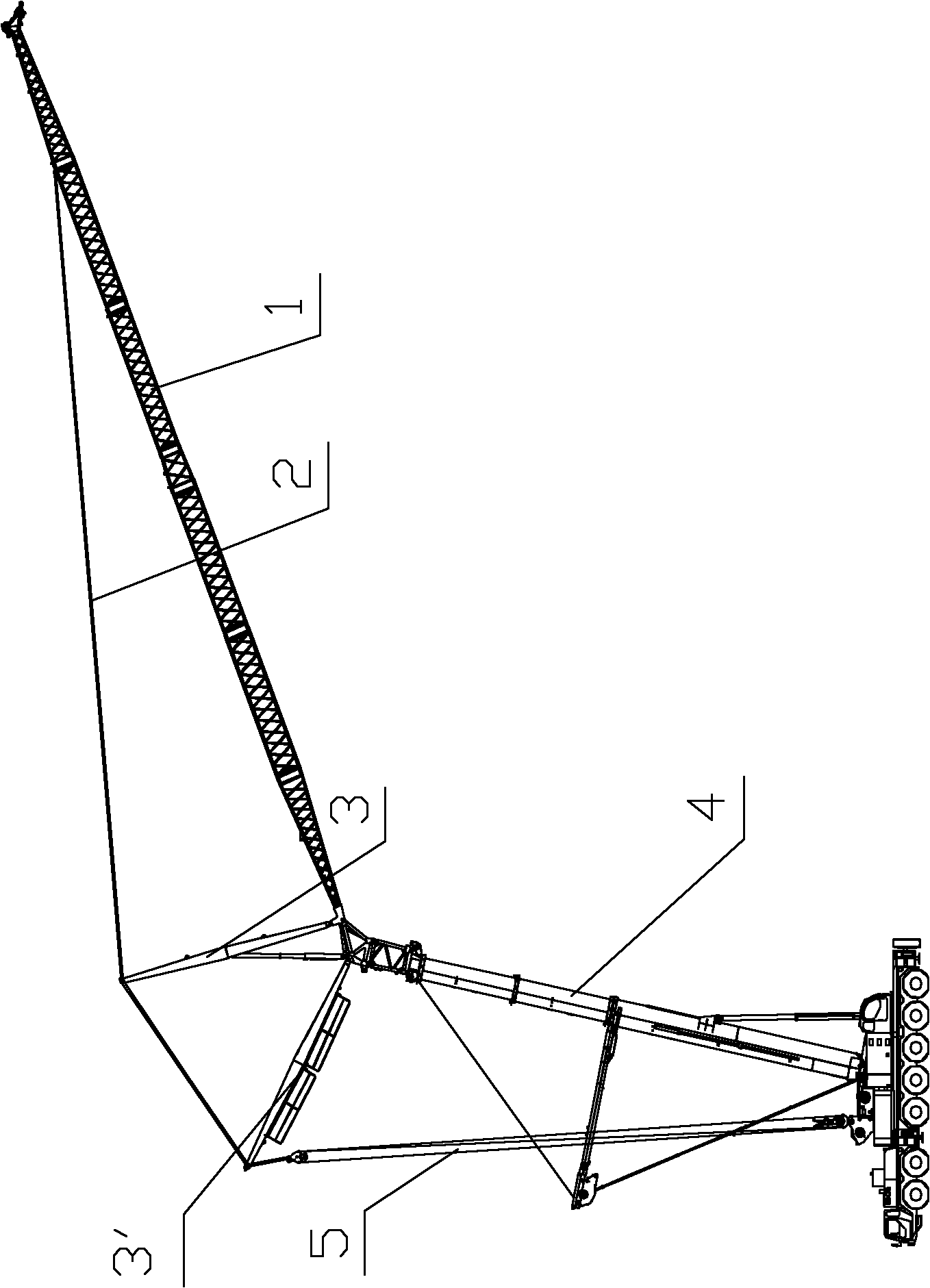

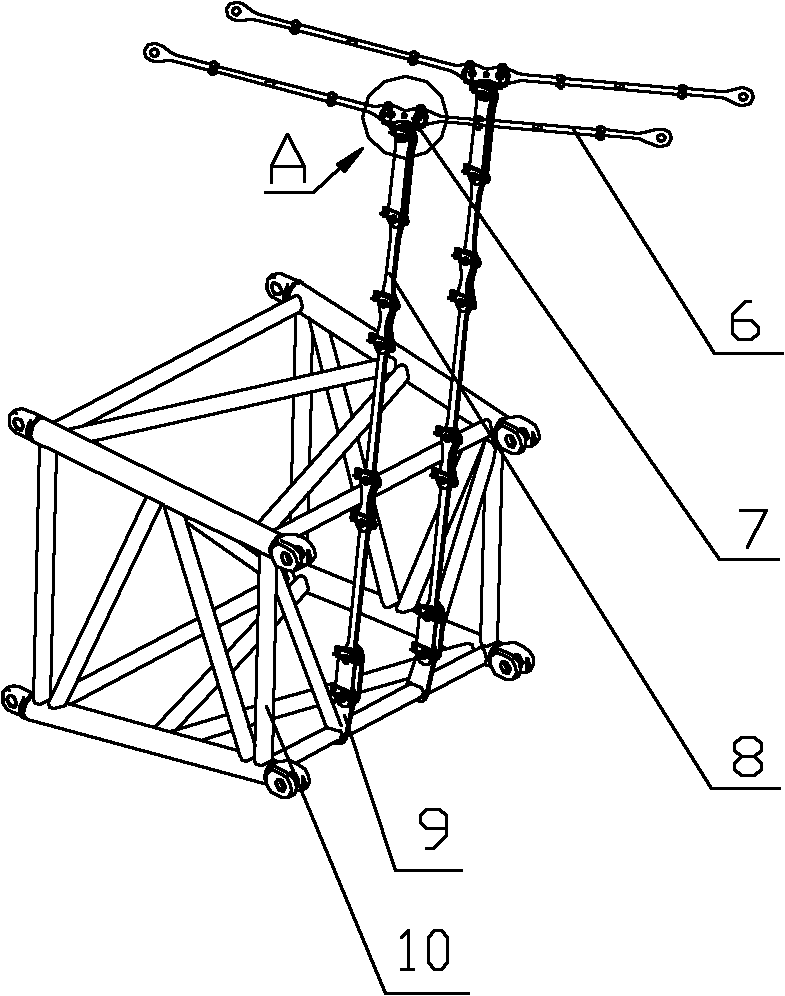

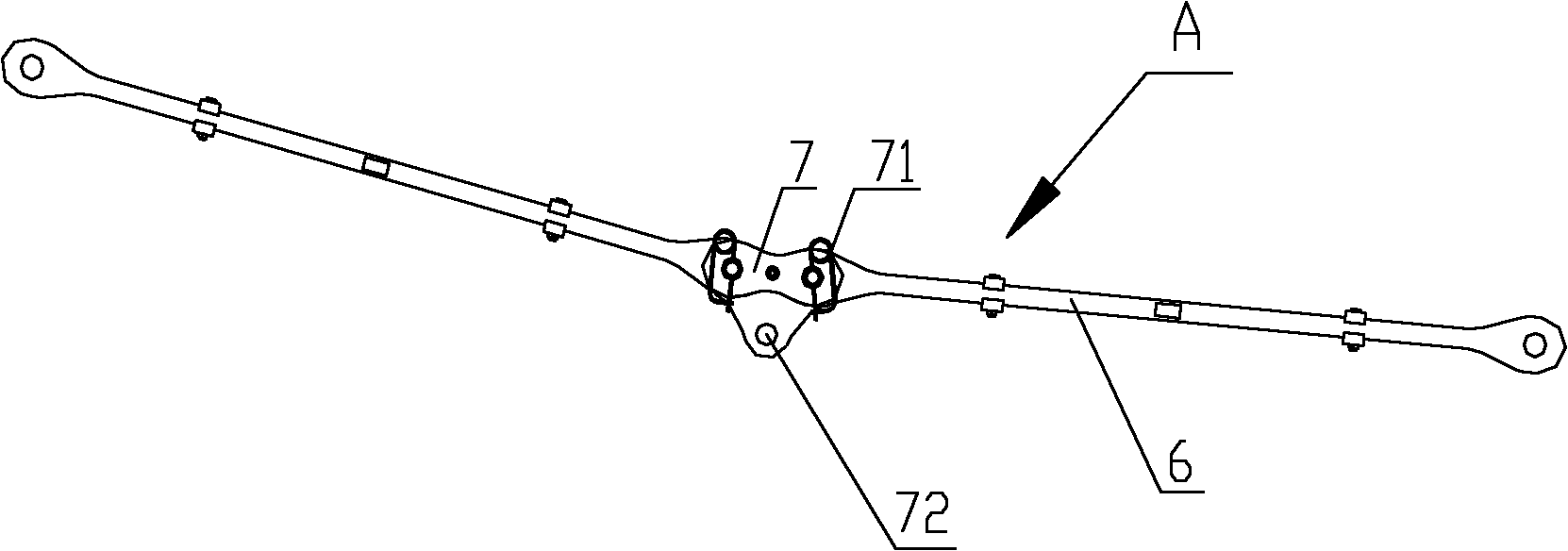

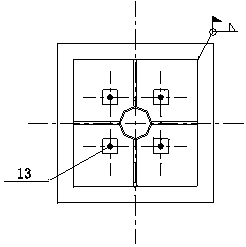

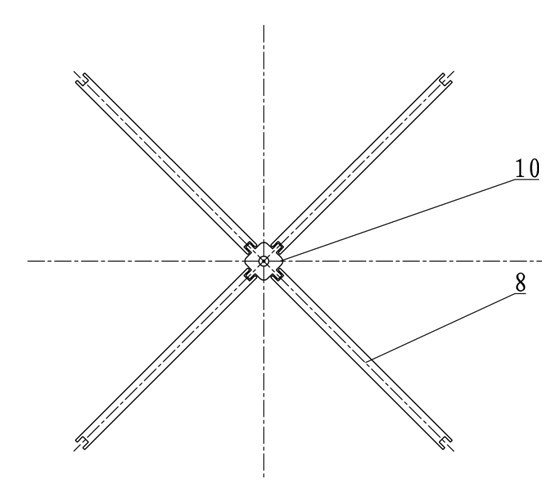

Wheeled crane and luffing jib thereof

The invention provides a luffing jib which comprises a jib boom main body (10), a tension device (6) and a spinal cord (8), wherein the tail end of the tension device (6) is connected with the tail end of the jib boom main body (10); a first articulating part (7) is arranged between both ends of the tension device (6); a second articulating part (9) is arranged between both ends of the jib boom main body (10); and both ends of the spinal cord (8) are respectively connected with the first articulating part (7) and the second articulating part (9). The luffing jib has the advantages of small self deflection, less additional bending moment after hoisting, and high lifting performance. The invention also provides a wheeled crane with the luffing jib.

Owner:XUZHOU HEAVY MASCH CO LTD

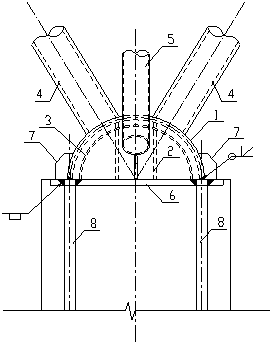

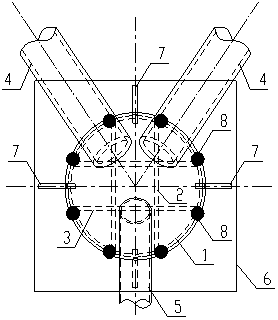

Hemispherical hollow welding sphere joint for large-span space steel structure support

InactiveCN104110072ALower the altitudeTensile benefitsBuilding constructionsEngineeringSteel structures

The invention provides a hemispherical hollow welding sphere joint for a large-span space steel structure support. The hemispherical hollow welding sphere joint at least comprises four foundation bolts which are connected with at least two embedded plates. At least one outer stiffening plate is welded to each embedded plate. A hemispherical case is respectively connected with the embedded plates and the outer stiffening plates in a welded mode. The hemispherical case is used as a sphere joint, at least one main pipe and one branch pipe are welded to the hemispherical case, and a transverse semicircular stiffening plate and a longitudinal semicircular stiffening plate are further welded to the hemispherical case. The hemispherical hollow welding sphere joint has the following advantages that a novel joint form is designed for the large-span space steel structure support, and the defects of the joint form in the application field are effectively made up; the height of the steel support is reduced, the length of the welding joint is increased, larger horizontal shearing force can be borne, and the tensile strength of the foundation bolts is benefited; the hemispherical case, the transverse semicircular stiffening plate, the longitudinal semicircular stiffening plate, the outer stiffening plates and the embedded plates are connected, and therefore the safety of the joint is ensured.

Owner:ZHEJIANG ELECTRIC POWER DESIGN INST

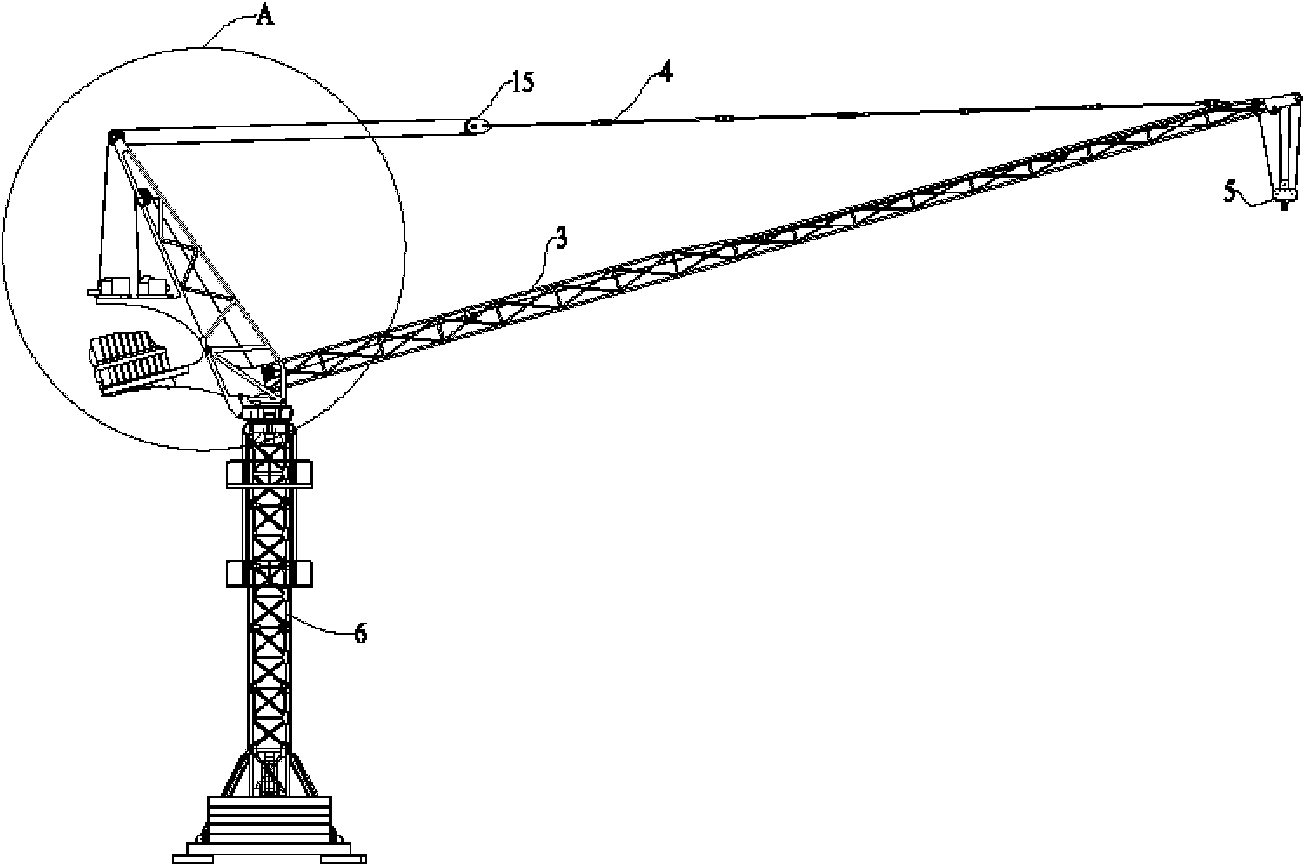

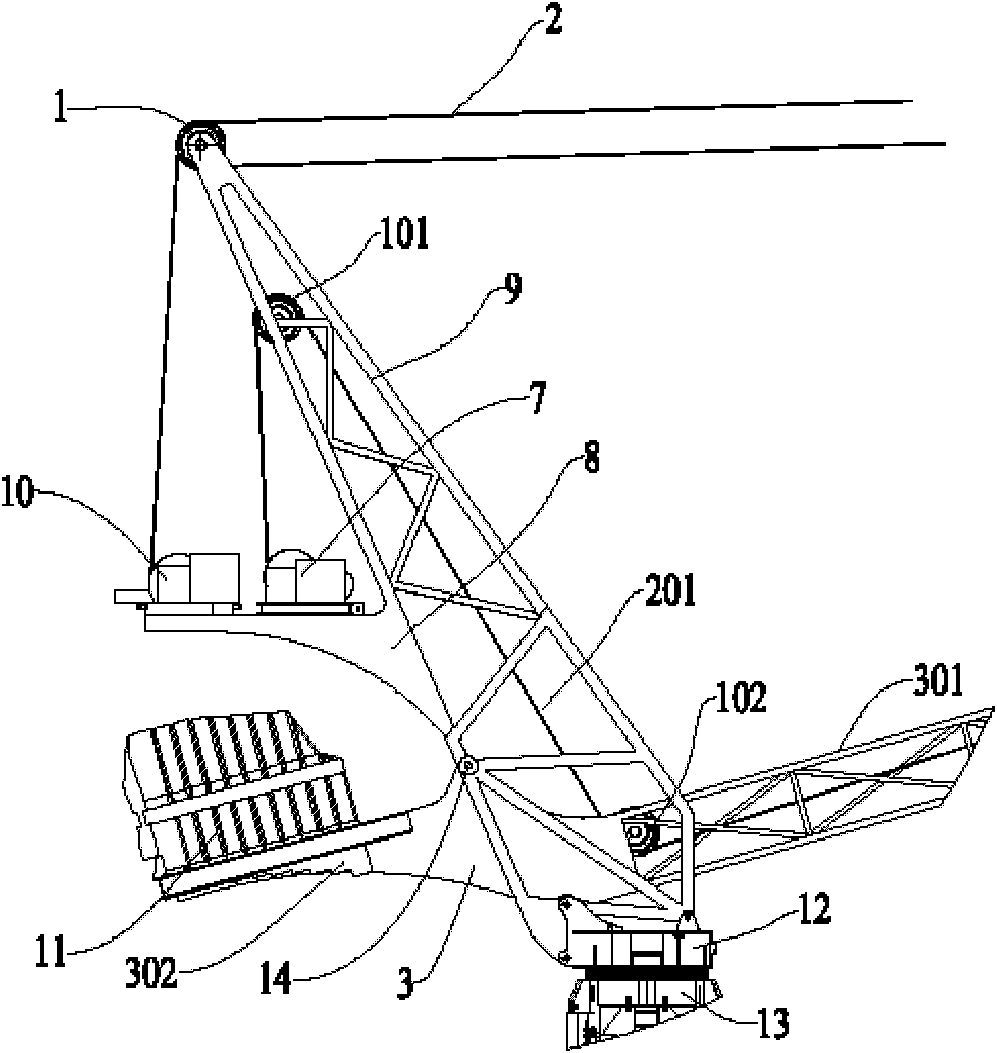

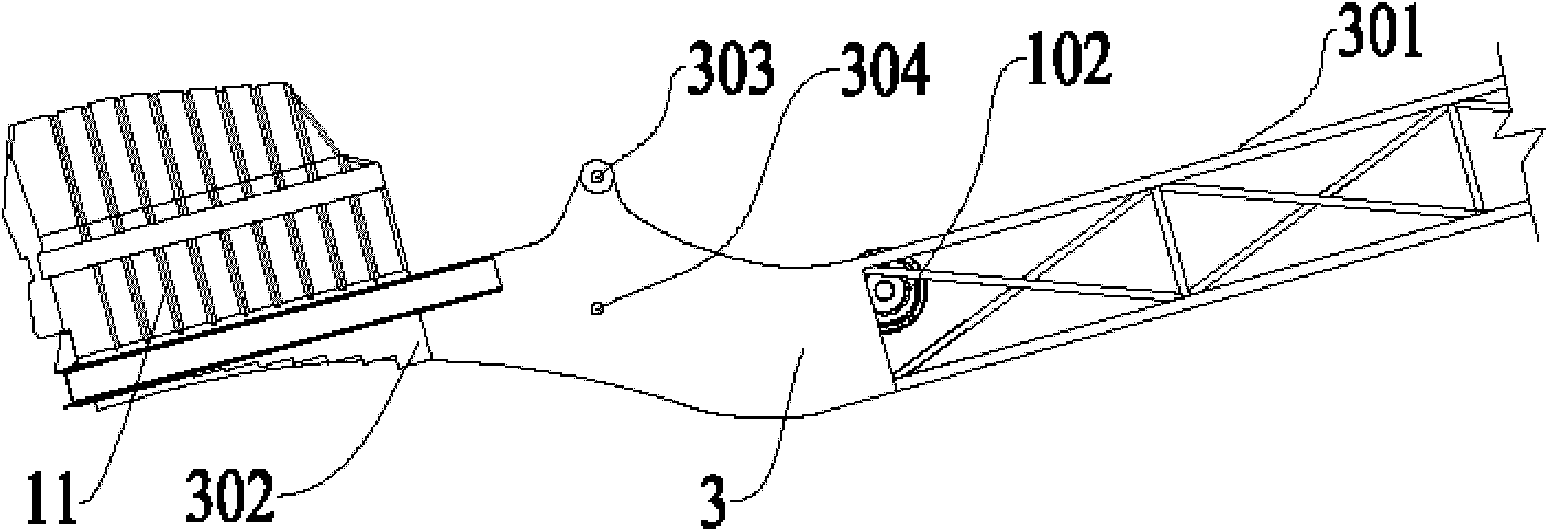

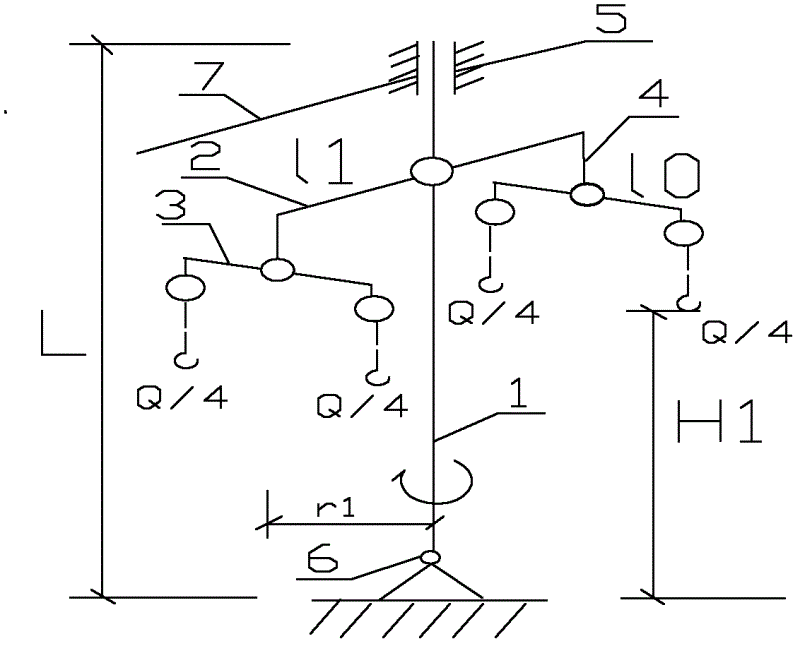

Luffing tower crane with balanced type suspension arm based on traction luffing of steel rope

The invention relates to a luffing tower crane with a balanced type suspension arm based on traction luffing of a steel rope. The luffing tower crane comprises a tower body (6), a rotation support (12), a tower top (9), a suspension arm (3), a lifting hook component (5), a balanced arm (8), a counter weight (11) and a luffing mechanism (10) and is characterized in that: the suspension arm (3) comprises a jack-up end (301) and an integrated structure which consists of a counter weight end (302) opposite to the jack-up end (301); the jack-up end (301) of the suspension arm (3) comprises the lifting hook component (5); a hinged seat (303) is arranged close to the gravity center position of the suspension arm (3) and hinged with the tower top (9); and one end of a luffing steel rope (2) of the luffing mechanism (10) is directly connected to the jack-up end (301) of the suspension arm (3) or connected to the jack-up end (301) through a pull rod group (4). By the tower crane, the additional bending moment of the suspension arm (3) on the tower body (1) can be effectively reduced, so the jack-up performance of the tower crane can be greatly improved, and the power of the luffing mechanism and the diameter of the luffing steel rope are reduced.

Owner:倪建军

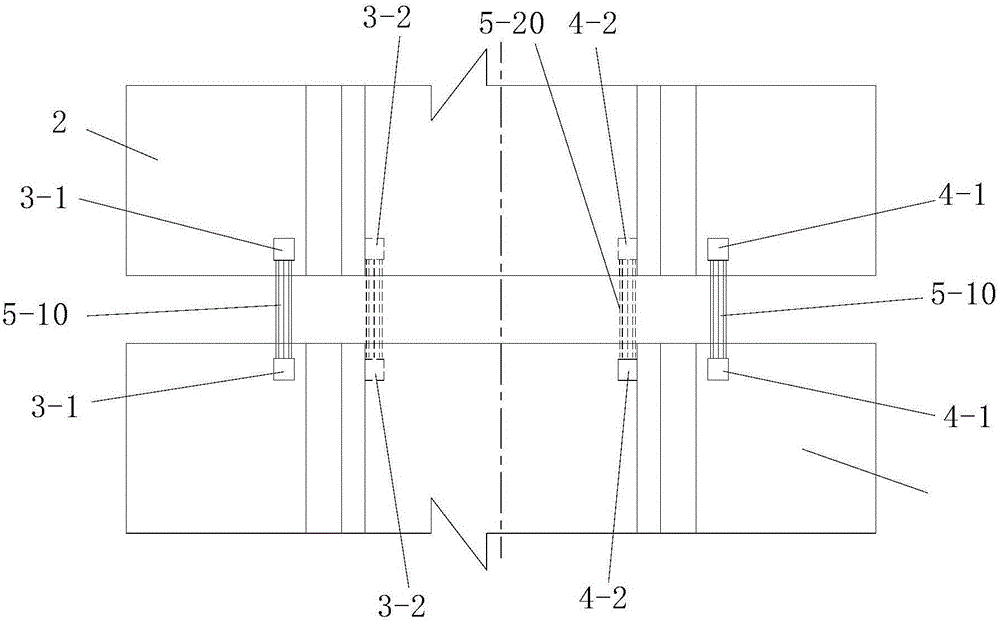

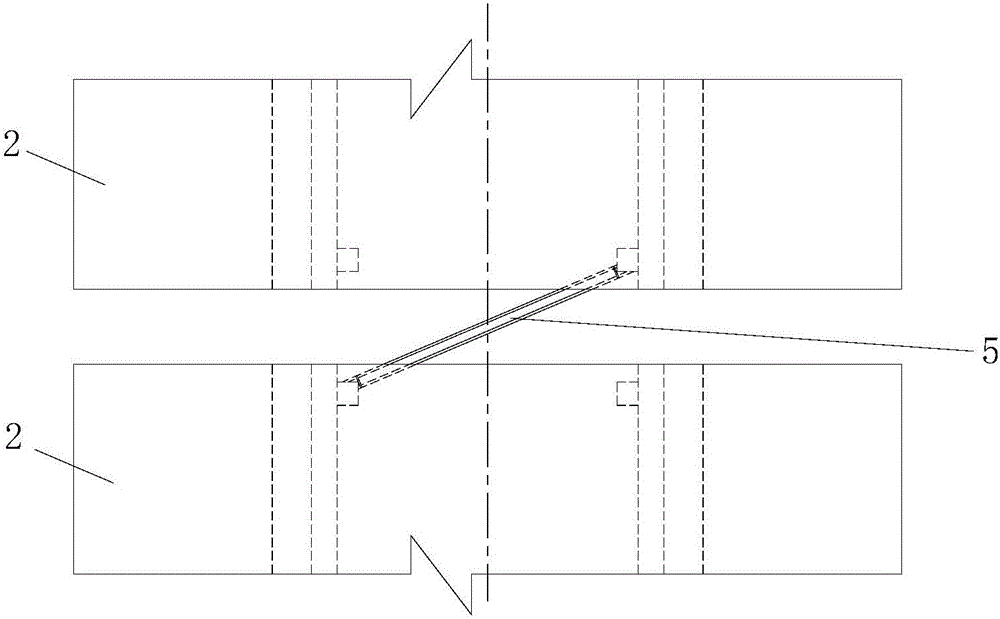

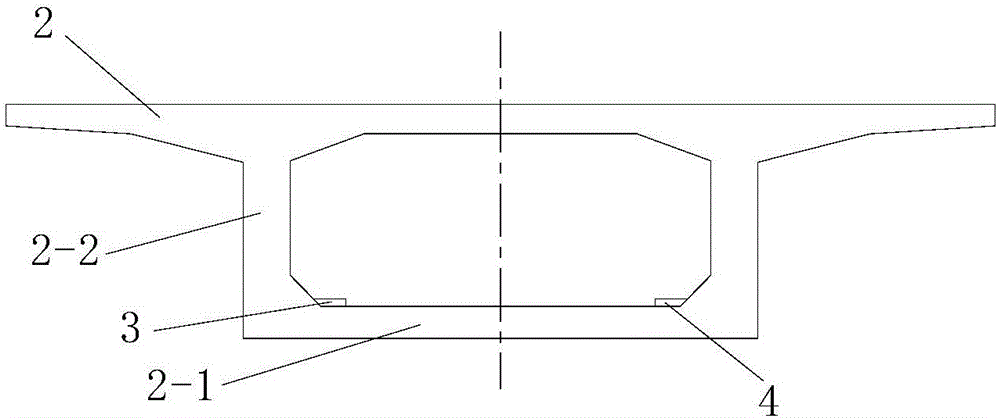

Jacking system for closure section of continuous rigid frame bridge and jacking deviation rectifying method

The invention discloses a jacking system for a closure section of a continuous rigid frame bridge and a jacking deviation rectifying method. The jacking system is composed of a top plate jacking system and a bottom plate jacking system. The top plate jacking system comprises two sets of top plate embedded bases arranged at the ends of two cantilever beam sections of the continuous rigid frame bridge correspondingly, top plate rigid supporting structures supported between the two sets of top plate embedded bases and a top plate jacking mechanism. The bottom plate jacking system comprises two sets of bottom plate embedded bases arranged at the ends of the two cantilever beam sections correspondingly, bottom plate rigid supporting structures supported between the two sets of bottom plate embedded bases and a bottom plate jacking mechanism. The jacking deviation rectifying method comprises the steps of (1) measurement of position deviation of the cantilever beam sections, (2) adjustment of elevation deviation of the cantilever beam sections, (3) deviation rectifying adjustment and (4) longitudinal jacking. The jacking system is simple in structure, reasonable in design, easy and convenient to construct and good in using effect, the jacking deviation rectifying process of the cantilever beam sections on the two sides of the closure section can be completed easily, conveniently and rapidly, and the rectifying requirements of lateral deviation and reverse deviation of the cantilever beam sections can be met.

Owner:XIAN HIGHWAY INST

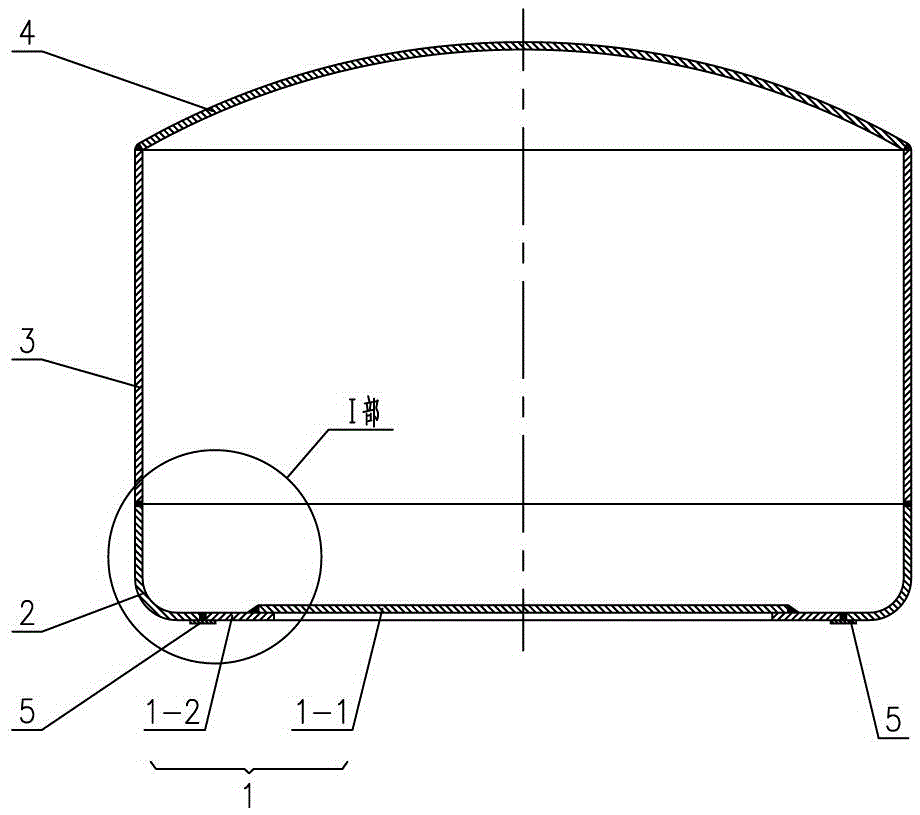

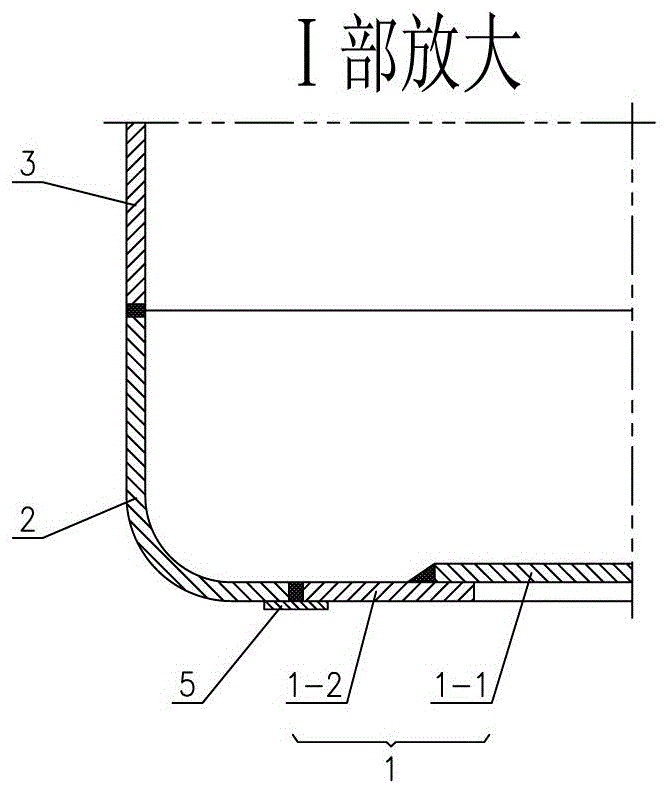

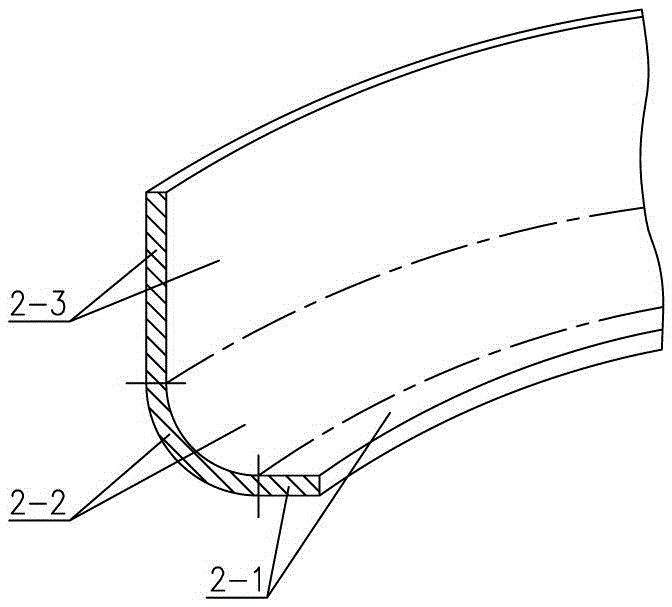

Large steel welded vertical oil tank

ActiveCN105600205AReduce edge stressEliminate welding residual stressLarge containersSafe operationWaste management

The invention provides a large steel welded vertical oil tank. The large steel welded vertical oil tank is provided with a tank bottom, a tank wall and a tank top. A transition connecting ring is arranged between the tank bottom and the tank wall and provided with an annular bottom section, an arc-shaped transition section and a vertical cylindrical section. The tank bottom is connected with the annular bottom section of the transition connecting ring in a welded mode. The tank wall is connected with the vertical cylindrical section of the transition connecting ring in a welded mode. The tank top can be a fixed top and can also be an outwards-floating top. The large steel welded vertical oil tank has the advantages that T-shaped joints of a tank wall and a tank bottom of an existing large oil tank and large fillet welds on the joints are omitted, main danger points of the whole oil tank are eliminated, and safe operation of the large oil tank is guaranteed, wherein the transition position between the tank wall and the tank bottom is not prone to low-cycle fatigue damage, an attachment weld of the transition portion between the tank wall and the tank bottom is not prone to tearing damage, the anti-seismic property of the large oil tank is greatly improved, and the anti-seismic property of the large oil tank is good.

Owner:JIANGSU CHEM EQUIP MFG & INSTALLATION CO LTD

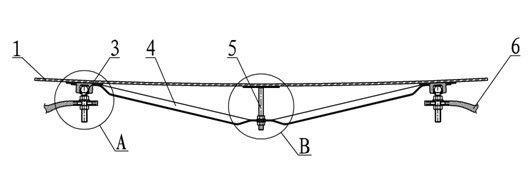

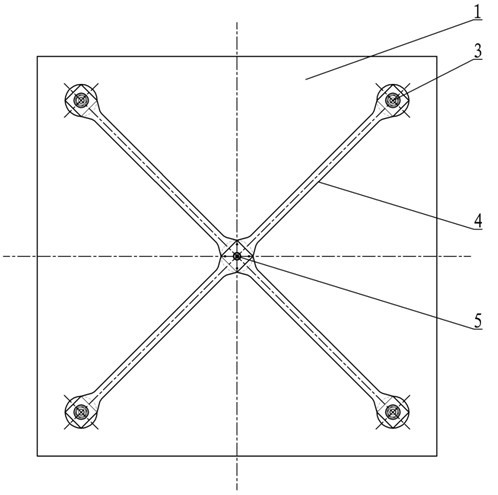

Overlap-connected shape-adjusting device used for reflecting mirror for heliostat

ActiveCN102566004AReduced strength requirementsLess materialSolar heating energySolar heat devicesHeliostatEngineering

The invention discloses an overlap-connected shape-adjusting device used for a reflecting mirror for a heliostat, which is arranged on the back of the reflecting mirror for the heliostat and fixedly connected with a bracket of the heliostat. The overlap-connected shape adjusting device comprises a plurality of overlap-connected shape-adjusting connecting pieces, at least one central shape-adjusting connecting piece and a shape adjusting claw; the central shape-adjusting connecting piece is arranged at the center of the corresponding shape adjusting claws; the shape adjusting claw is fixed on the back of the reflecting mirror through the central shape-adjusting connecting piece; the claw ends of the corresponding shape adjusting claw are fixed on the back of the reflecting mirror through the overlap-connected shape-adjusting connecting pieces; and the overlap-connected shape-adjusting connecting pieces are connected and fixed on the bracket of the heliostat. The overlap-connected shape-adjusting device used for the reflecting mirror for the heliostat has the advantages of simple structure, high shape-adjusting control efficiency and better focusing alignment quality.

Owner:NANJING SCIYON AUTOMATION GRP

Flash welding machine for fixed steel rail

ActiveCN100396421CImprove working conditionImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesTransformerFlash welding

The invention relates to a stationary rail flash welder, comprising main frame and two primary rail racks 40 and 41. The main frame rack 42 is equipped with moving rack 16, static rack 17 and centering rack 22. The moving and static rack are connected with moving rack rail clamping cylinder 6 and static rack rail clamping cylinder 7 on the upper side respectively, static rack rail clamping cylinder 7 is connected with potential transformer cover 37, and the lower part of potential transformer is connected to rail electrode 38. The moving rack 16 is connected with cradle 42vthrough supporting axis 18 and lower supporting axis 19, and the insulated heading cylinder 3 is connected with cradle 42 and moving rack 16. The horizontal centering cylinder I on right of centering rack 22 is connected with static rack 17, and vertical centering cylinder 2 is connected with cradle 42. The moving and static rack is equipped with a unit of horizontal adjusting and locating device respectively. The horizontal clamping device of primary rail racks 40 and 41 on rail bottom is drove by cylinder 21 through rack bar 30, and rack bar 30 drives two gears to rotate and locate rail in horizontal direction. The vertical location for rail is finished by lifting gearing. The invention can obviously improve welder working condition and increases welding quality.

Owner:BEIJING RAILWELD NEW MATERIAL TECH CO LTD +2

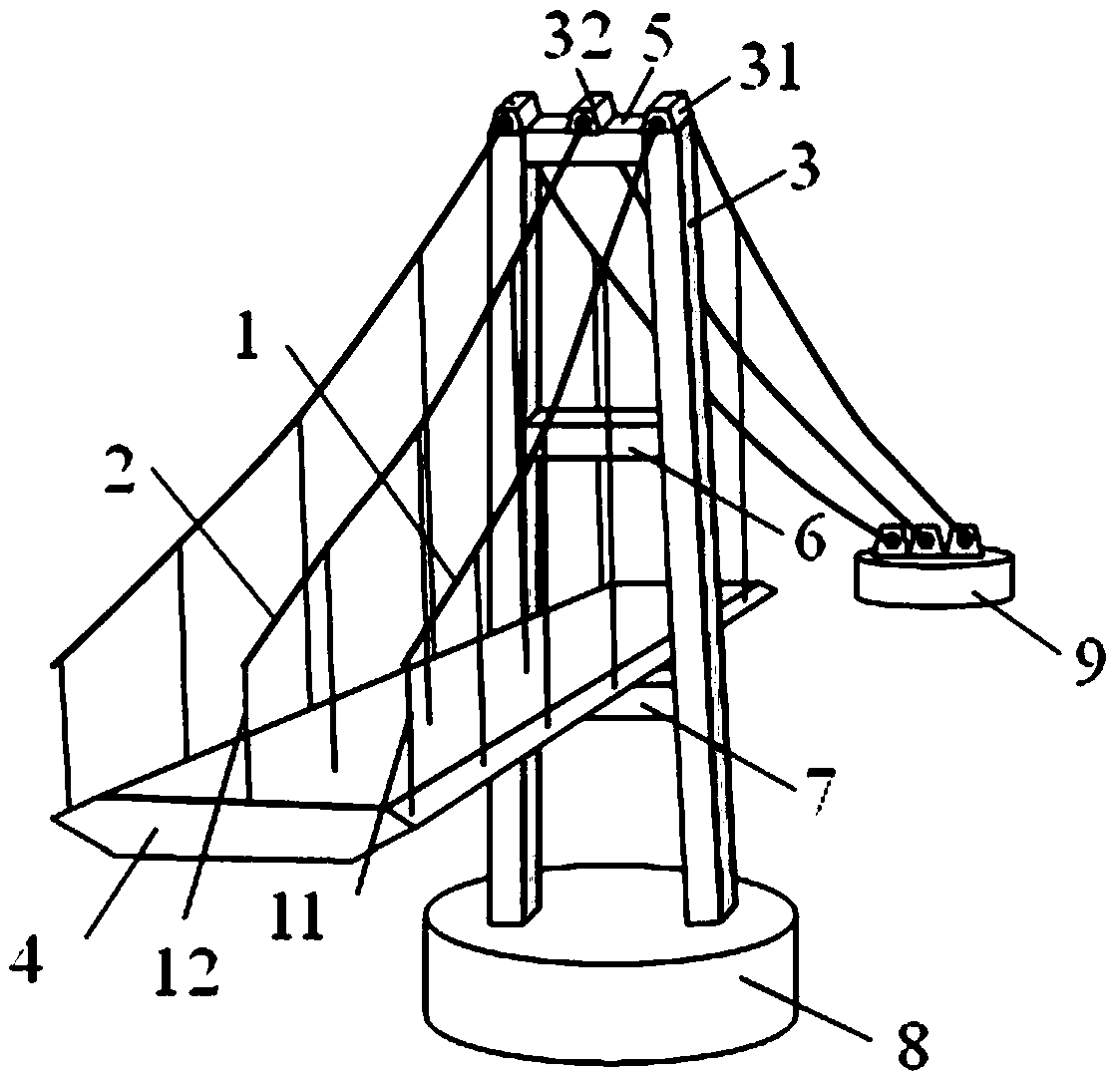

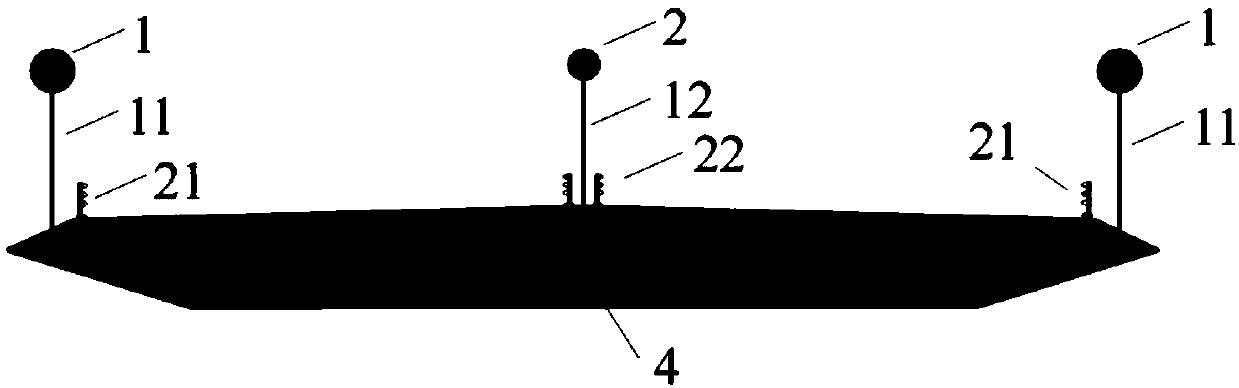

Suspension bridge with three main cables and double tower columns

The invention provides a suspension bridge with three main cables and double tower columns. The suspension bridge is characterized by comprising a main girder, the tower columns, bridge tower transverse beams, the edge side main cables, the middle main cable and anchorage; the main girder is of an integral type structure or a split type structure; the tower columns are arranged on two sides of themain girder in pairs, are positioned on upstream sides and downstream sides, are solidified with the earth and are used for bearing the edge side main cables and the main girder; the bridge tower transverse beams include an upper bridge tower transverse beam, a middle bridge tower transverse beam and a lower bridge tower transverse beam and are solidified between the tower columns arranged in pairs; the edge side main cables are mounted on the tops of the tower columns via edge side cable saddles and are connected with the tops of two sides of the main girder by edge side suspension cables; the middle main cable is mounted on the top of the middle of the upper bridge tower transverse beam via a middle cable saddle and is connected with the top of the middle of the main girder by a middlesuspension cable; the edge side main cables and the middle main cable are solidified with the earth via the anchorage. The suspension bridge with the three main cables and the double tower columns hasthe advantages that the sizes of the main girder and cable towers can be effectively diminished, the engineering cost can be lowered, and the stress performance of the main girder can be greatly enhanced.

Owner:CCCC HIGHWAY BRIDNAT ENG RES CENT

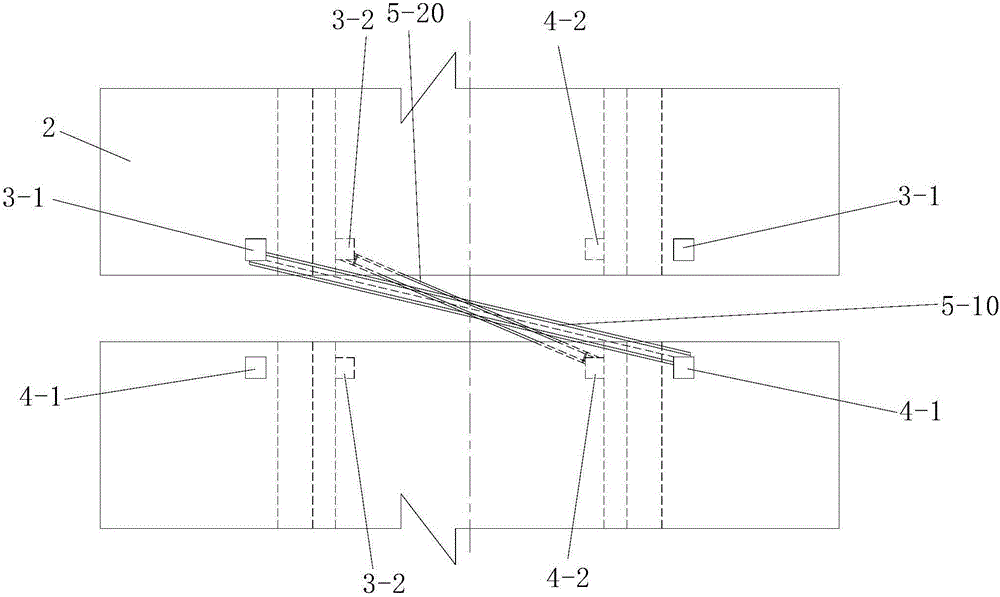

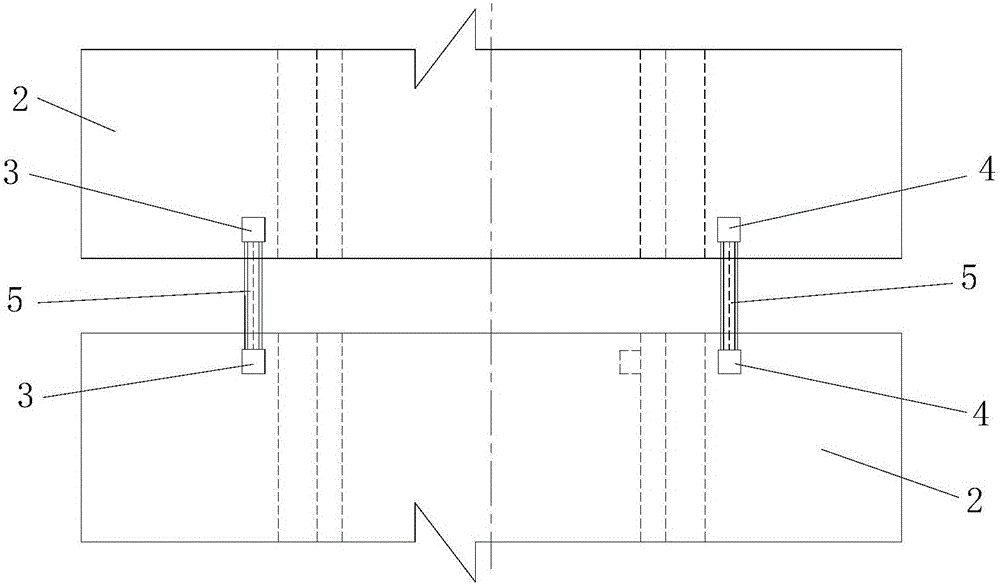

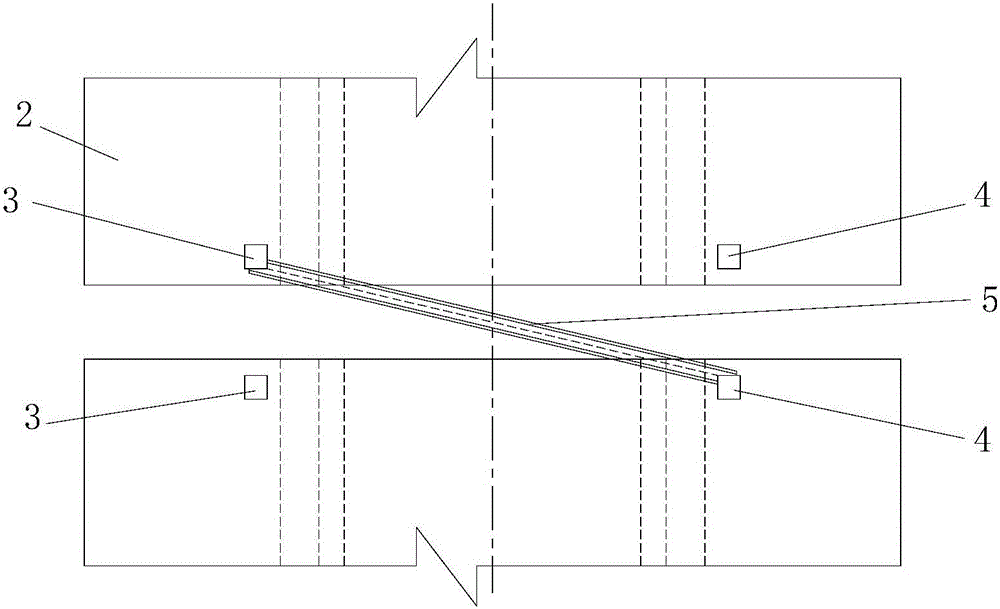

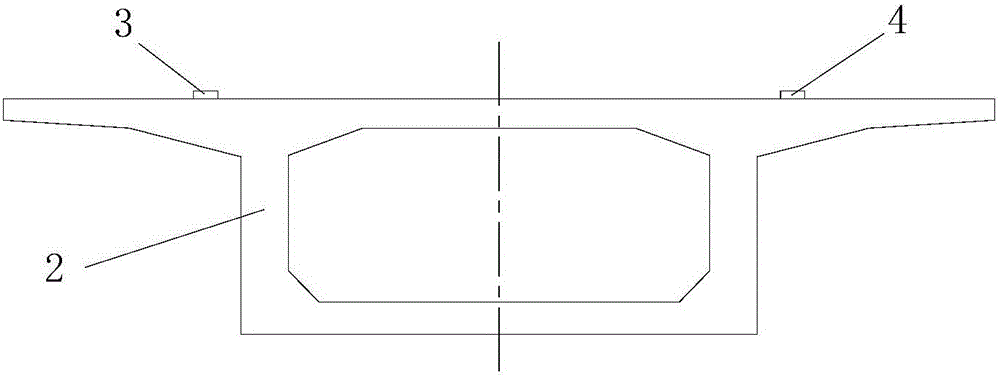

Top plate ejecting system for ejecting closure section of continuous rigid frame bridge and construction method thereof

The invention discloses a top plate ejecting system for ejecting closure section of a continuous rigid frame bridge and a construction method thereof. The top plate ejecting system comprises two groups of top plate pre-buried bases, a rigid support structure and an ejecting mechanism, wherein the two groups of top plate pre-buried bases are respectively arranged at two cantilever beam section ends of the continuous rigid frame bridge; the rigid support structure is supported between the two groups of top plate pre-buried bases; the ejecting mechanism is used for ejecting the rigid support structure; each group of top plate pre-buried bases comprises a left top plate pre-buried base and a right top plate pre-buried base arranged on the same cantilever beam sections; the rigid support structure is a longitudinal ejecting support structure or an oblique ejecting support structure; one end of the rigid support structure is a fixed end, and the other end of the rigid support structure is an ejecting end. The construction method comprises the following steps: step one, constructing the top plate pre-buried bases; step two, mounting the ejecting mechanism; and step three, mounting the rigid support structure. The top plate ejecting system is reasonable in design, simple and convenient to construct and good in using effect; the process of ejecting the cantilever beam sections of the closure section can be simply, conveniently and quickly completed; and the requirements on correction of lateral deviation and torsion deviation of the cantilever beam sections can be met.

Owner:XIAN HIGHWAY INST

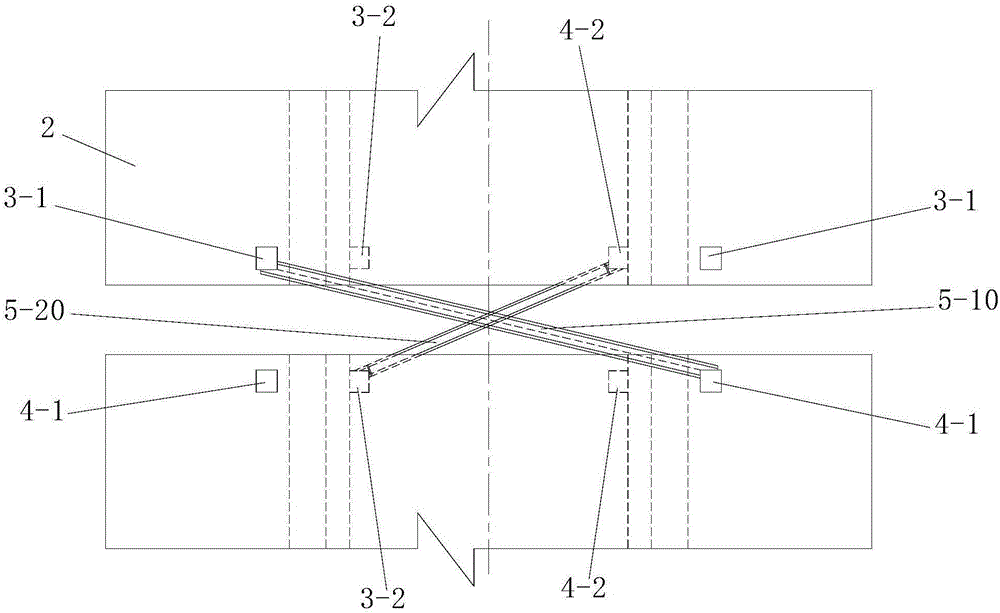

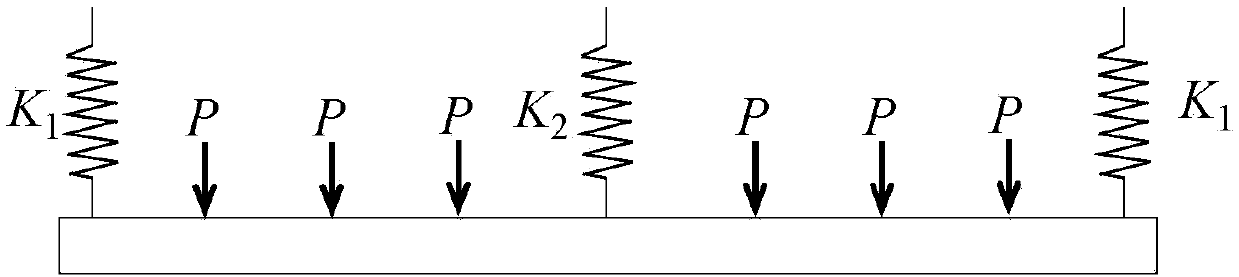

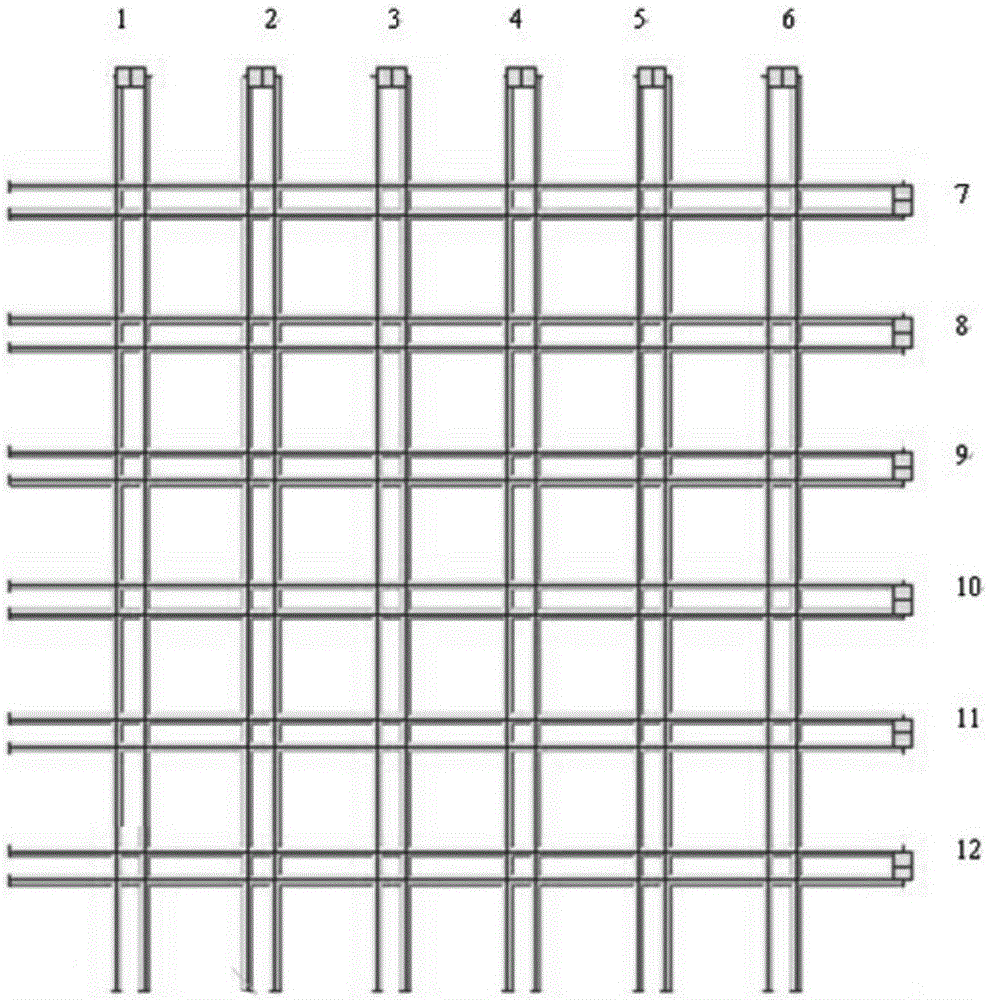

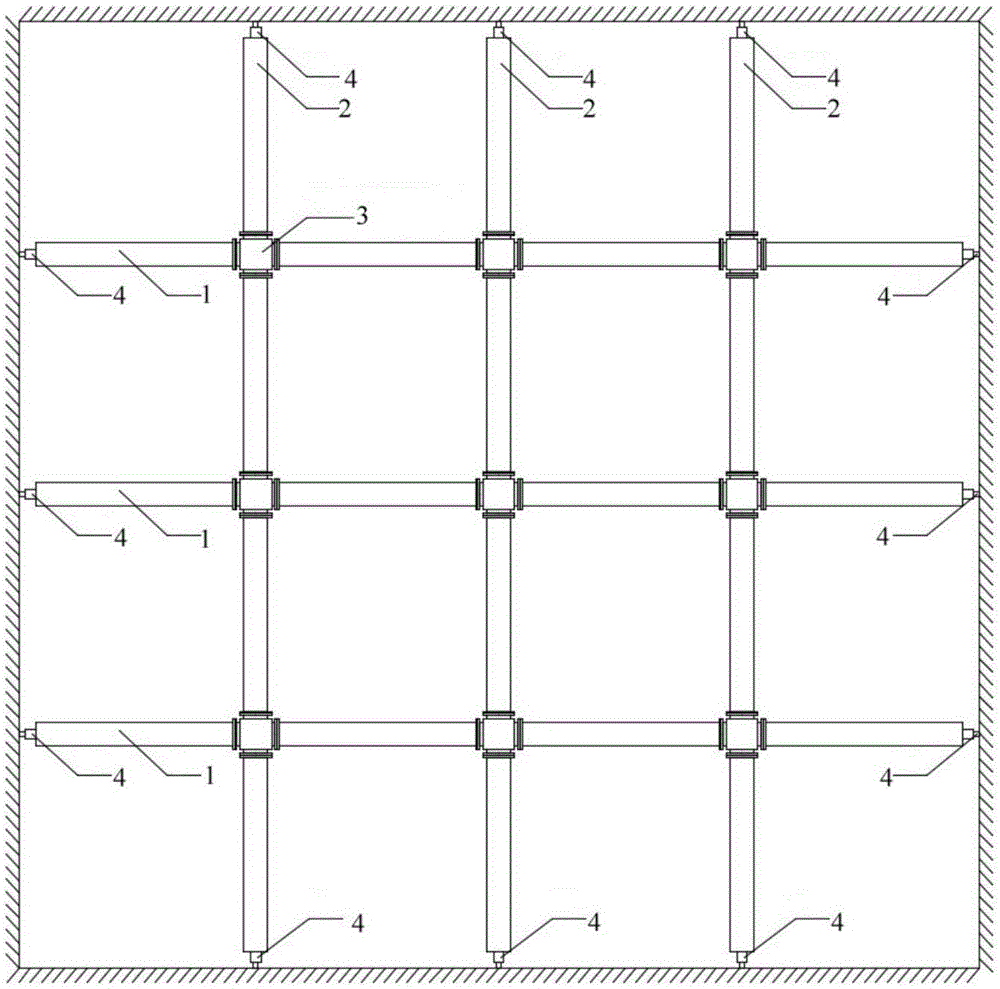

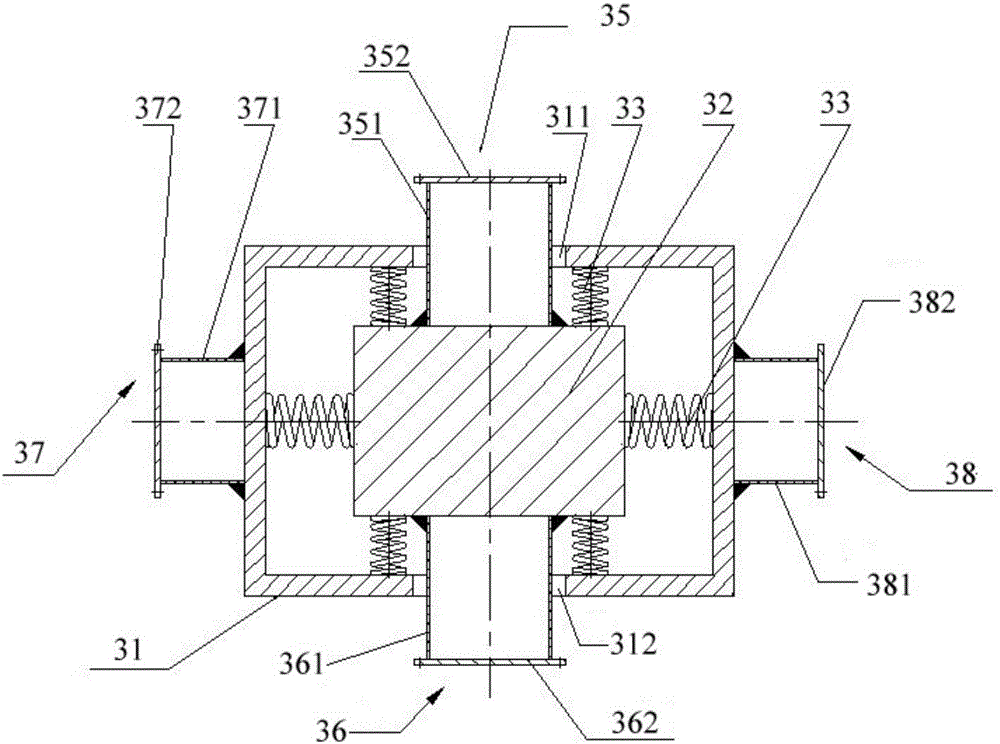

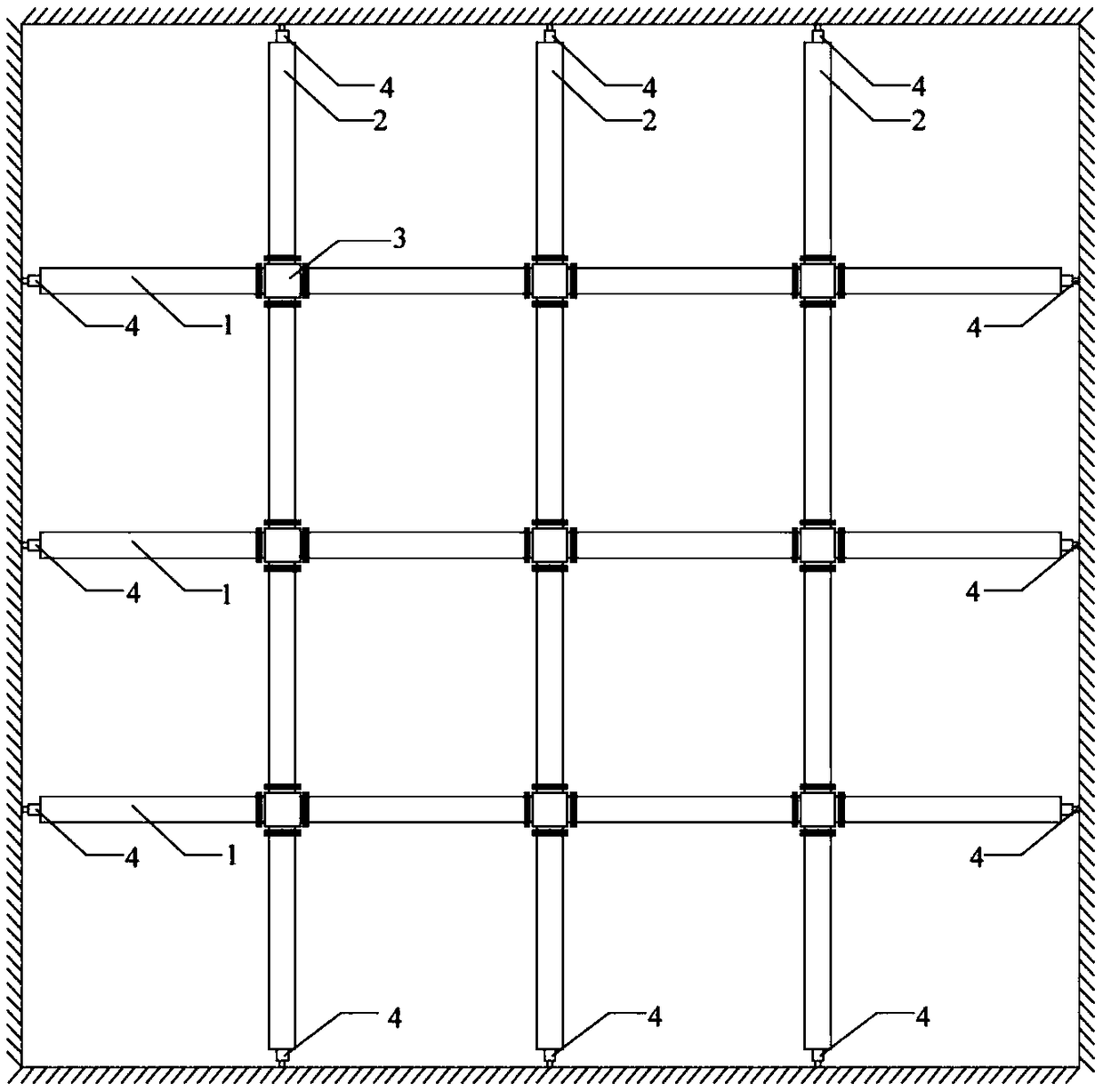

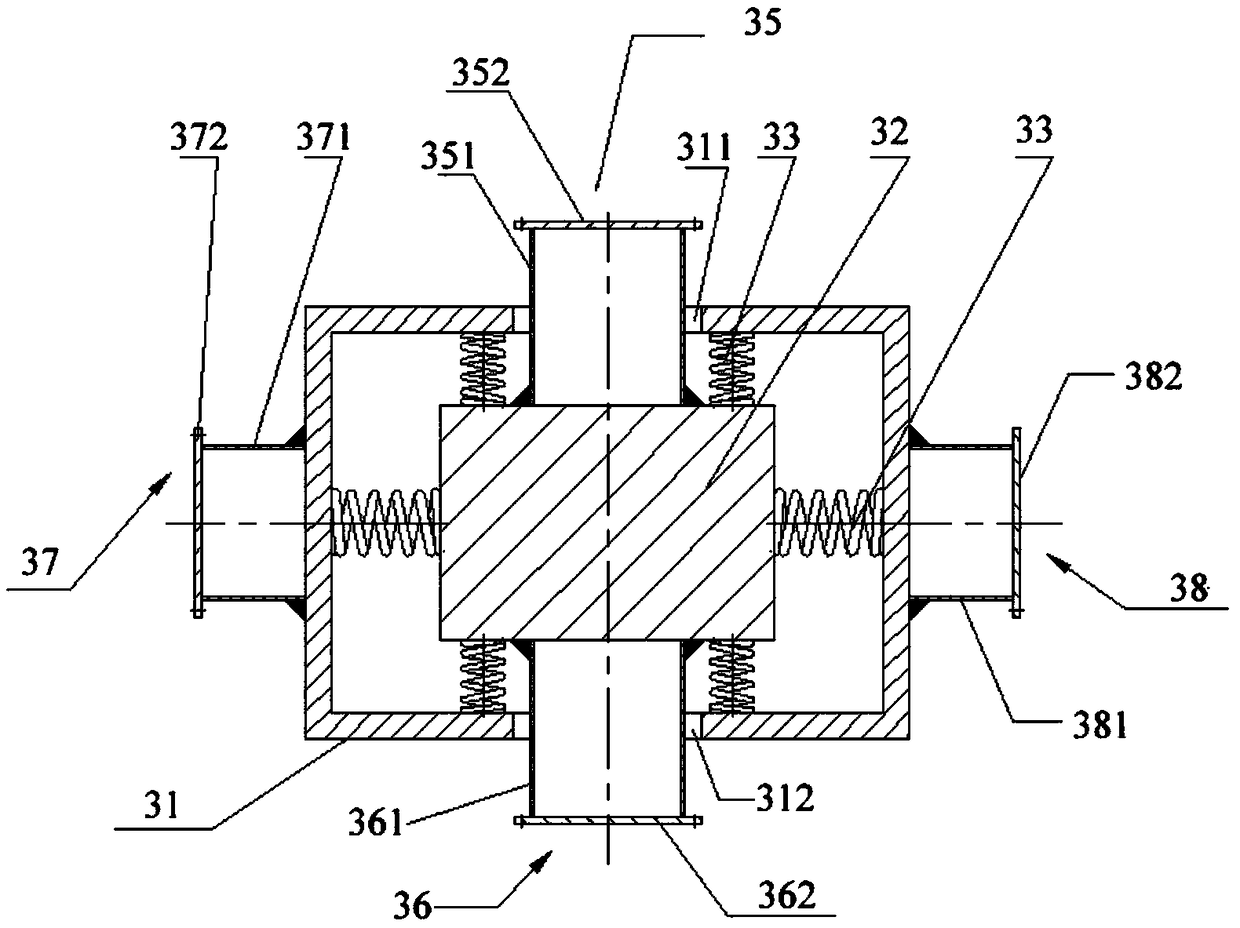

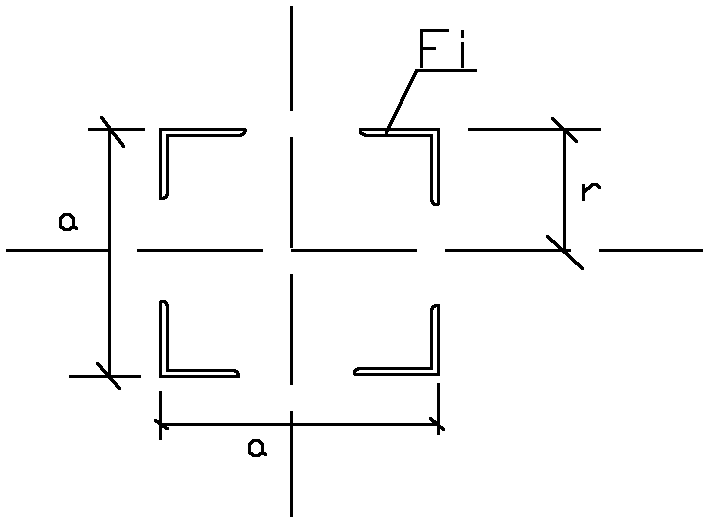

Dynamic regulation and control system and method for bidirectional steel supporting structure

ActiveCN106638614AImprove stress conditionReduce lateral displacementFoundation testingExcavationsControl systemAxial force

The invention provides a dynamic regulation and control system for a bidirectional steel supporting structure. The dynamic regulation and control system for the bidirectional steel supporting structure comprises the bidirectional steel supporting structure, axial force loading tools and a control center. The bidirectional steel supporting structure comprises flexible joints which are located at junctions of horizontal supports and vertical supports. Each flexible joint comprises an outer box, an inner box, a first connecting assembly and a second connecting assembly, wherein a first hole and a second hole coaxial with the first hole are formed in the surface of the outer box, and the inner box is arranged in the outer box; the first connecting assembly and the second connecting assembly penetrate through the first hole and the second hole correspondingly to be connected with the inner box; and elastic elements are arranged between the outer wall of the inner box and the inner wall of the outer box. The axial force loading tools are used for axial force loading of the horizontal supports or the vertical supports. The control center is used for controlling the working states of the axial force loading tools. By adoption of the dynamic regulation and control system for the bidirectional steel supporting structure, the problems that in the prior art, the additional bending moment of the bidirectional steel supporting structure is too large during axial force loading, and the bidirectional steel supporting structure cannot be regulated and controlled in real time are solved.

Owner:SHANGHAI MECHANIZED CONSTR GRP

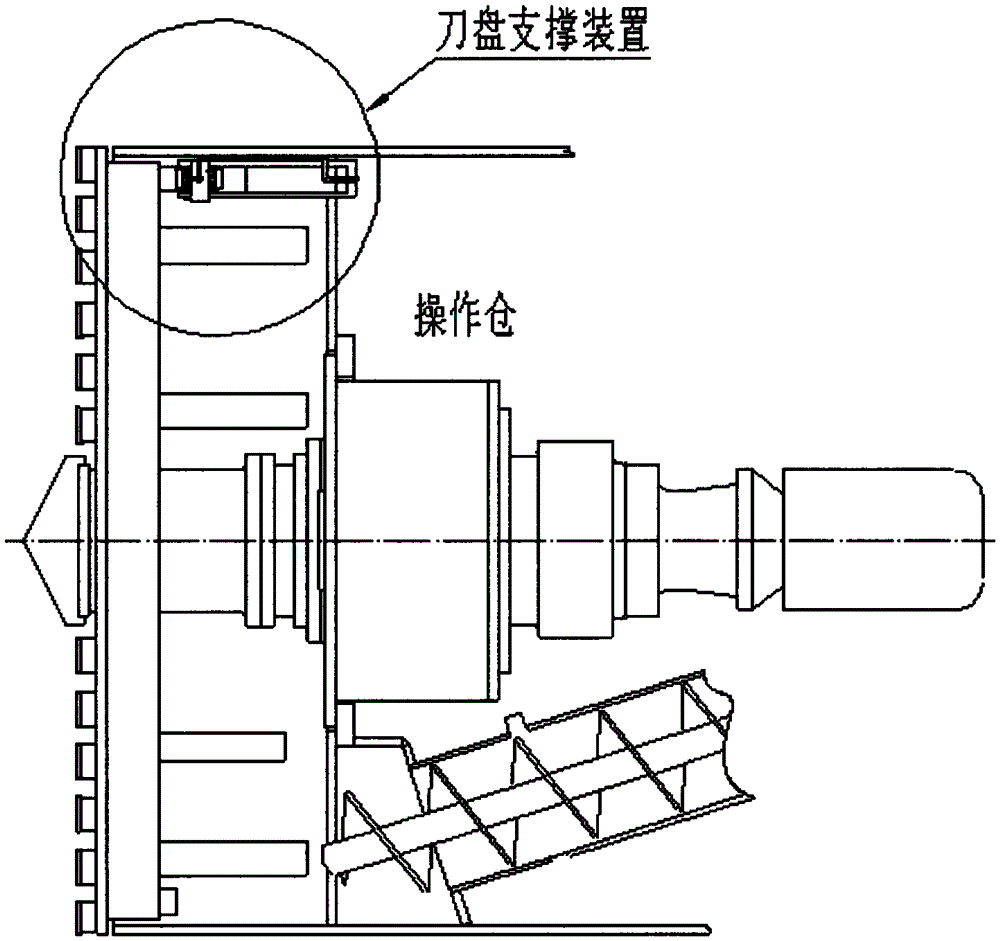

Cutterhead supporting device

InactiveCN105401949AReduce additional bending momentLow costTunnelsBiomedical engineeringBending moment

The invention provides a cutterhead supporting device. A plurality of cutterhead supporting units are arranged inside a heading machine to bear the rock-soil pressure. In this way, the additional bending moment applied on a cutterhead is reduced, and the expense in purchasing large bearings is reduced. Meanwhile, the device is convenient to install, repair and replace.

Owner:江苏银旭隧道机械有限公司

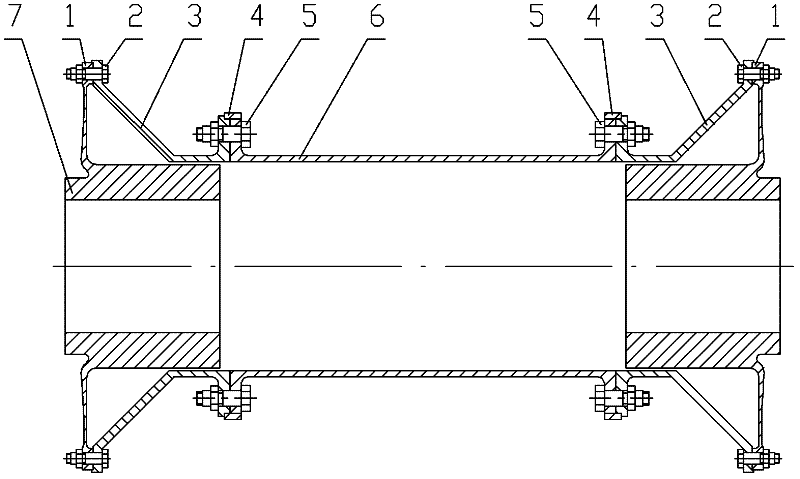

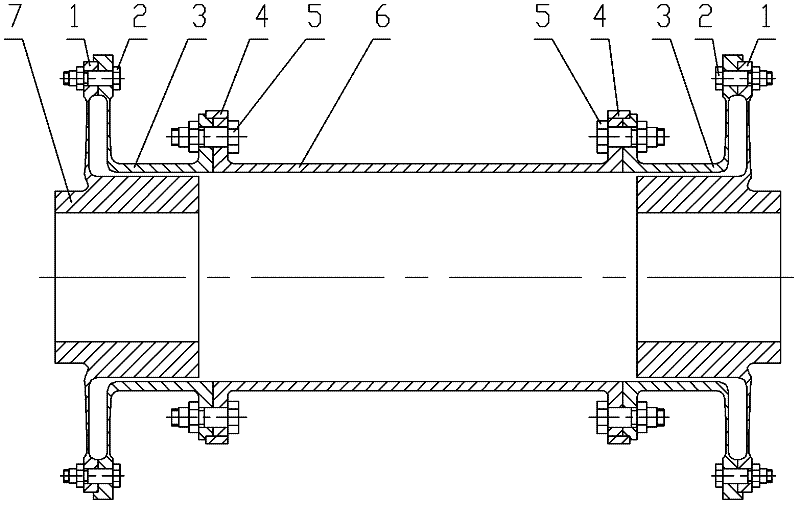

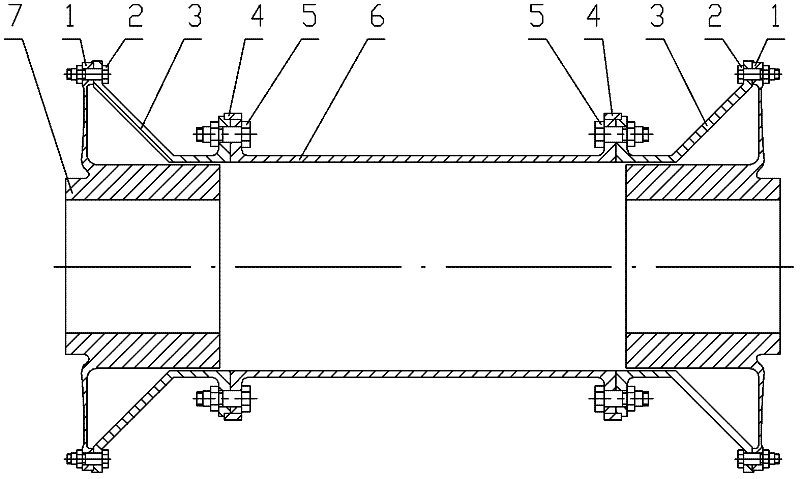

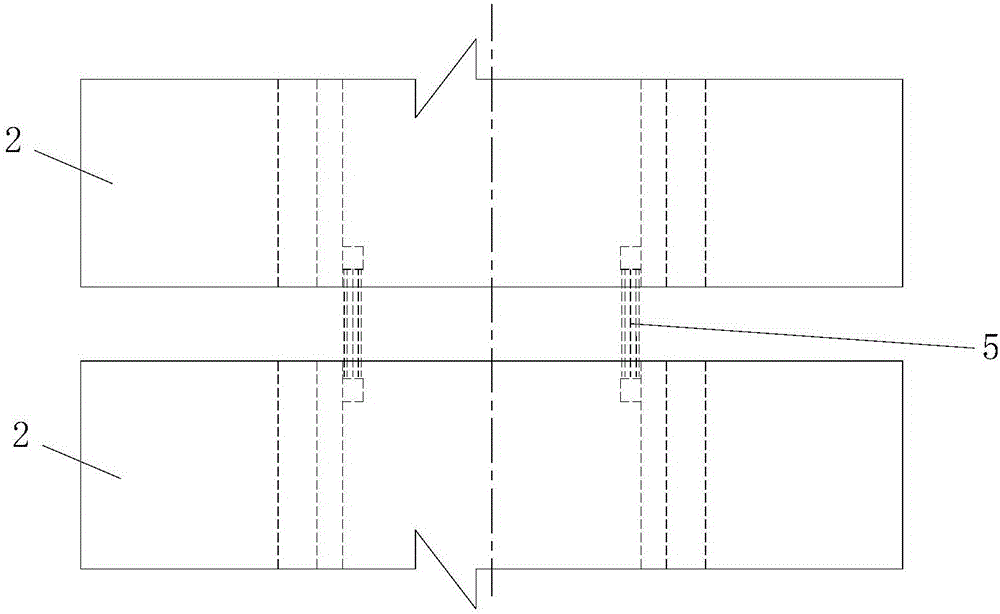

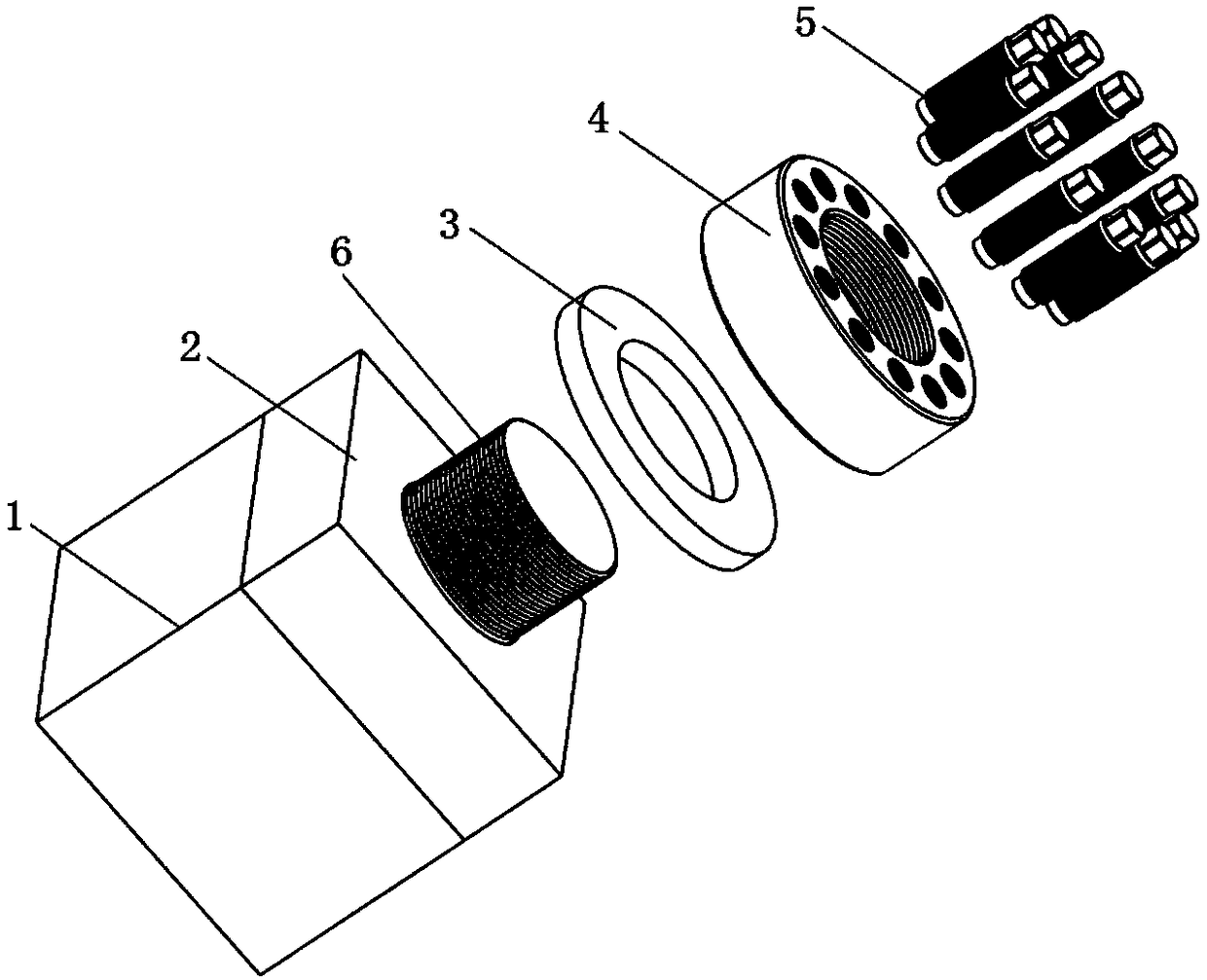

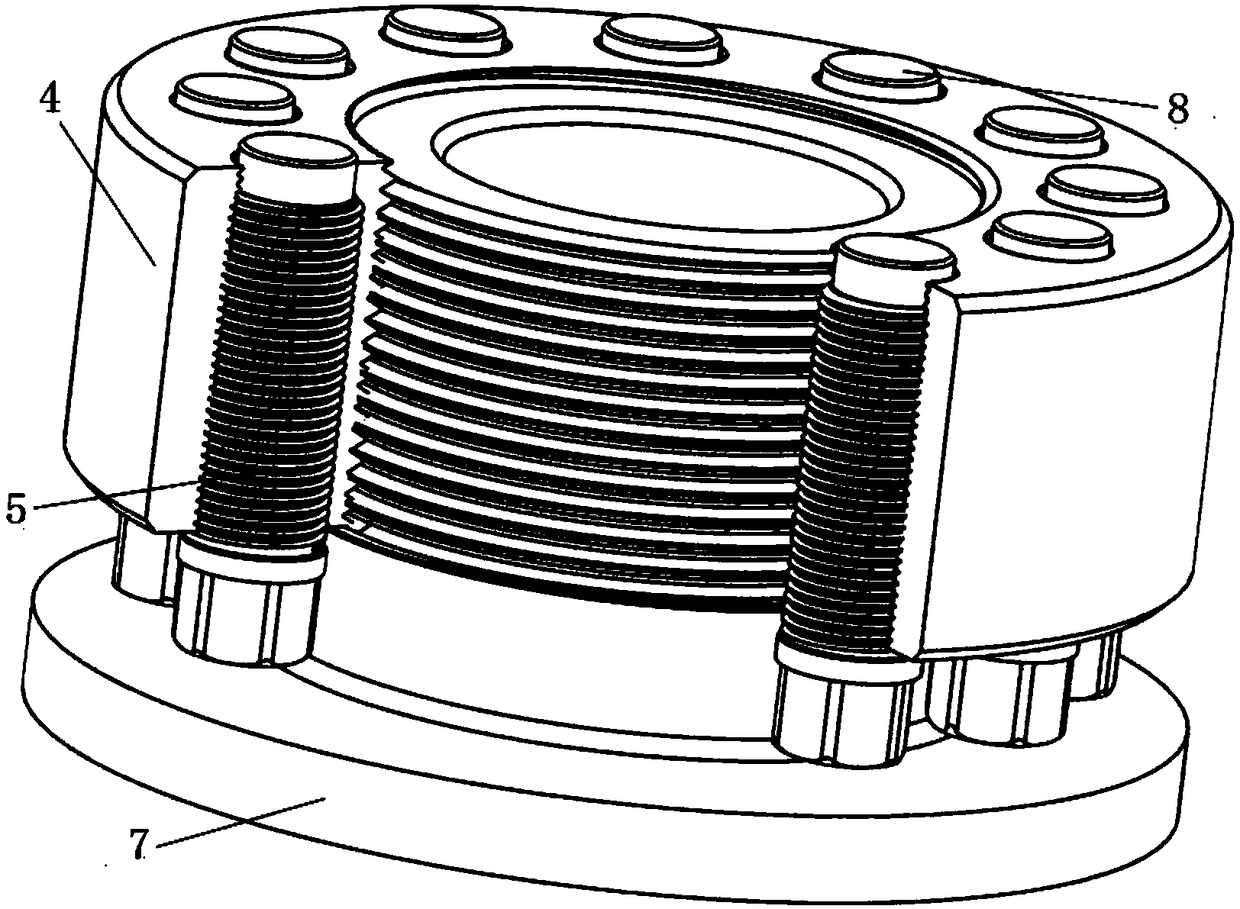

Diaphragm coupling with low additional bending moment

The invention relates to a diaphragm coupling with low additional bending moment. The diaphragm coupling comprises a middle isolating shaft, diaphragms, a mounting disc and switching discs, wherein the diaphragms are symmetrically arranged at the two ends of the middle isolating shaft; and the diaphragm coupling is characterized in that: the diaphragms and the mounting disc are in an integrated structure. The mounting disc is inserted into the switching discs; the diaphragms are positioned with the switching discs by using convex concave seams and are connected with the switching discs through first bolt components to transfer torsion moment; and the switching discs are positioned with the middle isolating shaft by using positioning rings and are connected with the middle isolating shaft through second bolt components to transfer torsion moment. One end of each switching disc is a first connecting end which is connected with the diaphragm, and the other end of the switching disc is a second connecting end which is connected with the middle isolating shaft; and a disc body of the switching disc is arranged between the first connecting end and the second connecting end. The profile of the disc body is right-angled or obtuse. In the diaphragm coupling, the diaphragms and the mounting disc are designed to be in the integrated structure; the diaphragm coupling has a simple structure and light weight; and the weight and the additional bending moment of the diaphragm coupling are effectively reduced.

Owner:无锡创明传动工程有限公司

Bottom plate jacking system for jacking closure section of continuous rigid frame bridge and construction method of bottom plate jacking system

The invention discloses a bottom plate jacking system for jacking a closure section of a continuous rigid frame bridge and a construction method of the bottom plate jacking system. The bottom plate jacking system comprises two sets of bottom plate embedded bases arranged at the ends of two cantilever beam sections of the continuous rigid frame bridge correspondingly, rigid supporting structures supported between the two sets of bottom plate embedded bases and a jacking mechanism used for jacking the rigid supporting structures. Each set of bottom plate embedded bases comprises a left bottom plate embedded base and a right bottom plate embedded base distributed on the same cantilever beam section. The rigid supporting structures are supporting structures for longitudinal jacking or supporting structures for oblique jacking. One ends of the rigid supporting structures are the fixing ends, and the other ends of the rigid supporting structures are jacking ends. The construction method comprises the steps of (1) construction of the bottom plate embedded bases, (2) mounting of the jacking mechanism and (3) mounting of the rigid supporting structures. The bottom plate jacking system is reasonable in design, easy and convenient to construct and good in use effect, the jacking process of the cantilever beam sections on the two sides of the closure section can be completed easily, conveniently and rapidly, and the correction requirements of lateral deviation and reverse deviation of the cantilever beam sections can be met.

Owner:XIAN HIGHWAY INST

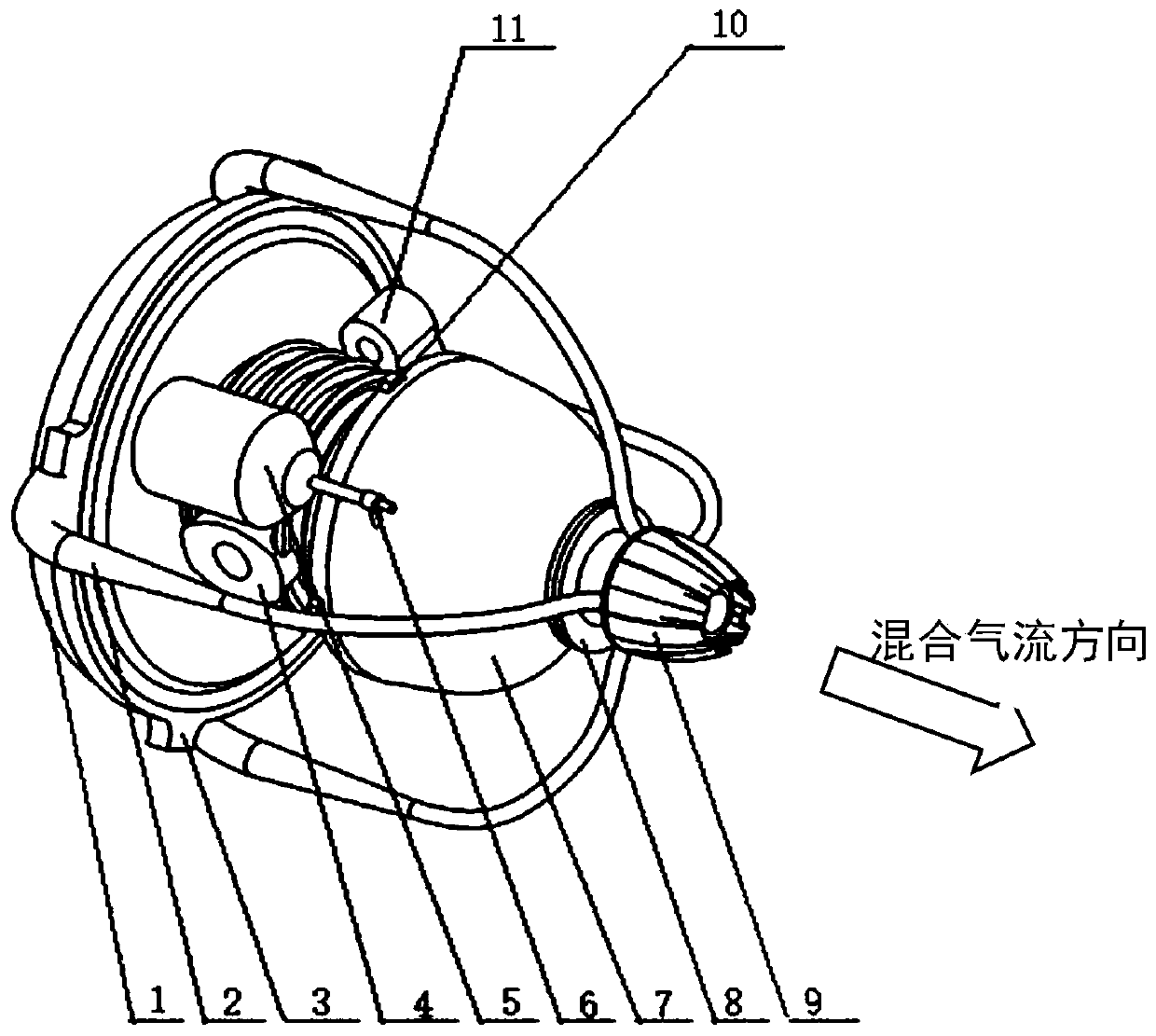

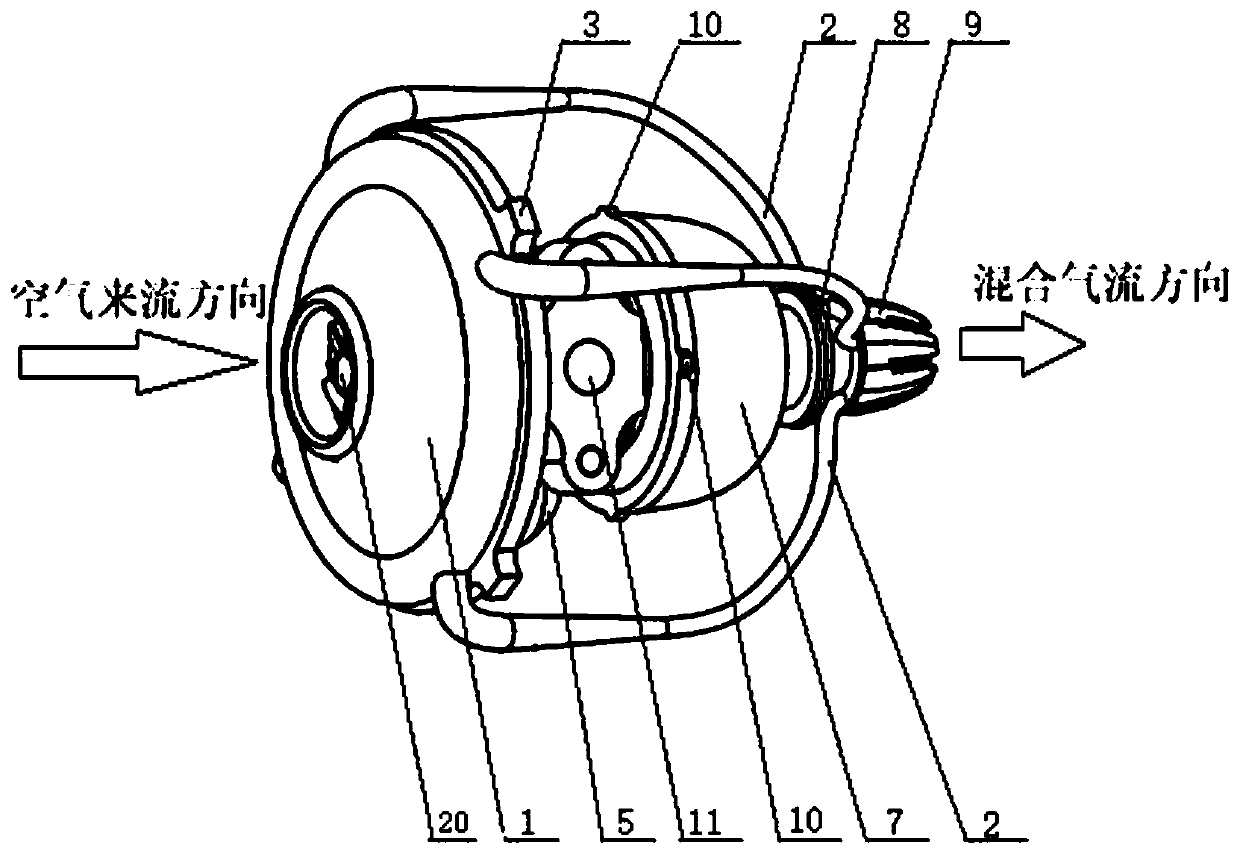

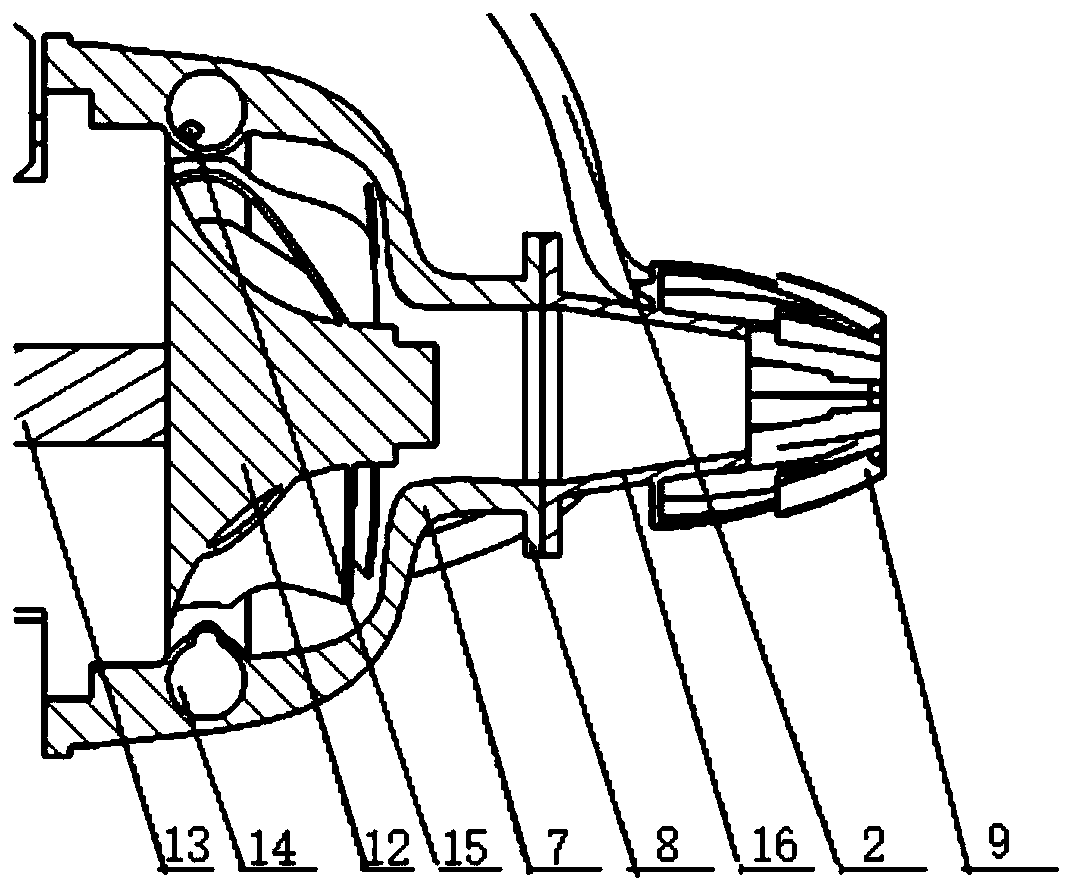

Device for providing air and rich combustion fuel gas and engine of deice

PendingCN109826721AWell mixedImprove combustion efficiencyGas turbine plantsRam jet enginesCombustion chamberTurbine

The invention discloses a device for providing air and rich combustion fuel gas. The device comprises a supercharger, a turbine assembly, an air conveying pipeline, a fuel gas generator and a mixer; the turbine assembly is arranged at the rear end of the supercharger; one end of the air conveying pipeline is connected with the supercharger, and the other end of the air conveying pipeline is connected with the mixer; the air conveying pipeline is used for conveying air; the fuel gas generator is connected with the turbine assembly and is used for conveying the rich combustion fuel gas; and themixer is arranged on the rear portion of the turbine assembly and communicates with the turbine assembly. The invention further provides an air turbine rocket engine. Due to the device, the air and the rich combustion fuel gas can be mixed uniformly, and the combustion efficiency of an engine combustion chamber is improved to a very large extent.

Owner:CENT SOUTH UNIV

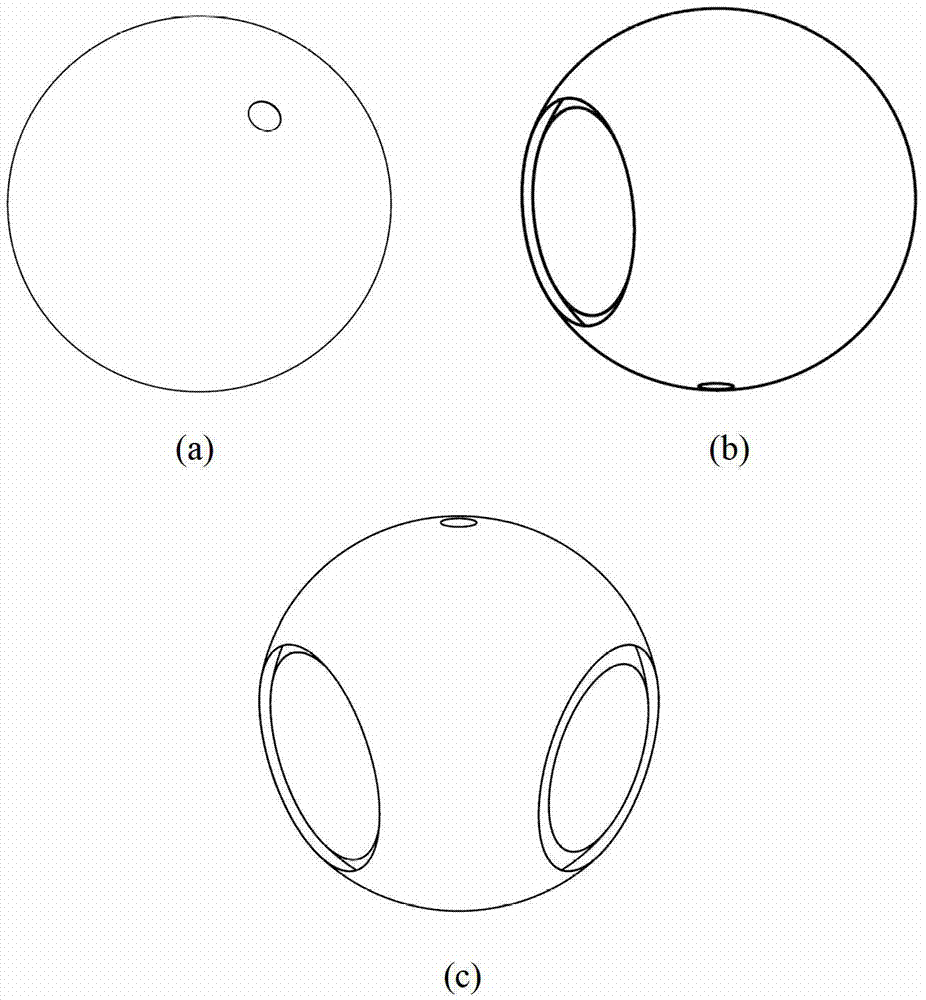

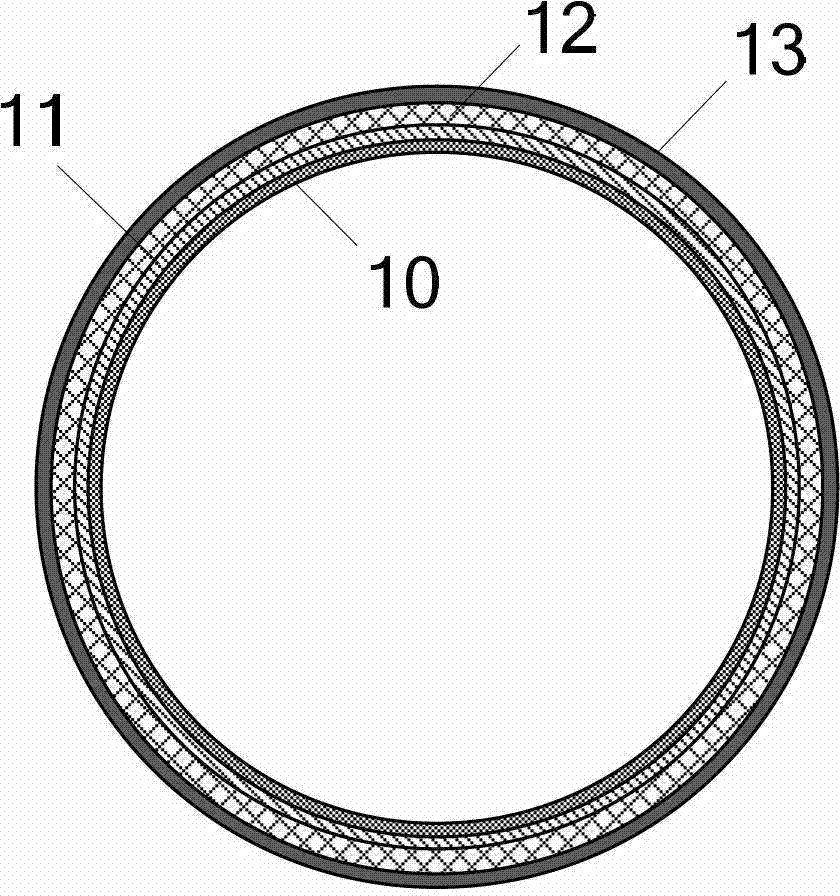

Insertion opening crack resisting structure for prestressed concrete cylinder pipes and manufacturing method of structure

InactiveCN105736851AImprove product qualityIncreased durabilityRigid pipesPre stressPrestressed concrete

The invention discloses an insertion opening crack resisting structure for prestressed concrete cylinder pipes (PCCPs) and a manufacturing method of the structure, and belongs to the technical field of composite concrete pipes. The insertion opening crack resisting structure for the PCCPs comprises a deformation joint reserved on the outer side of an insertion-opening-end special-shaped steel ring, a thin steel ring lined to an insertion-opening-end pipe core and steel fiber reinforced concrete adopted as the insertion-opening-end pipe core. The steel fiber reinforced concrete is used at the PCCP insertion opening end and the inner wall of the PCCP insertion opening end is lined with the thin steel ring, so as to improve bending resistance of the insertion opening end, resist to additional bending moment caused by the fact that pipelines wind prestressed wires and reduce large outward turning deformation of the insertion opening end pipe core; the deformation joint is reserved on the outer side of the insertion-opening-end special-shaped steel ring, so that pipeline deformation compatibility is met, additional bending moment is lowered, ring cracks are prevented from transferring to the concrete of the inner wall of the pipe core, and production quality and durability of the PCCPs can be improved significantly; the crack resisting structure can realize seamless joint with the existing PCCP production way, and has the advantages of simplicity in operation and low cost.

Owner:DALIAN UNIV OF TECH

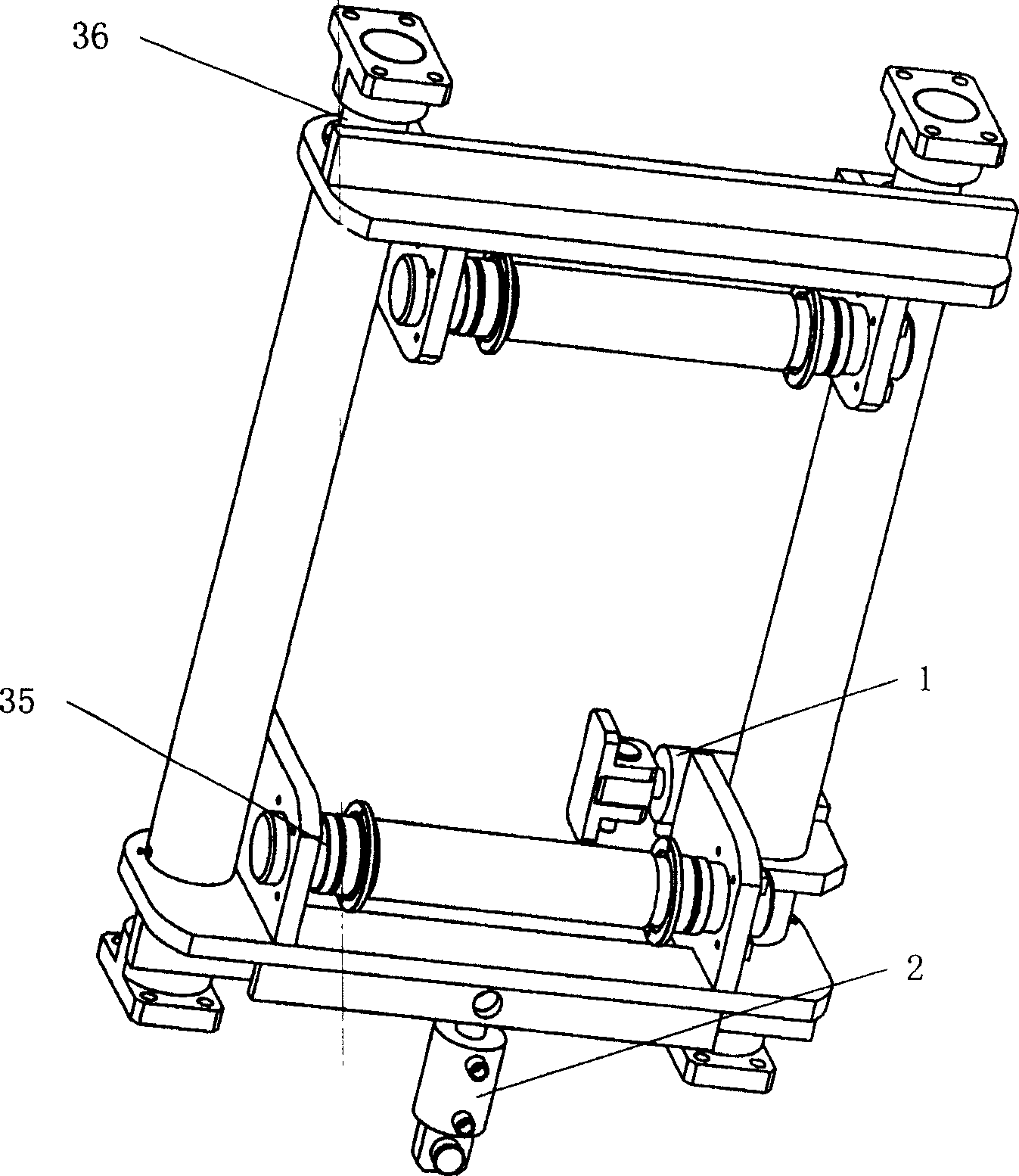

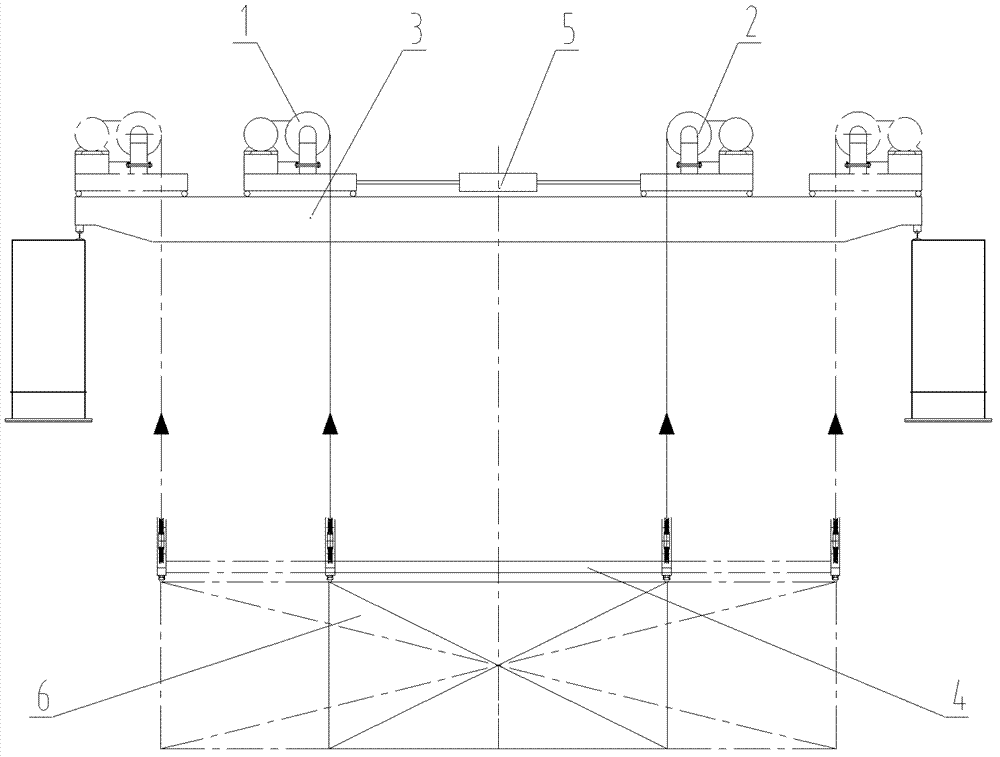

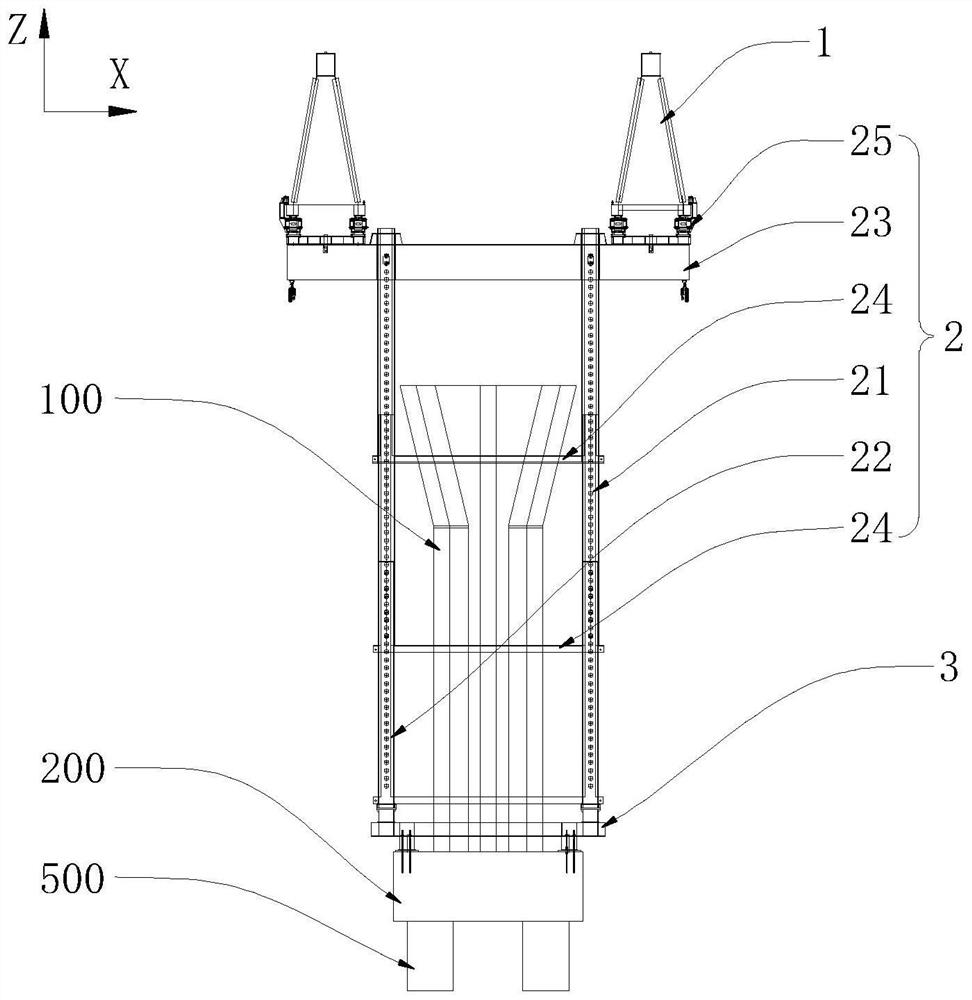

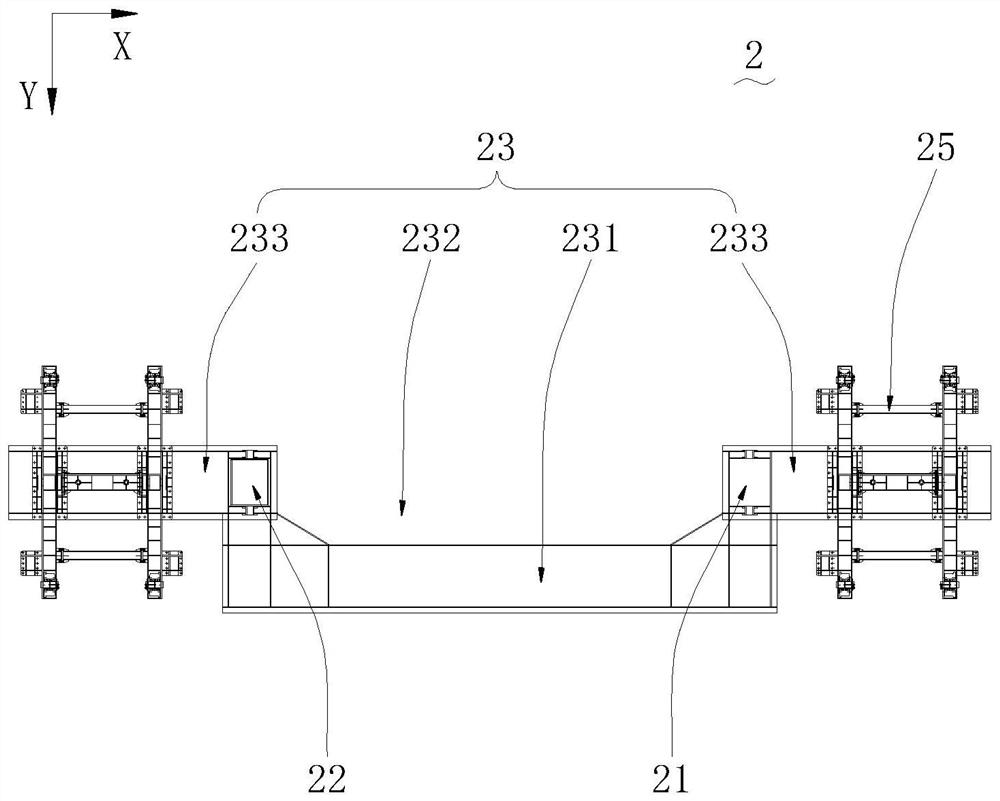

Gantry crane and hoisting mechanism thereof

InactiveCN102502417BGuaranteed locking forceReduce additional bending momentTravelling cranesLoad-engaging elementsEngineeringMechanical engineering

The invention discloses a hoisting mechanism of a gantry crane. The hoisting mechanism comprises a left hoisting assembly (1) and a right hoisting assembly (2) which are symmetrically arranged on a trolley rack (3), wherein the left hoisting assembly (1) and the right hoisting assembly (2) are in movable connection with the trolley rack (3), so that the left and right hoisting assemblies move leftward and rightward relatively to the trolley rack; and the contact hoisting points between the left hoisting assembly (1) and a hoisting tool (4) as well as between the right hoisting assembly (2) and the hoisting tool (4) are located just above the hoisting point of the locking and hoisting object of the hoisting tool (4). By adopting the hoisting mechanism, the stresses of the hoisting tool and the trolley rack are improved, thus the weights of the hoisting tool and the trolley rack are alleviated, the hoisting load is alleviated and the energy is saved. In addition, the invention also discloses the gantry crane comprising the hoisting mechanism.

Owner:SANY MARINE HEAVY IND

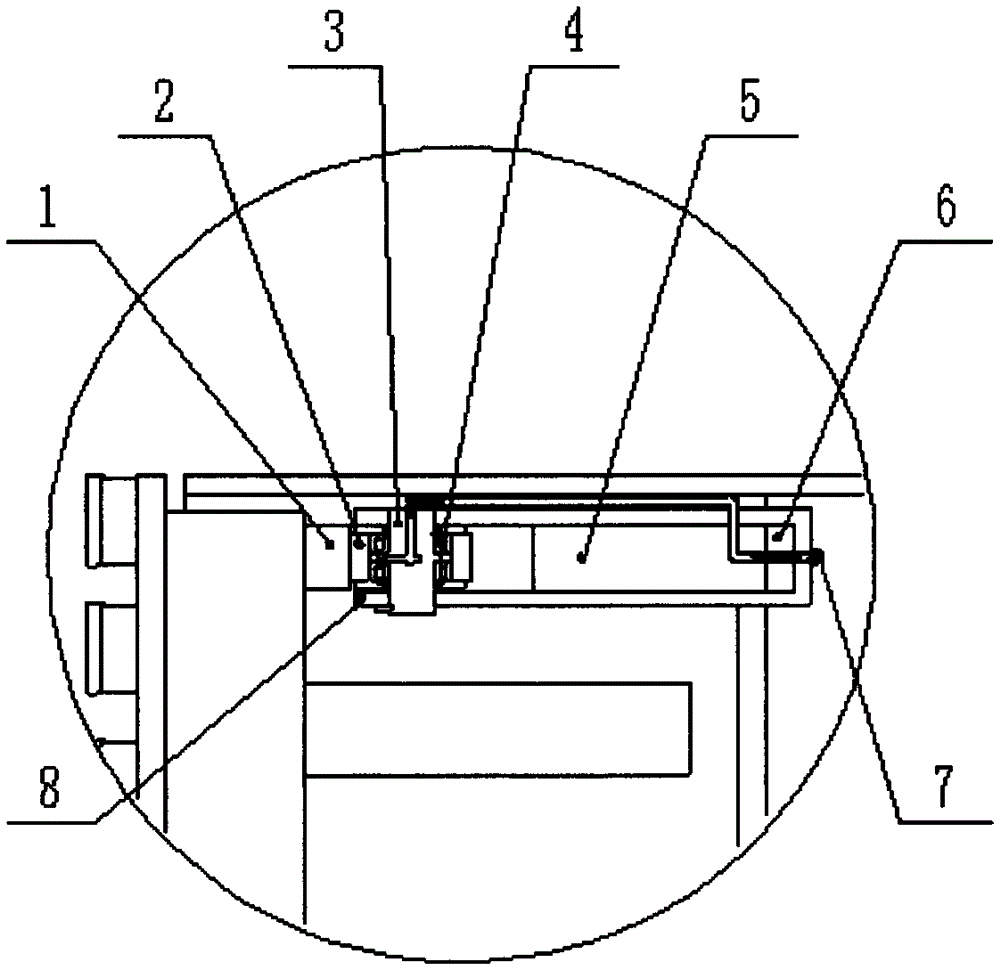

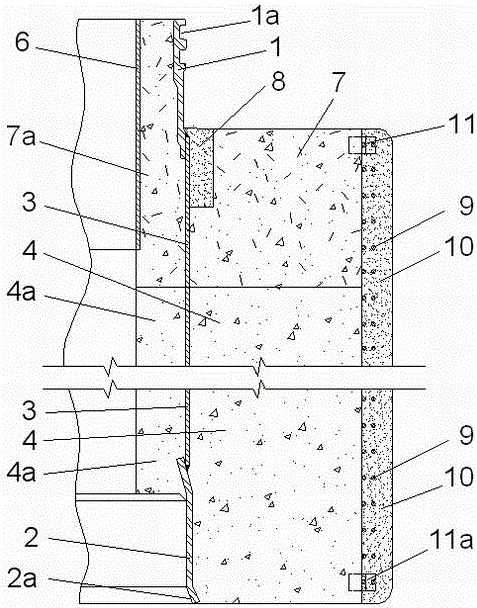

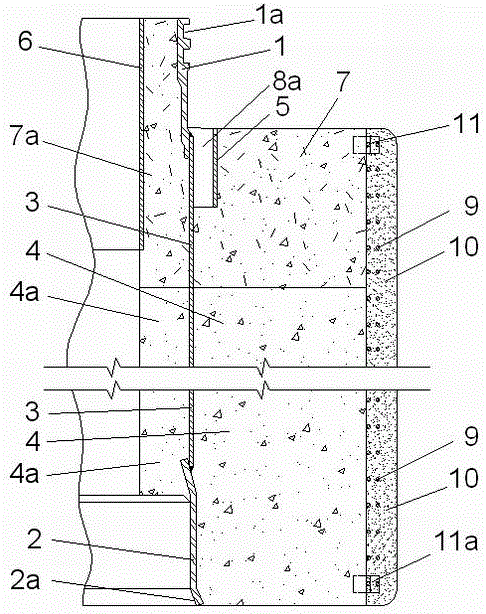

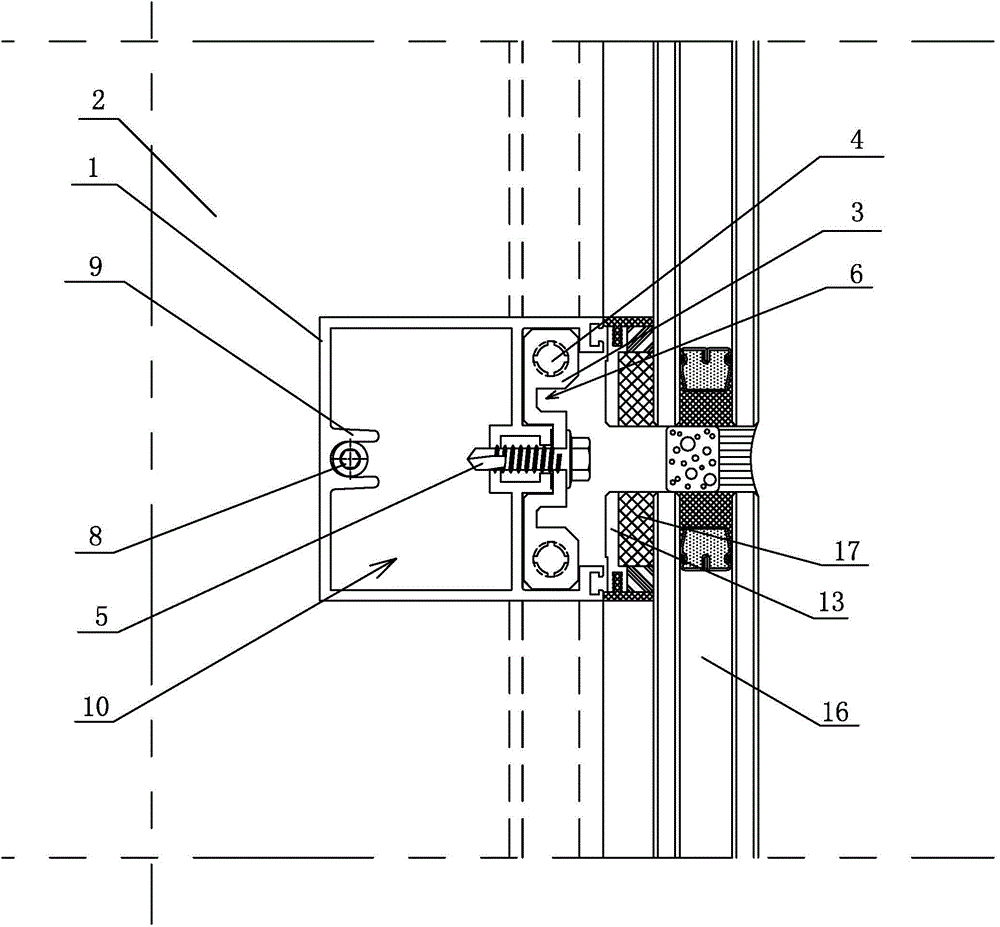

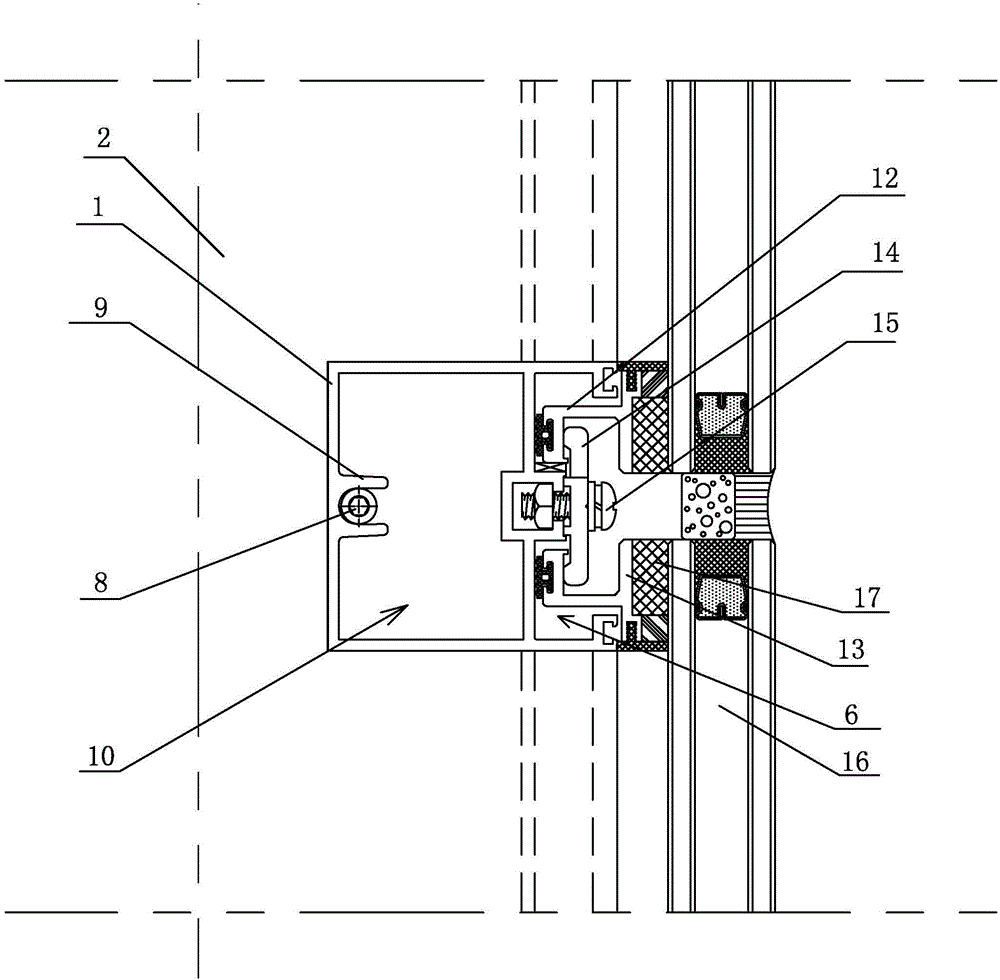

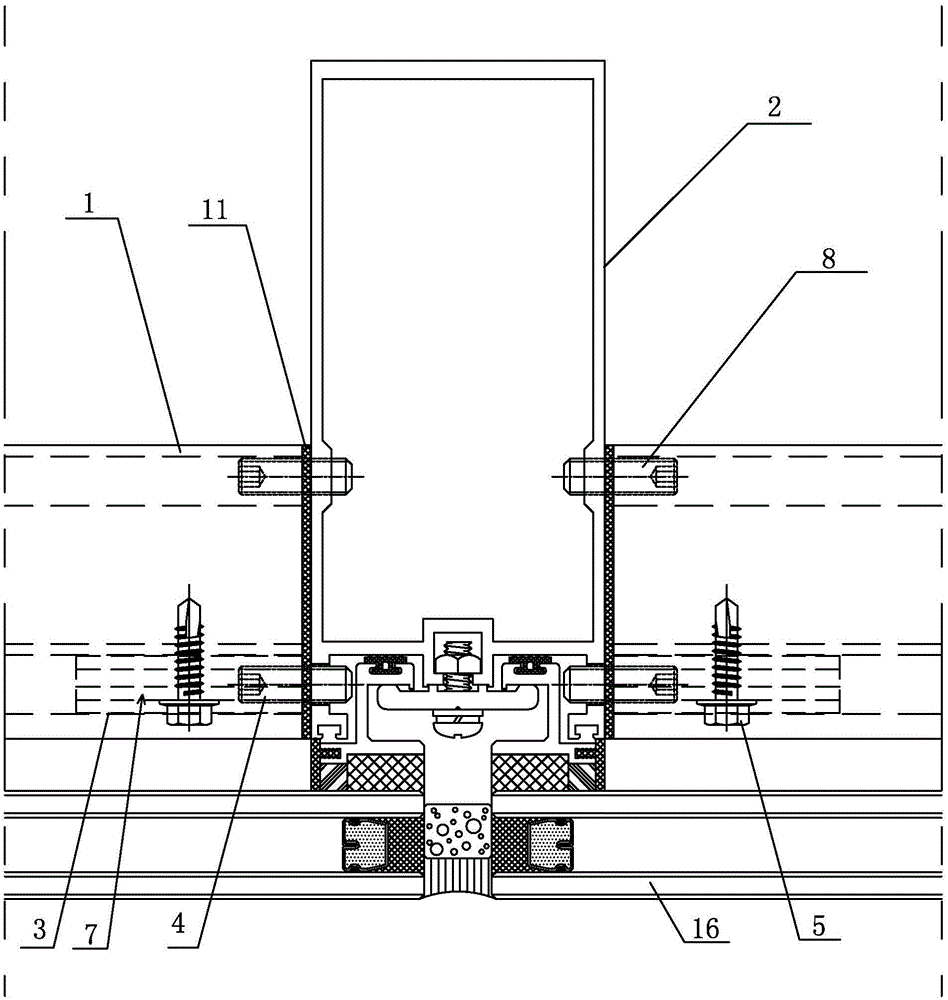

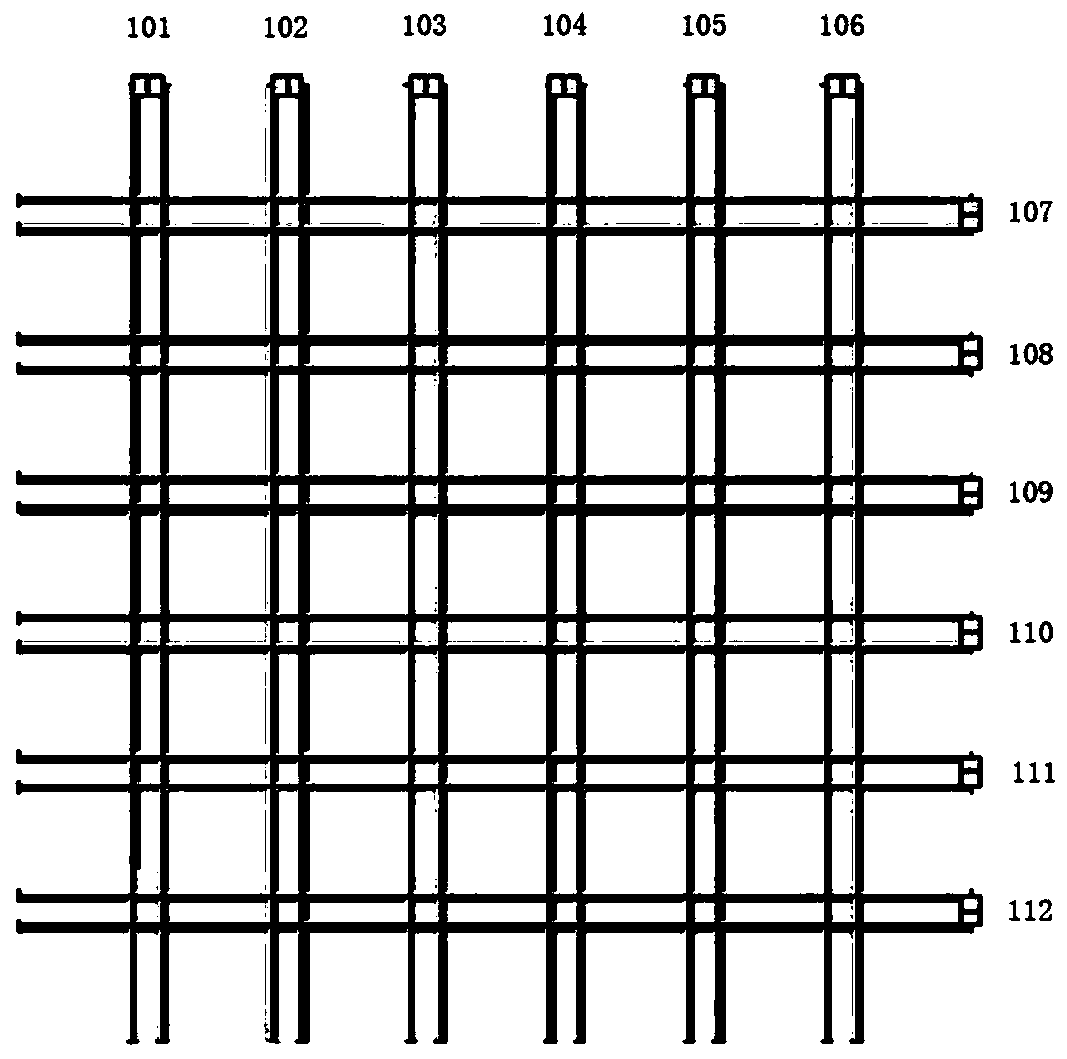

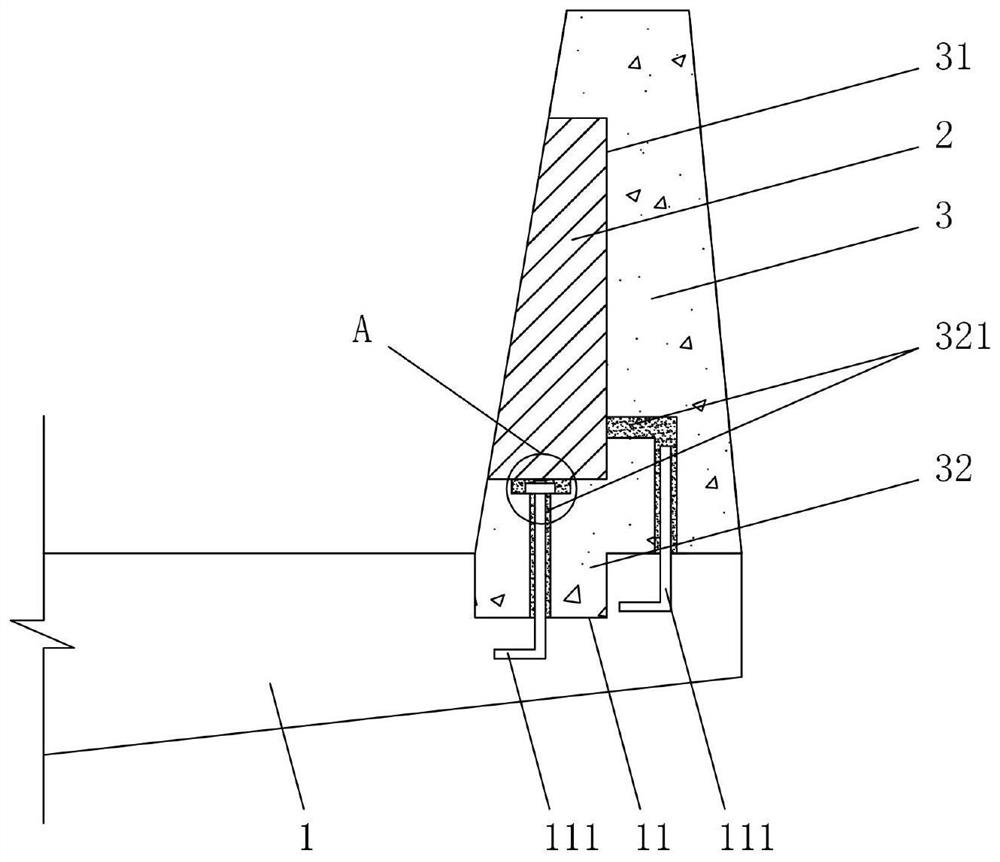

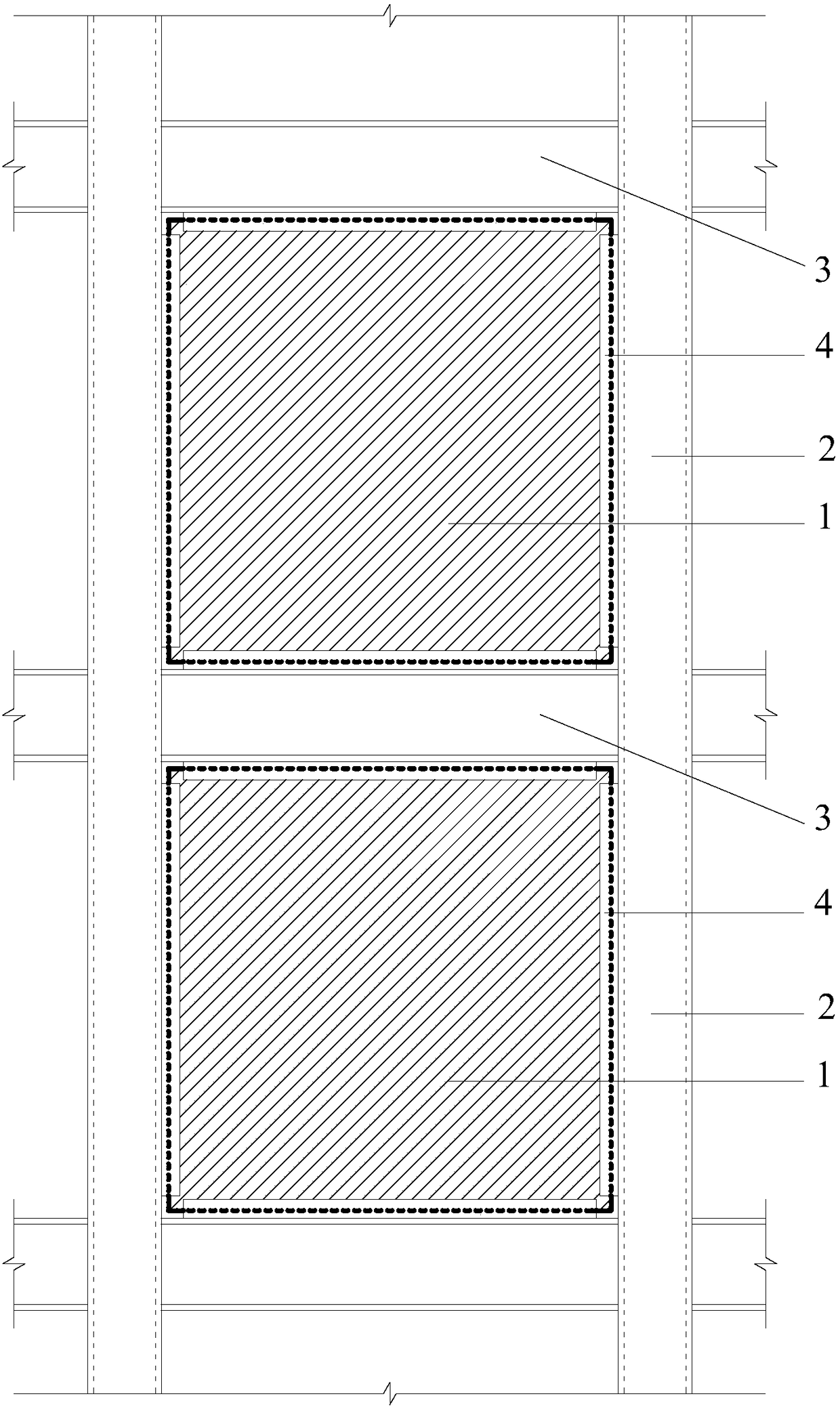

Construction method of beam and column connection structure in glass curtain wall

ActiveCN104695599BReduce additional bending momentQuick installationWallsCross connectionEngineering

Owner:苏州苏明装饰股份有限公司

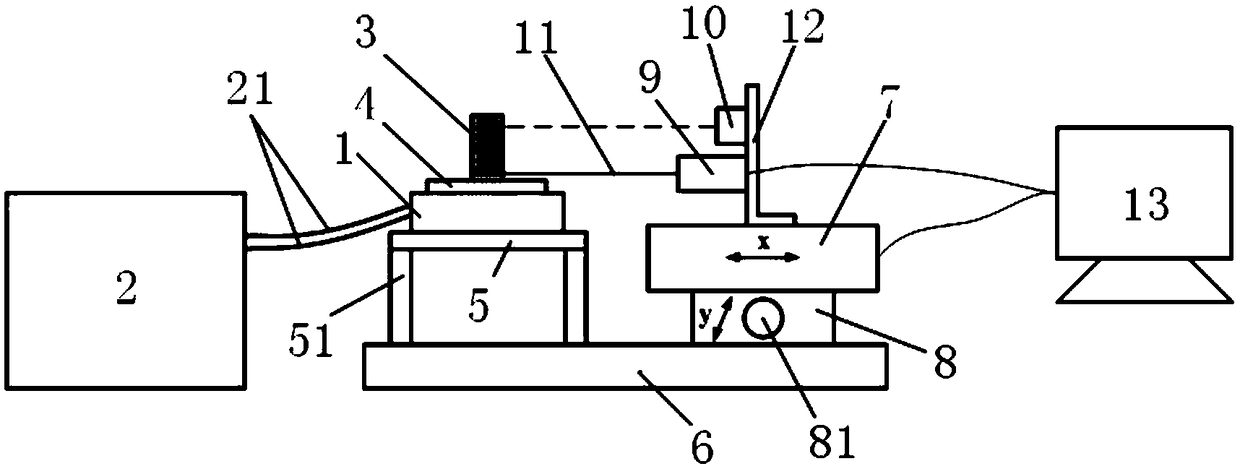

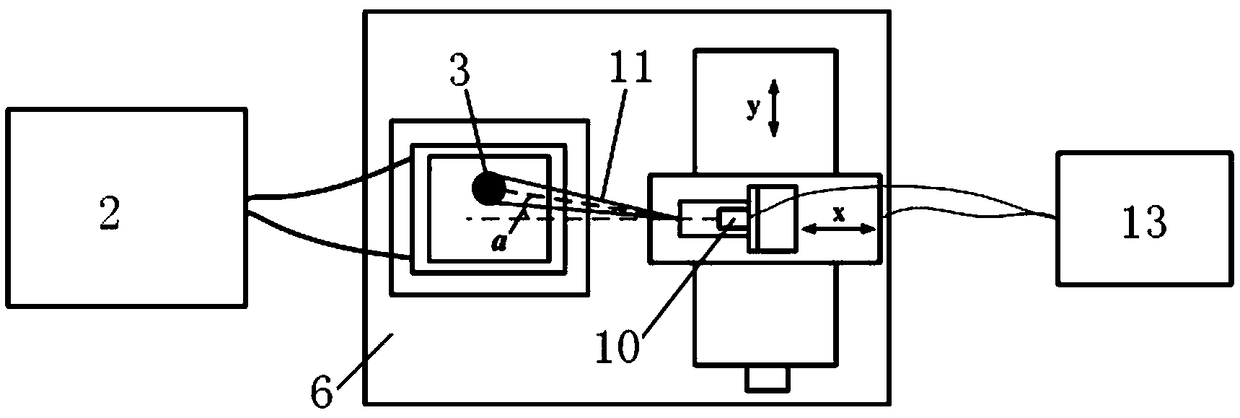

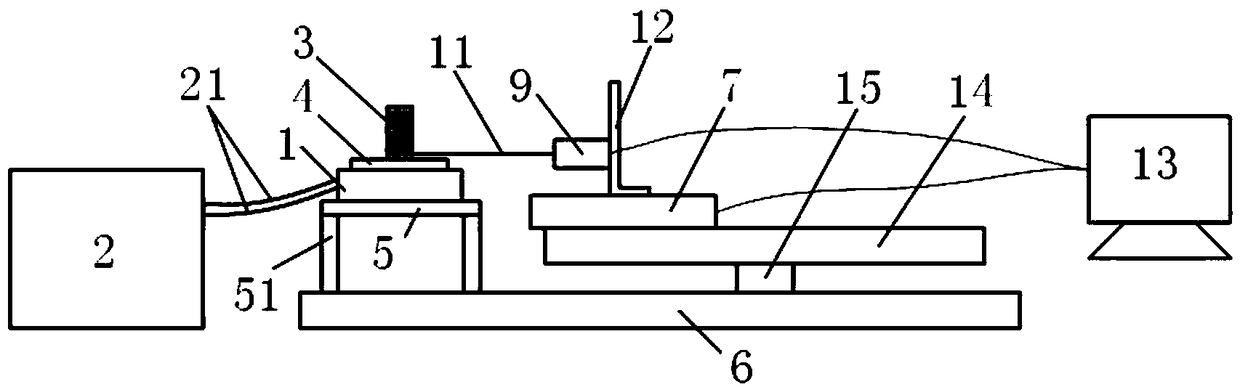

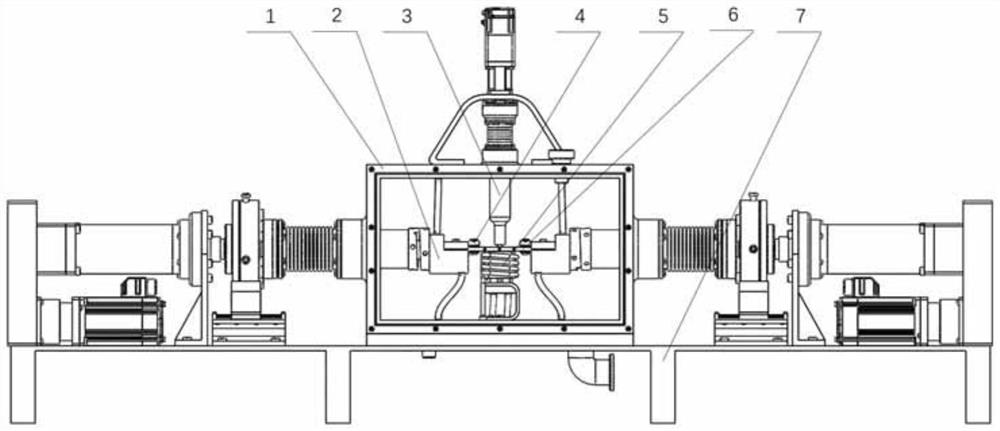

In-situ testing device and method for friction and wear of material under high-temperature prestress loading

PendingCN114062172AEasy to installNovel and compact structureInvestigating abrasion/wear resistanceAcoustic emissionModular design

The invention relates to an in-situ testing device and method for friction and wear of a material under high-temperature prestress loading, and belongs to the field of friction and wear performance testing of the material at a high temperature. The middle of the upper portion of a rack is fixedly connected with a test cavity, prestress loading and driving modules symmetrically arranged on the two sides horizontally penetrate through the test cavity respectively and are fixedly connected with the upper portion of the rack, the prestress loading and driving modules are fixedly connected with a friction test piece, an acoustic emission in-situ monitoring module is installed on the friction test piece, a high-temperature loading module is fixed in the test cavity through a bolt and located below the friction test piece, and a friction load loading module penetrates through the upper surface of the test cavity, is supported by a supporting frame and is in bolt connection with the test cavity through a corrugated pipe. The device and method have the advantages of novel structure, modular design, simplicity in installation and maintenance, capability of researching the damage mechanism of a material under the condition of simultaneous loading of frictional wear and axial load, high heating speed, energy conservation and capability of ensuring the accuracy of experimental data.

Owner:JILIN UNIV

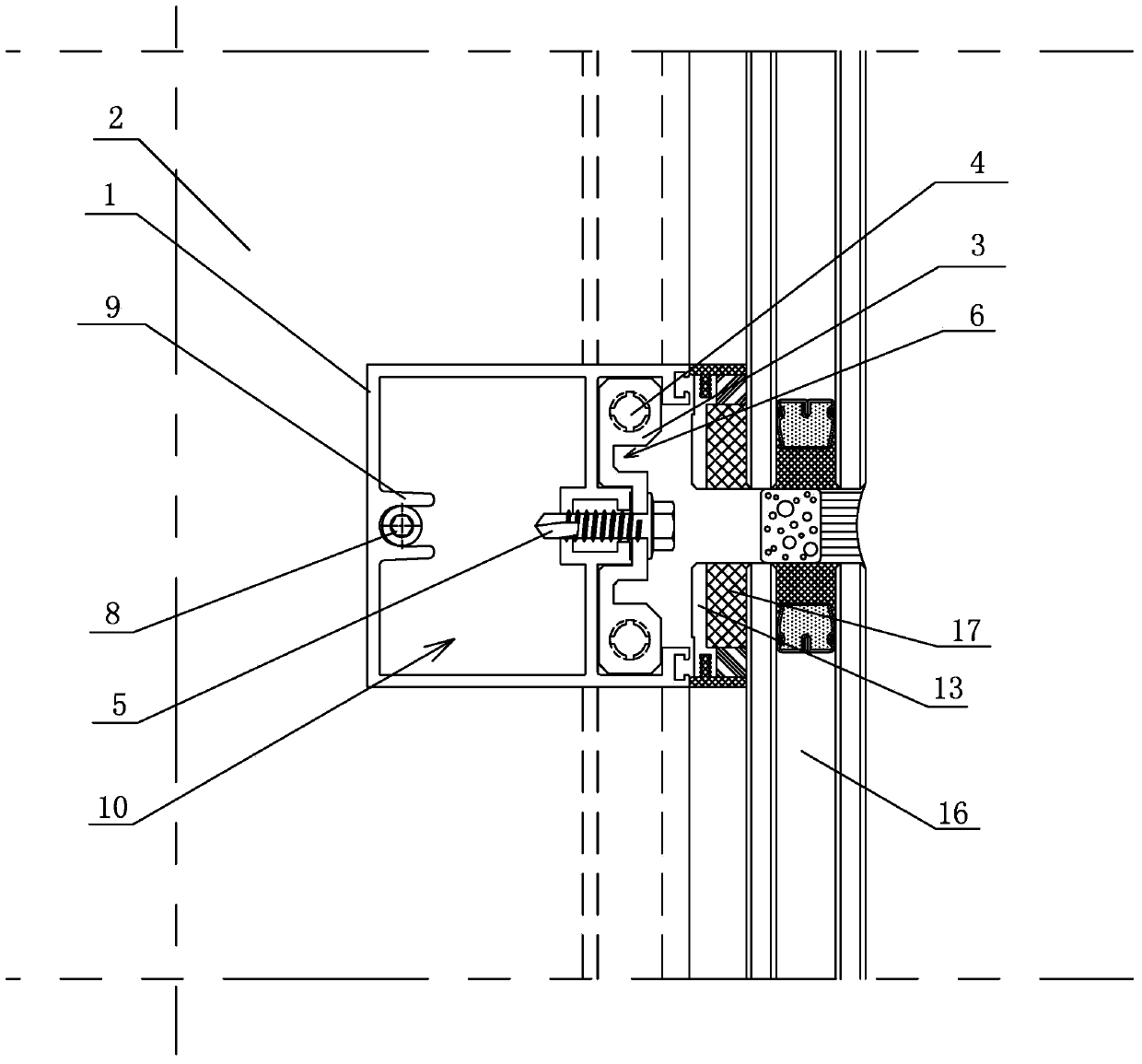

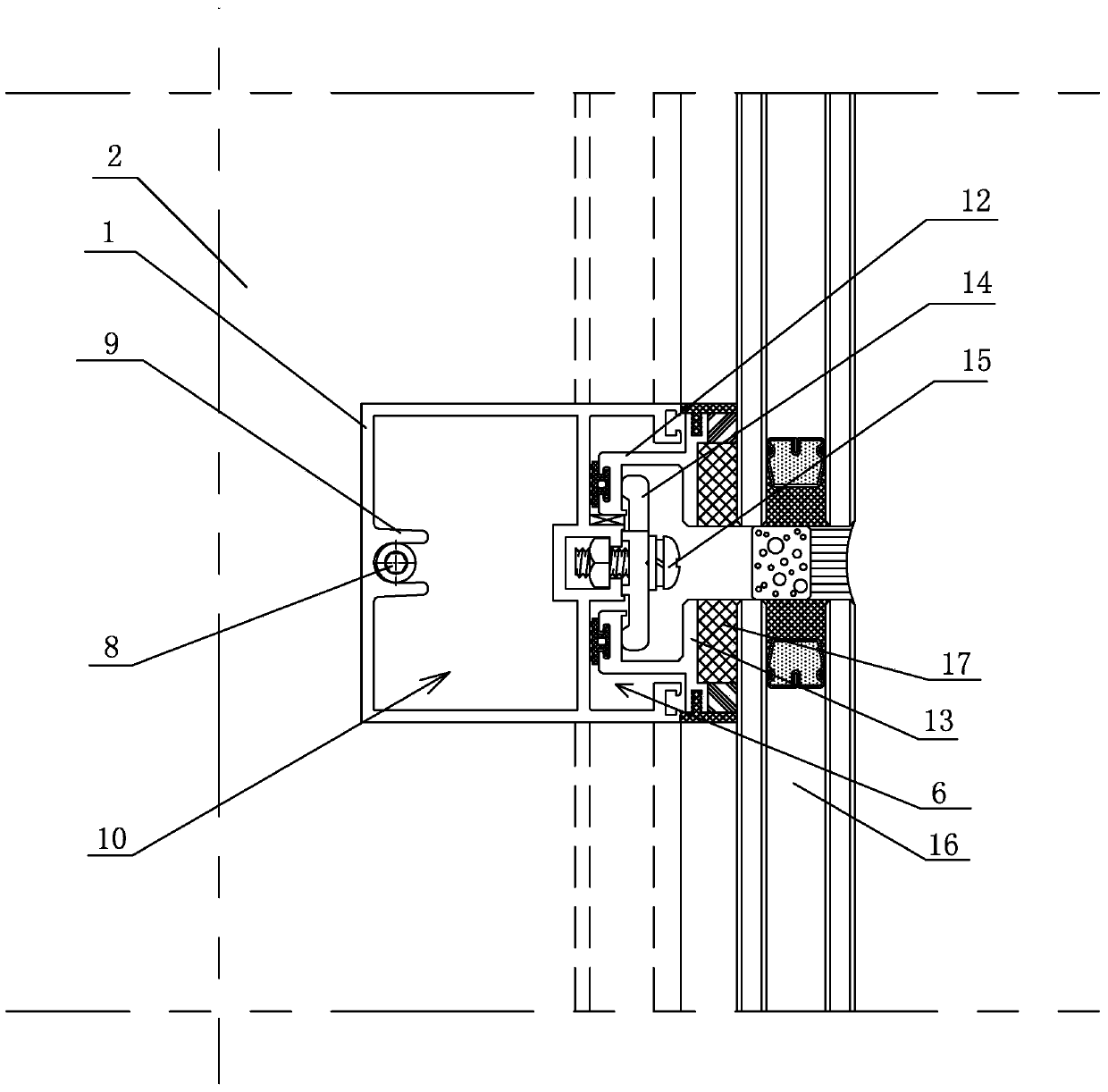

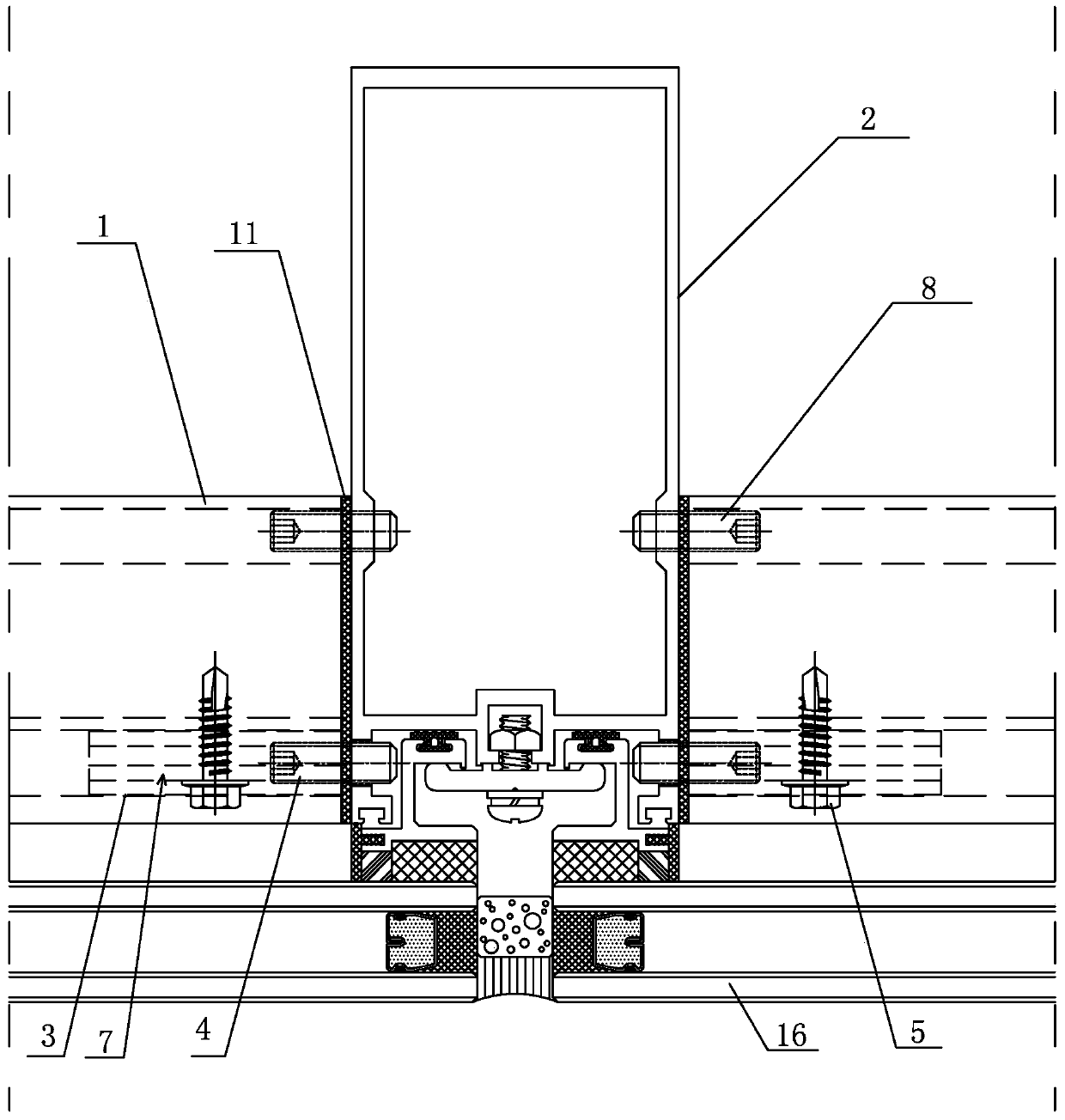

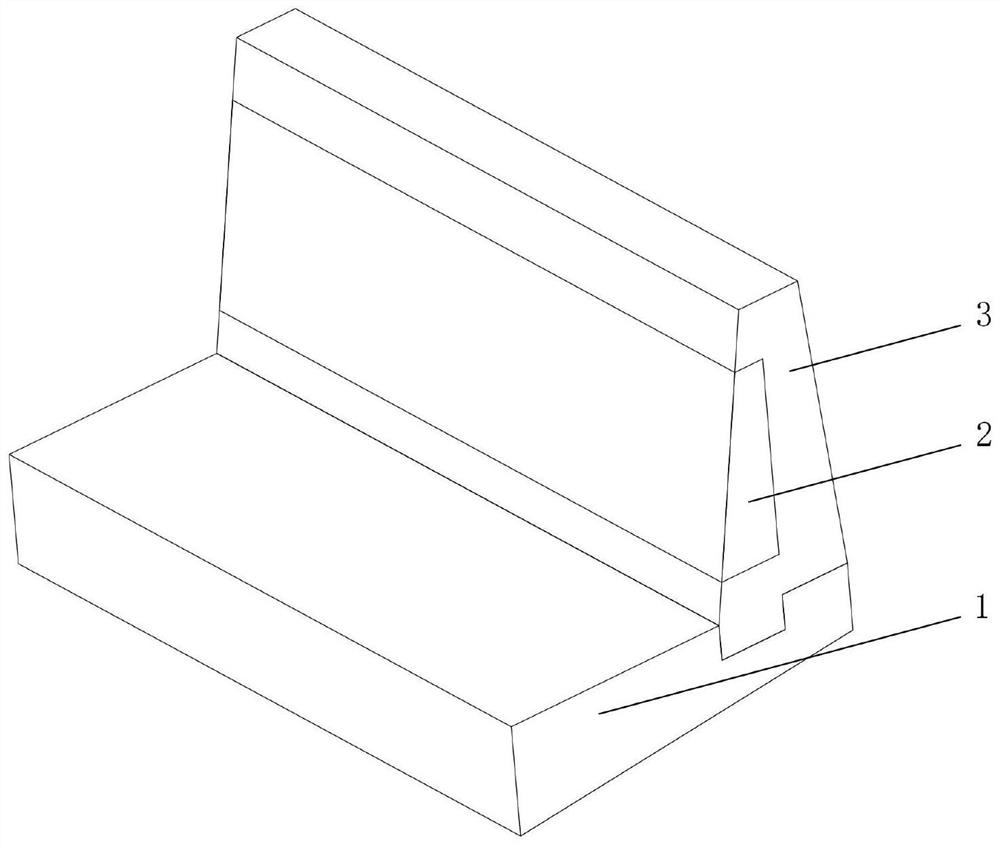

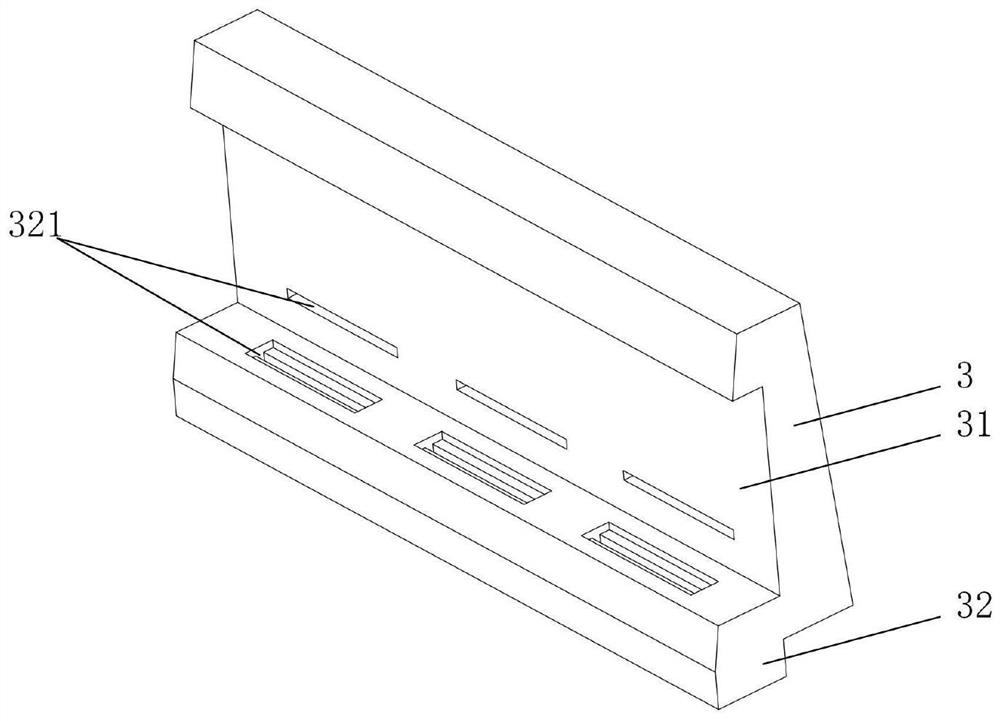

Beam and column connection structure in glass curtain wall and construction method thereof

The invention discloses a beam and column connection structure in a glass curtain wall and a construction method thereof. The beam and column connection structure is characterized by comprising a connecting piece at the position where a beam and a column are connected, transverse locating screws and longitudinal connecting screws, wherein the transverse locating screws and the longitudinal connecting screws are used for fixing the connecting piece. The connecting piece is inserted into an auxiliary frame insertion groove at the front end of the beam. The transverse locating screws are fixed with the column through screw holes and connecting holes. The longitudinal connecting screws are fixed with the beam through fixing holes. The beam and column connection structure further comprises a back end locating screw perpendicular to an outer wall of the column. A back side wall of the beam is provided with a limit groove. The back end locating screw is connected with the column through the limit groove and locating holes. The front end of the beam is connected with a cross rod and the column through the connecting piece in an screw inserting mode. The beam, the cross rod and the column can be connected conveniently and are easily to be dismantled and adjusted. The back end of the beam is connected with the column through the back end locating screw, the vertical position is limited by the limit groove to prevent the beam from overturning, and the installing precision and aesthetics of the outer wall are improved.

Owner:苏州苏明装饰股份有限公司

A dynamic control system and dynamic control method for a two-way steel support structure

ActiveCN106638614BImprove stress conditionReduce lateral displacementFoundation testingExcavationsControl systemAxial force

The invention provides a dynamic regulation and control system for a bidirectional steel supporting structure. The dynamic regulation and control system for the bidirectional steel supporting structure comprises the bidirectional steel supporting structure, axial force loading tools and a control center. The bidirectional steel supporting structure comprises flexible joints which are located at junctions of horizontal supports and vertical supports. Each flexible joint comprises an outer box, an inner box, a first connecting assembly and a second connecting assembly, wherein a first hole and a second hole coaxial with the first hole are formed in the surface of the outer box, and the inner box is arranged in the outer box; the first connecting assembly and the second connecting assembly penetrate through the first hole and the second hole correspondingly to be connected with the inner box; and elastic elements are arranged between the outer wall of the inner box and the inner wall of the outer box. The axial force loading tools are used for axial force loading of the horizontal supports or the vertical supports. The control center is used for controlling the working states of the axial force loading tools. By adoption of the dynamic regulation and control system for the bidirectional steel supporting structure, the problems that in the prior art, the additional bending moment of the bidirectional steel supporting structure is too large during axial force loading, and the bidirectional steel supporting structure cannot be regulated and controlled in real time are solved.

Owner:SHANGHAI MECHANIZED CONSTR GRP

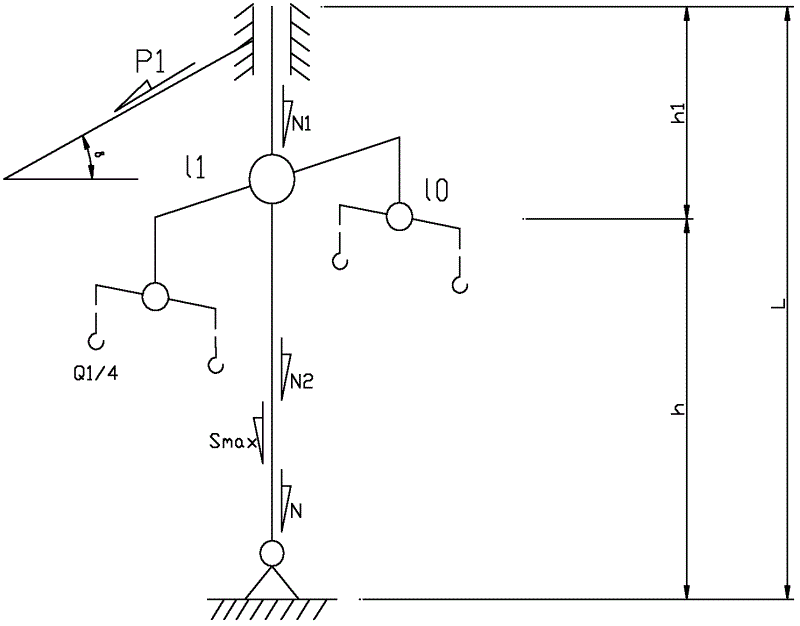

Mast crane

InactiveCN102616675ABalanced structureImprove reliabilityCargo handling apparatusPassenger handling apparatusEngineeringBalance performance

The invention relates to a mast crane, which comprises a mast, an upper hinge supporting piece, a plurality of cable wind ropes, a large arm, two lifting lugs, two small arms and a lower hinge supporting piece, wherein the mast is vertically arranged along the gravity direction; the upper hinge supporting piece is arranged on the top of the mast; the cable wind ropes are connected with the upper hinge supporting piece and a drag pit to fix the mast; the large arm is vertically arranged on the upper part of the mast; the lengths of the large arm on the two sides of the mast are the same as each other; one end of each of the two lifting lugs is connected with the two end parts of the large arm; the two small arms are connected with the other end of each of the lifting lugs and are vertical to the lifting lugs; the lengths of the small arms on the two sides of the lifting lugs are the same as each other; the two ends of the small arms are connected with the lifting lugs through hoisting steel wire ropes of a winch; and the lower hinge supporting piece is arranged at the bottom of the mast. According to the technical scheme, all the parts of the mast crane can be uniformly stressed as much as possible, the additional bending moment of the mast is reduced, and the balance performance of a complete machine is improved, so that the reliability of the mast crane is improved.

Owner:中色十二冶金建设有限公司

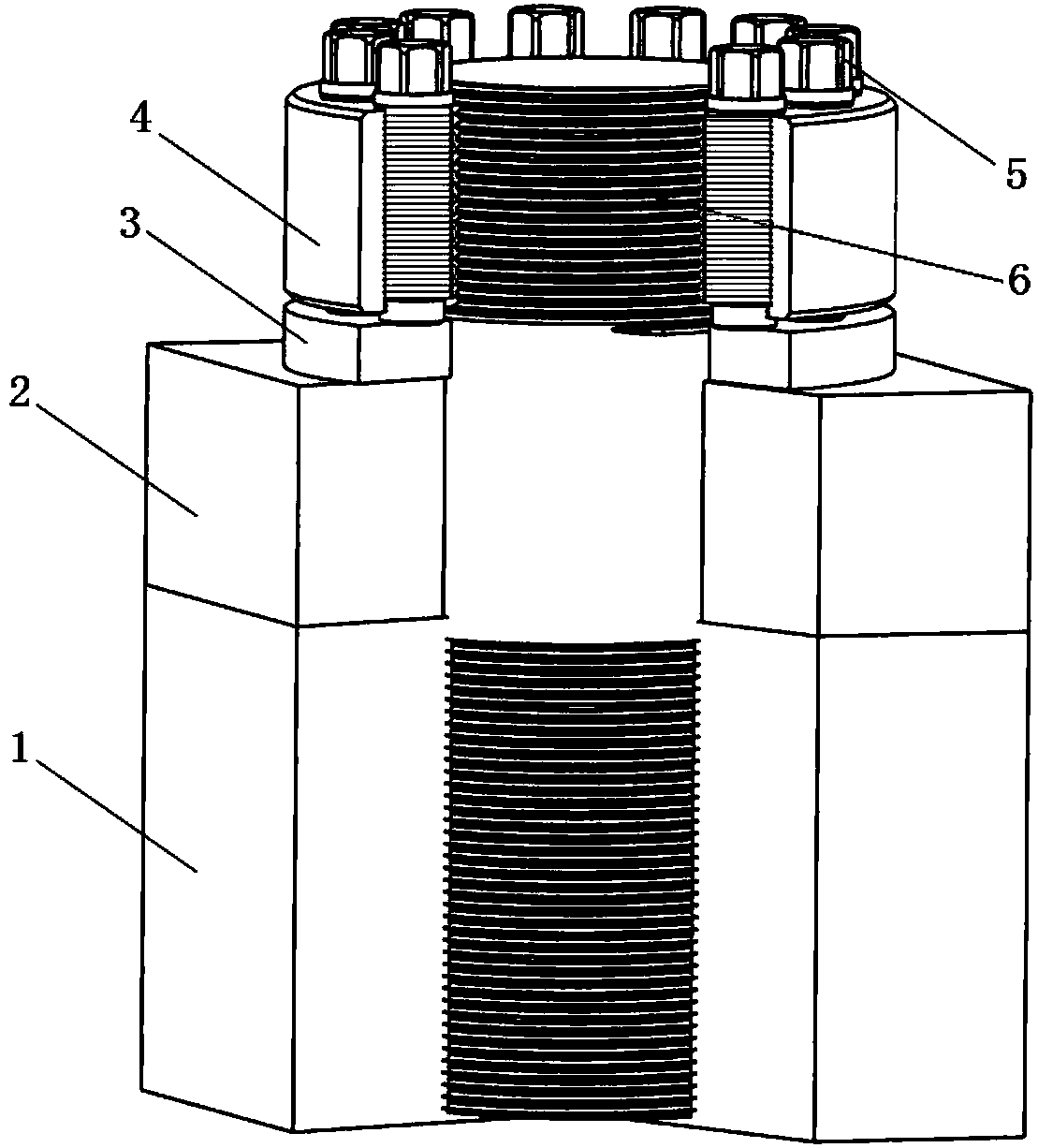

Method for improving contact precision of pushing screws small end surfaces in super nut and gasket

ActiveCN108481103AAvoid uneven forceImprove contact accuracyGrinding work supportsPlane surface grinding machinesScrew threadGrinding wheel

The invention discloses a method for improving the contact precision of pushing screws small end surfaces in a super nut and a gasket. The method specifically comprises the following steps of 1, a setof pushing screws to be machined are uniformly arranged in threaded holes in the periphery of a super nut before grinding, and a certain pre-tightening force is exerted on the pushing screws so as toprevent the pushing screws from loosening during grinding; 2, an external thread of a grinding tool is installed in the internal large threaded hole in the middle of the super nut with the pushing screws in the step 1 and is pre-tightened, enabling a small step surface of the grinding tool to be tightly attached to the bottom end surface of the super nut; and 3, a whole set of grinding tool to beground after being installed in the step 2 is placed on a workbench, so that the tool positioning surface of the grinding tool is sucked on a grinding machine sucking disc, a grinding machine wheel is used for carrying out unified grinding and machining on the small end surfaces of all the pushing screws, and until all the small end surfaces of the pushing screws are ground.

Owner:成都国科检测技术有限公司

Fabricated single-slope type bridge anti-collision guardrail

ActiveCN112853972AReduce intensityReduce harmBridge structural detailsRoadway safety arrangementsEnergy absorbingCantilever

The invention discloses an assembly type single-slope bridge anti-collision guardrail which is installed on a cantilever edge arranged on the edge of a bridge road surface and comprises a buffer block and at least one guardrail profile arranged in the longitudinal direction of a bridge, and a buffer groove formed in the longitudinal direction of the bridge is formed in the side face, facing the bridge road surface, of the guardrail profile. The buffer block is embedded in the buffer groove and can move relative to the buffer groove in the longitudinal direction of the bridge. The assembled single-slope type bridge anti-collision guardrail has the advantages of being simple, practical, high in guidance quality, good in buffering and energy absorbing effect, high in protection performance on passengers and a bridge and the like.

Owner:CENT SOUTH UNIV

Manufacture method of energy-dissipating shear wall system of steel plate with weakened strength by heat treatment

The invention discloses a steel plate energy dissipation shear wall system manufacturing method capable of adopting heat treatment to weaken strength. First, a body structure comprising frame columns and frame beams is constructed, after the top of the body structure is sealed, embedded steel plates of all steel plate shear walls are connected with fishplates, the embedded steel plates are carbon constructional steel plates obtained after heat treatment, the heat treatment process meets the following requirements that when the carbon constructional steel plates are made of Q235 steel plates, the yield strength is reduced by 24-31%, the limit strength is reduced by 10-12%, and the yield ratio is 0.49-0.54; when the carbon constructional steel plates are made of Q345 steel plates, the yield strength is reduced by 38-41%, the limit strength is reduced by 30-32%, and the yield ratio is 0.64-0.65. The common steel is adopted as the raw material and used for manufacturing shear walls after heat treatment, the shear walls have good performance similar to that of low-yield-point steel plate shear walls, manufacturing is convenient, and the raw material is common, easy to obtain and high in economical efficiency.

Owner:TIANJIN UNIV

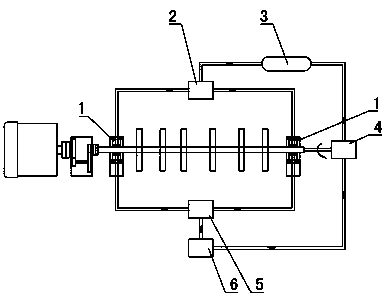

An Adaptive Circulating Lubrication System for Sliding Bearings

InactiveCN107366820BAffect lifeShort lifeValve arrangementsBearing componentsEngineeringSelf adaptive

The invention provides a self-adaptive circulating lubricating system for a sliding bearing and belongs to the technical field of bearing lubricating systems. The self-adaptive circulating lubricating system is characterized by comprising a filter (2), a pressure-cutting oil supply device (4) and a heat exchanger (6); the liquid outlet end of the filter (2) communicates with the liquid inlet end of the pressure-cutting oil supply device (4), and the liquid outlet end of the pressure-cutting oil supply device (4) communicates with the liquid inlet end of the heat exchanger (6); the sliding bearing (1) is provided with an oil inlet hole and an oil outlet hole, the liquid inlet end of the filter (2) communicates with the oil outlet hole of the sliding bearing (1), and the liquid outlet end of the heat exchanger (6) communicates with the oil inlet hole of the sliding bearing (1); and a rotary shaft for mounting the sliding bearing (1) is connected with the power input end of the pressure-cutting oil supply device (4). The self-adaptive circulating lubricating system for the sliding bearing has the beneficial effects that by simplifying an external circulating structure of the sliding bearing, lubricating oil is circulated by the adoption of the same power source, the capacity of a main drive device is fully utilized, the occupied area is saved, and the consumption of the electric energy is reduced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

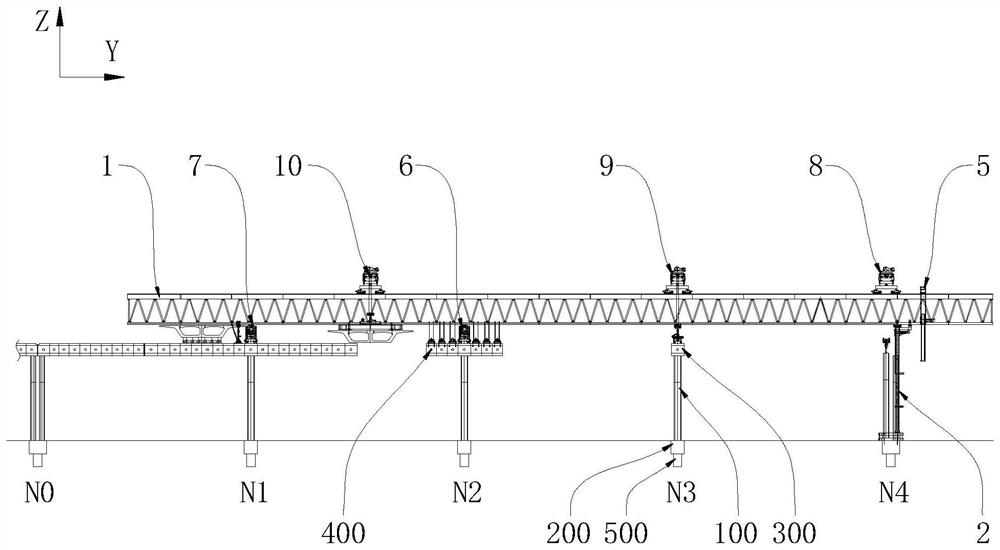

Fabricated bridge integrated construction platform and construction method

PendingCN114657895AConstruction safetyMeet the installation space requirementsBridge erection/assemblyArchitectural engineeringStructural engineering

The invention provides an assembly type bridge integrated construction platform and a construction method, and relates to the technical field of bridge erecting equipment, the assembly type bridge integrated construction platform comprises a main beam and a front supporting leg, the front supporting leg is arranged on the main beam and suitable for moving in the length direction of the main beam, and the front supporting leg comprises a first stand column, a second stand column and a first cross beam; the first cross beam comprises a first cross beam body and a first groove structure, the first groove structure is arranged on the first cross beam body, a notch of the first groove structure faces the pier body, and the first stand column is connected with the part, located on one side of the first groove structure, of the first cross beam body; the second stand column is connected with the part, located on the other side of the first groove structure, of the first beam body. The first stand column and the second stand column are suitable for being supported on a bearing platform. The front supporting legs can meet the requirement for the pier body installation space, the additional bending moment applied to the bearing platform is reduced, and construction of the integrated construction platform is safer under the condition that pier body assembling is not affected.

Owner:CHINA RAILWAY ENG MASCH RES & DESIGN INST CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com